Patents

Literature

74results about How to "Solve the gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

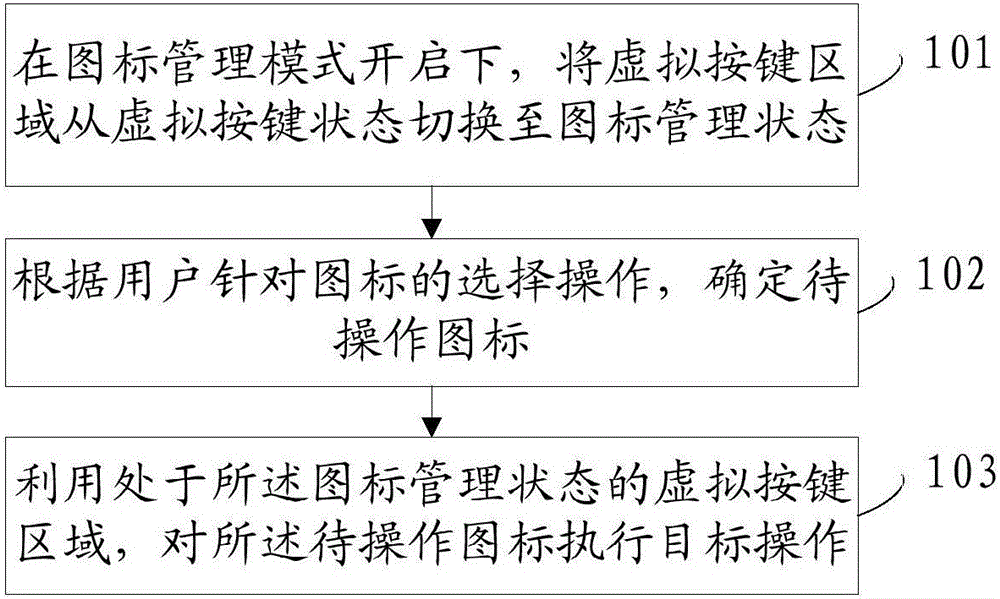

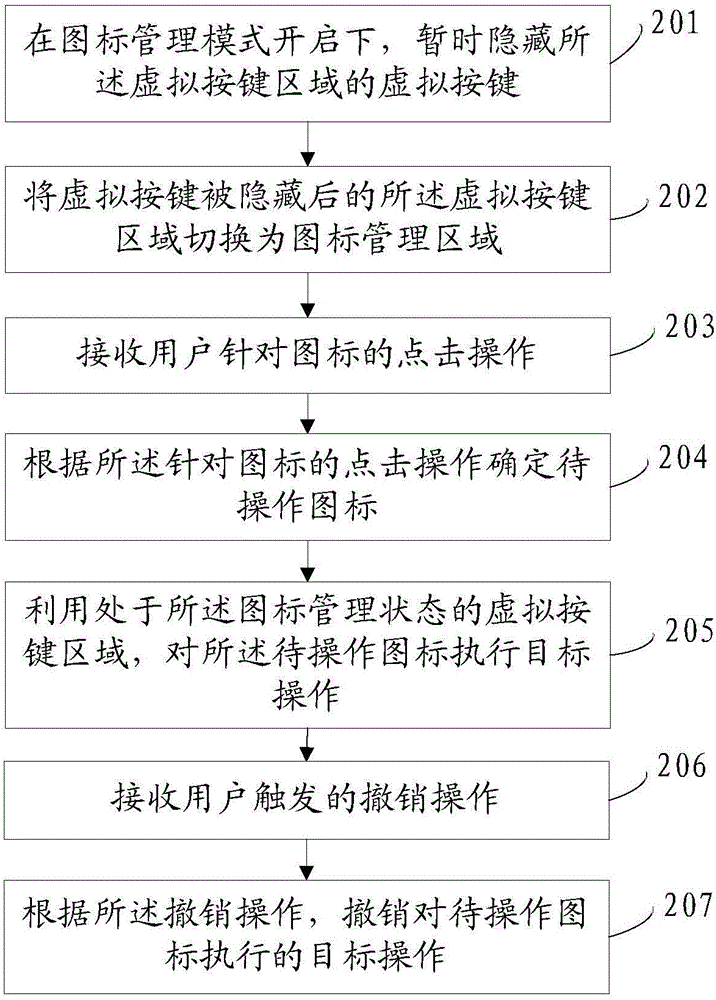

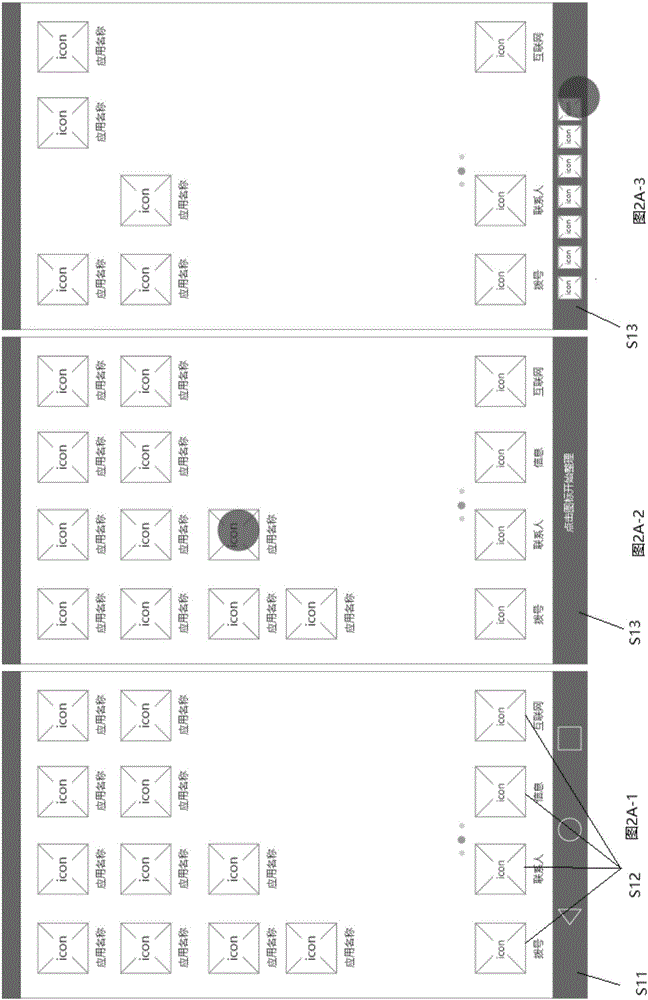

Icon batch processing method and device and mobile terminal

ActiveCN106126040AIntegrity guaranteedSolve the gapInput/output processes for data processingKey pressingBatch processing

The embodiment of the invention provides an icon batch processing method and device and a mobile terminal and relates to the technical field of terminal devices. The method includes the steps that when an icon management mode is started, a virtual key area is switched from a virtual key state to an icon management state, and then target operation is conducted on a to-be-operated icon selected by a user by means of the virtual key area in the icon management state. Thus, the problems that in the prior art, original icons of a DOCK bar are hidden and cannot be managed, and icon management has defects are solved. The method has the advantages that all icons on a desktop and in the DOCK bar can be managed, and icon management is more complete.

Owner:BEIJING ANYUNSHIJI TECH CO LTD

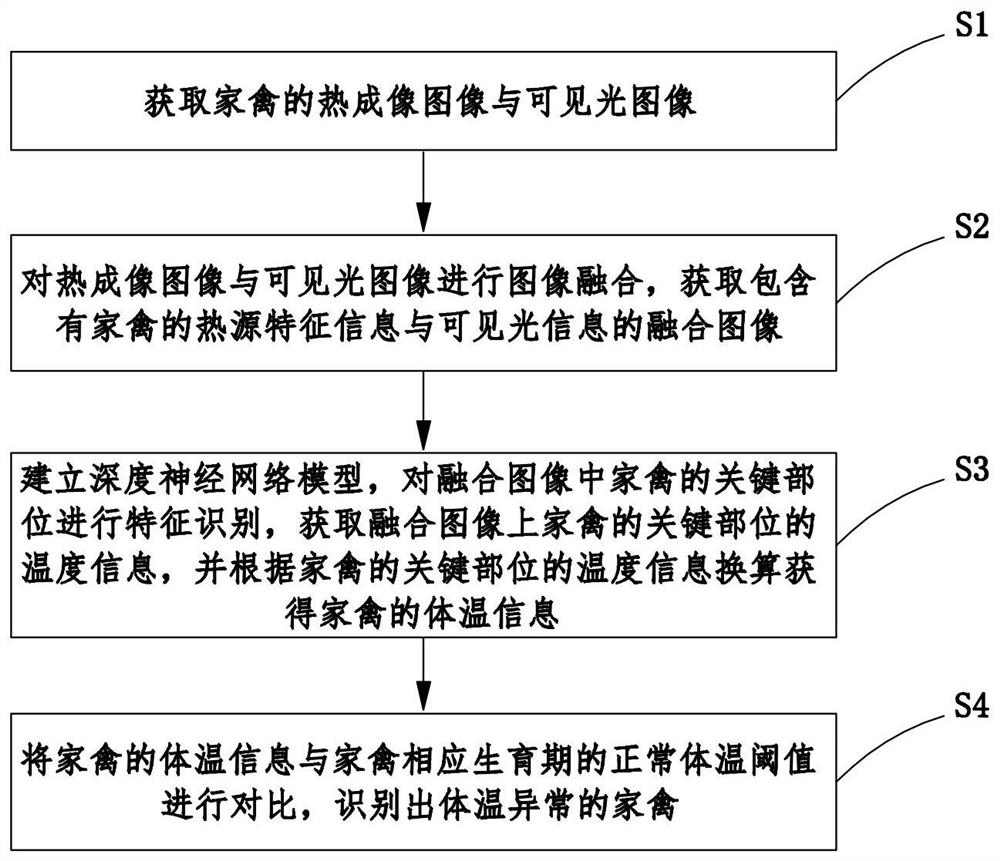

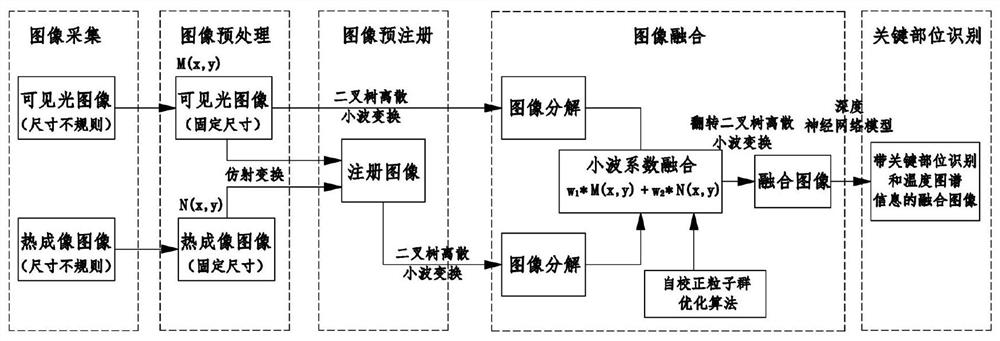

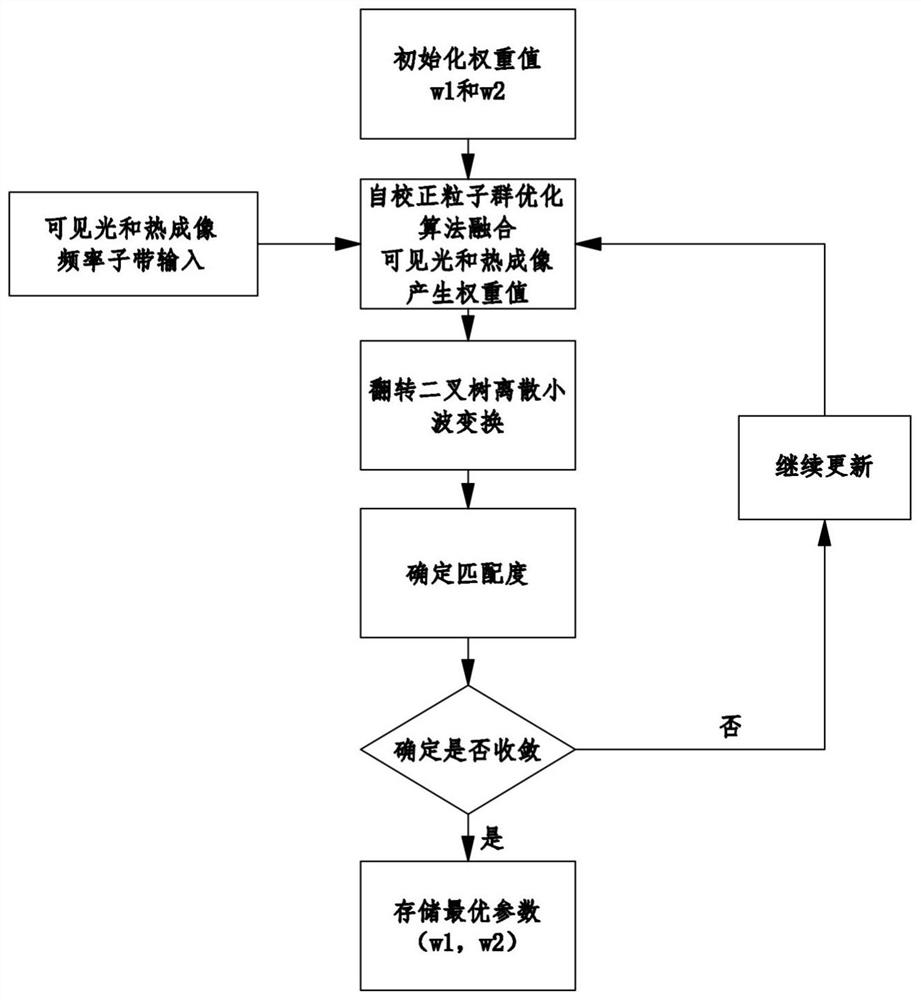

Poultry body temperature detection method based on image fusion and poultry house inspection system

PendingCN111626985ARealize intelligent detectionGuaranteed accuracyImage enhancementImage analysisAnimal scienceAgricultural science

The invention relates to the technical field of poultry farming, and discloses a poultry body temperature detection method based on image fusion and a poultry house inspection system. The poultry bodytemperature detection method comprises the following steps: acquiring a thermal imaging image and a visible light image of poultry; performing image fusion on the thermal imaging image and the visible light image to obtain a fused image; establishing a deep neural network model, performing feature recognition on the key parts of the poultry in the fusion image, obtaining temperature information of the key parts of the poultry in the fusion image, and performing conversion according to the temperature information of the key parts of the poultry to obtain body temperature information of the poultry. Based on image fusion of thermal imaging and visible light, and thrugh the feature recognition of the deep neural network model and the corresponding temperature conversion, the intelligent detection of the poultry body temperature is realized, the accuracy of the detection result is ensured, the inspection requirements of the poultry house in various breeding environments are met, the inspection efficiency of the poultry house is greatly improved, and the poultry breeding cost is saved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

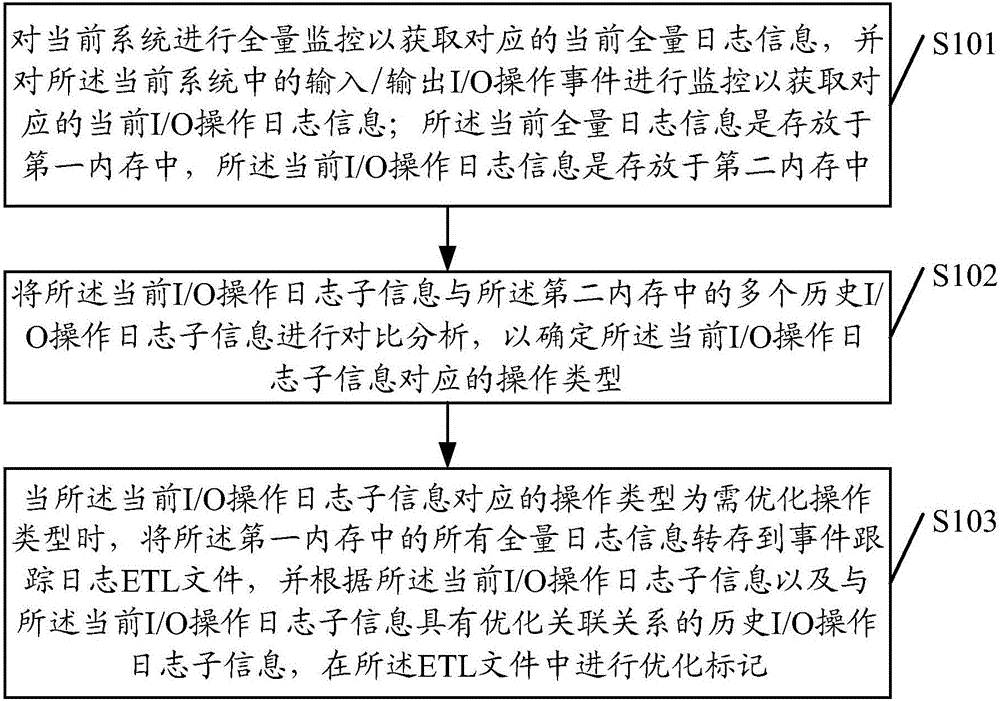

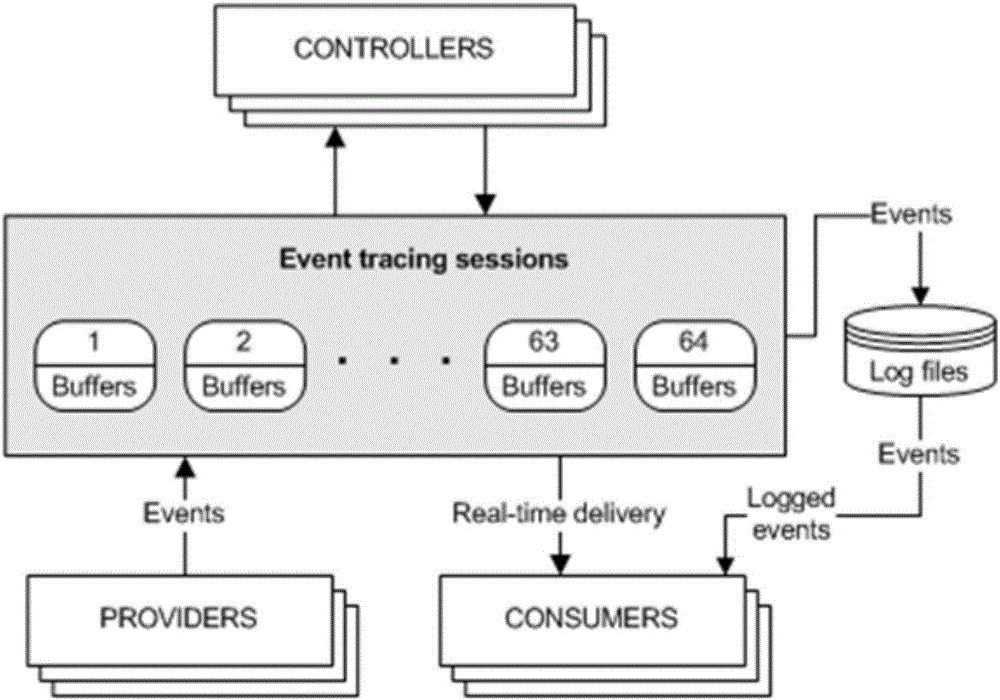

Data monitoring processing method and apparatus

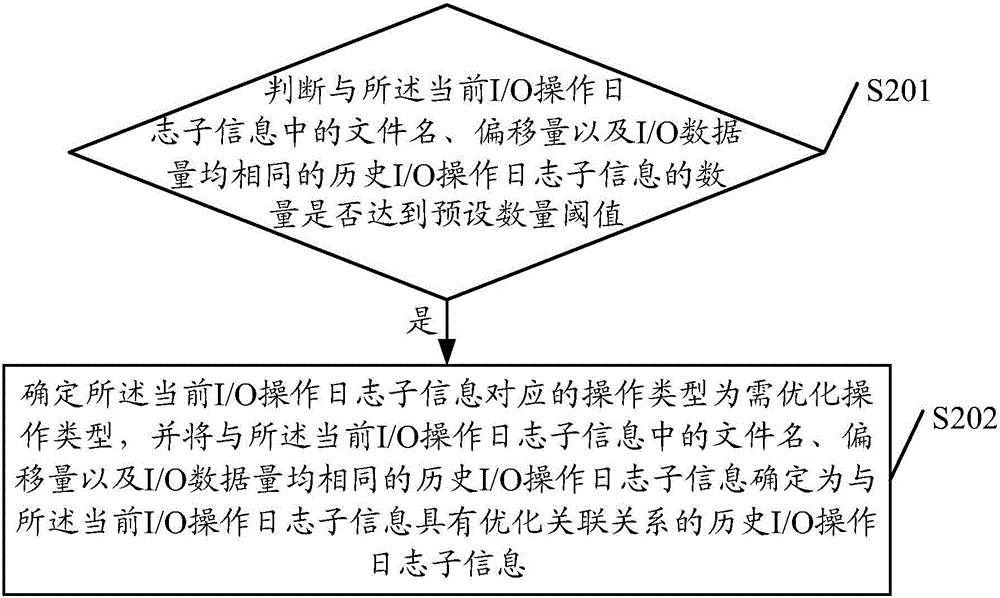

Embodiments of the invention disclose a data monitoring processing method and apparatus. The method comprises the steps of performing total monitoring on a current system to obtain corresponding current total log information, and monitoring an I / O operation event in the current system to obtain corresponding current I / O operation log information, wherein the current total log information is stored in a first memory, and the current I / O operation log information is stored in a second memory; performing comparative analysis on the current I / O operation log information and multiple pieces of historical I / O operation log information in the second memory to determine an operation type corresponding to the current I / O operation log information; and if the operation type corresponding to the current I / O operation log information is an operation type required to be optimized, transferring and storing all the total log information in the first memory into an ETL file, and performing optimization marking in the ETL file according to a comparative analysis result. With the adoption of the method and apparatus, the manpower cost can be reduced and the analytic efficiency and accuracy of I / O operation event information are improved.

Owner:云南腾云信息产业有限公司

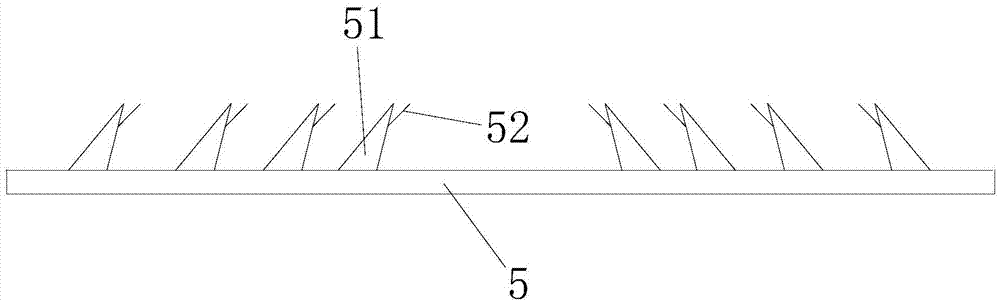

Method for mixing bamboo woods and bamboo broken materials to manufacture brick machine supporting plate

ActiveCN104400870AGuaranteed gluing effectAchieve fullnessLaminationLamination apparatusAdhesive gluePulp and paper industry

The invention provides a method for mixing bamboo woods and bamboo broken materials to manufacture a brick machine supporting plate. The method comprises the following steps of (1) grinding or slicing moso bamboos to form bamboo chips, weaving to form a bamboo mat or a bamboo curtain, and then drying; (2) gumming the bamboo mat, the bamboo curtain and bamboo splints by using phenolic resin glue, and drying through a low temperature way or a temperature reducing way; (3) smashing remained bamboo materials (hereafter referred to as the 'bamboo broken materials') after other bamboo products are processing by waste bamboo woods or moso bamboos; (4) drying, cooling and then mixing the bamboo broken materials (or drying, glue mixing and then cooling) with glue, wherein the glue is the phenolic resin glue; (5) mixing and assembling a bamboo mat, a bamboo curtain or thin bamboo strips which are dried by low temperature or dehumidification with 'glue bamboo broken materials' subjected to glue mixing; (6) performing hot pressing on a pre-processed bamboo wood brick machine supporting plate blank to form a bamboo plywood semi-finished product; (7) cutting and painting the semi-finished product bamboo wood brick machine support plate to form the bamboo wood brick machine supporting plate which has the advantages of high strength and the like.

Owner:龙泉市凯森板业有限公司

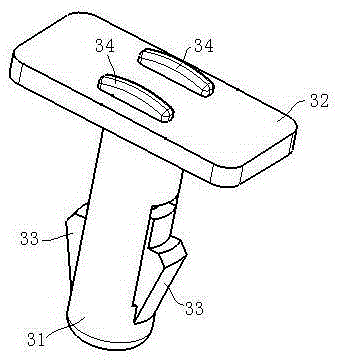

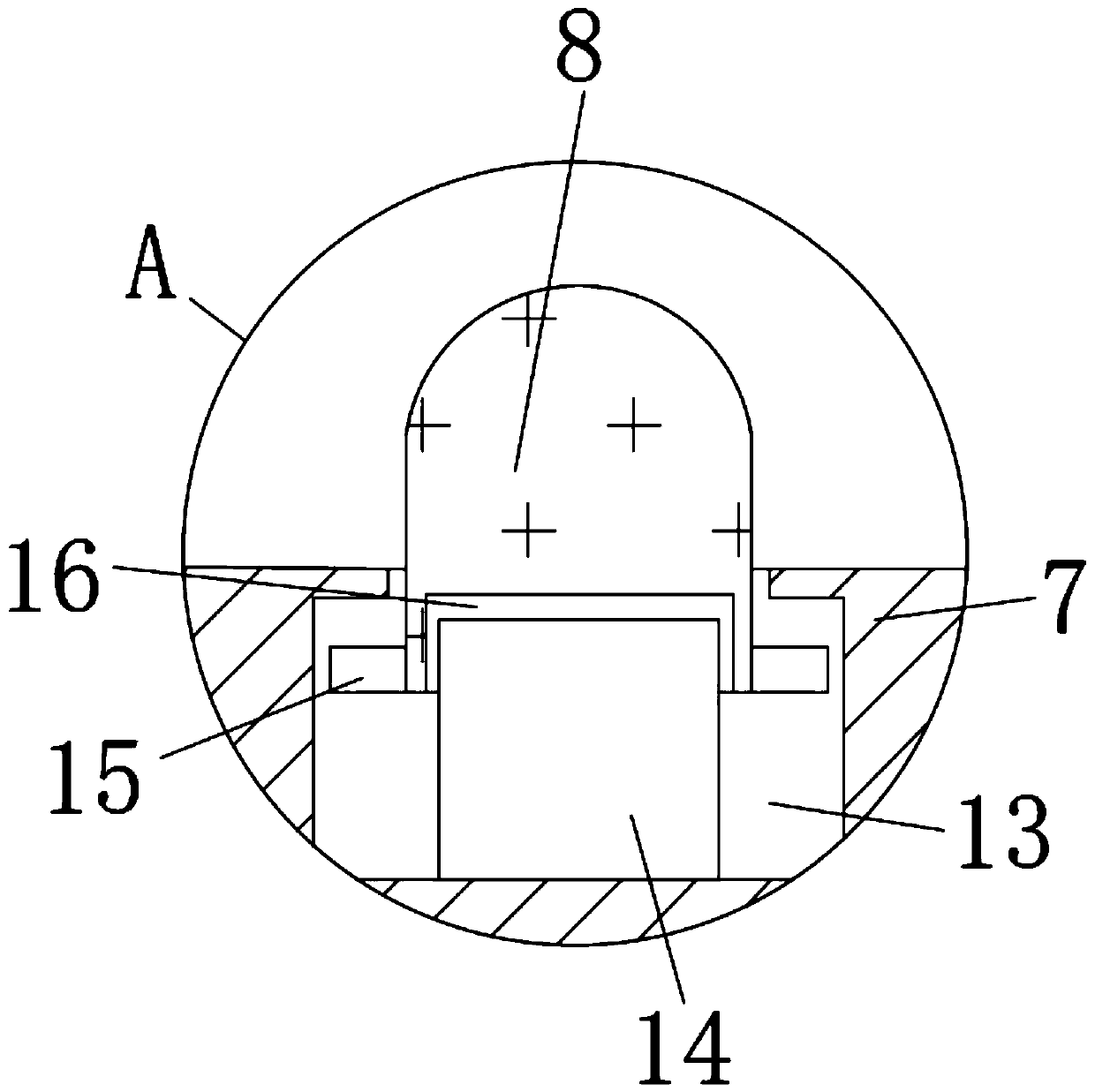

Front shell structure of mobile terminal and mobile terminal

ActiveCN105554191AInterfere with antenna performanceSolve the gapDigital processing power distributionTelephone set constructionsEngineeringComputer terminal

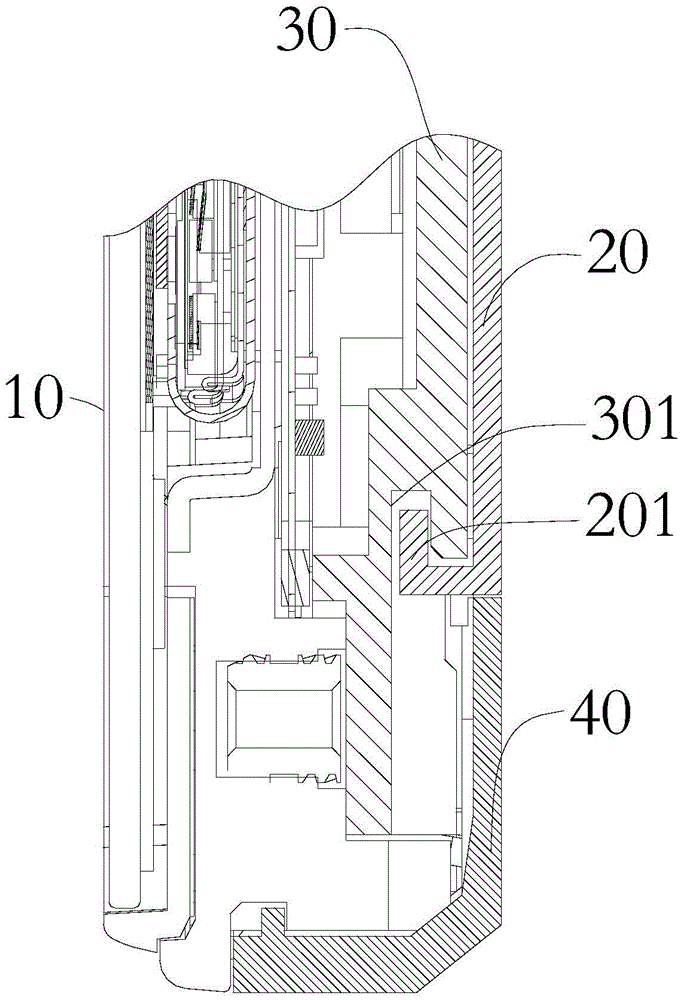

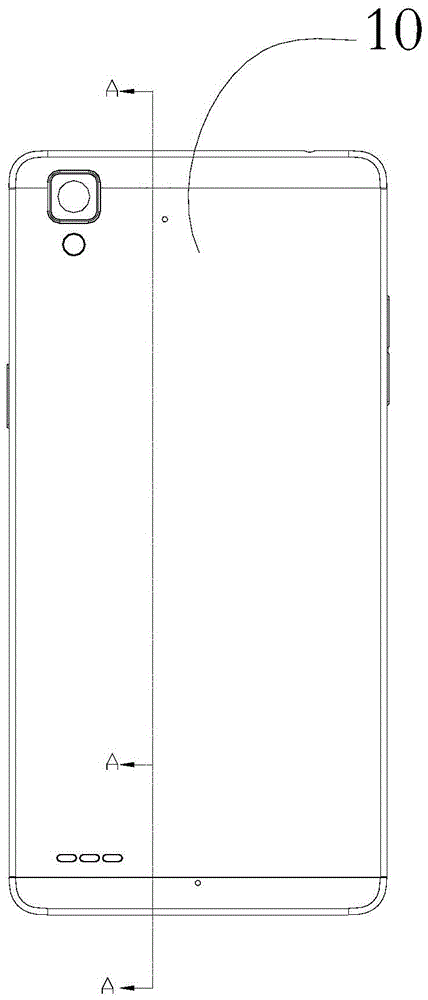

The invention discloses a front shell structure of a mobile terminal, which comprises a shell, a middle frame, a metal battery cover, decorative parts, wherein the middle frame is fixed at the middle part of the shell; the metal battery cover is positioned on the upper surface of the middle part of the middle frame; an antenna is arranged on the decorative parts; the decorative parts comprise an upper decorative part and a lower decorative part; the upper decorative part and the lower decorative part are respectively fixed at the upper part and the lower part of the middle frame; a decorative part zone is an antenna clearance zone; the middle frame is connected with the metal battery cover in a nesting manner; and the edge of the upper end and the edge of the lower end of the metal battery cover are respectively pressed against the edge of the lower end of the upper decorative part and the edge of the upper end of the lower decorative part, and do not extend into the antenna clearance zone. According to the front shell structure disclosed by the invention, a condition that part of both upper and lower ends of the metal battery cover extend to the antenna clearance zone to be fixed with the middle frame so as to interfere antenna performance of the antenna clearance zone of a mobile phone is avoided, and the problem of offset between the metal battery cover and the upper and lower decorative parts is solved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

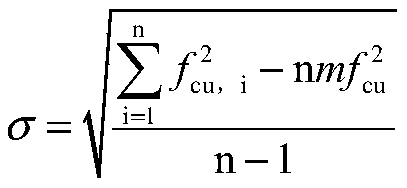

Impermeable concrete and proportioning method thereof

The invention discloses impermeable concrete and a proportioning method thereof. The impermeable concrete comprises cement; PII type Portland cement with strength of not lower than 42.5 grade; coarseaggregate containing 5-25 mm continuous graded broken stone; fine aggregate containing natural river sand; an admixture containing fly ash and mineral powder; and an additive, which comprises a waterreducing agent with a water reducing rate of not lower than 25% and a solid content of not lower than 20%; wherein the cement, the coarse aggregate, the fine aggregate, the admixture and the additiveare mixed and stirred under the action of water to form the impermeable concrete. The technical problems that a conventional impermeable concrete is large in gap, high in manufacturing cost and long in maintenance period due to the material ratio and is not suitable for the secondary lining waterproof requirement in tunnel engineering are solved.

Owner:ROAD & BRIDGE INT +1

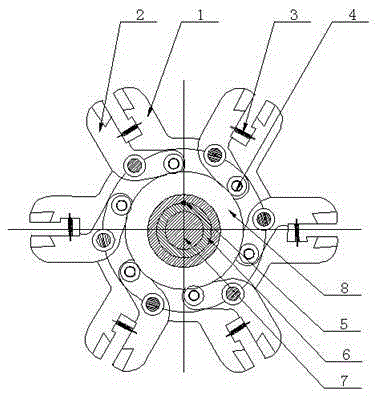

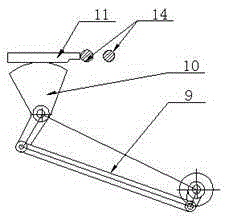

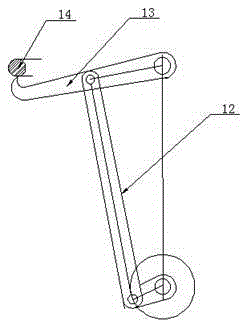

Aluminum-plated twisting packing machine

InactiveCN105235928ASolve the gapSolve the problem that the packaging material is difficult to stick to the candyConveyor wrappingEngineeringCopper

The invention provides an aluminum-plated twisting packing machine and relates to the technical field of packing equipment. A process disc comprises fixed tong hands, movable tong hands, springs, rollers, a key, a copper sleeve, a rotary disc shaft and a cam. The six fixed tong hands are evenly distributed on the rotary disc shaft circumferentially, and each fixed tong hand is fixedly connected with the rotary disc shaft through a cylindrical pin. One side of each fixed tong hand is provided with the corresponding movable tong hand, and the springs are connected between the fixed tong hands and the movable tong hands. The rotary disc shaft is sleeved with the copper sleeve. The rollers are arranged between the movable tong hands and the cam, and the cam is connected with the copper sleeve through the key. According to the aluminum-plated twisting packing machine, the packing speed and the candy conveying speed are consistent, no pack clamping or leaking phenomenon exists, and the problems that the interval between candy channels is large, and packing materials can be difficultly attached to the candies tightly are solved; and the aluminum-plated twisting packing machine has the beneficial effects of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:JIANGSU LEATER GREEN PACKAGING CORP LTD

Circuit board with high-density circuits and method for manufacturing the circuit board

InactiveCN104105337AImprove electrical performanceSolve the gapElectrical connection printed elementsPrinted element electric connection formationHigh densityEngineering

A circuit board with high-density circuits includes a dielectric layer, a plurality of metal pads embedded in the dielectric layer, a first conducting circuit layer and a second conducting circuit layer formed on two opposite surfaces of the dielectric layer, and a plurality of first through holes and a plurality of second through holes are formed in the dielectric layer. Each metal pad has a penetrating hole, each first through hole is communicated with a corresponding penetrating hole and a corresponding second through hole, the hole diameter of the penetrating hole is smaller than the hole diameters of the first through hole and the second through hole with which the penetrating hole is communicated, the communicated first through hole, second through hole and penetrating hole are filled with plated metal to form conducting holes, and the first conducting circuit layer and the second conducting circuit layer are electrically conducted through the conducting holes. The invention also provides a method for manufacturing the circuit board with the high-density circuits.

Owner:QI DING TECHNOLOGY QINHUANGDAO CO LTD +1

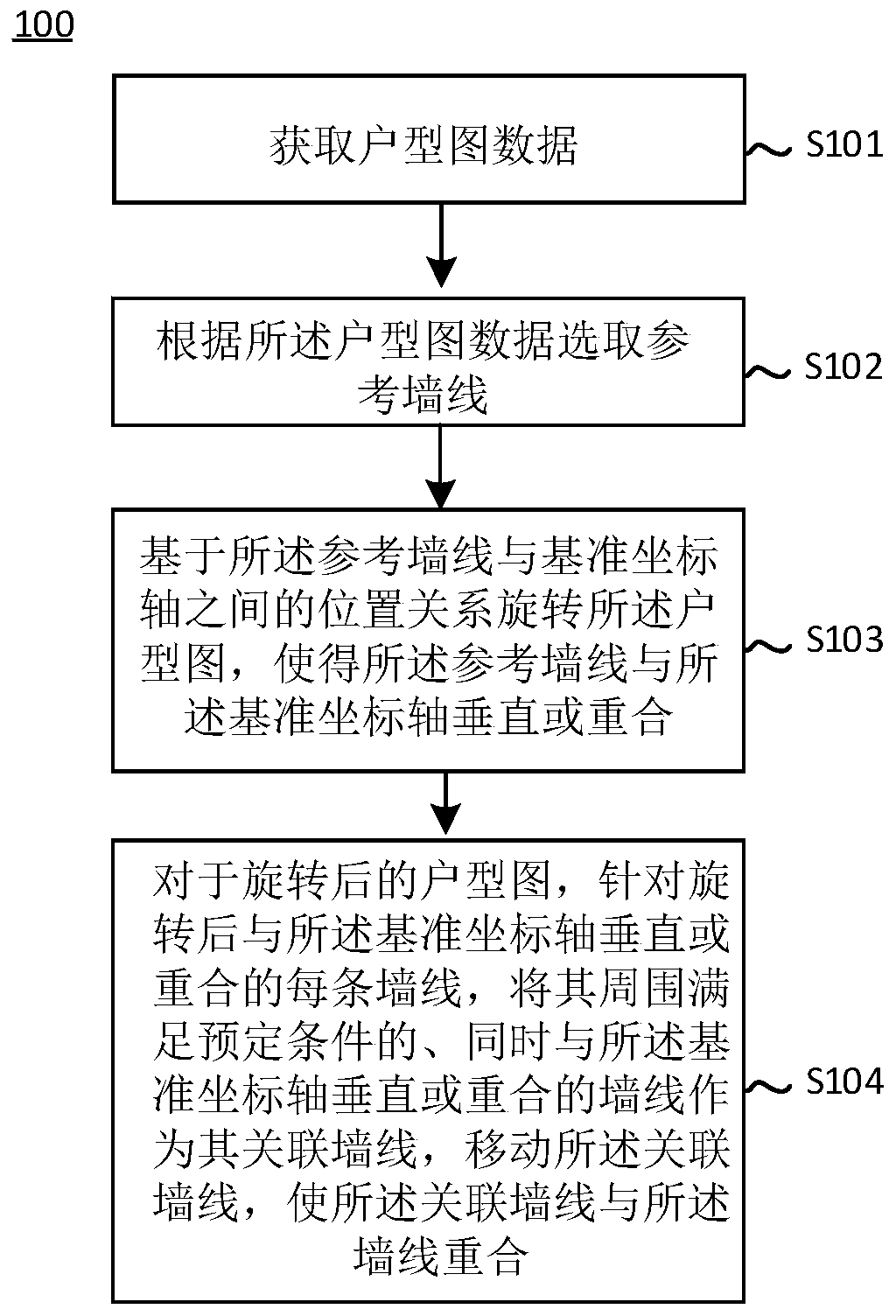

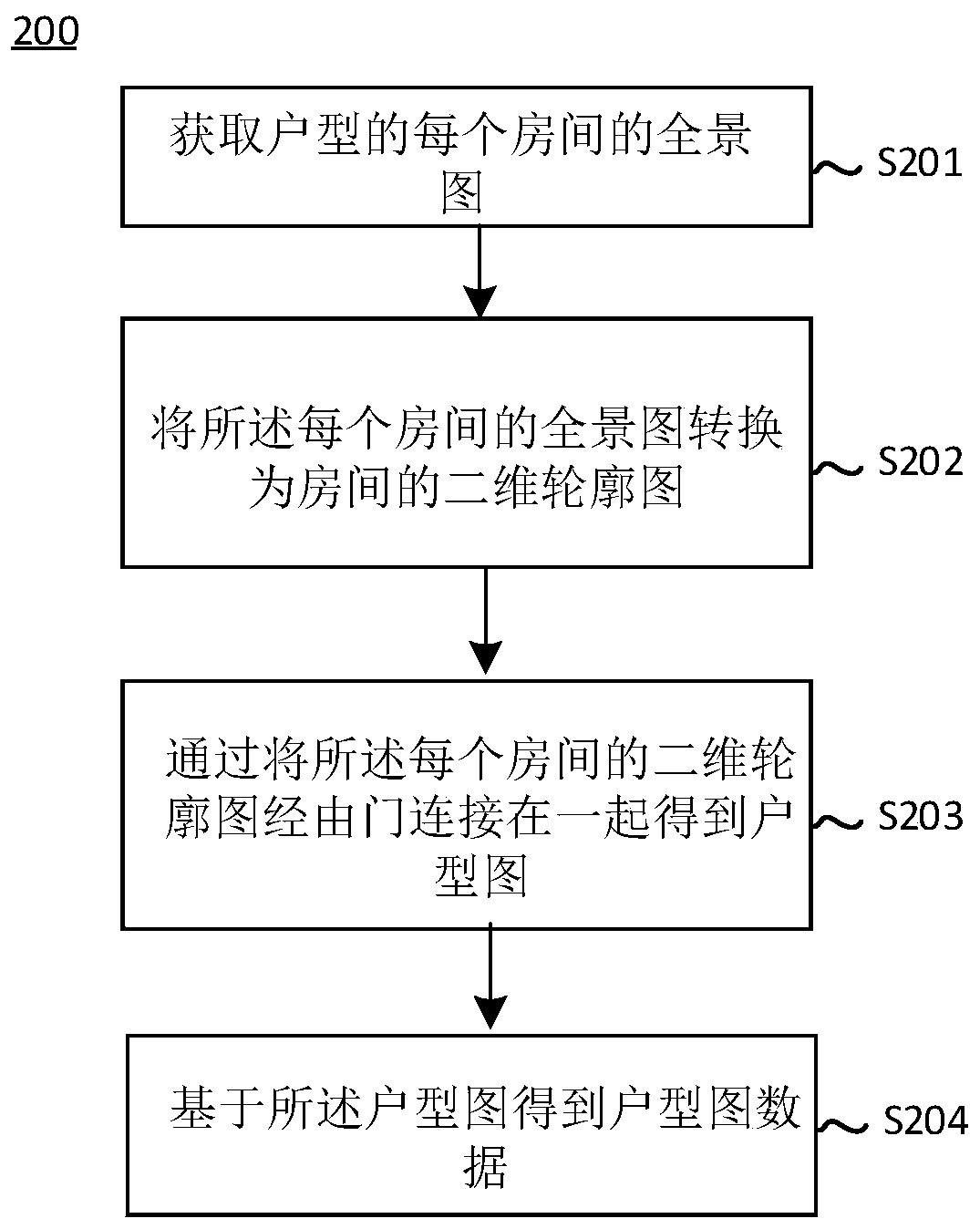

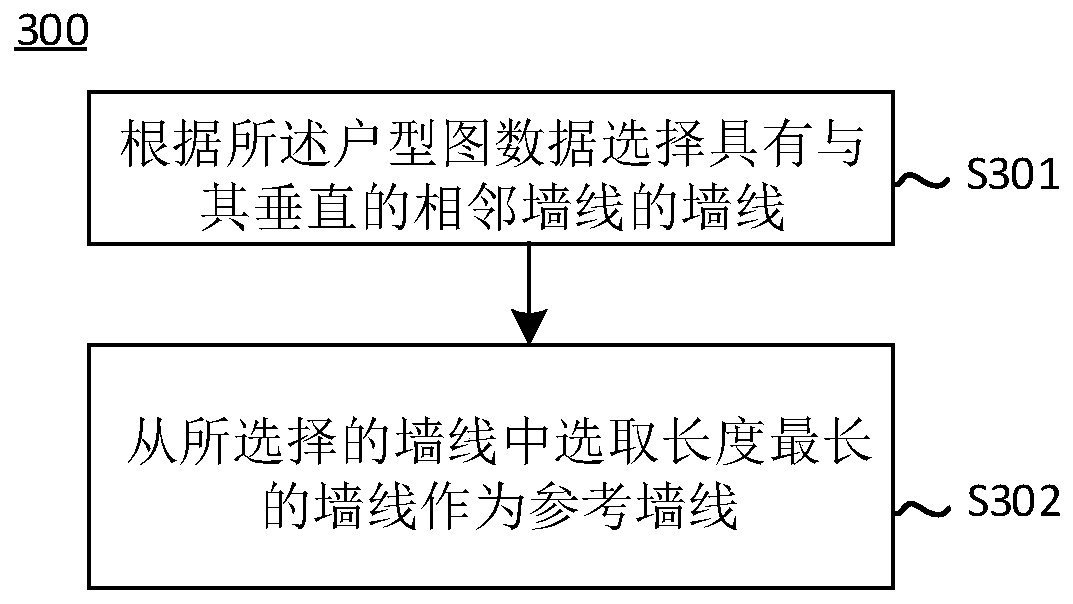

House type image processing method, system and device and computer readable storage medium

ActiveCN111159804ASolve the gapEasy to correctGeometric CADDrawing from basic elementsImaging processingMechanical engineering

The invention provides a house type image processing method, system and device and a computer readable storage medium. The house type image processing method comprises the following steps: acquiring house type image data; selecting a reference wall line according to the house type image data; rotating the house type drawing based on the position relationship between the reference wall line and thereference coordinate axis to enable the reference wall line to be perpendicular to or coincide with the reference coordinate axis; and for the rotated house type drawing, for each wall line which isperpendicular to or coincides with the reference coordinate axis after rotation, taking the wall lines which meet preset conditions and are perpendicular to or coincides with the reference coordinateaxis as associated wall lines, and moving the associated wall lines to enable the associated wall lines to coincide with the wall lines.

Owner:BEIJING CHENGSHI WANGLIN INFORMATION TECH CO LTD

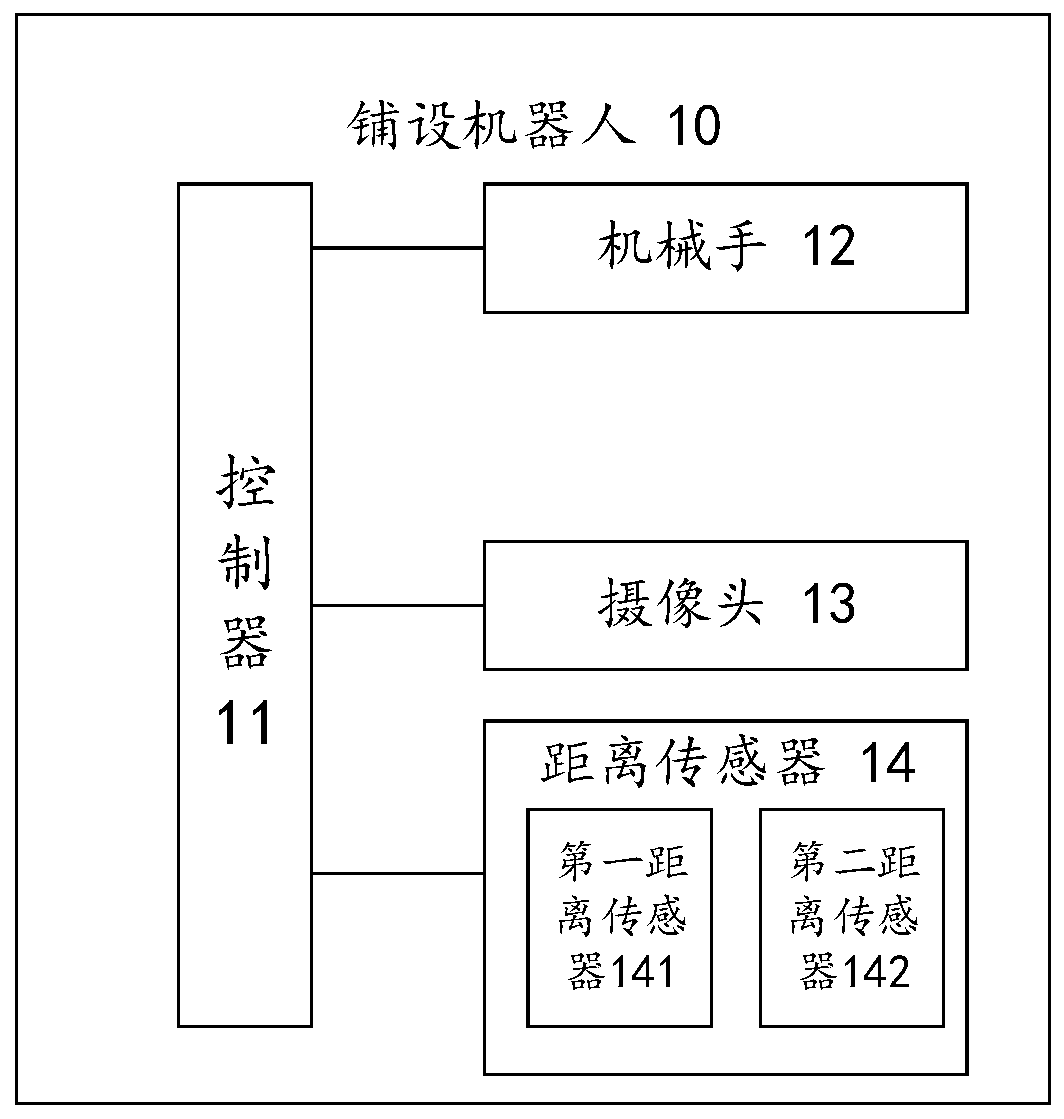

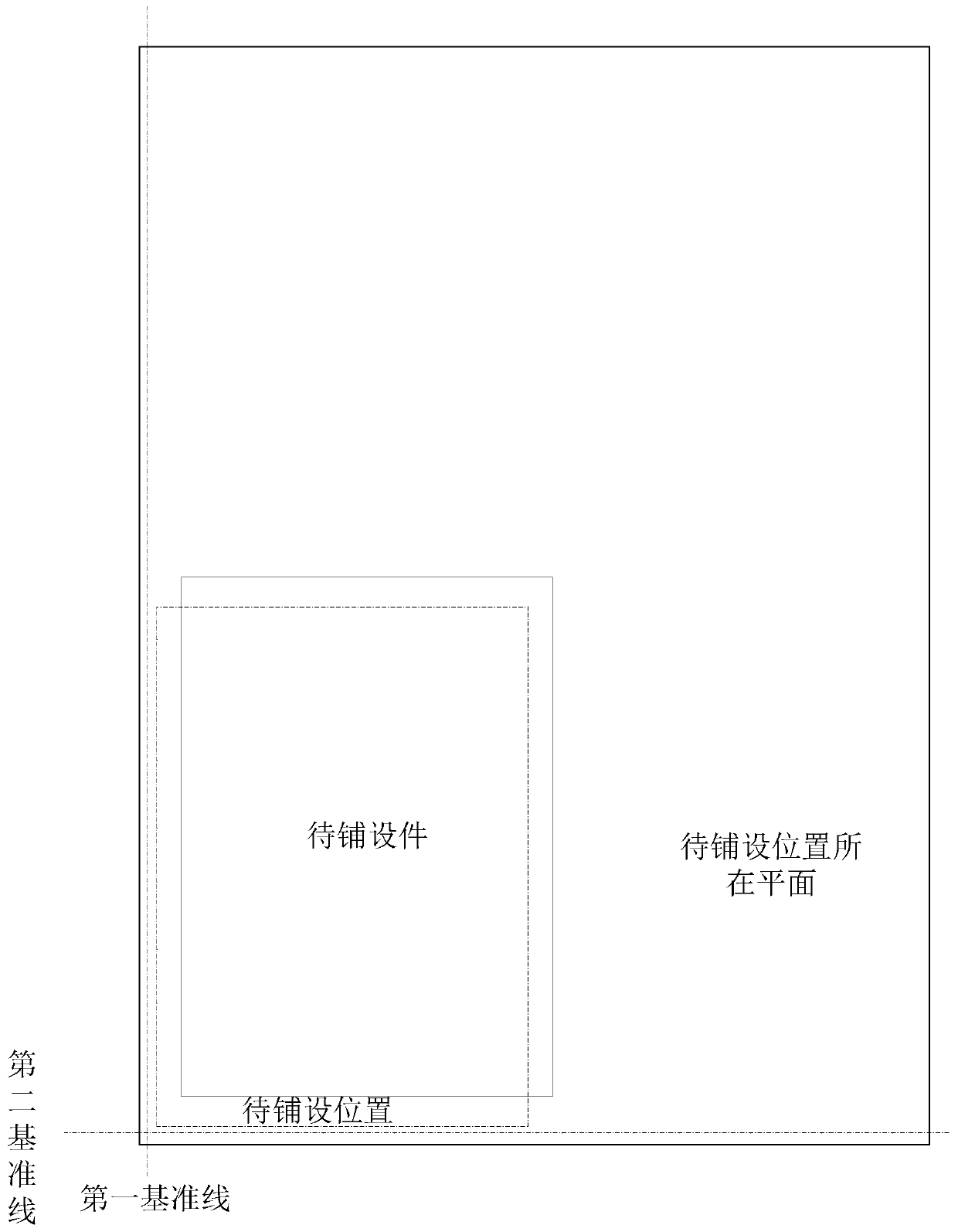

Laying method, laying robot and storage medium

ActiveCN110670860AAvoid the problem of large spacing and low laying accuracySolve the gapImage enhancementImage analysisStructural engineeringAlgorithm

The invention provides a laying method and a laying robot. The method is applied to a controller of the laying robot, and comprises the following steps that a first shooting instruction is sent to obtain a first image containing alignment edges of to-be-laid pieces parallel to each other and a laying reference line of a to-be-paved position; and a distance offset. generated by shooting visual deviation, between the alignment edges and the laying reference line is calculated based on the first image, and an alignment instruction for correcting the distance between the alignment edges and the laying reference line is generated and sent according to the distance offset, so that the laying robot realizes alignment between the alignment edges and the laying reference line. According to the laying method, the problem that when the laying robot acquires the image of the alignment edges and the laying reference line, due to the height difference between the surfaces of the to-be-laid piece andthe to-be-paved position, the distance offset caused by shooing visual deviation is generated between the alignment edges and the laying reference line is solved, the distance offset is corrected, the alignment precision can be improved, the problem that the distance among adjacent laying pieces after the laying is completed is large, and the laying precision is not high can be solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

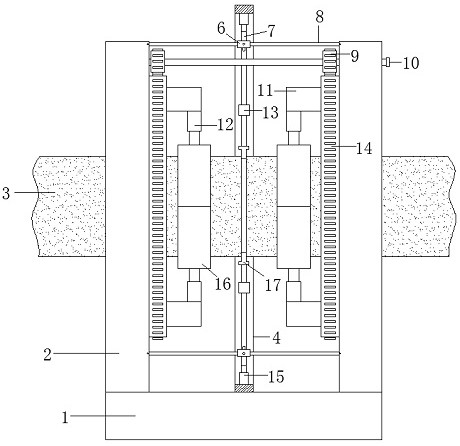

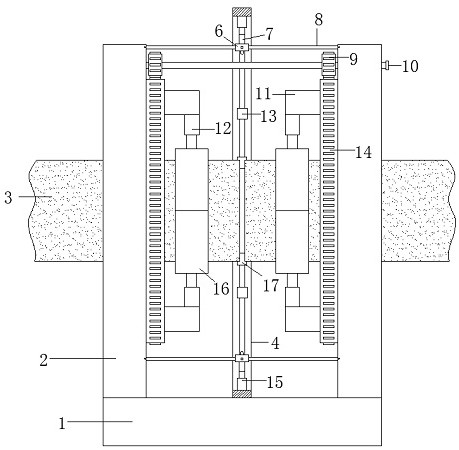

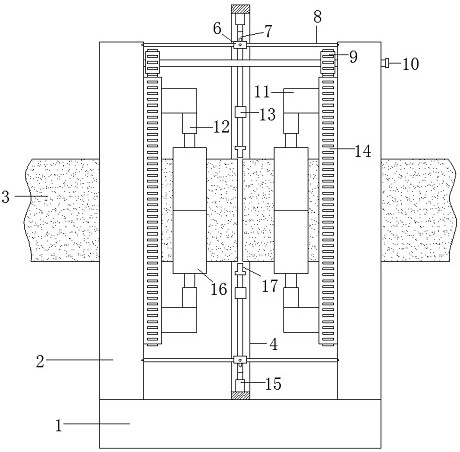

Secondary grouting method applied to space between bottom plate and foundation in installation work of mechanical equipment

ActiveCN102535471ASolve the gapSolve the lack of densityFoundation engineeringEngineeringMechanical equipment

The invention discloses a secondary grouting method applied to a space between a bottom plate and a foundation in installation work of mechanical equipment, belonging to the secondary grouting technology. The method concretely comprises the following steps: (1) washing and wetting a region to be grouted 1-2 days ahead; (2) calculating the using amount of a grouting material, and stirring and mixing into super-dry hard concrete grouting material; (3) pushing the grouting material into the grouting region by a booster specially for grouting, and grouting to be full and compact as required; (4) surrounding the grouting region tightly by plasticity concrete; (5) performing pressure grouting until the pressure grouting is operated to be full by cement plaster. The principle of the invention is as follows: the super-dry hard (zero slump) concrete is used as the grouting material, and the grouting material cannot settle and contract before the grouting material is solidified. The secondary grouting method has the beneficial effects that: the method solves the problem that the space between the equipment bottom plate and a grouting layer is provided with a gap and is incompact due to falling of the plasticity concrete, caused by dead weight before solidification when the plasticity concrete is used for grouting.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

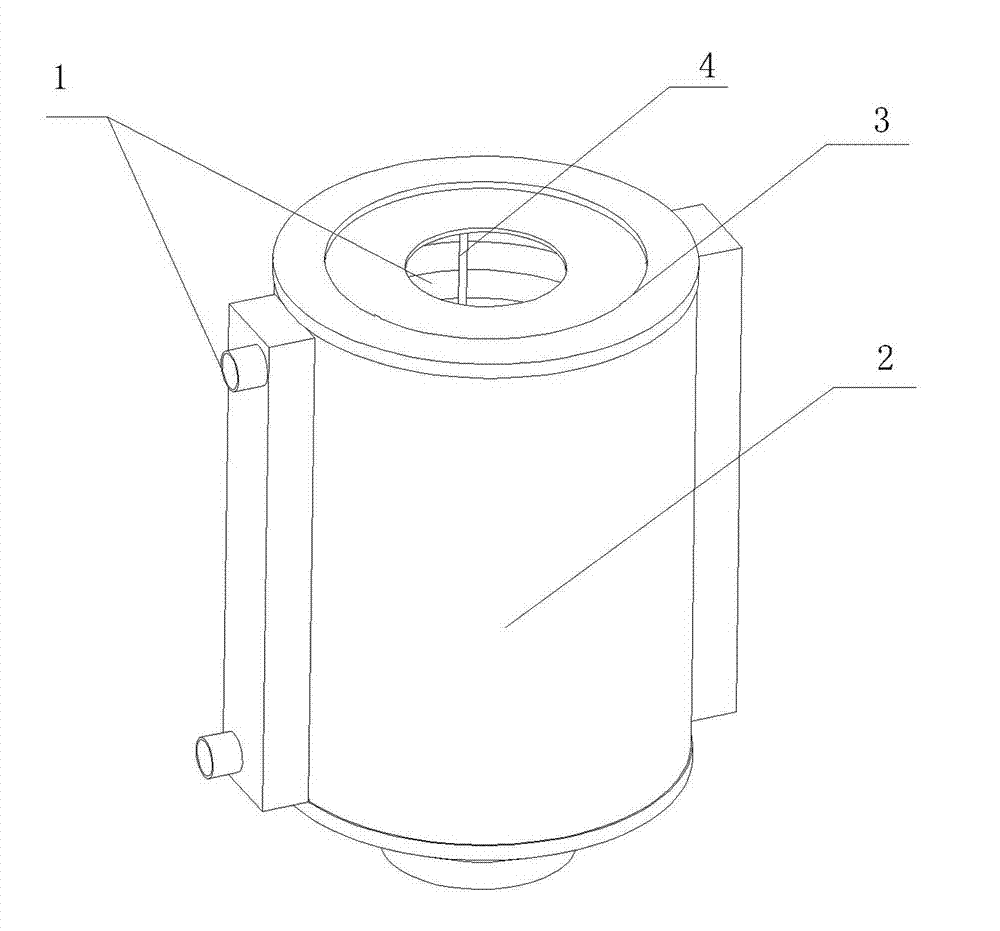

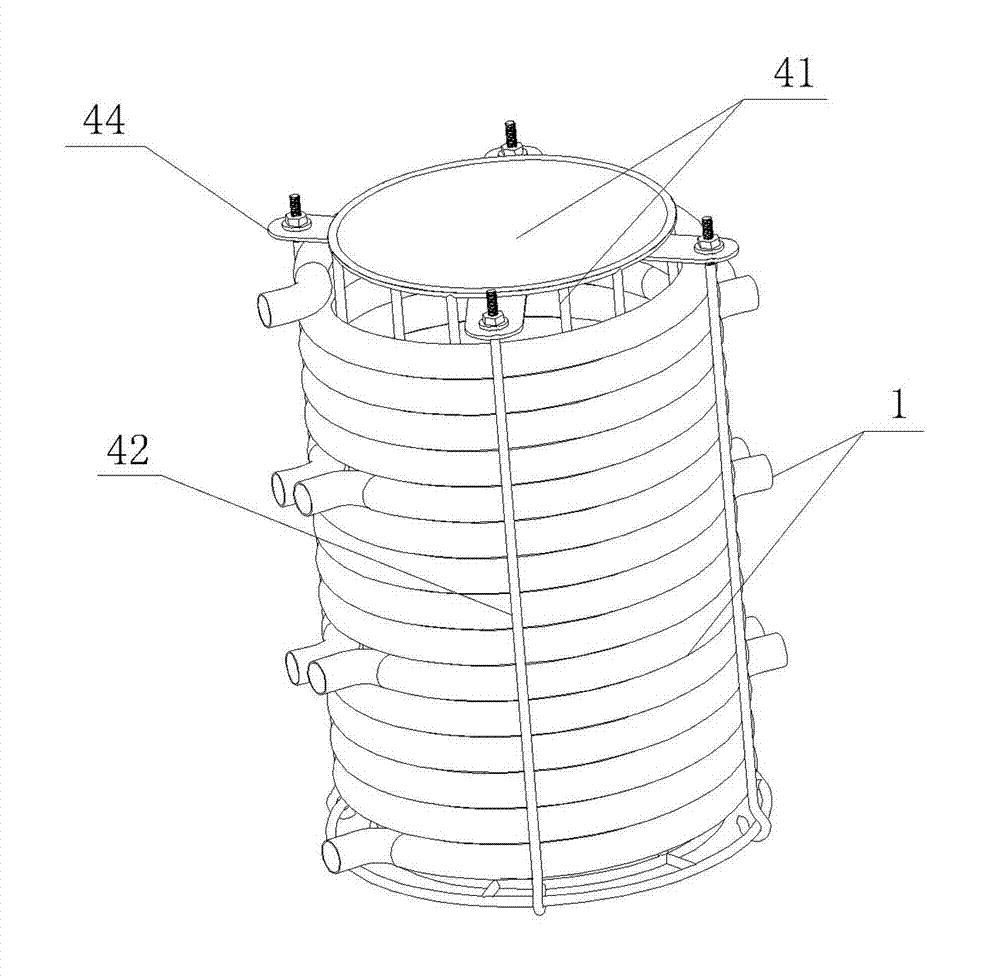

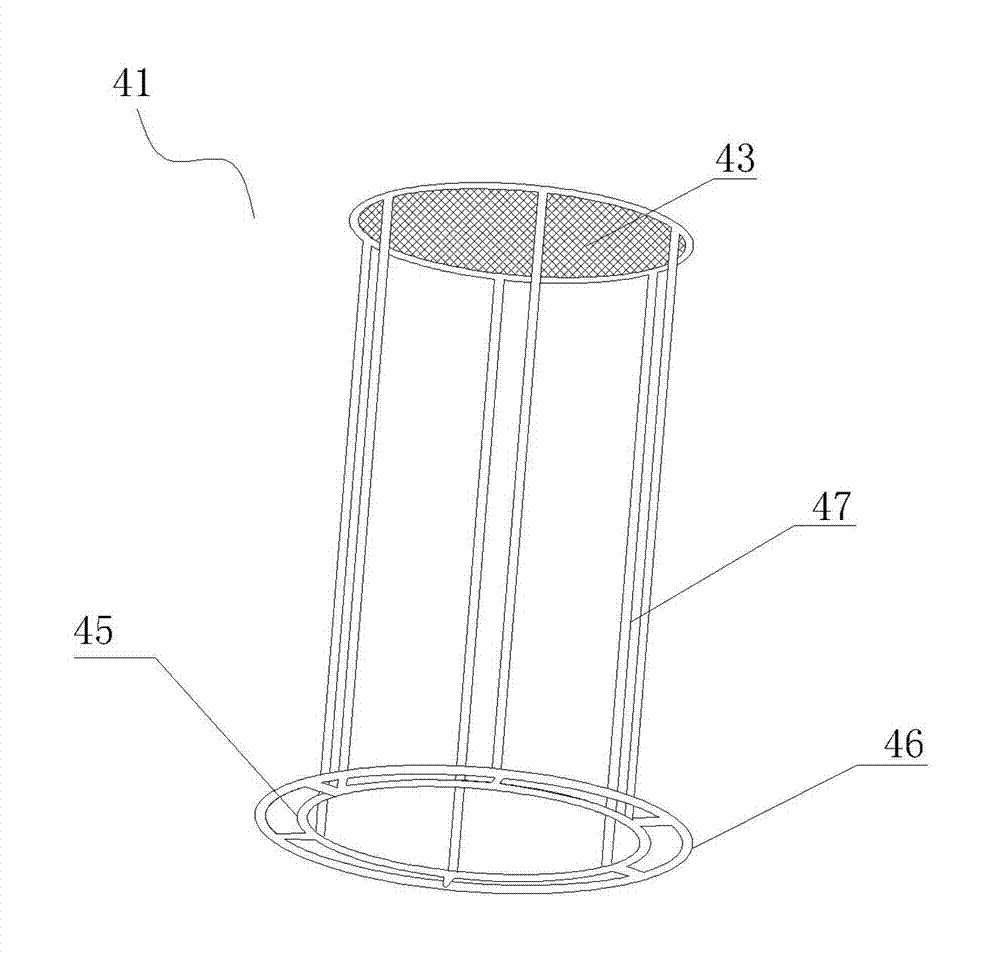

Corrugated pipe condensation heat exchanger and manufacture method thereof

InactiveCN102767903AConsistent sizeEasy to installEnergy efficient heating/coolingAir heatersBatch manufacturingPhysics

The invention provides a corrugated pipe condensation heat exchanger. The corrugated pipe condensation heat exchanger comprises corrugated pipes, a condensation heat exchanger casing, an upper end cover and a lower end cover, wherein a frame is arranged in the condensation heat exchanger casing, the corrugated pipes are coiled and fixed on the frame to form a spiral structure, the thread pitch of the spiral structure is identical, and spiral axes are the same straight line. The invention further provides a manufacture method of the corrugated pipe condensation heat exchanger. The manufacture method comprises the steps of frame manufacture, installation of the corrugated pipe and installation of the condensation heat exchanger casing. The step of the installation of the corrugated pipe is that the stainless steel corrugated pipes are first and sequentially coiled on a connecting rod of a frame main body for form a coaxial structure by means of a bamboo basket weaving mode and then are fixed on the connecting rod through fixing rods by means of an extruding mode to form the identical-thread-pitch structure. Compared with a traditional condensation heat exchanger, the corrugated pipe condensation heat exchanger has the advantages of being identical in size during batch production, further enables inner combustion to be full and achieves energy saving and environmental protection.

Owner:MACRO THERMAL ENERGY TECH

Crash bearer and manufacturing method thereof

ActiveCN105350475AExtended service lifeWon't ageCeramic shaping apparatusBridge structural detailsCorrosionAnchor bolt

The invention discloses a crash bearer. The crash bearer comprises a crash bearer core and crash bearer guard boards. The crash bearer guard boards are fixed to the crash bearer core from the side faces of the crash bearer guard boards, wherein the crash bearer guard boards are made of active powder concrete. By the adoption of the crash bearer, in a connecting manner adopting expansion anchoring bolts and grouting liquid, an external corrosion source cannot invade an existing concrete crash bearer any more, and the service life of the existing crash bearer can be prolonged; and the crash bearer guard boards cannot be aged, construction is convenient and easy, and the maintenance cost is reduced. The crash bearer guard boards serve as face layer formworks, the concrete is poured directly, and the thickness and the quality of face layers are guaranteed; and the crash bearer guard boards and the crash bearer core are all made of a concrete material, the bonding performance is good, the use number of the formworks is decreased, and formwork detaching time is shortened. The invention further discloses a manufacturing method of the crash bearer.

Owner:北京鸿锐嘉科技发展有限公司

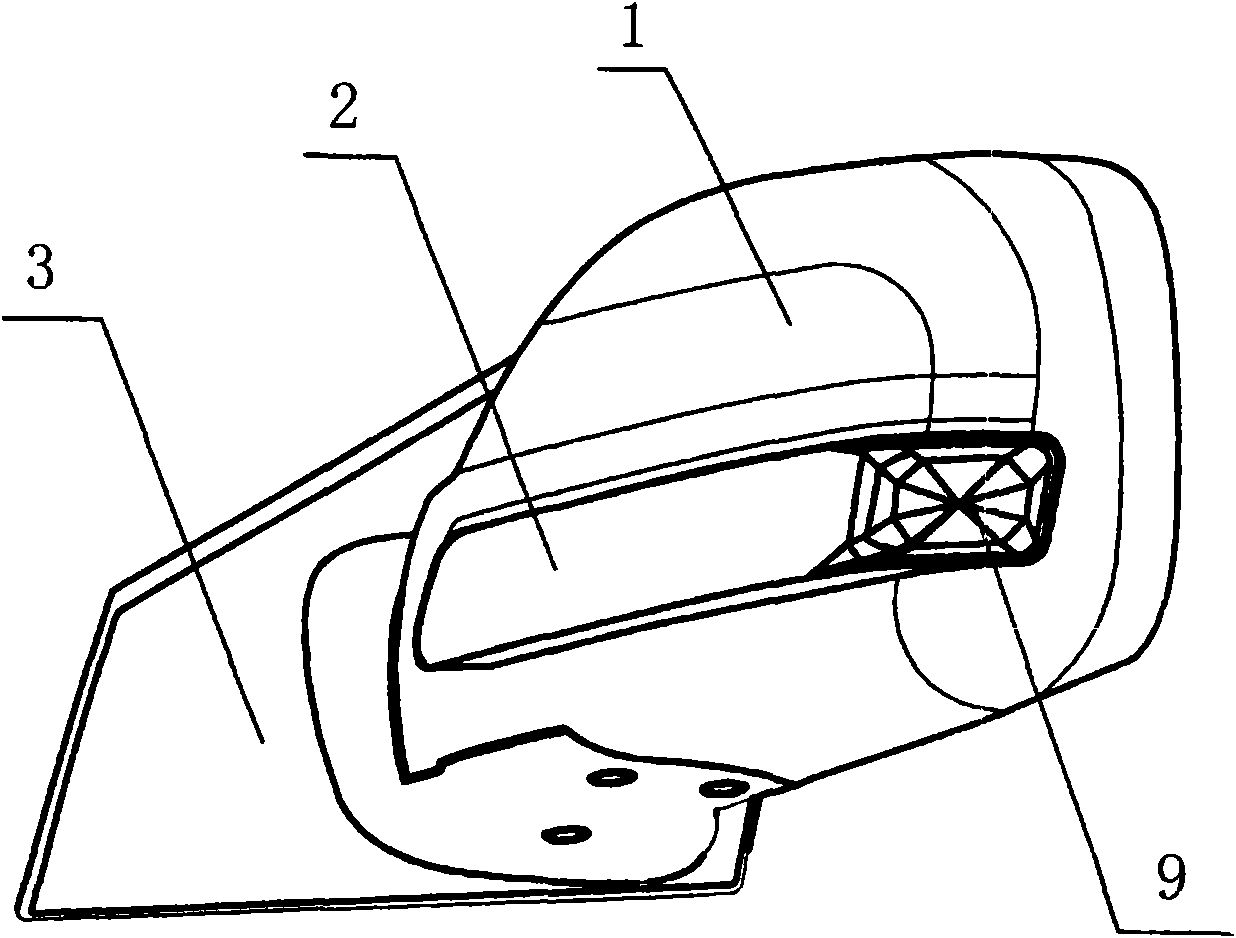

Rearview mirror mask and preparation process thereof

InactiveCN101570156ASolve the gapSolve aestheticsOptical signallingDomestic articlesWater leakageOptoelectronics

The invention relates to a rearview mirror mask which comprises a mask and a transparent element convenient for light rays emitted by a turning light to penetrate through the mask, wherein the outer surface of the mask is provided with a notch, and the transparent element is arranged at the notch of the mask and connected with the mask into a whole by a sealing way. The rearview mirror mask can be prepared by two methods, wherein one method is realized in such a way that two injector ports and two pouring channels are arranged in a same mould, two materials are simultaneously used for injection molding the mask and the transparent element, and after being cooled, the injection molded materials are demoulded to obtain the rearview mirror mask; while the other method is realized in such a way that the transparent element is molded firstly, and then the molded transparent element is arranged in a mask injection molding mould as an embedded piece; a mask molding material is injected into the mould, and after being cooled, the material is demoulded to obtain the rearview mirror mask. The transparent element and the mask of the rearview mirror mask are connected into a whole so as to solve the problems of large clearance, unattractive appearance and light and water leakage of the prior rearview mirror mask with a turning light.

Owner:上海干巷汽车镜有限公司 +1

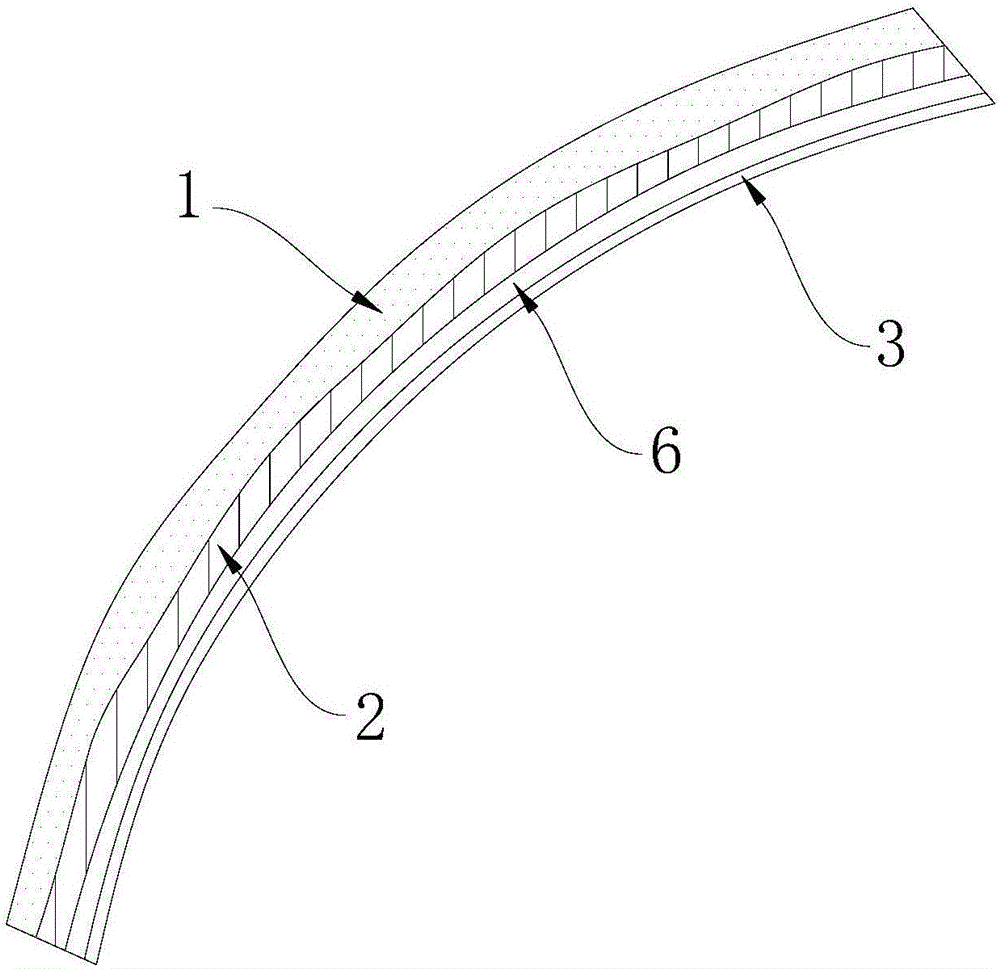

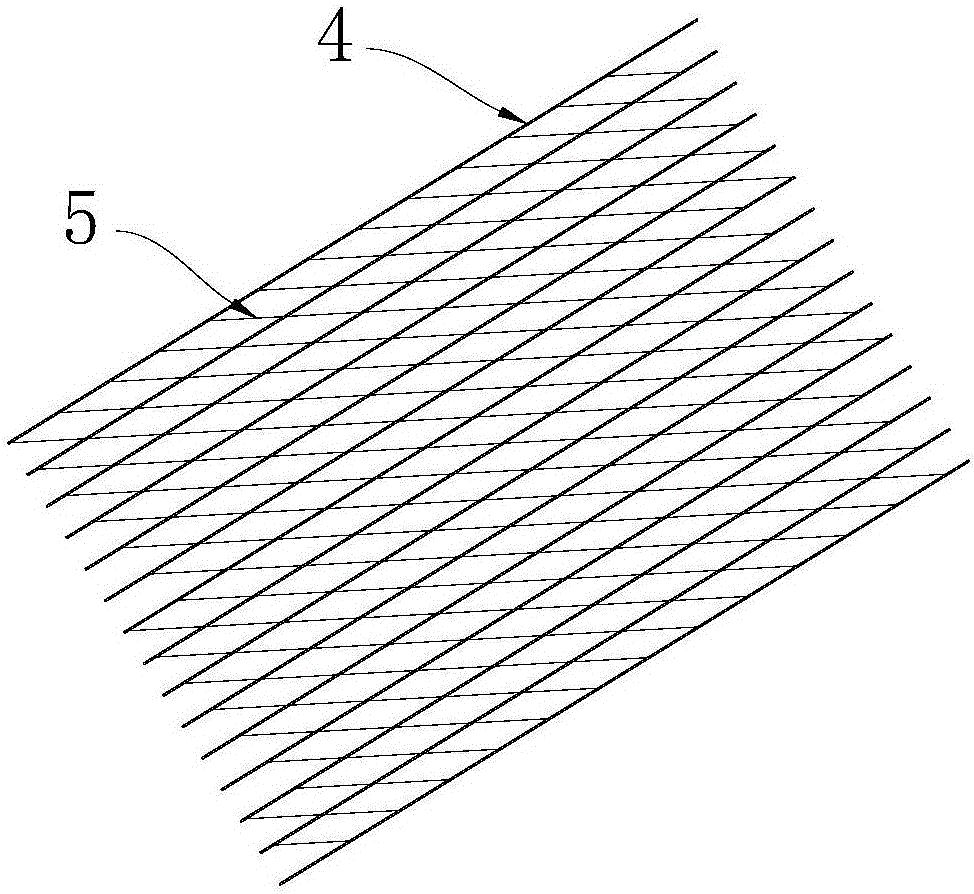

Radial tire of fiber cord fabric tire shoulders

ActiveCN106739832APrevent air leakageAvoid empty shouldersHeavy duty tyresHeavy duty vehicleFiberEngineering

Disclosed is a radial tire of fiber cord fabric tire shoulders. The radial tire comprises a wire cord fabric, a fiber cord fabric and an airtight layer, wherein the wire cord fabric, the fiber cord fabric and the airtight layer are located at the tire shoulders of the inner wall of the tire, and distributed in sequence from outside to inside; and steel wires are arranged in the wire cord fabric, fibers are arranged in the fiber cord fabric, and included angles of 5-45 degrees are formed between the fibers and the steel wires. The radial tire of fiber cord fabric tire shoulders has the advantages of solving the problems of bending deformation, seam production, cord exposure and the like of the carcass wire cord fabric of the on-load radial tire in the production process by virtue of a netlike structure formed due to different angles between the fibers of the fiber cord fabric and the steel wires of the wire cord fabric, thereby avoiding tire flat, shoulder separation, explosion, early damage and other similar situations, improving the running safety of the tire and prolonging the service life of the tire.

Owner:青岛泰谦科技服务有限公司

Air conditioner indoor unit

ActiveCN108180549ASolve the gapSolve chromatic aberrationLighting and heating apparatusHeating and ventilation casings/coversEngineeringColor difference

The invention provides an air conditioner indoor unit. The air conditioner indoor unit comprises a shell body formed in an integrated manner, an installation cavity is formed inside the shell body, the shell body is provided with an air outlet, the side, opposite to the position of the air outlet, of the shell body is provided with an air inlet, and a framework is arranged inside installation cavity and is fixed with a hood shell of the shell body in a clamping connection manner through a clamping connection structure. By means of the air conditioner indoor unit, the problems in the prior artthat the air conditioner indoor unit is inconvenient in disassembling operations due to the shell body is formed by connecting multiple parts in sequence, and segment difference, surface difference and color difference exist are solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Method for improving orifice burrs after mechanical drilling of rigid-flex board with height difference on board surface

The invention discloses a method for improving orifice burrs after mechanical drilling of a rigid-flex board with a height difference on a board surface. The method comprises the following steps: S1,preparing a cold punching board consistent with the rigid-flex board in size before drilling; S2, correspondingly designing the windowing of the cold punching plate according to the position of a convex part on the surface of the rigid-flex board and the position of a heat capacity block on the edge of the board, and manufacturing the windowing cold punching plate for later use; S3, during mechanical drilling, mechanically drilling below the rigid-flex board by using the windowed cold-punched board clamping pad, enabling the back surface of the drilling position of the rigid-flex board to be in complete contact with the windowed cold-punched board, replacing the drilling base plate by the windowed cold-punched board, and correspondingly stacking the non-porous bulge part position and the board edge heat capacity block position of the rigid-flex board at the windowed position. The invention has the beneficial effects that the problem of a gap between the rigid-flex board and the drilling base plate is solved, orifice burrs after mechanical drilling of the rigid-flex board with height difference on the board surface are effectively improved, the quality yield is improved, the qualityscrap rate is reduced, and the product processing material cost is reduced.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD +1

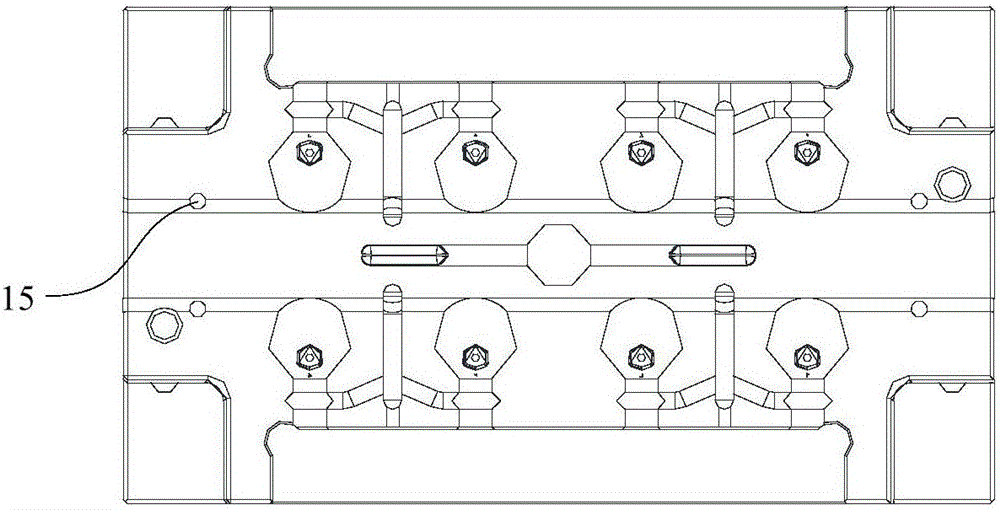

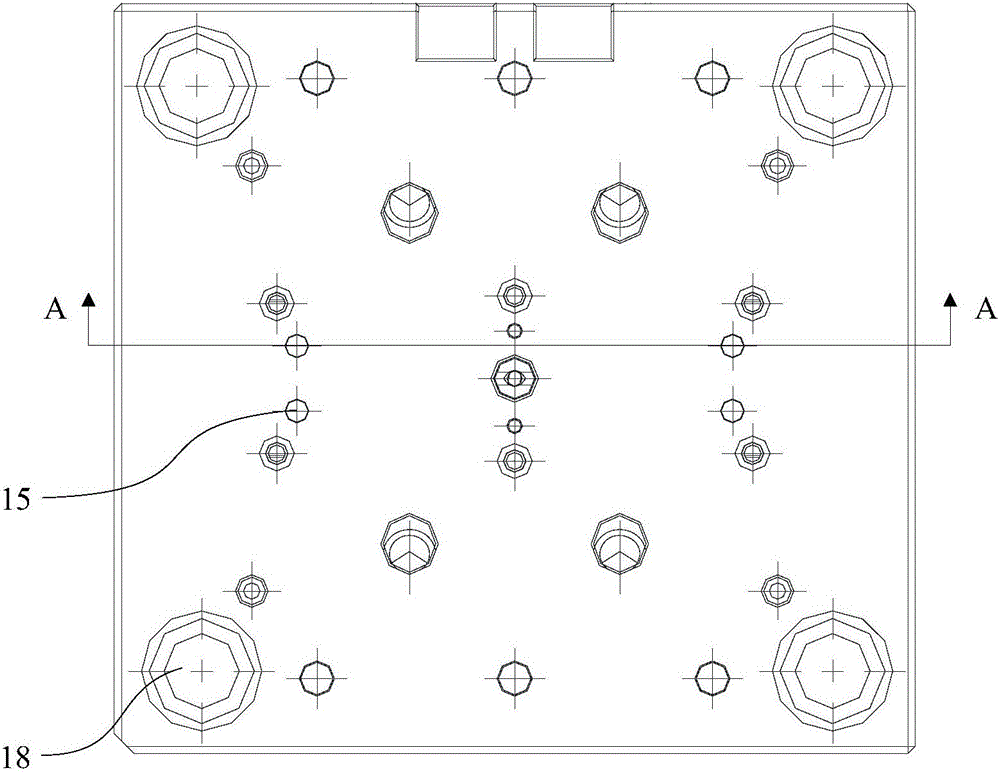

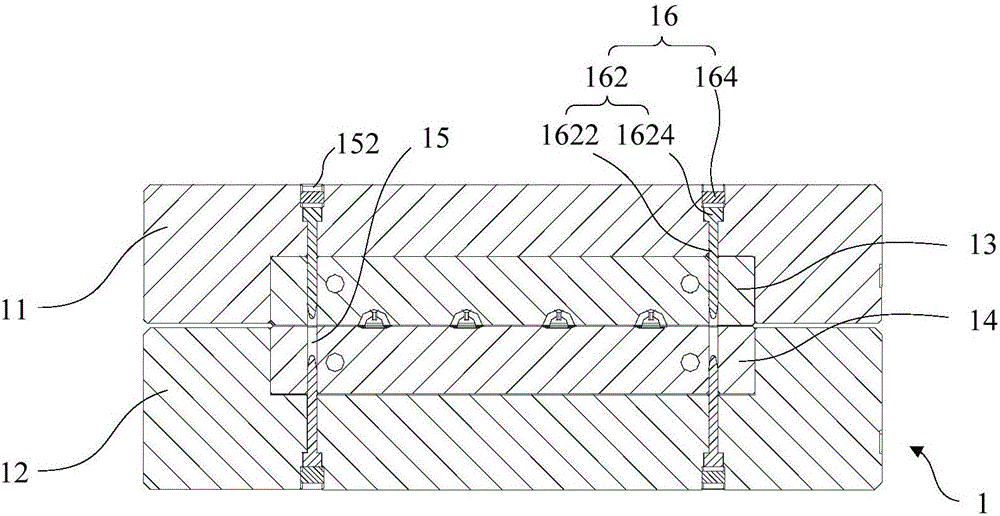

Injection mold and machining and assembling technology

The invention provides an injection mold and a machining and assembling technology. The injection mold comprises a fixed mold plate, a movable mold plate, a first inner mold, a second inner mold, at least one datum hole and locating pieces, wherein the first inner mold and the second inner mold are installed in the fixed mold plate and the movable mold plate correspondingly, each datum hole penetrates through the fixed mold plate, the first inner mold, the second inner mold and the movable mold plate at the same time, and the locating pieces are inserted into the datum holes. According to the injection mold, through the uniform datum, the inner mold of the injection mold is machined according to the uniform datum, the machining datum is also used as the assembling datum, and the precise locating effect is achieved; and in this way, the defects that the frame forming precision is low, the datum faces of the inner molds deviate, screw receding locating is ineffective and the datums are respectively independent are overcome, the machining precision is improved, and finally the problems of dislocation, segment gaps and flashes of products are solved. The products are made to reach the ideal state that the appearance and the hand feeling are both good. Meanwhile, zero-error one-time machining is ensured, repeated machining and the risk of scraping of the inner molds are avoided, the products produced through the mold discharging one product once or the mold discharging multiple products once are significantly improved, and the mold precision is also significantly improved.

Owner:FOSHAN CITY SHUNDE DISTRICT BAINIAN TECH CO LTD

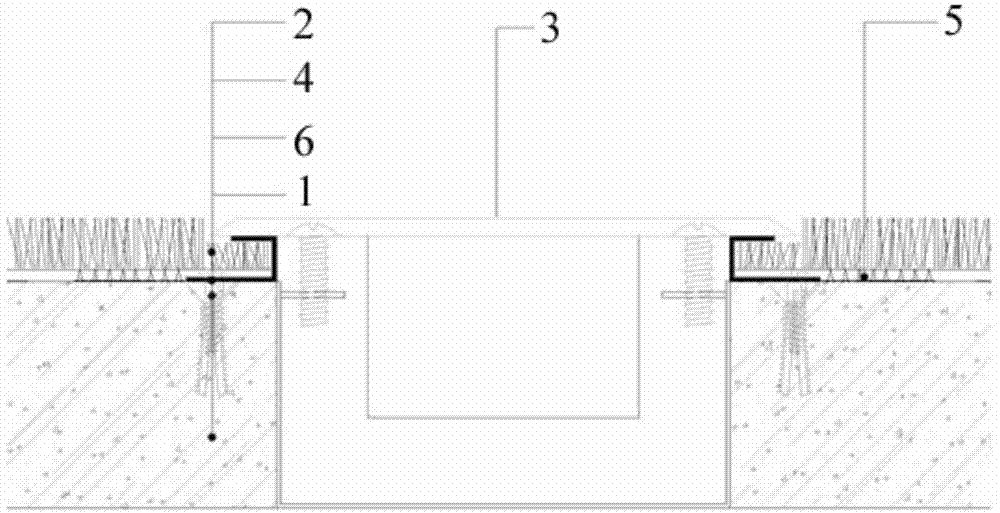

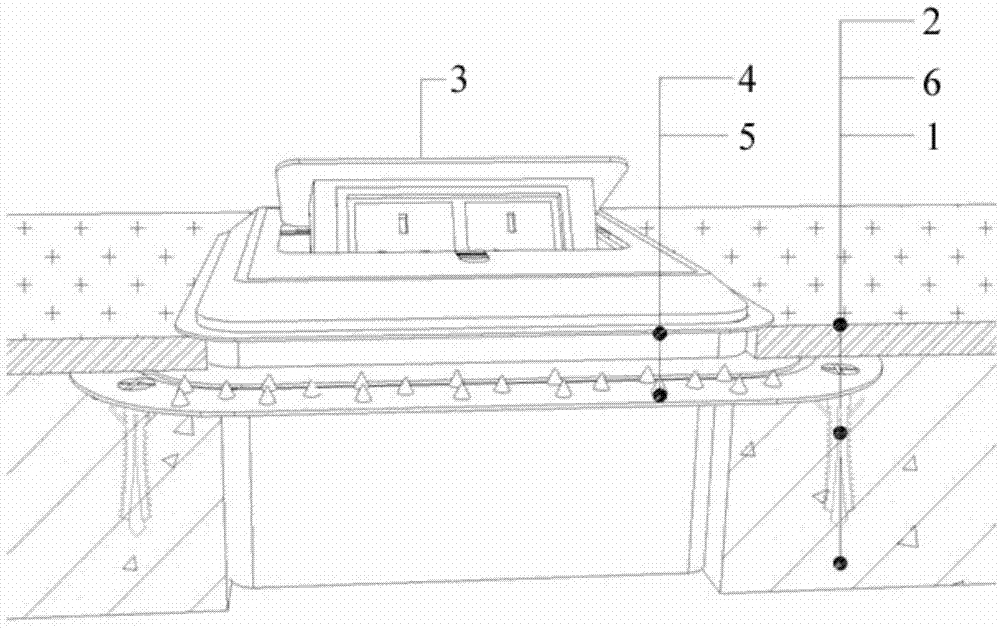

Novel necking structure of carpet and ground socket

The invention discloses a novel necking structure of a carpet and a ground socket. The novel necking structure comprises the carpet and the ground socket which are both arranged on a ground base layer. The carpet is laid around the periphery of the ground socket. A necking strip is arranged between the carpet and the ground socket in the vertical direction and covers the edge of the carpet. A connecting piece for fixing the position of the carpet is arranged between the carpet and the ground base layer along the edge area of the periphery of the ground socket. By means of the novel necking structure, deformation or indentation is not prone to happening to the joint of the carpet and the ground socket, the necking effect of the carpet and the ground socket is improved, and the safety performance of the ground socket is higher.

Owner:GOLD MANTIS CONSTR DECORATION

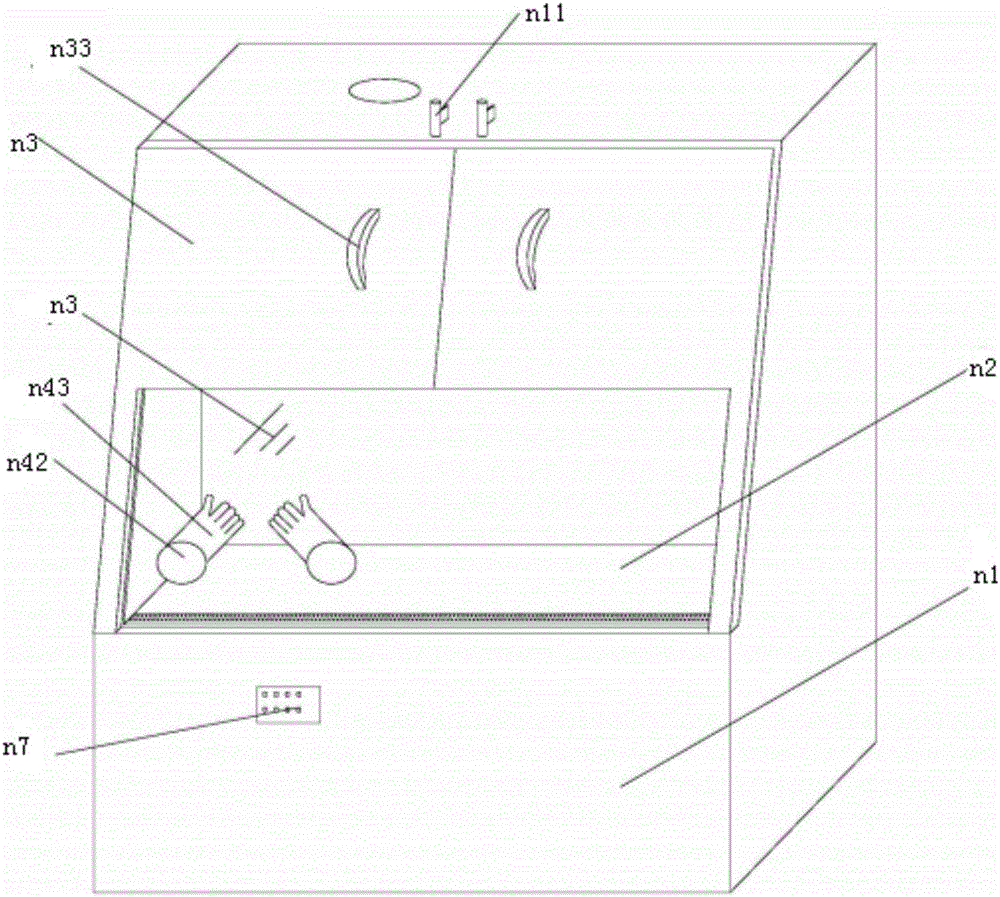

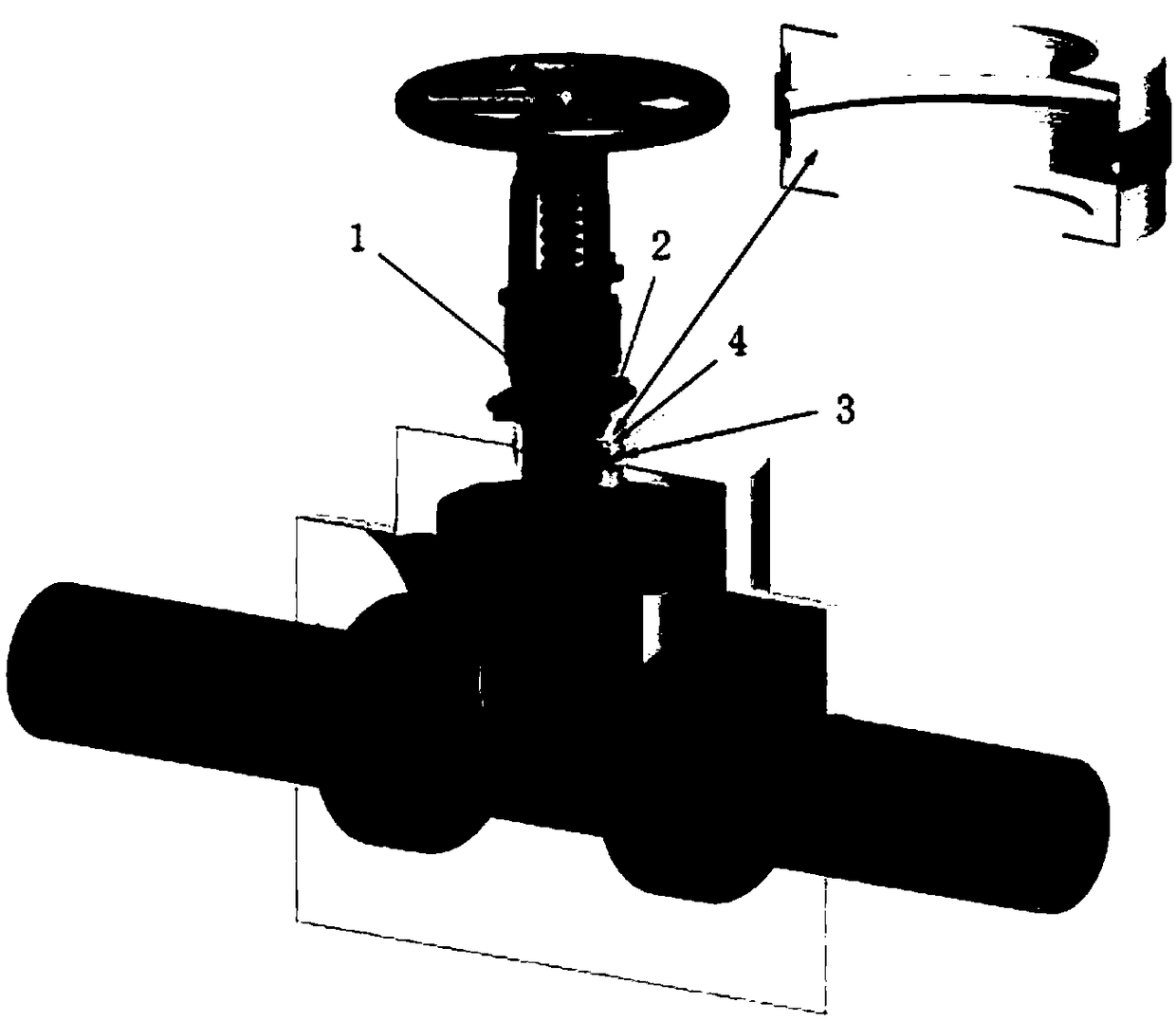

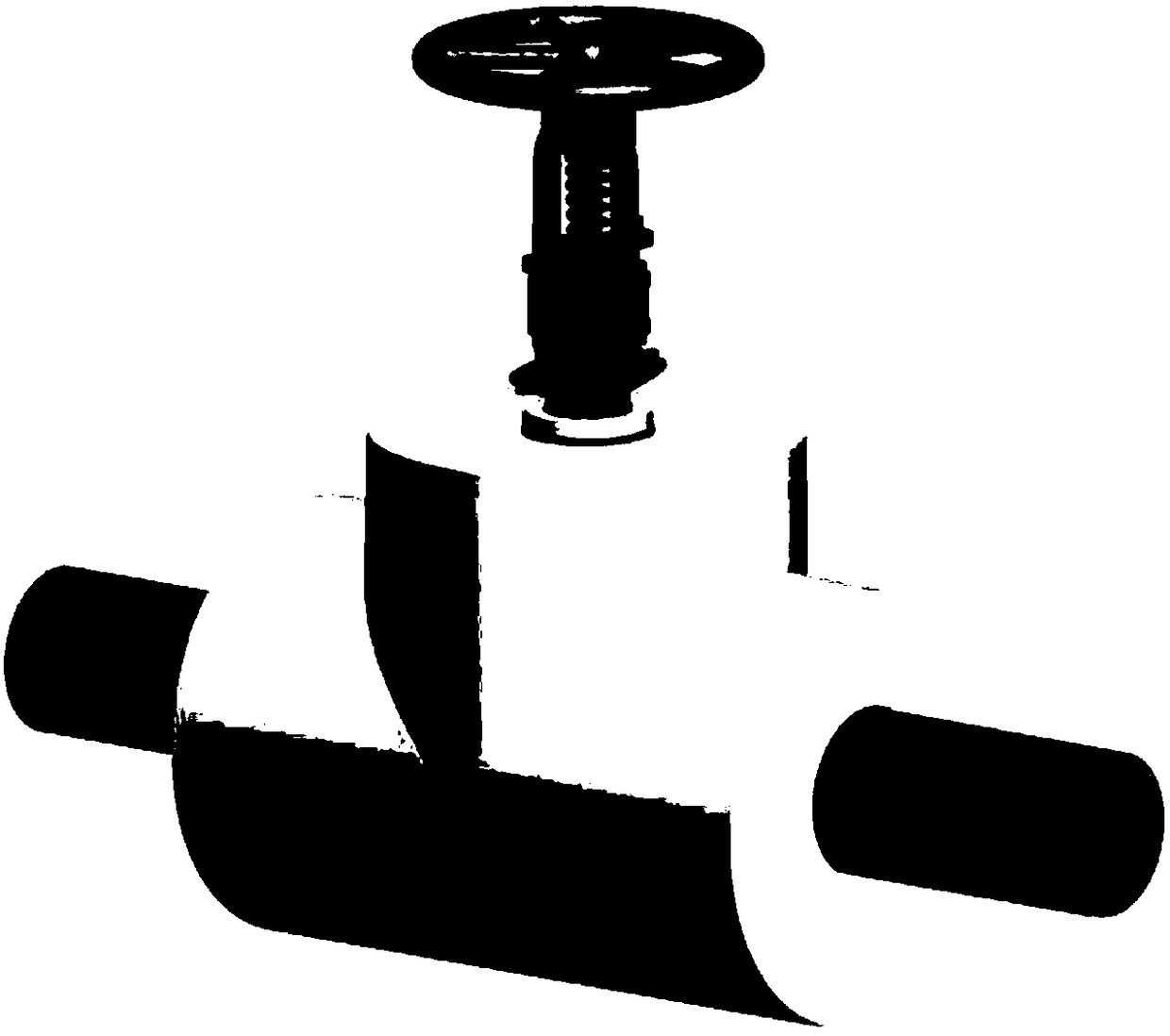

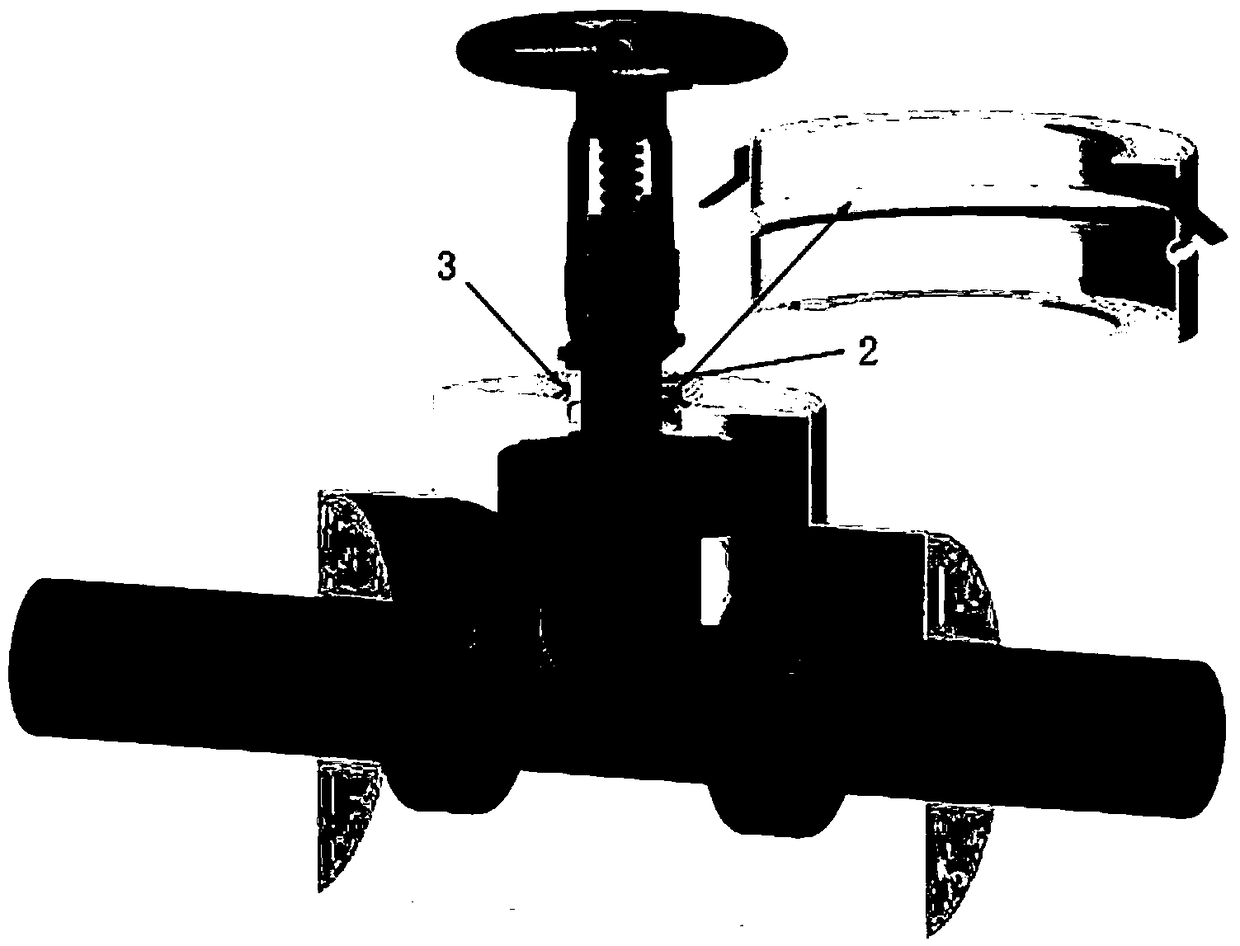

Highly waterproof removable energy-saving insulation shell

ActiveCN108548050ASolve the gapAvoid enteringThermal insulationPipe protection by thermal insulationEngineeringContact position

The invention discloses a highly waterproof removable energy-saving insulation shell. The highly waterproof removable energy-saving insulation shell comprises two shell bodies, wherein the two shell bodies are of the same structure and are combined so as to form an integrated whole for wrapping a tee structure; the tee structure comprises a vertical valve and a horizontal pipeline; the packing position of the valve makes contact with upper openings of the two shell bodies, and vertical waterproofing treatment devices are arranged in the contact positions; and the insulation position of the horizontal pipeline makes contact with two horizontal openings of the two shell bodies, and side waterproofing treatment devices are arranged in the contact positions. According to the device, waterproofflanges or conical caps are additionally arranged in the packing position of the insulation shell and the valve, and sealing strips are additionally arranged in the insulation contact position of theinsulation shell and the pipeline, so that external liquid cannot enter the insulation shell.

Owner:徐卫海

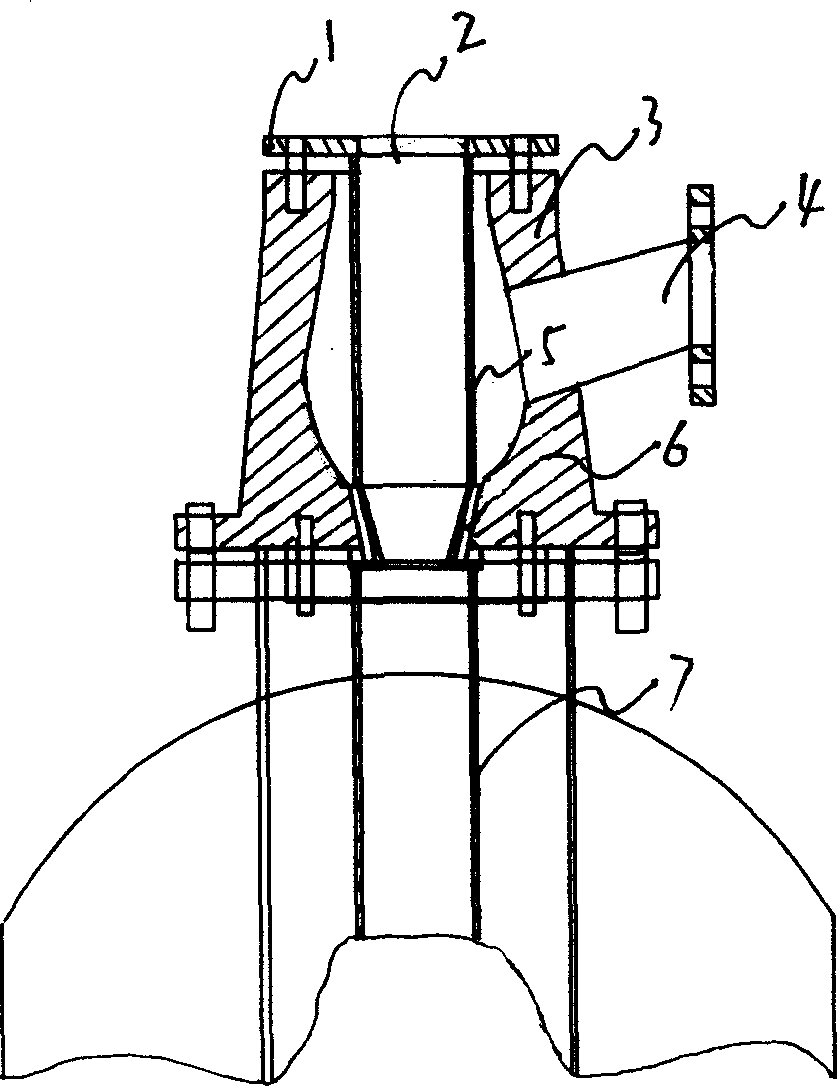

Automatic butt joint machine for flue pipe production

InactiveCN112621095ASolve the lack of contactSolve the gapWelding/cutting auxillary devicesAuxillary welding devicesButt jointPower apparatus

The invention discloses an automatic butt joint machine for flue pipe production, relates to the technical field of smoke pipe production, and aims at solving the problem that when common flue pipe bodies are in butt joint, butt joint openings are not in tight contact and have gaps. According to the automatic butt joint machine, the automatic butt joint machine comprises a base plate, and is characterized in that two supporting plates are slidably connected to the top of the base plate in the length direction; transmission devices are rotatably connected to the faces, close to each other, of the two supporting plates respectively, power devices are arranged above the transmission devices respectively, clamping devices are fixedly arranged on the faces, close to each other, of the two transmission devices respectively, and an arc-shaped fixing plate is fixedly connected to the top of the base plate; and lifting devices are arranged at the upper side and the lower side of the arc-shaped fixing plate respectively, and grinding devices are arranged on the faces, close to each other, of the two lifting devices respectively. The automatic butt joint machine is novel in design and easy to operate; not only can the butt joint openings of the flue pipe bodies be polished conveniently, but also butt joint of the flue pipe bodies is facilitated; and meanwhile, the process can be completed automatically, and the automation degree is improved.

Owner:湖南森鸿环保建材有限公司

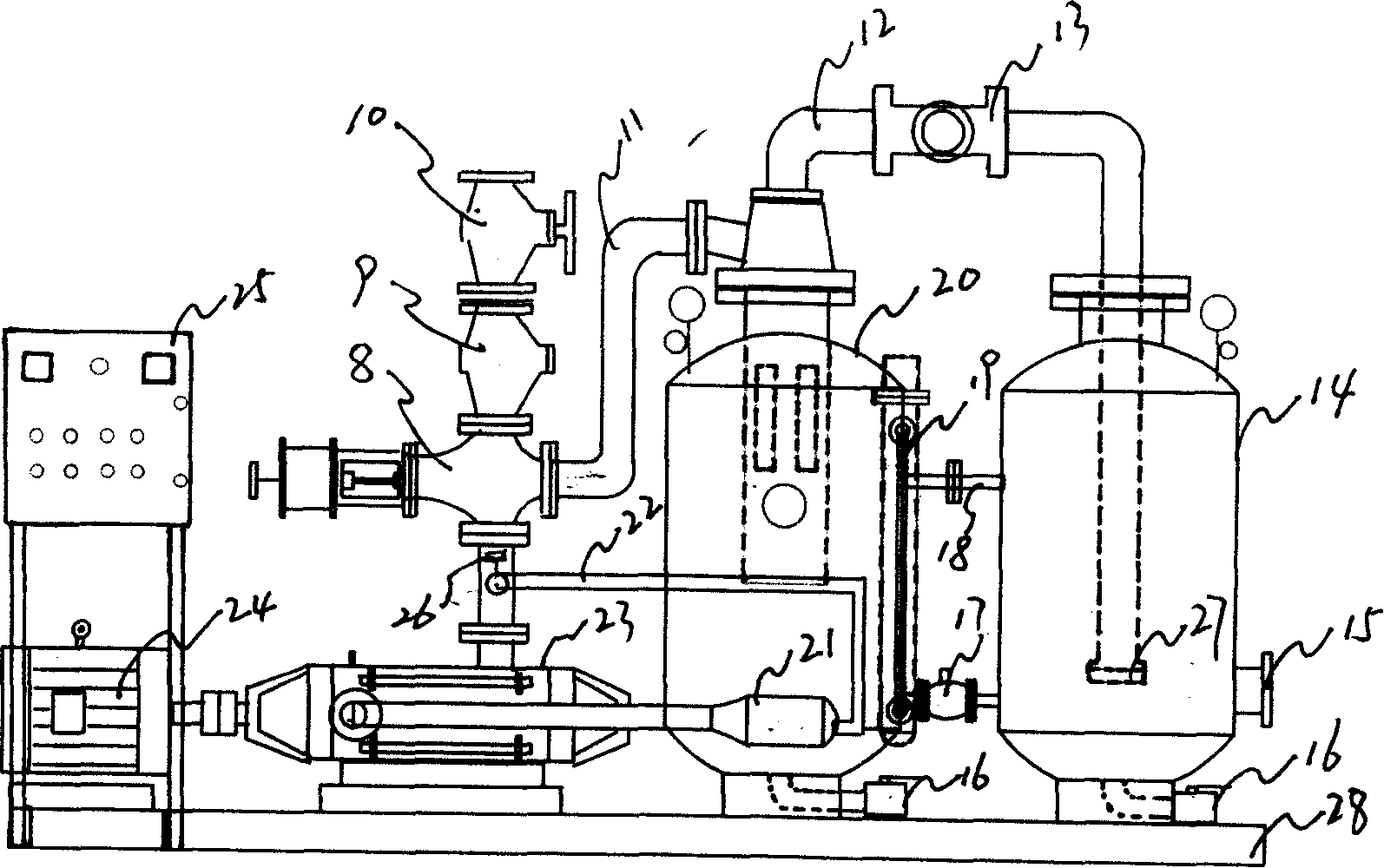

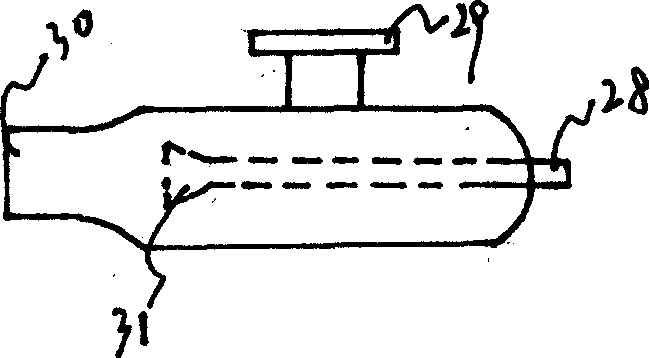

Adjustable high temperature condensate water circulating and recovering system and recovering method

InactiveCN1654830ASmooth recyclingGood siphon effectSteam/vapor condensersMachines/enginesRecovery methodSiphon

This invention relates to a high temperature condensed water recycling system and its recycling method, which comprises the following steps: connecting the siphon down mouth of the water circle with water storing tar; connecting the upper mouth of the siphon pipe through connection pipes with the storing tar; connecting the recycle pressure loading pipe with one pass of the three-way valve through recycling pipe; connecting the other two passes of the valve with the high pressure water pump through the three-pass valve; connecting the third pass with water storing tar; connecting one pass of three-pass auxiliary boost with storing tar and the second one with water pump with high pressure and third one with the three-pass valve through connection pipe and valve.

Owner:杭州鸿德节能设备有限公司

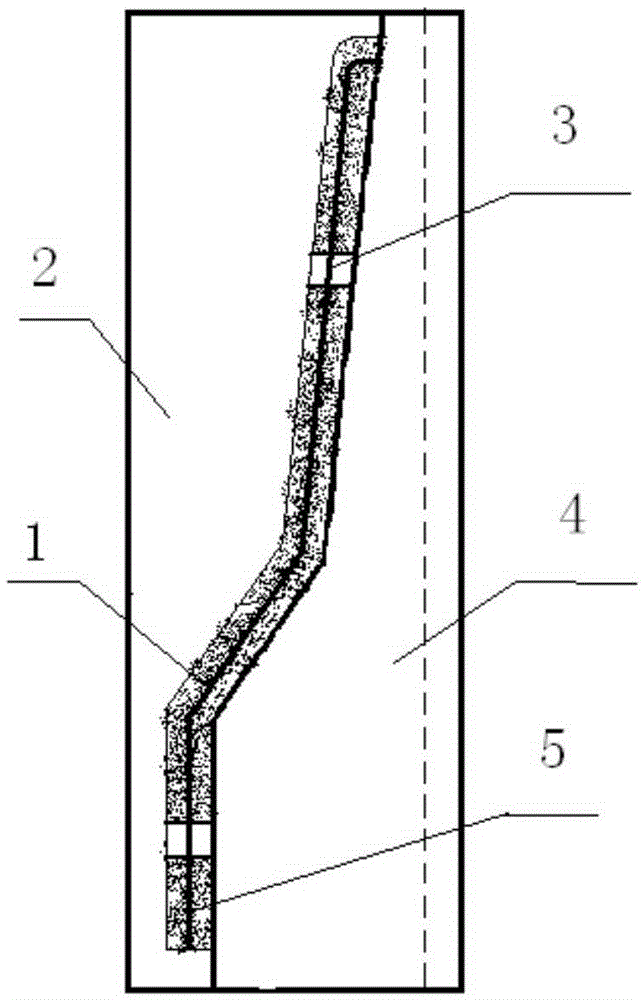

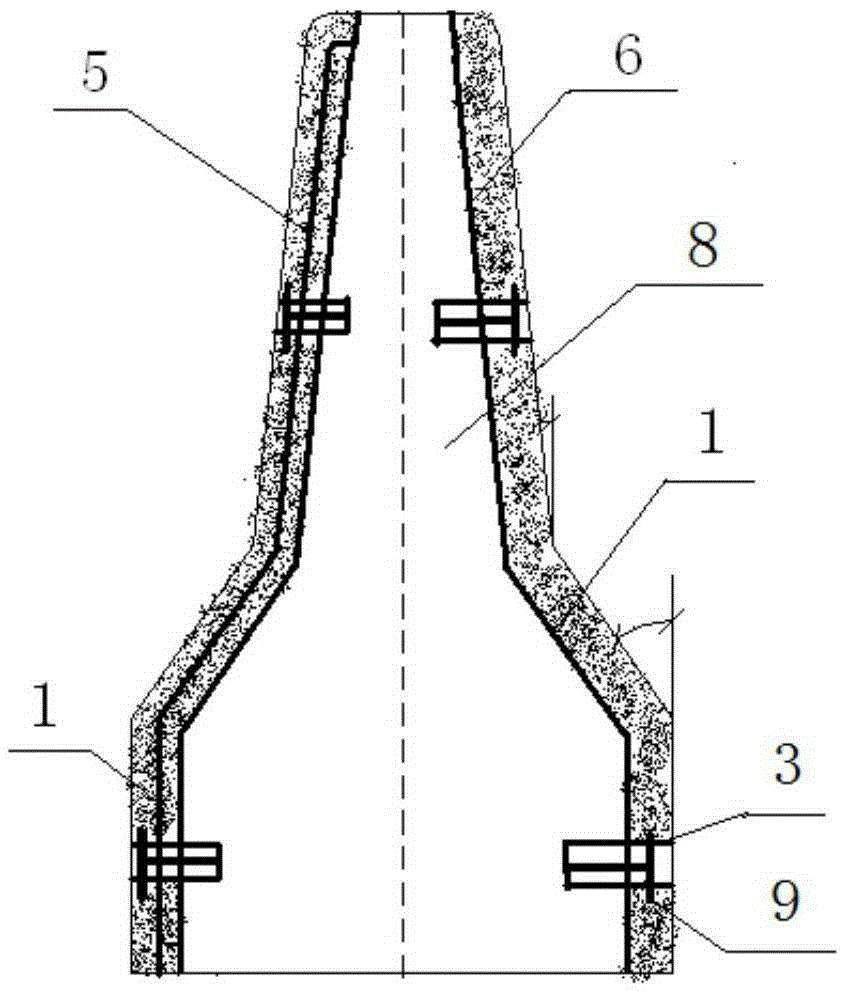

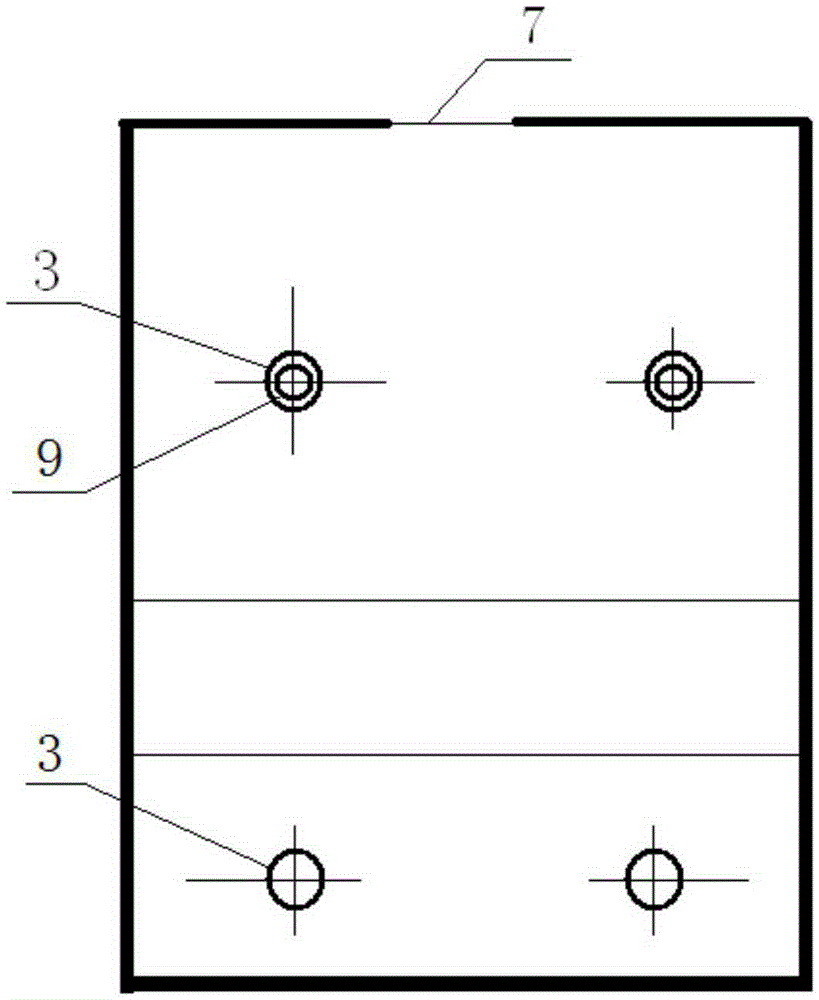

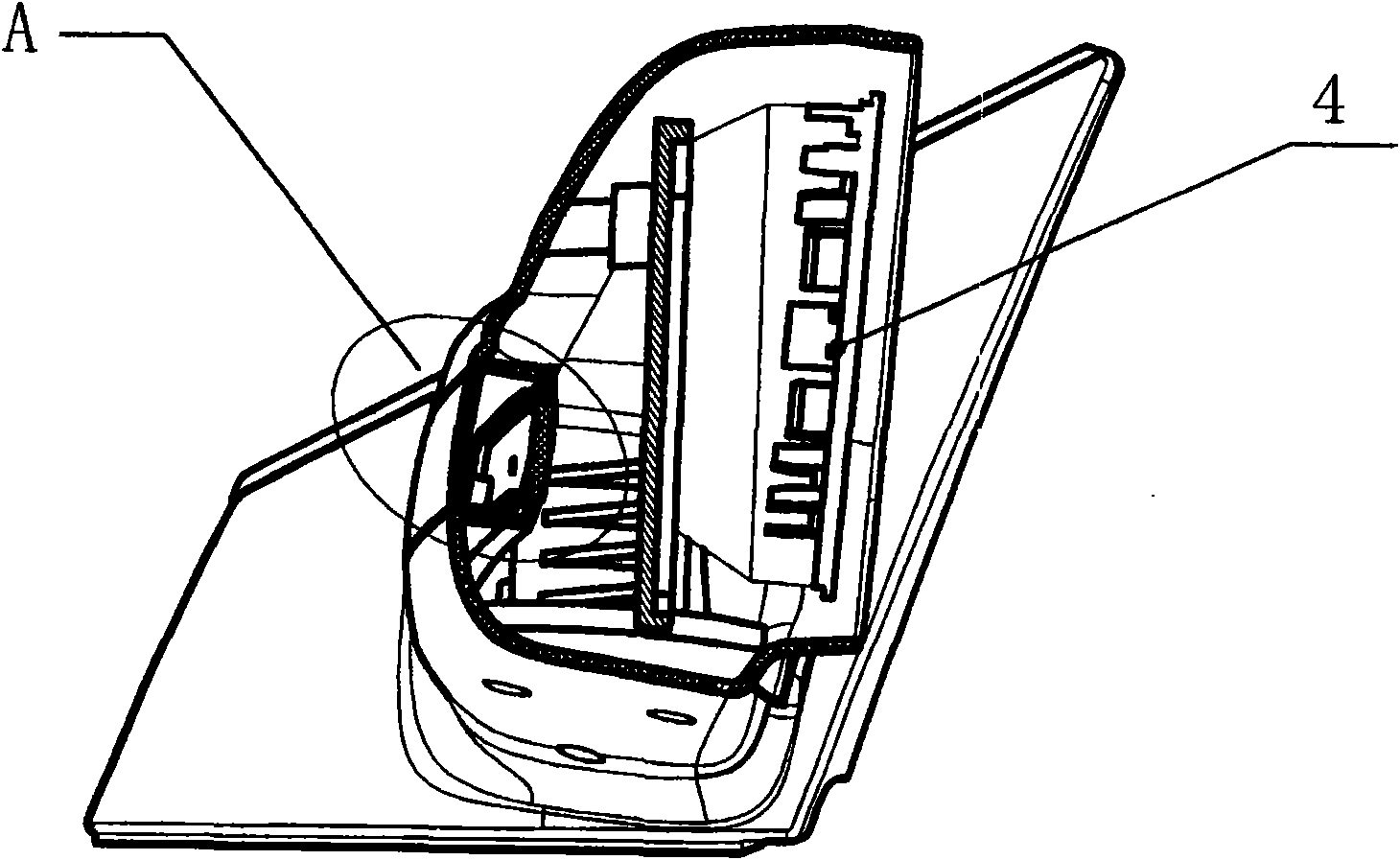

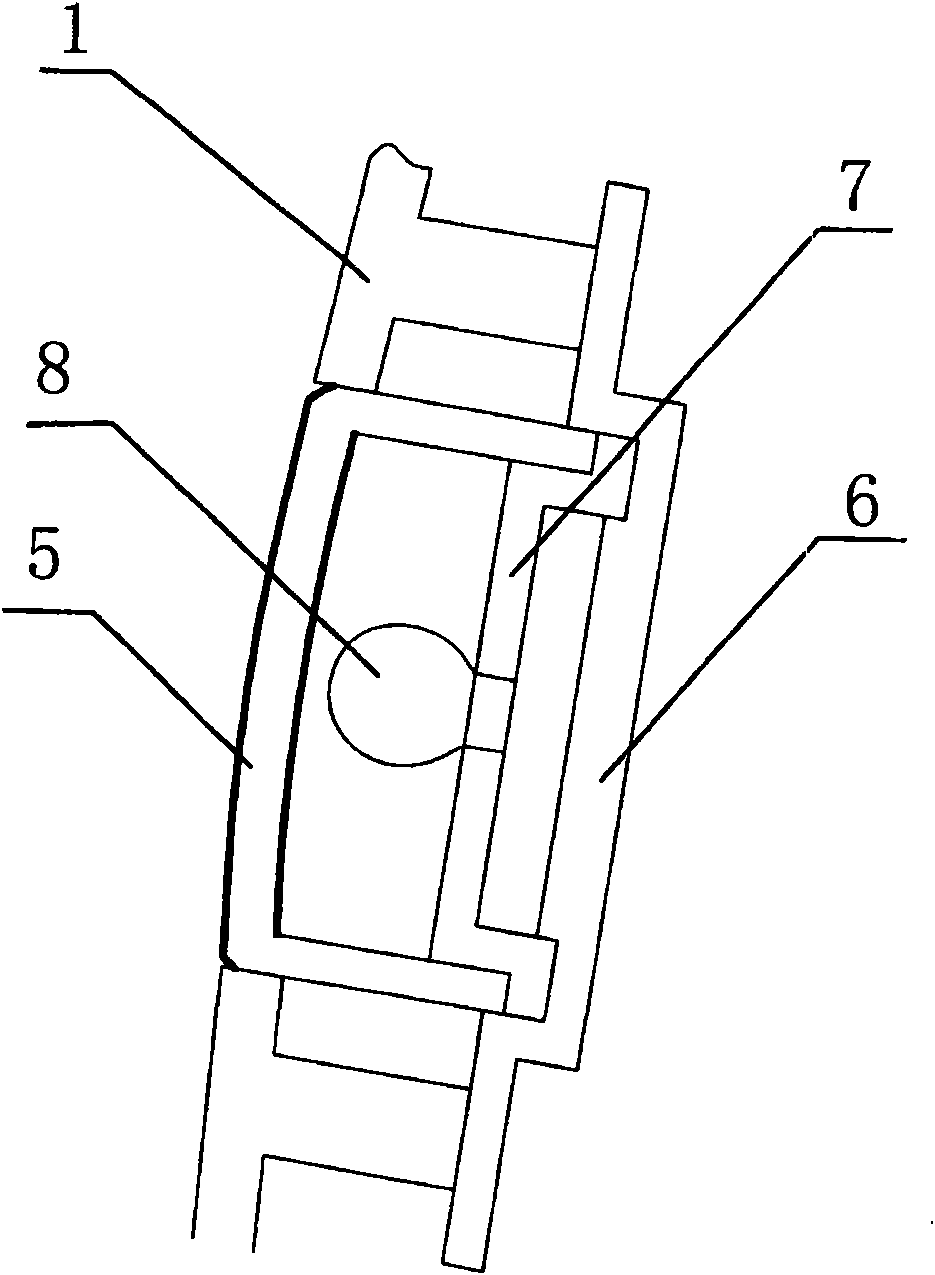

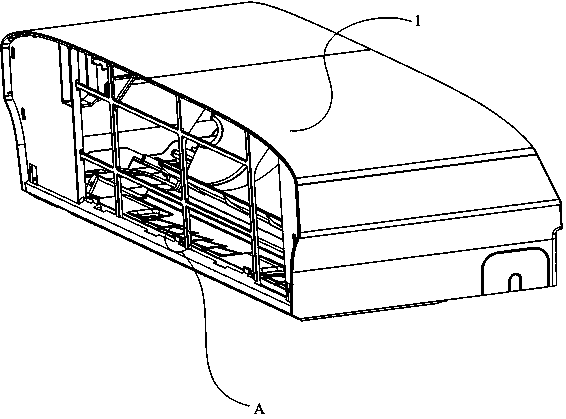

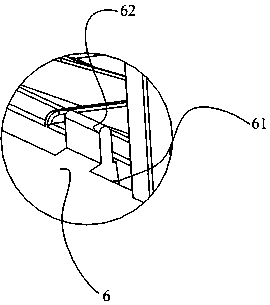

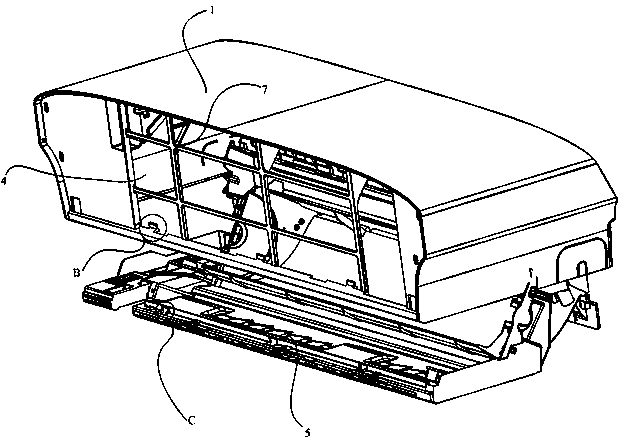

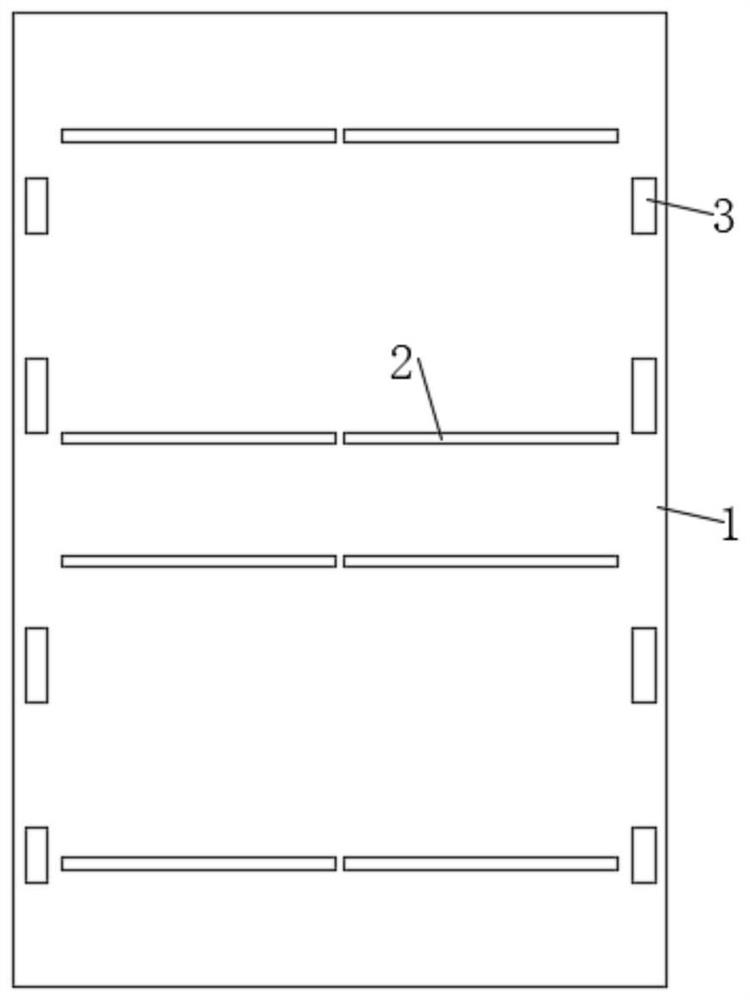

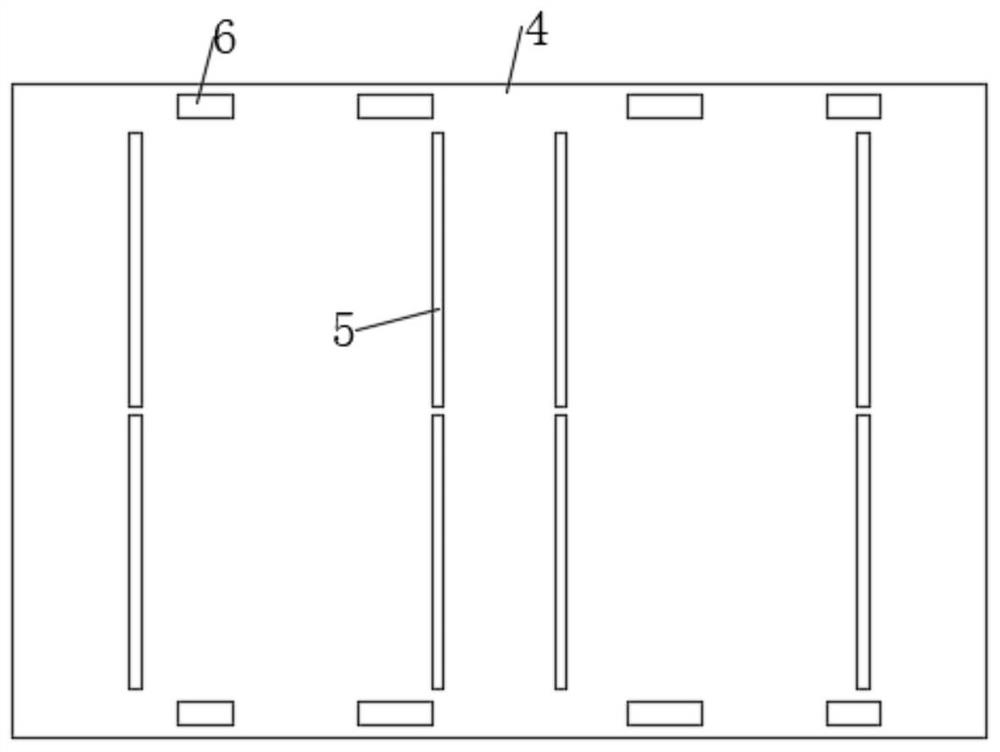

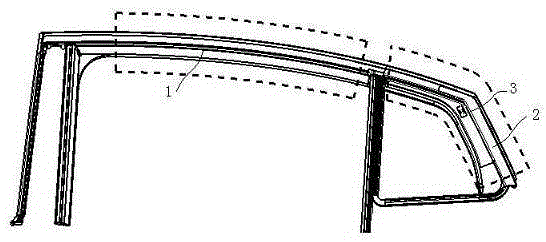

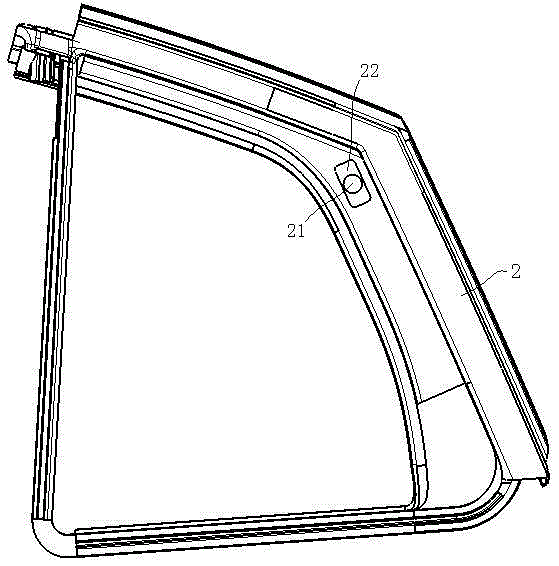

Glass guide rail structure for automobile rear door

ActiveCN105346364ASolve warpingSolve the gapEngine sealsVehicle sealing arrangementsMetal frameworkJoint injection

The invention relates to a glass guide rail structure for an automobile rear door. The guide rail structure is characterized by comprising a uniform section part (1), a variable section part (2) and a buckle (3); the uniform section part (1) is formed in an extrusion manner, and the variable section part (2) is formed in an injection manner; during injection molding, the uniform section part (1) is placed in a mold for joint injection molding, and therefore the uniform section part (1) and the variable section part (2) are combined; and the glass guide rail structure is fixed to an automobile door metal plate through the buckle (3). The uniform section part (1) is formed by dense rubber and a metal framework (13) in a composite extrusion manner. The variable section part (2) is formed by dense rubber and a metal insert (24) in a secondary injection molding manner.

Owner:CHERY AUTOMOBILE CO LTD

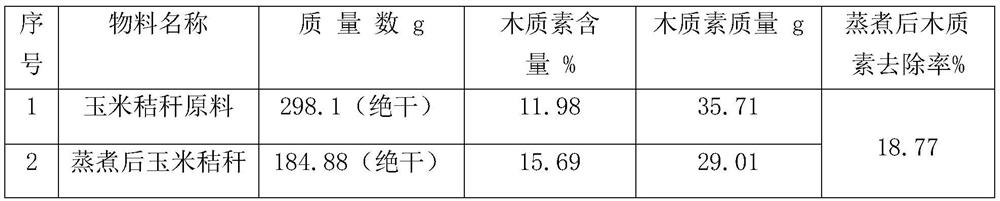

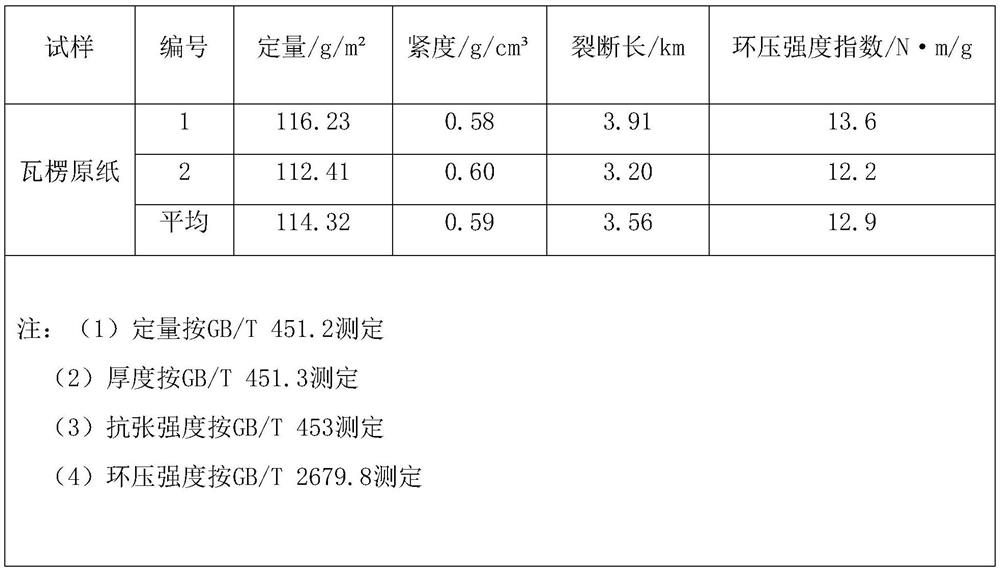

Process for producing papermaking pulp by taking corn straws as raw materials

InactiveCN111676726ASolve the problem of resource utilizationRealize resource utilizationPulp beating/refining methodsNon-woody plant/crop pulpSocial benefitsPapermaking

The invention discloses a process for producing papermaking pulp by taking corn stalks as raw materials. The process comprises the following steps: I, cooking treated corn stalks at a low temperature;II, washing the material subjected to low-temperature cooking; III, separating out residual washing liquid in the materials; IV, cooking the materials at a high temperature; V, mixing the material subjected to high-temperature cooking with low-temperature water to reduce the temperature of the material to 90-95 DEG C; VI, screening and washing, wherein the oversize part is coarse pulp for papermaking; and VII, changing the coarse pulp into fine pulp by a conventional pulping process, and further using the fine pulp for papermaking. The corn straws are used as a raw material to produce the papermaking pulp, the problem of resource utilization of corn straws is solved, the problem of large gaps of papermaking raw materials in China is solved, and considerable economic benefits and social benefits are generated.

Owner:吴学军 +4

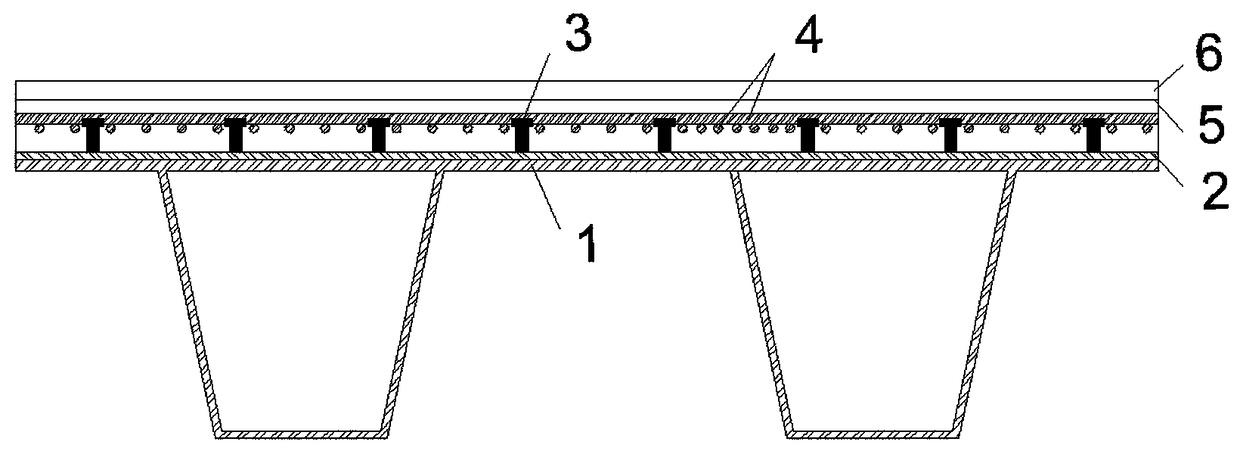

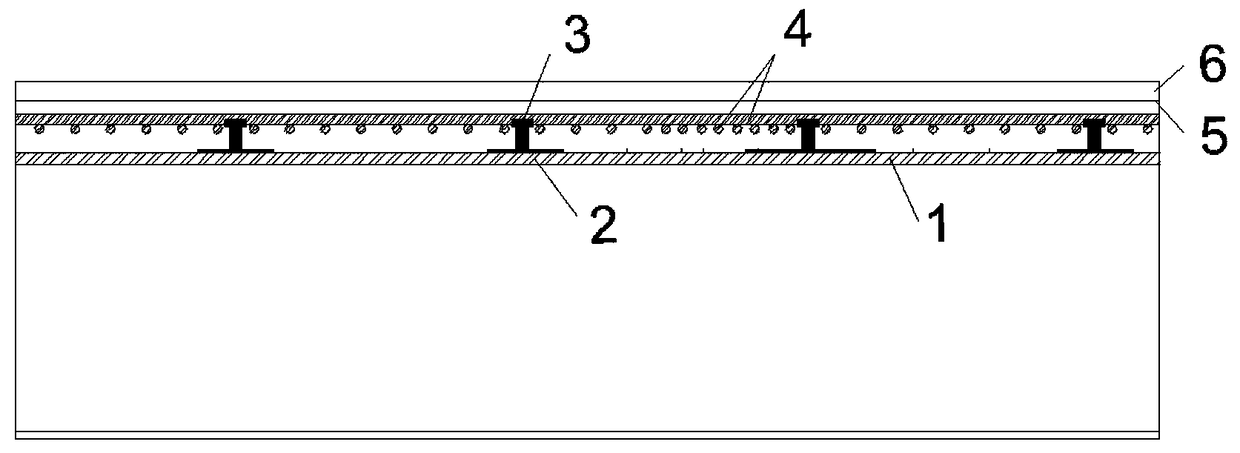

Combined reinforcement structure for solving cracked steel bridge deck by additionally arranging fiber-reinforced layer

InactiveCN109338903AMake up for the lack of fatigue crackingFit tightlyBridge structural detailsBridge erection/assemblyBridge deckFiber-reinforced composite

The invention relates to a combined reinforcement structure for solving a cracked steel bridge deck by additionally arranging a fiber-reinforced layer. The combined reinforcement structure for solvingthe cracked steel bridge deck by additionally arranging the fiber-reinforced layer is characterized in that the combined reinforcement structure for solving the cracked steel bridge deck by additionally arranging the fiber-reinforced layer comprises the fatigue cracked steel bridge deck, a fiber-reinforced composite material layer, shear connecting parts, steel fabrics and a concrete layer, wherein the shear connecting parts are arranged on the fiber-reinforced composite material layer, the fiber-reinforced composite material layer is laid to a cracked part of the fatigue cracked steel bridgedeck, the steel fabrics are placed on the fatigue cracked steel bridge deck, the concrete layer is arranged on the fatigue cracked steel bridge deck in a pouring mode, the shear connecting parts andthe steel fabrics are covered with the concrete layer, and the concrete layer is connected with the fatigue cracked steel bridge deck.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

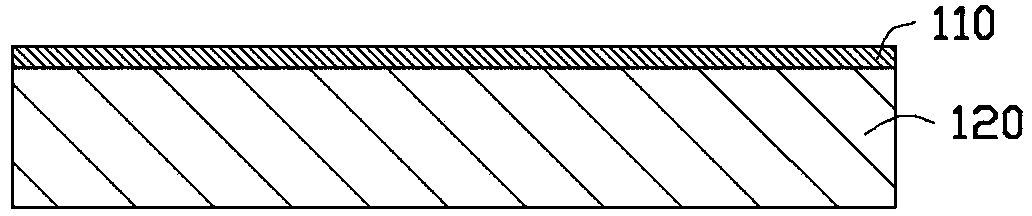

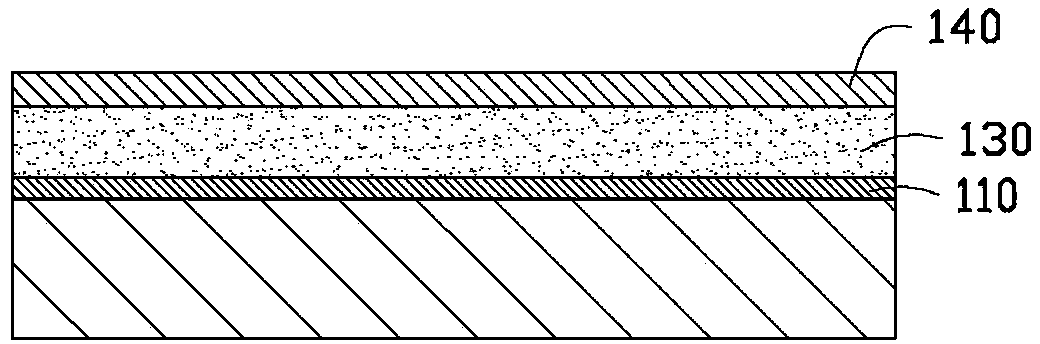

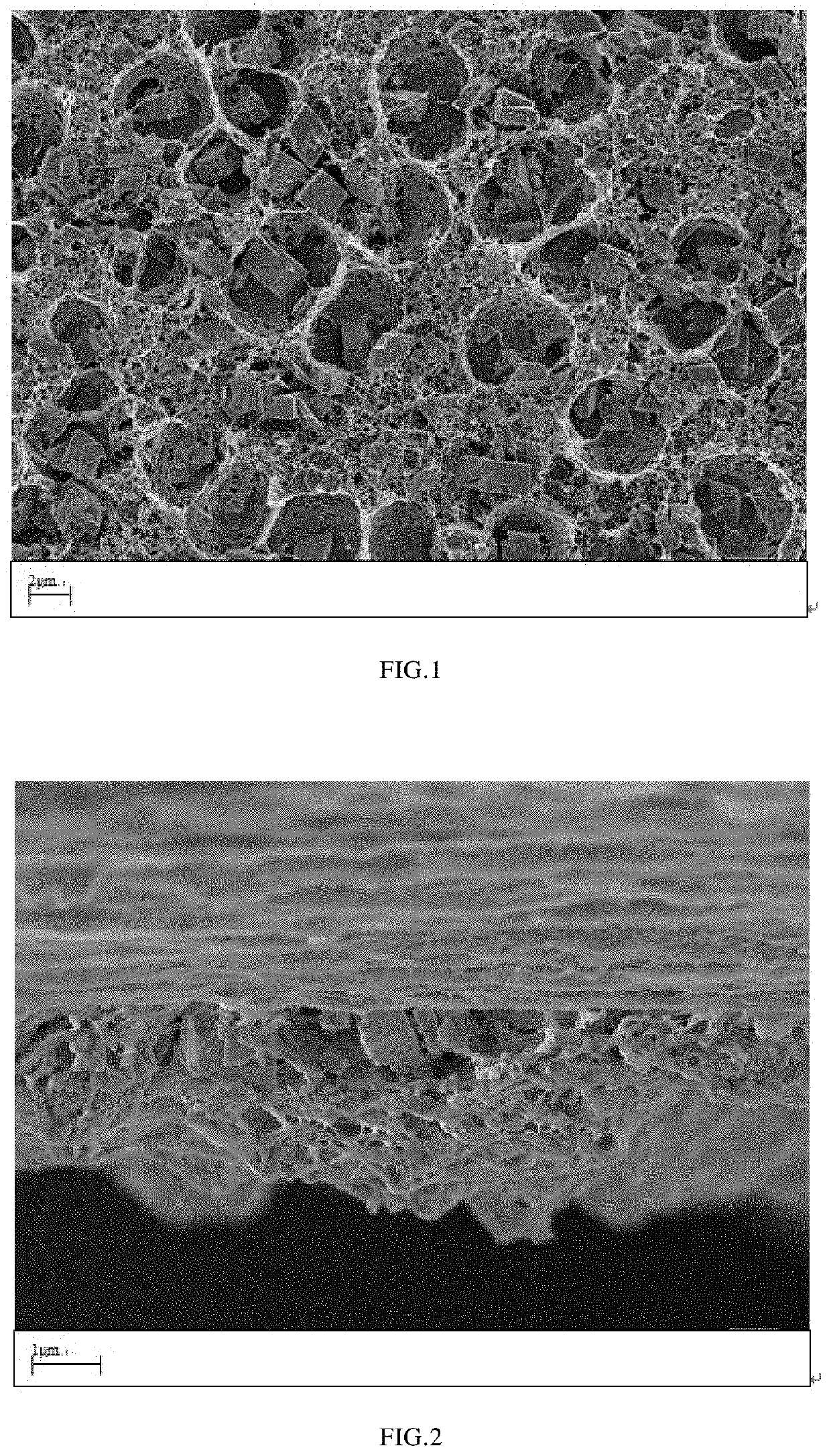

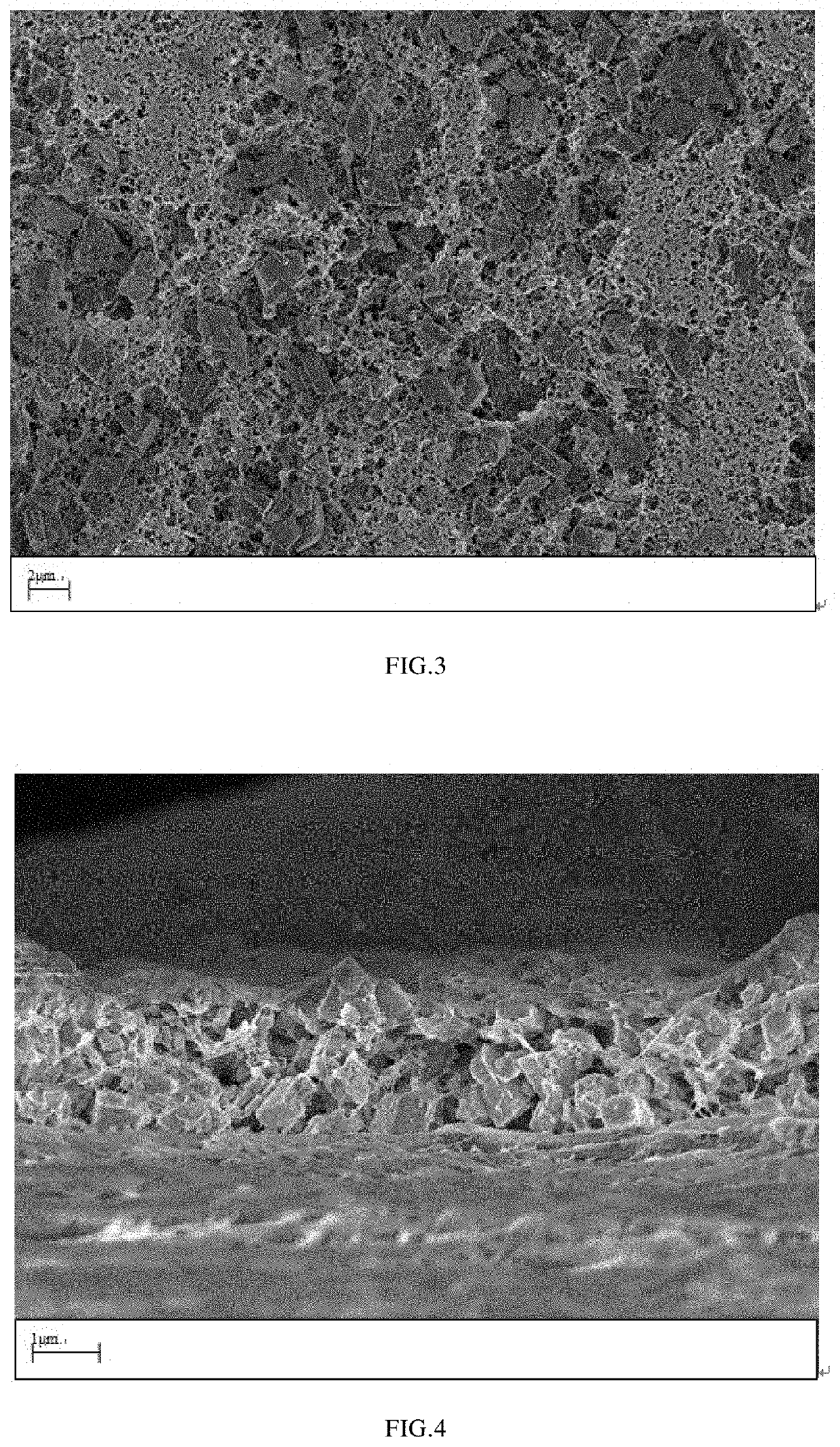

Separator and energy storage device

ActiveUS10964987B2Improve energy storage performanceSolve the gapCell seperators/membranes/diaphragms/spacersSecondary cellsPorous substrateInorganic particle

Owner:NINGDE AMPEREX TECH

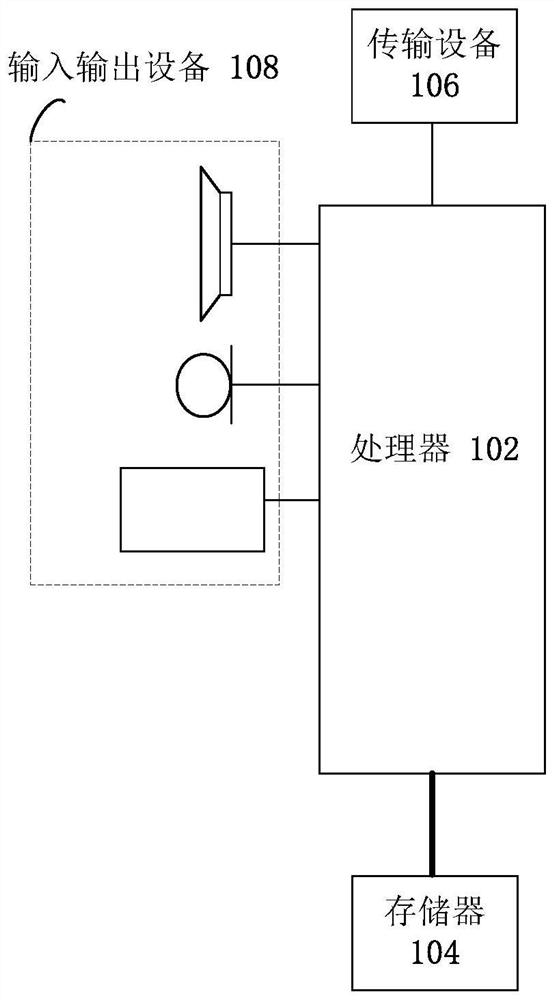

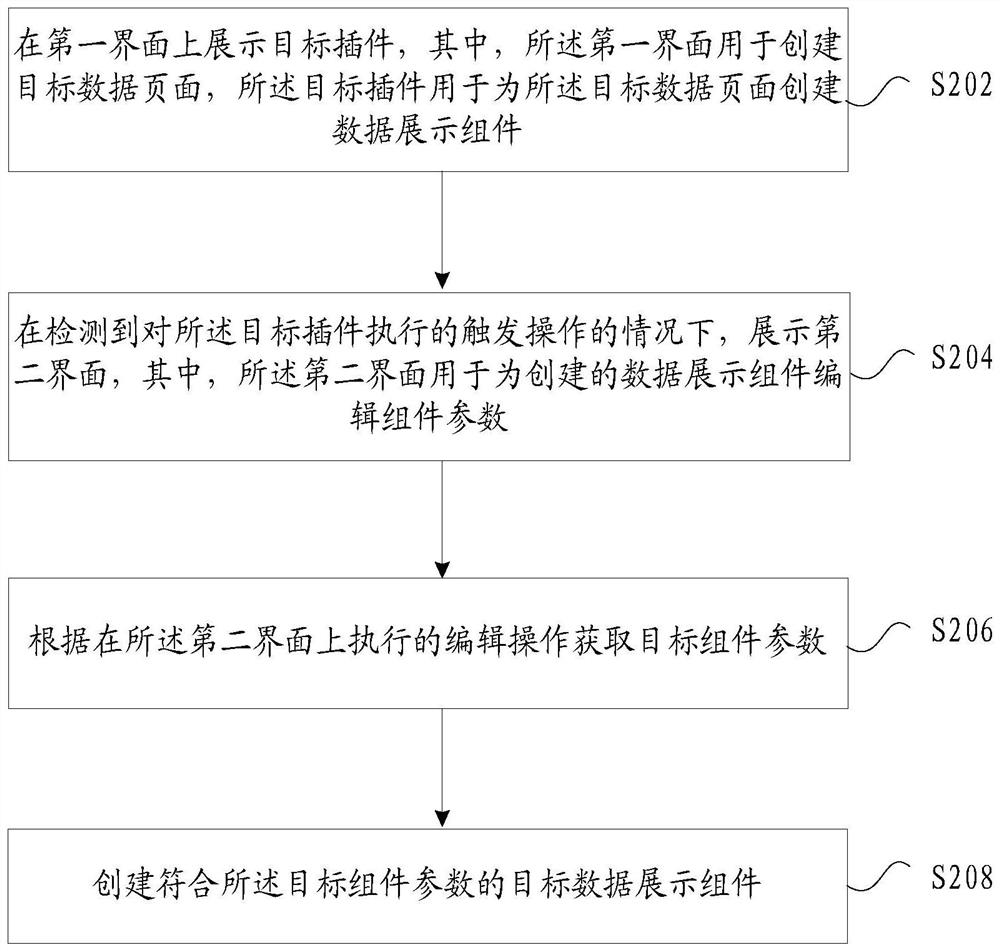

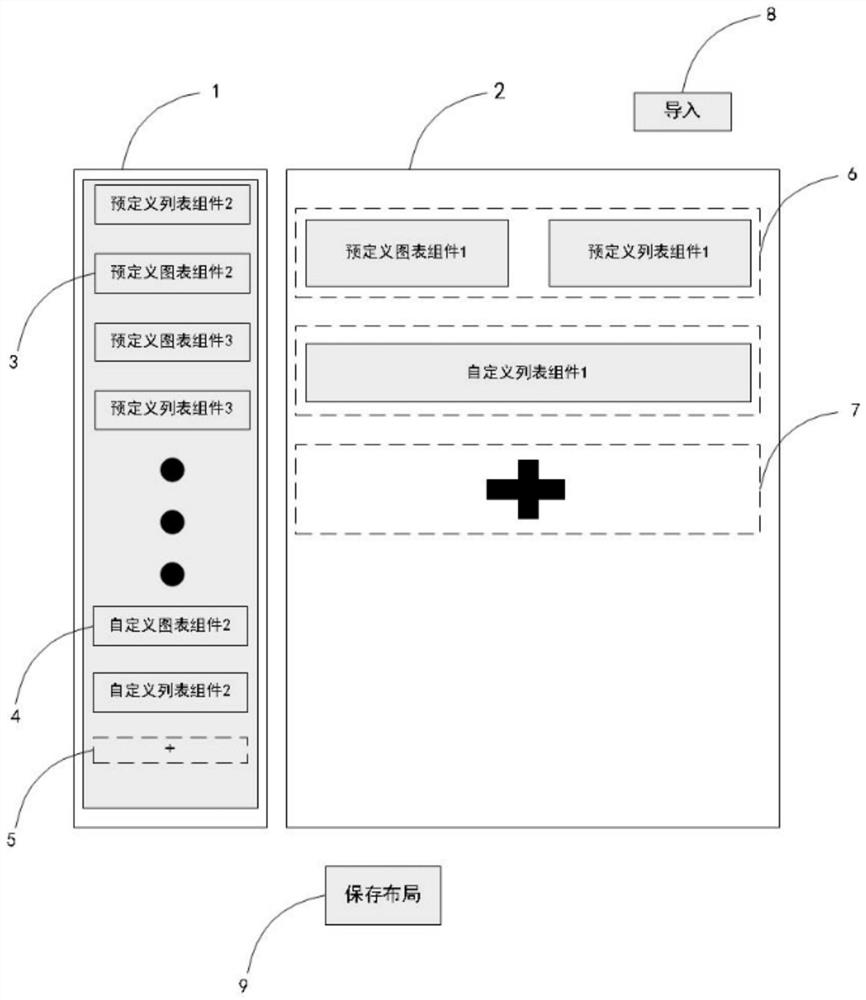

Data display component creation method and device, storage medium and electronic device

PendingCN114003329AReduce gapSmall demand gapExecution for user interfacesComputer hardwareData display

The embodiment of the invention provides a data display component creation method and device, a storage medium and an electronic device. The method comprises the steps of: displaying a target plug-in on a first interface, wherein the first interface is used for creating a target data page, and the target plug-in is used for creating a data display component for the target data page; under the condition that a trigger operation executed on the target plug-in is detected, displaying a second interface, wherein the second interface is used for editing component parameters for the created data display component; acquiring a target component parameter according to an editing operation executed on the second interface; and creating a target data display component conforming to the target component parameter. By means of the method and device, the problem that the difference between the content displayed on the data page and the content required by the user is large is solved, and then the effect of reducing the difference between the content displayed on the data page and the content required by the user is achieved.

Owner:SUNWAVE COMM

Airtight and waterproof type polypropylene film

The invention provides an airtight and waterproof type polypropylene film. The polypropylene film is prepared from components in percentage by weight as follows: 25%-80% of polypropylene, 5%-40% of natural fiber, 10%-50% of calcium carbonate and 2%-6% of an adhesive, wherein the polypropylene can form a good and stable system and become a support component of the film in combination with the natural fiber, the calcium carbonate component is a good decomposition time regulating component, the degradation time is short in large addition amount and long in small addition amount, thus, the use amount of calcium carbonate can be regulated according to different use environments, and the adhesive can provide better toughness and increase the tear-resistant degree of the film.

Owner:广东乐将生物科技有限公司

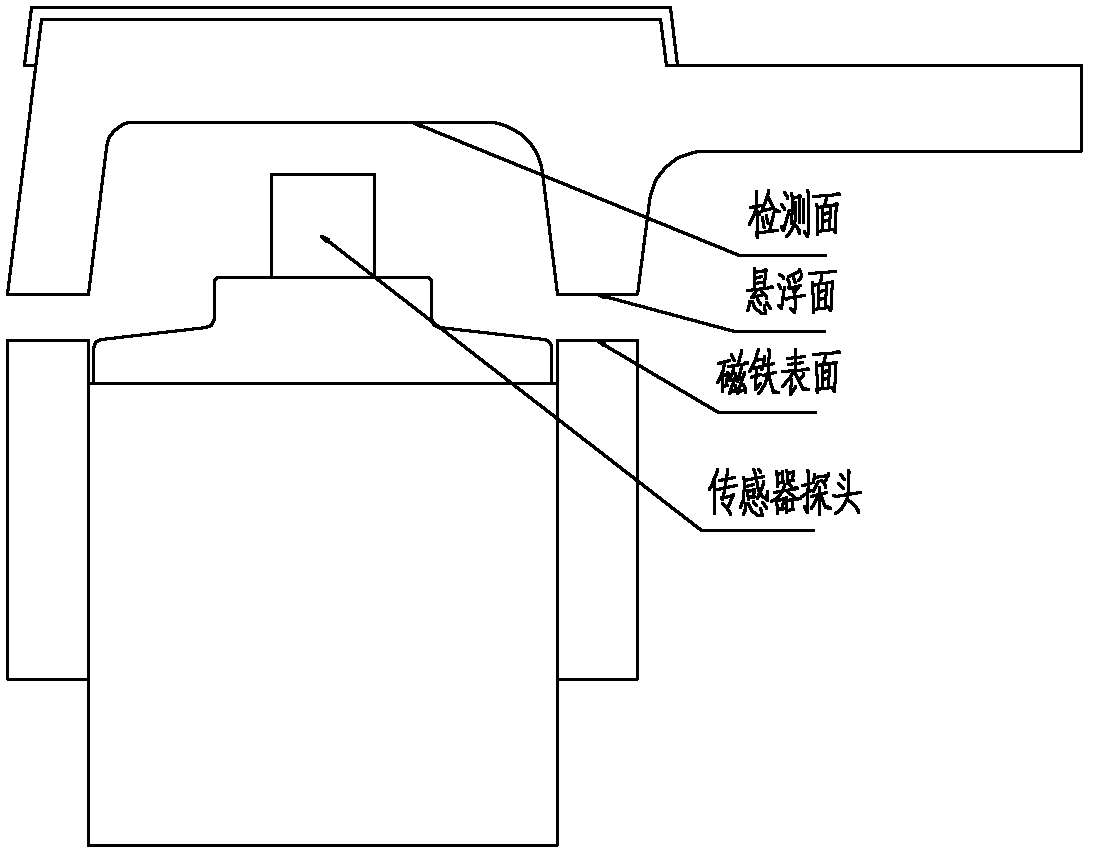

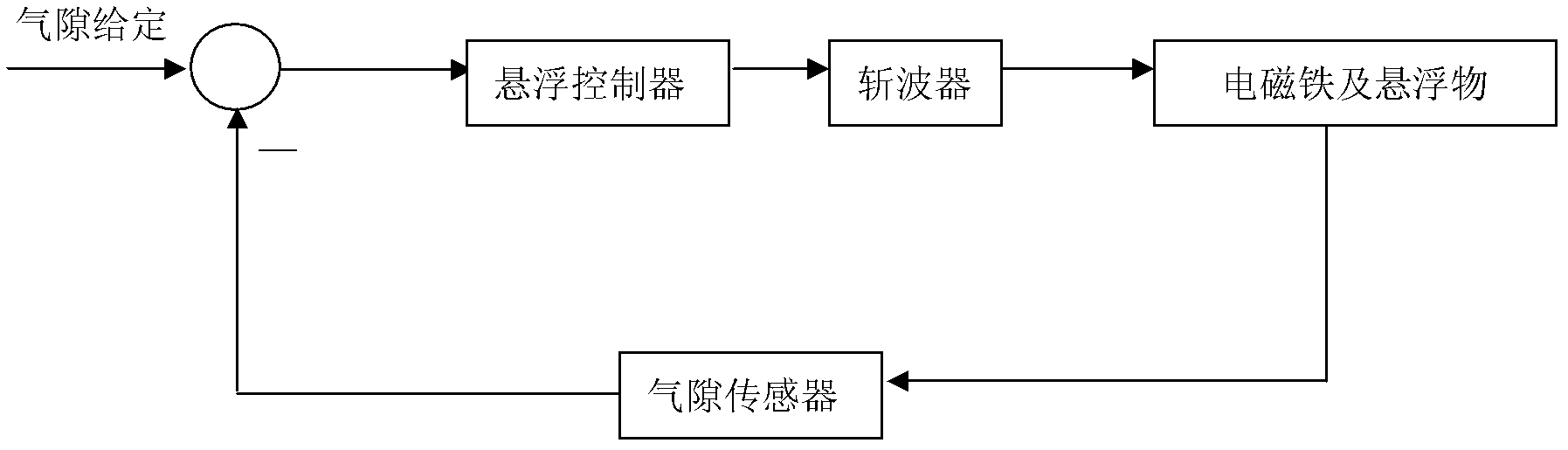

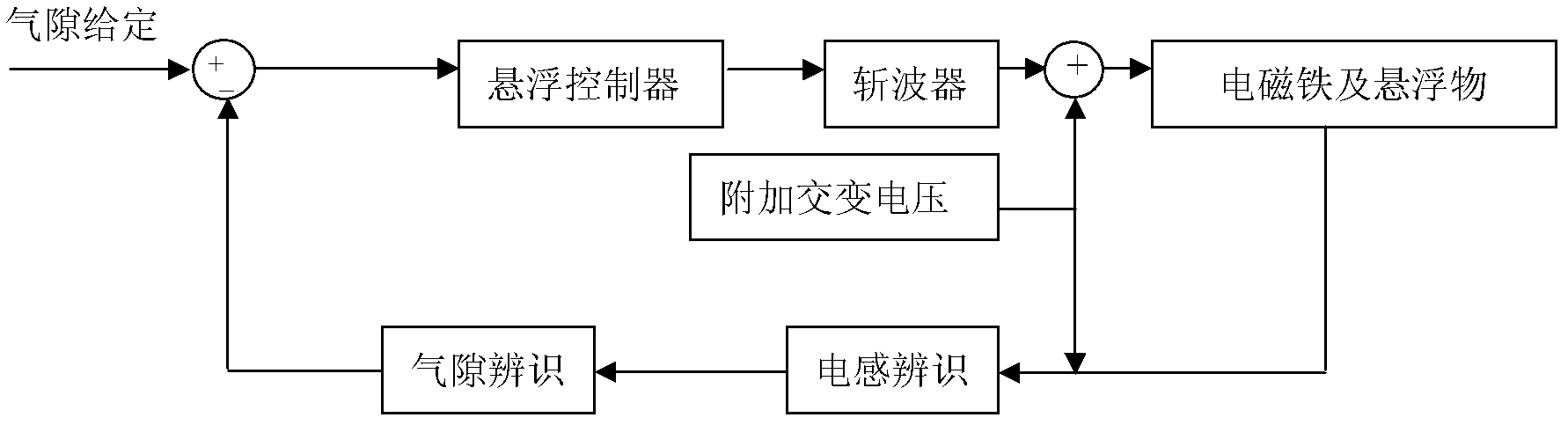

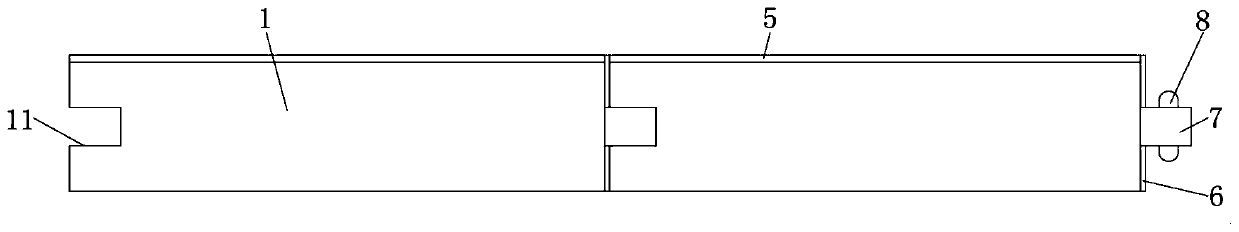

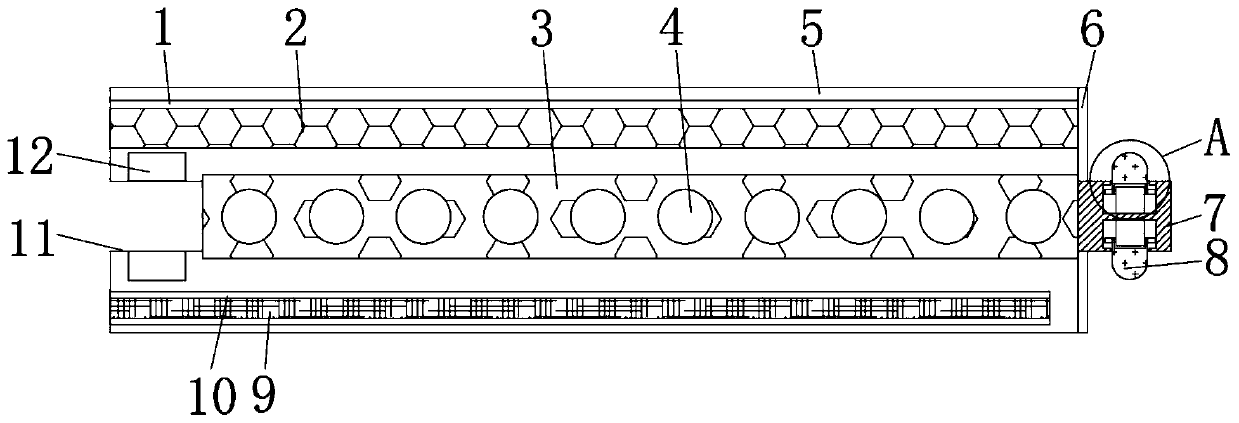

Method for controlling electromagnetic attractive force suspension without adopting gas gap sensor on basis of additional alternating voltage

InactiveCN102255581AReduced track requirementsSolve the gapMagnetic holding devicesInstabilityInductance

The invention discloses a method for controlling the electromagnetic attractive force suspension without adopting a gas gap sensor on the basis of an additional alternating voltage. The alternating voltage with certain features is doped in a closed-loop control voltage of a suspension electromagnet coil; the obtained voltage is applied to the suspension electromagnet coil; a current of a component with the same features is obtained in the coil; according to the input and doped feature alternating voltage and the current component with the same features in the current of the coil, the inductance of the suspension electromagnet coil is identified; a suspension electromagnet gas gap is obtained by the inductance; and the gas gap value is used for carrying out closed-loop control. Due to no adoption of the gas gap sensor, a system can be greatly simplified and the real suspension gas gap can be reflected by the inductance obtained by the additional coil. Due to the adoption of the method,the requirement on the rail accuracy of a maglev vehicle system can be lowered, the control instability of the system cannot be caused by inaccurate measurement of the gas gap sensor, and the problems of rail gap passing, cogging and the like of a maglev vehicle can be well solved. The method for controlling the electromagnetic attractive force suspension without adopting the gas gap sensor on the basis of the additional alternating voltage has the advantages of high reliability, low cost, safety and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Splicing structure for environment-friendly wood floor

InactiveCN110821095ASolve the gapSolve the problem of easy moistureFlooring insulationsMechanical engineeringWood plank

The invention discloses a splicing structure for an environment-friendly wood floor and relates to the technical field of indoor decoration. The splicing structure comprises a wood board body, a softwood core layer and a reinforcing layer are fixedly connected to the interior of the wood board body, the soft wood core layer is located on the reinforcing layer, reinforcing ribs are fixedly connected to the interior of the reinforcing layer, a waterproof layer is fixedly connected to the top of the wood board body, a groove is formed in the middle of one side of the wood board body, fixing grooves are formed in the two sides of the groove, and a damp-proof cavity is formed in the inner bottom wall of the wood board body. According to the splicing structure, through the cooperative arrangement of a sealing pad, a damp-proof pad and the damp-proof cavity, gaps can be reduced to avoid dampness, the problem that after wood boards are spliced, the gaps are large and damping is likely to occur are solved, and the service life of the wood floor is prolonged; through the cooperative arrangement of the soft wood core layer, the reinforcing layer and the reinforcing ribs, the toughness of thewood floor can be increased, and the problem that wood floors are likely to warp up and deform is solved.

Owner:JIANGSU FUHUA NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com