Radial tire of fiber cord fabric tire shoulders

A radial tire and fiber wire technology, used in heavy-duty tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of thin lines, uneven extrusion, exposed steel wires in the tire, etc., to improve safety and use. Longevity and the effect of avoiding flat tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be described below in conjunction with specific embodiments.

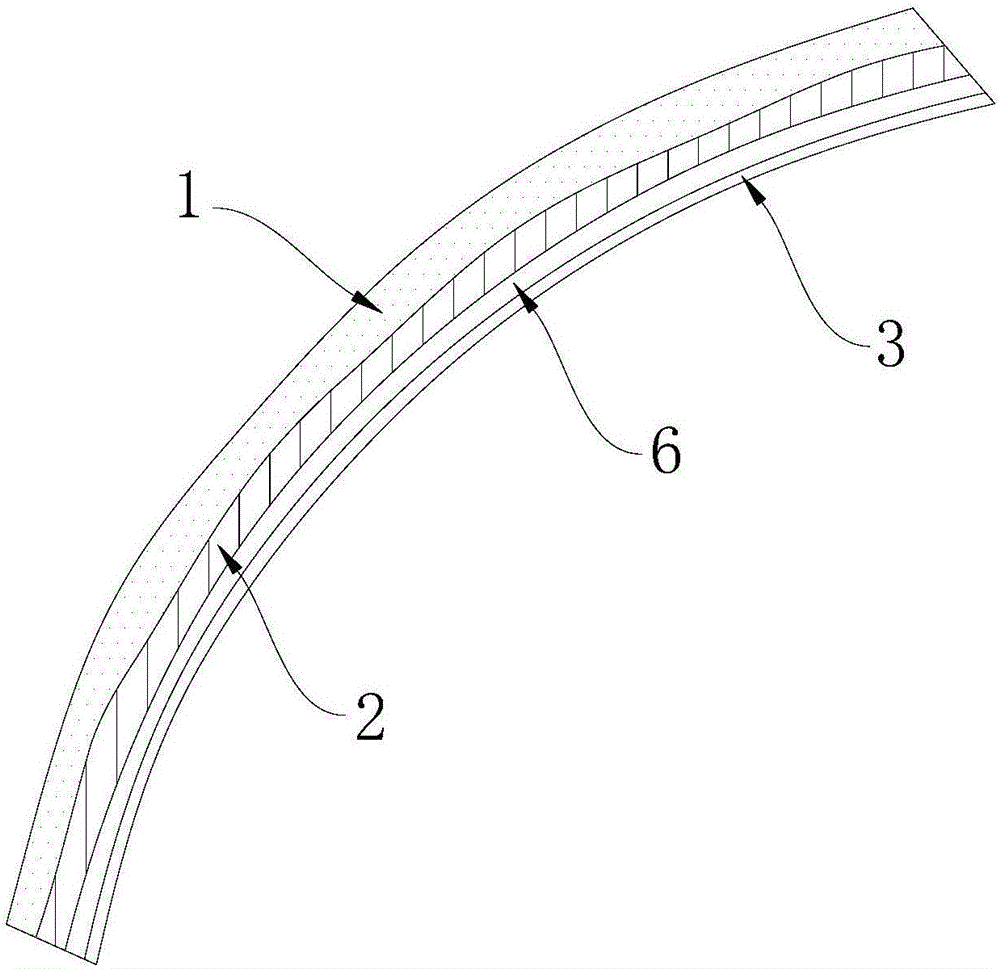

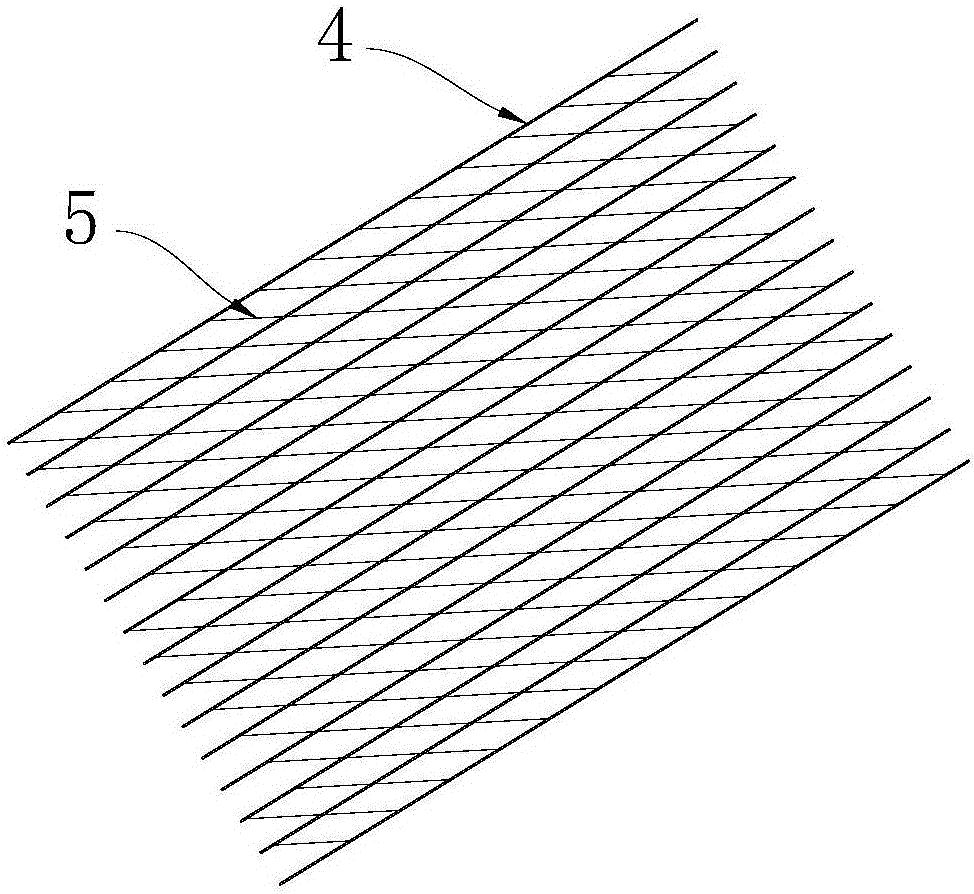

[0018] Such as Figure 1-Figure 5 As shown, the radial tire of a fiber cord shoulder includes a steel cord 1, a fiber cord 2 and an airtight layer 3, and the steel cord 1, fiber cord 2 and airtight layer 3 are located at the tire inner wall shoulder, and Distributed sequentially from outside to inside, the steel cord 1 is provided with a steel wire 4, and the fiber cord 2 is provided with a fiber wire 5, and the angle between the fiber wire 5 and the steel wire 4 is 5-45 degrees.

[0019] The aforementioned radial tire with fiber cord tires reduces the uneven distribution of materials during tire vulcanization through the network structure formed by the different angles between the fiber lines 5 of the fiber cord 2 and the steel wires 4 of the steel cord 1 Or insufficient material, to avoid bending deformation, displacement of carcass steel wire and inward migration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com