Thick film circuit board and manufacturing method thereof

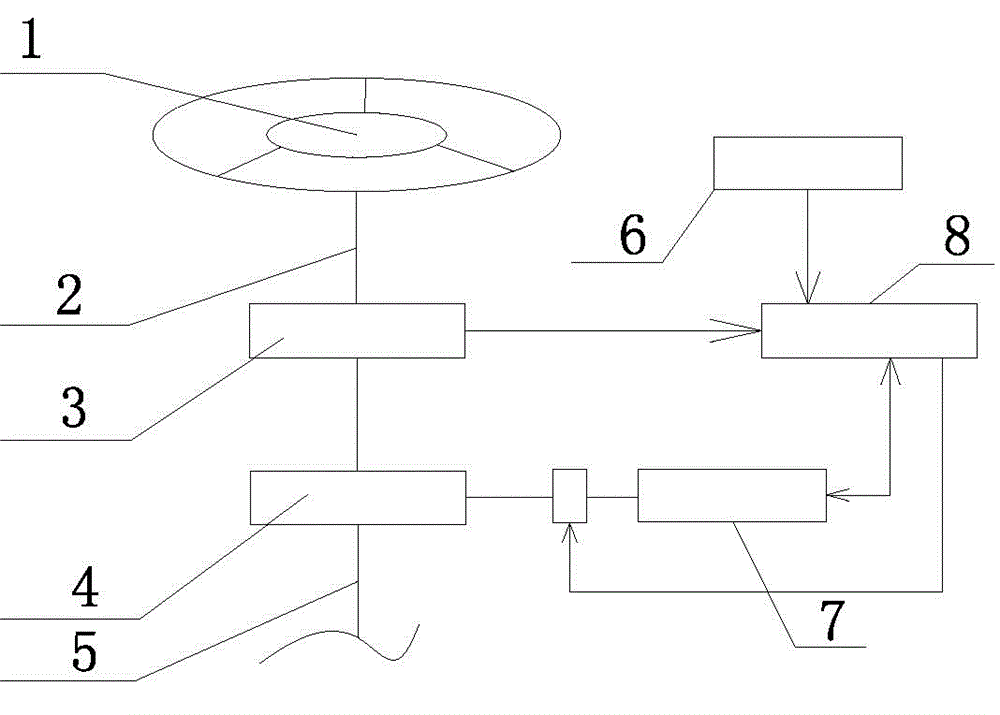

A technology of thick film circuit and manufacturing method, which is applied in the direction of printed circuit components, conductive pattern formation, containing printed electrical components, etc., can solve the problems of poor output voltage consistency, short service life, and poor linearity of output voltage, etc., to achieve Improve the wear-resistant working life, improve symmetry and linearity, and improve the effect of wear-resistant life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

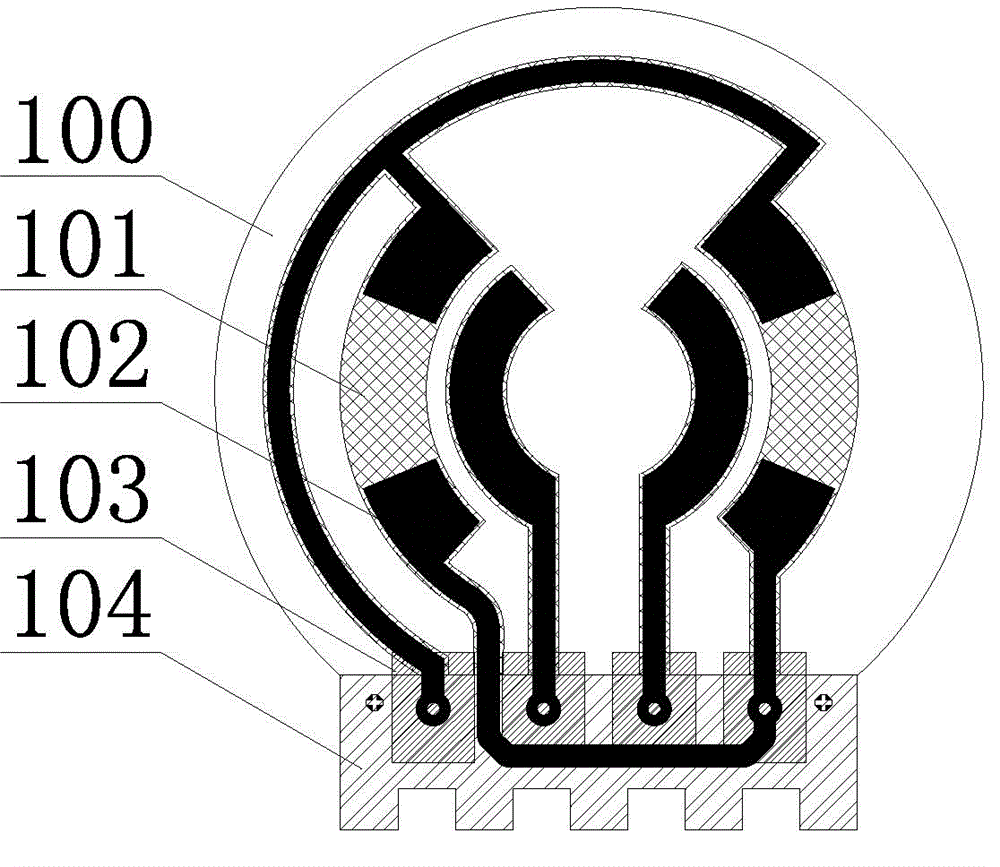

[0060] Example 1: see image 3 .

[0061] A thick film circuit board, comprising a PCB substrate 200, the PCB substrate 200 is provided with a front pad 201, a via hole 202 and a back pad 203, and the lower end of the front of the PCB substrate 200 is provided with a front insulating layer 204, And the lower end of the front pad 201 is located in the front insulating layer 204, the front side of the PCB substrate 200 is also provided with a front conductor circuit layer 205 connected to the upper end of the front solder pad 201, and the front conductor circuit layer 205 includes a first branch Line layer 23 and the second branch line layer 24, and the third branch line layer 25, the third branch line layer 25 is respectively connected with the first branch line layer 23 and the second branch line layer 24, and the front conductor line layer 205 is The silver-containing conductive paste is printed on the PCB substrate 200 and is a conductive layer with a thickness of less than...

Embodiment 2

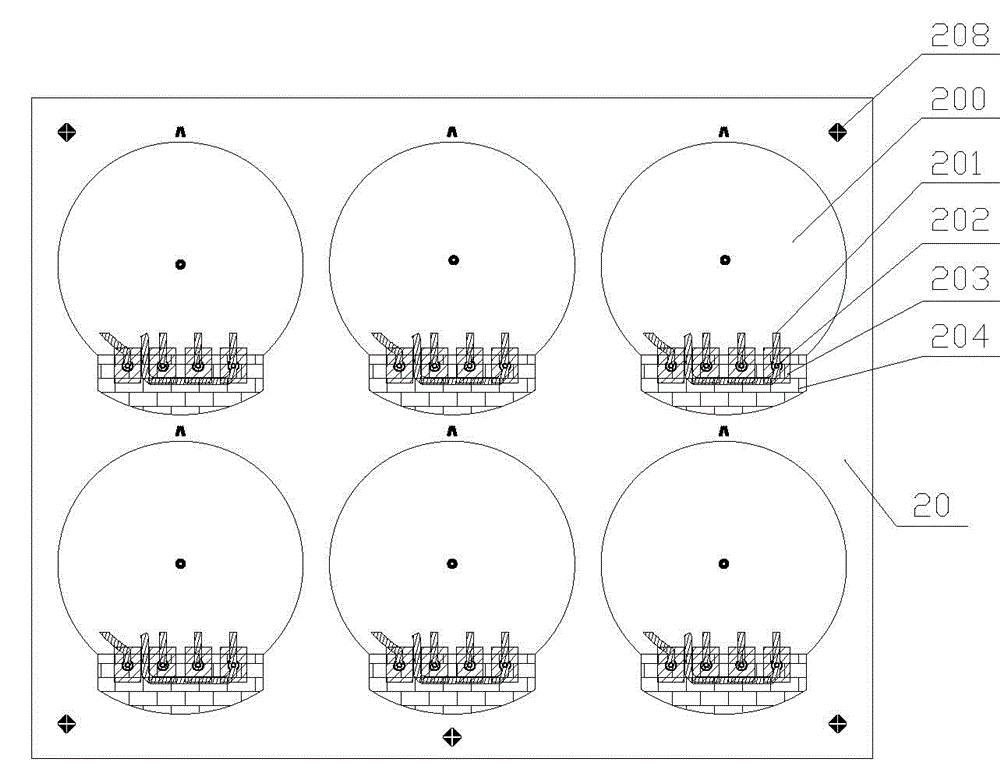

[0067] Example 2: see Figure 3 to Figure 7 .

[0068] A method for manufacturing a thick film circuit board, comprising the following steps:

[0069] Step 1 Through drilling, electroless copper deposition, yellow light lithography, etching, electroplating and other production processes, on the PCB substrate

[0070] A via hole 202, a front pad 201, a back pad 203, and a front insulating layer 204 are sequentially formed on the board 200

[0071] Wherein, the inner wall of the via hole 202 is provided with a conductive layer, and the conductive layer connects the front pad 201 and the back pad 203 .

[0072] The conductive layer of the via hole 202, the front pad 201, and the back pad 203 are sequentially formed with copper layer, nickel layer, and gold layer materials from the inside to the outside;

[0073] In the specific implementation, the copper layer is firstly covered with copper foil and bonded on the substrate, and then the copper layer is formed by masking, yello...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com