Patents

Literature

69 results about "Thick film technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick-film technology is used to produce electronic devices such as surface mount devices, hybrid integrated circuits, heating elements and sensors. Thick-film circuits are widely used in the automotive industry, both in sensors, e.g. mixture of fuel/air, pressure sensors, engine and gearbox controls, sensor for releasing airbags, ignitors to airbags; common is that high reliability is required, often extended temperature range also along massive thermocycling of circuits without failure.

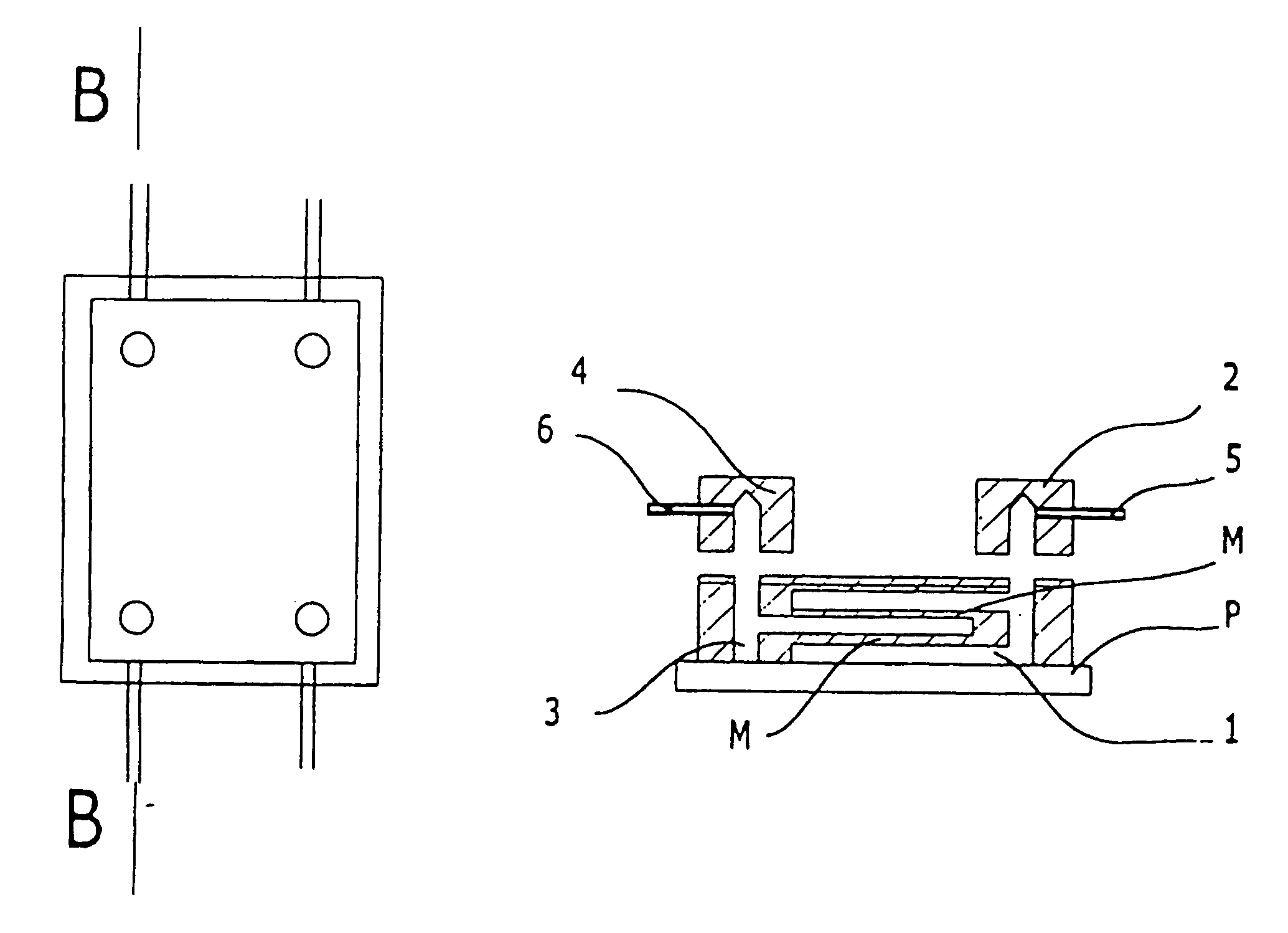

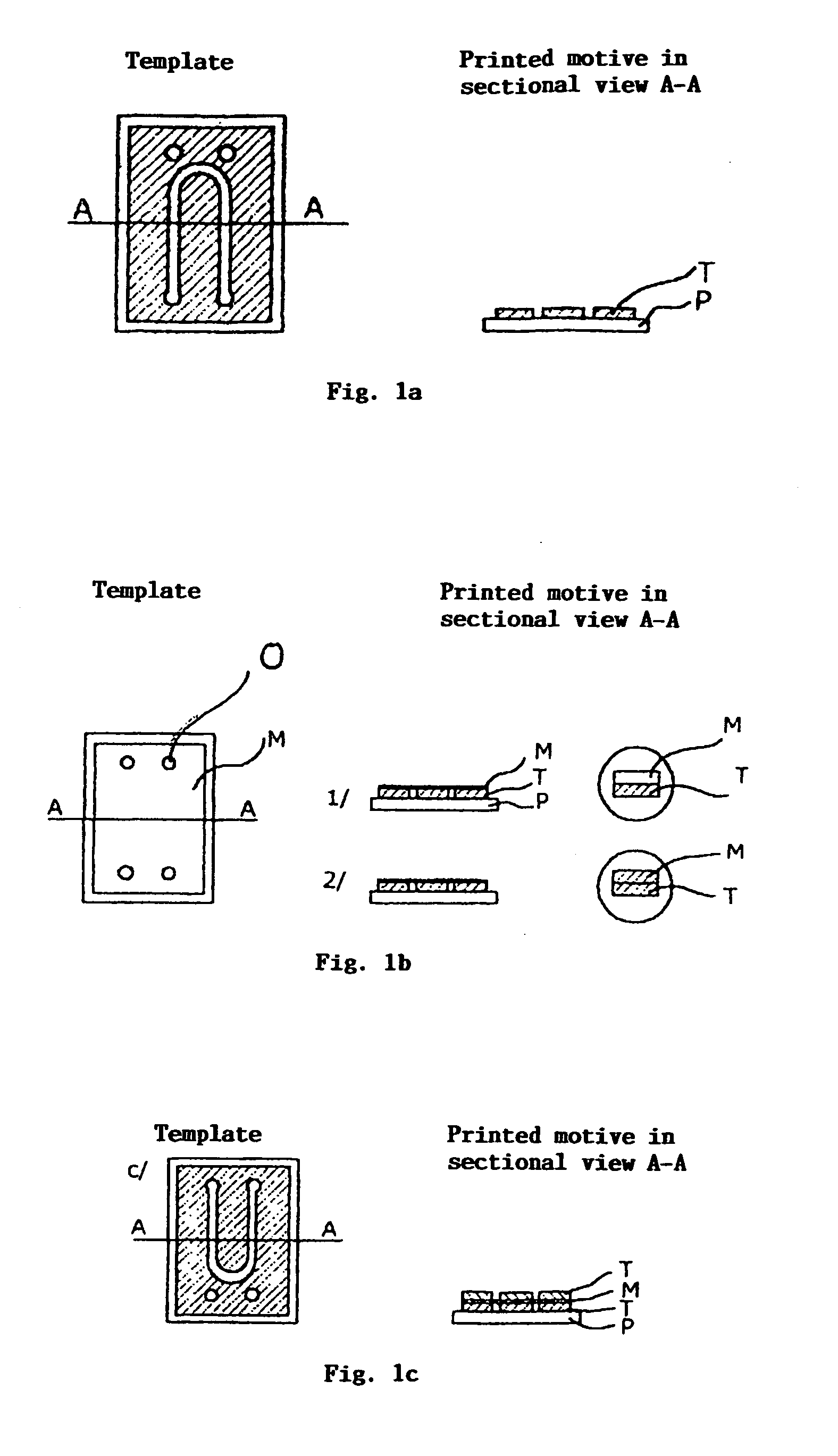

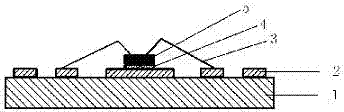

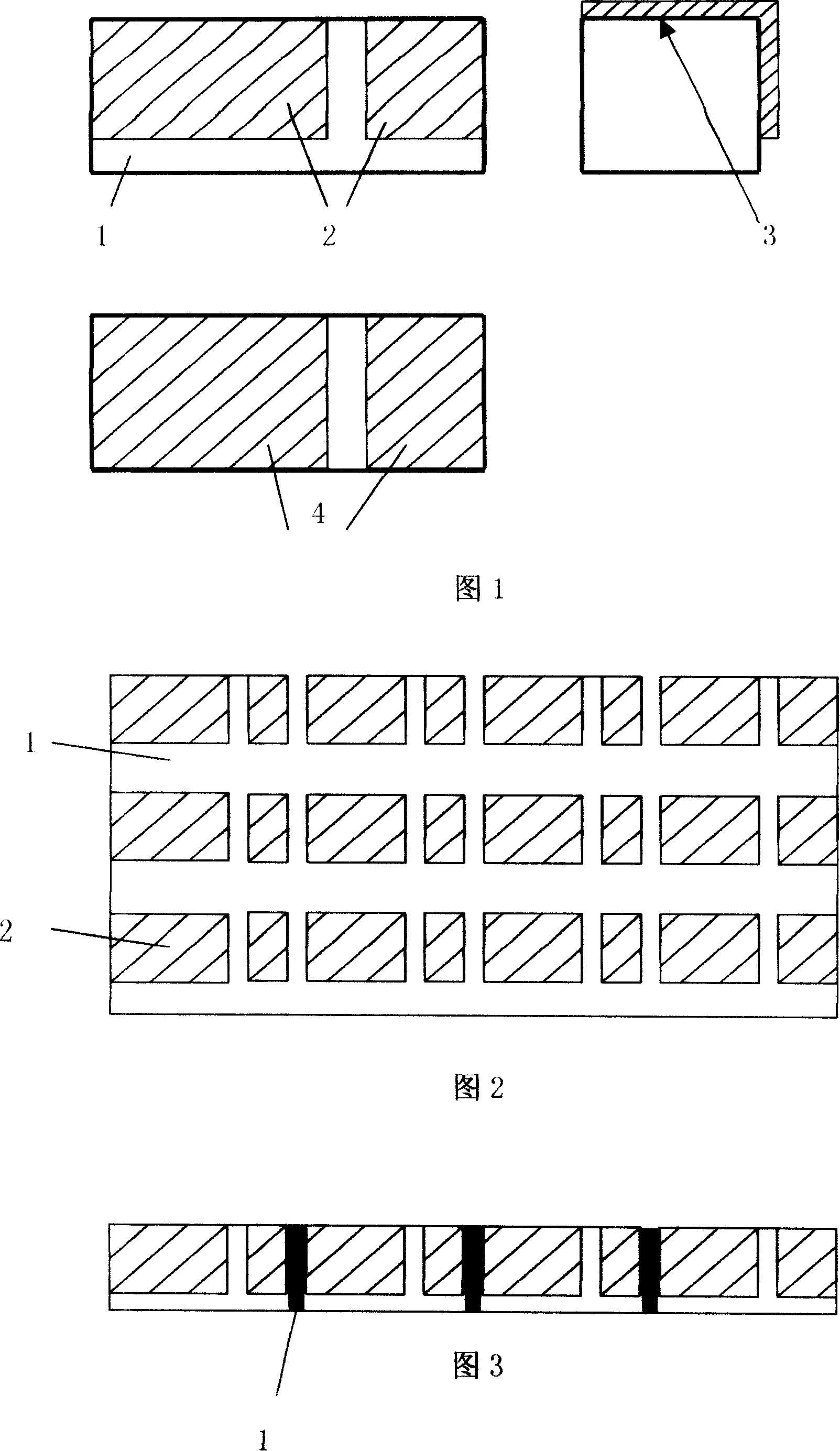

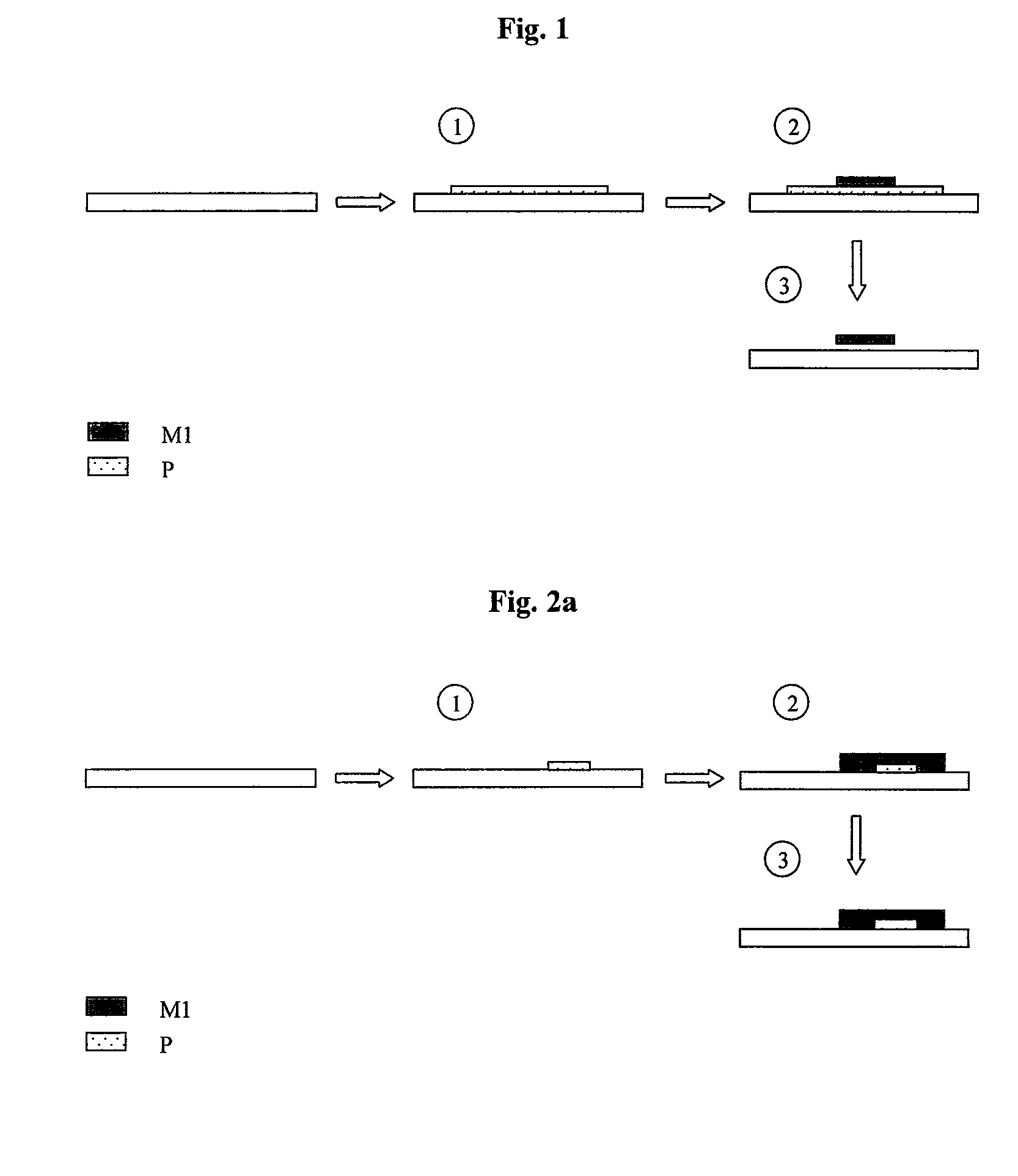

Three-dimentional components prepared by thick film technology and method of producing thereof

Object of the present invention are components with three dimensional structure prepared by thick film technology by print, where between the printed layers is inserted at least one membrane. The membrane is according to the present to invention at least in a part of the final product. The membrane can be provided with holes which are necessary for next technological steps. The inserted membranes can have pores of the size of 50˜tm to 10 nm and a thickness of 1 to 200˜tm. Method of producing of components with three-dimensional structure by thick film printing technology according to the invention lies in that between some of the printed layers is inserted a suitable membrane, which allows to lay on next layers without influence to previous layers. The printing can be done by screen-printing.

Owner:ING ILJA KREJCI ENG

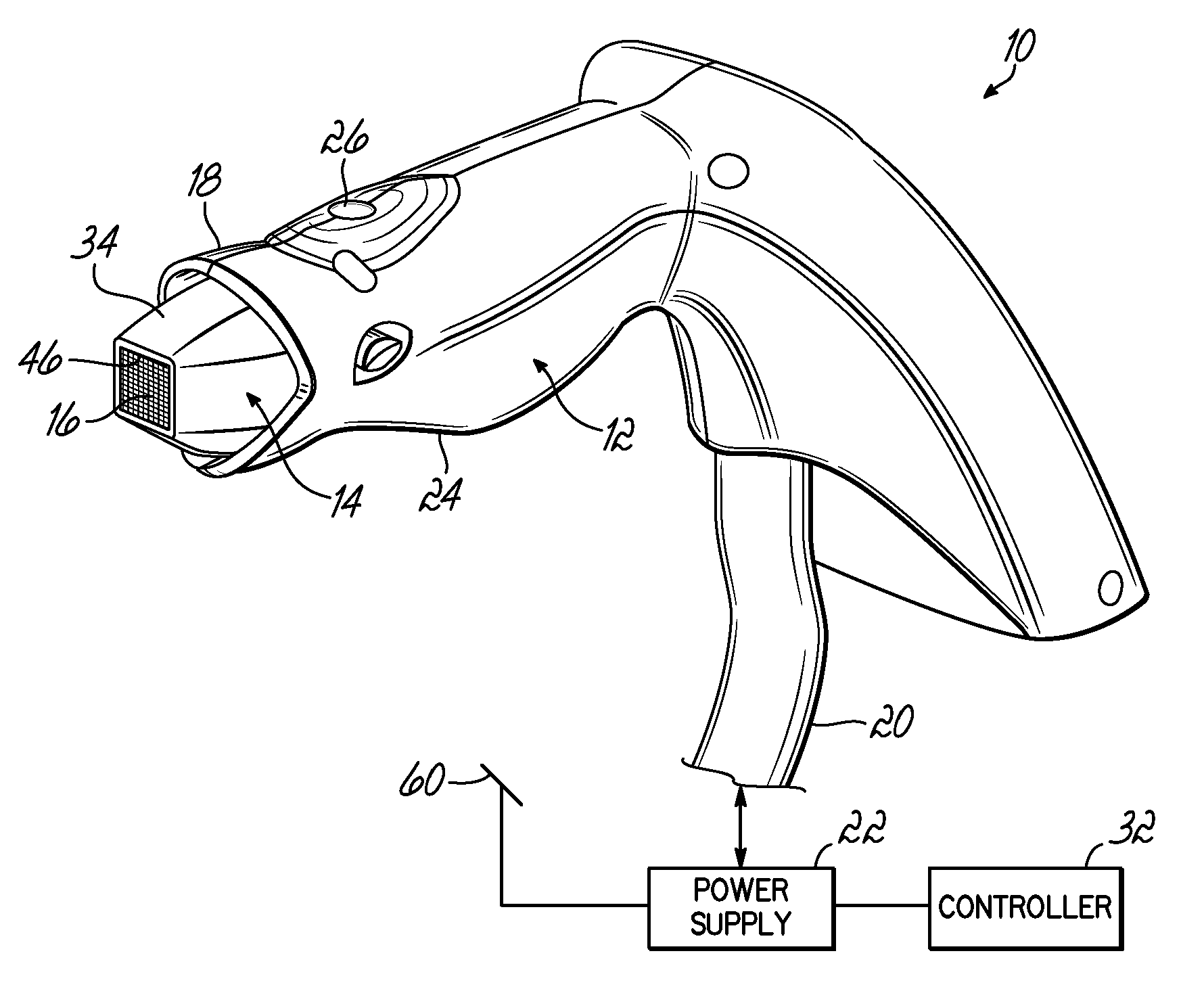

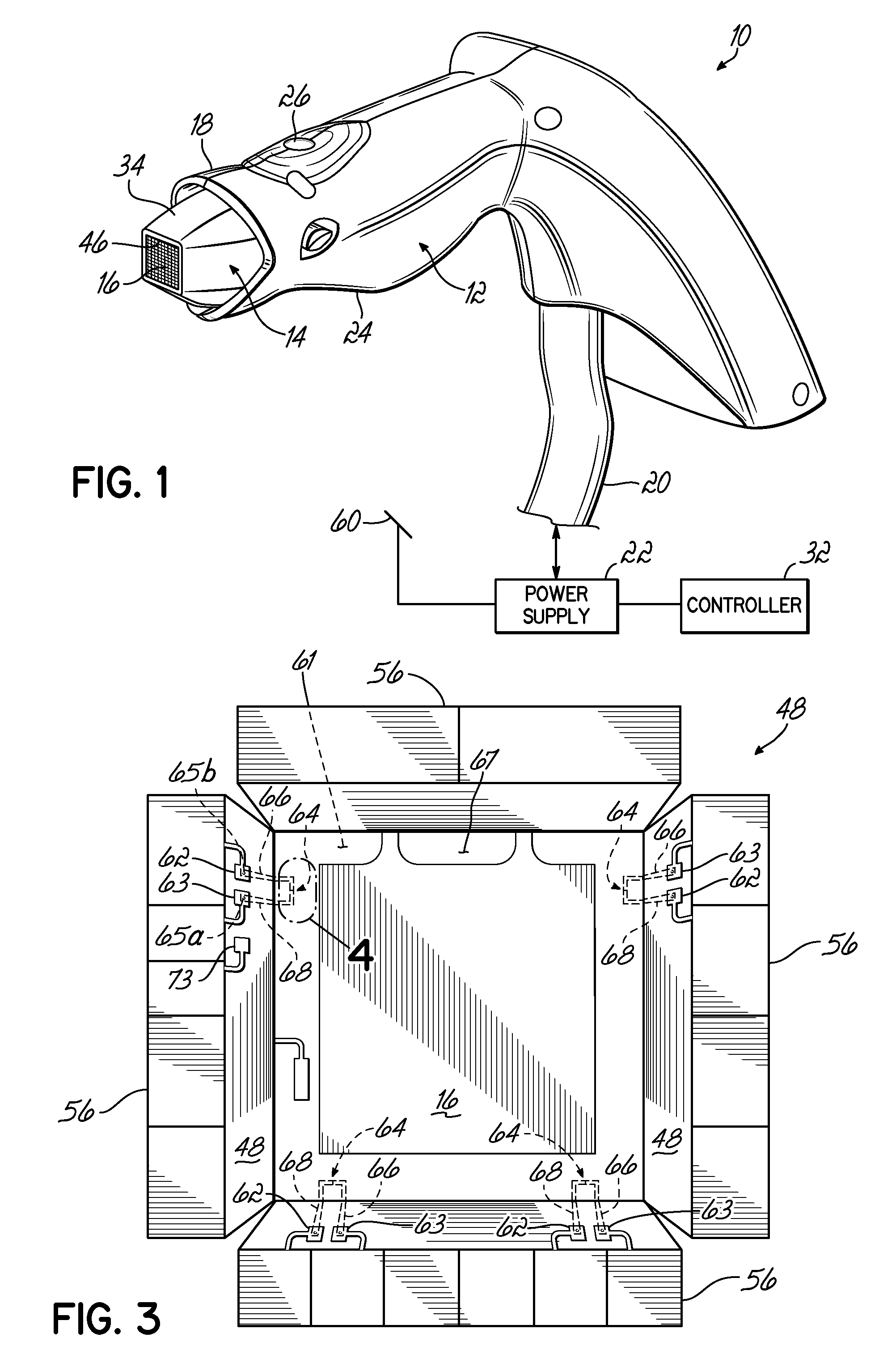

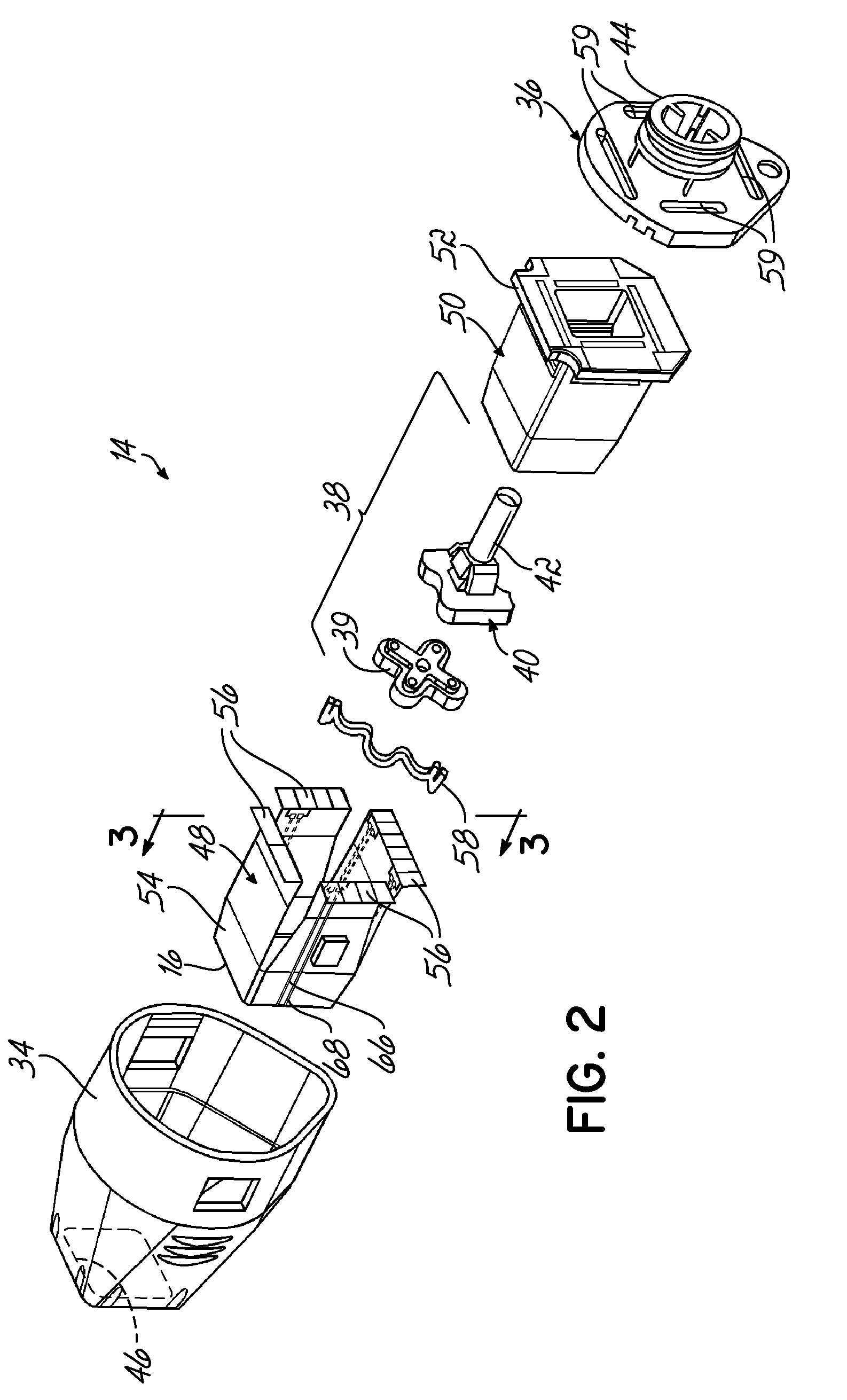

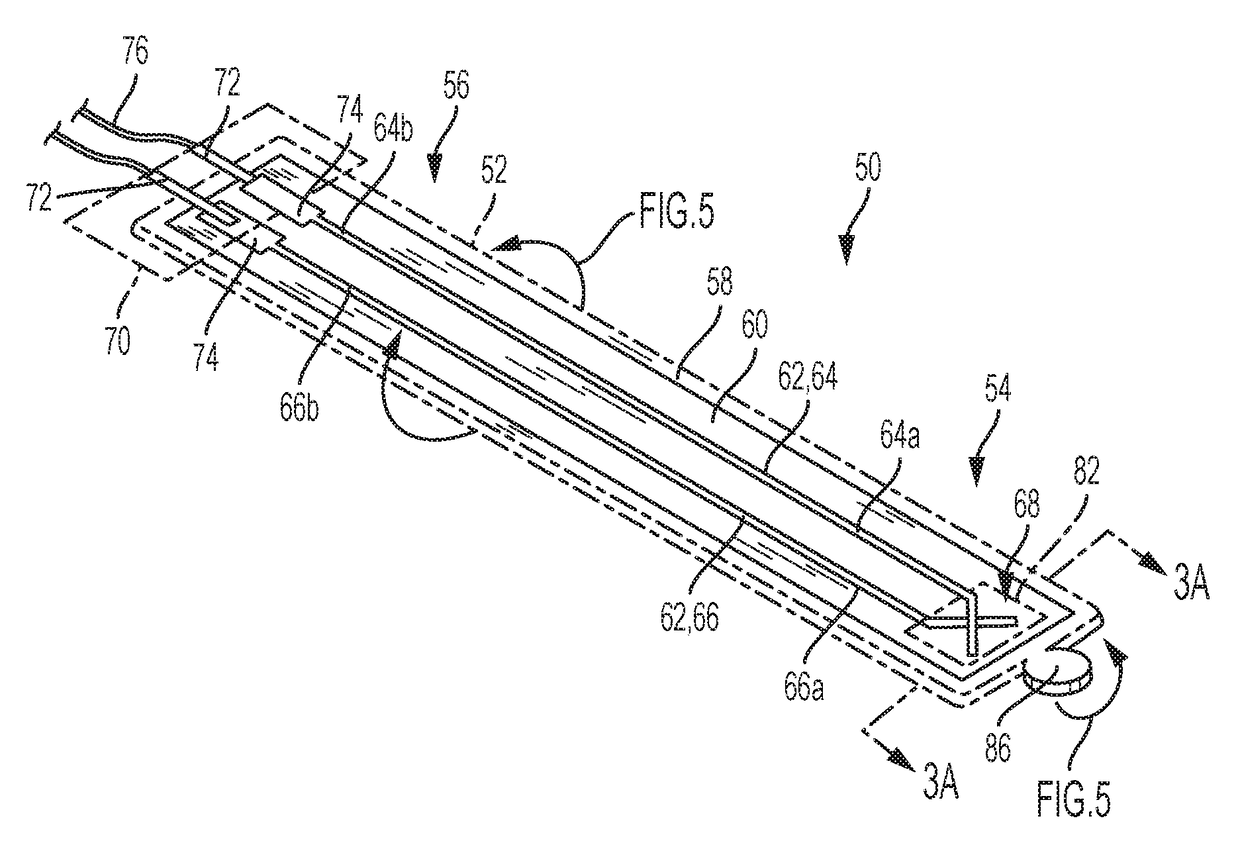

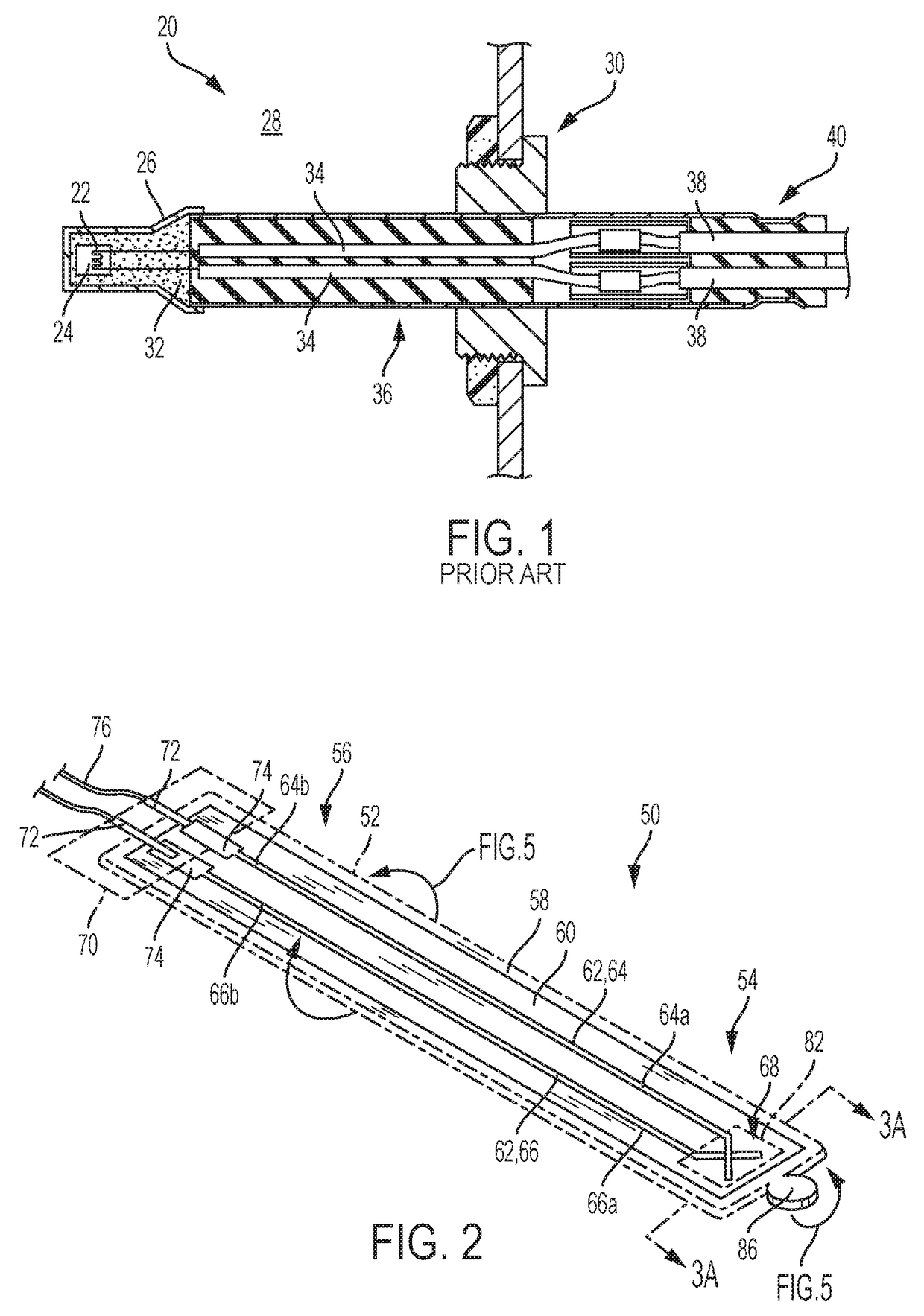

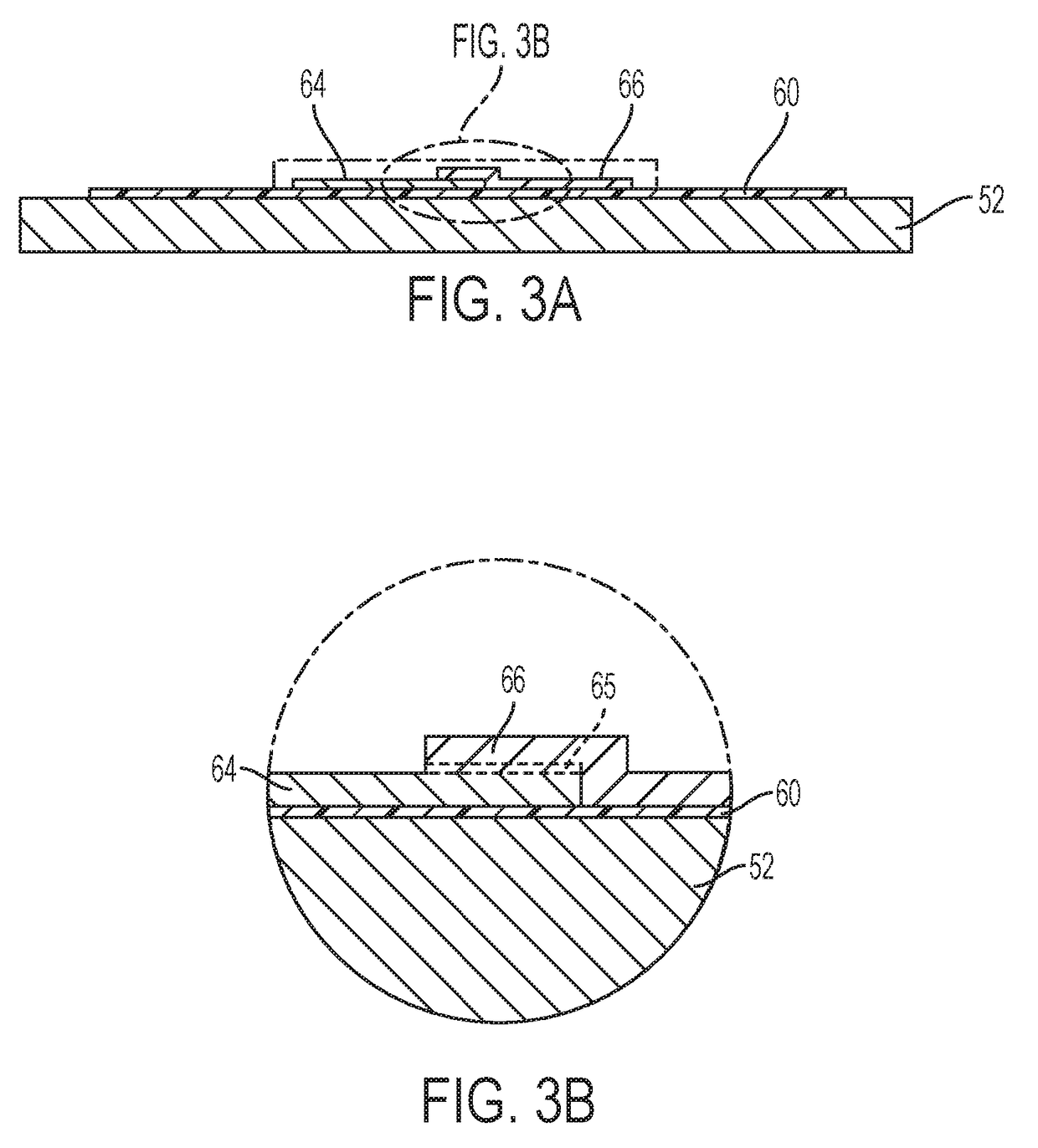

Temperature sensing apparatus and methods for treatment devices used to deliver high frequency energy to tissue

InactiveUS20080200969A1Improved thermal sensingReduce the impactElectrotherapyThermometers using electric/magnetic elementsThick film technologyEngineering

Apparatus and methods for delivering high frequency energy to tissue with improved temperature sensing. The treatment apparatus may be a delivery device positionable adjacent to the tissue. The delivery device may further include an electrode adapted to deliver high frequency energy to the tissue and at least one thermal sensor. In one embodiment, the thermal sensor may include a thermocouple junction of dissimilar metals formed by either thin film or thick film techniques. Alternatively, the thermal sensor may include a body composed of a resistive material having a resistance that varies with temperature to an extent sufficient to measure the skin temperature. A region of the delivery device near the thermal sensor may be heated, before skin contact is established during treatment, for purposes of detecting contact by the occurrence of heat loss from the delivery device region.

Owner:THERMAGE INC

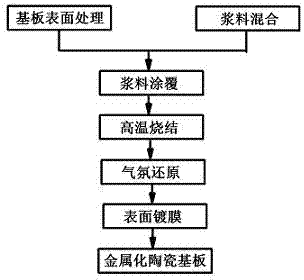

Preparation method of ceramic substrate for high-power LED packaging

The invention provides a preparation method of a ceramic substrate for high-power LED packaging, comprising the following steps of: preparing for the surface-processed ceramic substrate, covering the ceramic substrate with prepared cuprous oxide slurry, forming a circuit diagram, drying, sintering, reducing and plating a film to prepare ceramic substrate with a smooth and compact metal surface. With the combination of a thick film technology and a bonded copper principle on the surface of the ceramic substrate, metallization is realized without coating equipment and a complex technology required by a thin preparation technology and a special technology for direct bonded copper. In addition, with the combination of a direct bonded copper principle, the bonding strength of the metal layer and ceramic is raised and the spalling problem caused by thermal shock is minimized. According to the invention, the technology is simple; large-scale equipment is not required; raw materials are low-priced; the yield is high; metal patterning is convenient; surface fineness is high; and the copper layer thickness on the surface of the substrate is especially controllable so as to make the operation of a power electronic device more stable.

Owner:江苏景邦照明科技有限公司

Thick film conductor paste compositions for aluminum nitride substrates

InactiveUS6103146ANon-metal conductorsSemiconductor/solid-state device detailsBorideElectrical conductor

The invention relates to thick film conductor paste compositions with which thick film technology can be applied to aluminum nitride substrates and which can form a conductor as a thick film on a substrate by printing or coating and then firing and paste compositions as dispersions, which are obtained by dispersing a conductive powder and a boride in an organic medium.

Owner:EI DU PONT DE NEMOURS & CO

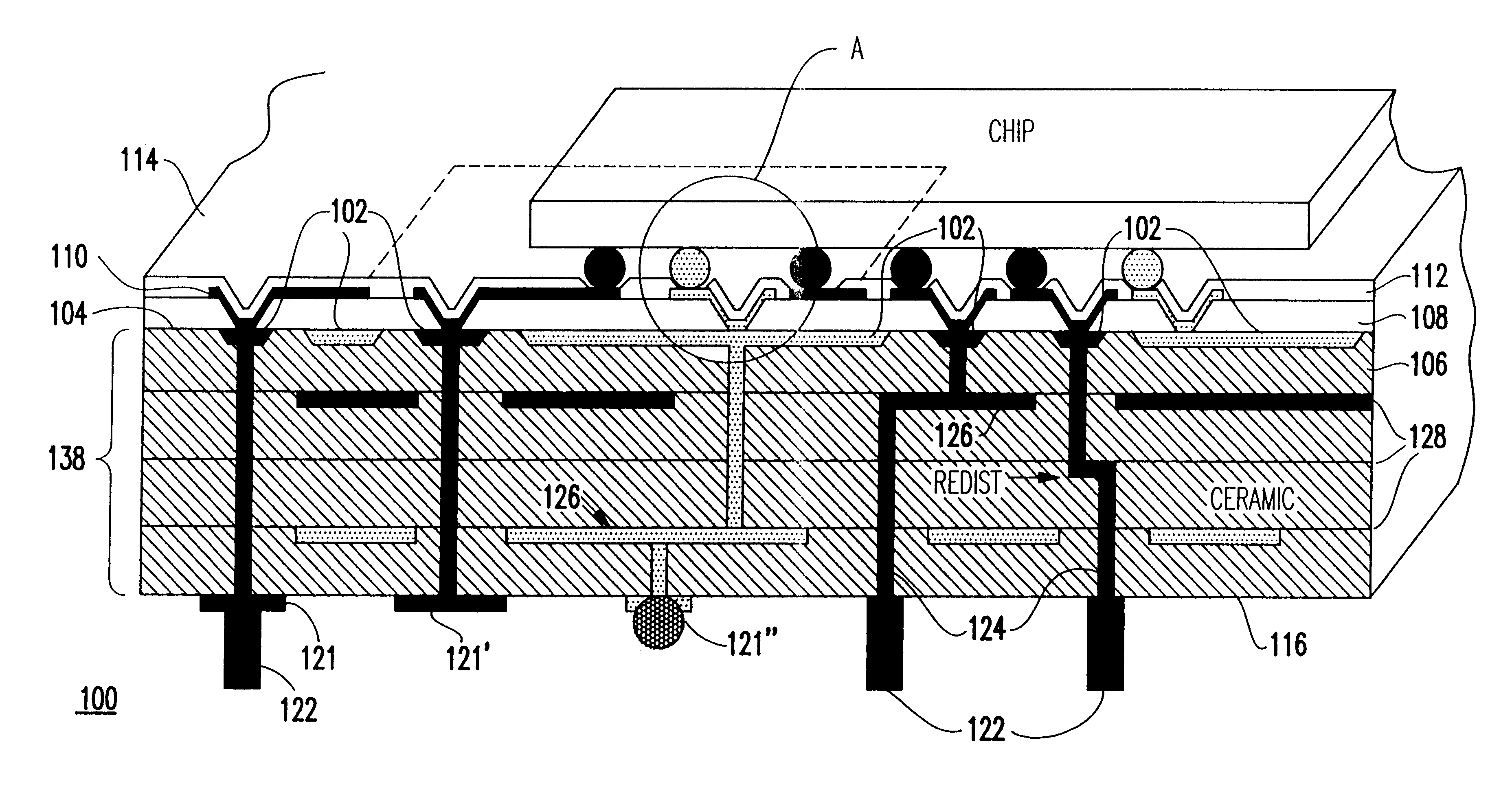

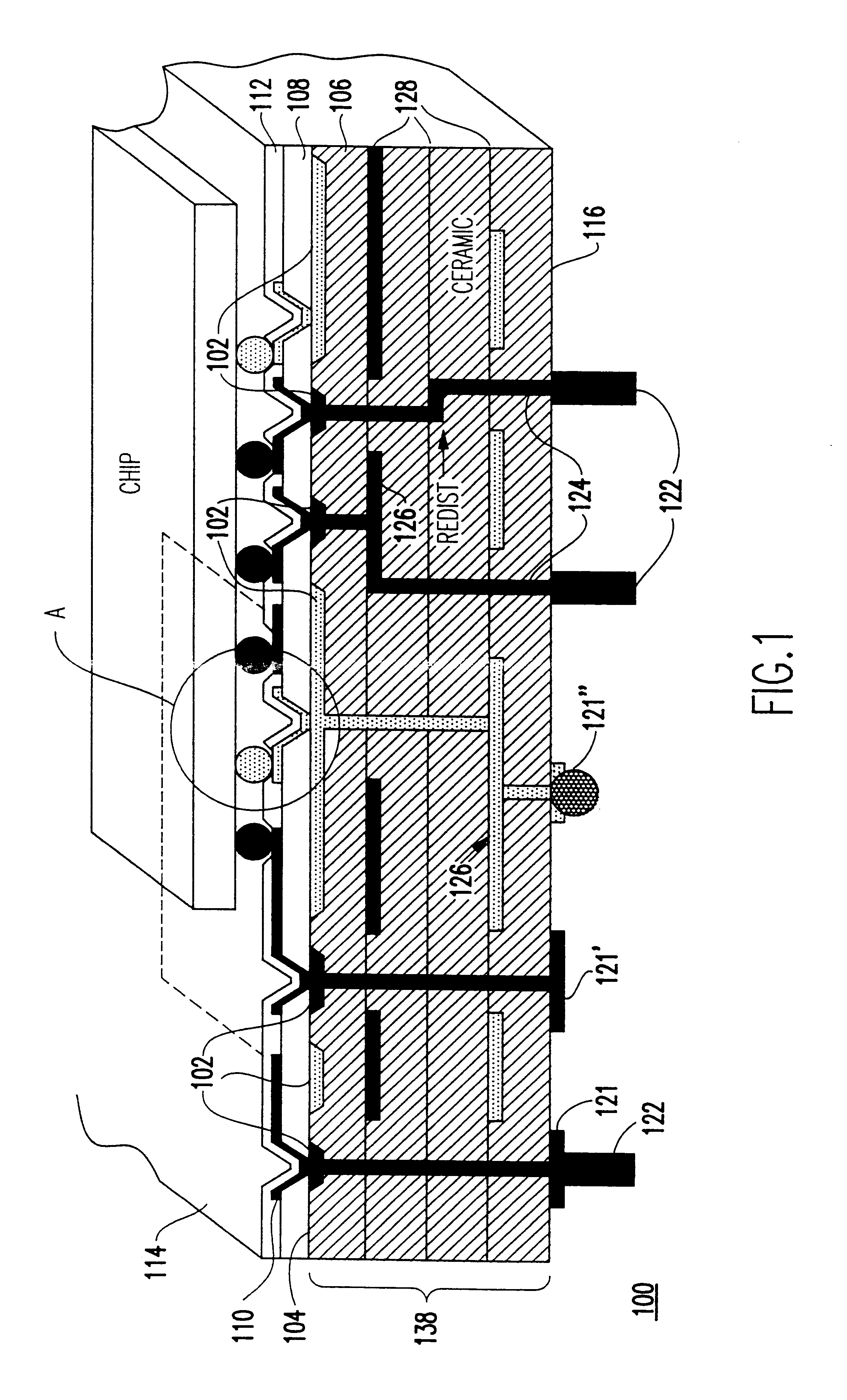

Direct deposit thin film single/multi chip module

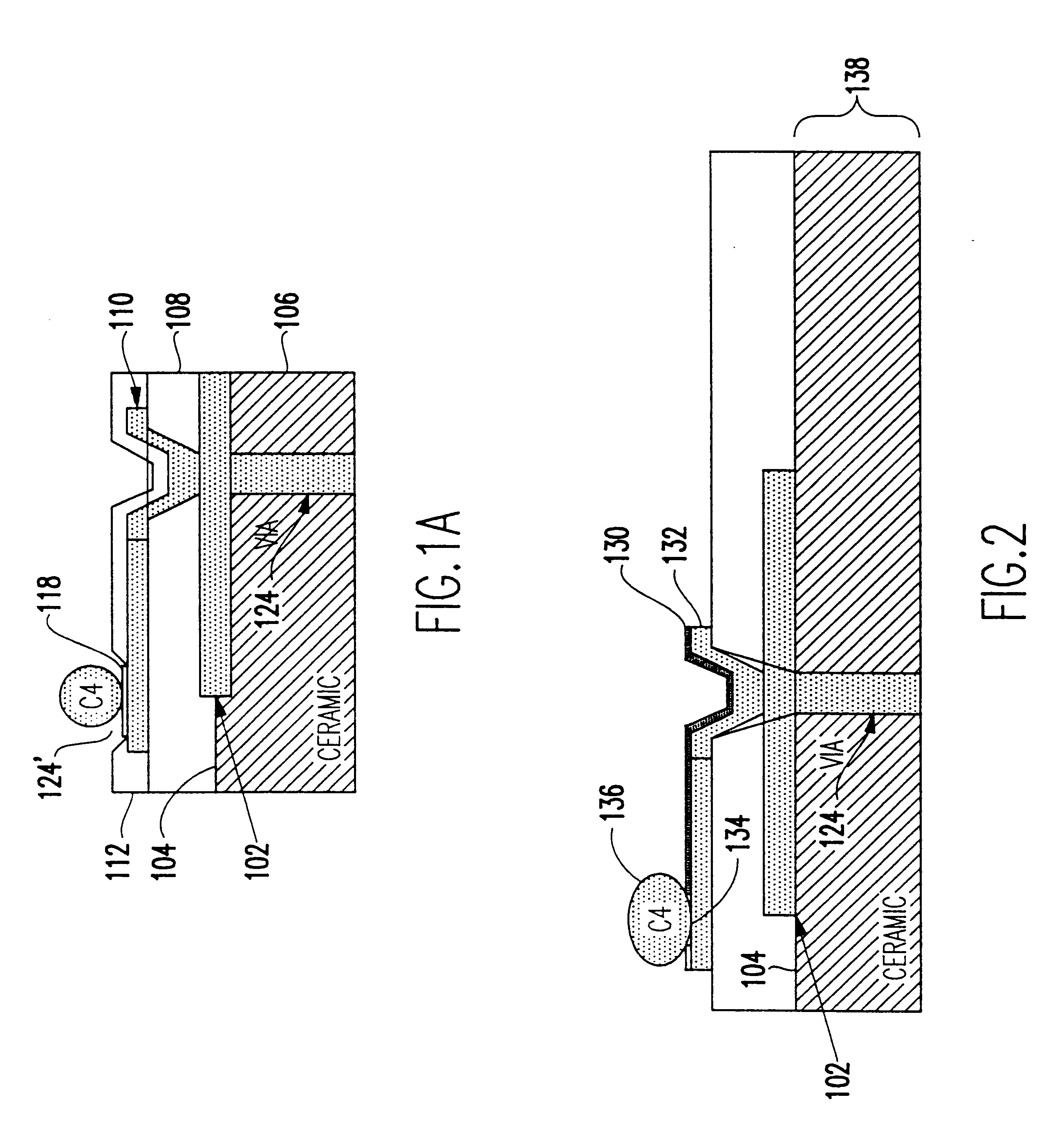

InactiveUS6261467B1Semiconductor/solid-state device detailsSolid-state devicesGas phaseThick film technology

A high performance TF-ceramic module for mounting integrated circuit chips thereto and a method of fabricating the module at reduced cost. The substrate includes thin film (TF) layers formed directly on a layered ceramic base. A first thick film wiring layer is formed on or embedded in a top surface of the thick film layered ceramic base using thick film techniques. A first dielectric layer of a polyimide or other organic material, or an insulating material different than the ceramic material is formed on top of the first wiring layer. The dielectric layer may be spun on or sprayed on and baked; vapor deposited; laminated to the ceramic base; or an inorganic layer may be deposited using plasma enhanced chemical vapor deposition (PECVD). Vias are formed through the first dielectric layer. A second wiring layer is formed on the first dielectric layer. A second dielectric layer is formed on the second wiring layer. At least one mounting location suitable for mounting an electronic component is formed on the second dielectric layer. The substrate may be attached a printed circuit board by direct attachment, pin grid array (PGA), land grid array (LGA), ball grid array (BGA), column grid array (CGA) and miniBGA on the bottom layer of the ceramic base.

Owner:INT BUSINESS MASCH CORP

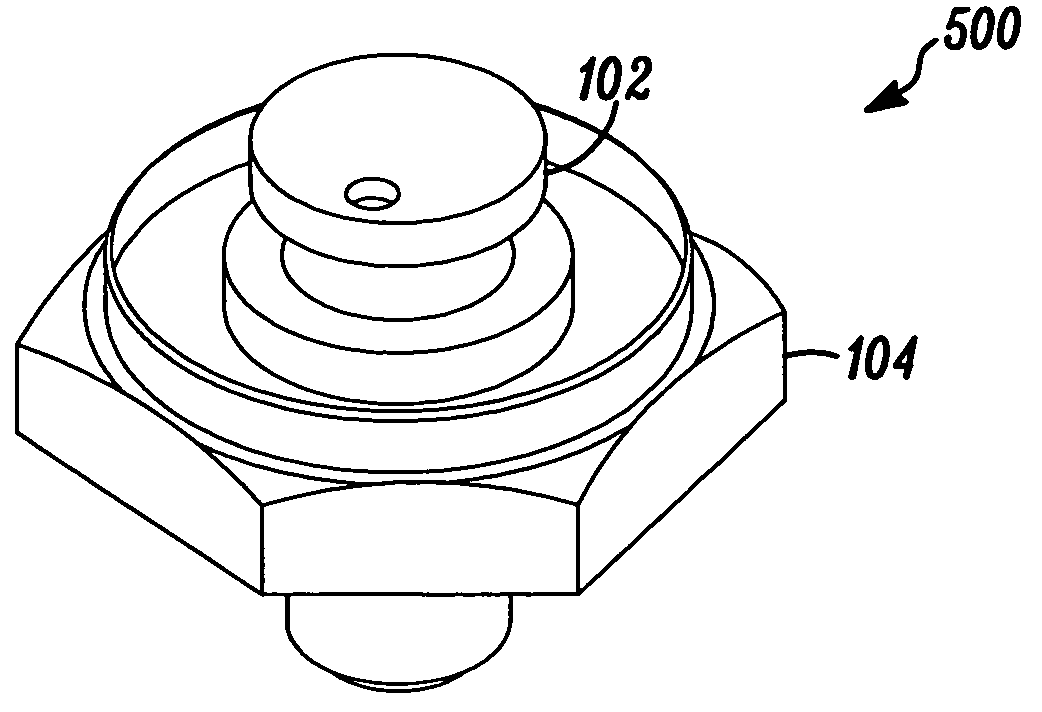

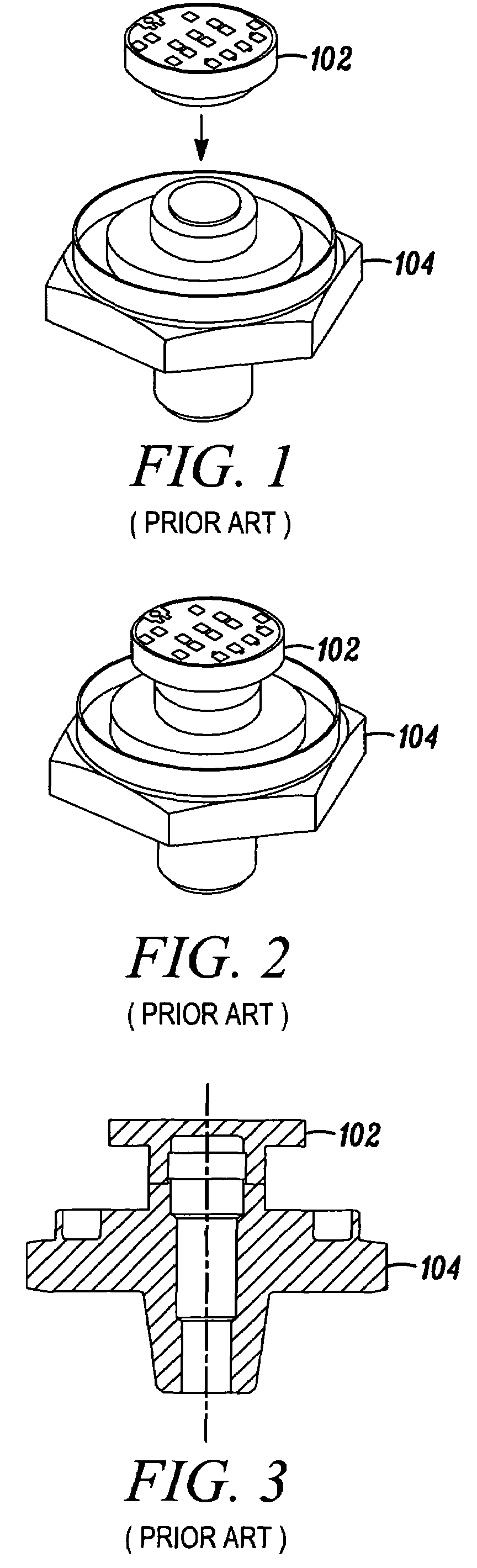

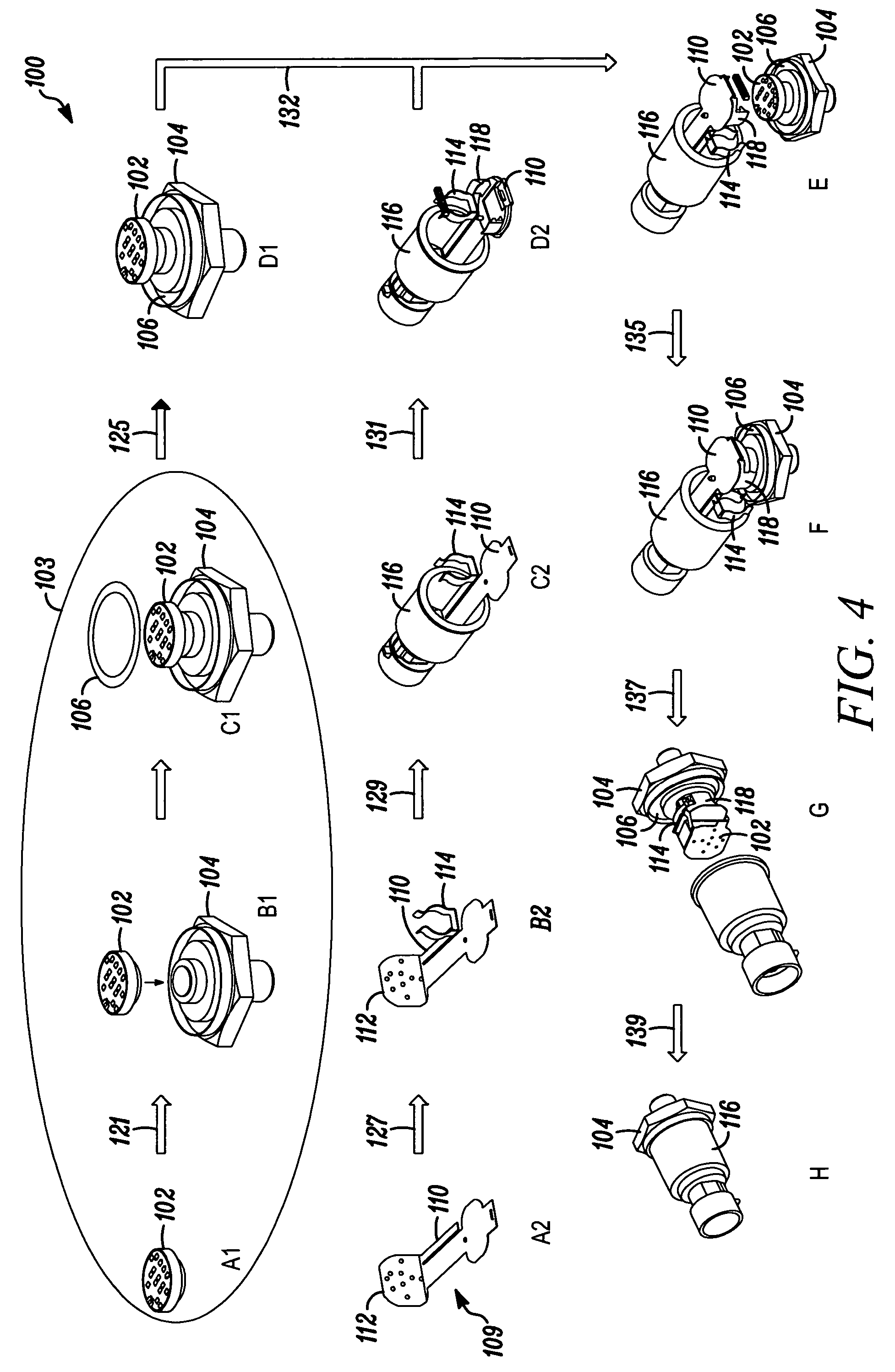

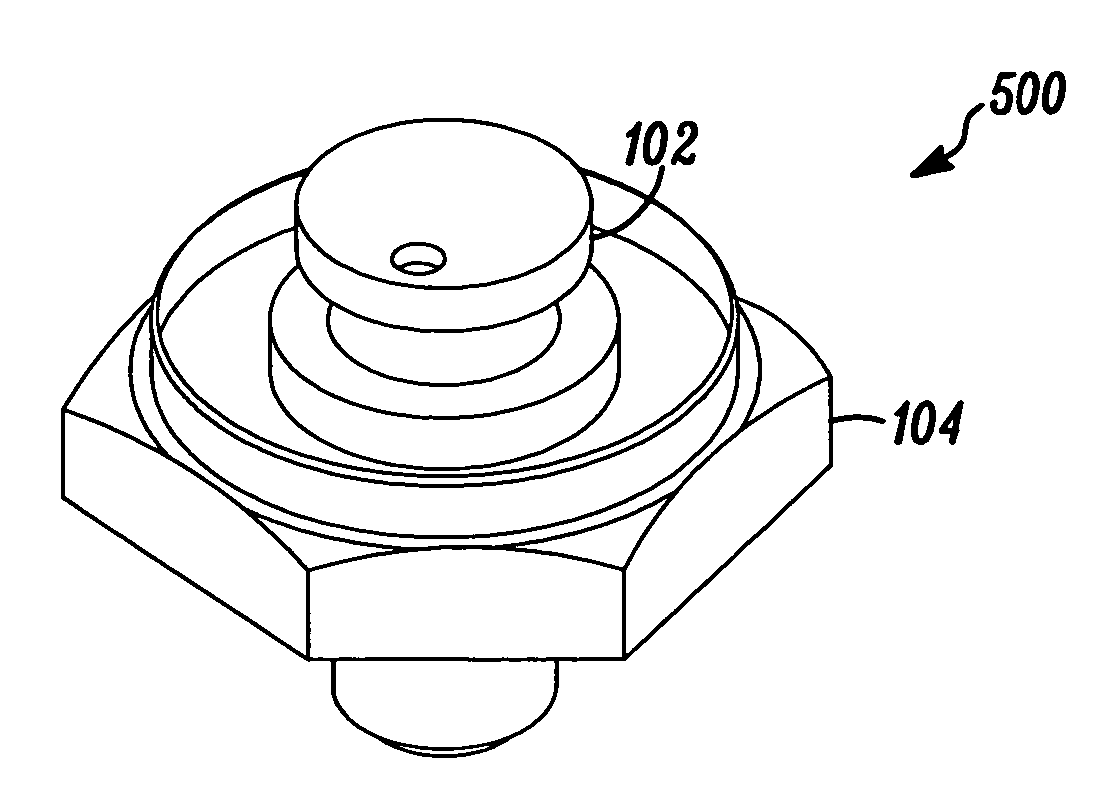

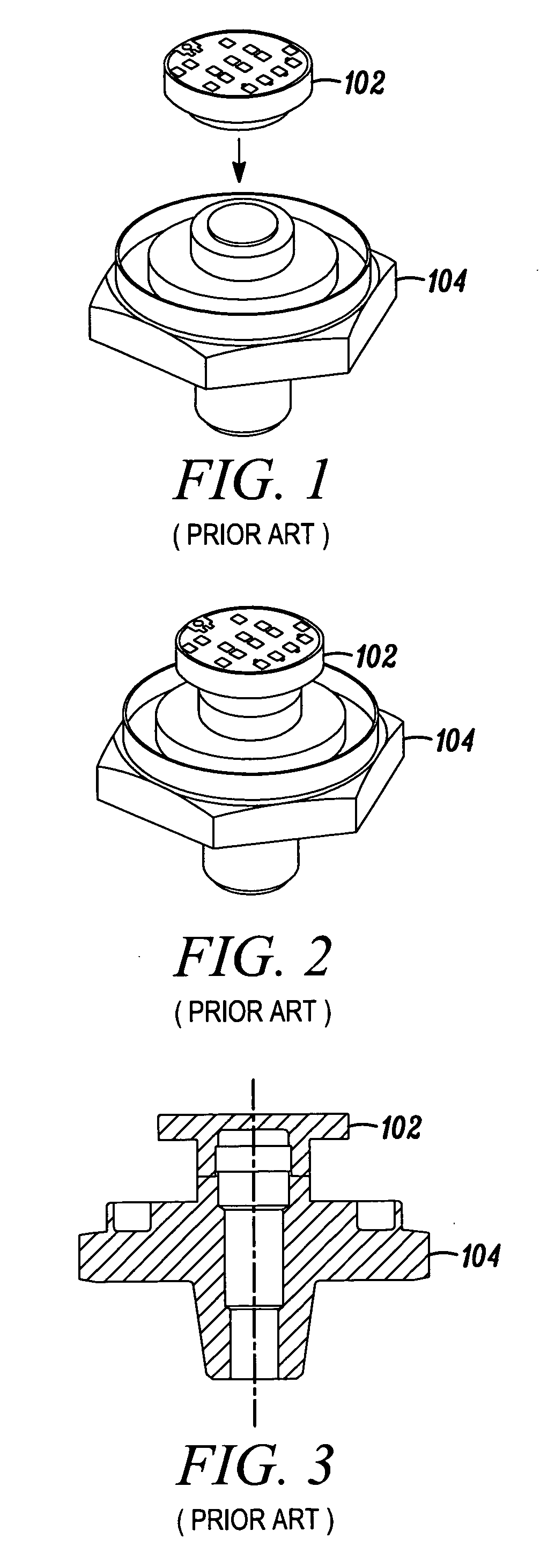

Thick film technology based ultra high pressure sensor utilizing integral port and diaphragm construction

ActiveUS7266999B2Fluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsUltra high pressureEngineering

A method and apparatus for configuring a pressure sensor. A homogeneous piece of metal can be provided. A pressure port and a machined diaphragm are integrated onto the homogeneous piece of metal, wherein the machined diaphragm is connected to the pressure port. The machined diaphragm can be configured utilizing Advanced Thick Film (ATF) technology, thereby providing a high-pressure pressure sensor for use in high-pressure sensing application based on the pressure port and the machined diaphragm and related pressure sensor components thereof.

Owner:HONEYWELL INT INC

Substrate for heating, heating plate, humidifier and machining methods of substrate and heating plate

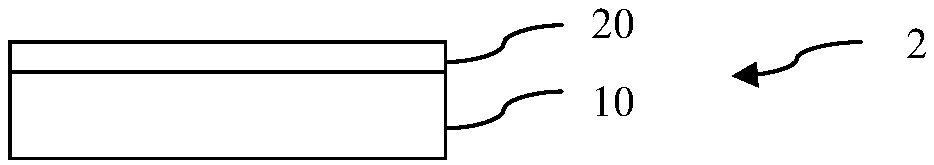

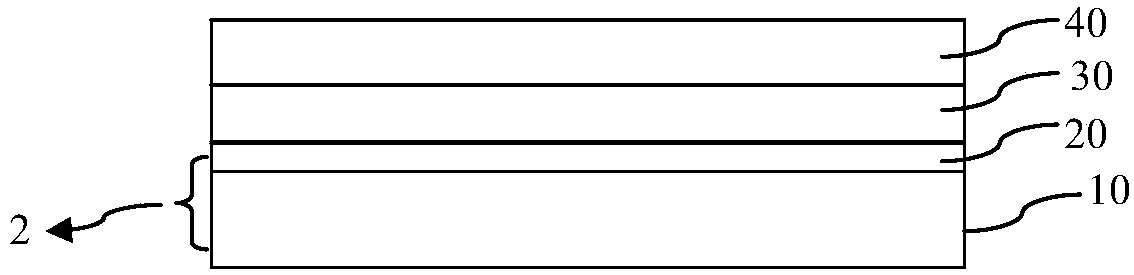

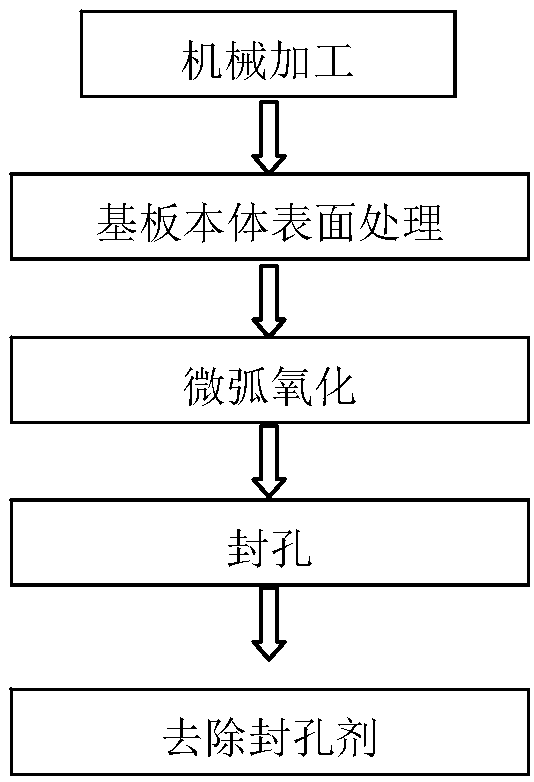

PendingCN107829125AImprove thermal shock resistanceImprove reliabilityAnodisationVacuum evaporation coatingOxide ceramicMicro arc oxidation

The invention discloses a substrate for heating, a heating plate, a humidifier and machining method of the substrate and the heating plate. The substrate for heating comprises a substrate body, and anoxide ceramic layer which is obtained through surface ceramic treatment is arranged on the surface of the substrate body. According to the substrate for heating, a micro-arc oxidation technology is adopted to generate an aluminum oxide ceramic layer on the substrate in situ, metallurgical bonding is achieved between the ceramic layer and the aluminum substrate, the adhesive force is far larger than the adhesive force between a medium heat conduction film layer made through the thick film technology and the aluminum substrate, and the cold-proof and heat-roof impinge properties are excellent;and in addition, the thermal conductivity of the oxide ceramic layer is high, the heat loss of the interface between the substrate and the oxide ceramic layer is small, the temperature gradient is reduced, and the heating efficiency and the temperature control response speed of the heating plate are greatly improved.

Owner:RESGOOD MEDICAL CO LTD

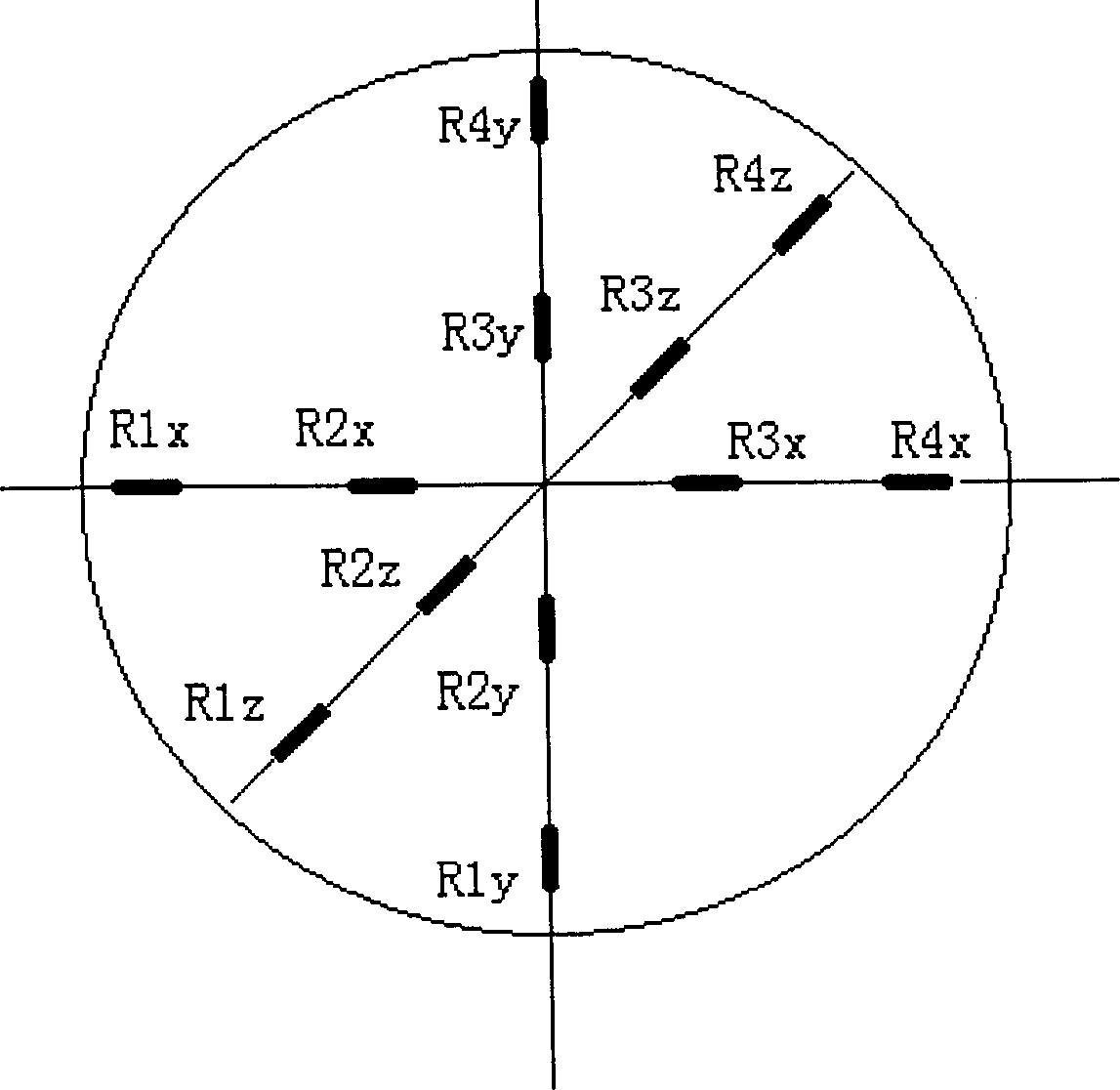

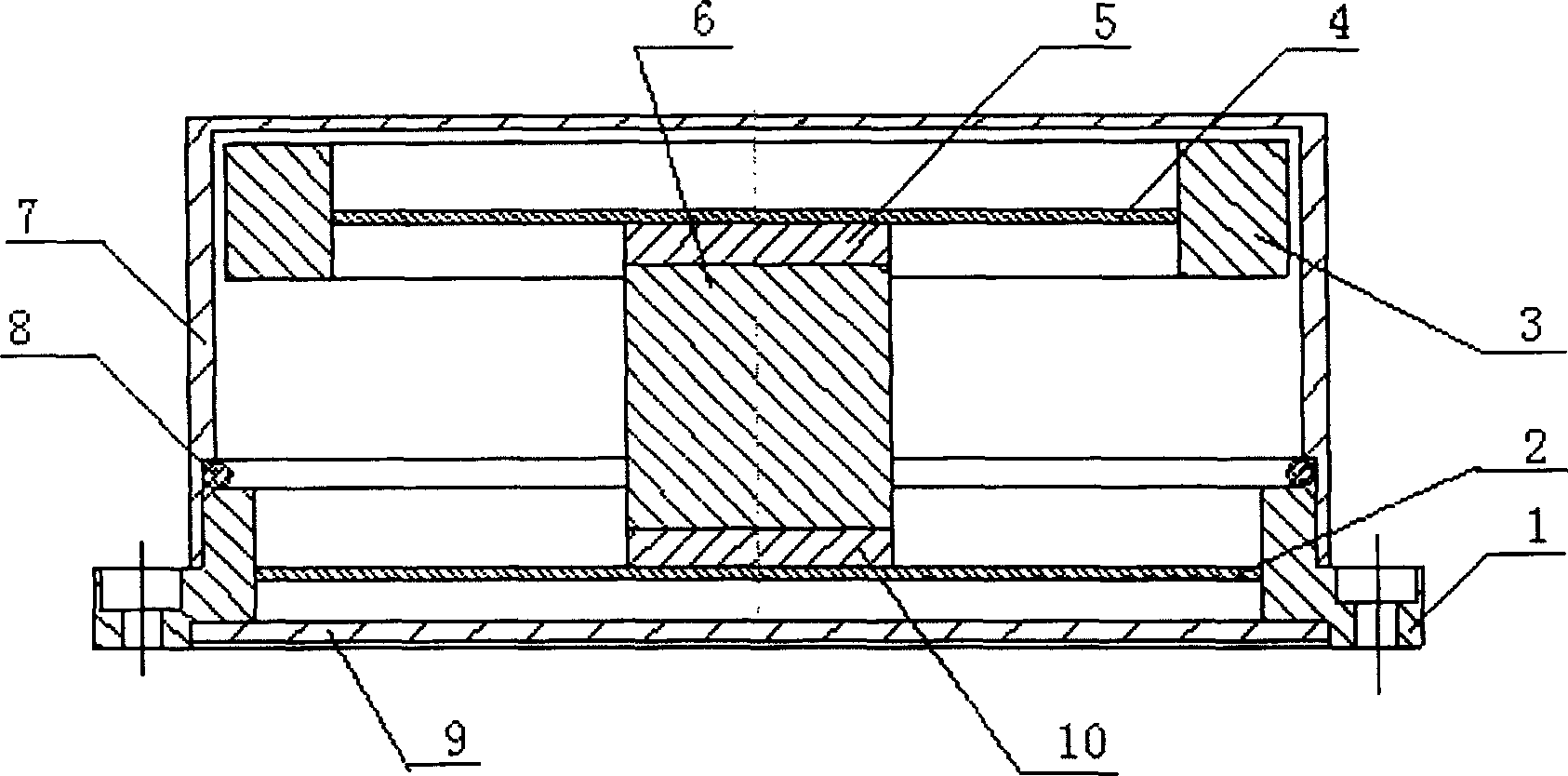

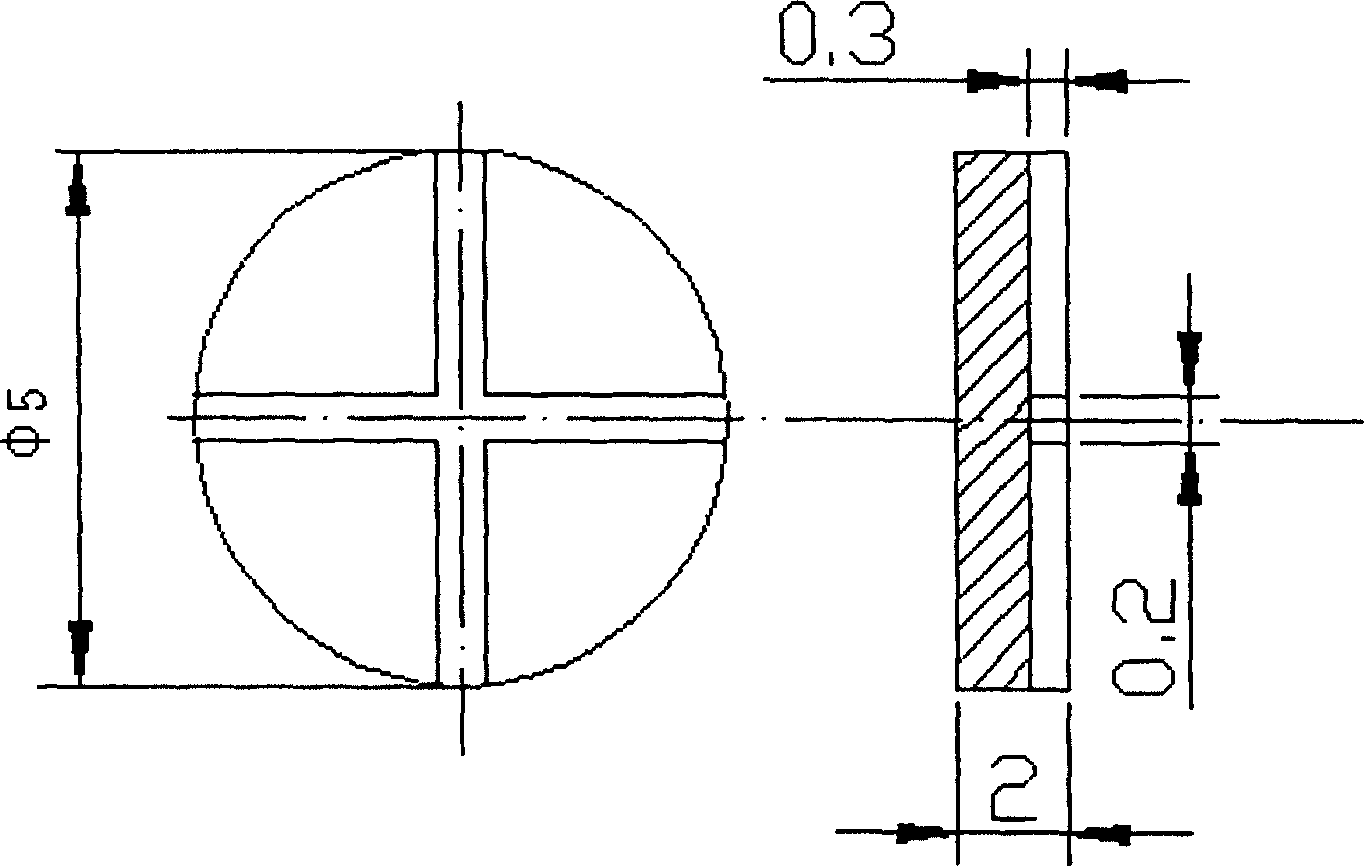

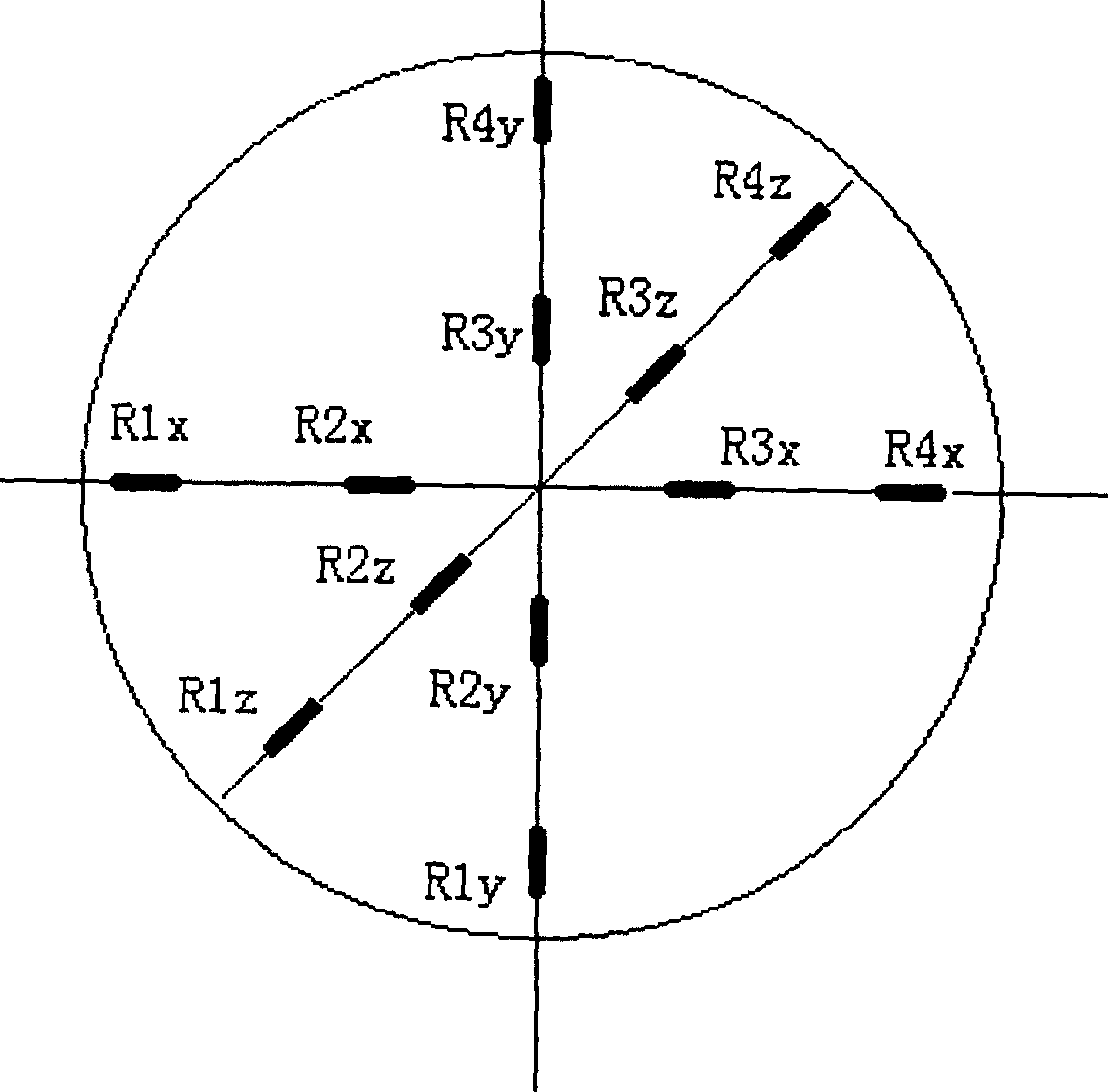

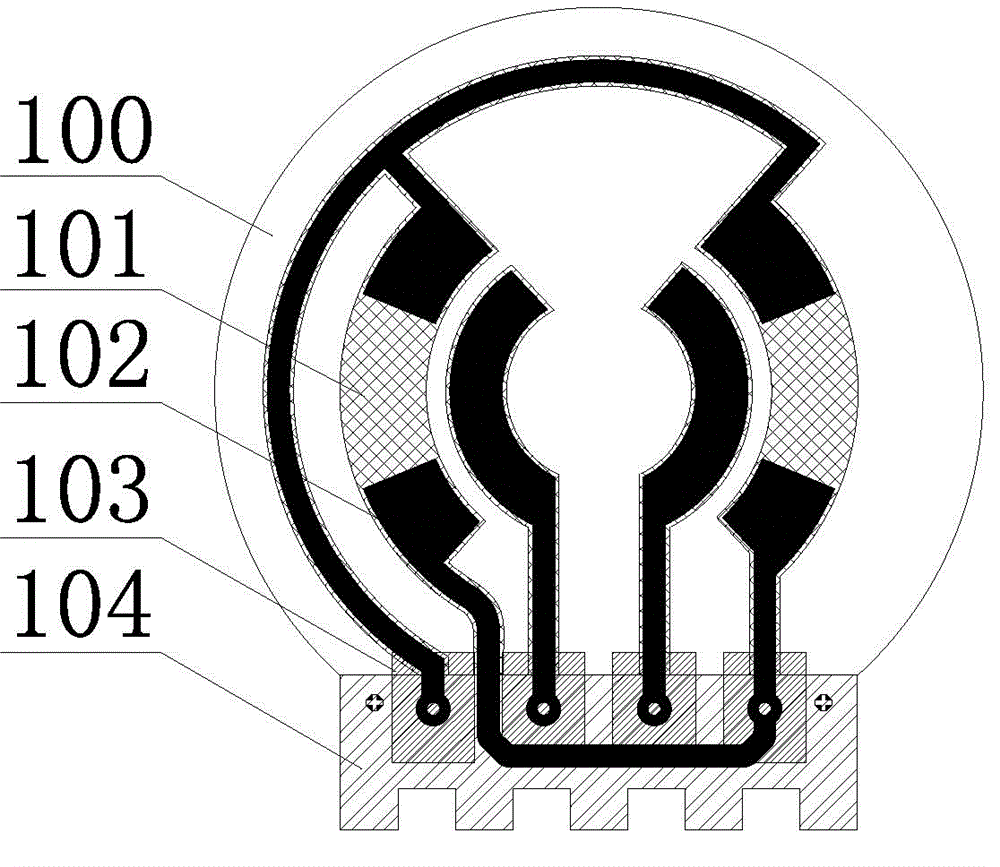

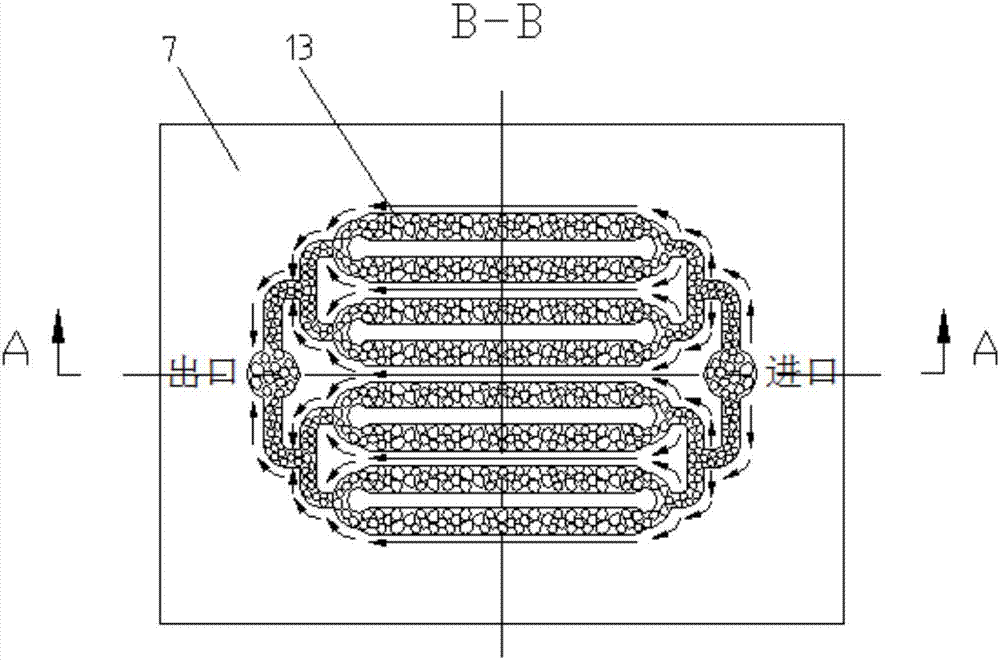

Six-axle acceleration sensor with dual E-shaped circular membranes and cross beam structure

InactiveCN1396458ARealize rangeRealize regulationAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsMembrane configurationThick film technology

A 6D acceleration sensor for measuring three axial accelerations and angular accelerations in 3D space coordinate system features that the thick-film technology is used, the dual E-shaped circular ceramic membranes and cross beam are used as sensitive elastic substance, and the force-sensitive thick-film resistors are sintered on the ceramic substance for bridging. It can be used for the robot.

Owner:HEFEI INST OF INTELLIGENT MACHINERY CHINESE ACAD OF SCI

Steel and titanium alloy low-temperature pulse ion nitrocarburizing and cathode arc ion plating M/MN alternate plating thick-film technology

InactiveCN104862643AGood adhesionReduce distortionVacuum evaporation coatingSputtering coatingWear resistantStress relief

The invention discloses a steel and titanium alloy low-temperature pulse ion nitrocarburizing and cathode arc ion plating M / MN alternate plating thick-film technology, and belongs to the technical field of material surfaces. The technology is characterized in that the stress relief annealing is performed for a workpiece 3 by cold rolling or cold drawing; a nitrocarburizing layer and M / MN alternate composite thick-film layer with a mildly transitional hardness of a wear resistant layer on the surface of the workpiece is prepared to prevent the falling of a coating film; a transition layer with a thickness of 1-3 microns is formed between a modified layer and an ion plating M film layer to improve the adhesiveness of the coating film; ion plating M and MN alternate coating films are prepared; the ion plating M film can partially absorb the internal stress of the MN plating film; and the plating film is not liable to fall. The technology has the effects and benefits of solving low hardness and weak wear resistance of a titanium alloy, replacing electroplating hard chromium, having no environmental pollution, having no harm to human bodies and having wide application range, such as molds, machine tool parts, mine machinery, locomotives and piston rings.

Owner:DALIAN UNIV OF TECH

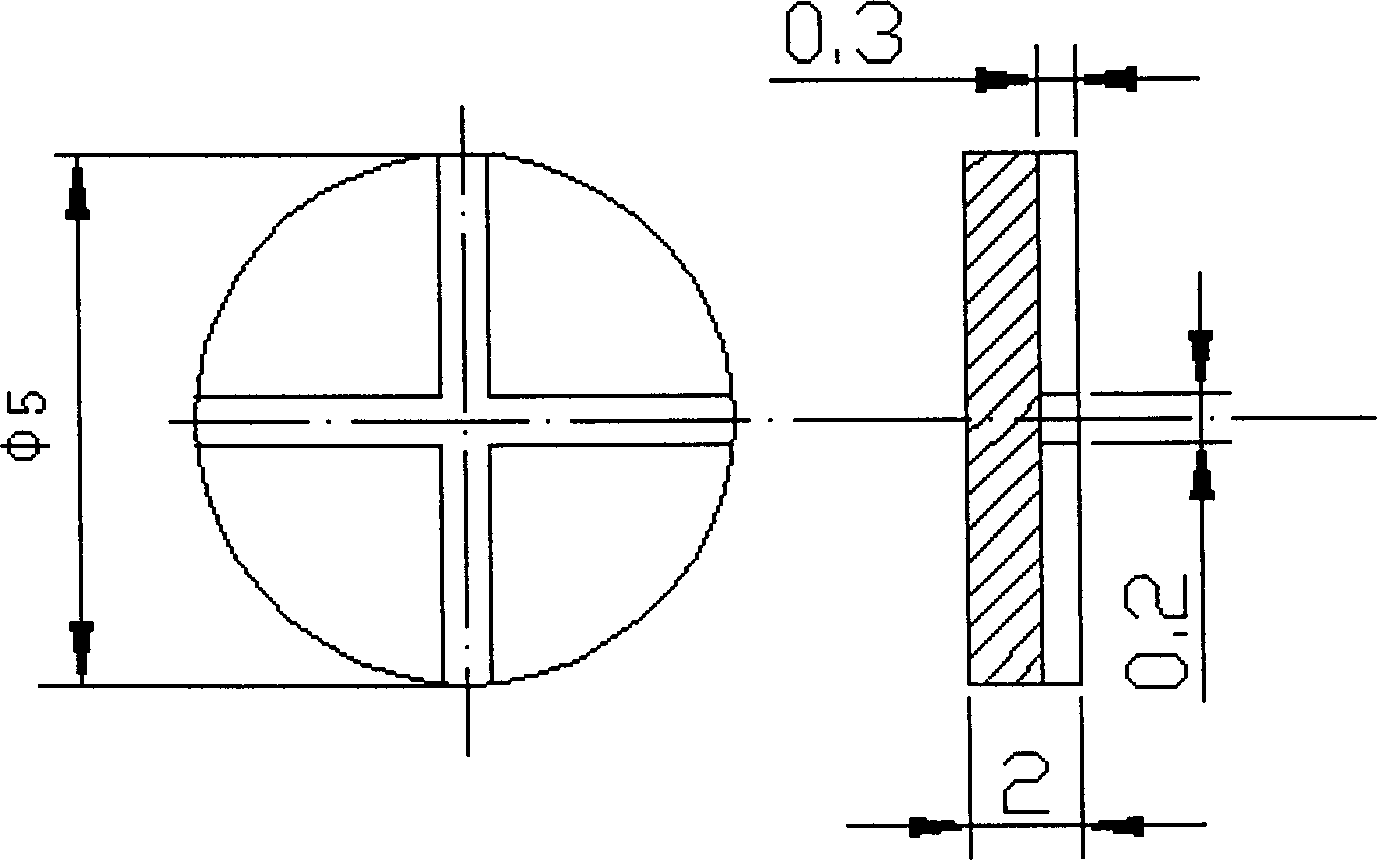

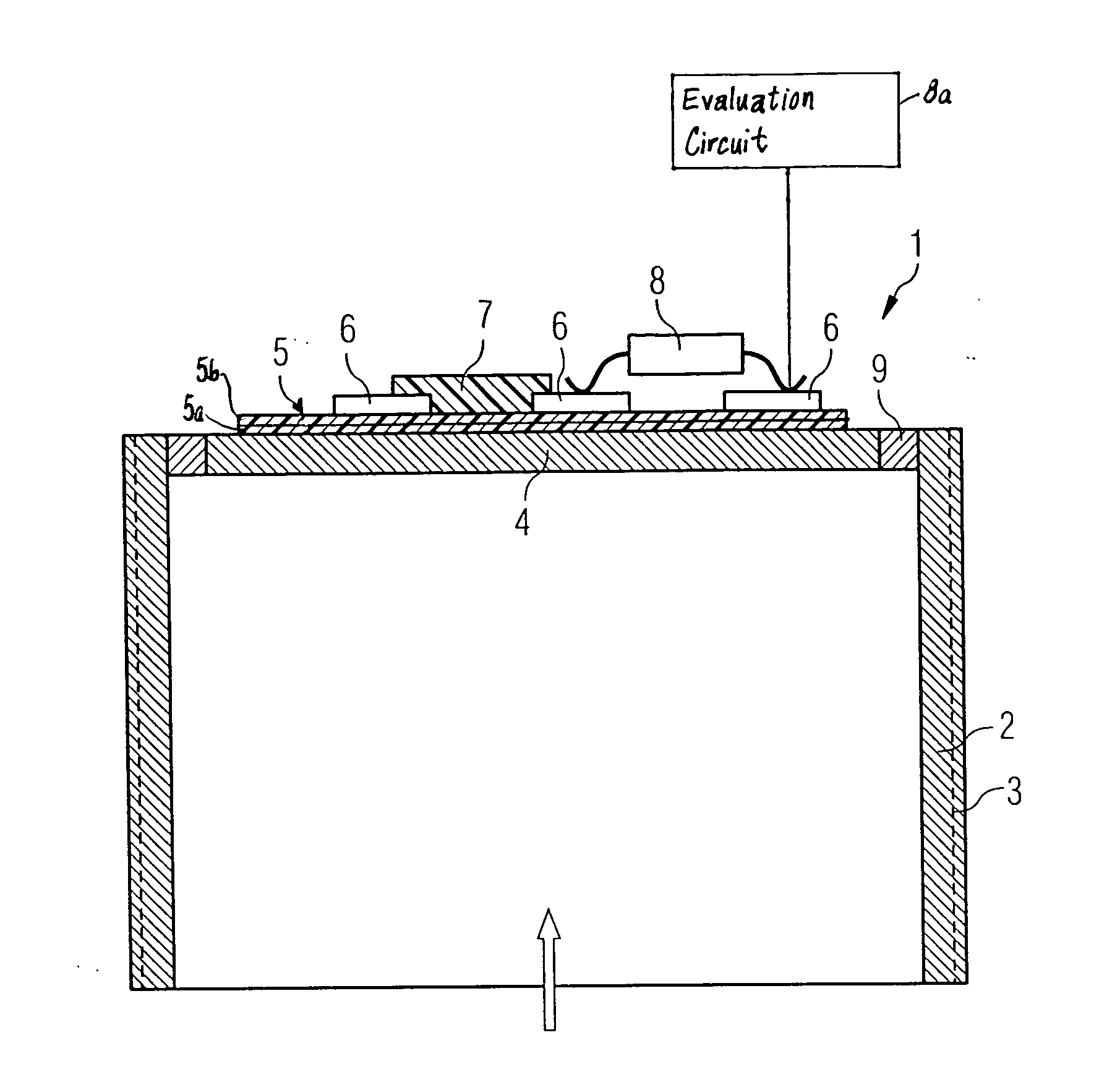

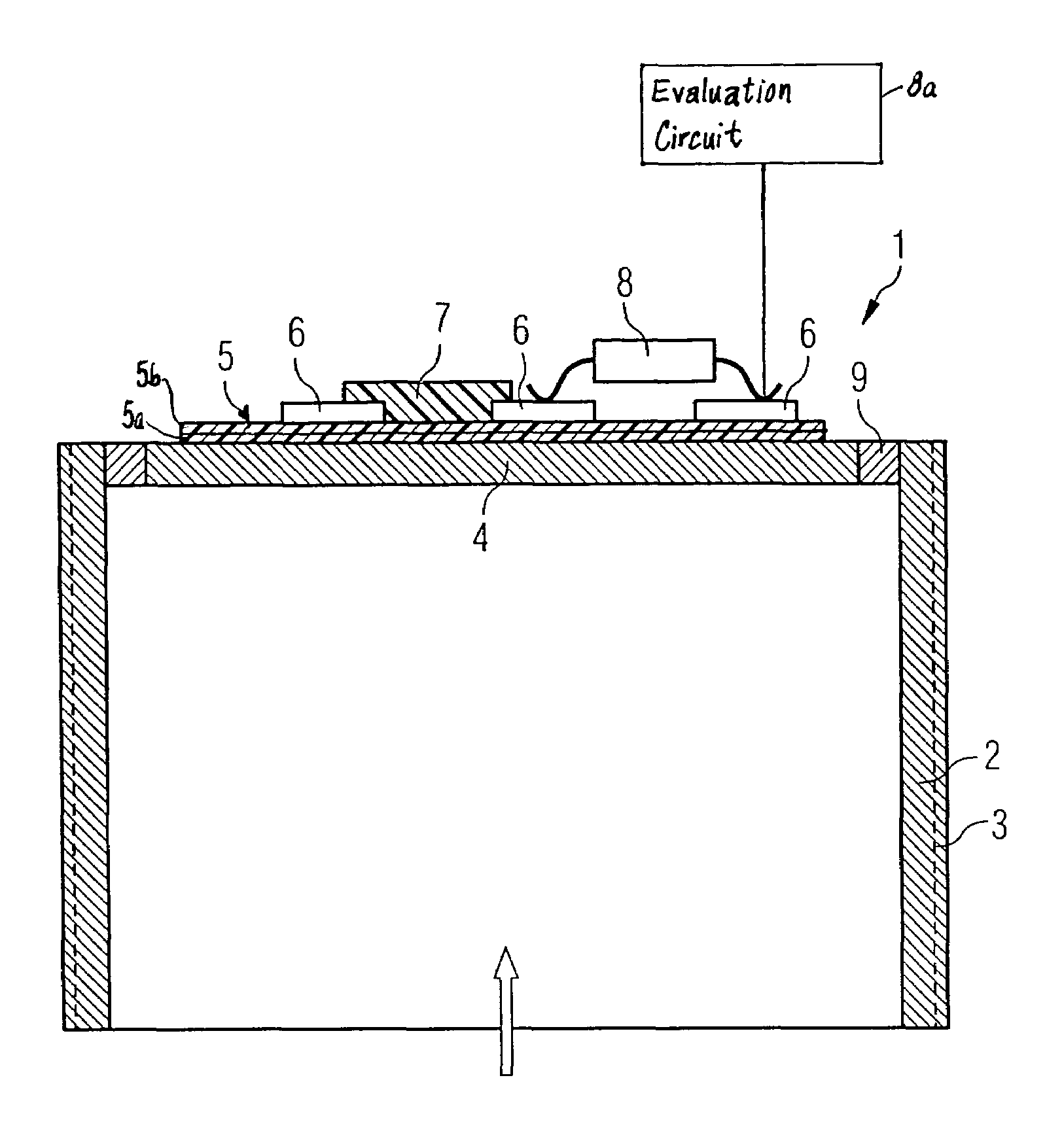

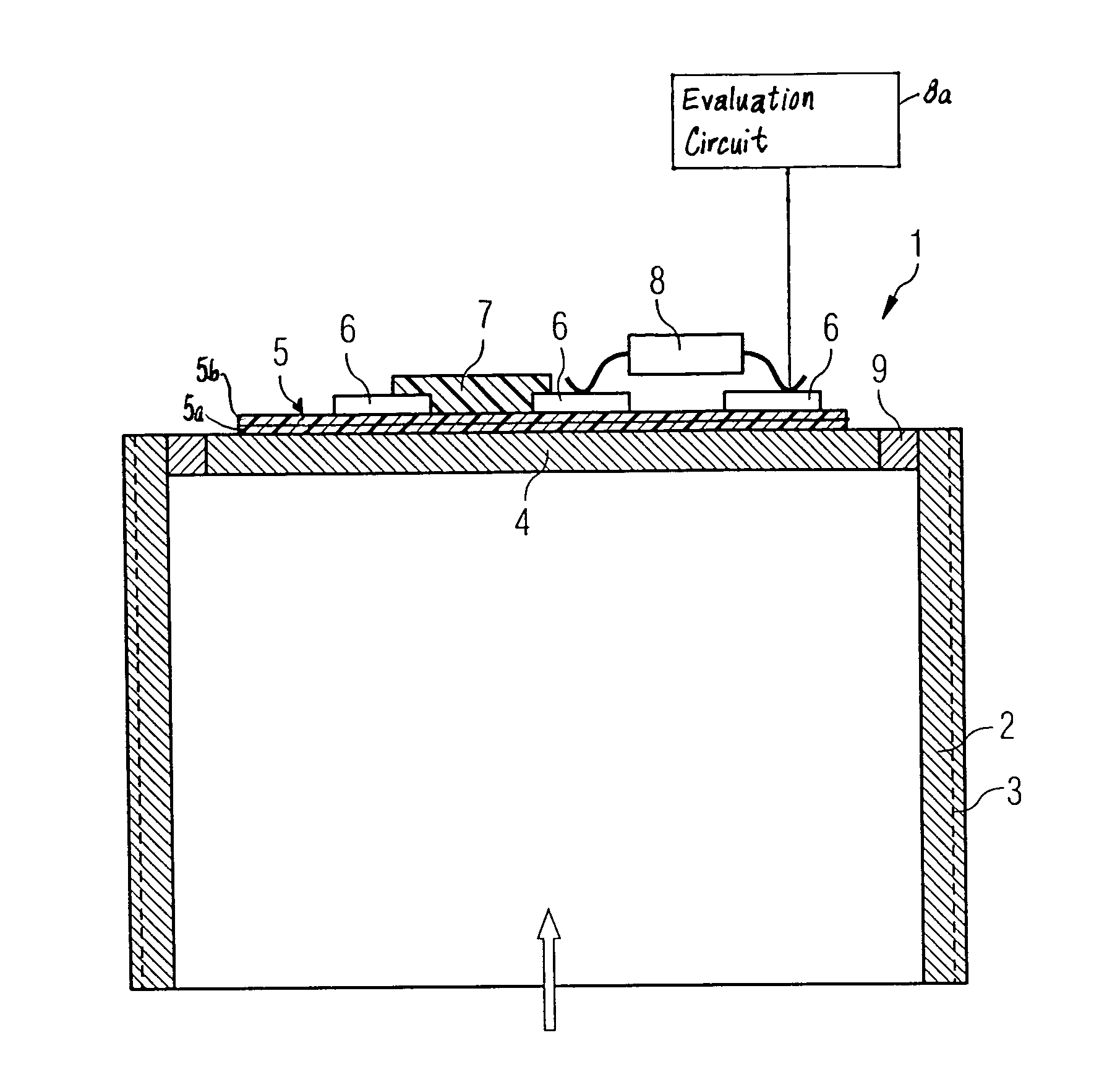

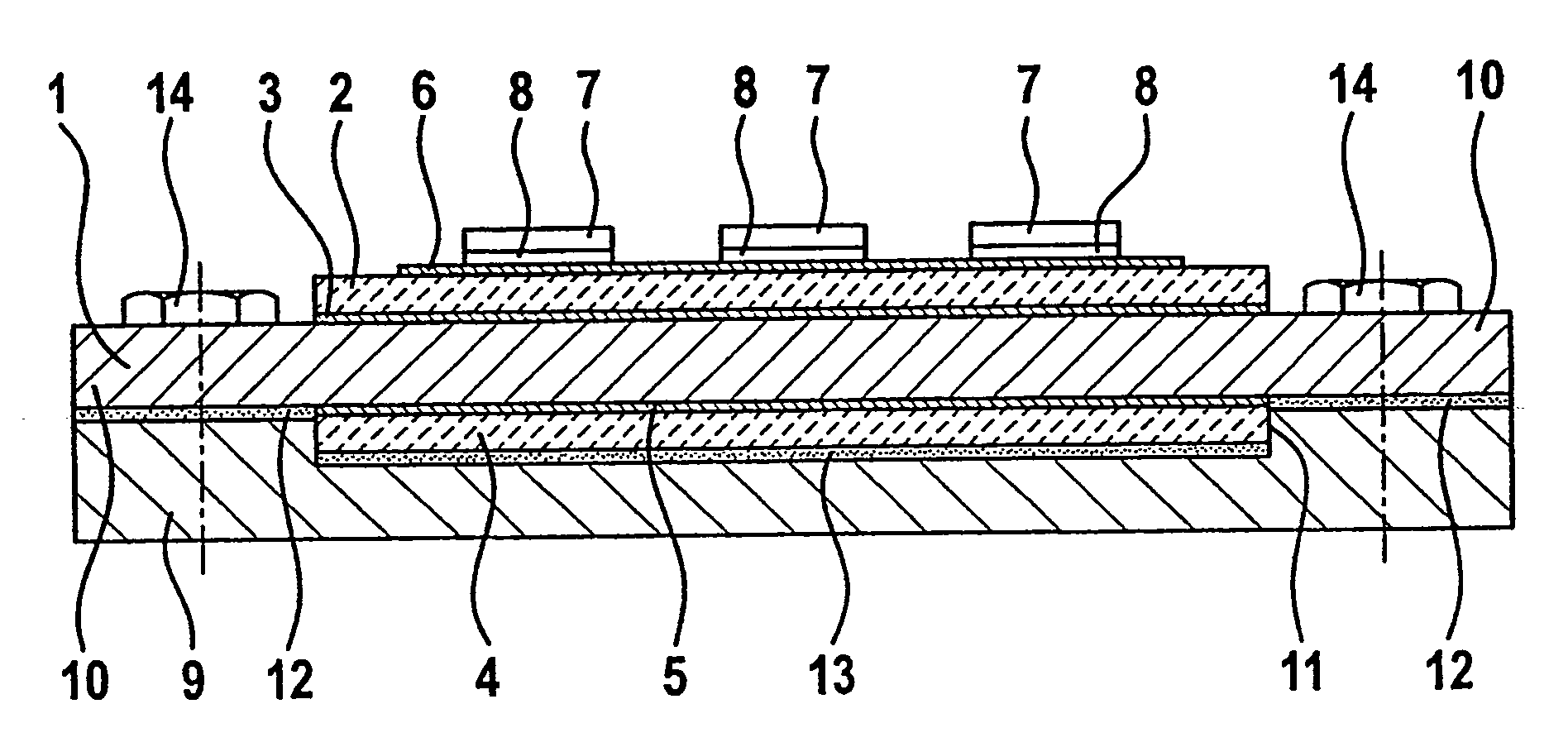

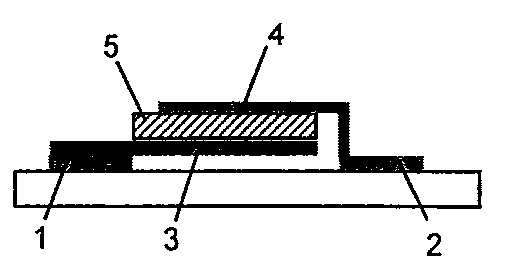

Pressure sensor

InactiveUS20040237659A1Simple and low-costBlocking may occurFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesThick film technologyEngineering

A pressure sensor includes a membrane having a radially peripheral edge region fixedly arranged on a support. One side of the membrane can be acted on by a medium being measured and the membrane can be deflected in response to pressure of the medium. Measuring elements and an electric circuit interconnecting the measuring elements are arranged on the membrane, the measuring elements and the circuit being applied by the thick-film technique and sintered on in a thermal process. The membrane is made of an electrically conducting metal and bears an insulating layer, on which the measuring elements and the electric circuit are arranged. In this case, the insulating layer consists of a material having a coefficient of expansion that lies between the coefficient of expansion of the metal of the membrane and the coefficient of expansion of the material of the measuring elements and the electric circuit.

Owner:SIEMENS AG

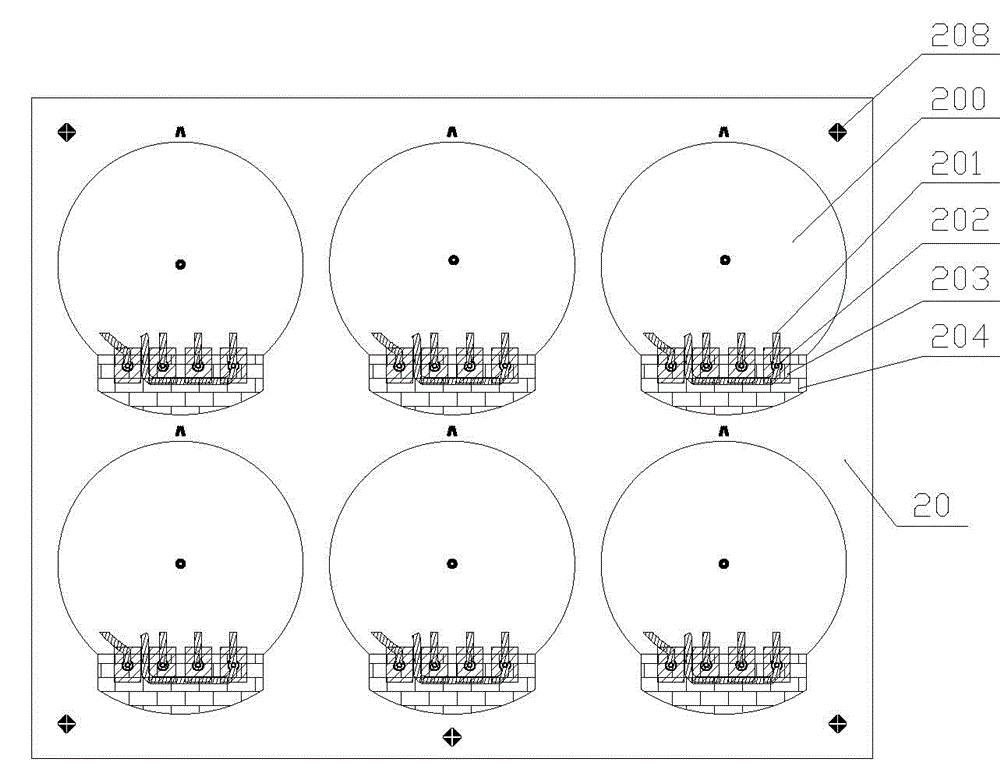

Device and method for improving screen printing precise alignment by using contact photoetching machine

ActiveCN101727026APrinting height adjustableWon't touchSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingThick film technology

The invention provides a device and a method for improving screen printing precise alignment by using a contact photoetching machine. The method comprises the following steps: when photoetching, inserting a positioning jig frame provided with a screen printing mask image into the contact photoetching machine, adjusting brightness through an auxiliary spacer, setting compressed air to upwards move a spacer bearing platform, realizing X-Y-Z photoetching pre-positioning through sensor induction, aligning the screen printing image with a silicon wafer image on the spacer bearing platform through a microscopical alignment system, putting printing paint on a silk screen, and printing the image with a scraper blade, and when the spacer bearing platform moves downwards to the original position, taking the silicon wafer out. The device and the method have the following advantages that: the screen printing alignment precision is improved to + / -3 mum of the microelectronic technology from 10 to 15 mum of the common thick film technology; coating and alignment of substrates of a plurality of layers of stacked silicon wafers, which have different thicknesses, are realized; and application range is obviously widened. The device has simple structure, method and operation, is easily integrated and popularized, and realizes the substitution of a contact photoetching mask plate with the screen printing mask image.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

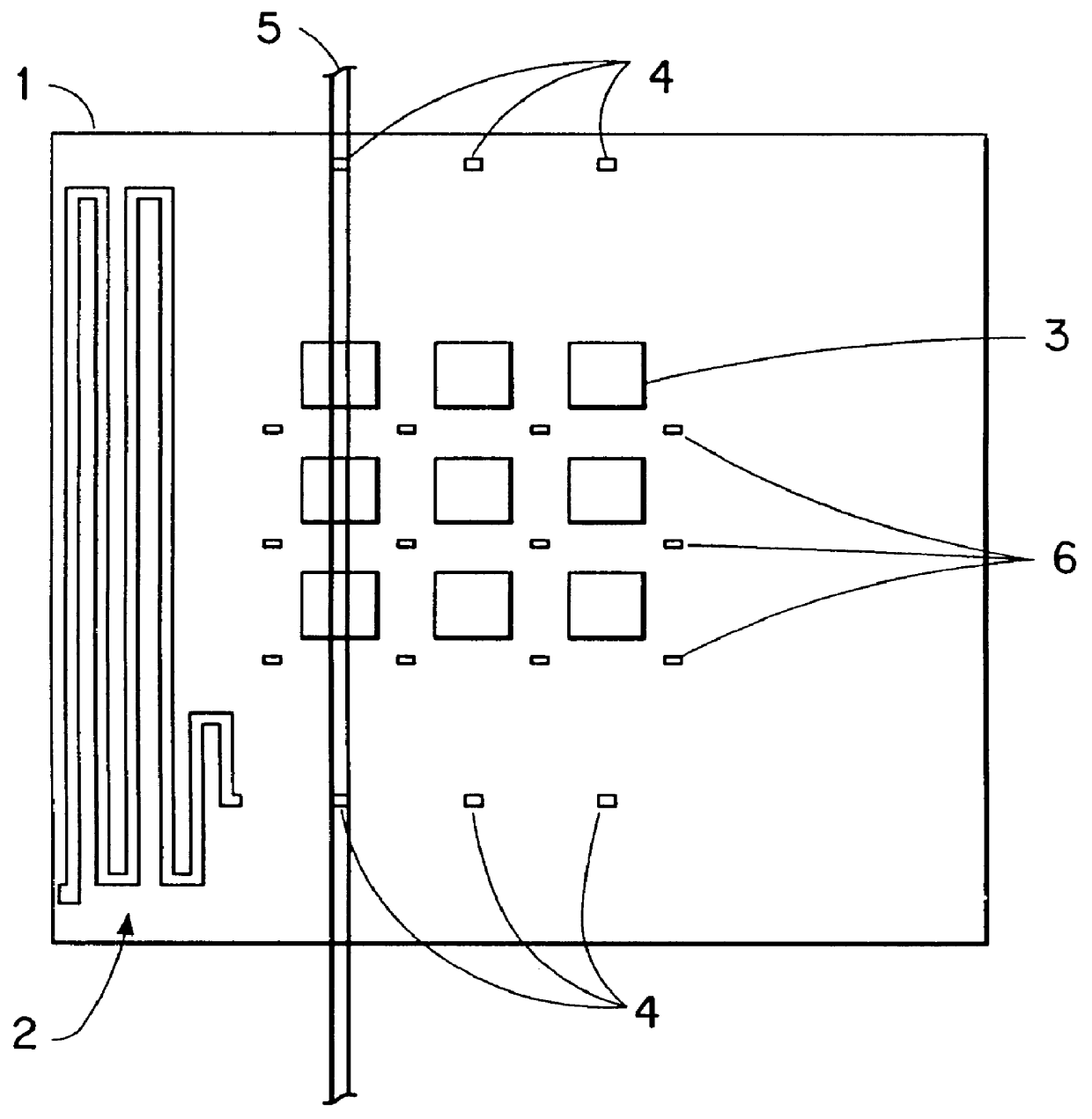

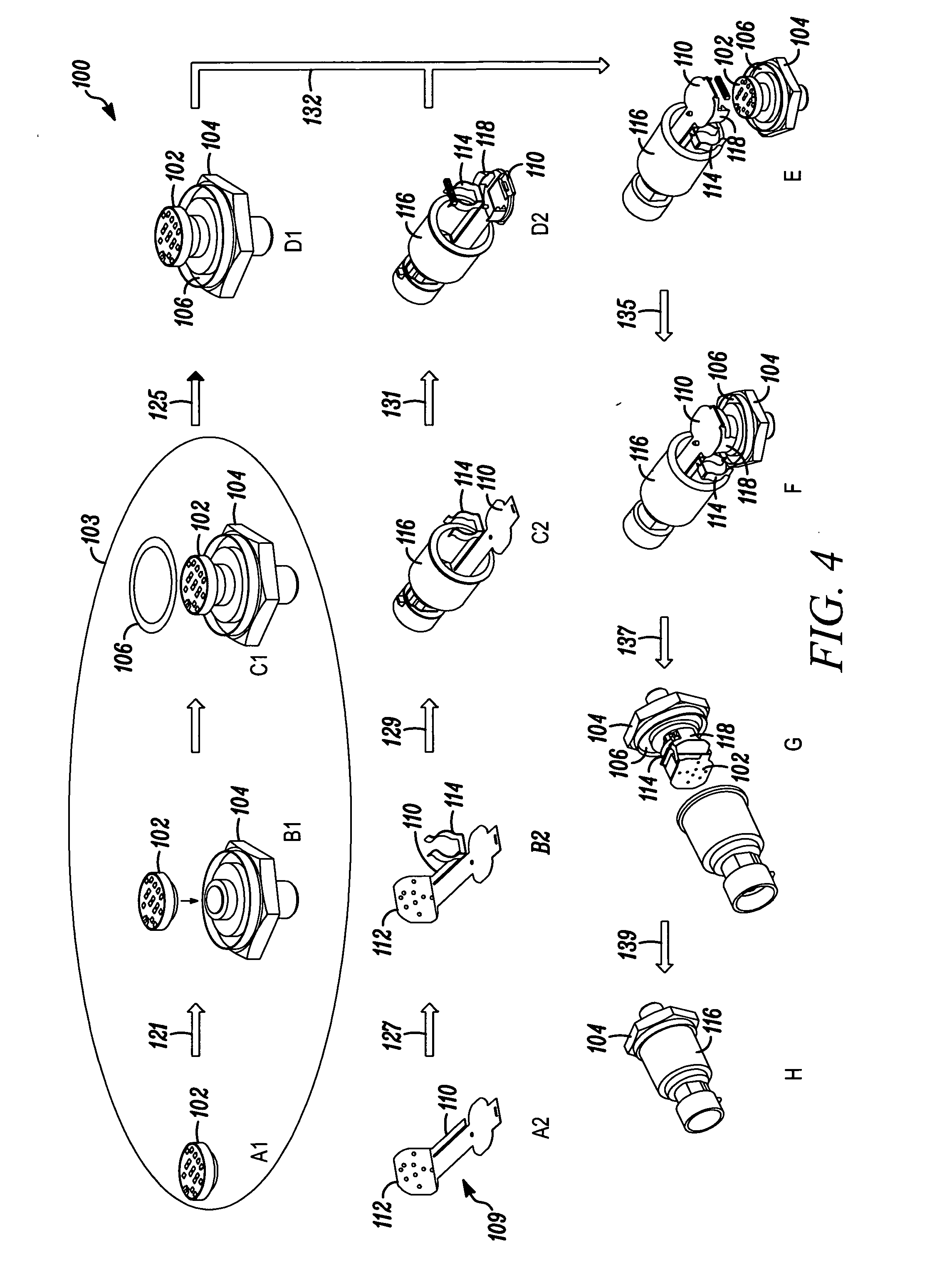

Device chip carriers, modules, and methods of forming thereof

ActiveUS20080035943A1Dielectric materialsSemiconductor/solid-state device detailsLight equipmentThick film technology

The present invention provides novel methods of forming component carriers, component modules, and the carriers and modules formed therefrom which utilize thick film technology. In some embodiments, these methods are used to form lighting device chip carriers and modules. In further embodiments, these lighting device chip carriers and modules are used in LED applications.

Owner:DU PONT CHINA LTD

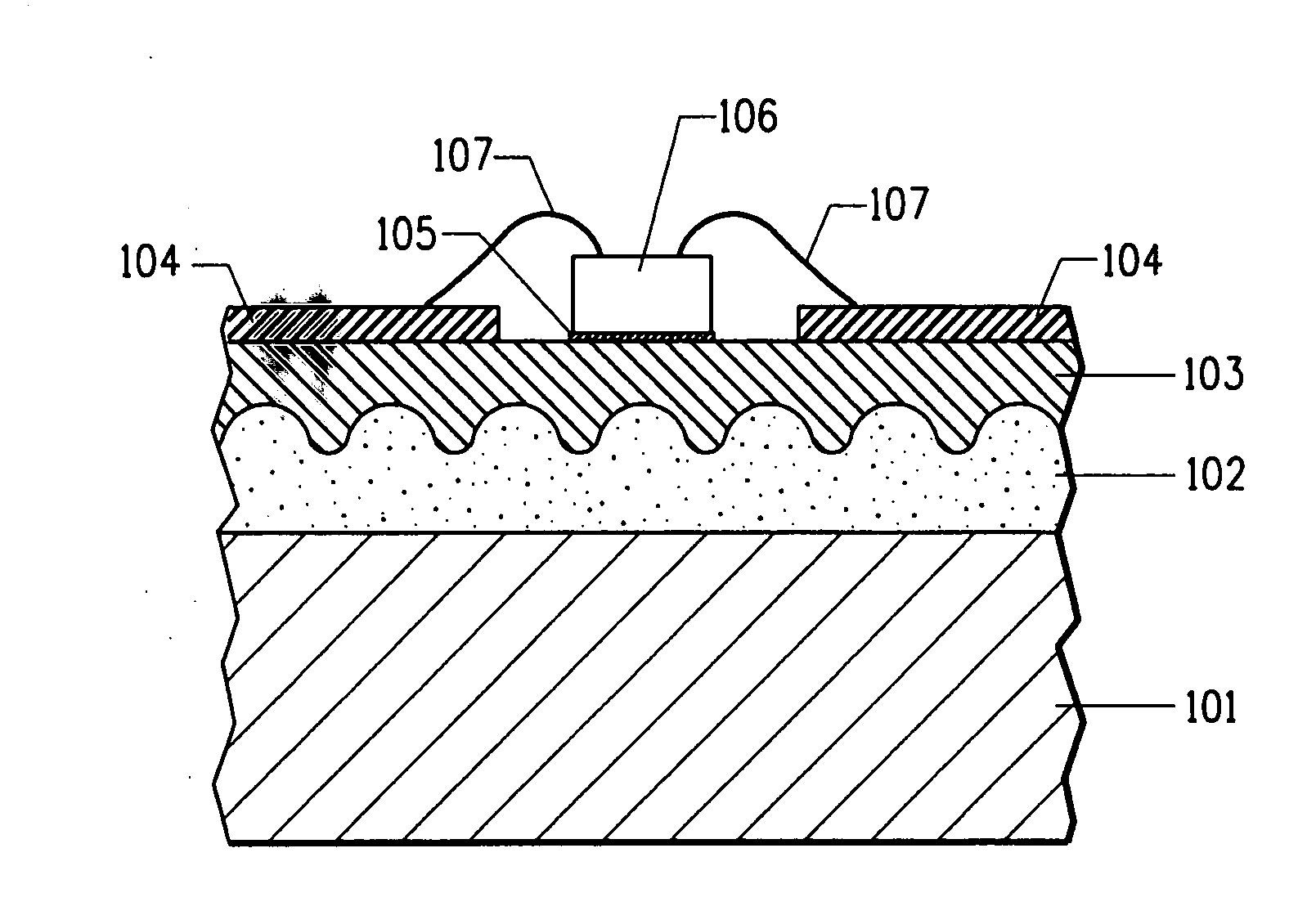

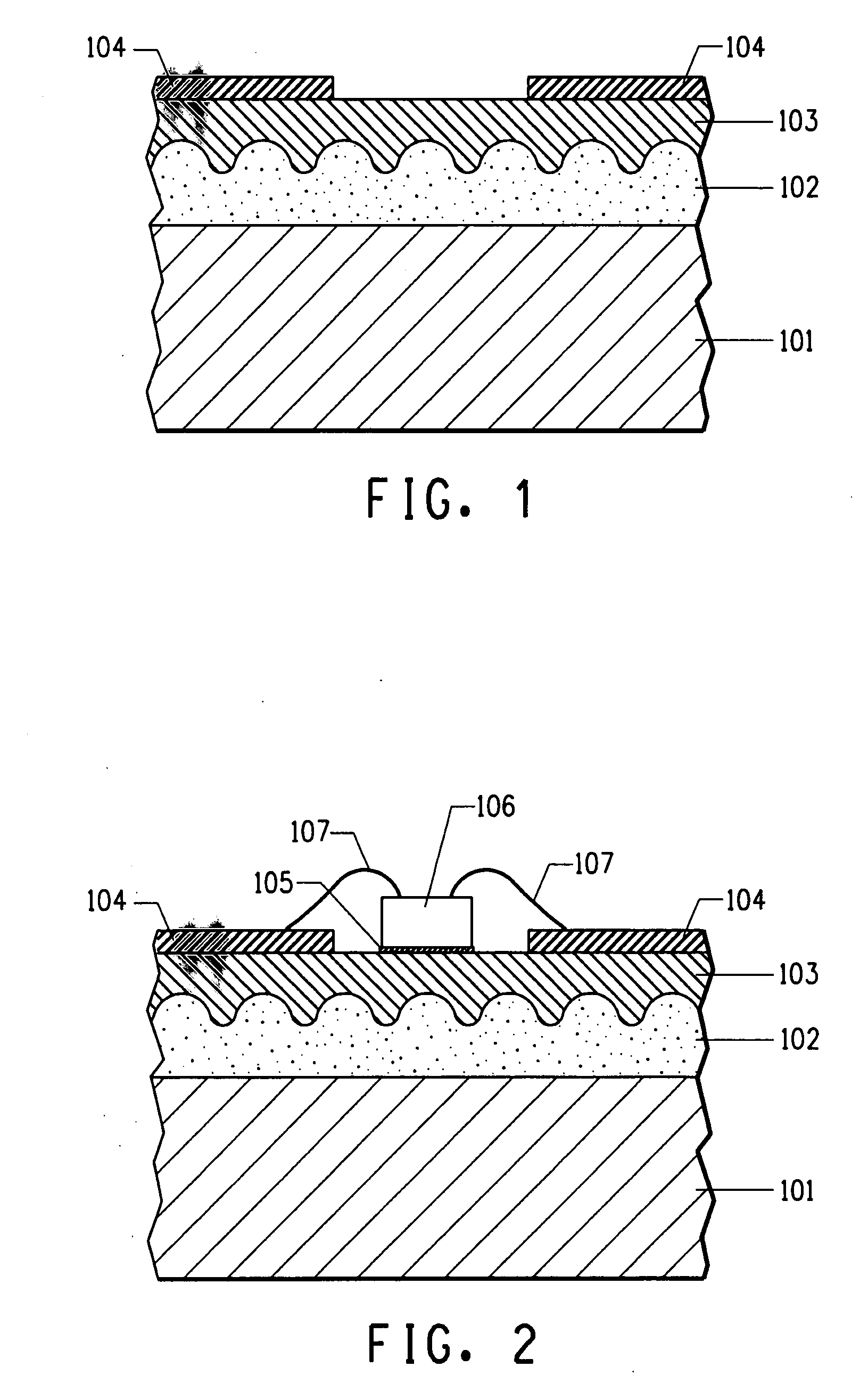

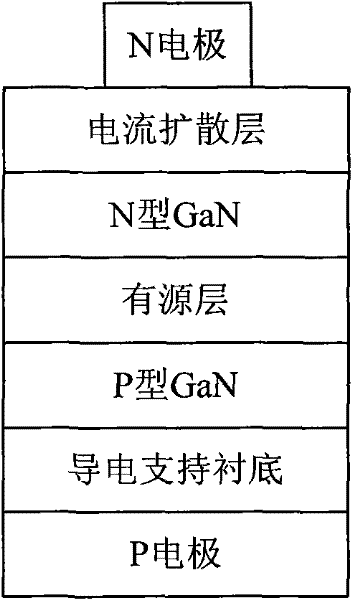

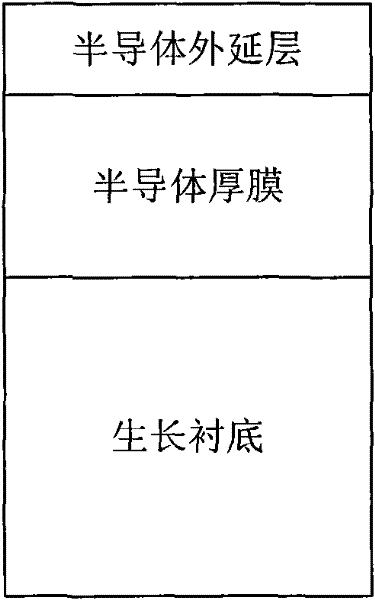

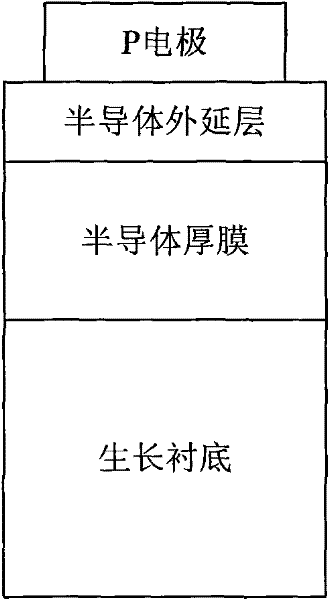

A kind of vertical structure light-emitting diode and its manufacturing method

ActiveCN102299226AImprove yield rateAvoid damageSemiconductor devicesBonding processThick film technology

The invention discloses an LED (light emitting diode) with a vertical structure and a manufacturing method thereof. The LED structure comprises an N electrode, a semiconductor thick film arranged on the N electrode, a semiconductor epitaxial layer arranged on the semiconductor thick film and a P electrode arranged on the semiconductor epitaxial layer. The structure uses a P-type semiconductor layer as a light emitting surface, the light-emitting area can be increased and the light-emitting efficiency can be improved compared with that of an electrode structure at the same side. The manufacturing method of the LED with the vertical structure utilizes a temporary bonding process and a thick film process and uses a temporary substrate to support grinding and remove the growing substrate; compared with the usual vertical structure process, a laser lift-off process can be used to reduce the damage to GaN and the fragment phenomenon caused by the problems such as bonding process unevenness and the like, thus the rate of qualified products of the chip with the vertical structure can be improved.

Owner:EPILIGHT TECH

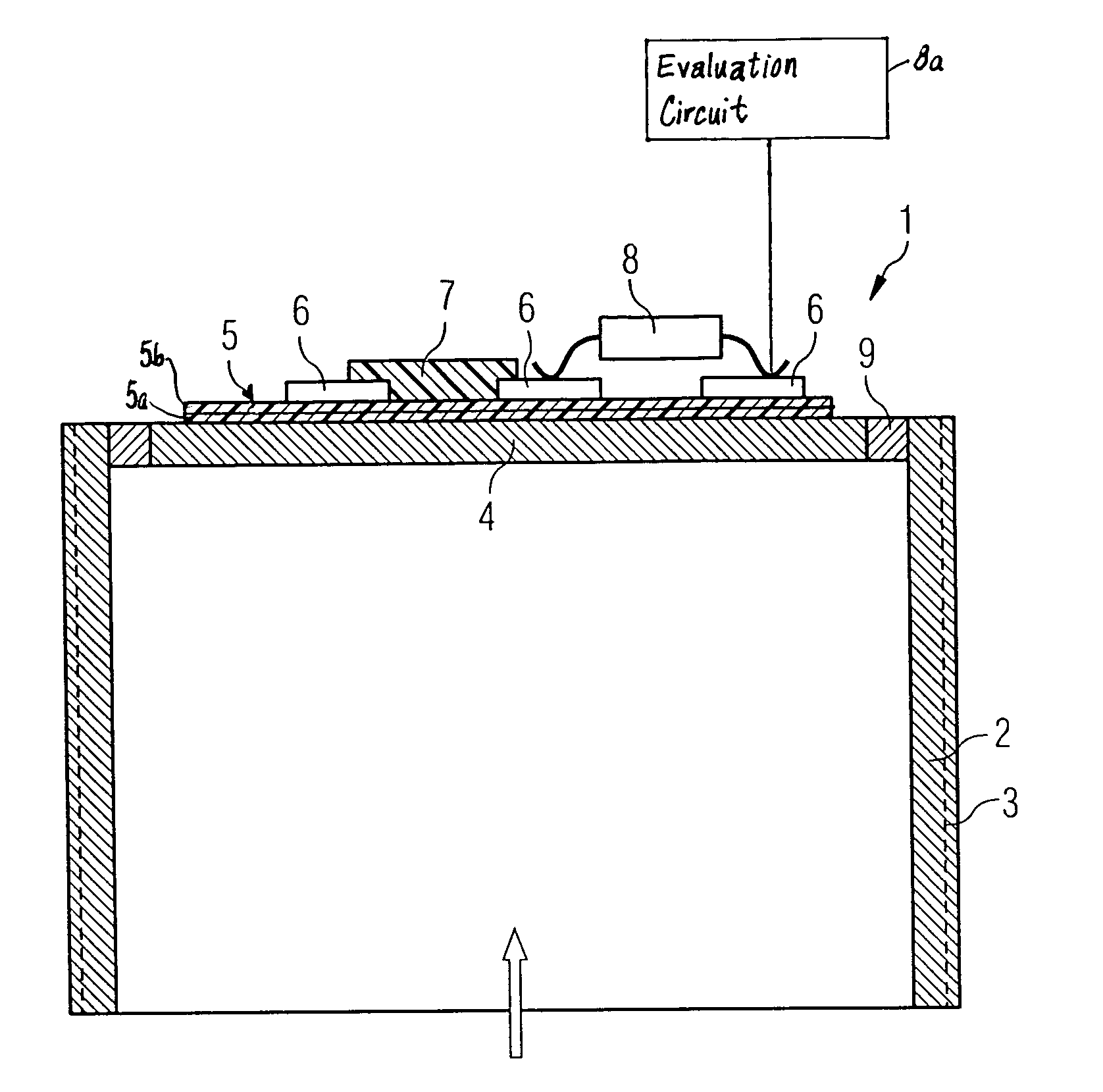

Temperature sensors with integrated sensing components

InactiveUS20170191879A1Minimize the numberReduce pointsThermometers using electric/magnetic elementsPrinted circuit aspectsElectrical resistance and conductanceElectricity

Temperature sensors and, in particular, temperature sensors of the thermocouple (TC) and resistance temperature detector (RTD) types. The temperature sensors are manufactured by sequential deposition of insulating and temperature sensor layers onto a substrate via thick film techniques. The temperature sensor layer includes a temperature sensor element, which may be configured as a conductor pair forming a thermocouple junction or as a resistance temperature detector filament. The substrate may optionally be roll formed after thick film processing from a flat, manufacturing configuration into a tube shaped use configuration, in which the layers and temperature sensor elements are disposed within an interior of the device. The conductors or filaments of temperature sensor elements may extend along the length of the sensor substrate to minimize the number of electrical connections present, thereby easing manufacture and decreasing points of potential operational failure.

Owner:APPLIED ELECTRONICS MATERIALS LLC

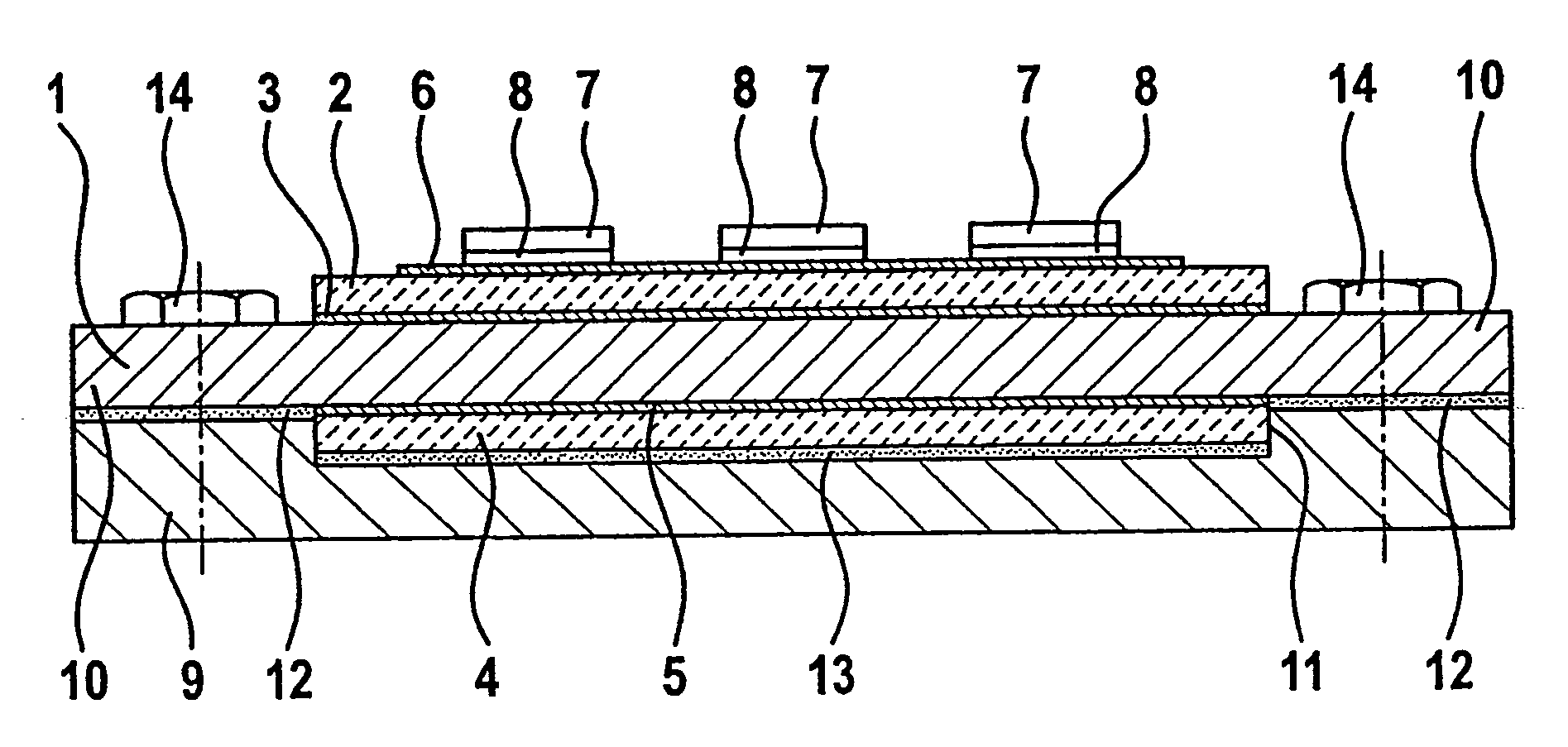

Pressure sensor with membrane and measuring elements arranged on the membrane

InactiveUS7043995B2Simple methodFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesThick film technologyMembrane configuration

A pressure sensor includes a membrane having a radially peripheral edge region fixedly arranged on a support. One side of the membrane can be acted on by a medium being measured and the membrane can be deflected in response to pressure of the medium. Measuring elements and an electric circuit interconnecting the measuring elements are arranged on the membrane, the measuring elements and the circuit being applied by the thick-film technique and sintered on in a thermal process. The membrane is made of an electrically conducting metal and bears an insulating layer, on which the measuring elements and the electric circuit are arranged. In this case, the insulating layer consists of a material having a coefficient of expansion that lies between the coefficient of expansion of the metal of the membrane and the coefficient of expansion of the material of the measuring elements and the electric circuit.

Owner:SIEMENS AG

Method for making printed circuit board (PCB)

InactiveCN102159034AThe production process is simpleShorten the production cyclePrinted circuit manufactureHigh densityInterconnection density

The invention discloses a method for making a printed circuit board (PCB) and belongs to an integrated high density interconnection (HDI) technology, in particular to a new high density interconnection technology which combines the present dry method, thick film technology, laser engraved technology and plasma cleaning technology of the PCB. In the method, processes of image transferring, soldering-resistant exposure developing, plating holes and electroplating are not required, so the production process is simplified and higher interconnection density can be obtained; the method can be used for chip level assembly and 3G products, thereby realizing energy saving and emission reduction and reducing cost.

Owner:HUIZHOU CITY GREEN MARK PHOTOELECTRIC TECH

Differential scanning calorimeter and manufacturing method thereof

InactiveCN104502405ASmall time constantHigh sensitivityMaterial heat developmentEngineeringHeat losses

The invention provides a differential scanning calorimeter and a manufacturing method thereof. The differential scanning calorimeter comprises a main body core part formed by using a thick-film technology and a heat insulating layer arranged on the outer side of the main body core part, wherein the main body core part comprises a conducting layer, a first insulating layer, a sensor layer and a second insulating layer which are sequentially arranged on one side of the conducting layer, and a third insulating layer, a heating layer and a fourth insulating layer which are arranged on the other side of the conducting layer; the sensor layer comprises a sample-side sensor and a reference-side sensor which are symmetrically distributed; the second insulating layer completely covers the sample-side sensor and the reference-side sensor. The integrally-formed main body core part is insulated from the outside by using the heat insulating layer, so that the heat loss is reduced, the complete machine is relatively small in heat capacity, and the high sensitivity and the relatively-small time constant of the differential scanning calorimeter are realized.

Owner:上海铂石机电科技有限公司

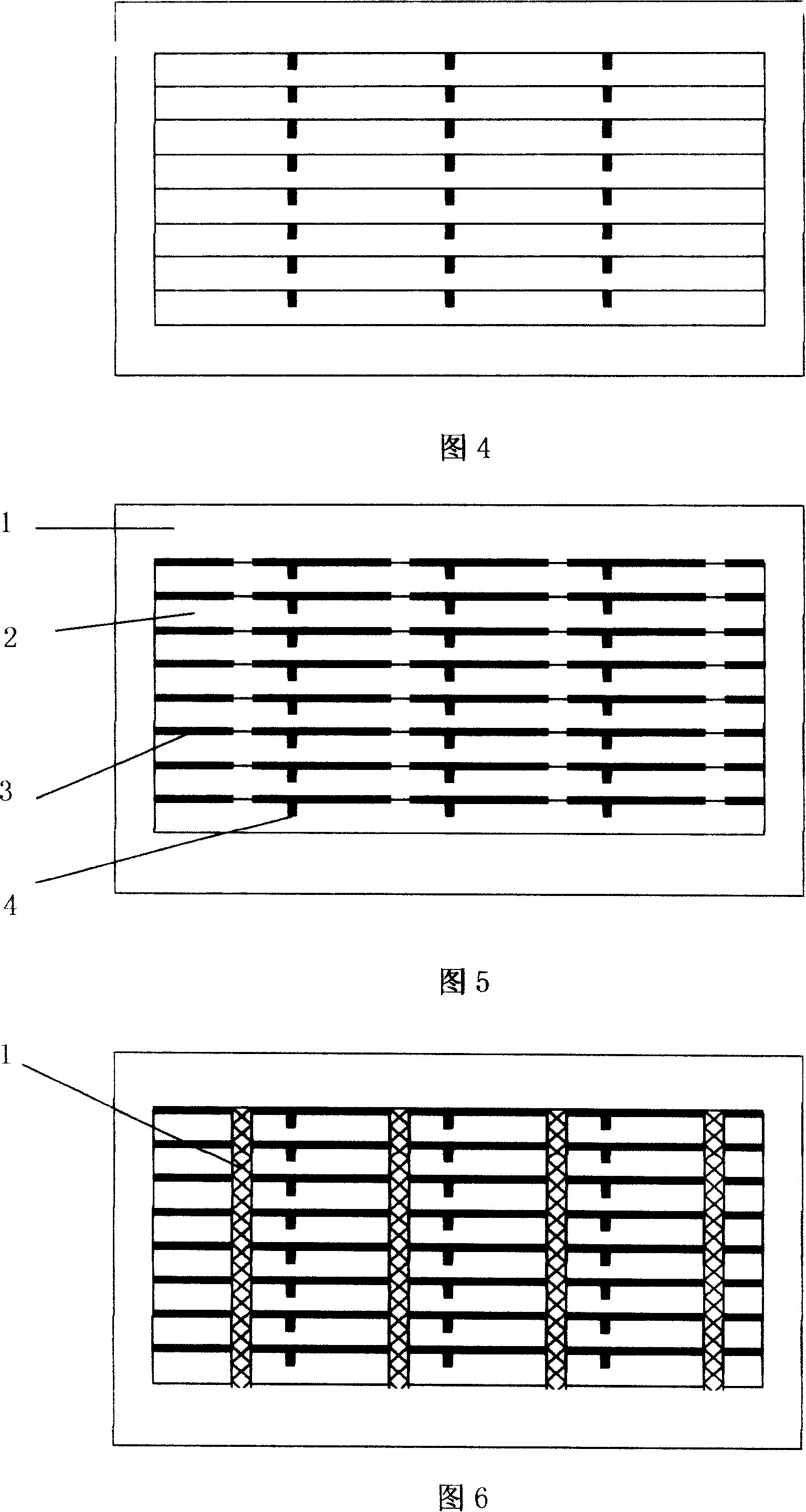

Manufacturing technique for three-dimensional structure carrier of ceramic metal membrane

InactiveCN101131937ASemiconductor/solid-state device manufacturingPrinted circuit manufactureLithographic artistMetallurgy

The invention is about processing technology field in the production of ceramic metal film thick film products. Commonly used production of ceramic membrane two-dimensional structure of metal products is implemented on the plane of the ceramic substrate. On the basis of one or two metallization of substrate, through one or two lithography or the print or sinter of the metal slurry, the design flat rectangular structure is cut to complete the production. This invention involves the production technology of the three-dimensional structure carrier of metal ceramic membrane, so it is much more complicated than that of the two-dimensional structure, but it is entirely suitable for the related products of two thick-films processing including the pottery film and ceramic film. Whether using film techniques, or using thick-film technology, the key point of production and processing of the metal ceramic with 3-D carrier structure in this invention, is as follows. Use the grinding wheel machine to cut ceramic galley proof with groovy and then complete the production of the front and side metal pattern, in this way, carrier three-dimensional structure of the ceramic metal film is obtained.

Owner:CHONGQING PINJIAN TECH

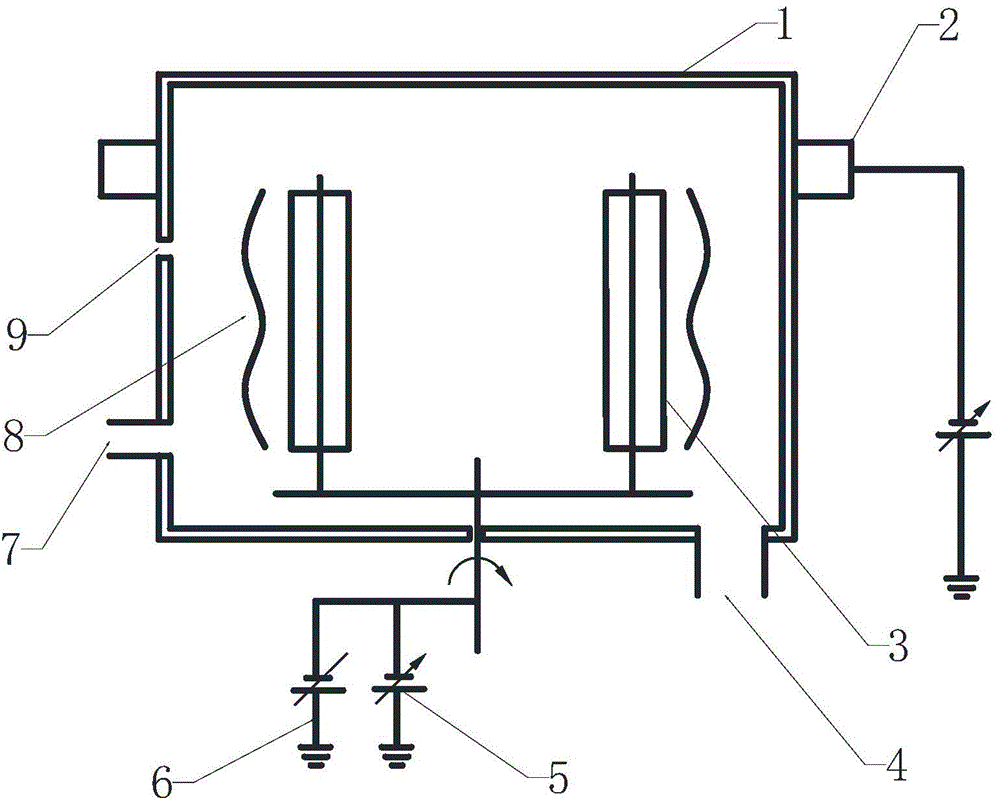

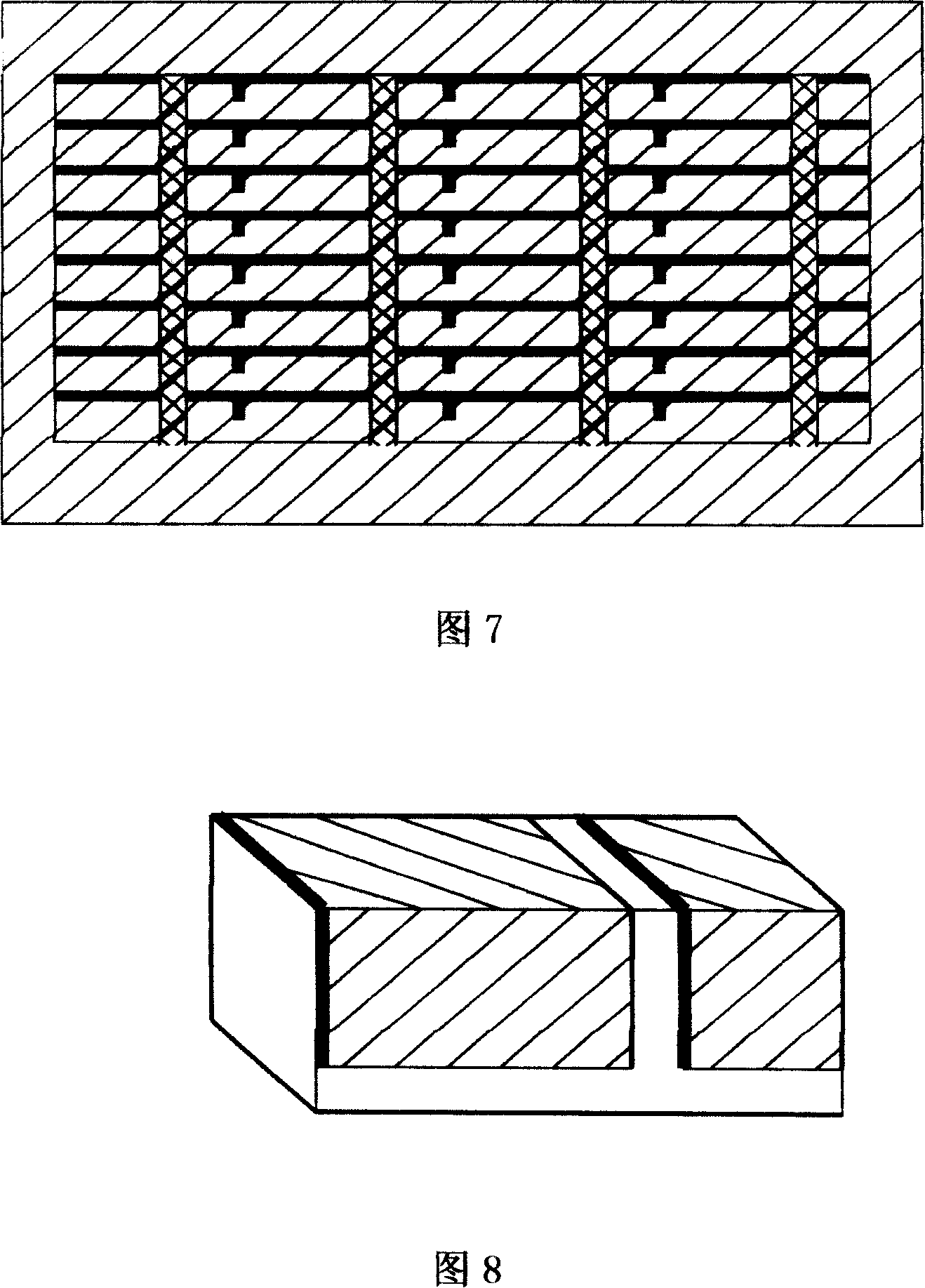

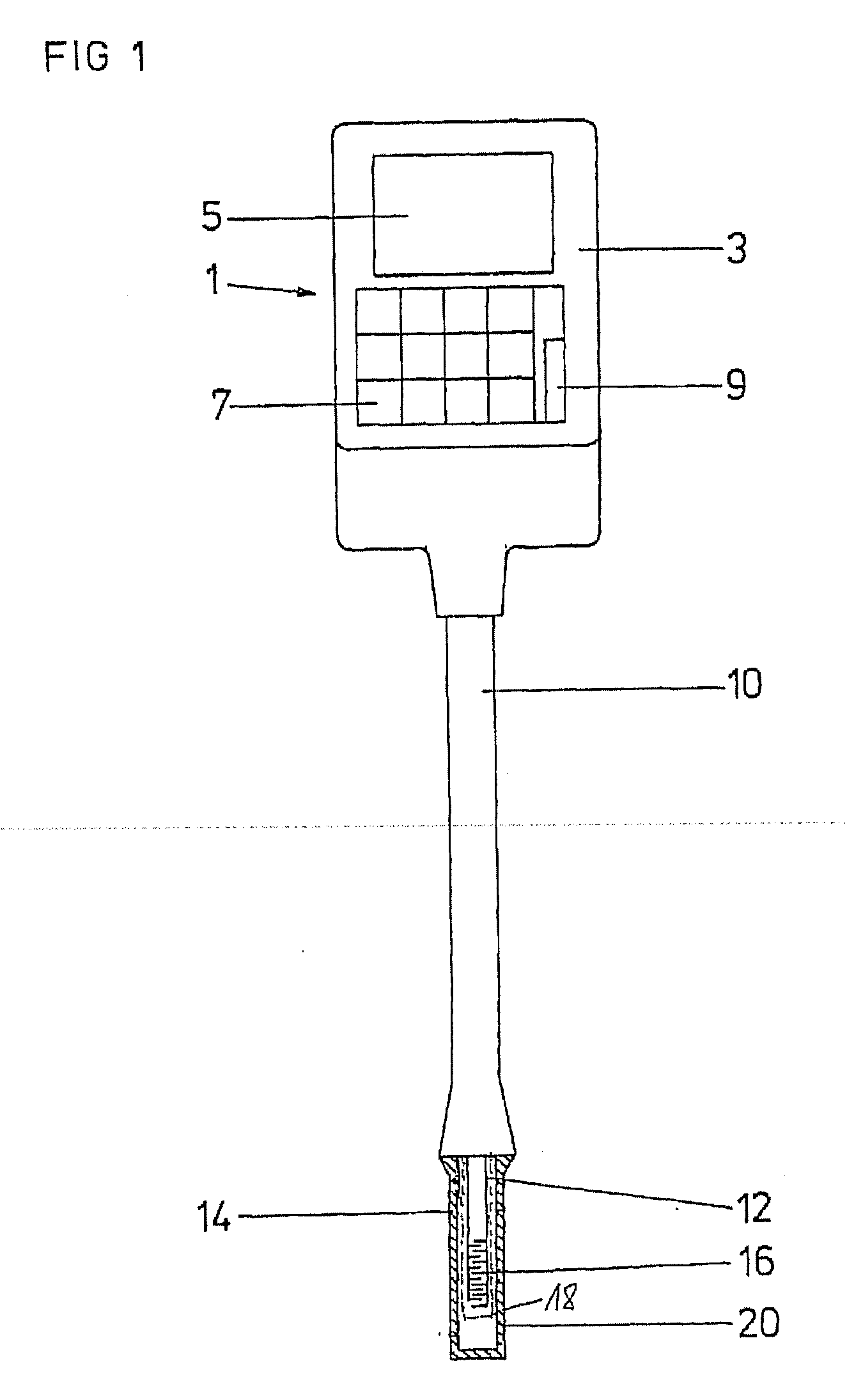

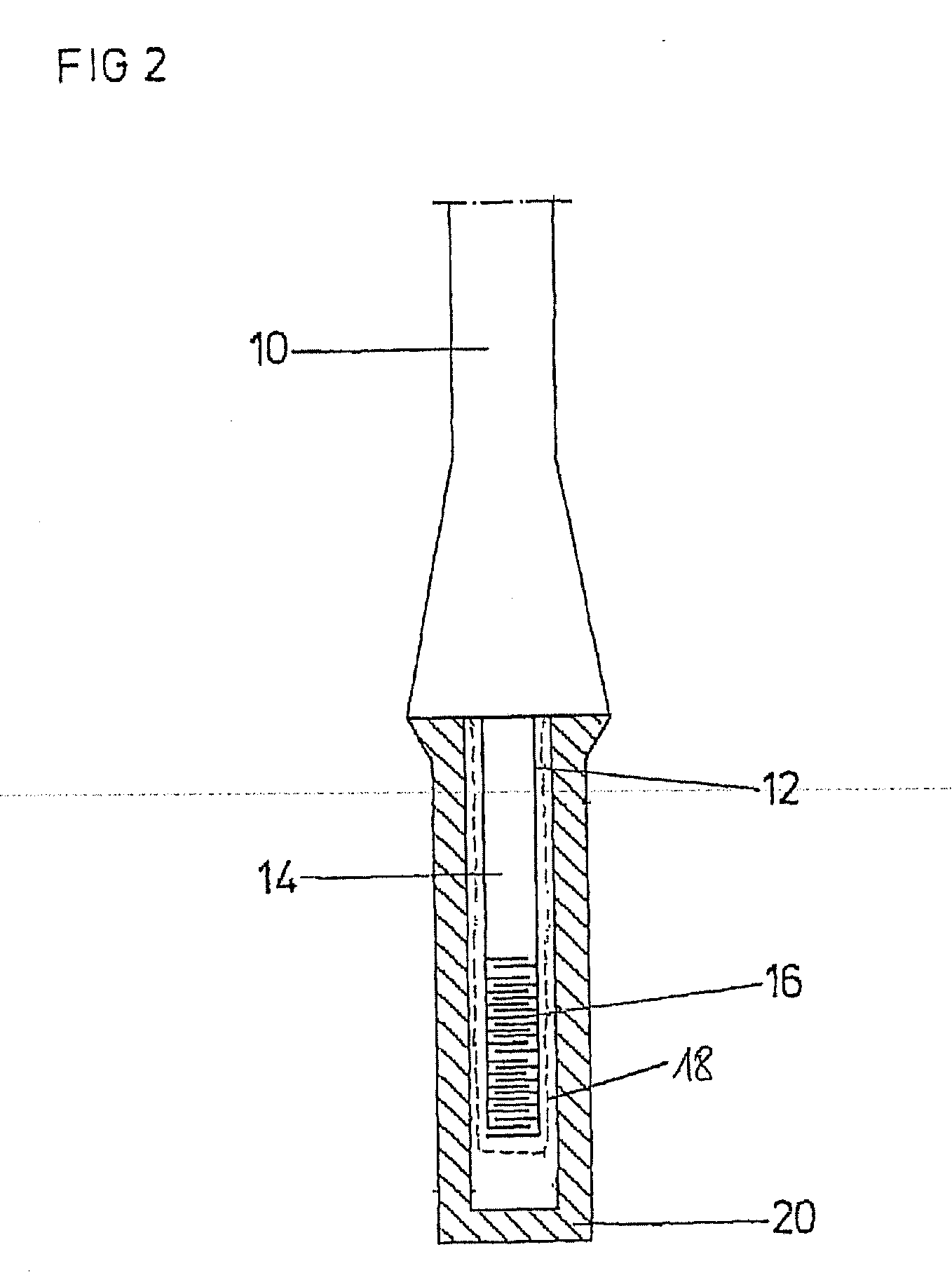

Device for gauging the status of a material especially of oils or fats

InactiveUS20110030486A1Improve mechanical stabilityEasy to cleanMaterial analysis by electric/magnetic meansTesting foodProximateThick film technology

The invention is a device for gauging the status of a material such as a fat or an oil. The device comprises: a housing; a hollow connecting element; a substrate, attached at the opposite end of the hollow connecting element; a sensor, proximate the substrate, for measuring an electrical property of the material being tested; a protective coating, wherein the protective coating covers the sensor and can be applied using either a thin-film or a thick-film technology; and, an electronic evaluation unit connected via at least one electric line to the sensor; and, is arranged proximate the housing and / or proximate the end of the connecting element that faces the housing.

Owner:TESTO AG

Thick film technology based ultra high pressure sensor utilizing integral port and diaphragm construction

ActiveUS20070186661A1Easy to understandFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsUltra high pressureEngineering

A method and apparatus for configuring a pressure sensor. A homogeneous piece of metal can be provided. A pressure port and a machined diaphragm are integrated onto the homogeneous piece of metal, wherein the machined diaphragm is connected to the pressure port. The machined diaphragm can be configured utilizing Advanced Thick Film (ATF) technology, thereby providing a high-pressure pressure sensor for use in high-pressure sensing application based on the pressure port and the machined diaphragm and related pressure sensor components thereof.

Owner:HONEYWELL INT INC

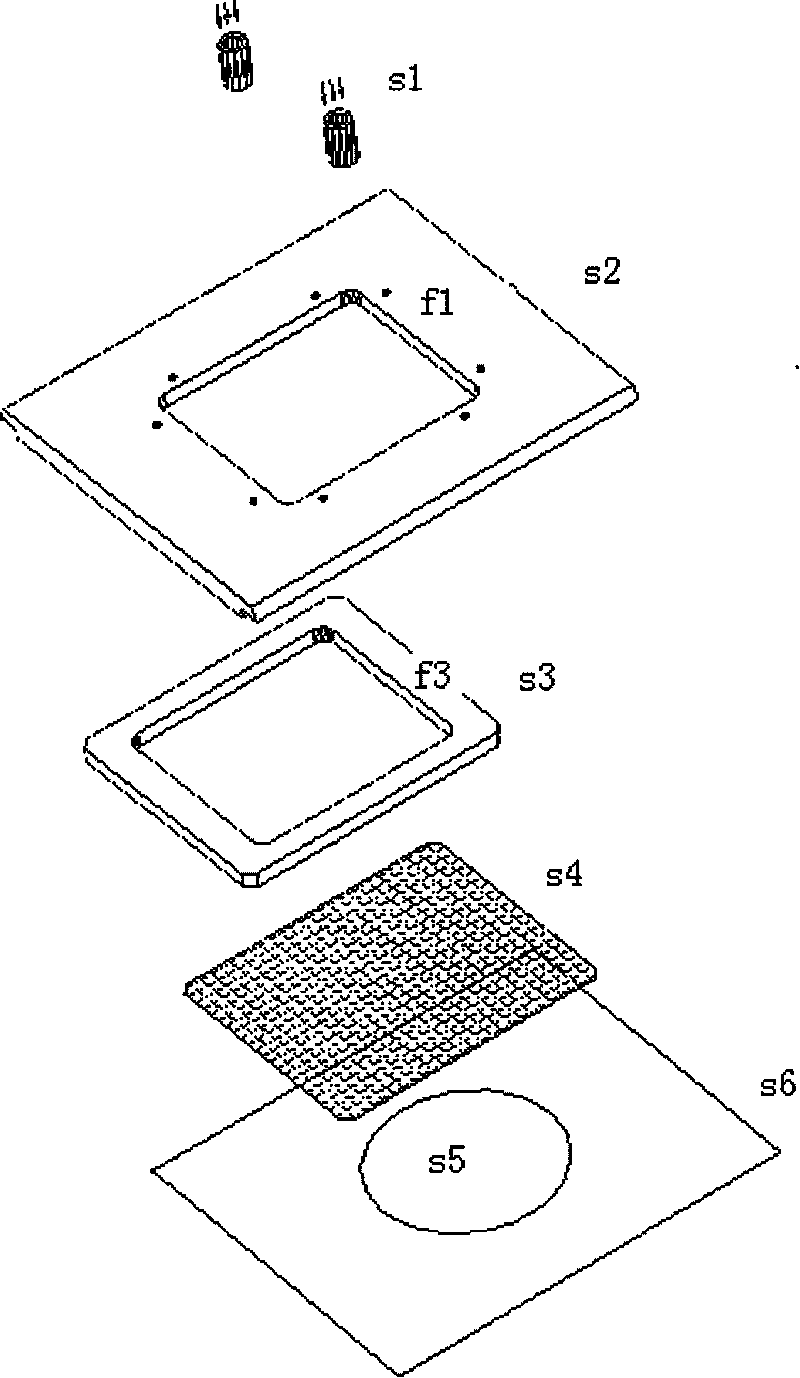

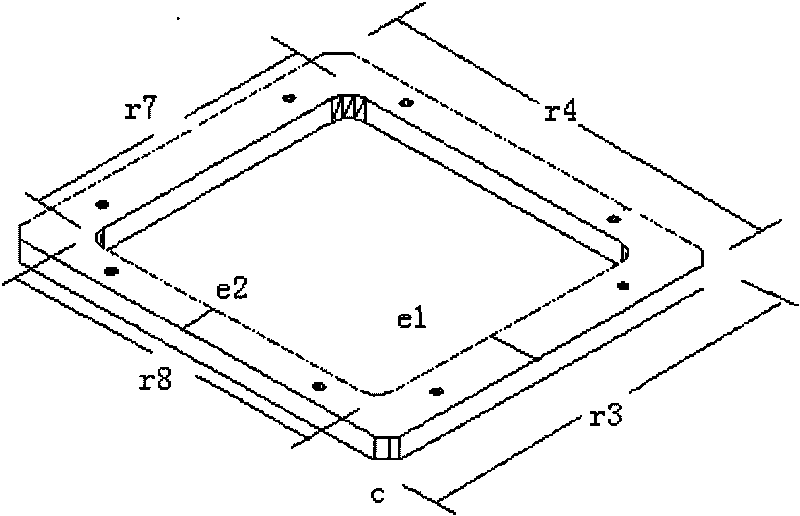

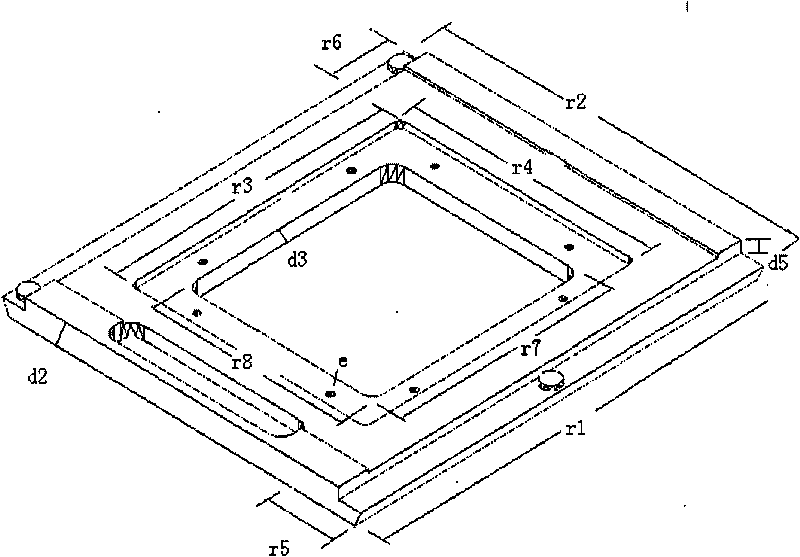

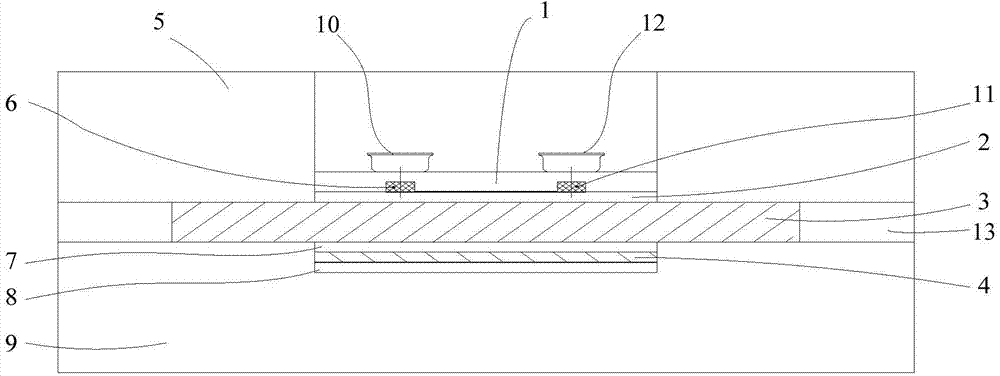

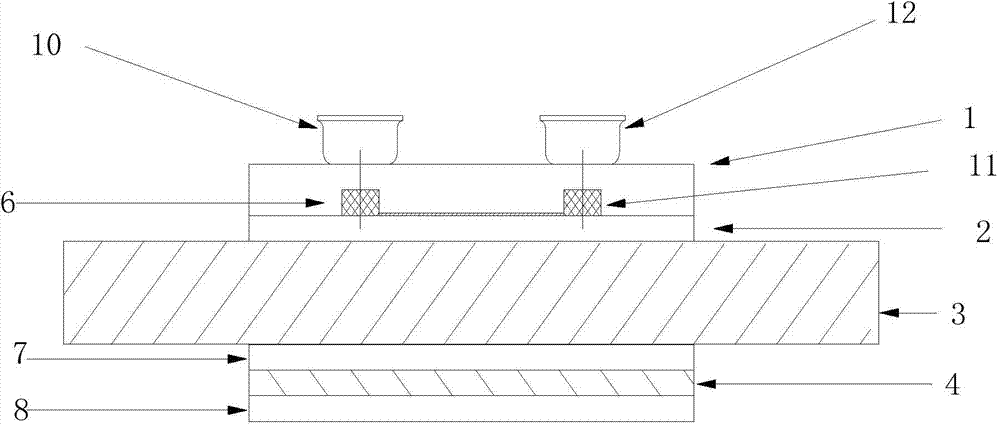

Power electronics component

InactiveUS7236367B2Improve cooling effectAvoid damageSemiconductor/solid-state device detailsPrinted circuits stress/warp reductionThick film technologyOptoelectronics

The invention relates to a power electronics component that comprises a planar ceramics substrate (2) on whose one face condutor tracks (6), applied in thick-film technique, are disposed for electrically connecting electrical power components (7) of a circuit that are also disposed on the ceramics substrate (2). The ceramics substrate (2), with its other face, is brazed onto a metal a metal support element (1) that serves as a heat spreader. The support element (1) is linked with a thermoconducting housing part housing that accommodates the support element (1) in a thermoconductive manner. On the face of the support element (1) facing away from the ceramics substrate (2), approximately opposite the ceramics substrate (2), a second ceramics substrate (4) is brazed onto the ceramics substrate (2) that carries the circuit and has approximately the same dimensions.

Owner:CONTINENTAL AUTOMOTIVE GMBH

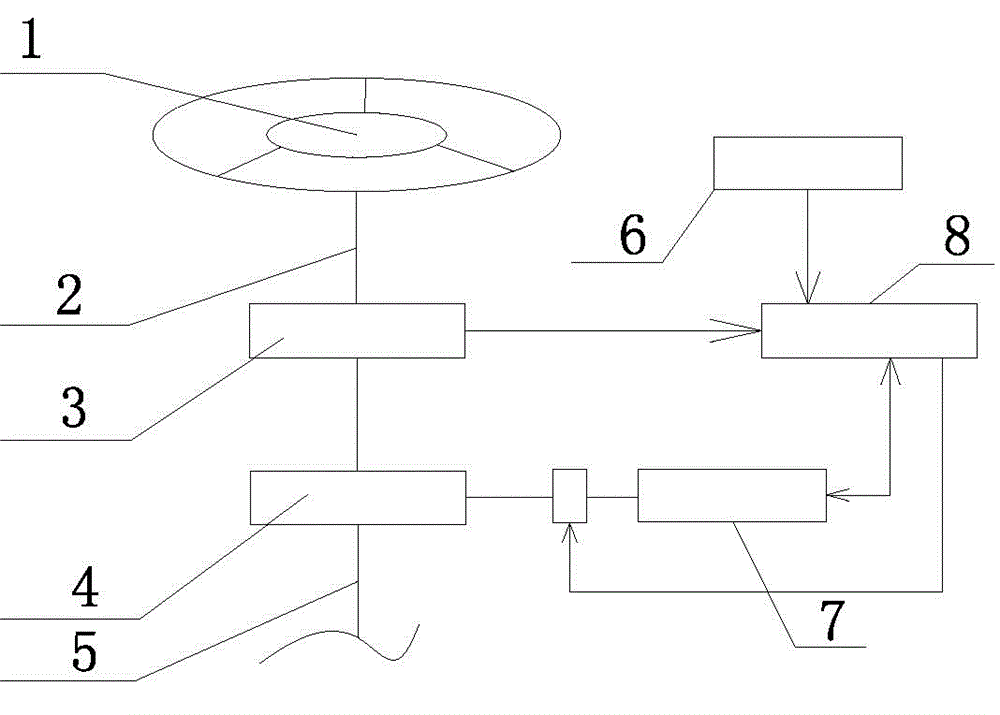

Temperature measurement feedback electromagnetic induction heating body based on thick film technology

PendingCN111465131AAccurate detectionGood adhesionThermometer detailsCoil arrangementsHemt circuitsEngineering

The invention discloses a thick film technology-based temperature measurement feedback electromagnetic induction heating body, which comprises an eddy current heating body base material, wherein the eddy current heating body base material generates heat through changed current in an electromagnetic coil, an insulating coupling material layer is arranged on the surface of the eddy current heating body base material, a thermistor wire layer is arranged on the surface of the insulating coupling material layer, the insulating coupling material layer relatively insulates and isolates the thermistorwire layer from the eddy current heating body base material while a good attachment effect is generated, the thermistor wire layer is located on a loop of a sensor circuit, the resistance value of the thermistor wire layer changes along with the temperature, and the sensor circuit detects the temperature according to the change of the resistance value of the thermistor wire layer. The thermistorwire layer directly detects the temperature of the eddy current heating body base material, so that the temperature can be accurately detected in real time, and the detection is direct compared with the detection of the temperature of a heated object.

Owner:ZHUZHOU LEEDINK ELECTRONICS TECH CO LTD

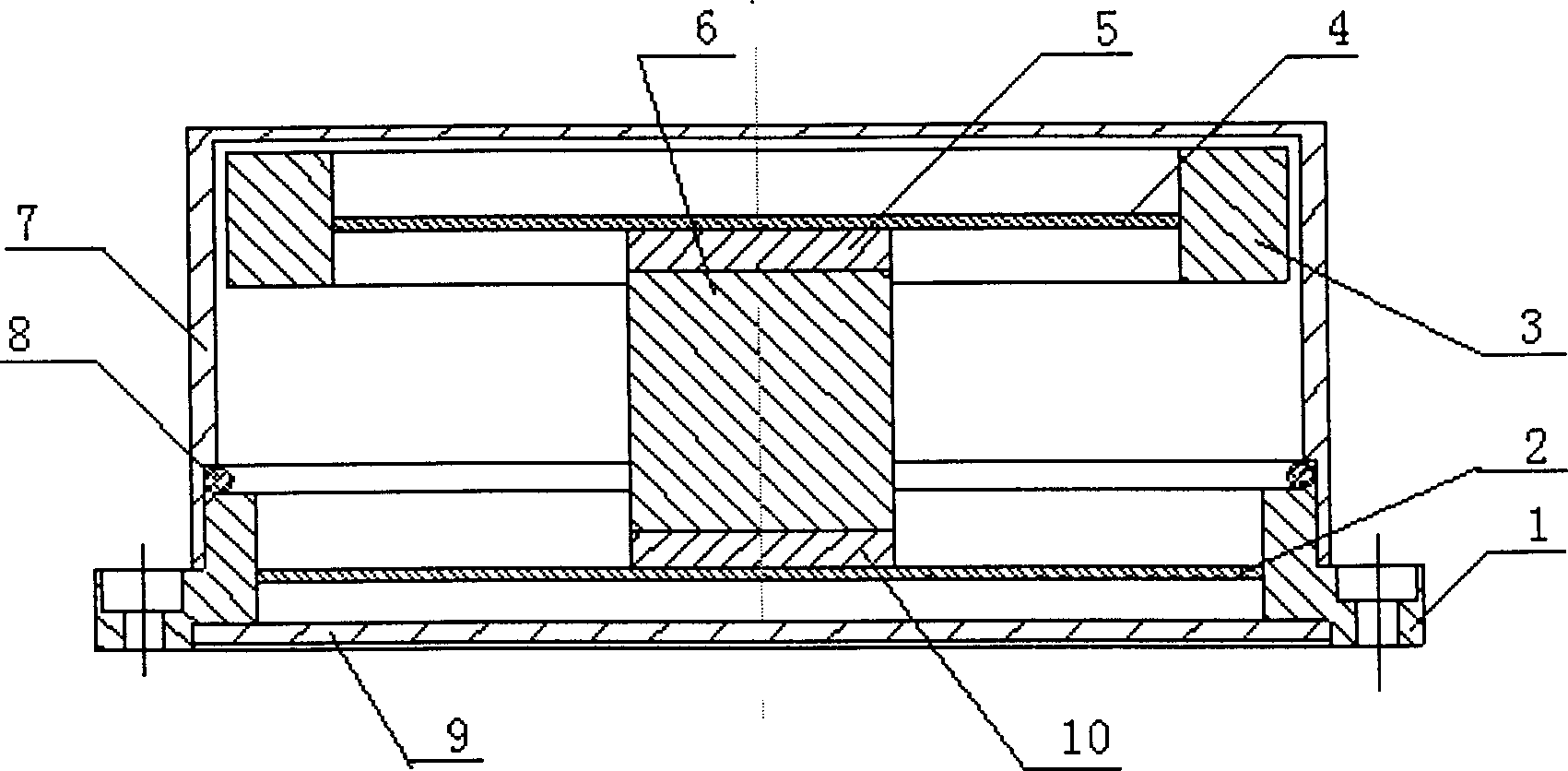

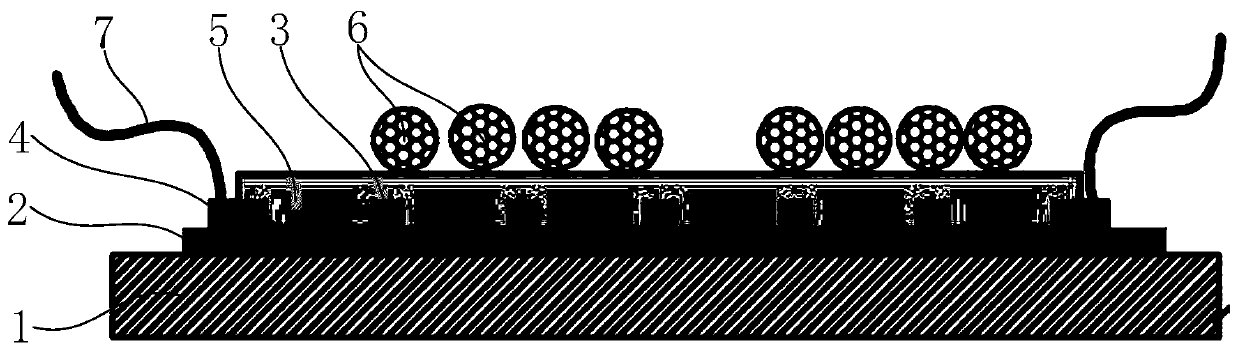

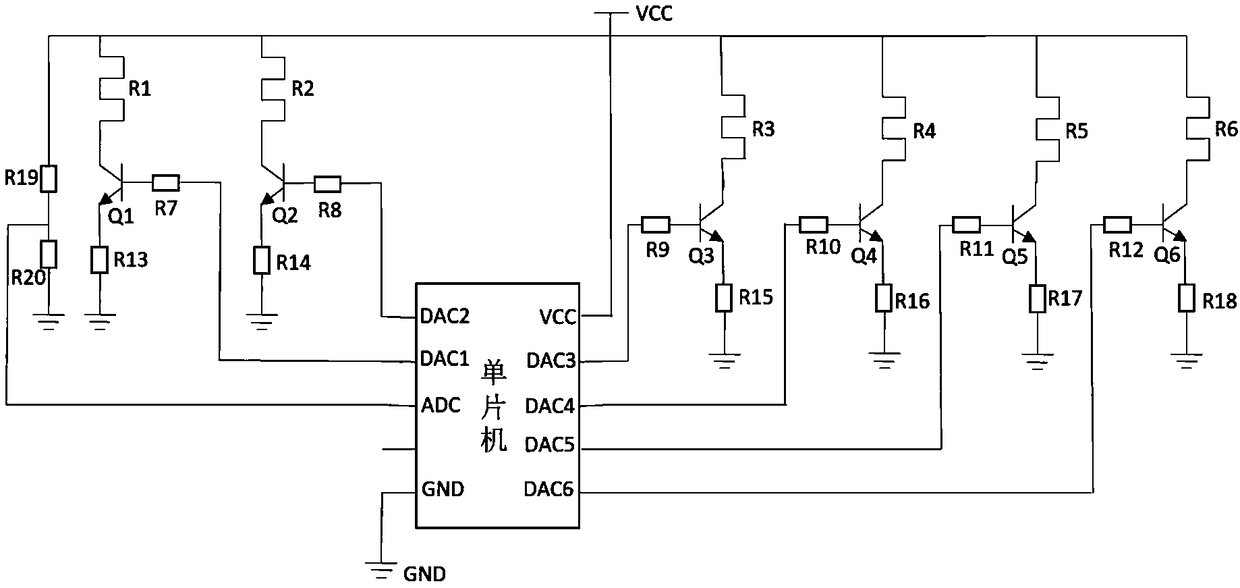

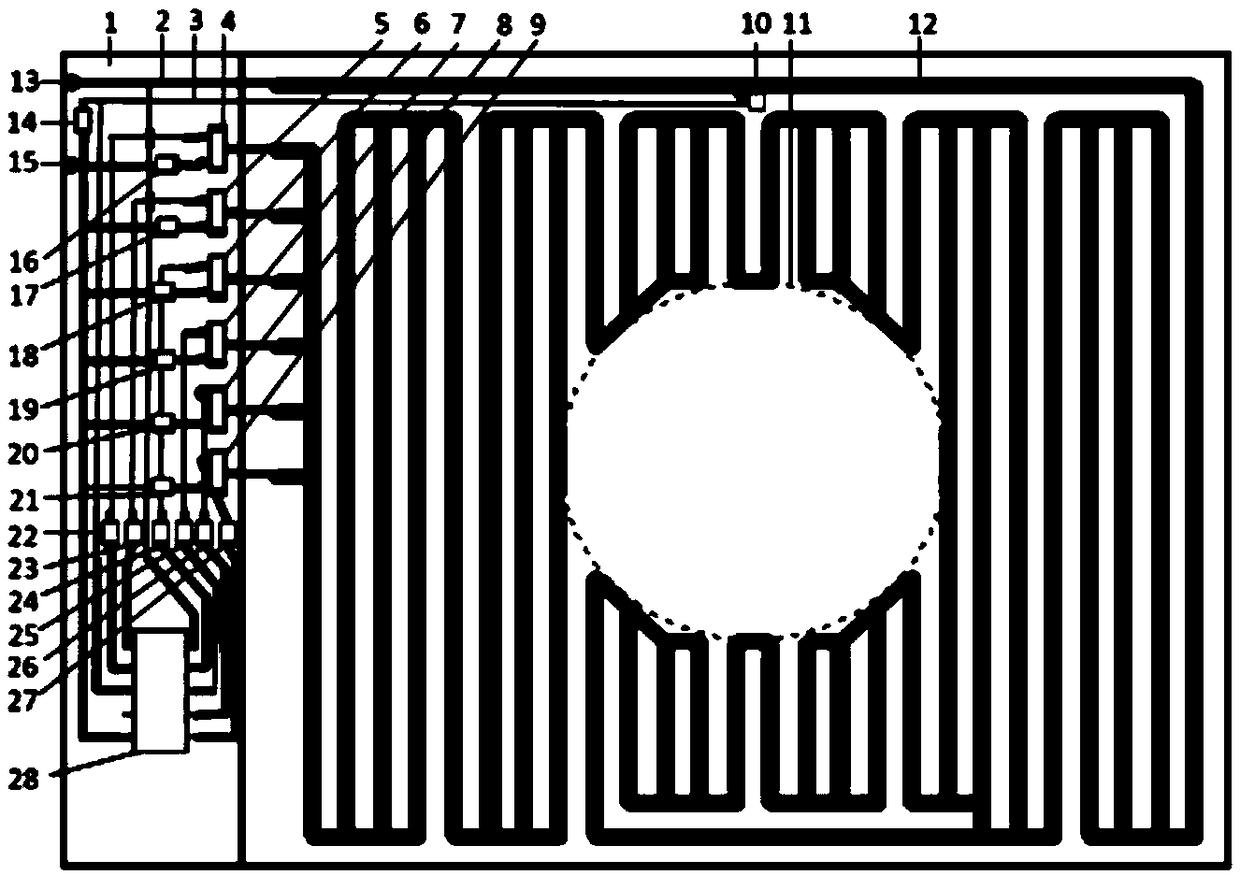

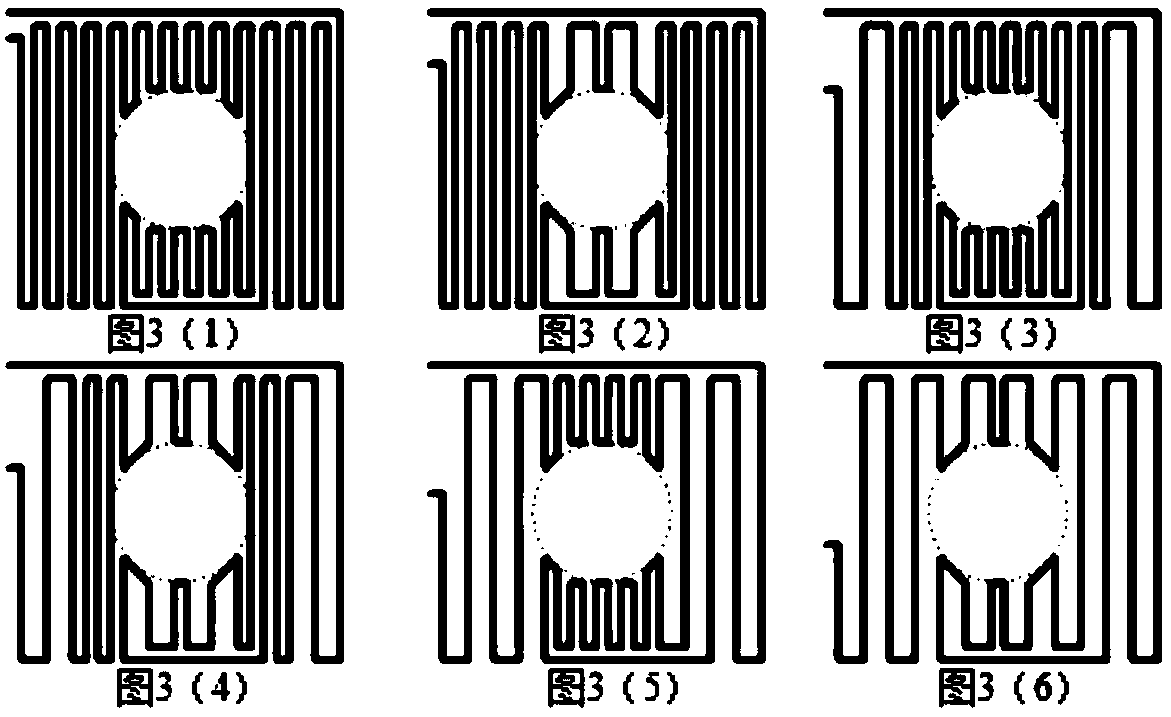

Hybrid integrated thick film heating device for micro atomic gas chamber, and preparation method thereof

ActiveCN109068414ASimple structureEasy to manufactureHeating element materialsElectrical resistance and conductanceHeat sensitive

The invention provides a hybrid integrated thick film heating device for a micro atomic gas chamber, and a preparation method thereof. With the thick film technology, heating resistors are printed ona substrate layer by layer and insulated isolation is carried out to form a multi-layer heating structure; a triode, a thermistor and a single-chip microcomputer and other elements are integrated on the substrate and each heating resistor is connected with the triode and is controlled by a DAC output port of the single-chip microcomputer; the single-chip microcomputer collects the voltage of the thermistor and a temperature signal by a ADC module; after processing based on a PID algorithm, the heating power of the heating resistor at each layer is controlled by the DAC to realize multi-gear continuously controlled high-integration heating device. According to the invention, the heating device has advantages of simple circuit structure, high integration degree and integration of controllingand heating; and various problems of the existing micro atomic gas chamber heating device can be solved. The hybrid integrated thick film heating device can be applied to more devices needing heat; moreover, the process is simple and the heating device is easy to prepare.

Owner:ZHONGBEI UNIV

Six-axle acceleration sensor with dual E-shaped circular membranes and cross beam structure

InactiveCN1227535CSimple designMeet the use requirementsAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsClassical mechanicsThick film technology

A 6D acceleration sensor for measuring three axial accelerations and angular accelerations in 3D space coordinate system features that the thick-film technology is used, the dual E-shaped circular ceramic membranes and cross beam are used as sensitive elastic substance, and the force-sensitive thick-film resistors are sintered on the ceramic substance for bridging. It can be used for the robot.

Owner:HEFEI INST OF INTELLIGENT MACHINERY CHINESE ACAD OF SCI

Thick film circuit board and manufacturing method thereof

ActiveCN103152981ASolve the gapImprove wear lifePrinted electric component incorporationConductive pattern formationElectrical conductorPunching

The invention relates to a thick film circuit board and a manufacturing method thereof. The thick film circuit board comprises a PCB (Printed Circuit Board) substrate, wherein the PCB substrate is provided with a front bonding pad, a via hole, a back bonding pad and a front insulating layer; the lower end of the front bonding pad is positioned in the front insulating layer; the front face of the PCB substrate is also provided with a front conductor circuit layer; the front conductor circuit layer comprises a first branch circuit layer, a second branch circuit layer and a third branch circuit layer and is a conductive layer with thickness of less than 10 mu m; and the middle part of the first branch circuit layer and the middle part of the second branch circuit layer are symmetrically provided with a first resistive layer and a second resistive layer respectively. The manufacturing method comprises the following steps of: forming the front bonding pad, the back bonding pad, the front insulating layer, the via hole, the front resistive layers and a bridging conductor on the PCB substrate through a thick film technology and punching. The front conductor circuit layer has small thickness, low resistive layer fall and a long service life; and by arranging a cut-off point, the resistive layer performance can be improved.

Owner:东莞市东思电子技术有限公司

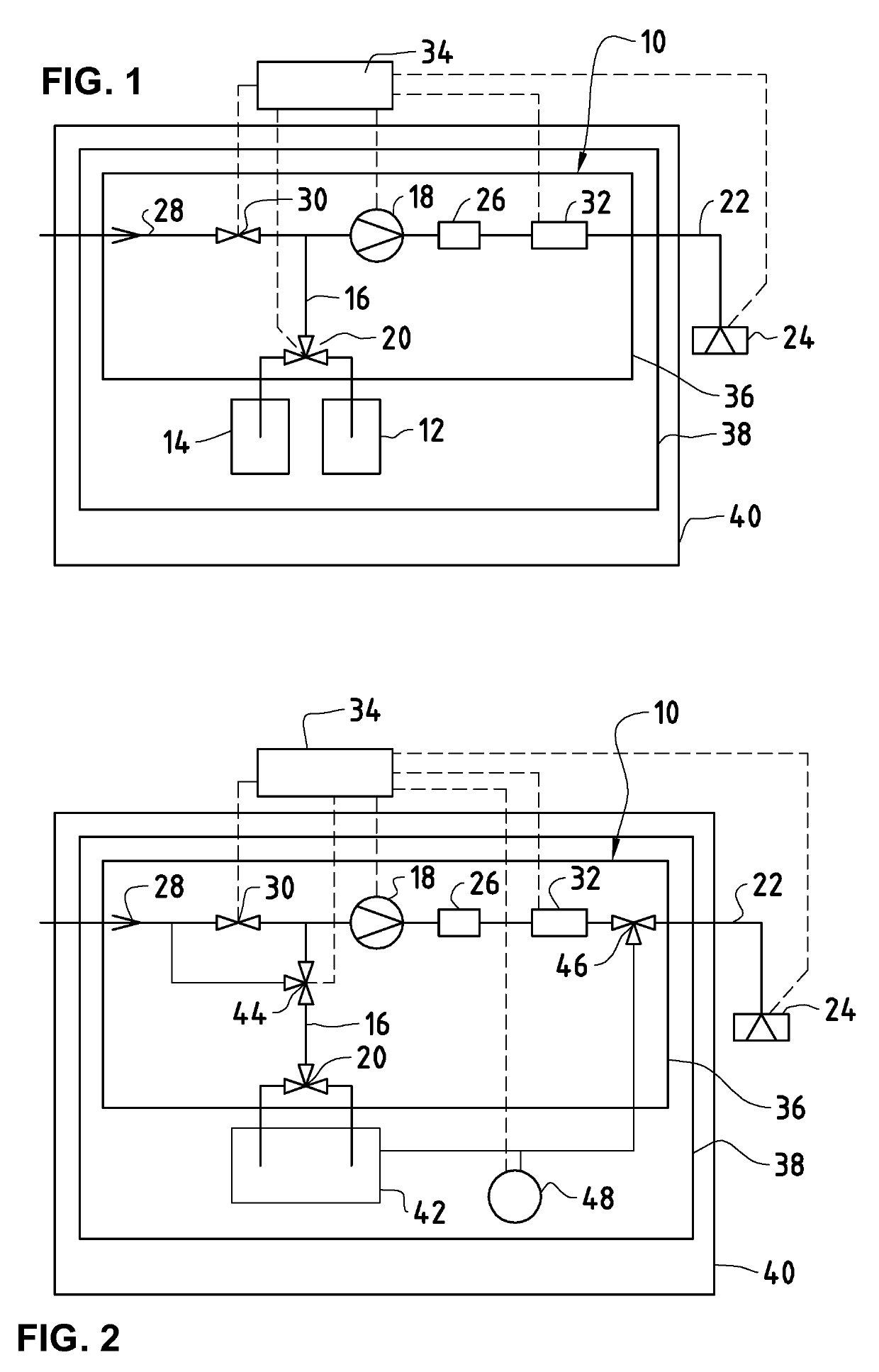

Modular foaming unit

A device for foaming liquid includes a line system and a pump, via which at least one first line of the line system is connectible to at least one storage container in which the liquid to be foamed is stored, and via a second line of the line system is connectible to at least one outlet nozzle, an air-enrichment element by means of which air can pass through the liquid, and a heating element designed as a continuous flow heater. Furthermore, the heating element is arranged in the second line of the line system of the device and is designed as a thick-film heater in which an electric heating resistor is attached to a carrier using thick-film technology, on which carrier a flow path is provided for the liquid.

Owner:CUP&CINO KAFFEESYST VERTRIEB GMBH & CO KG

Process for preparing air/fuel ratio thick-film sensor with wide temp range and narrow resistance band

InactiveCN1334461AImprove performanceImprove controlElectrical controlSolid-state devicesThick film technologyRutile

An air / fuel ratio sensor with wide temp range and narrow resistance band and its preparing process are disclosed. The rutile-type TiO2 structure is used for internal N-type doping and the P-type complex diffusion is performed to crystal interface. As a result, the electric conductivity of specimen is sharply lowered in oxidizing atmosphere, or sharply raised in reducing atmosphere. The thick film technology is used to make the specimen have 1-3 orders of magnitude of resistance difference in 250-800 deg.C. Its advantages are greatly improved performance and low cost.

Owner:XI AN JIAOTONG UNIV

Method for preparing static-suppressor functional slurry cured at low temperature

InactiveCN104464993AHigh mechanical strengthImprove electrical performanceResistor manufactureOvervoltage protection resistorsSolid componentEpoxy

The invention discloses a method for preparing static-suppressor functional slurry cured at low temperature. The slurry is composed by adding solid constituents using low-temperature-cured organic matter as a carrier. The carrier consists of a resin, a diluent, a curing agent and a curing accelerator at a certain mass ratio, wherein the resin includes epoxy resin and phenolic resin; the diluent is a mixture of dimethyl glutarate, dimethyl adipate and dimethyl succinate; the curing agent is dicyandiamide; and the curing accelerator is organic carbamide. The solid constituents are composed of talcum powder, silica and aluminium powder at a certain mass ratio. According to the invention, the static-suppressor slurry is suitable for a thick-film technology platform and is used to prepare a chip-type static suppressor. Stronger adhesive force is realized between the cured slurry and an alumina ceramic substrate. The slurry has characteristics of great mechanical strength itself, damp and heat resistance, low trigger voltage, and good consistency.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

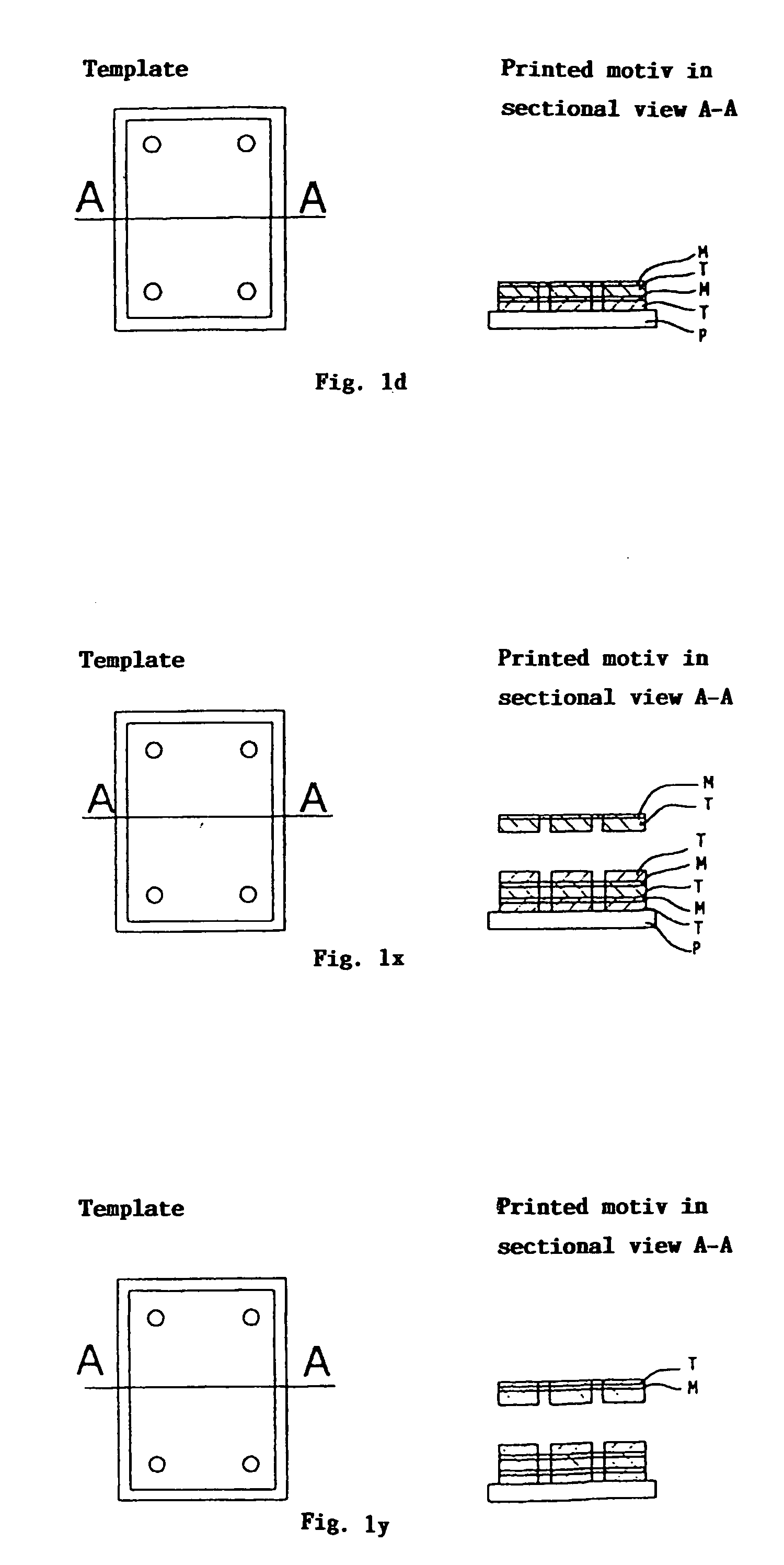

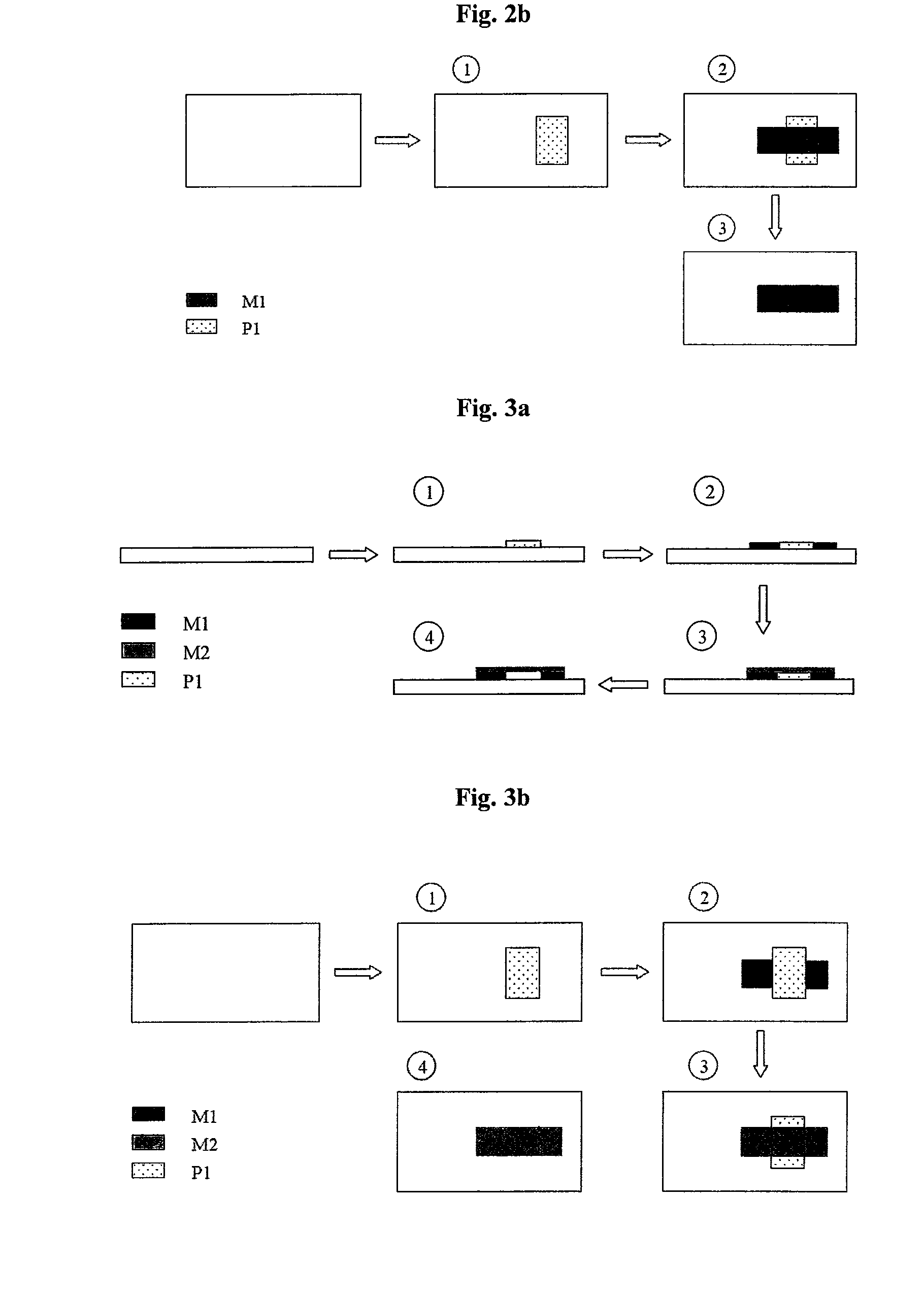

Method for producing a multilayer piezoelectric microcomponent using sacrificial thick film technology

InactiveUS8287943B2Piezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device manufacturingMetal alloyThick film technology

The invention relates to the preparation of multilayer microcomponents which comprise one or more films, each consisting of a material M selected from metals, metal alloys, glasses, ceramics and glass-ceramics.The method consists in depositing on a substrate one or more films of an ink P, and one or more films of an ink M, each film being deposited in a predefined pattern selected according to the structure of the microcomponent, each film of ink P and each film of ink M being at least partially consolidated before deposition of the next film; effecting a total consolidation of the films of ink M partially consolidated after their deposition, to convert them to films of material M; totally or partially removing the material of each of the films of ink P. An ink P consists of a thermoset resin containing a mineral filler or a mixture comprising a mineral filler and an organic binder. An ink M consists of a mineral material precursor of the material M and an organic binder. The inks are deposited by pouring or by extrusion.

Owner:CENT NAT DE LA RECHERCHE SCI

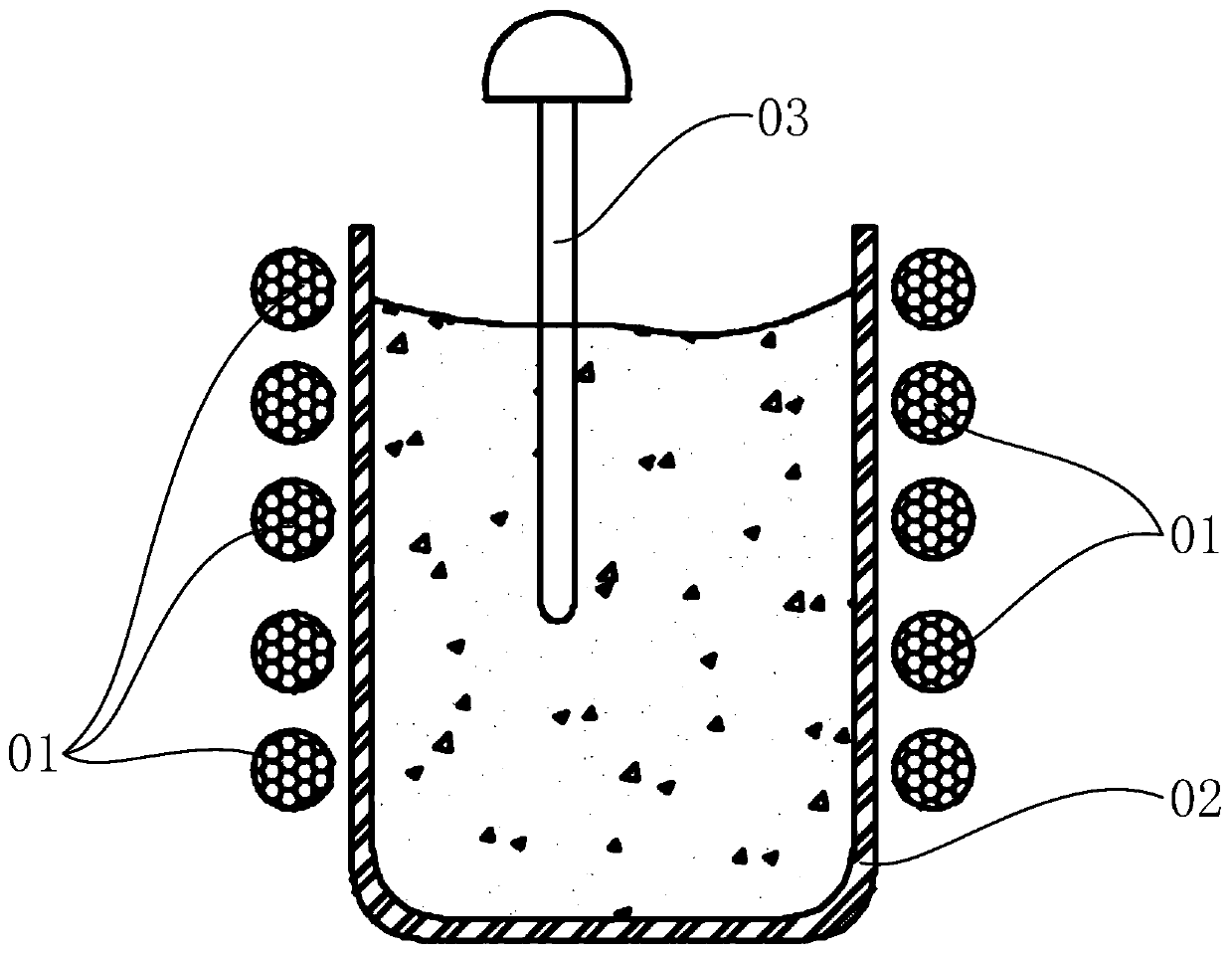

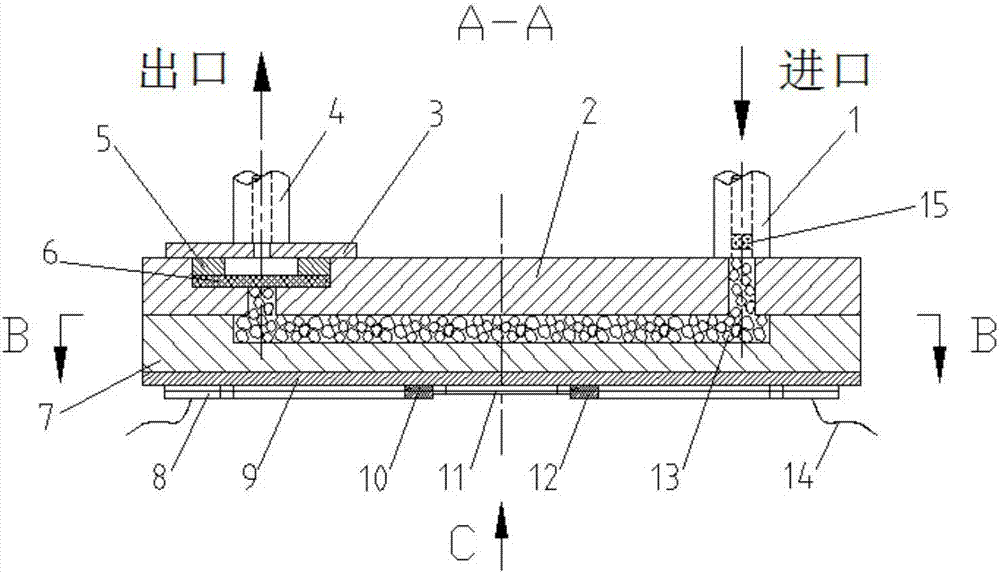

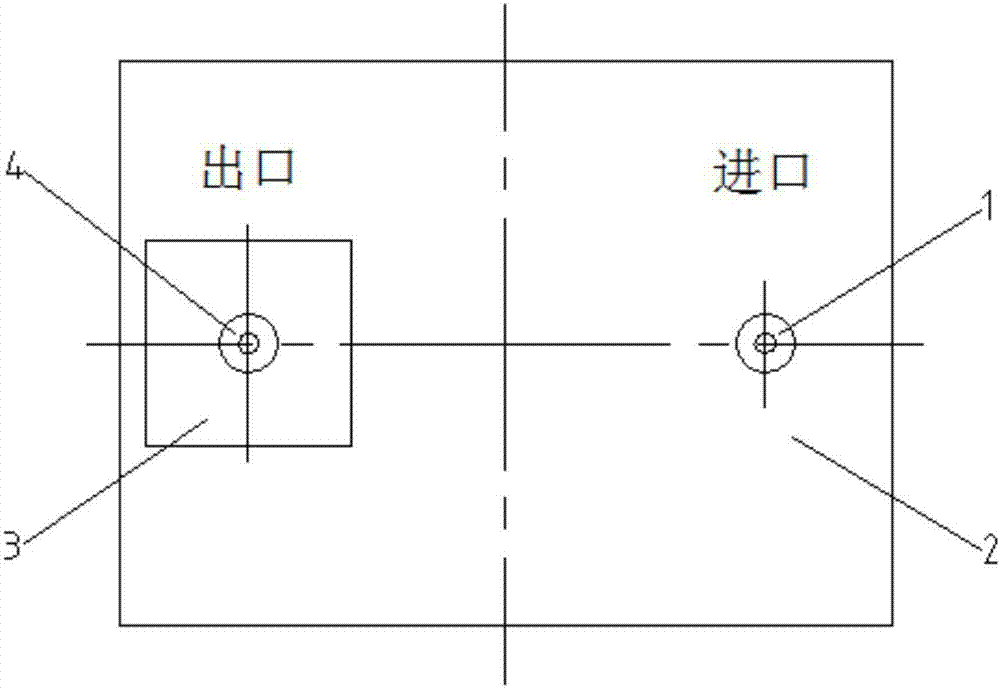

Miniature gas enricher and preparation method thereof

ActiveCN107014666AMiniaturizationHigh enrichment ratePreparing sample for investigationMiniaturizationEngineering

The invention discloses a miniature gas enricher and a preparation method thereof. The miniature gas enricher comprises a filling layer and a packaging layer covered on the filling layer, wherein a symmetrically distributed miniature spitting channel is processed on the upper surface of the filling layer; absorbing grains are filled in the channel; an air inlet and an air outlet which are communicated with the miniature spitting channel are formed on the packaging layer; a counter bore which is used for fixing a filtering layer is formed at the air outlet; an inlet adapter and an outlet adapter are hermetically arranged corresponding to the air inlet and the air outlet; a SiO2 dielectric layer is arranged on the filling layer; a pair of quick heating elements and a pair of sensitive temperature measurers are respectively arranged on the SiO2 dielectric layer. The enriched gas enters from the inlet adapter, is concentrated and enriched under the physical absorption effect of the absorbing grains and then passes through the filtering layer and is discharged from the outlet adapter. The miniature gas enricher disclosed by the invention can realize miniaturization and has the characteristics of high enriching rate, low power consumption, low cost, easiness in processing, stable materials, easiness in integration, and the like. The thick-film technology of the heating element is simple and the cost is low.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com