Aluminum-plated twisting packing machine

A packaging machine and aluminum plating technology, which is applied in the direction of conveyor belt wrapping, etc., can solve the problems of large gap, asynchronous, and deviation of packaging materials in the candy channel, and achieve the effects of low production cost, simple structure and reasonable setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described.

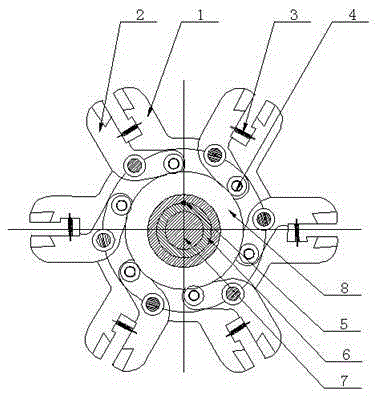

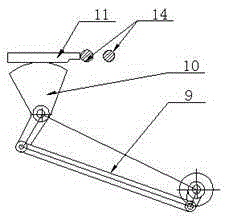

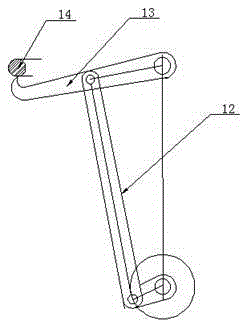

[0020] see as figure 1 —— image 3 As shown, this specific embodiment adopts the following technical solutions: it includes a candy delivery mechanism, a process tray, a kink mechanism, a sugar pushing mechanism, an origami mechanism, and a finished product output mechanism; the candy delivery mechanism is provided with a procedure tray; The mechanism includes a sugar pushing mechanism and an origami mechanism, the sugar pushing mechanism is connected to the origami mechanism; the candy conveying mechanism is connected to the kink mechanism; the kink mechanism is connected to the finished product output mechanism; the process plate includes fixed pincers 1, Movable pliers 2, spring 3, roller 4, key 5, copper sleeve 6, turntable shaft 7, cam 8; said turntable shaft 7 is evenly distributed with six fixed pliers 1 on the circumference, each fixed pliers 1 It is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com