Secondary grouting method applied to space between bottom plate and foundation in installation work of mechanical equipment

A technology for installation engineering and secondary grouting, applied in infrastructure engineering, construction, etc., can solve problems such as inability to work, equipment in poor working condition, and high plasticity of concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

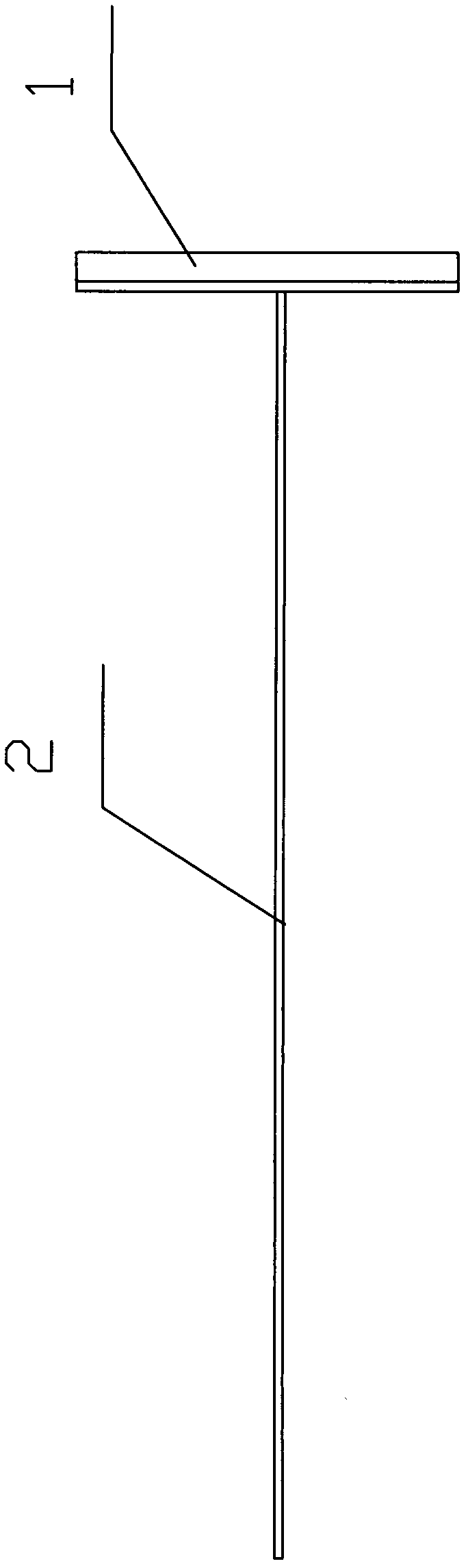

[0018] The booster used consists of a shovel and a push rod fixed at one end on the shovel; the shovel is an angle steel with a side length of 45×45 mm and a length of 500 mm; the push rod is a steel bar with a length of 5 meters and a diameter of 20 mm; One end of the push rod is fixed in the middle of either side of the shovel, and the angle steel opening is forward.

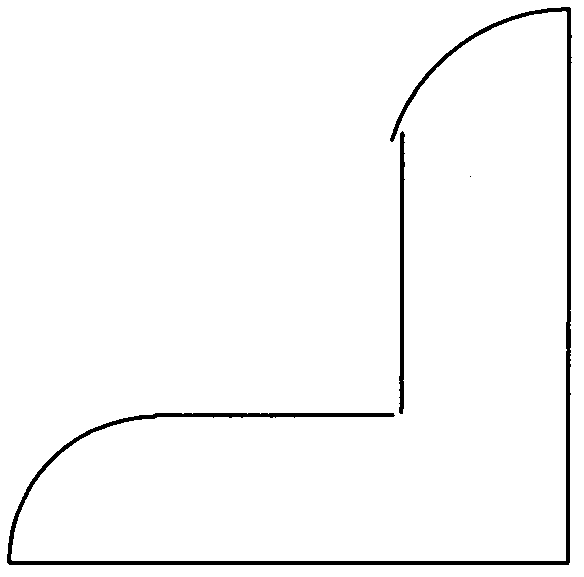

[0019] The bottom plate of a new hot blast stove in a certain ironworks has a diameter of 9 meters, and the bottom plate is shaped like a pot bottom. There are more than 6,000 tons of checker bricks and other refractory bricks in the hot blast stove. These checker bricks are not built with cement, but placed in the hot blast stove. . The design uses C30 fine stone concrete grouting material for secondary grouting. The normal high temperature of the hot air in the hot blast stove is 1250-1500°C, and the incoming cold air is 250°C. If there are gaps in the secondary grouting, the checker bricks placed in the h...

Embodiment 2

[0022] A 300,000-watt large-scale motor in a project caused excessive vibration during the test run of the equipment due to insufficient grouting. After the diagnosis was that the grouting was not dense, the equipment had to be hoisted again, the undense grouting layer was removed, and the dry hard concrete grouting material was used for re-grouting. The special booster pushed the dry hard concrete into place, and after 14 days of maintenance, the test run was successful again. After being put into production, the equipment has been operating normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com