Patents

Literature

57results about How to "Solve bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

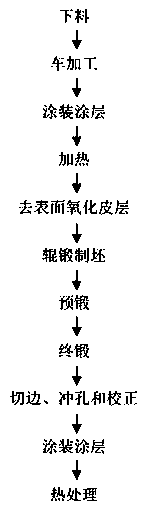

Large-scale locomotive connecting rod forging technology

ActiveCN104057263AReduce depthGuarantee the quality of raw materialsShaping toolsRailway componentsPunchingSurface oxidation

The invention discloses a large-scale locomotive connecting rod forging technology which comprises the steps of blanking, lathing, anti-decarburization coating application, blank heating, surface oxidation layer removal, roll forging of blanks, pre-forging, finish forging, trimming, punching and calibration, anti-decarburization coating application and heat treatment. According to the large-scale locomotive connecting rod forging technology, forming can be achieved through one time of heating only. Compared with the traditional technology that heating needs to be conducted twice or more, the technology has the advantages that surface oxidation and decarburization of a connecting rod are effectively reduced, the mechanical performance of the connecting rod is guaranteed, and time and energy resources are saved. Due to the adoption of roll forging of blanks, speed is high, labor is saved, the consistency of manufactured blanks is high, and time and labor are saved during forging in later periods. Due to the fact that high-temperature-resistant and oxidation-resistant anti-decarburization coating application is conducted twice during the whole technology, the decarburized layer on the surface of a final forged piece is thinner than 0.3 mm, and product quality is improved effectively. Due to the fact that the connecting rod forged piece is vertically hoisted for heat treatment, bending deformation of the forged piece is effectively prevented during heat treatment.

Owner:SICHUAN HAOTE JINGGONG EQUIP CO LTD

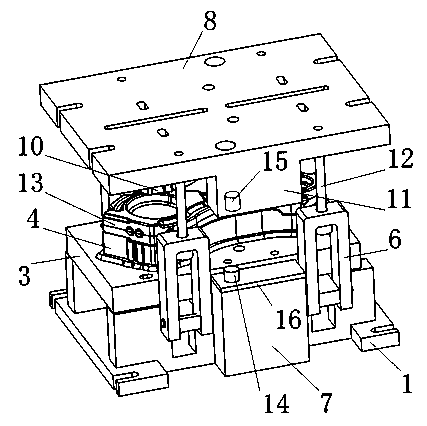

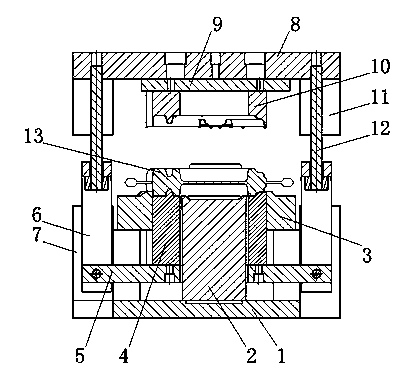

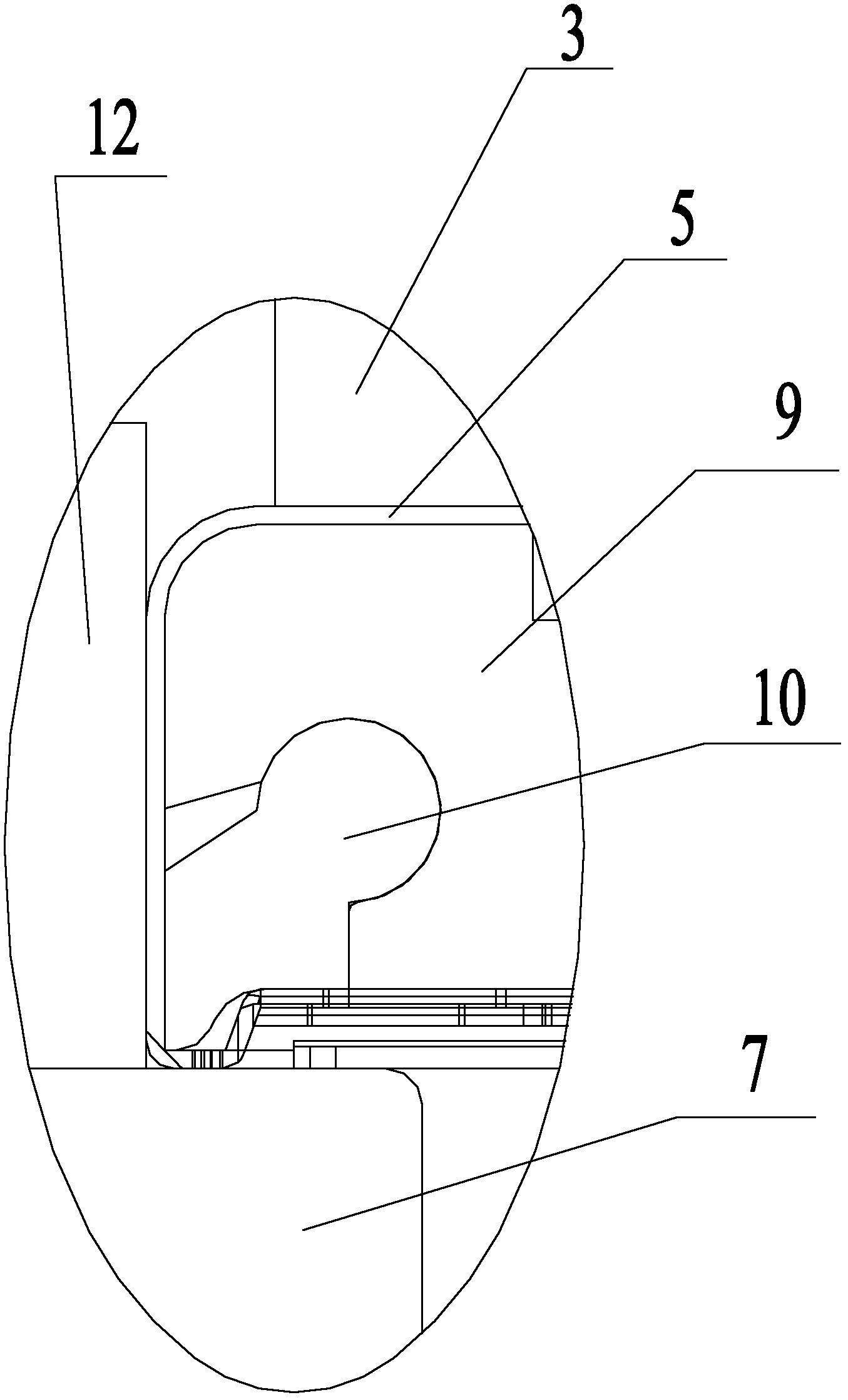

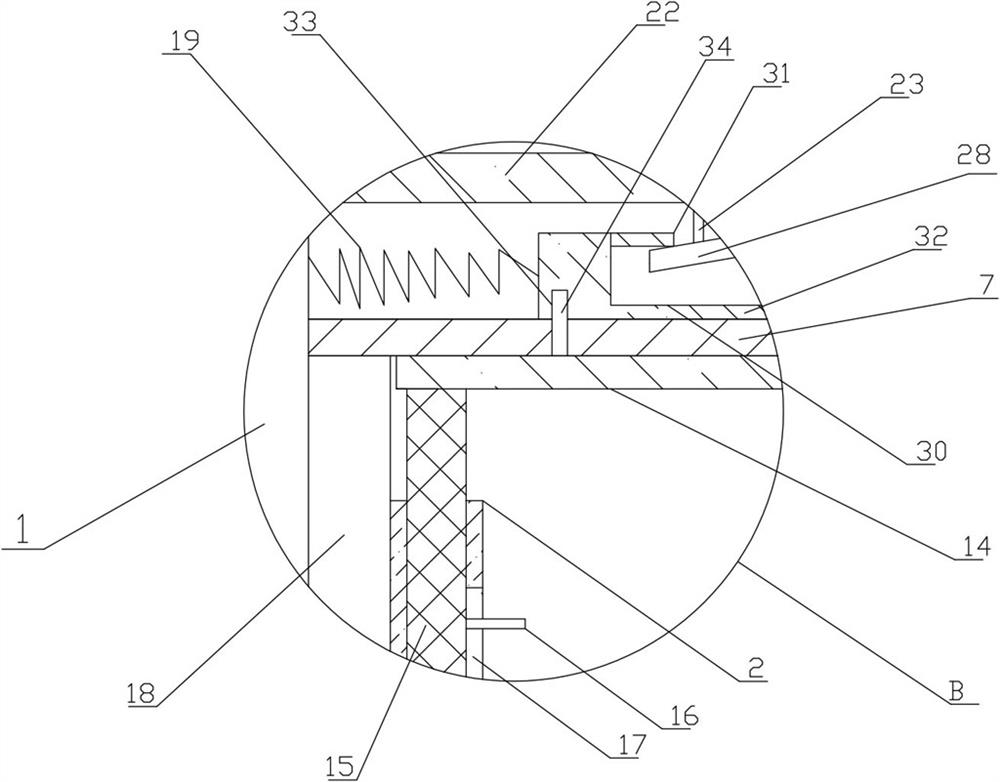

Mold with swing type stripping structure

ActiveCN102581141ASimple structureEasy to operateShaping toolsStructural engineeringClassical mechanics

The invention discloses a mold with a swing type stripping structure. A bending mold matches with a bending slider to form a covered edge of a workpiece to be processed, notches are disposed at the end, which is attached to the workpiece to be processed, of the bending mold, and a swing part capable of forming a convex closure in the covered edge is rotationally connected into the notch, and is properly arranged in the notch so that the swing part can vertically swing. The swing part is provided with a first limiting surface and a second limiting surface which respectively limit two lateral edges of the swing part when the swing part swings, the covered edge is bent when the swing part swings so that an end surface of the swing part is abutted onto the first limiting surface, the bending mold moves inwards to withdraw materials after the covered edge is bent, at the moment, the swing part swings outwards in the notch to be separated from the first limit surface, and accordingly, the materials can be prevented from being jammed in the convex closure and cannot be withdrawn. The mold is simple in structure and convenient in operation, the problems of incapability of withdrawing materials and bending deformation during stretching of a shell part with a convex closure and a covered edge in an existing mold are resolved, and the production quality of a product is guaranteed.

Owner:重庆中舜微电子有限公司

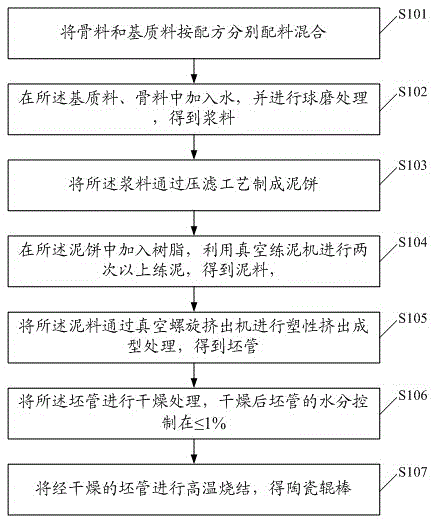

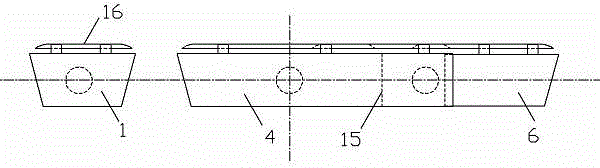

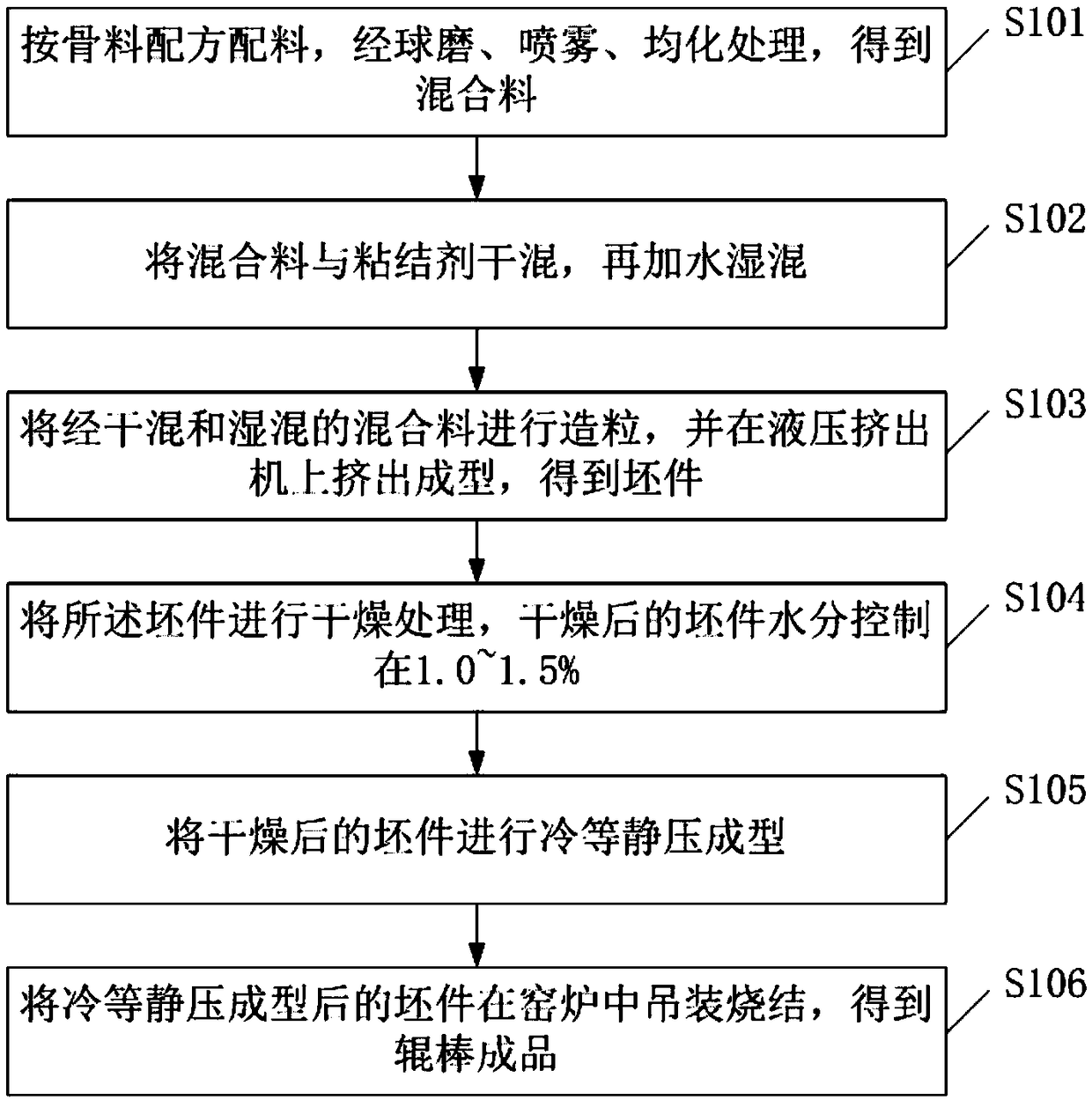

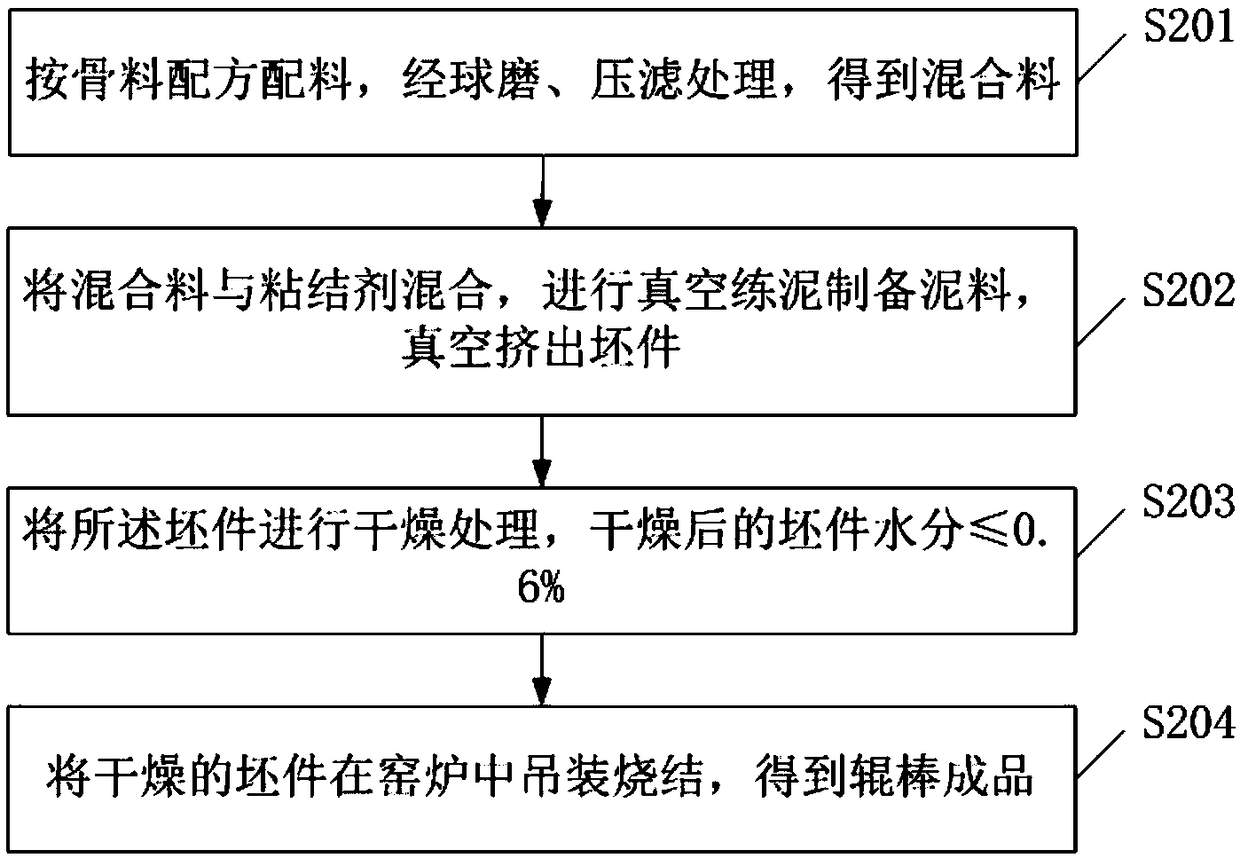

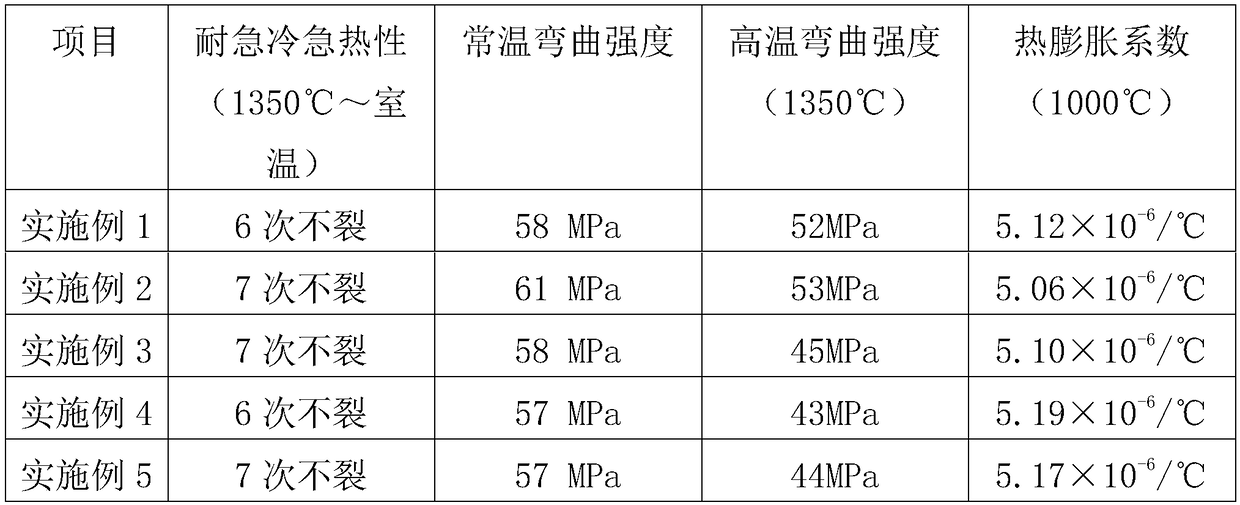

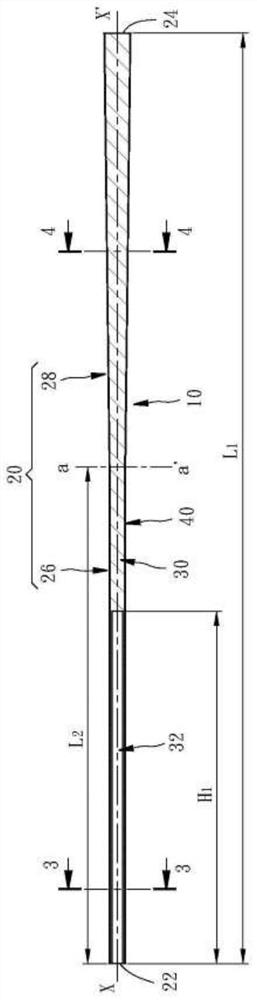

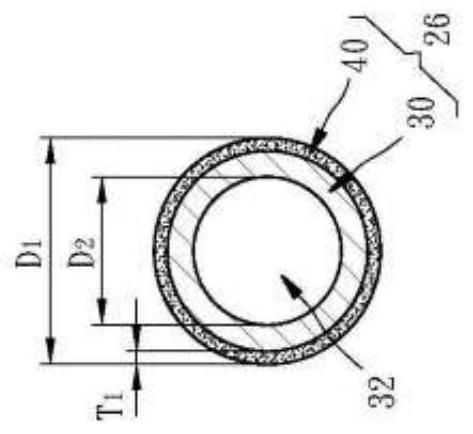

Low cost antibending ceramic roller rod and preparing method thereof

ActiveCN105481349ASolve the problem of easy bending deformationImprove brick walkingCeramic materials productionClaywaresBrickMullite

The invention discloses a low cost antibending ceramic roller rod, comprising aggregate, a matrix material and resin, wherein the aggregate has a main raw material formula of 30-60 parts of ceramic roller rod waste material in parts by weight, the matrix material has a main raw material formula of 15-40 parts of cordierite, 2-15 pars of aluminium oxide, 0.1-8 parts of yttrium oxide and 15-35 parts of clay in parts by weight; the resin selects water soluble resin in 0.1-2 parts by weight. Correspondingly, the invention further discloses a preparing method of the low cost antibending ceramic roller rod. By adopting the low cost antibending ceramic roller rod and the preparing method thereof, the ceramic roller rod waste material is reused, the problem that a corundum-mullite ceramic roller rod easily generates bending and deforming in a quenching belt or a large temperature difference region, and the condition of sliding of a tile in a roller kiln is improved.

Owner:JIN GANG NEW MATERIALS +1

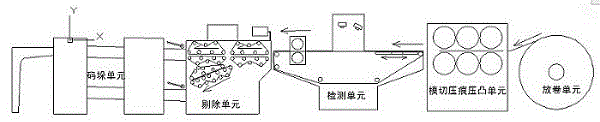

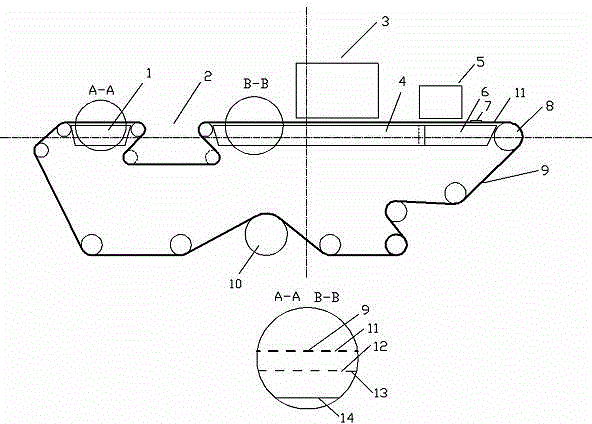

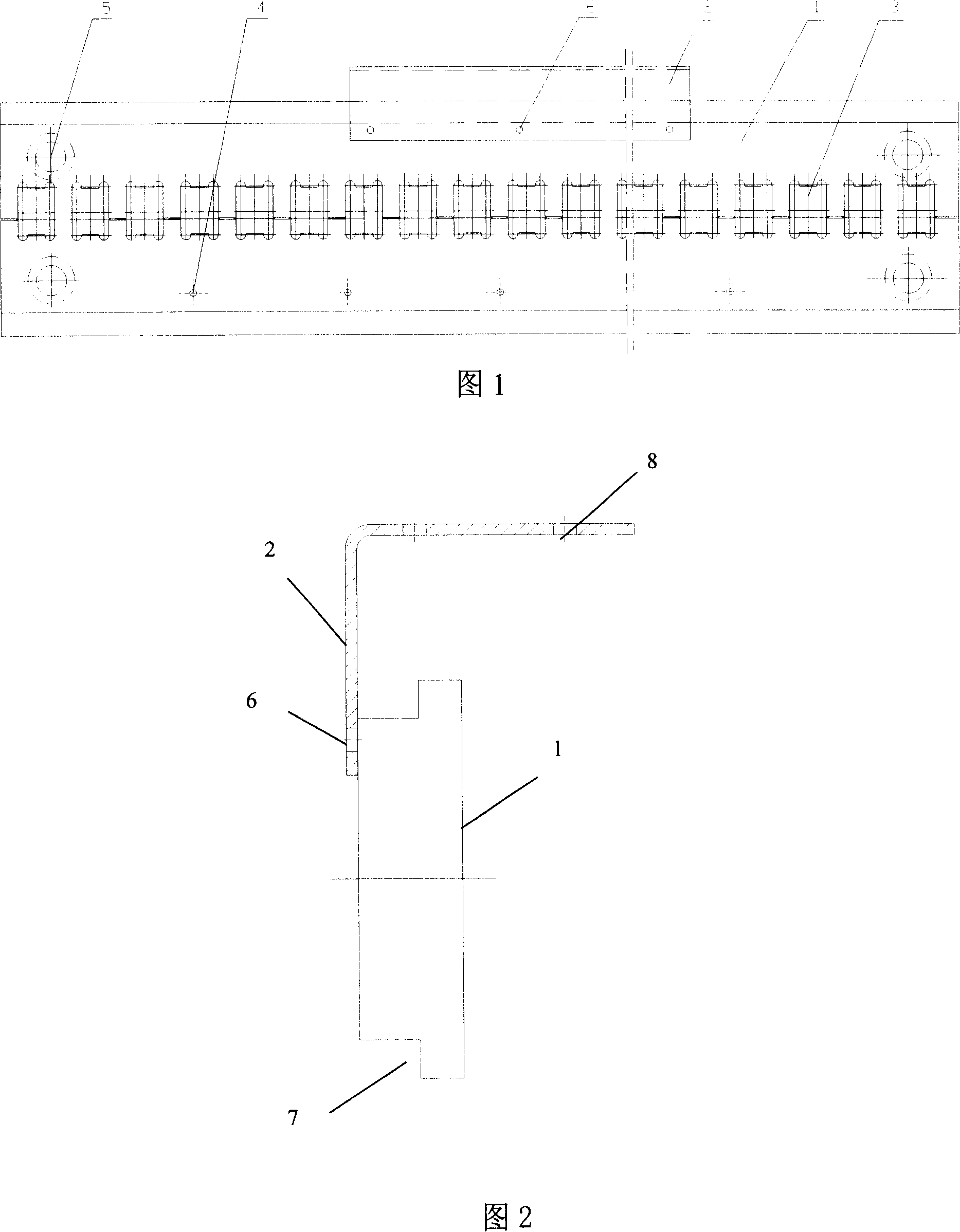

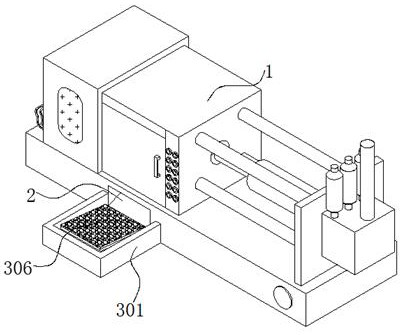

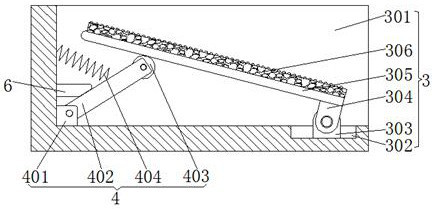

Detection unit for online negative pressure air suction conveying device of roll paper die-cutting machine belt

ActiveCN104528419AAccurate and smooth deliverySmooth and accurate deliveryCleaning using gasesArticle feedersRolling paperEngineering

The invention discloses a detection unit for an online negative pressure air suction conveying device of a roll paper die-cutting machine belt. The detection unit comprises the conveying device, negative pressure cavity boxes, a foldable negative pressure cavity box, a sliding device of the foldable negative pressure cavity box and a belt supporting frame. The negative pressure cavity boxes and the foldable negative pressure cavity box are arranged on the lower face of a conveyor belt and the foldable negative pressure cavity box can slide, stretch and retract in one negative pressure cavity box. A negative pressure cavity panel is arranged on the negative pressure cavity boxes and the foldable negative pressure cavity box. The negative pressure cavity boxes are fixed to a rack, the foldable negative pressure cavity box is fixed to the sliding device, and the sliding device is connected with a cylinder. The negative pressure cavity boxes and the foldable negative pressure cavity box are provided with connectors and connected with an exhaust fan. The belt supporting frame is a mesh type frame arranged on the negative pressure cavity panel. A dust removal device and a connection device can be additionally arranged on the detection unit. Products can be stably and accurately conveyed to a detection device through the negative pressure air suction conveying device.

Owner:CHANGDE JINPENG PRINTING

Multiphase ceramic roller and preparation method thereof

The invention discloses a multiphase ceramic roller. The raw raw materials include aggregate and a binder. The aggregate includes 25-35 parts of a corundum material, 25-35 parts of clay, 18-24 parts of alumina micropowder, 3-6 parts of yttrium oxide, 4-11 parts of titanium dioxide, 3-10 parts of zirconium silicate and 3-6 parts of fine mineral powder. The corundum material includes 7-11 parts of corundum with a particle size of 60-100 meshes, 14-17 parts of corundum with a particle size of 100-200 meshes, and 4-7 parts of corundum with a particle size of 250 meshes and a content of less than or equal to 10%. Accordingly, the invention also discloses a preparation method of the multiphase ceramic roller. The multiphase ceramic roller provided by the invention has the characteristics of highfire resistance degree, good high temperature creep resistance, low thermal expansion coefficient, high service temperature, good thermal shock stability, long service life, etc., and effectively solves the problem of roller bending deformation caused by large temperature gradient in a roller kiln.

Owner:广东金刚新材料有限公司 +1

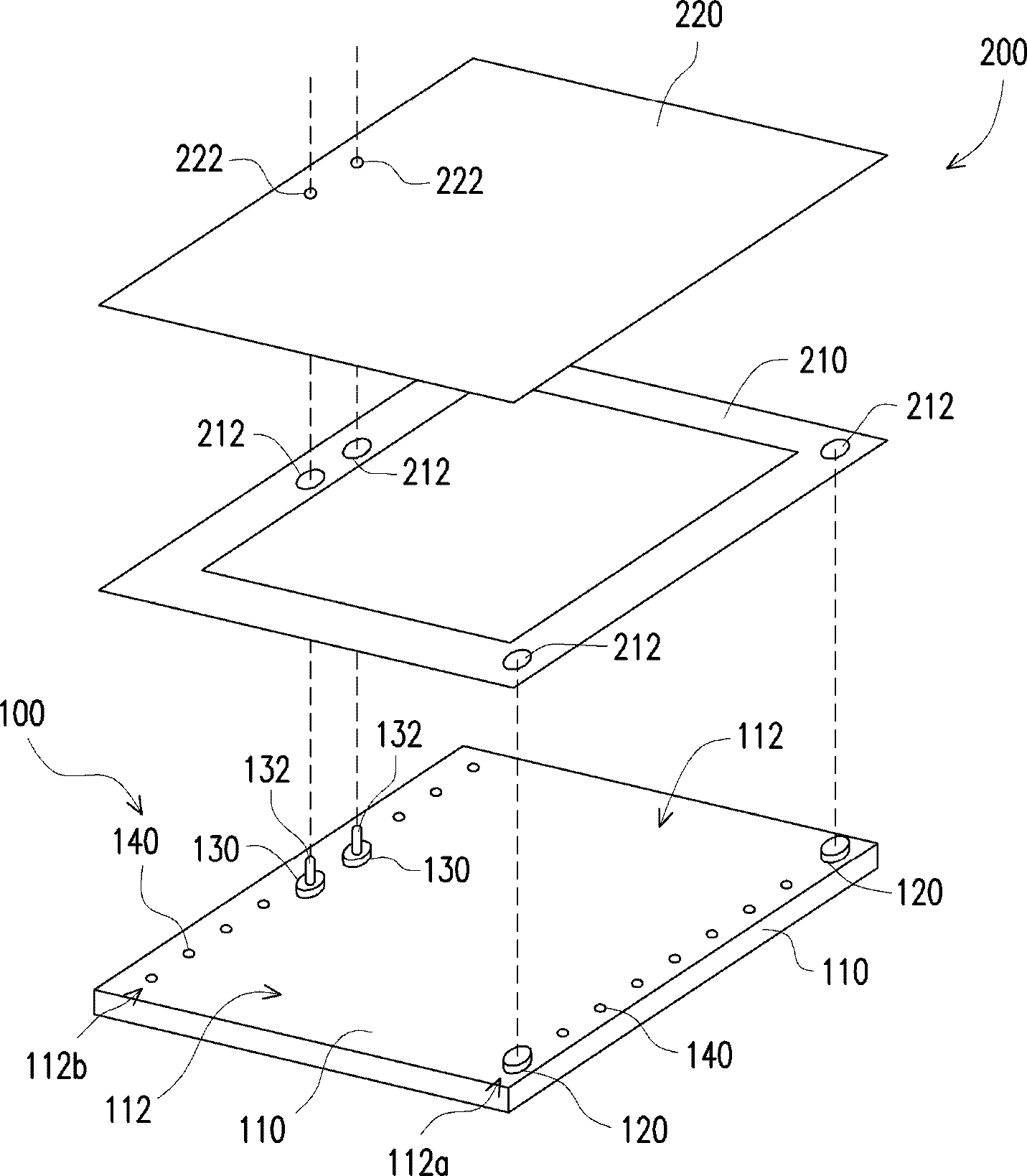

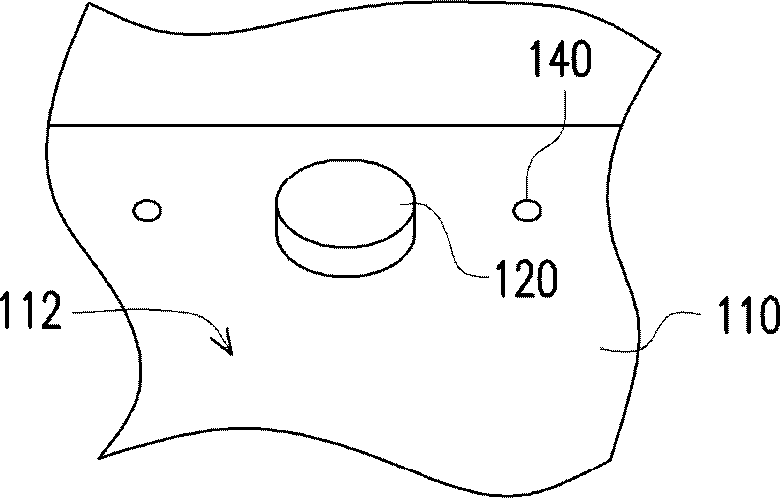

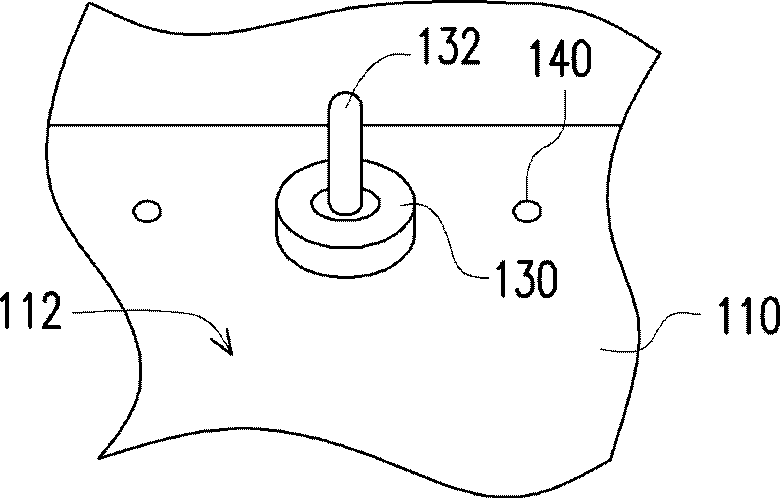

Locating jig

InactiveCN103163667ASolve bending deformationImprove positioning efficiencyNon-linear opticsEngineeringDisplay device

Owner:INVENTEC CORP

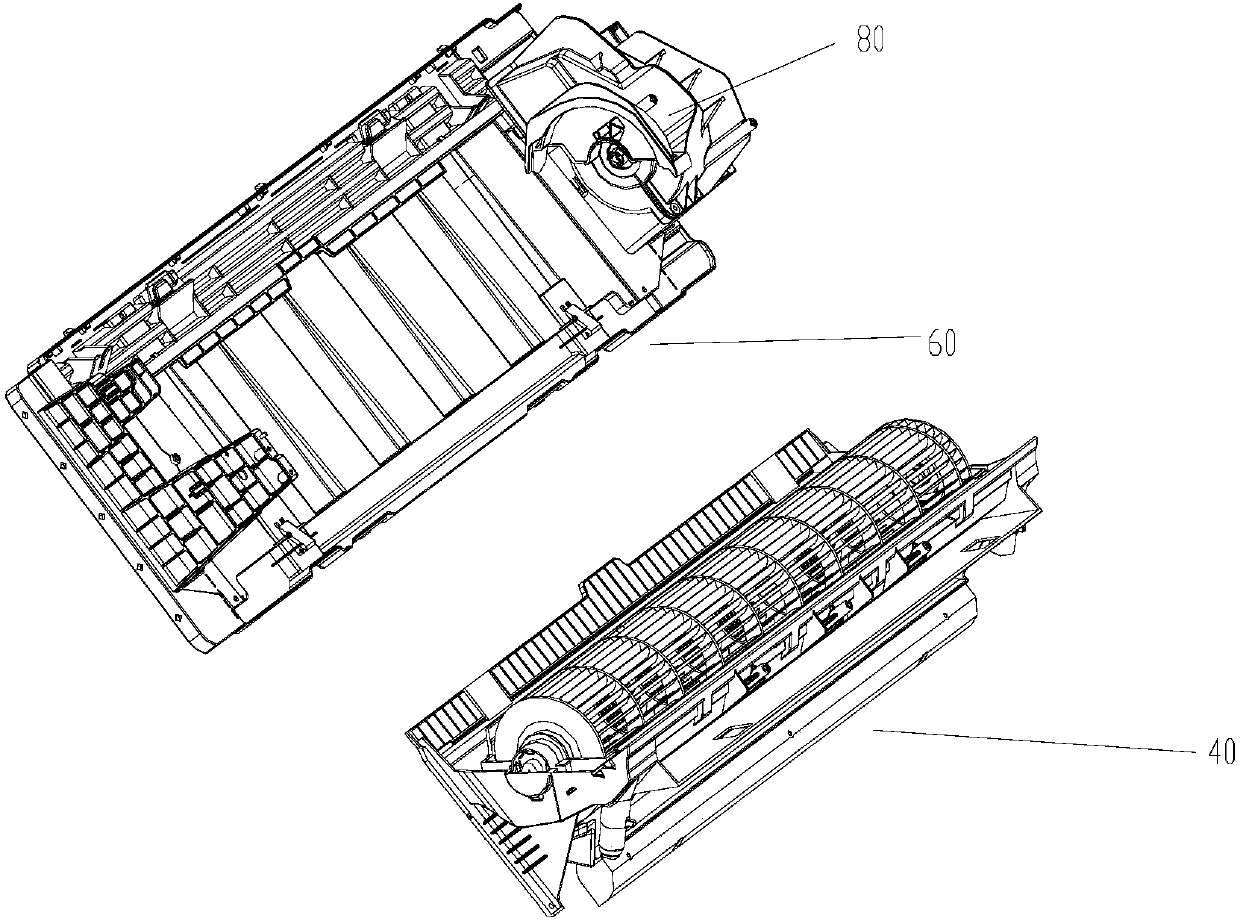

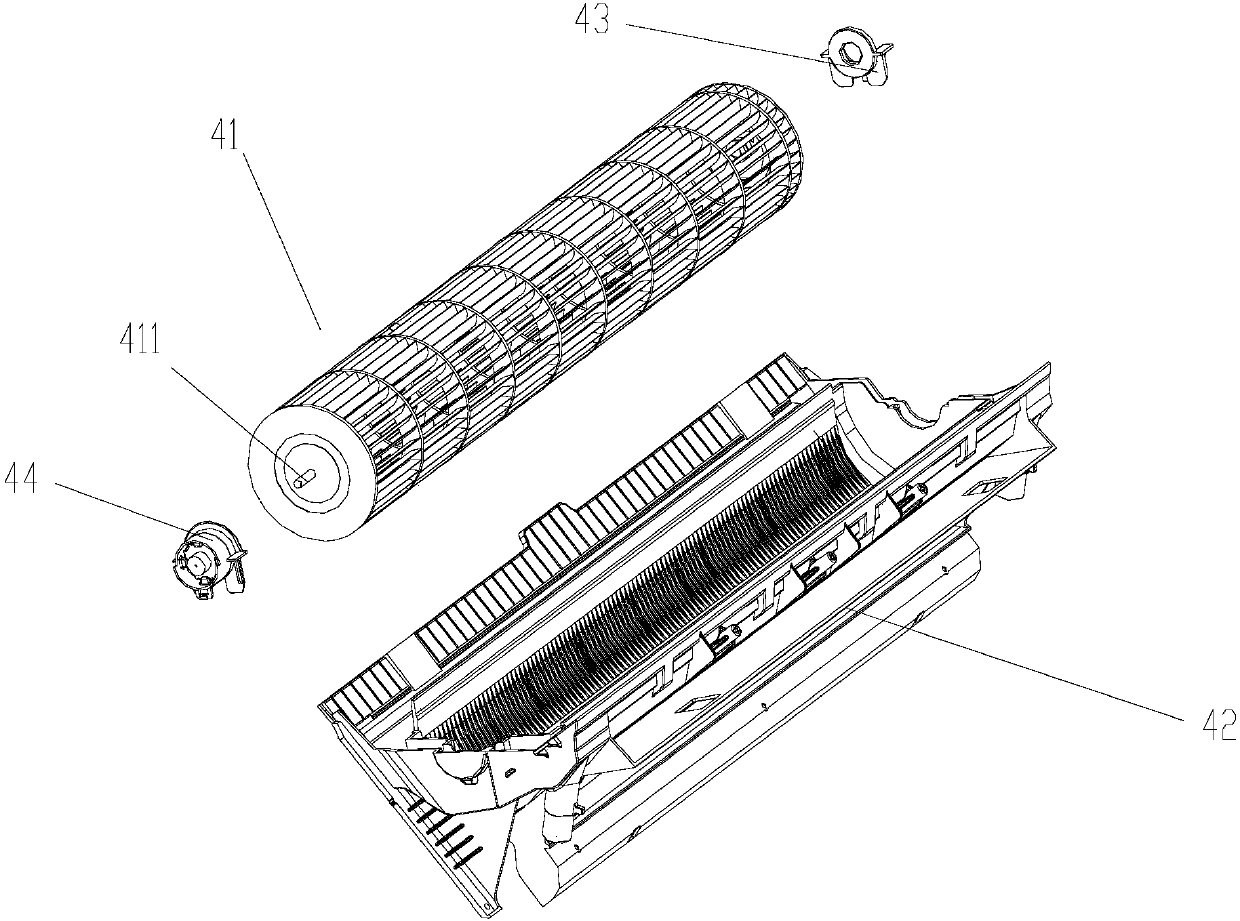

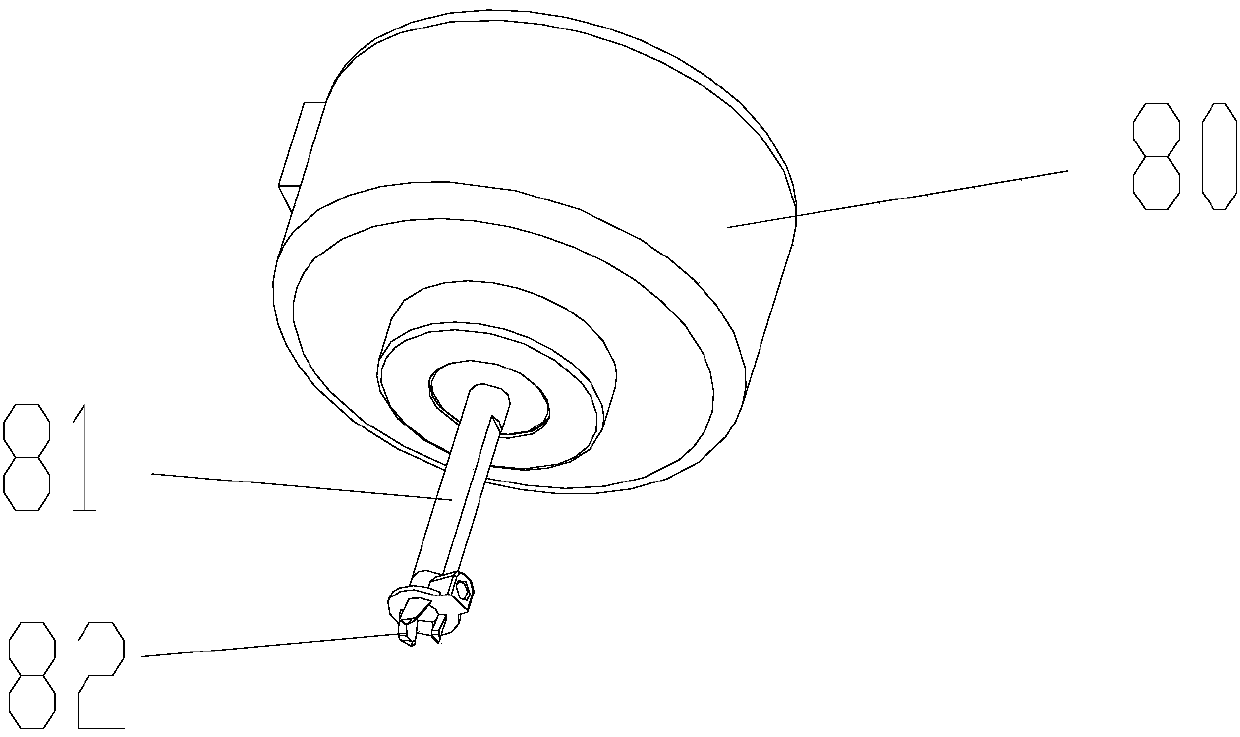

Air-conditioner

InactiveCN107631352ASolve bending deformationAvoid distortionLighting and heating apparatusCouplings for rigid shaftsAir channelAerospace engineering

The invention provides an air-conditioner. The air-conditioner comprises a base, a motor, an electric appliance box and an air channel assembly, wherein the motor and electric appliance box are both mounted on the base; the air channel assembly is detachably arranged on the base; and the base comprises a base body and reinforcing plates which are arranged on the base body. By means of the air-conditioner, the problem that in the prior art, a whole base bends or deforms after an air-conditioner complete appliance is mounted is solved.

Owner:GREE ELECTRIC APPLIANCES INC

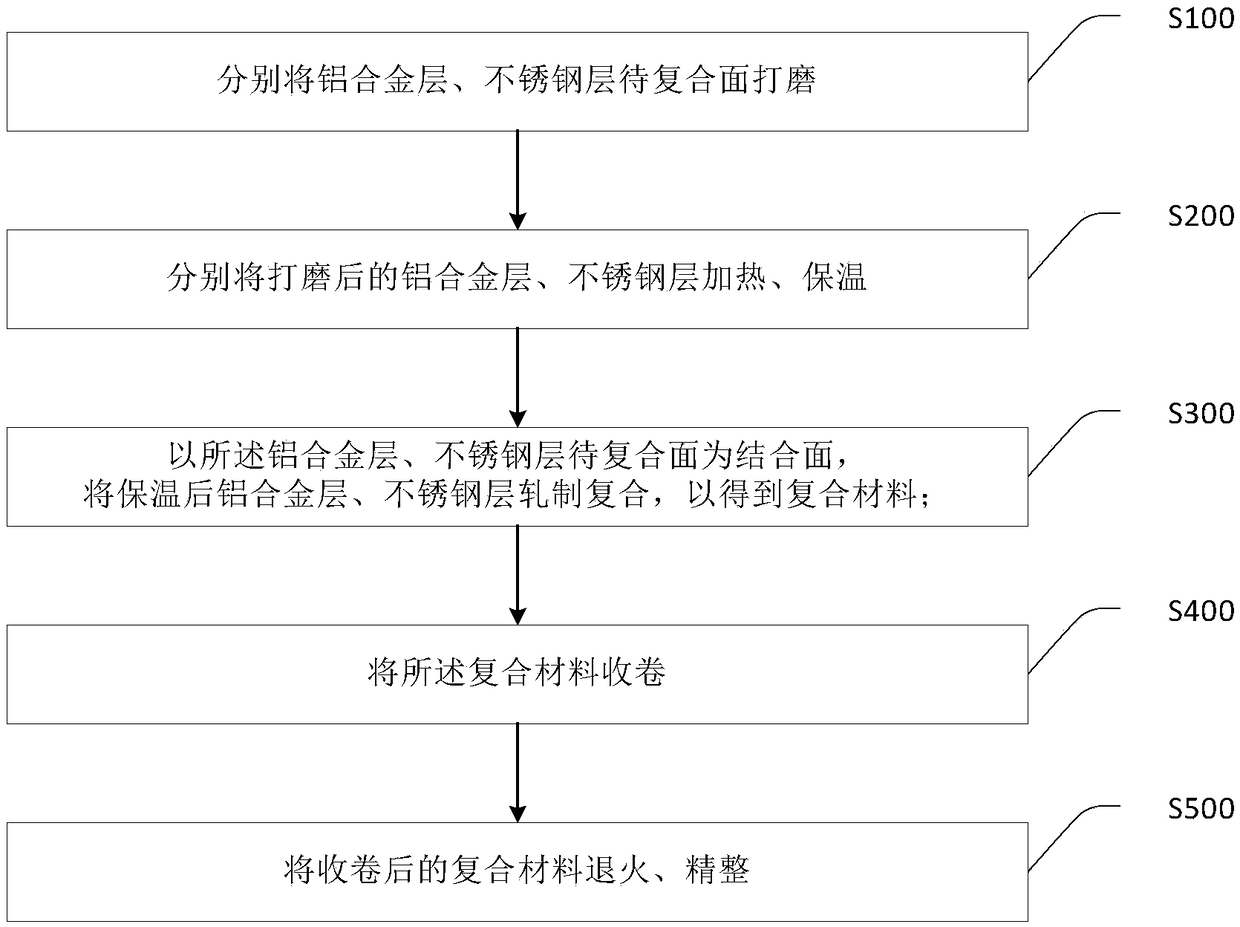

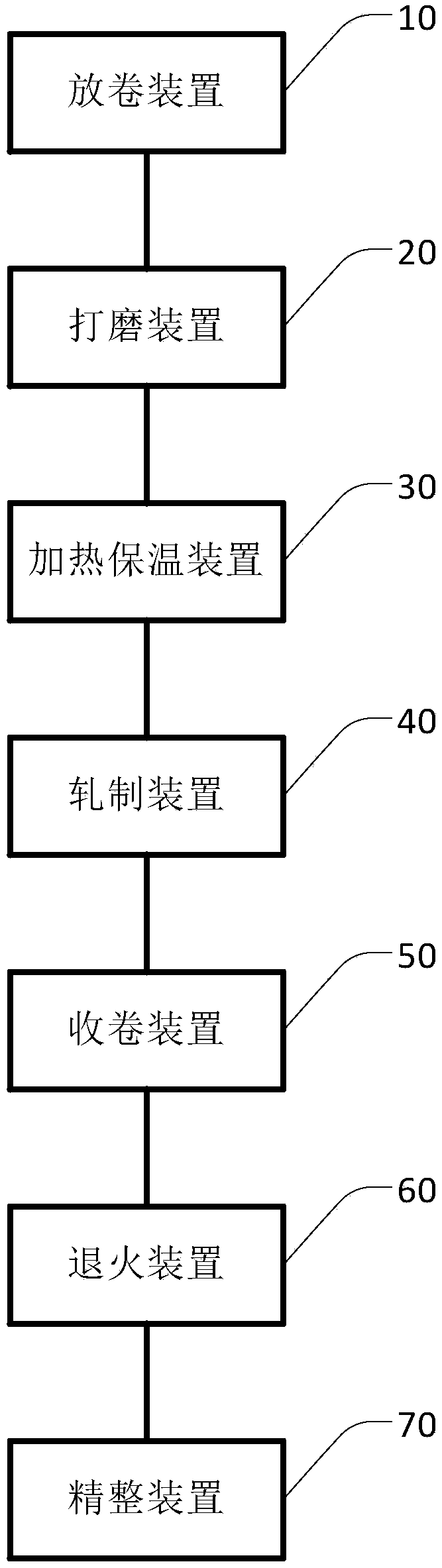

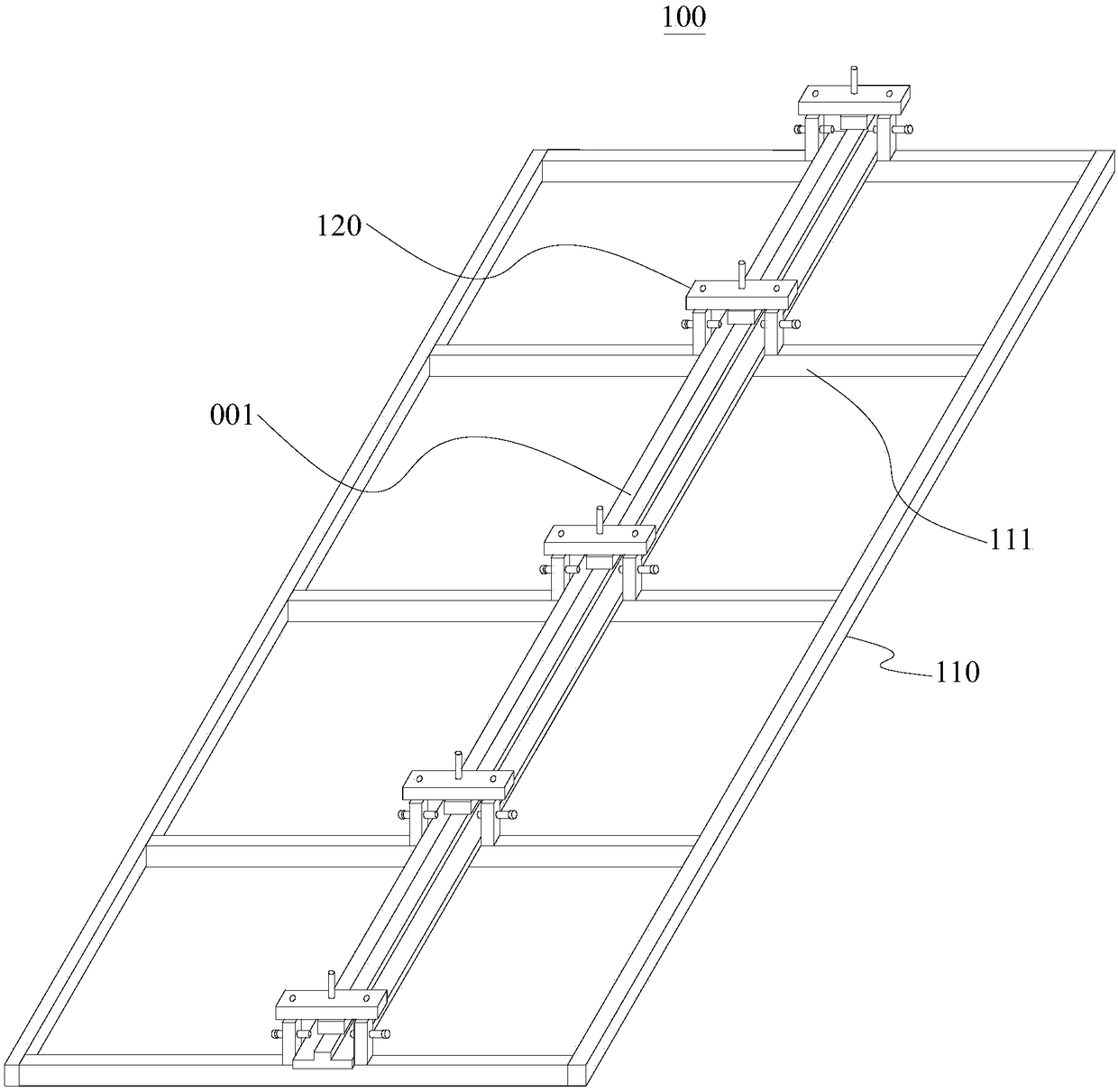

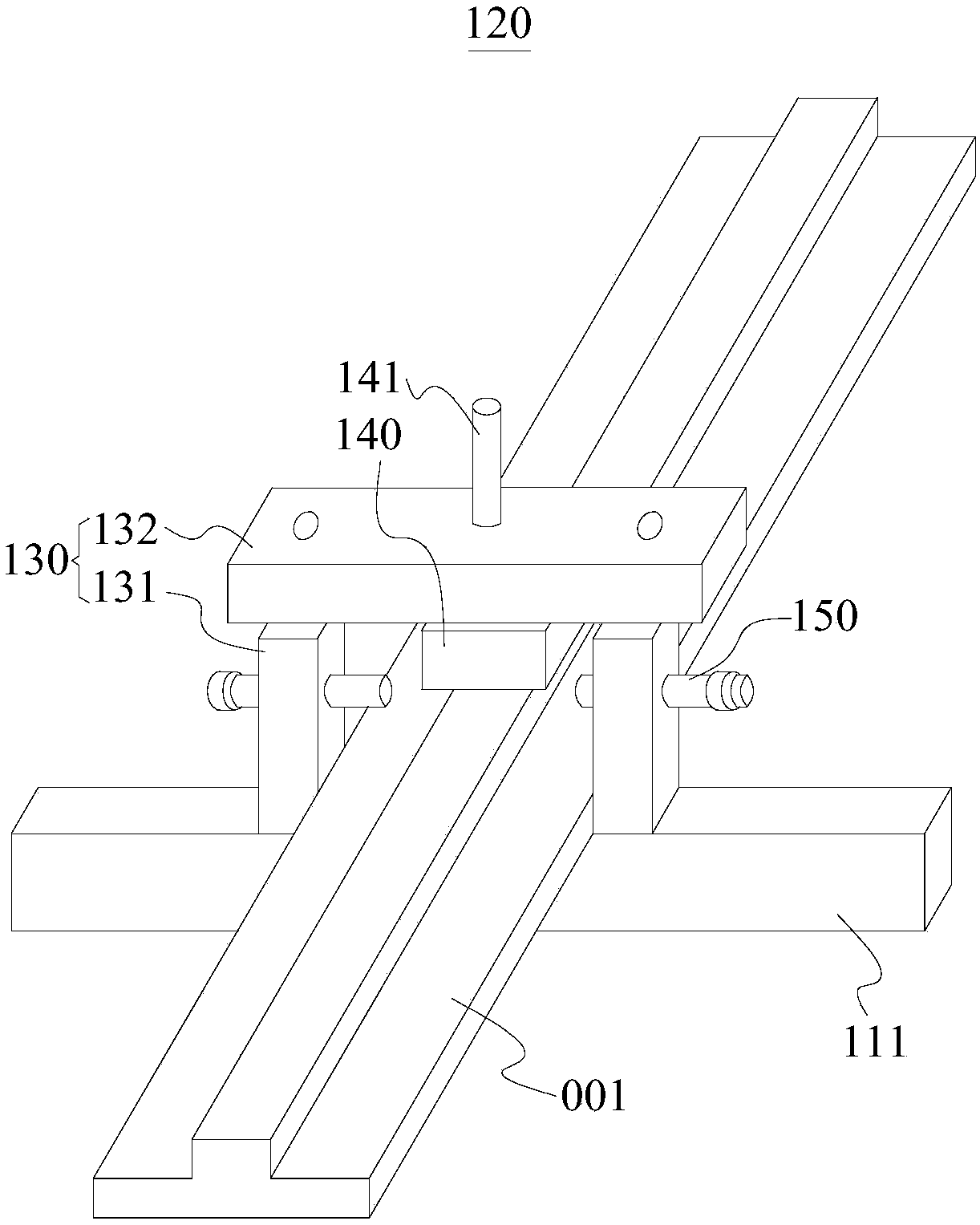

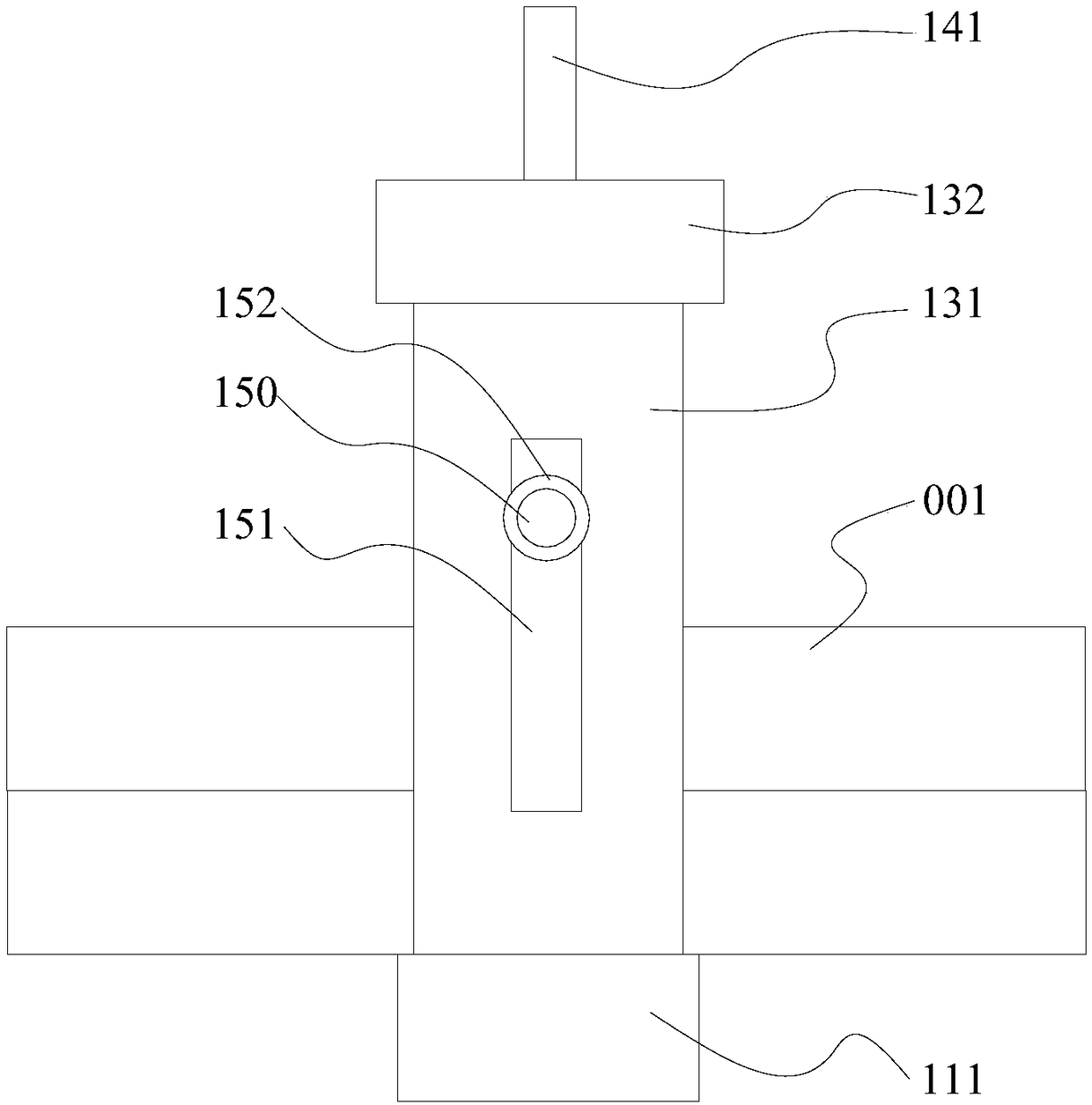

Method and system for continuously producing aluminium/stainless-steel compound material

ActiveCN108913867AWill not deformSolve bending deformationFurnace typesMetal rolling arrangementsAluminium alloyContinuous production

The invention relates to a method and system for continuously producing an aluminium / stainless-steel compound material. The method comprises the following steps of: grinding surfaces to be compoundedof an aluminium-alloy layer and a stainless-steel layer; carrying out heating and insulating on the ground aluminium-alloy layer and stainless-steel layer; adopting surfaces to be compounded of the aluminium-alloy layer and the stainless-steel layer as combining surfaces, and rolling and compounding the aluminium-alloy layer and the stainless-steel layer to obtain a compound material; carrying outwinding, annealing and finishing on the compound material, wherein before grinding the surfaces to be compounded of the aluminium-alloy layer and the stainless-steel layer, using an unwinding deviceto supply the aluminium-alloy layer and the stainless-steel layer and apply front tension, wherein the supplying speed of the aluminium-alloy layer is lower than that of the stainless-steel layer; using a winding device to wind the compound material and apply back tension; tightening the aluminium-alloy layer and the stainless-steel layer by the front tension and the back tension. The method and system have the beneficial effects that continuous taped type production of the aluminium / stainless-steel compound material can be finished, short-process and high-efficiency industrial production of the aluminium / stainless-steel compound material can be realized, the yield can be increased and the productivity can be improved.

Owner:YINBANG CLAD MATERIAL

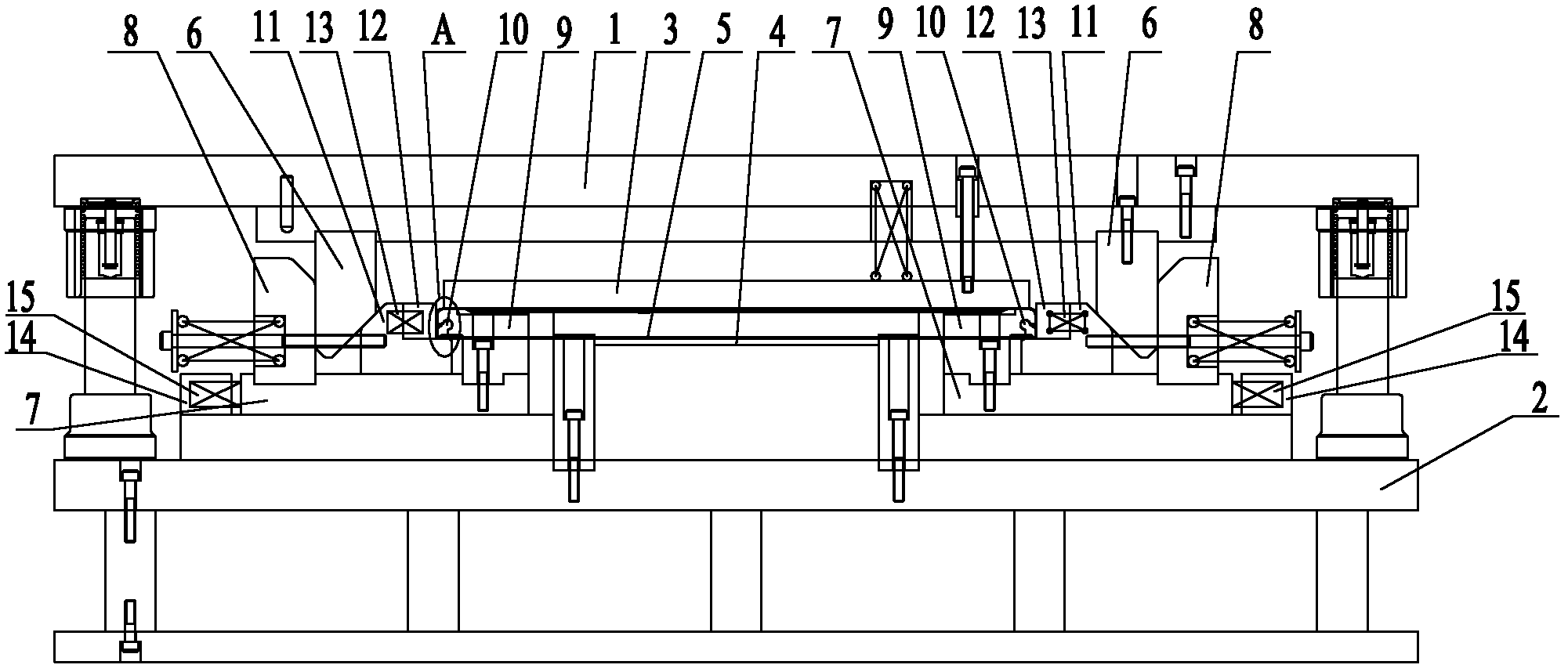

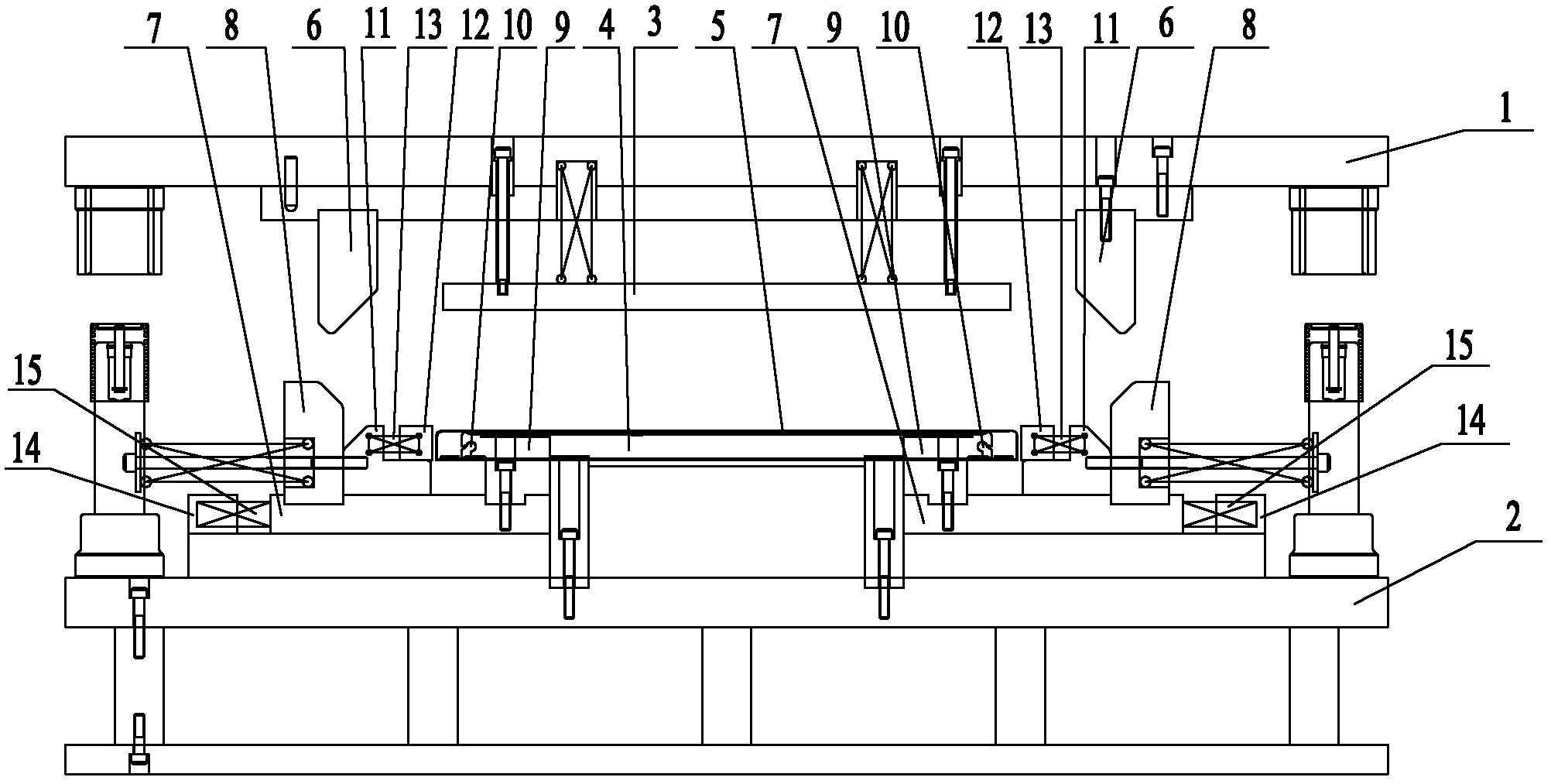

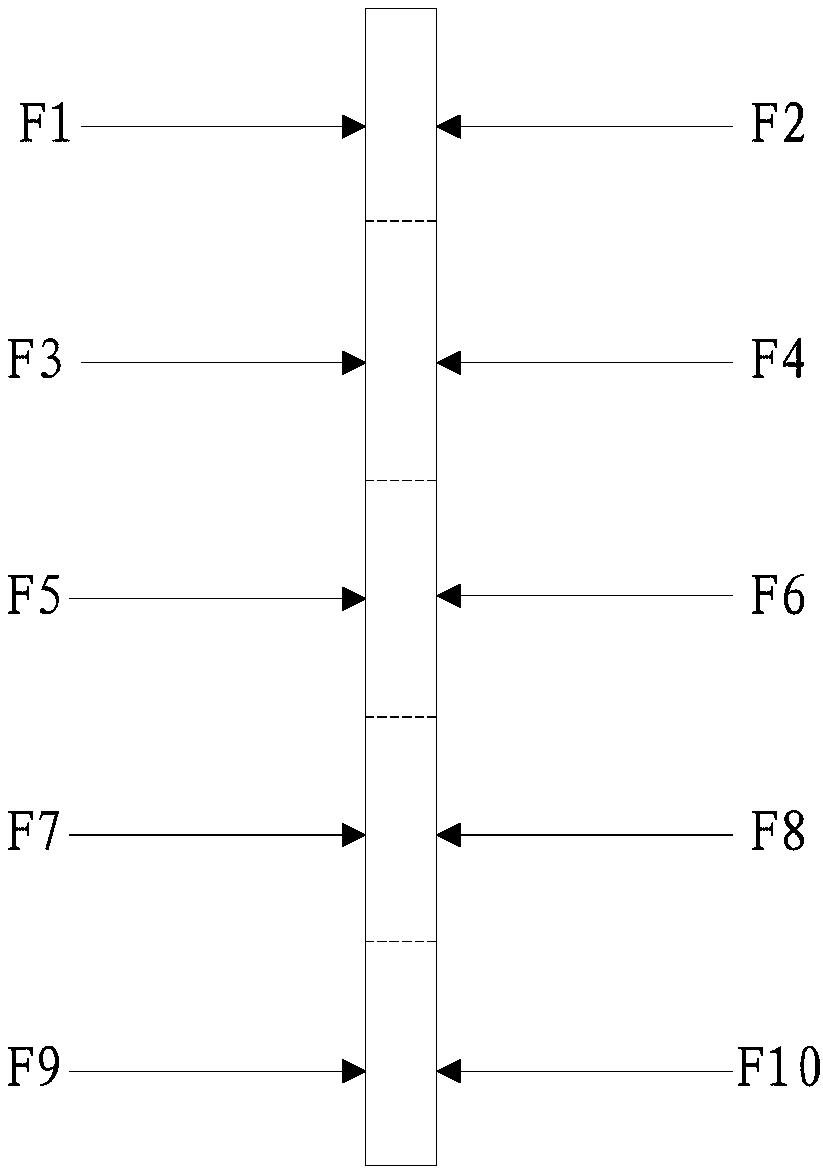

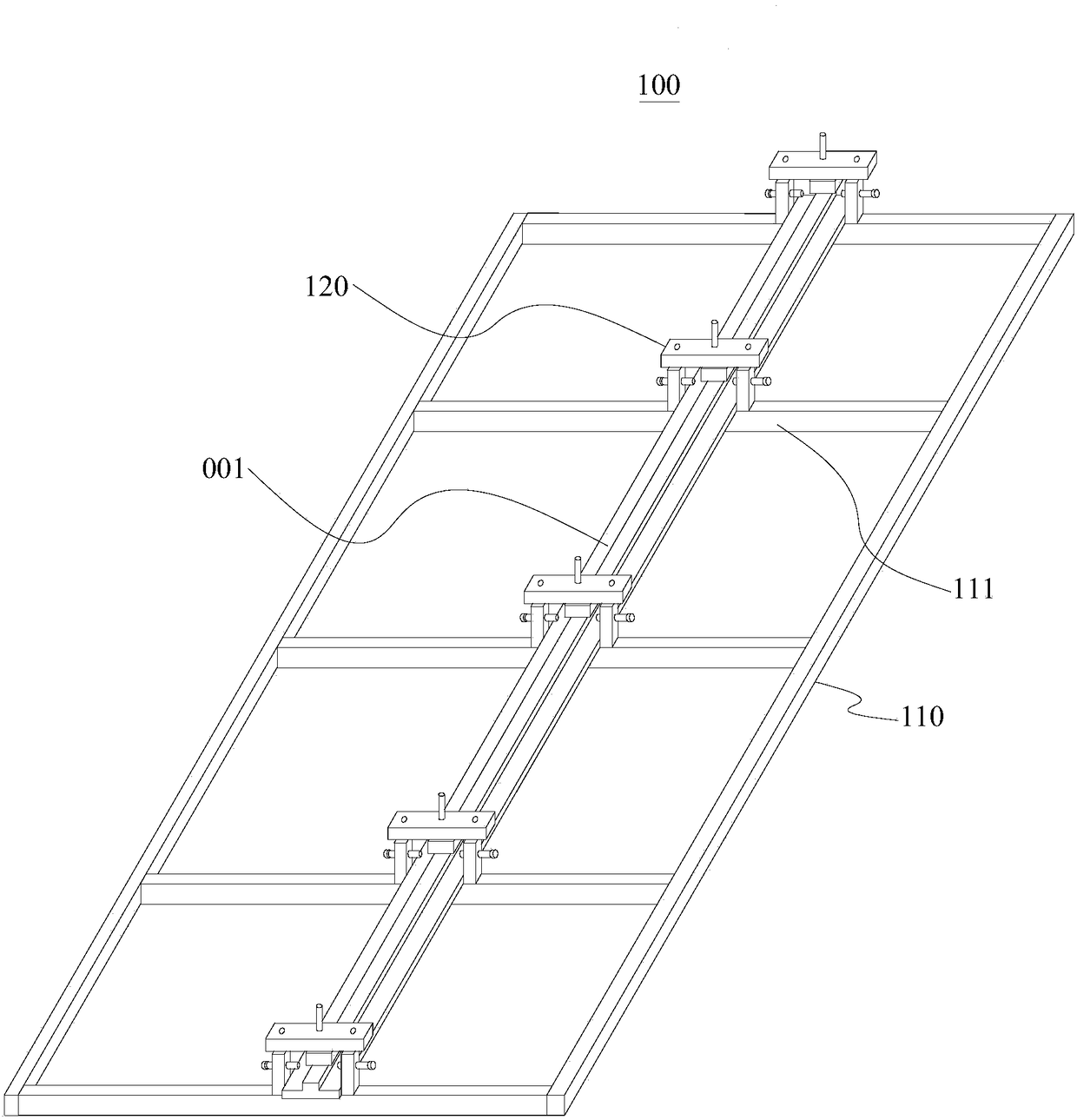

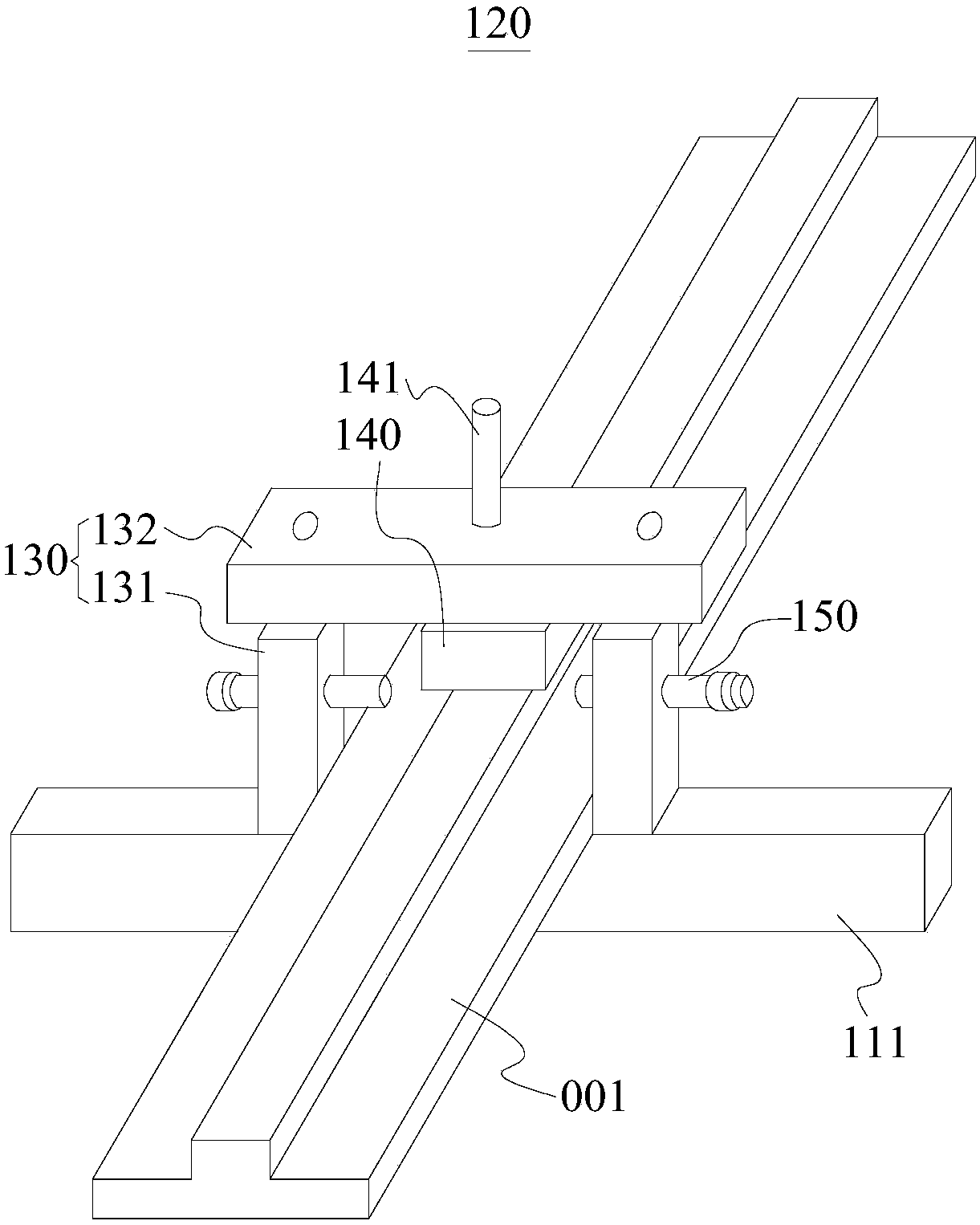

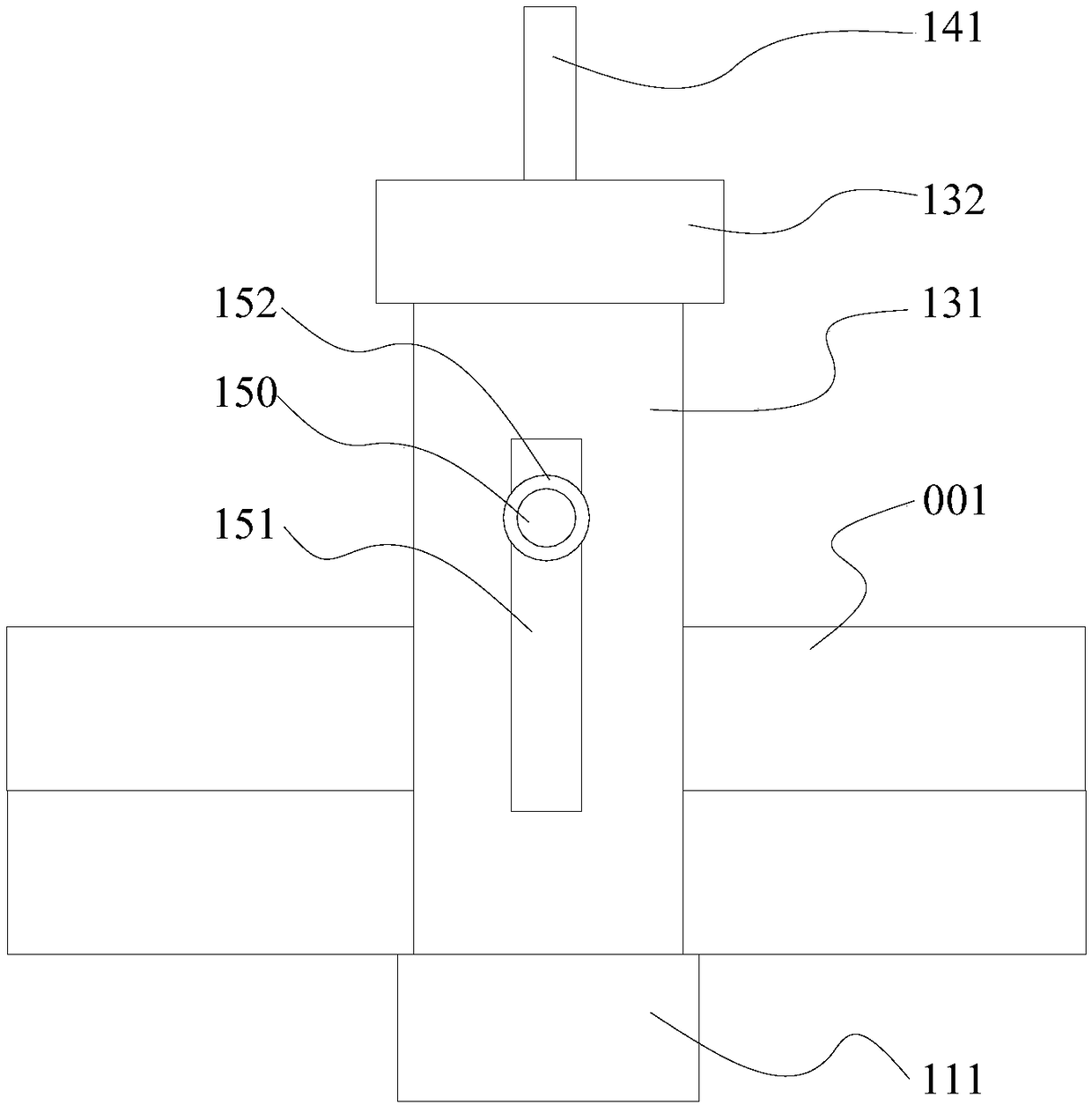

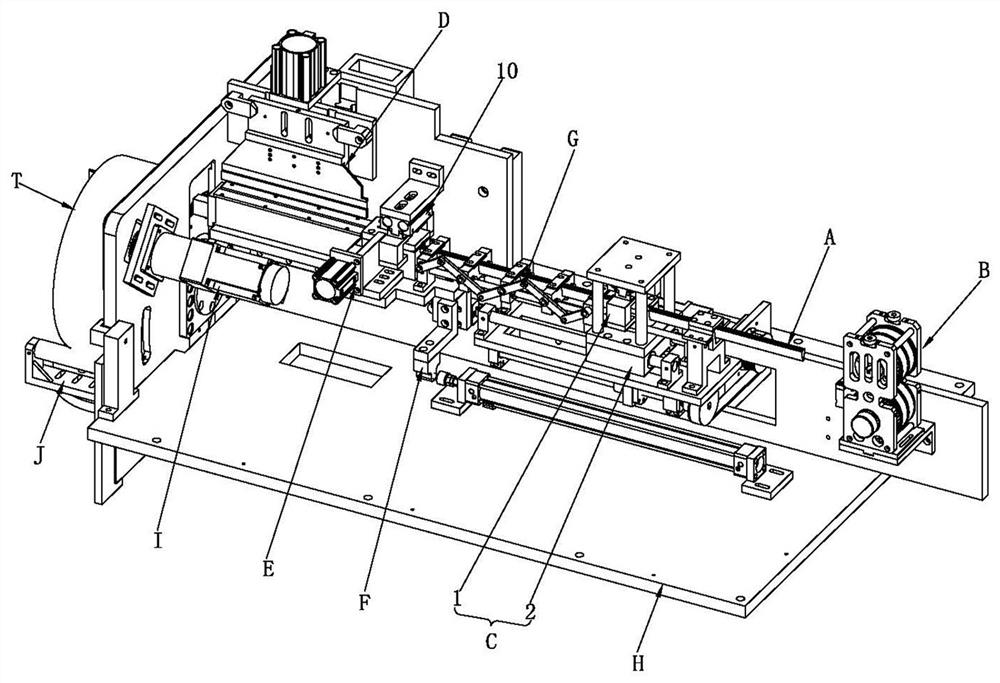

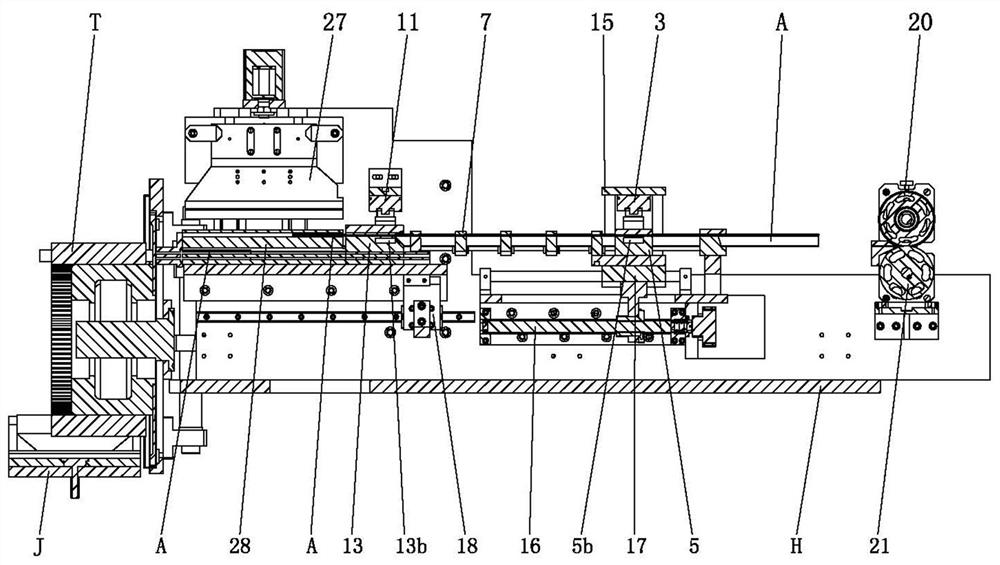

Aluminum alloy forced sizing device and aluminum alloy heat treatment method

ActiveCN108588358ASolve bending deformationImprove straightnessFurnace typesHeat treatment furnacesSizingHeat treated

The invention relates to the technical field of aluminum alloy processing, in particular to an aluminum alloy forced sizing device and an aluminum alloy heat treatment method. The aluminum alloy forced sizing device comprises a base and multiple single part clamps arranged linearly. Each single part clamp comprises a framework, a locating block and two straightening parts, wherein the framework isperpendicular to the base and allows an aluminum alloy profile to penetrate, and the locating block and the two straightening parts are arranged on the framework. The locating blocks abut against theupper surface of the aluminum alloy profile in the frameworks, and the two straightening parts of each single part clamp abut against the two side faces of the aluminum alloy profile in the frameworks in a one-to-one correspondence manner. According to the aluminum alloy forced sizing device, an aluminum alloy product can be sized, and deformation is prevented from happening during heat treatment. The aluminum alloy heat treatment method comprises the steps that the aluminum alloy forced sizing device is adopted for locating the aluminum alloy profile, and then quenching treatment or aging treatment or quenching and aging treatment is carried out. According to the method, the problem of bending deformation happening during aluminum alloy heat treatment can be effectively solved, the aluminum alloy product good in straightness can be obtained, and the requirement of aviation use can be met.

Owner:SHANDONG NANSHAN ALUMINUM +1

Preparation method of ultra-thin glass, ultra-thin glass and application thereof

PendingCN113636758AReduce roughnessImprove transmittanceGlass reforming apparatusGlass tempering apparatusHigh transmittanceMaterials science

The invention relates to the technical field of glass production, and discloses a preparation method of ultra-thin glass, the ultra-thin glass and an application of the ultra-thin glass. The method comprises the following steps: (1) carrying out secondary thinning on a glass material to obtain an ultrathin glass material; (2) in the presence of a binder, pasting the ultrathin glass material on one side or two sides of a support member to obtain a first composite glass sample; (3) carrying out chemical thinning on the first composite glass sample to obtain a second composite glass sample; (4) removing the supporting piece and the cured binder in the second composite glass sample, and then carrying out finish machining to obtain an ultra-thin glass initial product; and (5) carrying out toughening treatment on the ultra-thin glass initial product to obtain the ultra-thin glass. According to the method provided by the invention, the problem that the glass with the thickness of 0.3 mm or below is easy to bend and deform when being subjected to chemical thinning can be solved, and the prepared ultrathin glass has the advantages of low roughness, high transmittance and high coaxial double-ring compressive strength.

Owner:河北光兴半导体技术有限公司

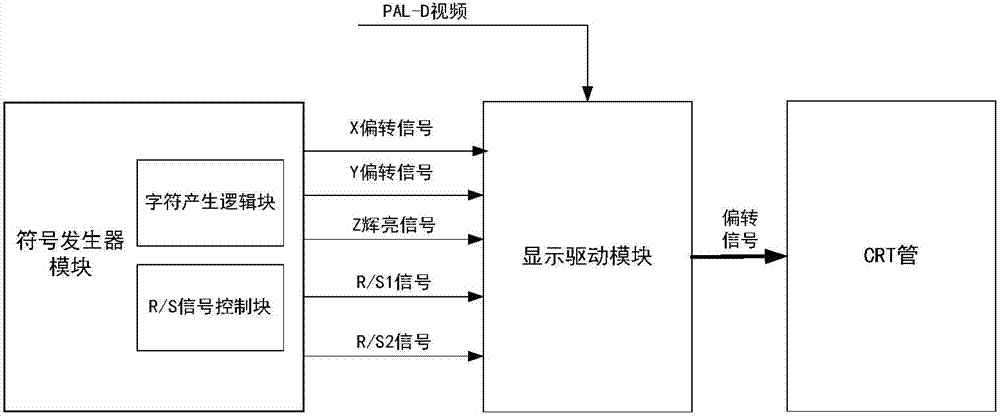

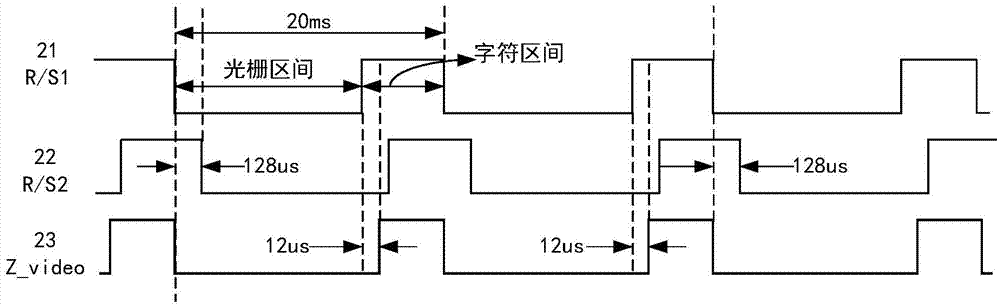

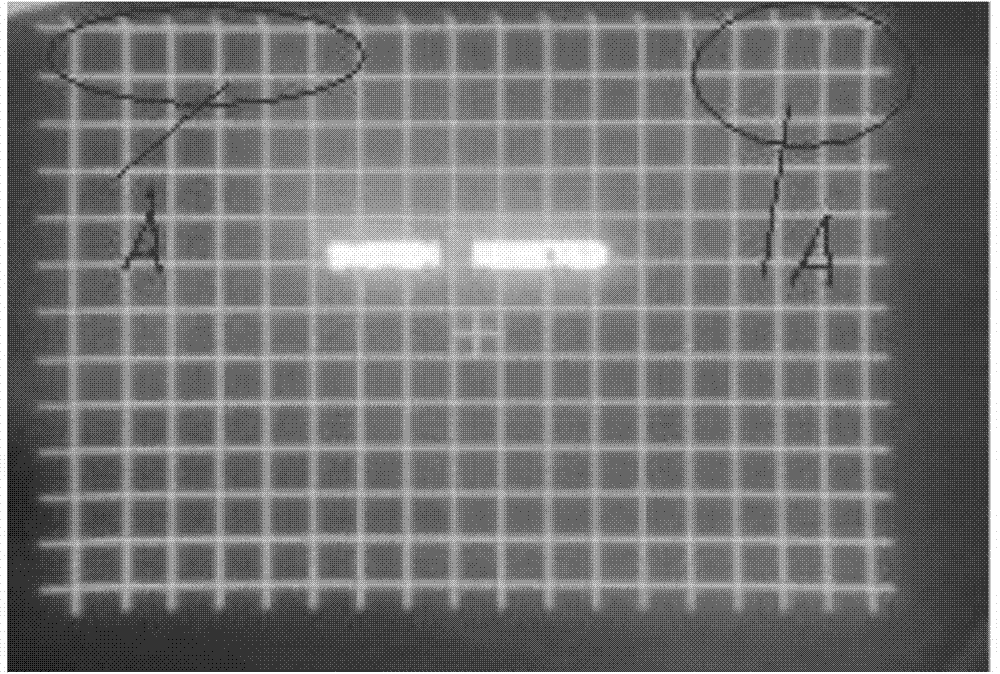

Head-up display and method for improving time-sharing overlapping display effect

ActiveCN104299544AImprove image displaySolve bending deformationCathode-ray tube indicatorsTime-sharingCharacter generator

The invention relates to a head-up display and a method for improving the time-sharing overlapping display effect, and belongs to the technical field of airborne display equipment. Two control signals R / S1 and R / S2 are generated. In the display period of the head-up display, the changes of R / S1 and R / S2 are controlled to show that the head-up display works in a grating / stroke time-sharing overlapping mode. The rising edge timing sequences of R / S1 and R / S2 are the same, and the falling edge of R / S2 is delayed by a set period of time relative to the falling edge timing sequence of R / S1. With the falling edge of R / S1 as a benchmark and in a set period of time, a brightness signal is logically controlled by a character generator to be low, and the head-up display is forced to have no display. In a set period of time of the rising edges of R / S1 and R / S2, the brightness signal is controlled to be low, and the head-up display is forced to have no display. According to the method, delayed display is carried out at the rising edge (grating to stroke) and the falling edge (stroke to grating) of an R / S signal. The problem that the first stroke of a character is bright and the top end of a grating is bent and deformed in a grating / stroke overlapping state of the head-up display is solved, and the image display effect of the head-up display is improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

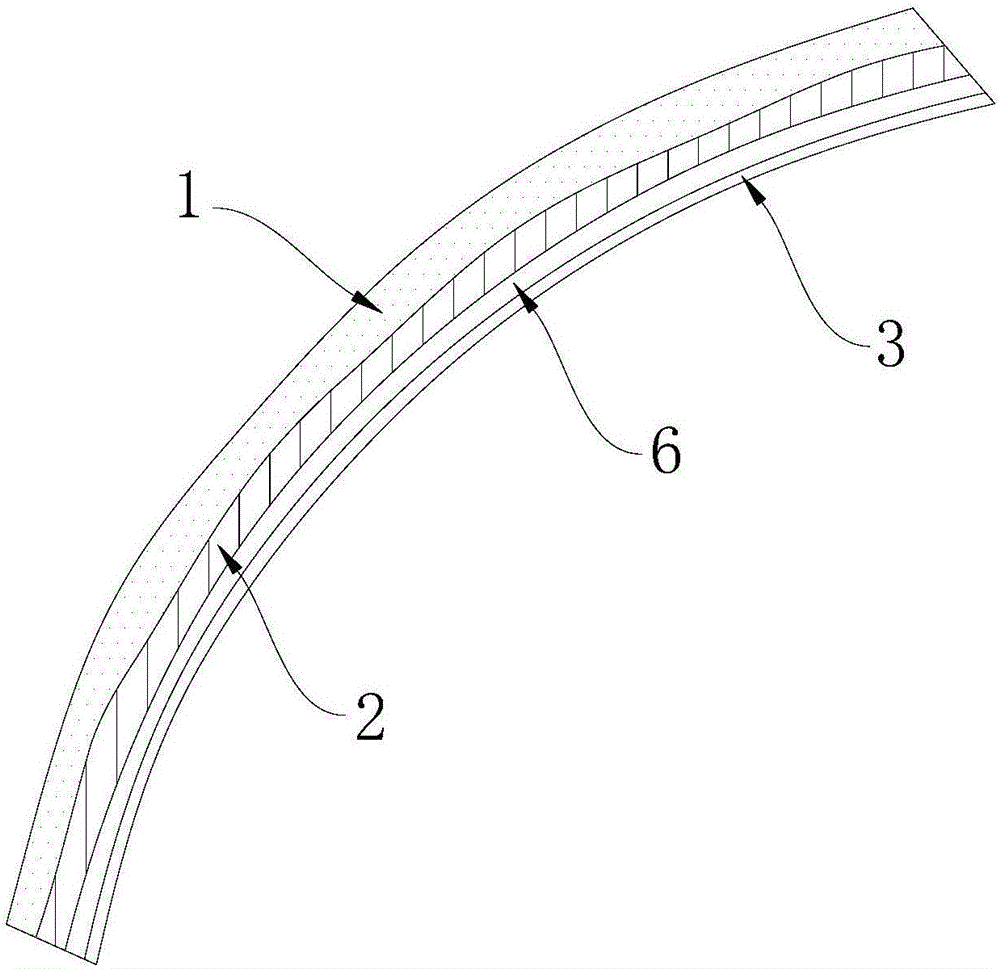

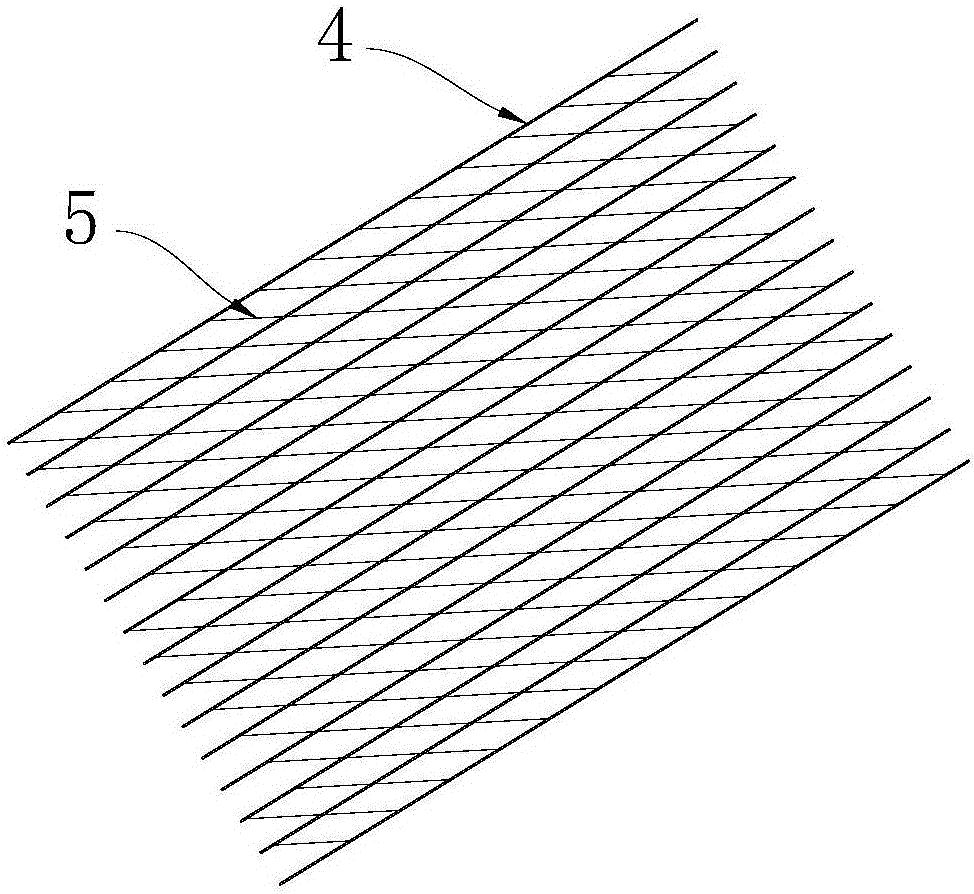

Radial tire of fiber cord fabric tire shoulders

ActiveCN106739832APrevent air leakageAvoid empty shouldersHeavy duty tyresHeavy duty vehicleFiberEngineering

Disclosed is a radial tire of fiber cord fabric tire shoulders. The radial tire comprises a wire cord fabric, a fiber cord fabric and an airtight layer, wherein the wire cord fabric, the fiber cord fabric and the airtight layer are located at the tire shoulders of the inner wall of the tire, and distributed in sequence from outside to inside; and steel wires are arranged in the wire cord fabric, fibers are arranged in the fiber cord fabric, and included angles of 5-45 degrees are formed between the fibers and the steel wires. The radial tire of fiber cord fabric tire shoulders has the advantages of solving the problems of bending deformation, seam production, cord exposure and the like of the carcass wire cord fabric of the on-load radial tire in the production process by virtue of a netlike structure formed due to different angles between the fibers of the fiber cord fabric and the steel wires of the wire cord fabric, thereby avoiding tire flat, shoulder separation, explosion, early damage and other similar situations, improving the running safety of the tire and prolonging the service life of the tire.

Owner:青岛泰谦科技服务有限公司

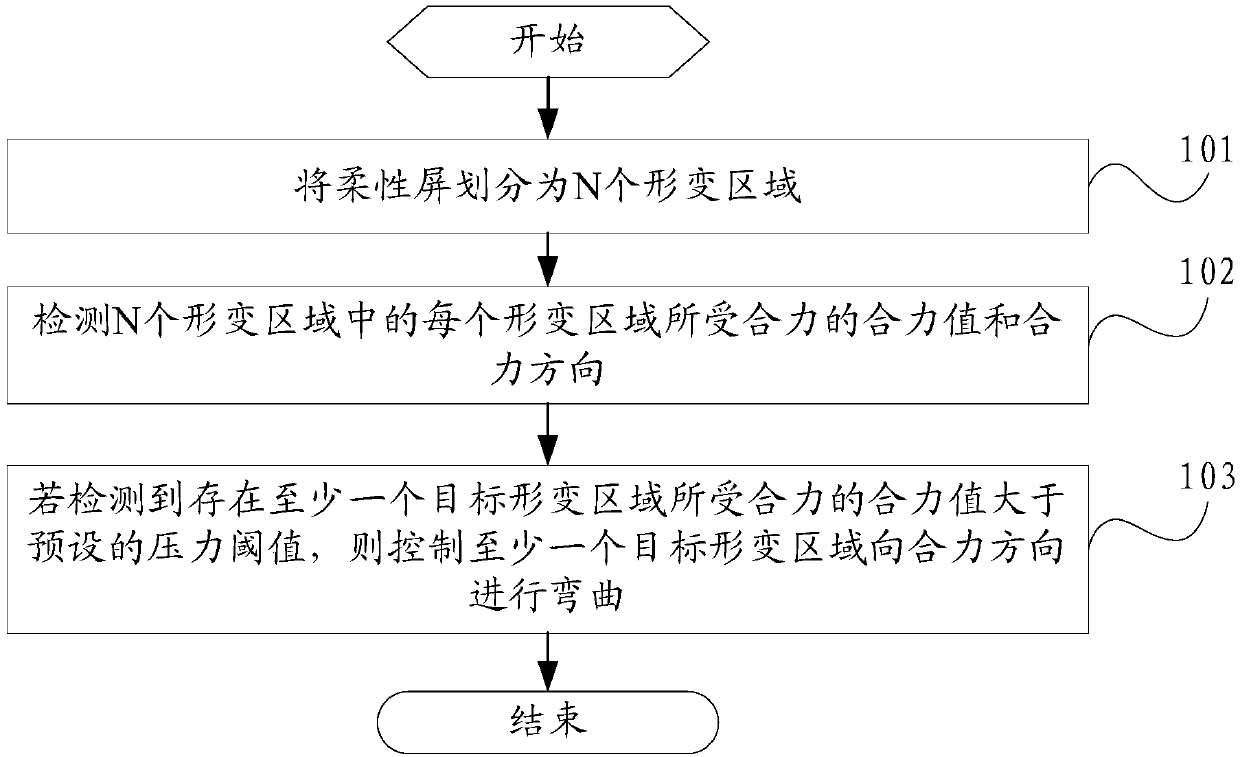

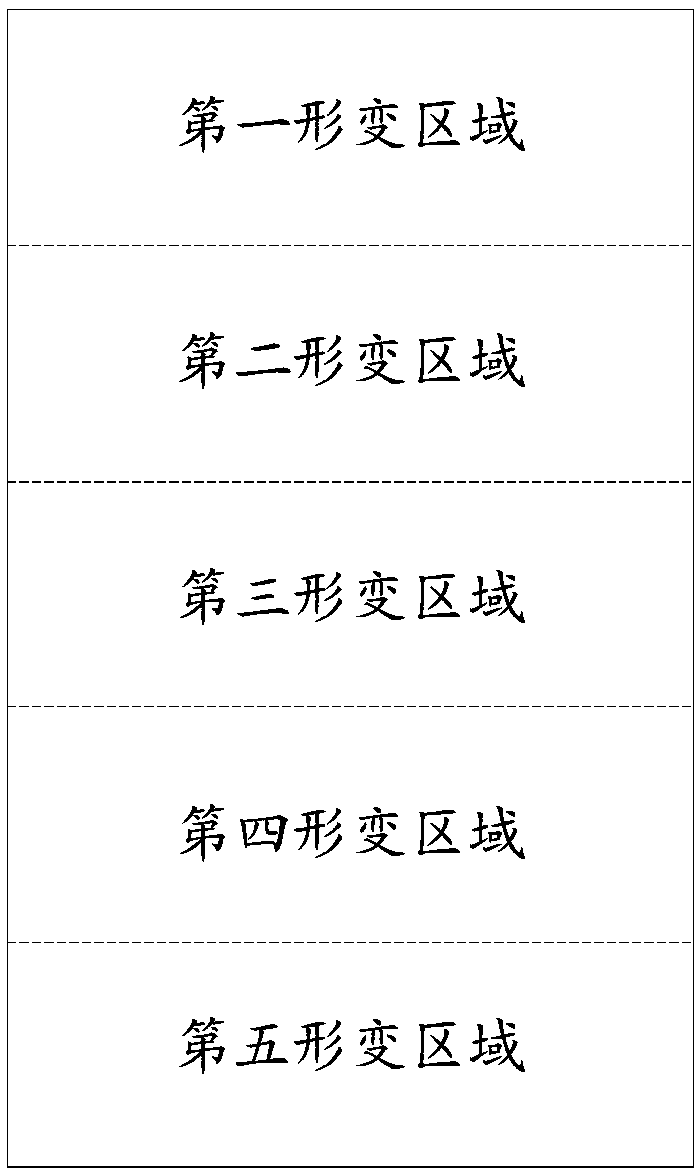

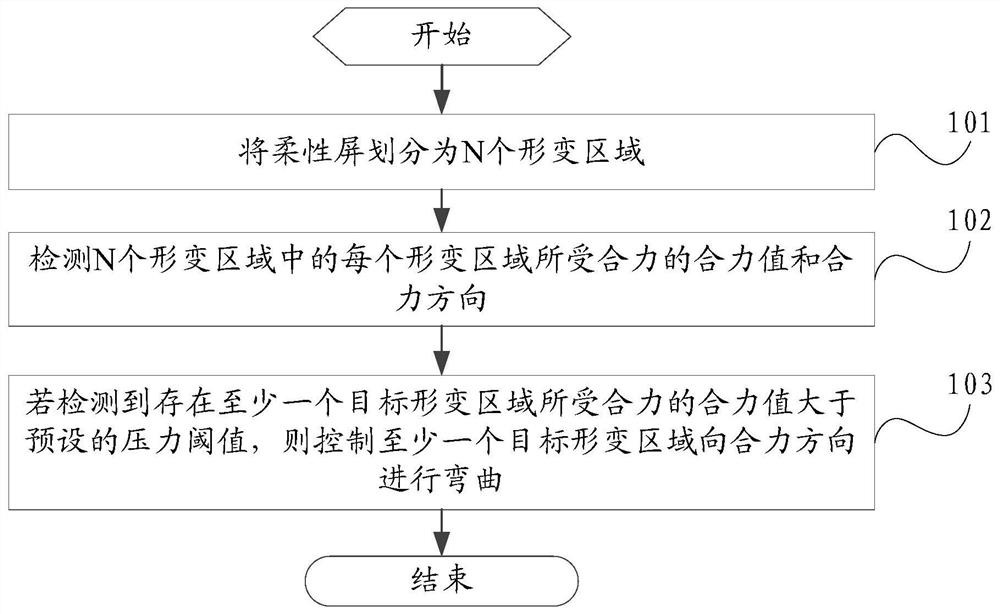

Mobile terminal control method and mobile terminal

ActiveCN107659711AProtect the screenExtended service lifeDevices with sensorTelephone set constructionsPressure thresholdResultant force

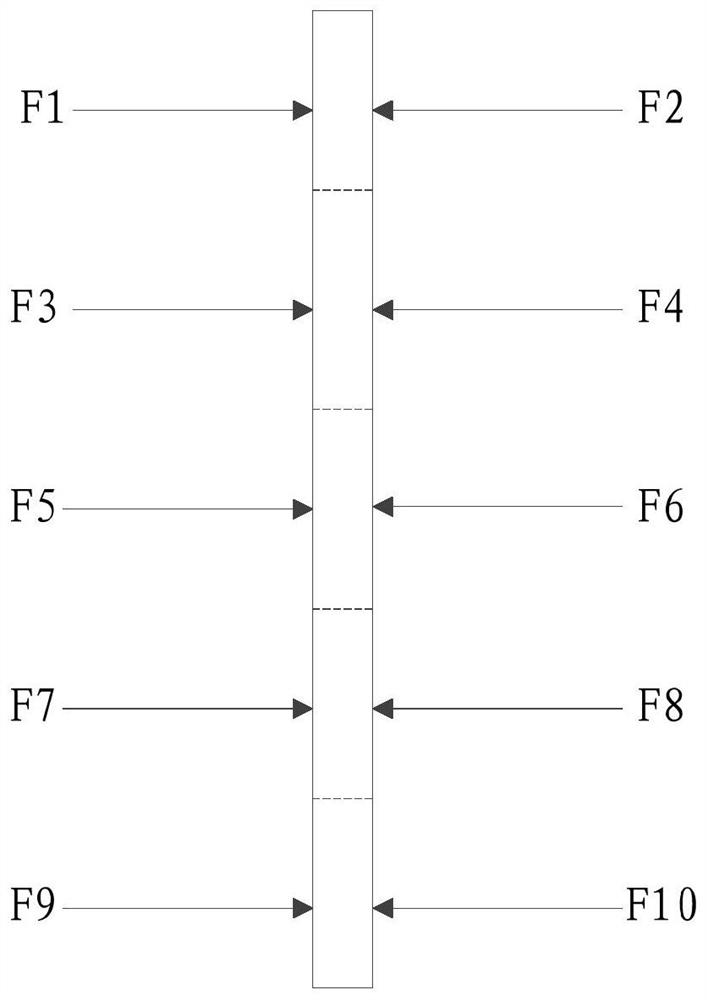

The invention provides a mobile terminal control method and a mobile terminal. The mobile terminal is provided with a flexible screen. The method comprises the steps of dividing the flexible screen into N deformed areas; detecting a resultant force value and a resultant force direction of a resultant force applied to each of N deformed areas; and if it is detected that the resultant force value ofthe resultant force applied to at least one target deformed area is greater than a preset pressure threshold, controlling the at least one target deformed area to bend toward the resultant force direction, wherein N is an integer greater than 1. In the prior art, when being pressed by an external force, the mobile terminal is easy to bend and deform and the screen is easy to crack. The mobile terminal control method and the mobile terminal solve the problem in the prior art.

Owner:VIVO MOBILE COMM CO LTD

Heat treatment method for aluminum alloy forcing shaping and aluminum alloy section for aviation

The invention discloses a heat treatment method for aluminum alloy forcing shaping and an aluminum alloy section for aviation, and relates to the technical field of aluminum alloy machining. The heattreatment method for aluminum alloy forcing shaping provided by the embodiment comprises the following steps that an aluminum alloy cast rod is extruded to obtain an extruded section; an aluminum alloy forcing shaping device is adopted to enable the extruded section to be fixed to be linear, then quenching treatment is carried out, and a quenched section is obtained; stretching treatment and bending treatment are carried out on the quenched section, and a shaped section is obtained; and aging treatment is carried out on the shaped section. According to the method, the problem that the aluminumalloy subjected to quenching can bend and deform can be effectively solved; and the prepared aluminum alloy section for the aviation is good in straightness and meets the requirement of the aviationuse.

Owner:SHANDONG NANSHAN ALUMINUM +1

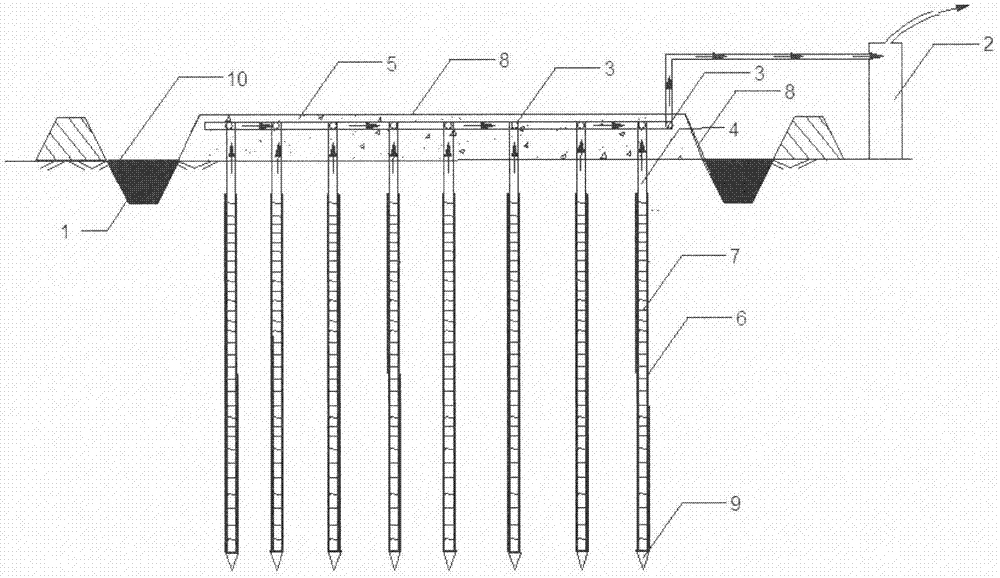

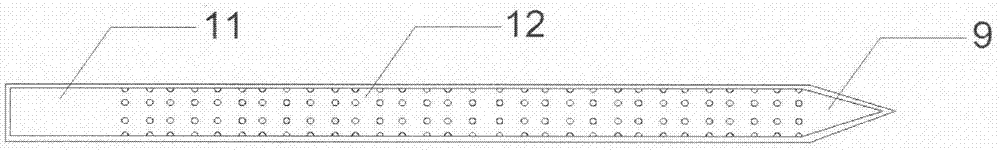

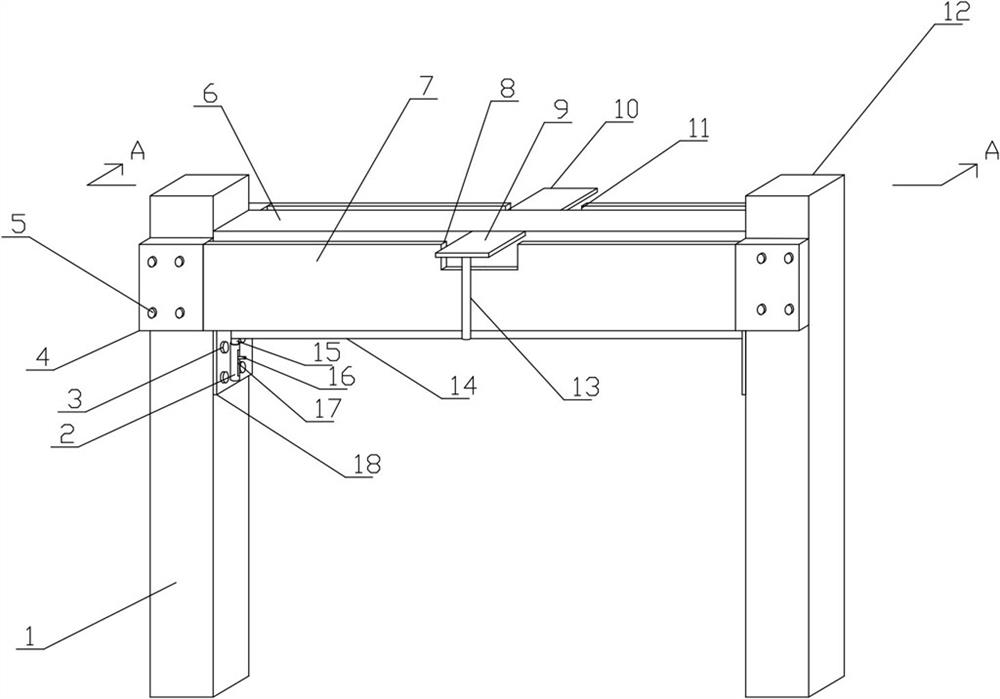

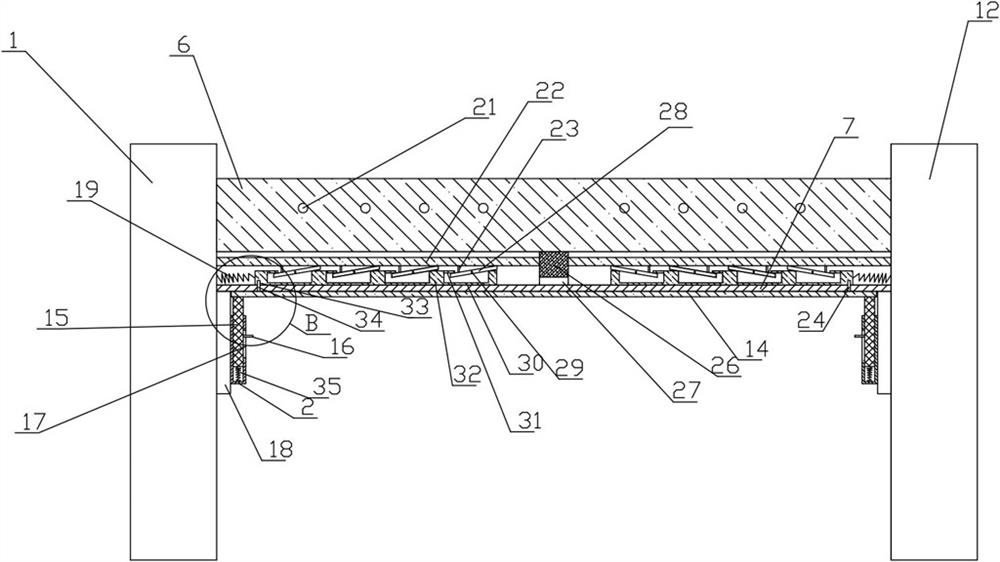

Method for treating foundation by vacuum prepressing method through positionable water permeable pipes

The invention discloses a method for treating a foundation by a vacuum prepressing method through positionable water permeable pipes, and belongs to the field of geotechnical engineering. The method comprises the following steps of (1) leveling a site; (2) paving a sand cushion; (3) performing measurement to determine hole positions of the water permeable pipes, and arranging the positionable water permeable pipes to a designed depth in an inserting manner; (4) laying vacuum pipes, and enabling each vacuum pipe to be connected with the corresponding positionable water permeable pipe; (5) laying another sand cushion and a sealing film; (6) enabling a vacuumizing device to be connected with the vacuum pipes; (7) turning on the vacuumizing device to pump out gas and water under the sealing film, and continuing vacuumizing until the vacuumizing device is unloaded; and (8) after the project is completed, recovering the positionable water permeable pipes. The method disclosed by the invention can be flexibly applied in a complex stratum situation, and the flow cross-section of a draining well is enlarged, so that the problems of clogging of plastic draining plates and 'mud columns' formed in the periphery of the plastic draining plates can be solved; and the water permeable pipes can be recovered and utilized, so that the engineering cost is reduced, and the treating effect of the foundation is greatly improved.

Owner:NANJING UNIV OF TECH

Steel structure for concrete reinforcement

PendingCN113585800ASolve bending deformationOffset stressBuilding repairsConcrete beamsClassical mechanics

The invention relates to a steel structure for concrete reinforcement. The steel structure comprises a concrete structure and a reinforced steel structure, wherein the reinforced steel structure comprises a bearing box, a top plate assembly, traction assemblies and a driving assembly; the bearing box comprises a box body and a fixing plate; the top plate assembly is arranged between the bottom surface inside the box body and the bottom surface of a concrete beam; the top plate assembly comprises a left top plate assembly and a right top plate assembly with the same structure and size; the traction assemblies comprise a left traction assembly and a right traction assembly with the same structure and size; the left traction assembly and the right traction assembly are respectively arranged at the upper part of the concrete beam above the left top plate assembly and the right top plate assembly and are in a bilateral symmetry state; the driving assembly comprises a sleeve, a bearing plate, a driving rod and a transverse plate; and the sleeve comprises a left sleeve and a right sleeve with the same structure and size. The steel structure solves the problem that the concrete beam can generate bending deformation in the process of bearing great load.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Thermal treatment technology for ball screws of machine tool

InactiveCN104831023ASolve bending deformationSolve cracking phenomenonFurnace typesHeat treatment furnacesQuenchingHot press

The invention provides a thermal treatment technology for ball screws of a machine tool. The thermal treatment technology comprises the steps of: step 1, putting the ball screws into a medium-frequency induction machine to carry out quenching heating; step 2, putting the ball screws into a hardening furnace with nitrate to carry out second quenching; step 3, putting the ball screws into forging equipment to carry out hot-pressing straightening treatment; step 4, putting the ball screws into a tempering box to carry out tempering treatment; step 5, checking the sizes of the ball screws; step 6, putting the ball screws into the tempering tank again to carry out second tempering treatment; step 7, putting the ball screws on the table top of a cleaning machine to clean the ball screws; step 8, putting the ball screws on a fixture body of the machine tool to carry out machining; and step 9, carrying out aging treatment on the machined ball screws at a room temperature or a relatively high temperature. The thermal treatment technology solves the phenomenon of bending deformation or cracking of long and thin ball screws. The ball screws treated by adopting the thermal treatment technology have good wear resistance, long service life and relatively good popularization and application values in mechanical industries.

Owner:HENGYANG FENGSHUN AXLE CO LTD

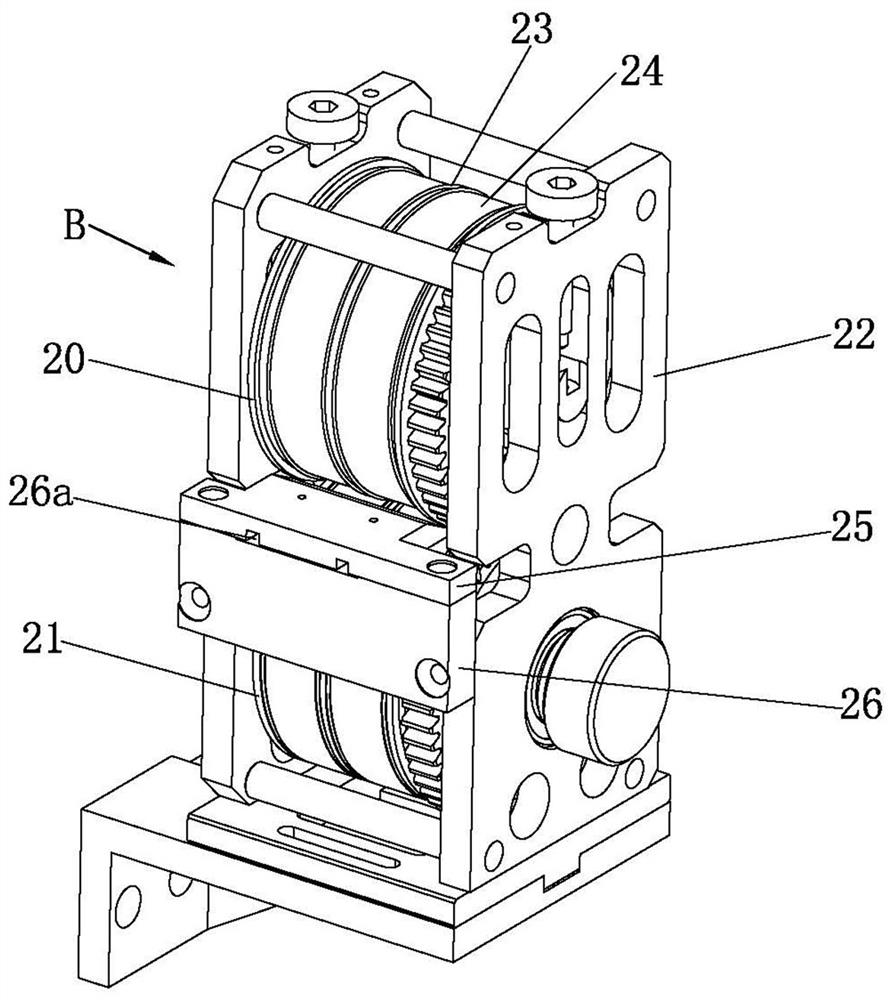

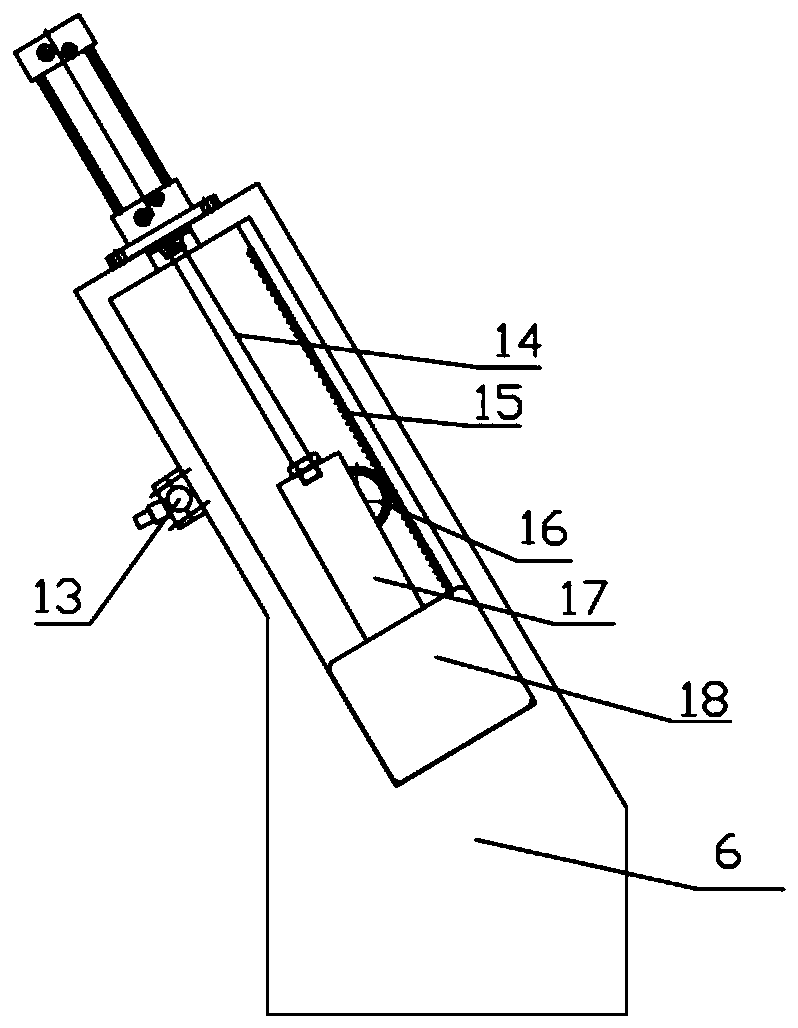

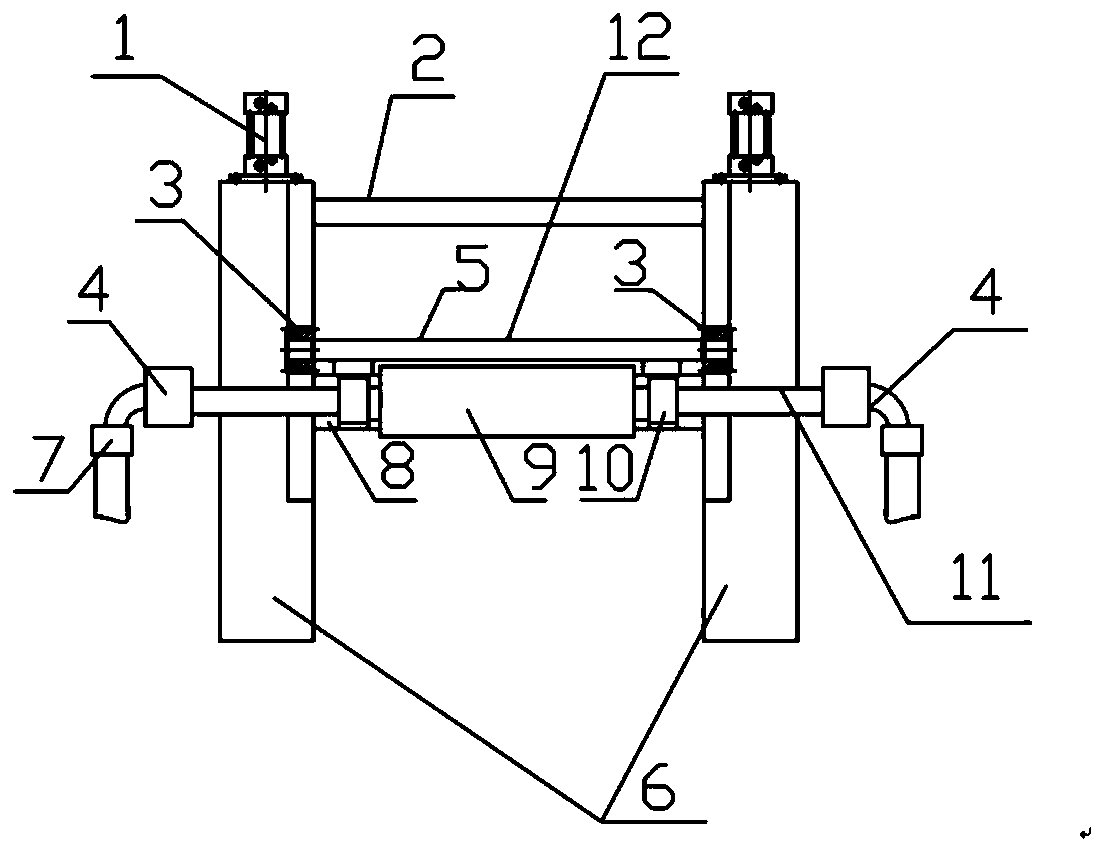

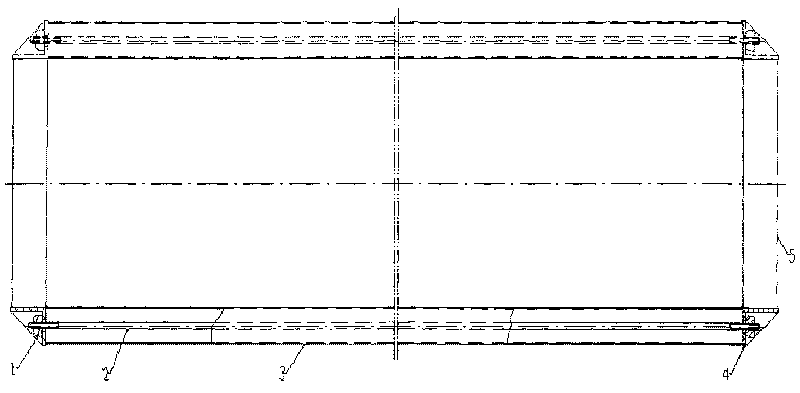

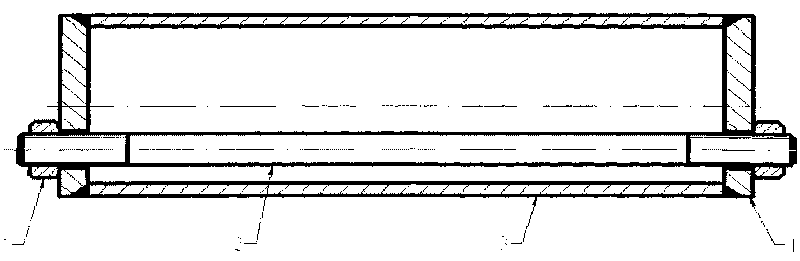

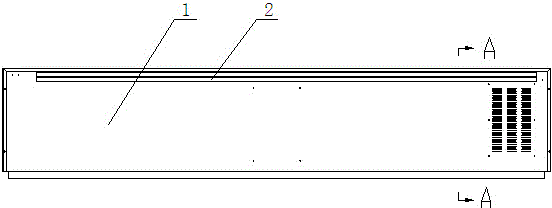

Rack bar reinforced structure of conveyer belt riveting machine

Owner:SHANGHAI GORO CONVEYOR EQUIP CO LTD

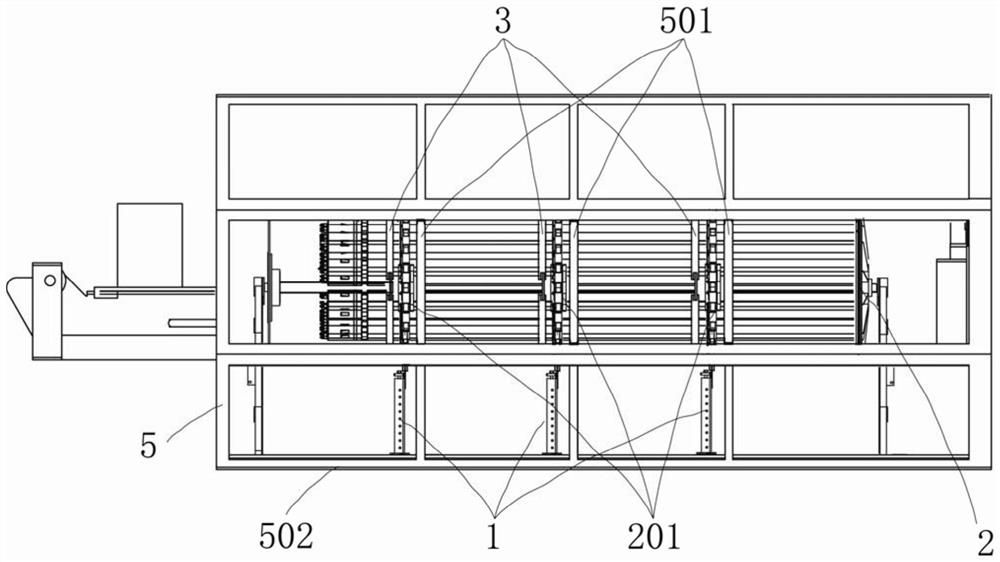

Paper inserting machine of card issuing motor iron core

ActiveCN112290766ASolve bending deformationSolve wrinkleApplying solid insulationMolding machineElectric machinery

The invention discloses a paper inserting machine of a card issuing motor iron core, the paper inserting machine comprises a paper folding mechanism, a paper feeding mechanism, a forming mechanism, apaper cutting mechanism and a paper pushing mechanism, wherein the paper feeding mechanism comprises: a first loosening and clamping mechanism; and a first driving mechanism used for driving the firstloosening and clamping mechanism to move back and forth between a first position and a second position; when the first loosening and clamping mechanism is located at the first position, the first loosening and clamping mechanism clamps insulation paper, and when the first driving mechanism drives the first loosening and clamping mechanism to move from the first position to the second position, the first loosening and clamping mechanism applies a pulling force to the insulation paper located on the upstream of the loosening and clamping mechanism, so that the insulation paper with creases moves towards the forming mechanism, and meanwhile, after the insulation paper located on the downstream of the first loosening and clamping mechanism is conveyed into the forming mechanism, the first loosening and clamping mechanism loosens the insulation paper and returns to the first position under driving of the first driving mechanism. The paper inserting machine has the advantage of preventing the insulation paper from deforming or wrinkling when the insulation paper is pushed.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

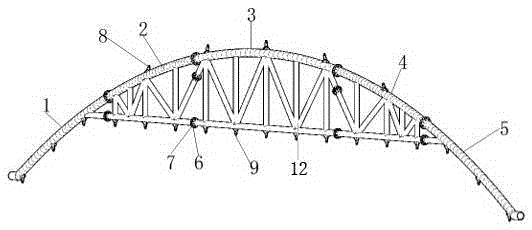

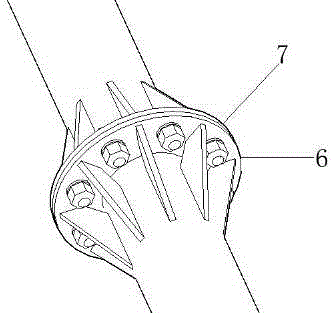

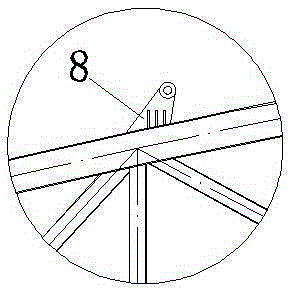

Arch-shaped hoisting jig for ultralong profiled metal roof board

ActiveCN106677447AGuaranteed Out-of-Plane StiffnessSolve severe deformationRoof toolsLower gradeLow graded

The invention provides an arch-shaped hoisting jig for an ultralong profiled metal roof board. The arch-shaped hoisting jig for the ultralong profiled metal roof board comprises five frame bodies which are all formed by welding a plurality of steel pipes in a communicating mode; the positions of the steel pipes between the spaced frame bodies correspond to one another; flange connection end boards are installed at openings of the steel pipes; the flange connection end boards at the corresponding positions are connected through bolts; upper-grade lifting lug boards are arranged on the steel pipes at the top ends; lower-grade lifting lug boards are arranged on the steel pipes at the bottom ends of the hoisting jig; the upper-grade lifting lug boards are connected with upper-grade sheep-horn slide hooks; and the lower-grade lifting lug boards are connected with lower-grade sheep-horn slide hooks. Hoisting points are arranged on the above structures evenly, hoisting loads of the roof board are dispersed, the problem that the ultralong profiled metal roof board cannot be hoisted or as the ultralong profiled metal roof board is too long during hoisting, out-of-plane stiffness is not sufficient and the ultralong profiled metal roof board deforms severely or is crushed is solved effectively, and the problems of bending deformation, edge extrusion deformation, warping and the like in the vertical transportation process of the ultralong metal roof board are well solved.

Owner:广东精工钢结构有限公司

A kind of vacuum die casting equipment for aluminum alloy manufacturing

The invention discloses a vacuum die-casting device for aluminum alloy manufacturing, which comprises a vacuum die-casting device, and a discharge port is arranged inside the vacuum die-casting device. In the present invention, the vacuum die casting equipment, the discharge port, the material receiving mechanism, the collection frame, the storage groove, the first fixed block, the second fixed block, the buffer plate, the first buffer pad, the reset mechanism, the third fixed block, the first fixed block, the first fixed block, the first fixed block, the first fixed block, the first fixed block, the first fixed Fixed rod, roller, tension spring, buffer mechanism, buffer belt, fixed ring, buffer block, second fixed rod, slider, fixed shell, first spring, limit block, sealing ring, second buffer pad, third buffer The use of the pad, the buffer cover and the second spring solves the problem that the workpiece will fall down after the die casting of the existing aluminum alloy vacuum die casting equipment during use. Because the aluminum alloy material is soft, it is easy to cause bending and deformation of the finished product. The vacuum die-casting equipment used for aluminum alloy manufacturing has the advantage of buffering aluminum alloy workpieces and meets the needs of the market.

Owner:ANHUI GAODE ALUMINUM

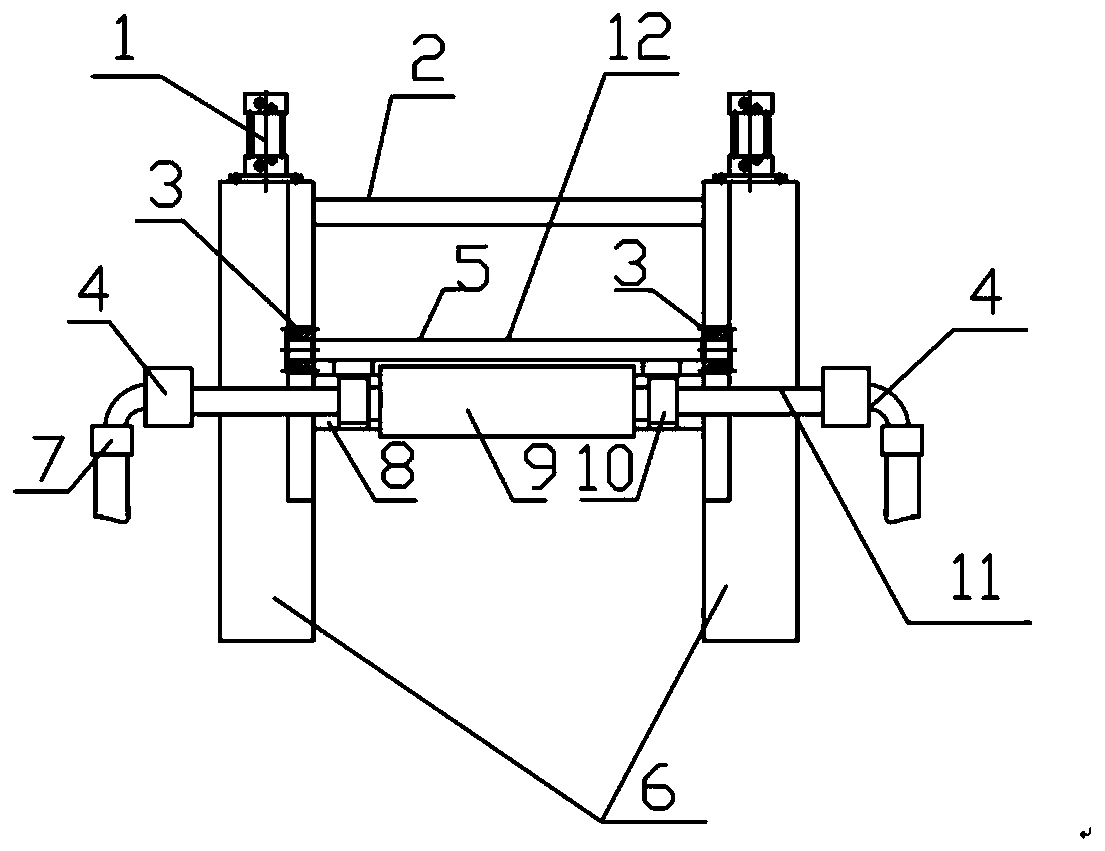

Rolling deoiling device

PendingCN111167867AReasonable structural designSolve bending deformationWork cleaning devicesMetal rolling arrangementsEngineeringStructural engineering

The invention discloses a rolling deoiling device. The rolling deoiling device comprises a pair of stands, a deoiling mechanism and lifting cylinders, wherein the stands are used for bearing and installing the deoiling mechanism and the lifting cylinders; the deoiling mechanism comprises an oil suction roller, a pair of bearing structures, bottom plates and slide bases, the end portions of the oilsuction roller are arranged on the bottom plates on the corresponding sides through the bearing structures, and the bottom plates are arranged on the slide bases on the corresponding sides; the lifting cylinders are fixed to the stands, and piston rods of the lifting cylinders are connected with the slide bases. By means of the rolling deoiling device, the problems that an oil suction roller is deformed and bent, and the ascending and descending motions of the two sides of the oil suction roller are non-synchronous, it is effectively ensured that the oil suction roller stably runs for a longperiod, and the efficiency and effect of adsorbing remaining lubricating oil / emulsions are improved. Through the internal negative-pressure adsorption, the oil suction roller can further improve the deoiling effect.

Owner:MAANSHAN IRON & STEEL CO LTD

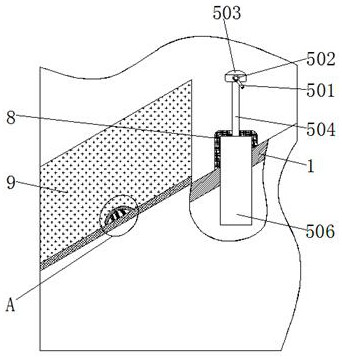

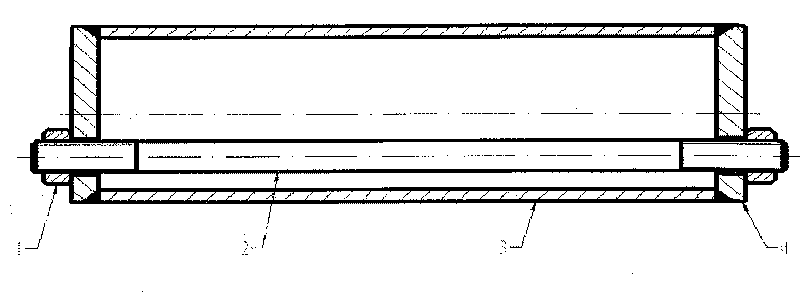

Method for correcting bending deformation of thin and long thin walled pipe under gravity force

ActiveCN101363567BSolve bending deformationSimple structureStands/trestlesEngineeringGravitational force

The invention relates to a method for correcting the kickdown distortion of slender thin-wall pipes owing to gravity. The invention comprises a slender thin-wall rectangular pipe; at least one rigid round bar, the two ends of which is provide with screw threads, runs through near the bottom pipe wall in an inner cavity of the slender thin-wall rectangular pipe along the length direction of the pipe. The rigid round bar passes through the closing flange clamp hole which is fixedly connected with the two ends of the slender thin-wall rectangular pipe and is corrected by fastening the nuts at thetwo ends. The invention can overcome the kickdown of the slender thin-wall pipes by the following steps: the rigid round bar is tightly strained by fastening the screw threads at the two ends of theslender thin-wall rectangular pipe, which forces the middle part of the slender thin-wall rectangular pipe to bend upwards; the bending degree balancing out the downwards bending degree, thereby correcting the kickdown distortion of slender thin-wall pipes owing to the gravity.

Owner:AVIC CHENGFEI COMML AIRCRAFT COMPANY

Back door of automated matching electrical cabinet

InactiveCN106033868ASolve bending deformationReduce wasteSubstation/switching arrangement casingsHigh intensityBack door

A back door of an automated matching electrical cabinet relates to the field of electrical equipment, especially to fittings of the automated matching electrical cabinet. The back door comprises a door body and a reinforcing rib arranged in the inner side of the door body in an integrated manner. According to the above design, the bending size of the reinforcing rib after integrated folding is accurate and errorless, the problem that the door body deforms due to bending is solved, the back door is made beautiful, waste of board material is reduced, and the back door further has advantages including simple structure, convenient manufacture, high intensity and long service life.

Owner:扬州市庆源电气成套设备有限公司

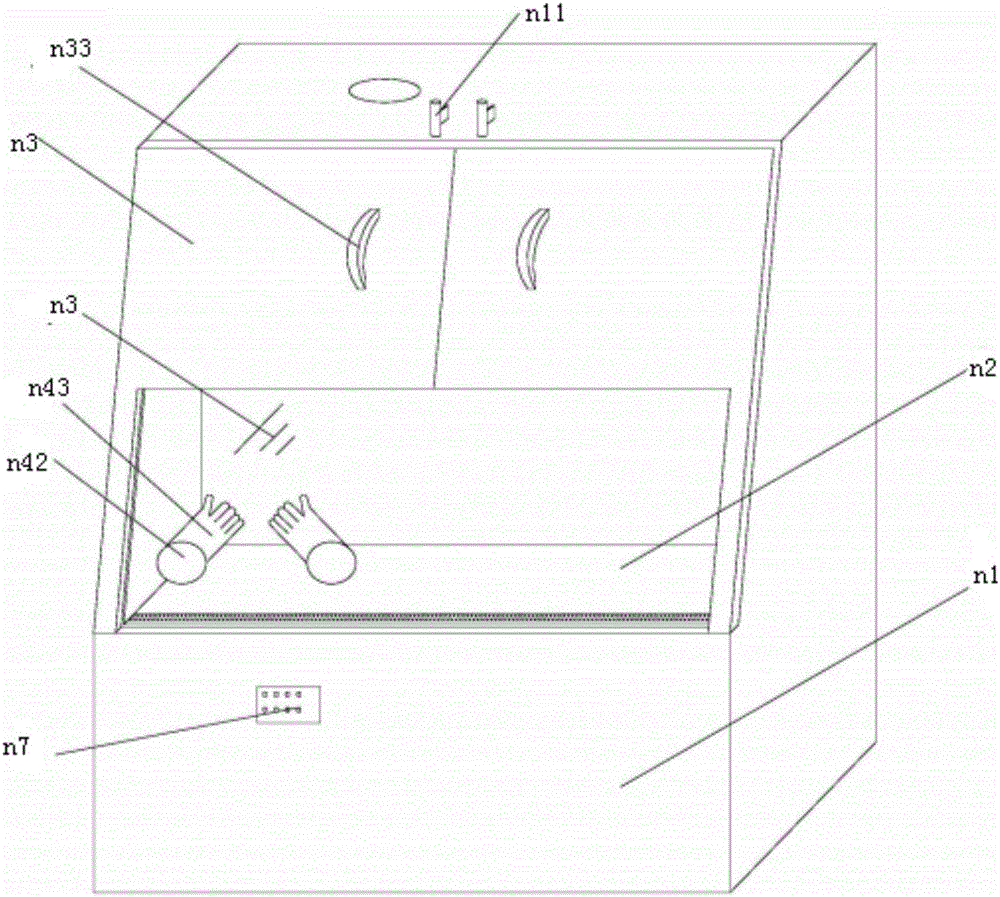

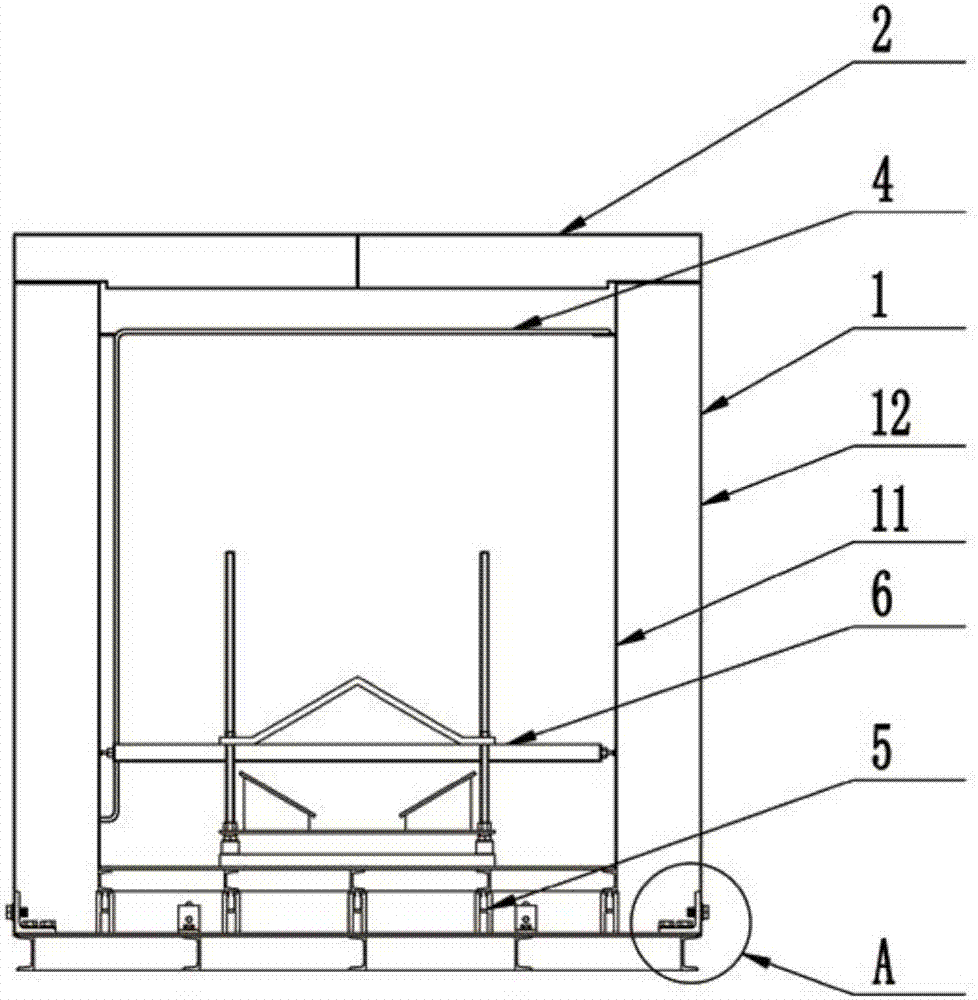

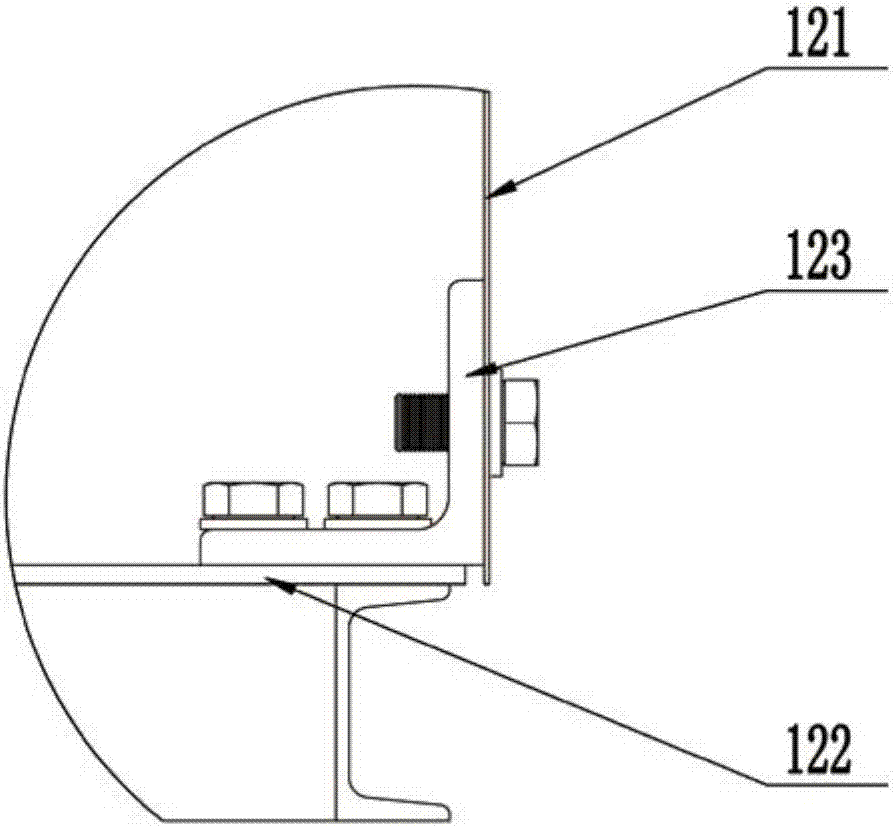

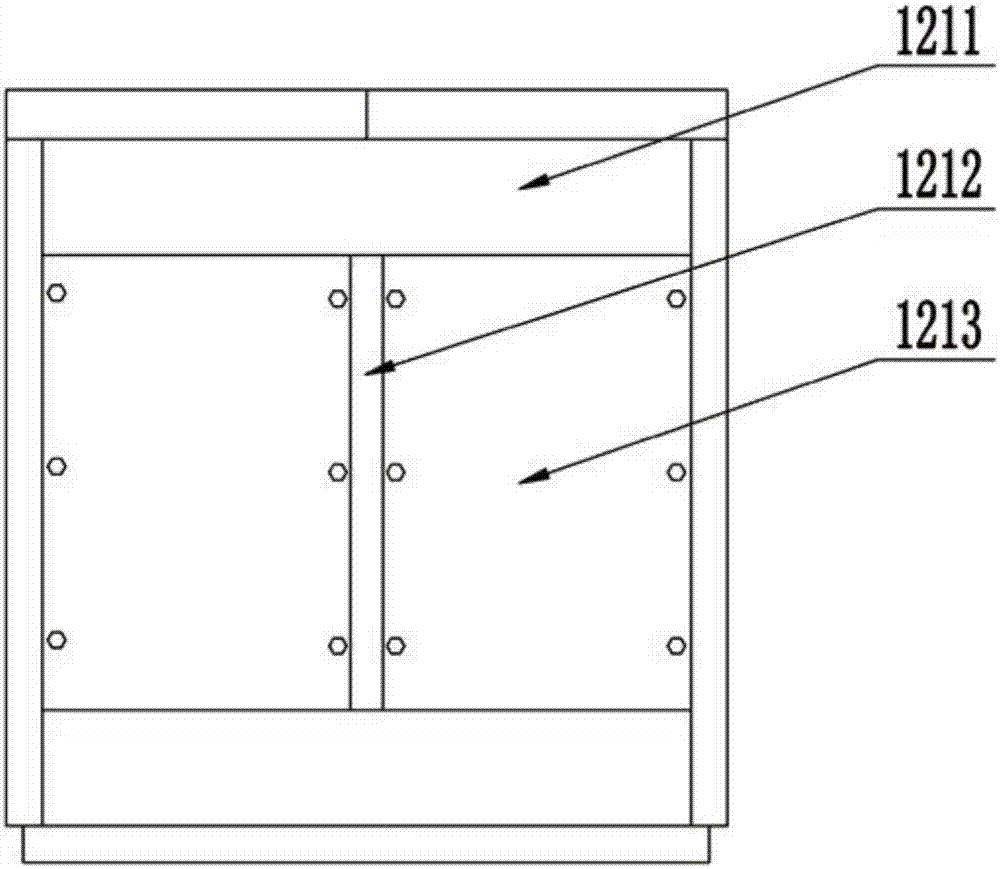

Low-temperature testing tank

PendingCN107063656ASolve bending deformationGuaranteed closureMachine part testingEngineeringMechanical engineering

The invention discloses a low-temperature testing tank, which comprises a box body with an opening facing upward and a heat preservation upper cover arranged at the upper end of the box body, wherein the box body comprises an inner container and an outer container, the inner container is sheathed in the outer container, and the part between the inner container and the outer container is filled with a foam material. The low-temperature testing tank is characterized in that the outer container comprises a side plate, a bottom plate and an L-shaped support base, one end of the L-shaped support base is fixedly connected with the bottom plate, the other end of the L-shaped support base is provided with a sliding slot extending along the vertical direction and is movably connected with the side plate through a bolt penetrating through the sliding slot, and the side plate can move up and down relative to the bottom plate. The testing tank can solve a problem bending deformation, which is caused by a low temperature, of the outer container, so that the sealing performance of the testing tank is ensured.

Owner:VACREE TECH

A mobile terminal control method and mobile terminal

ActiveCN107659711BCurved automaticAvoid situations that are prone to deformation or even ruptureDevices with sensorTelephone set constructionsSimulationMechanical engineering

The present invention provides a mobile terminal control method and a mobile terminal. The mobile terminal is provided with a flexible screen. The method includes: dividing the flexible screen into N deformation areas; detecting the impact of each deformation area in the N deformation areas; The resultant force value and resultant force direction of the resultant force; if it is detected that there is at least one target deformation zone whose resultant force value is greater than the preset pressure threshold, then control the at least one target deformation zone to bend in the direction of the resultant force; wherein, N is an integer greater than 1. The embodiments of the present invention solve the problems existing in the prior art that when the mobile terminal is squeezed by an external force, the mobile terminal is likely to be bent and deformed and the screen is broken.

Owner:VIVO MOBILE COMM CO LTD

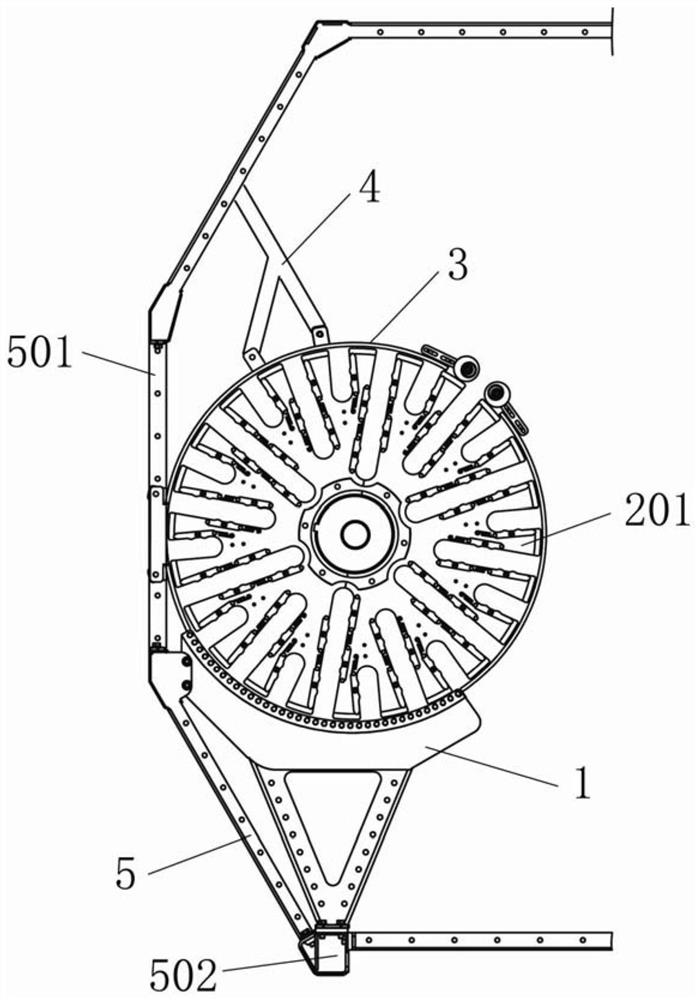

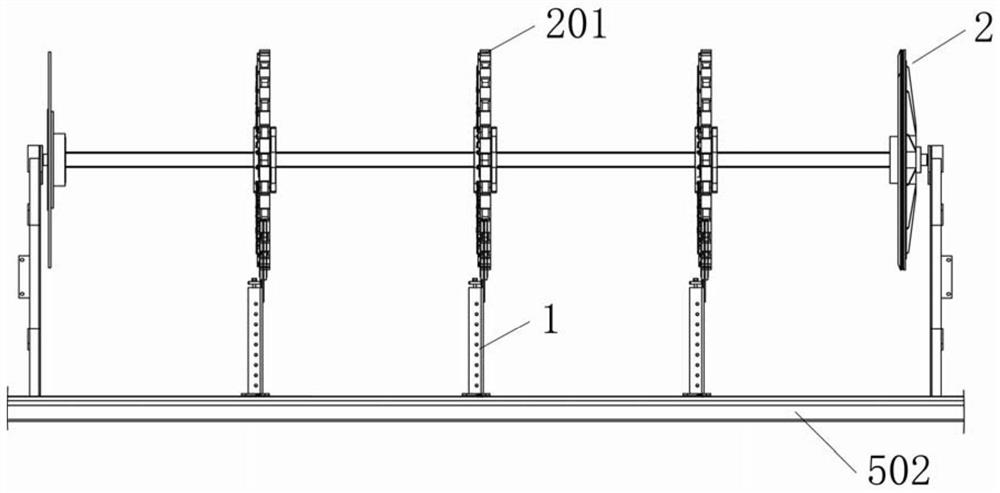

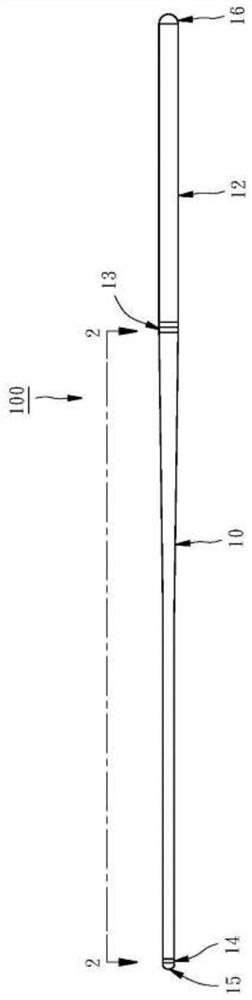

The arc-shaped rotating support mechanism of the drill pipe magazine of the subsea drilling rig stored in a horizontal manner

ActiveCN110306941BSolve bending deformationImprove protectionDrilling rodsDrilling casingsSubmarineSupport surface

The invention discloses an arc-shaped rotating and supporting mechanism of a drill pipe library of a seabed drilling rig stored in a horizontal lying mode. The arc-shaped rotating and supporting mechanism comprises a frame, n circular separating discs with pipe storage grooves and n arc-shaped supporting frames, wherein n is an integer larger than or equal to 2, and the n arc-shaped supporting frames are fixedly mounted on a back sliding rail of the frame and are arranged parallelly and coaxially; the n separating discs are supported on the n arc-shaped support frames correspondingly, and thearc-shaped support surfaces of the arc-shaped support frames are in contact with the arc surfaces of the edges of the corresponding separating discs; and the separating discs are used for forming a rotatable auxiliary support for the whole drill pipe library and drill pipes stored thereon. According to the arc-shaped rotating and supporting mechanism, the arc-shaped support frames are used for rotating and supporting the circular separating discs with the pipe storage grooves in the drill pipe library, so that the problems that the rotation cannot be realized due to the bending deformation easily caused by the fact that the drill pipe library is large in weight and long in length, and a main shaft and bearings at two ends of the main shaft of the drill pipe library are small are solved; and the arc-shaped rotating and supporting mechanism has the advantages of being simple and compact in structure, convenient to control, low in cost and the like.

Owner:HUNAN SEA BULL GEOLOGICAL EXPLORATION CO LTD

Billiard cue forelimb capable of reducing batting deflection curvature

The invention discloses a billiard cue forelimb capable of reducing batting deflection curvature, which comprises a forelimb body, the forelimb body is provided with a straight section and a push-pull section, the straight section has the same first outer diameter, and the outer diameter of the push-pull section is gradually increased from the tail end of the straight section to the bottom end of the forelimb body. The forelimb body comprises a wooden rod body and a fiber reinforced plastic (FRP) outer layer with a preset thickness. The wooden rod body comprises a shaft hole, and the shaft hole has a preset depth and a preset inner diameter. Therefore, the front limb of the billiard cue not only can reduce the deflection curvature during ball hitting, but also can solve the problems that wood materials are affected with damp, bent and deformed and are sunken due to collision.

Owner:CUETEC CO LTD

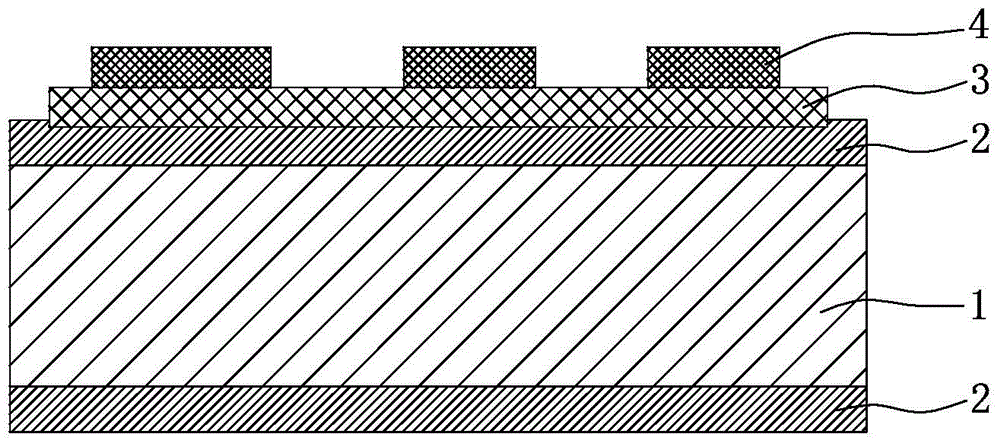

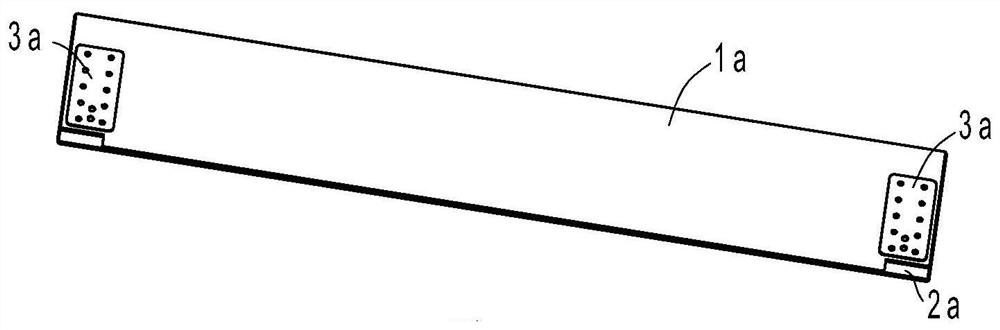

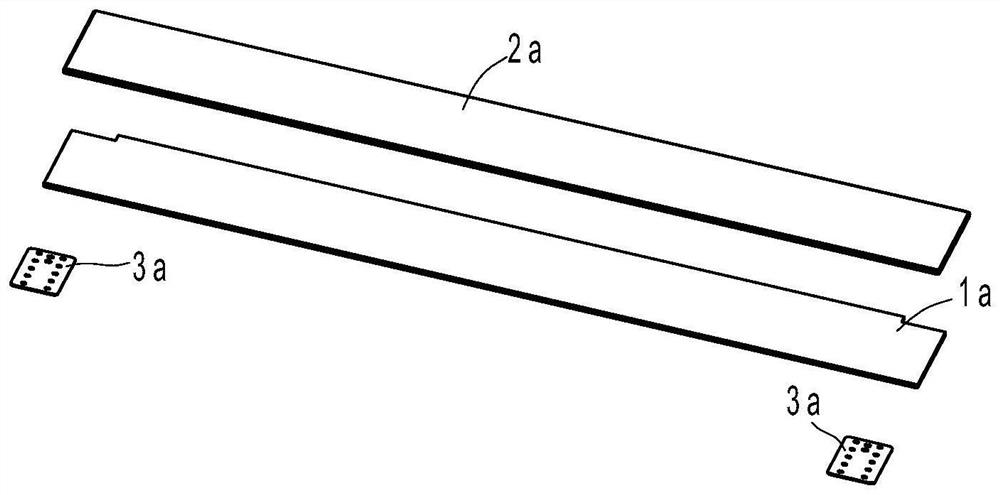

A positive electrode oxide film printed substrate for a power module

ActiveCN103716980BAvoid bending deformationAvoid degradation of heat dissipation characteristicsPrinted circuit detailsSemiconductor/solid-state device detailsManufacturing cost reductionDBc

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

Decorative panel assembly bonding method

ActiveCN108999852BSolve the deformationImprove surface qualityDomestic stoves or rangesLighting and heating apparatusStructural engineeringWorkbench

The invention discloses a decorative board assembly bonding tool. The tool is characterized in that the tool includes a worktable (1), positioning frames (5), first stop blocks (51), second stop blocks (52), down-pressing air cylinders (2) and a down-pressing plate (3); the vertical directions of the positioning frames (5) have elasticity, and the inner rings of the positioning frames (5) fit a glass face plate (1a); the inner sides of the positioning frames (5) have supporting parts (57) used for supporting the glass face plate (1a); the down-pressing air cylinders (2) have vertically downward power output ends; the power output ends are provided with the down-pressing plate (3) whose appearance accords with a decorative plate (2a); and the down-pressing plate (3) is located above the worktable (1). A decorative board assembly bonding method is also disclosed. Compared with the prior art, the advantages of the tool and the method are that accurate positioning can be guaranteed by adopting the elastic positioning frames to combine the first stop blocks and the second stop blocks; and through the bonding of three parts, dimensional stability can be solved, the surface quality of decorative boards can be improved, labor productivity can be enhanced, and production costs can be reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com