Patents

Literature

122results about How to "Offset stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

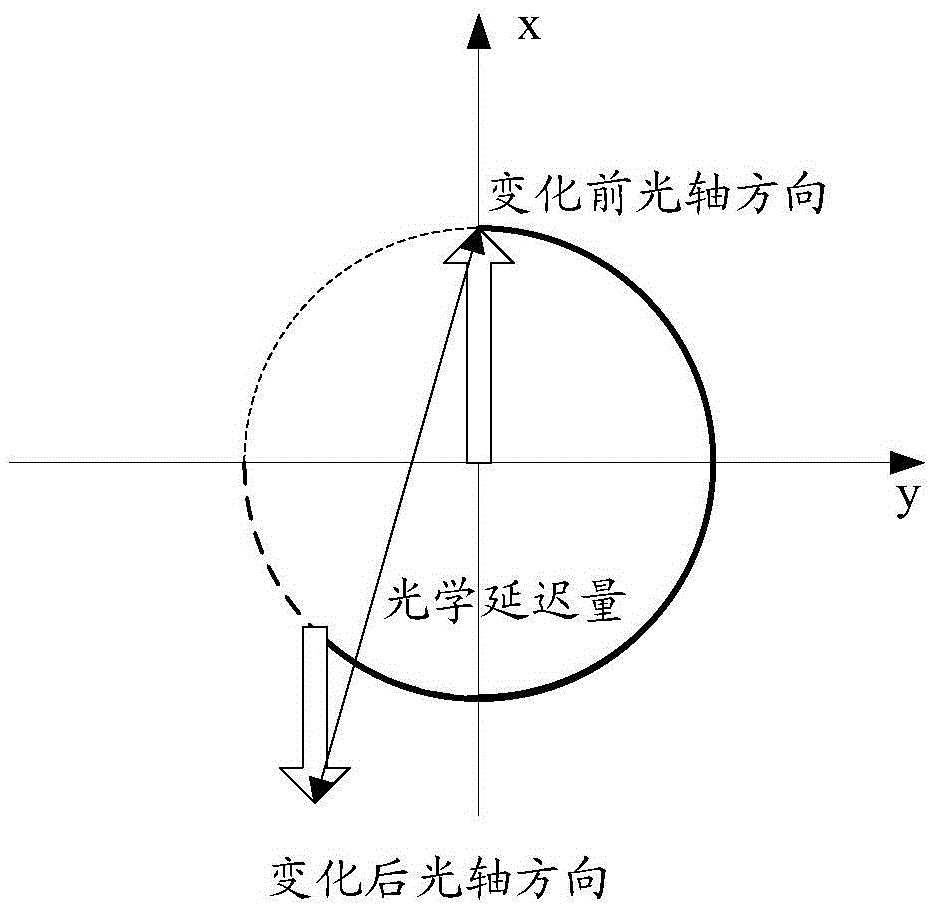

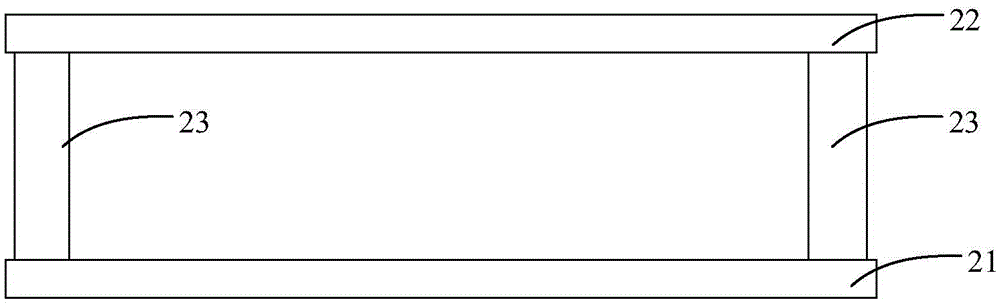

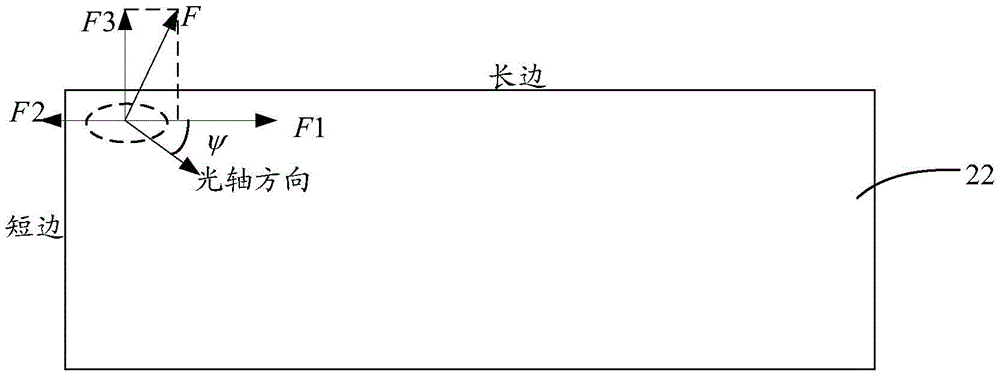

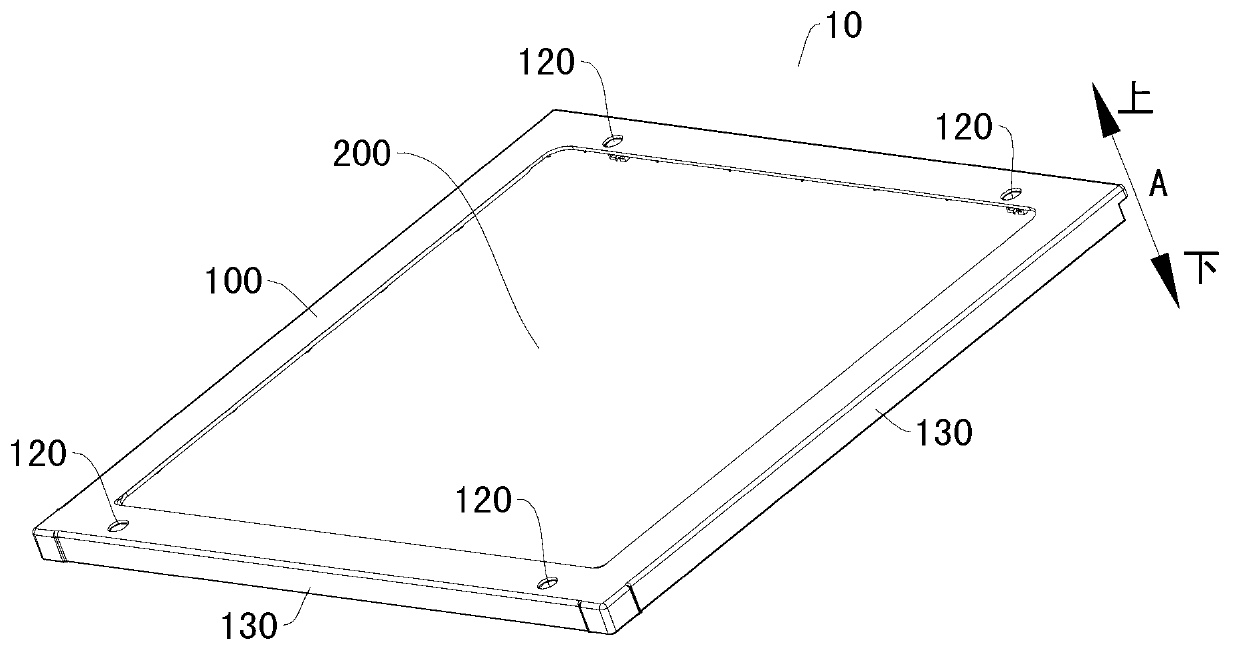

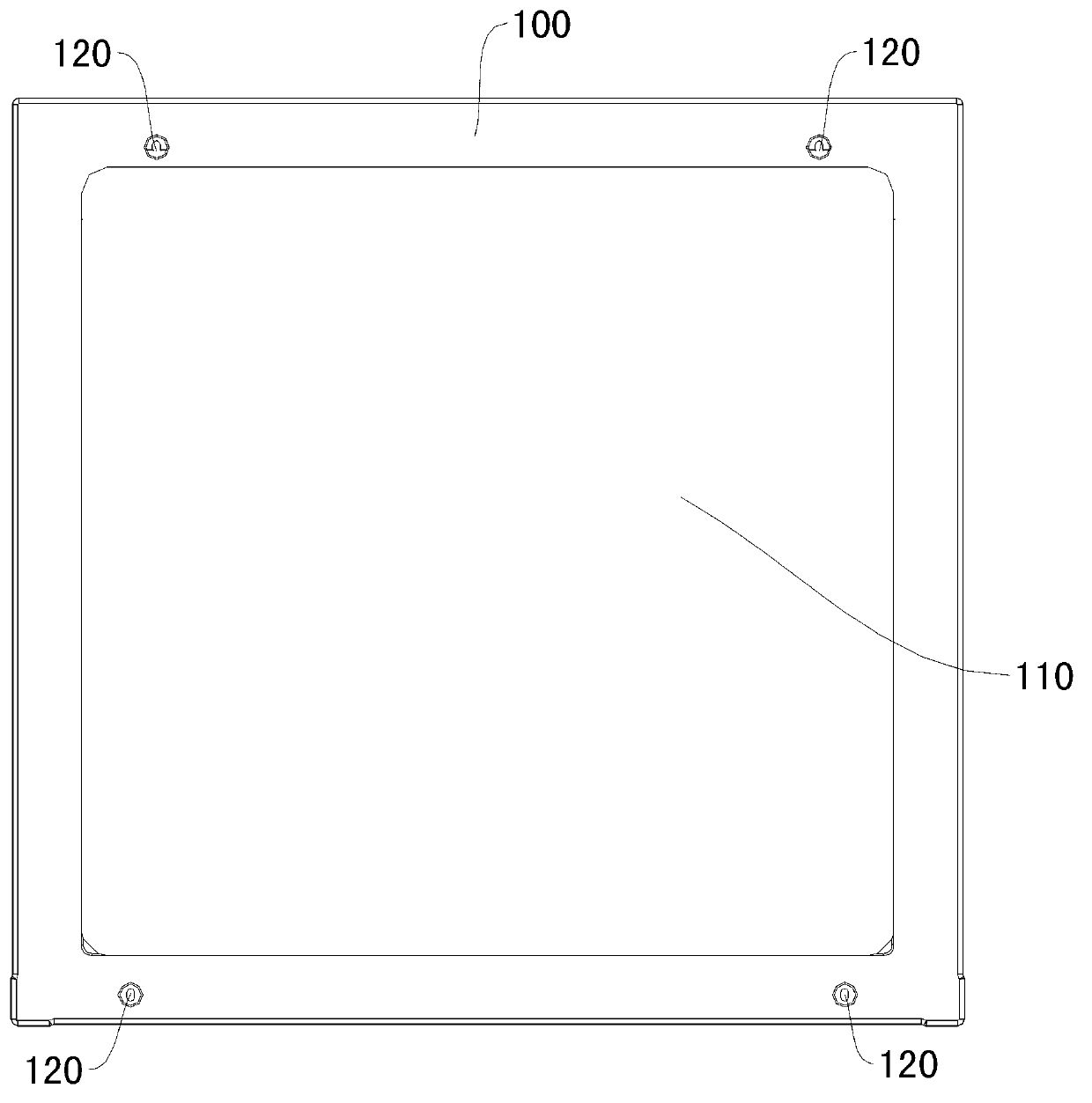

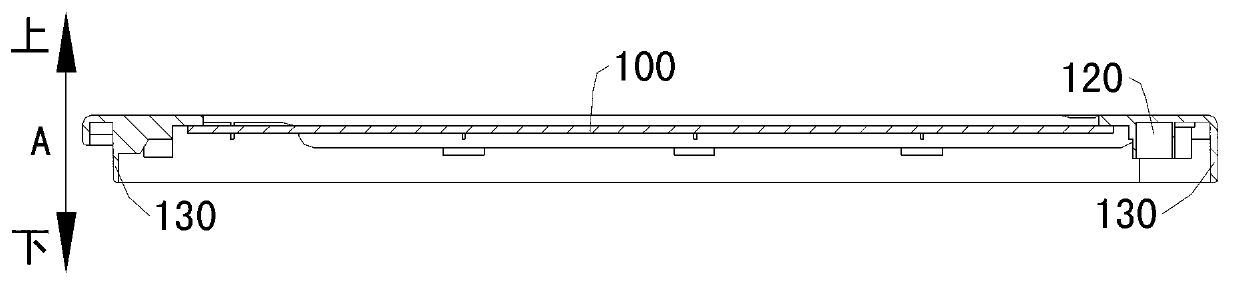

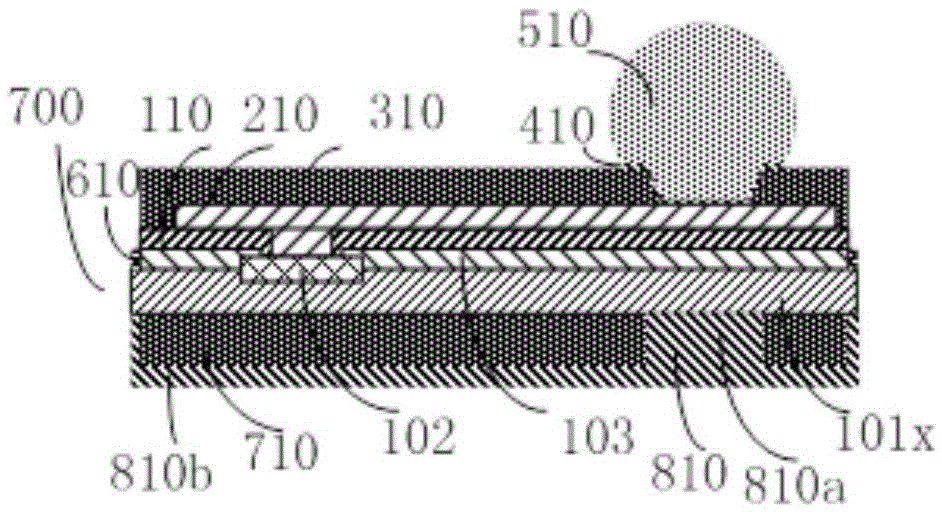

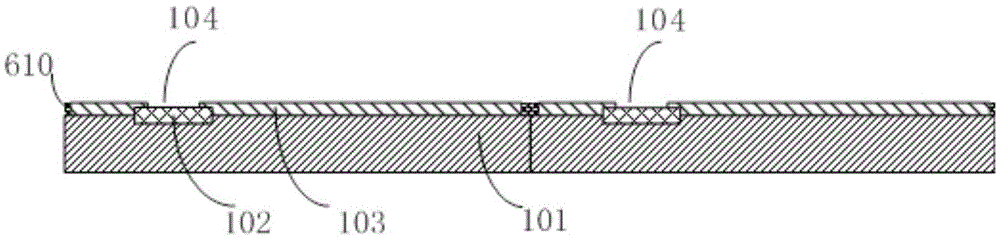

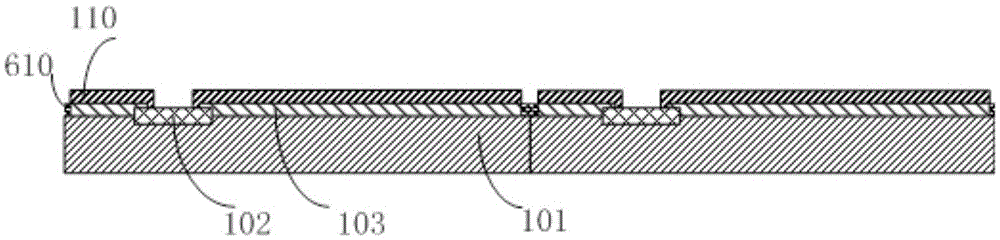

Curved surface display panel and display device

ActiveCN105629589AImprove picture display qualityReduce deflectionNon-linear opticsSurface displayOptical axis

The embodiment of the invention discloses a curved surface display panel and a display device. The curved surface display panel comprises an array substrate, an opposite substrate and a plurality of floating spacers positioned in a non-display region; a height of each floating spacer is smaller than a box thickness between the array substrate and the opposite substrate; at a position of at least one floating spacer at side edges adjacent to bent side edges of the array substrate and the opposite substrate, a frame sealing glue structure positioned between the array substrate and the opposite substrate is cushioned; the sum of a thickness of the frame sealing glue structure and a thickness of the floating spacer in contact with the frame sealing glue structure is equal to the box thickness. Therefore, a stress of the array substrate and the opposite substrate, which is generated due to resistance to acting forces of the floating spacers and the frame sealing glue structure, is increased, and part of a stress generated due to bending can be balanced out, so that a combined stress is reduced and deflection of an optical axis is reduced, thereby reducing dark-state light leakage and improving image display quantity of the curved surface display panel.

Owner:BOE TECH GRP CO LTD

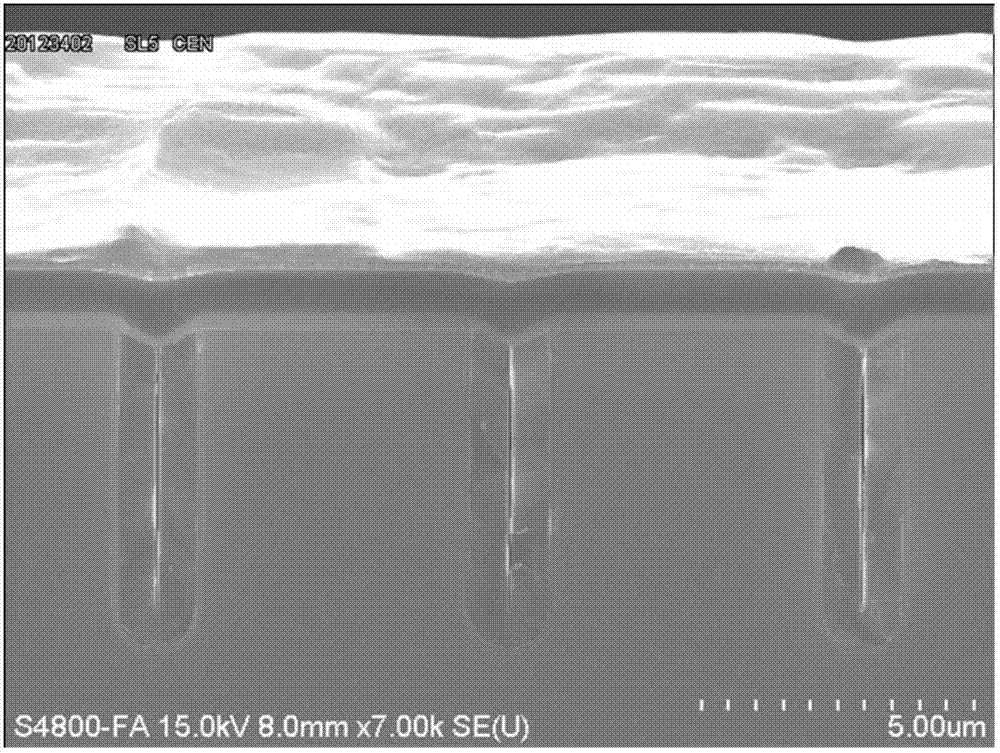

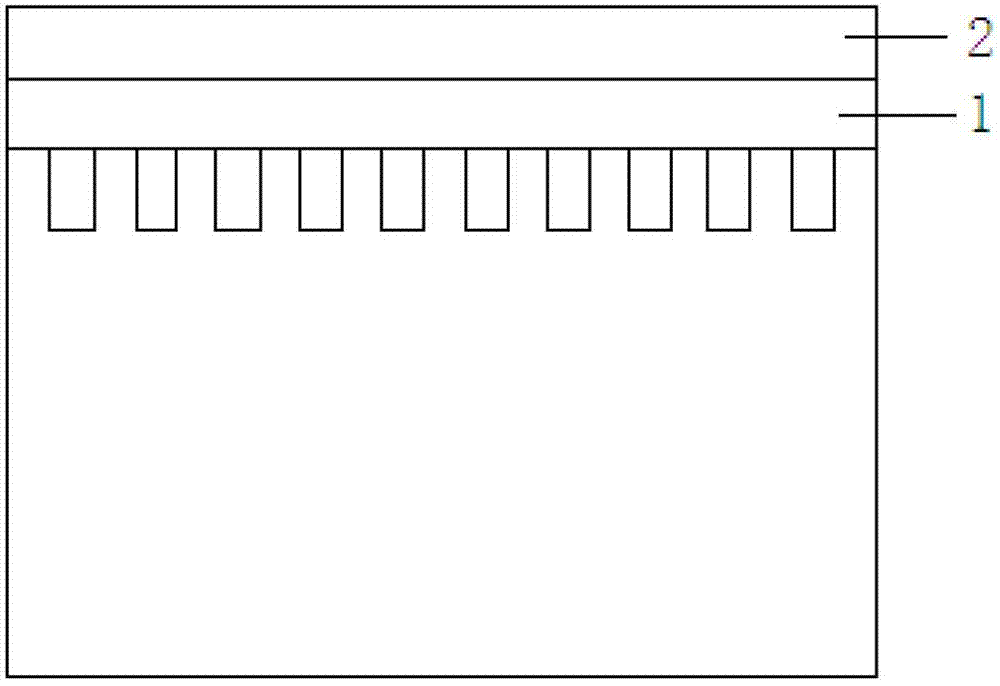

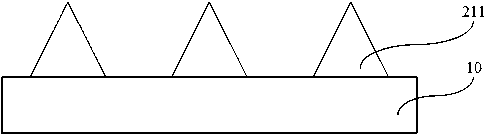

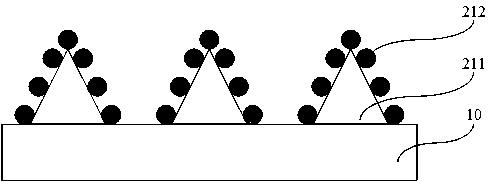

Preparation method of low-stress gallium nitride epitaxial layer

The invention relates to a preparation method of a low-stress gallium nitride epitaxial layer. The preparation method includes: etching square or round patterns on the front or the back of a substrate; corroding the etched substrate layer with sulfuric acid or sulfuric acid / phosphoric acid mixed solution, cleaning with deionized water, and growing the gallium nitride epitaxial layer on the processed front of the substrate by an MOCVD (metal organic chemical vapor deposition) method; wherein etching depth of the patterns is 1-100 micrometers, and space between each two patterns is 1-10 micrometers. By the preparation method, low stress is borne by the gallium nitride epitaxial layer when the gallium nitride epitaxial layer grows on the processed substrate, production process is simplified, production stability is improved, piezoelectric polarization of active area of a light-emitting diode is avoided, and light-emitting efficiency of the light-emitting diode is improved. The light-emitting efficiency of the light-emitting diode made by the low-stress gallium nitride epitaxial layer is improved by 10%.

Owner:吴江市民福电缆附件厂

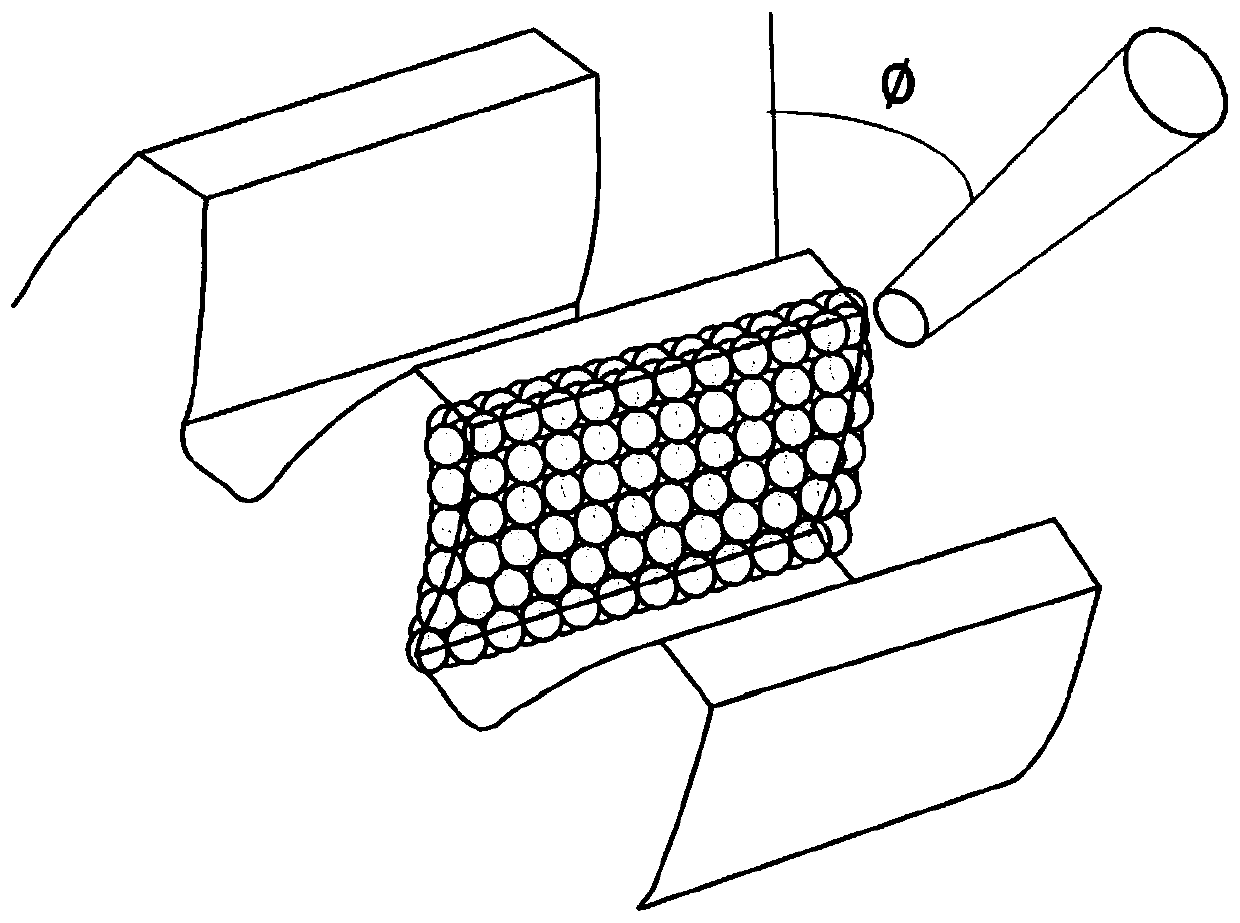

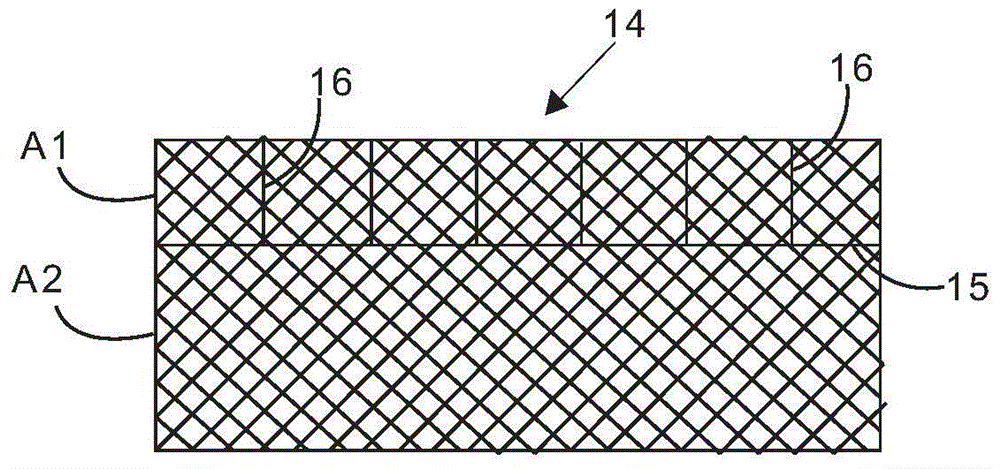

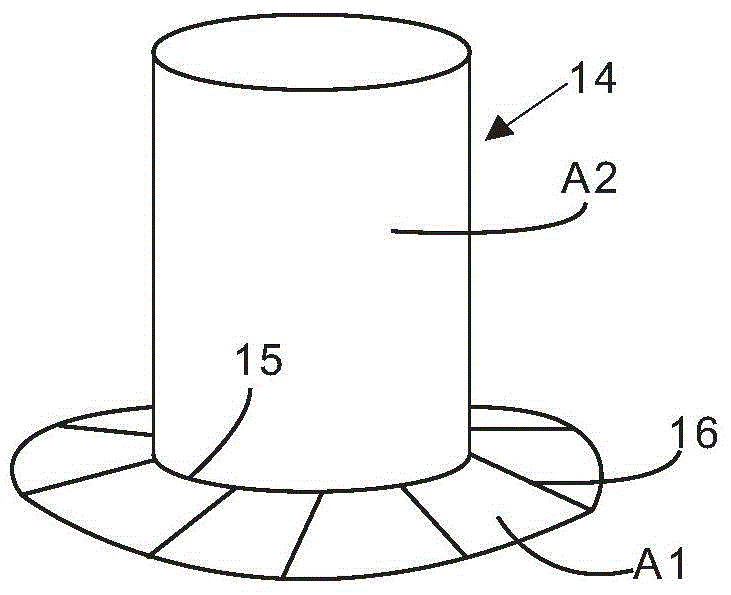

Method for manufacturing pre-deformation line diamond line saw through powder metallurgy

InactiveCN102218537AImprove gripExtended service lifeMetal sawing toolsStone-like material working toolsBLENDER/MIXERPre deformation

The invention provides a method for manufacturing a pre-deformation line diamond line saw through powder metallurgy, comprising the following steps: basic line manufacturing: selecting metal wires, stranding at least two metal wires into a line, and deforming the stranded line by a deformer to obtain a pre-deformation base line; powder preparation: weighing metal powder, a binder and diamond by mass percent, and adding the mixture into a blender mixer to evenly mixing; line blank manufacturing: putting the base line and powder into a mould, and taking the pre-deformation base line as a center to prepare a line blank by using a forming technology; and line saw manufacturing: putting the line blank to a sintering furnace for sintering, and cooling with the furnace to obtain the line saw. The manufacturing method provided by the invention has the advantages of simple process, low cost and high production efficiency. The produced line saw has excellent performance, high strength, good flexibility, high hold to diamonds, stable cutting performance, good chip discharging performance and long service life, and is not easy to crack.

Owner:长沙和谦新材料科技有限公司

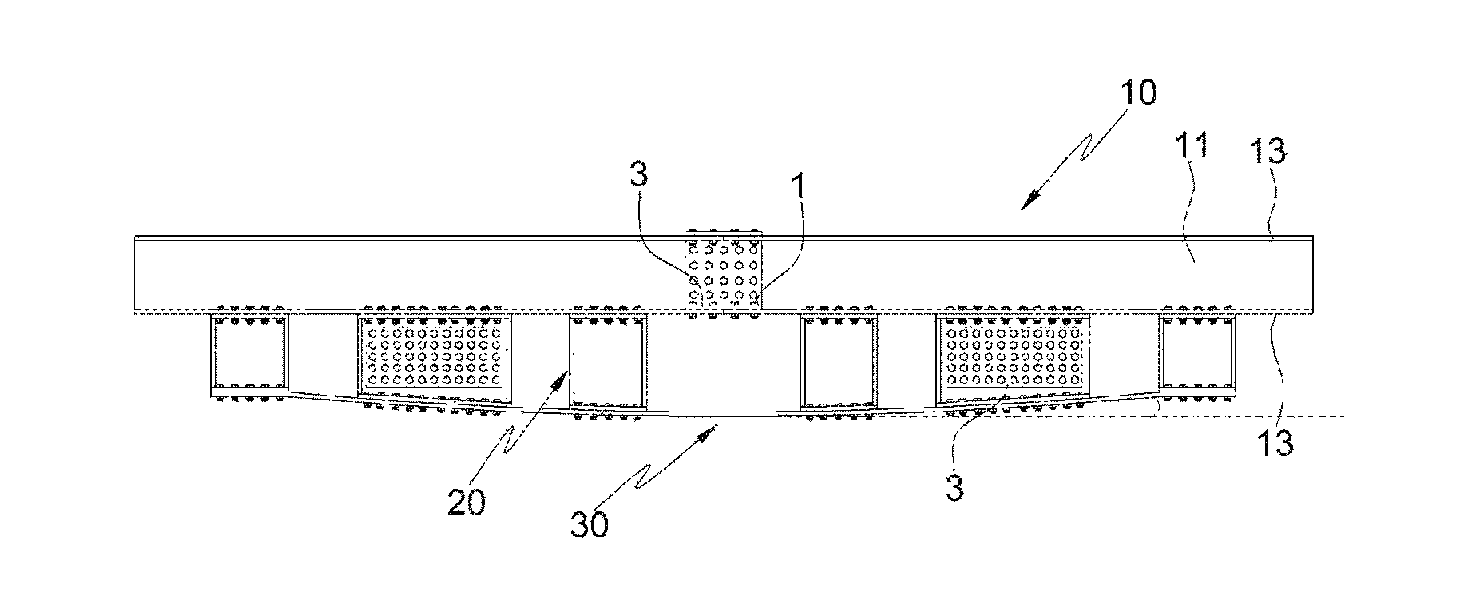

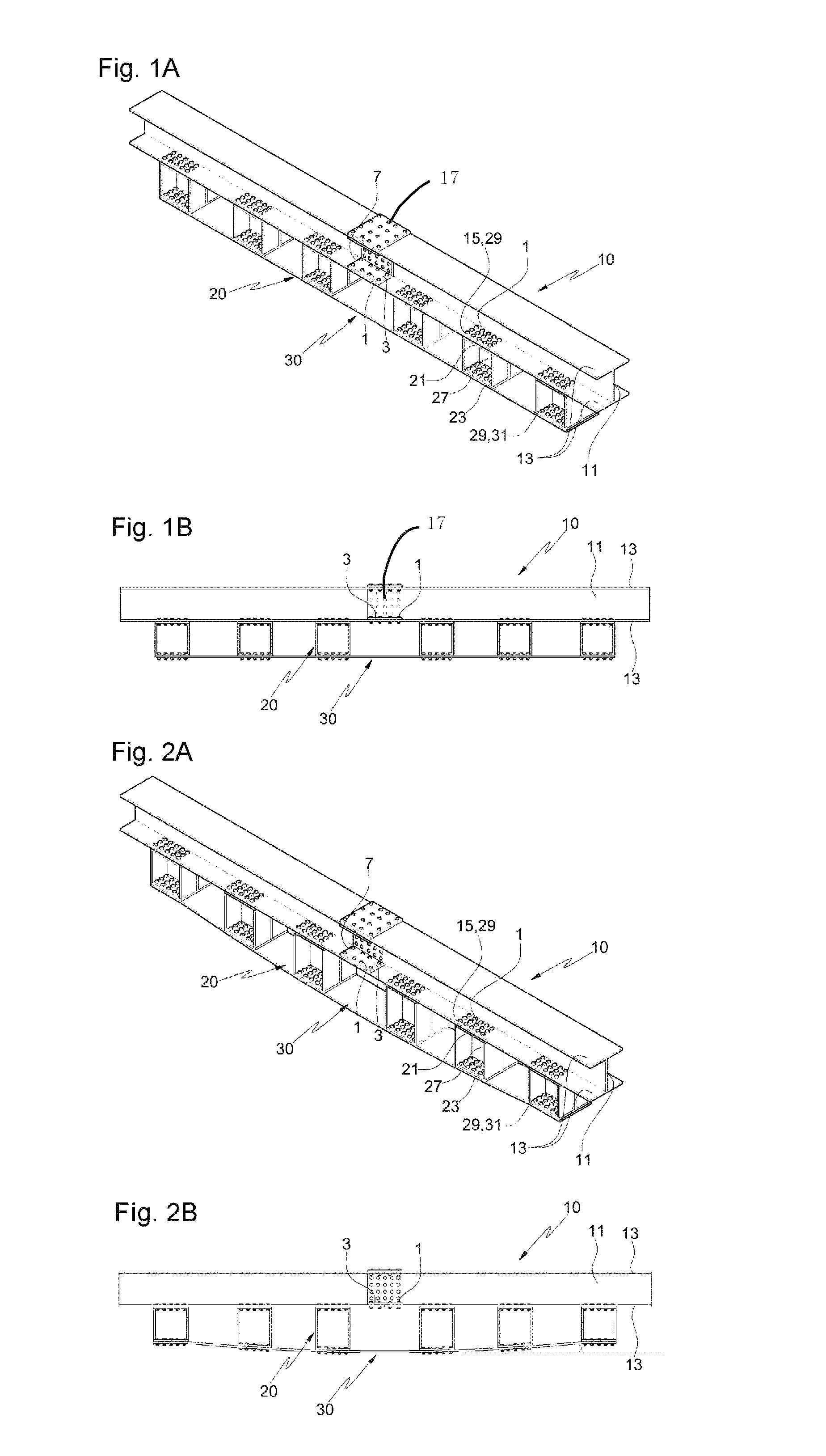

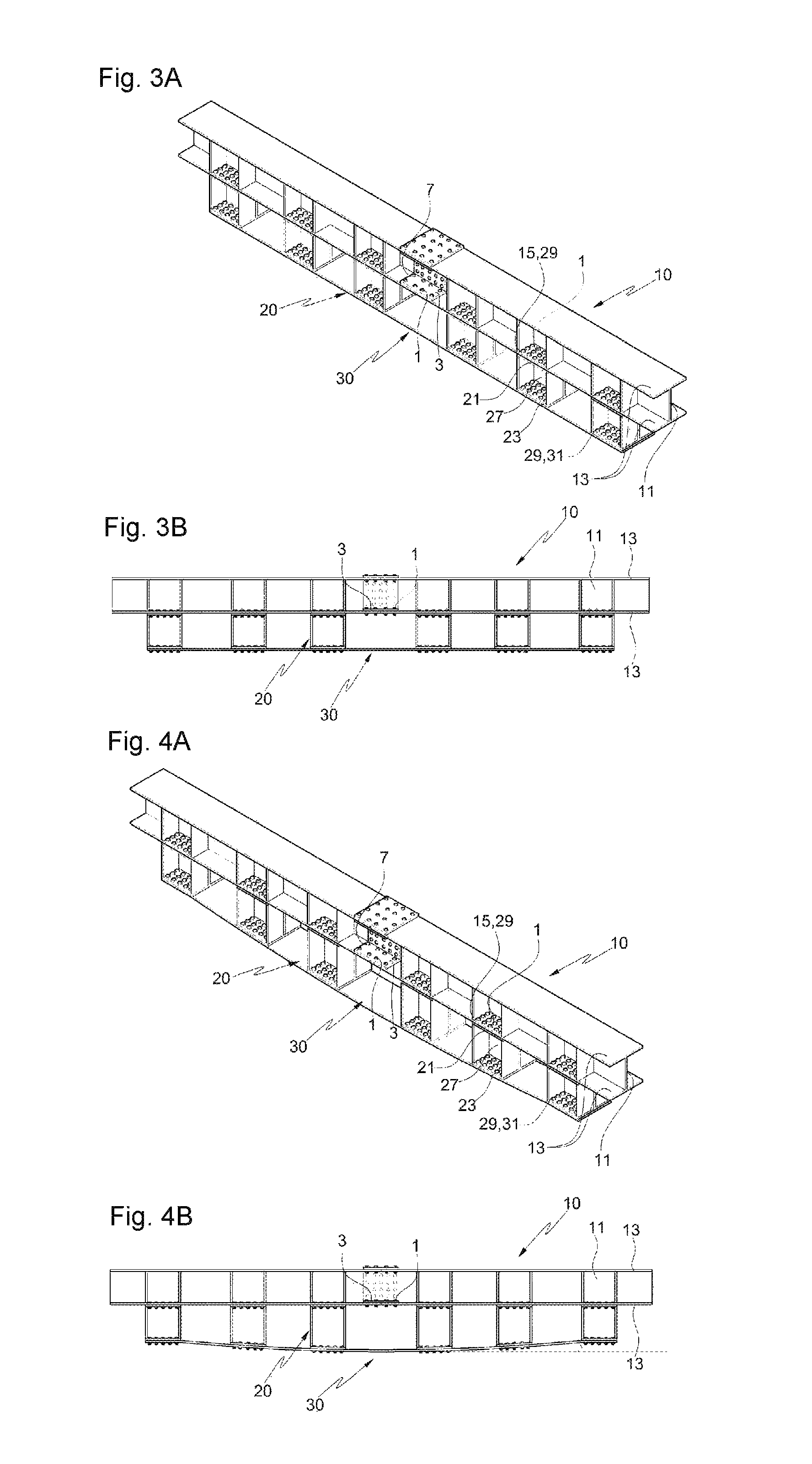

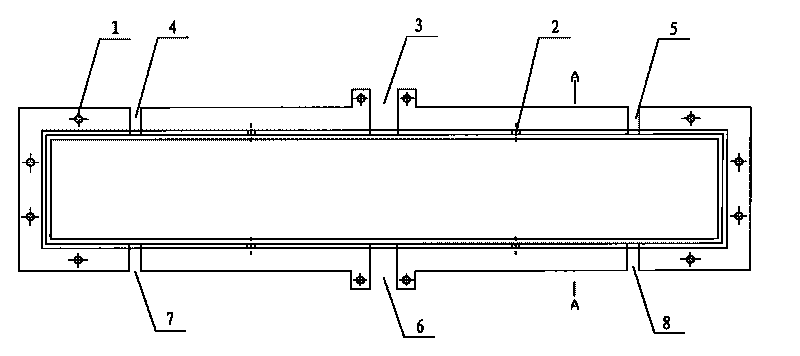

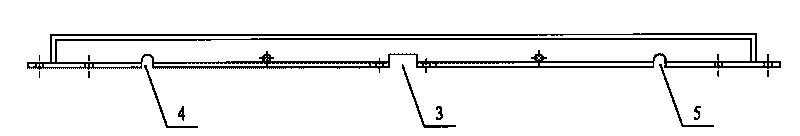

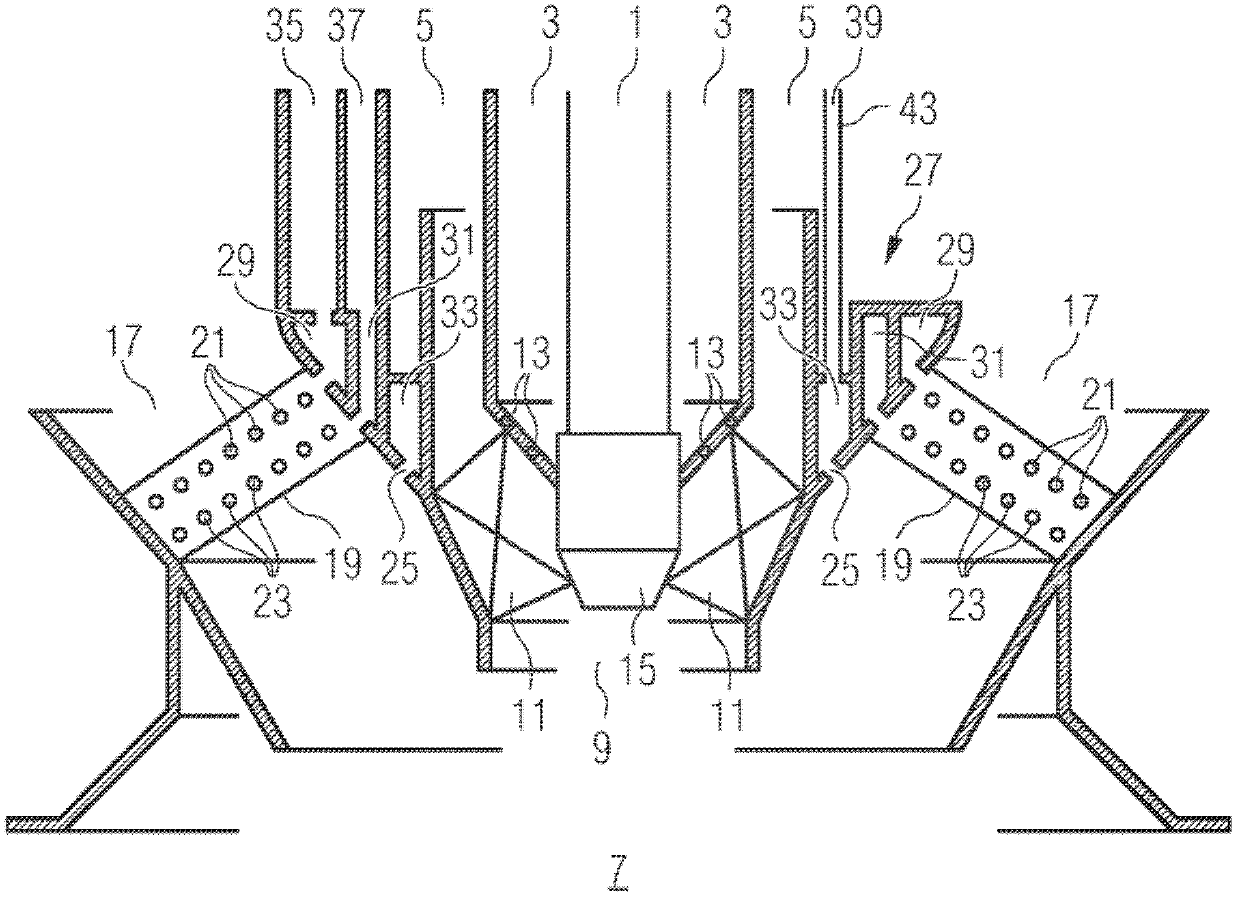

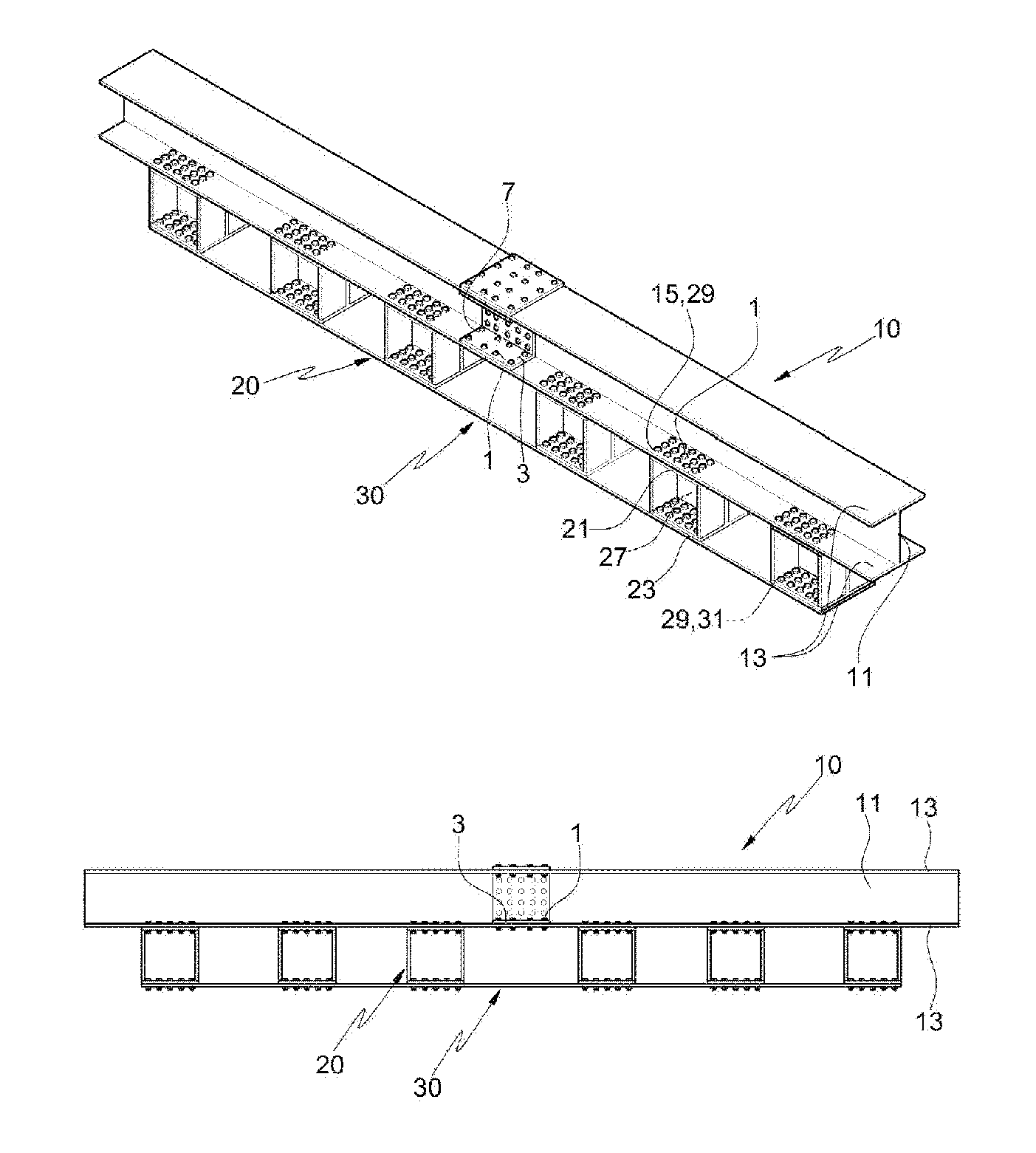

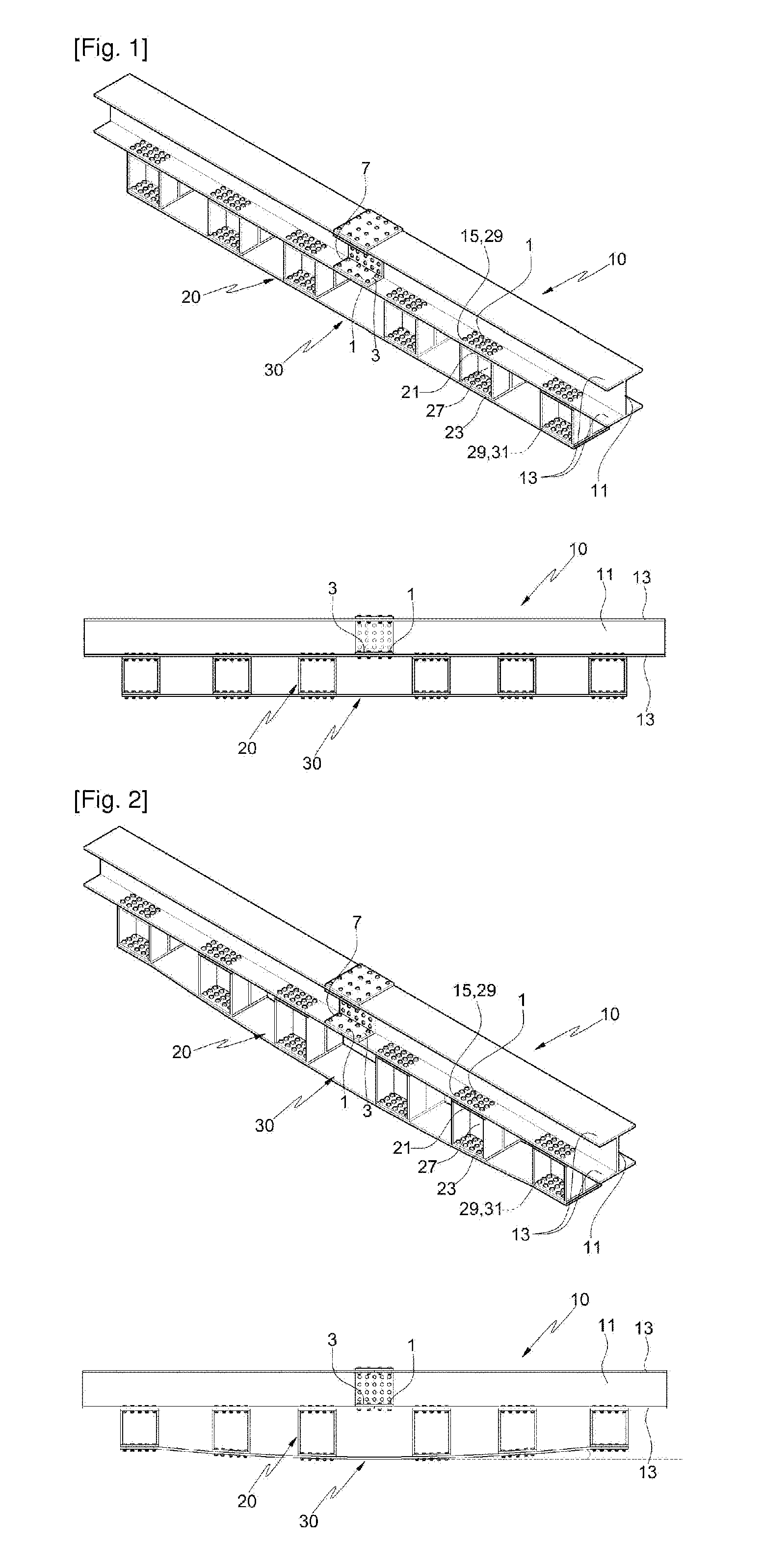

Steel structure including pre-stressing brackets for improving load-carrying capacity and serviceability

A steel structure including pre-stressing brackets for improving load-carrying capacity and serviceability comprises: a steel girder; a plurality of connecting brackets connected to the bottom surface of the steel girder spaced and apart from one; and a cover plate connected to the bottom surfaces of the connecting brackets. Since the cover plate is installed regardless of the connecting portion of the steel girder, pre-stressing section can be consecutively formed therefore pre-stress effect is improved. Moreover, since the connecting brackets space the cover plate a constant distance from the steel girder, the moment of inertia is increased so the span of a bridge might be increased.

Owner:YOOHO DEV & CONSTR +1

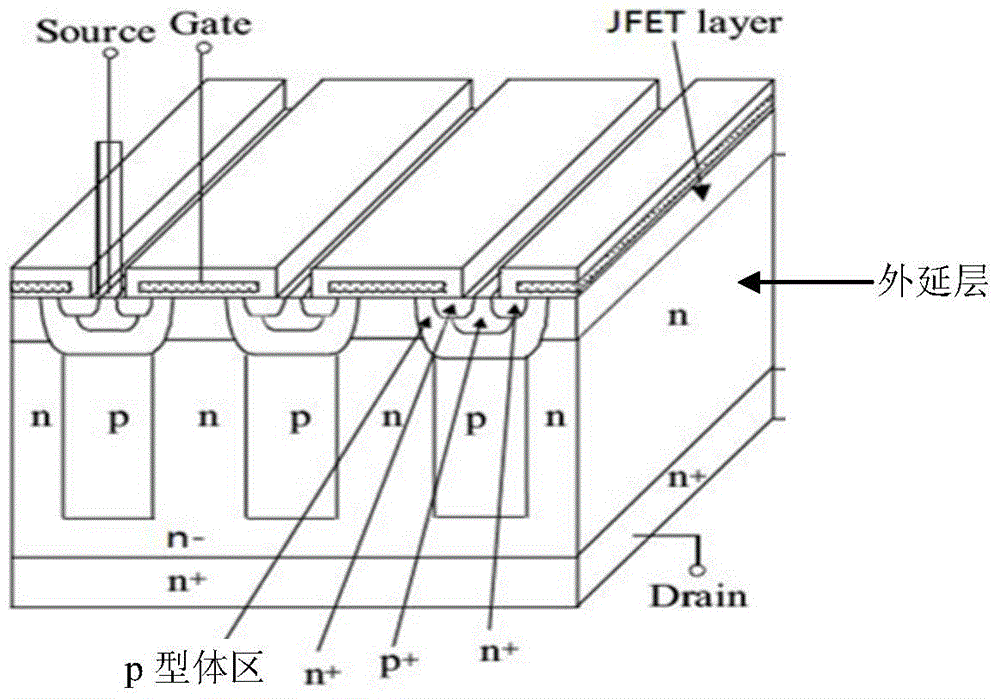

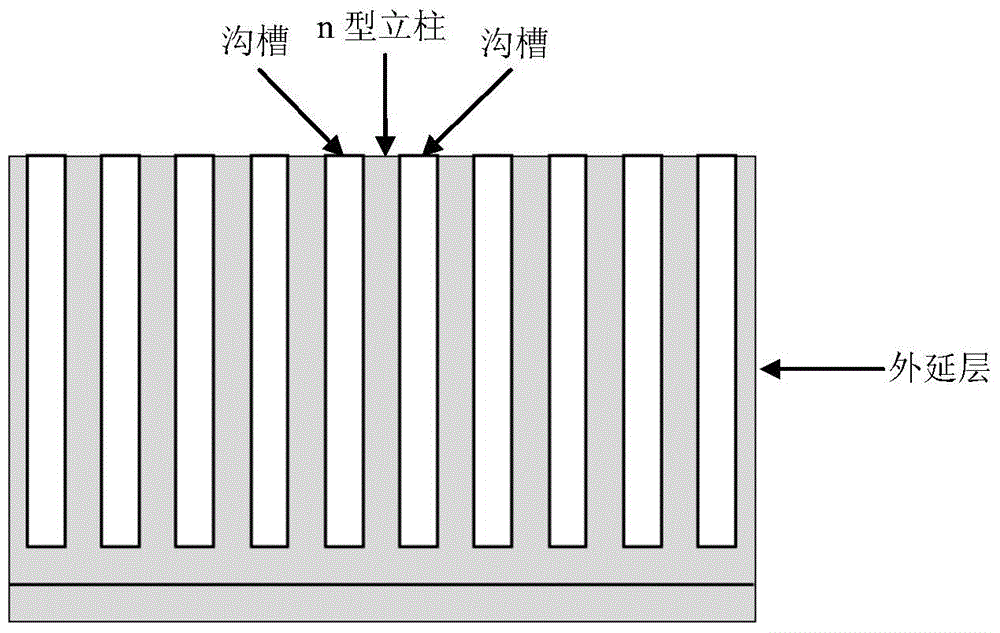

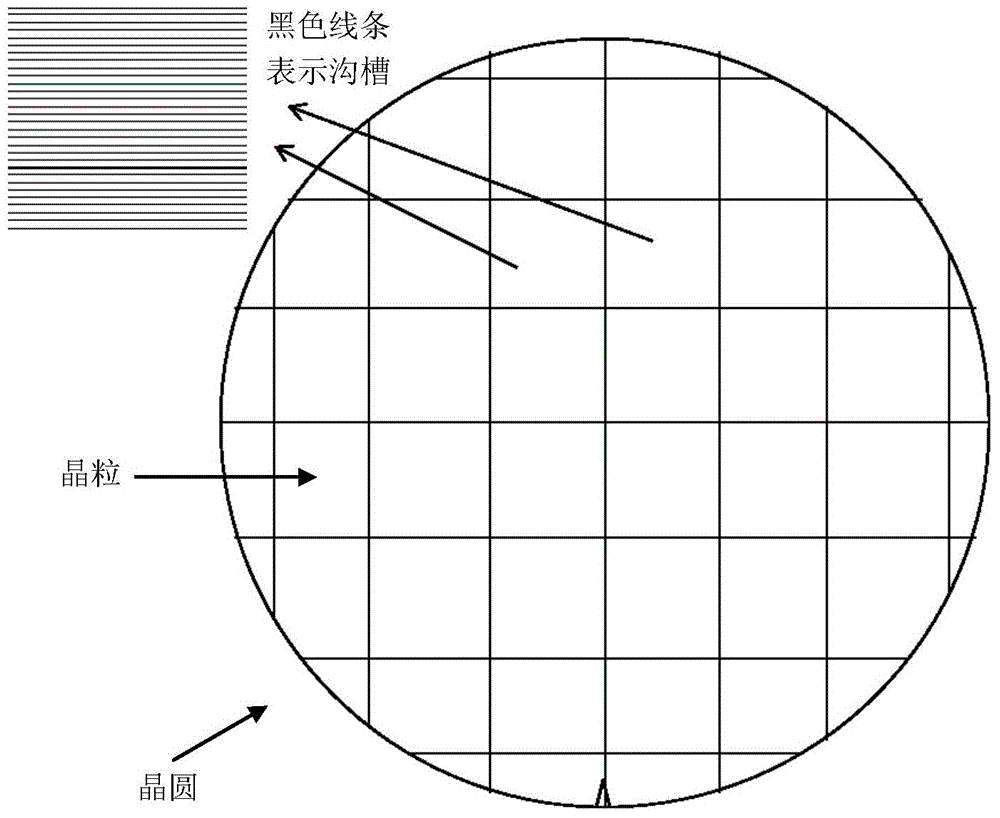

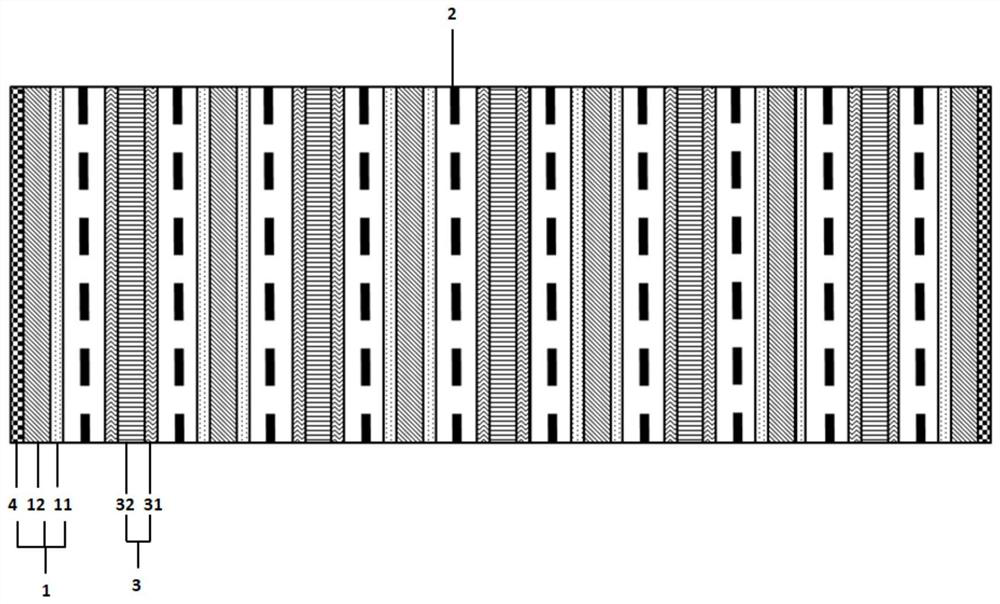

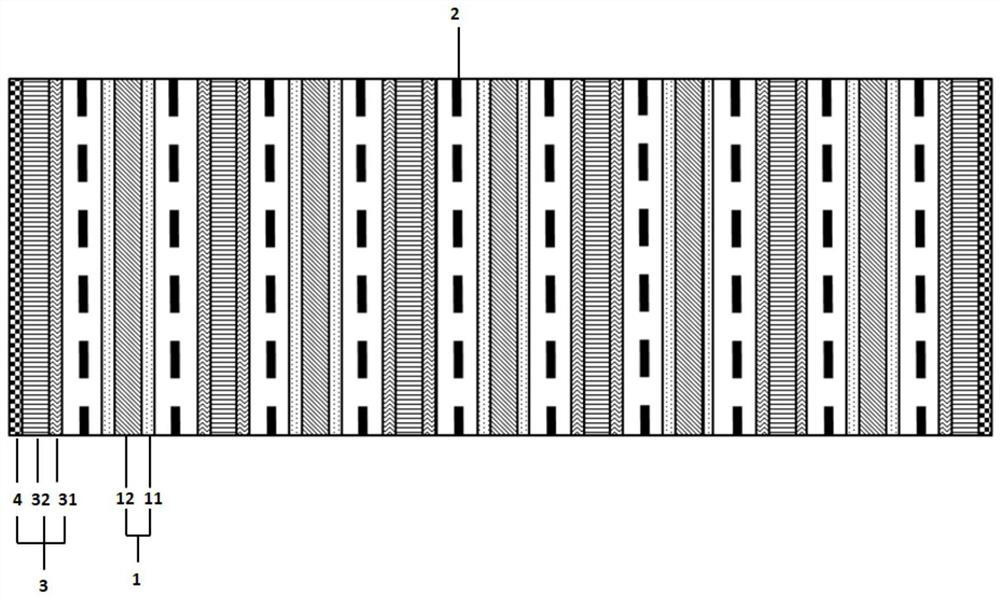

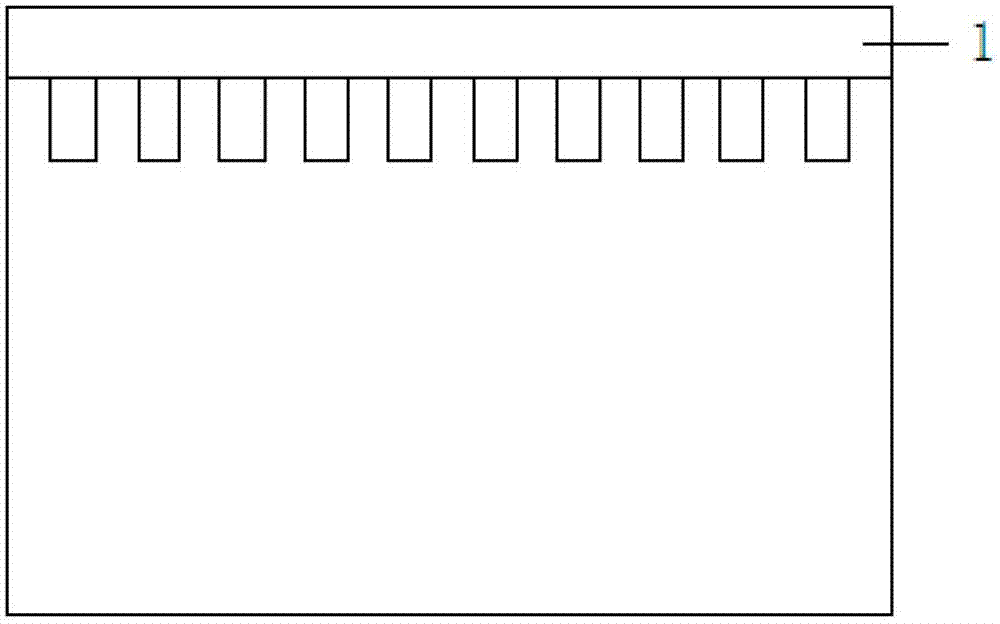

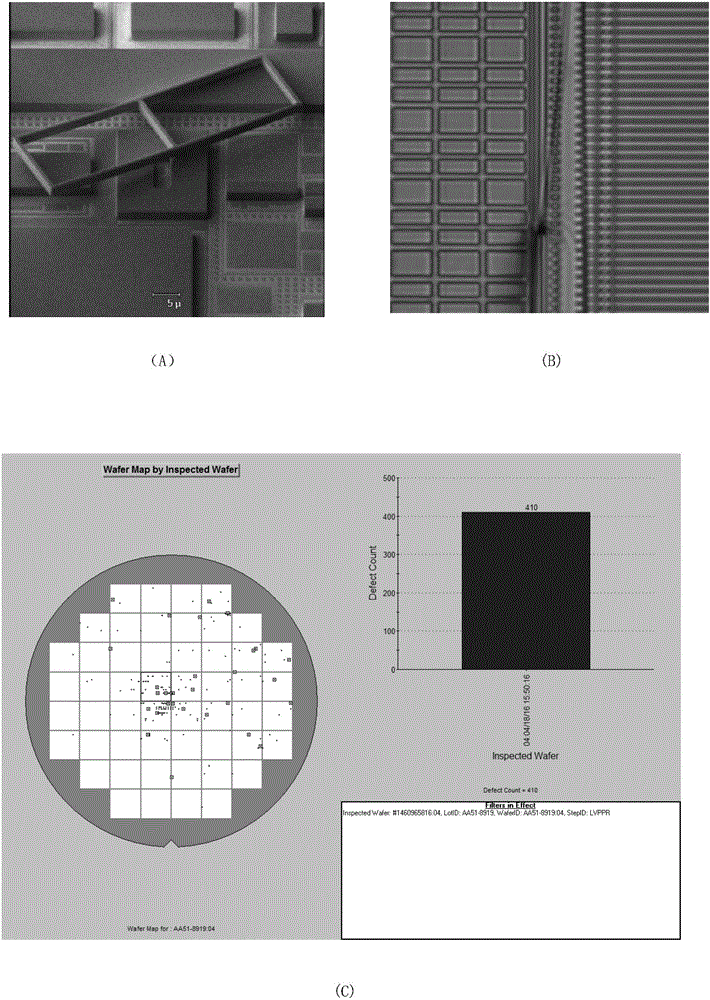

Trench-type super-junction device layout structure and manufacturing method thereof

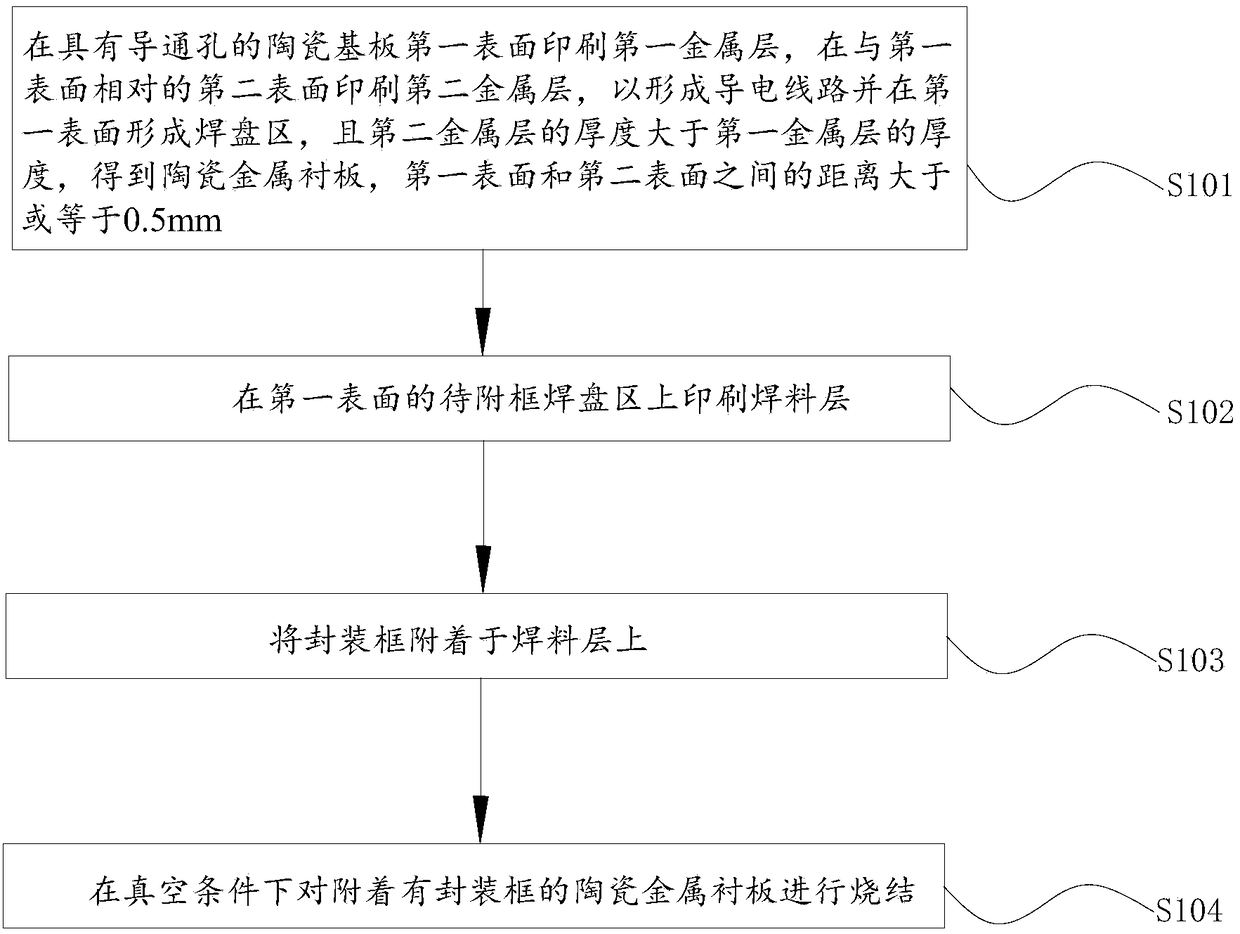

ActiveCN104617133AAvoid Wafer WarpageOffset stressSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDislocation

The invention discloses a trench-type super-junction device layout structure. A plurality of grooves for forming a column in each grain, the adjacent parallel grooves as a groove array, the array direction of the grooves adjacent to each other perpendicular to the array. The present application also discloses a method of manufacturing a trench-type super junction devices, it has formed a super junction structure having two or more of an array of channels in each grain, each groove by adjacent and parallel array composed of grooves, the grooves adjacent to the array direction of the array perpendicular to each other; said method comprising the ion implantation process is formed to cover all the grooves of the array ion-implanted region, ion-implanted region is formed at least one groove parallel to the array and at least another array of channels perpendicular to; final on all array of channels are formed super junction devices. This application is arranged perpendicular to each other by adjacent grains or cell array of channels, and to counteract the stress of deep trenches etched, and overcome the dislocations and other defects.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

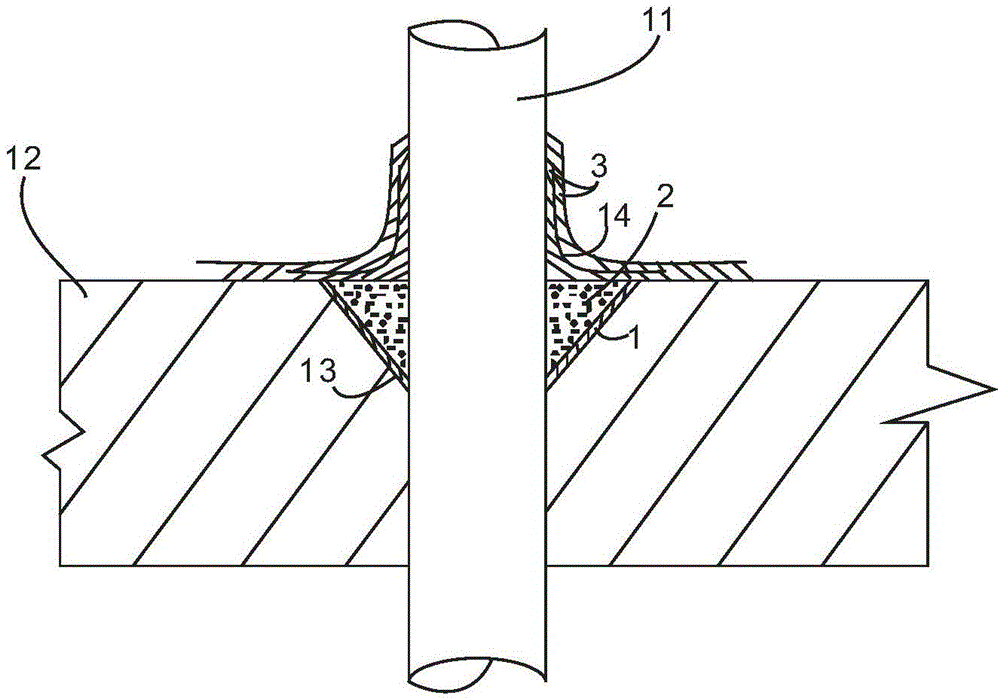

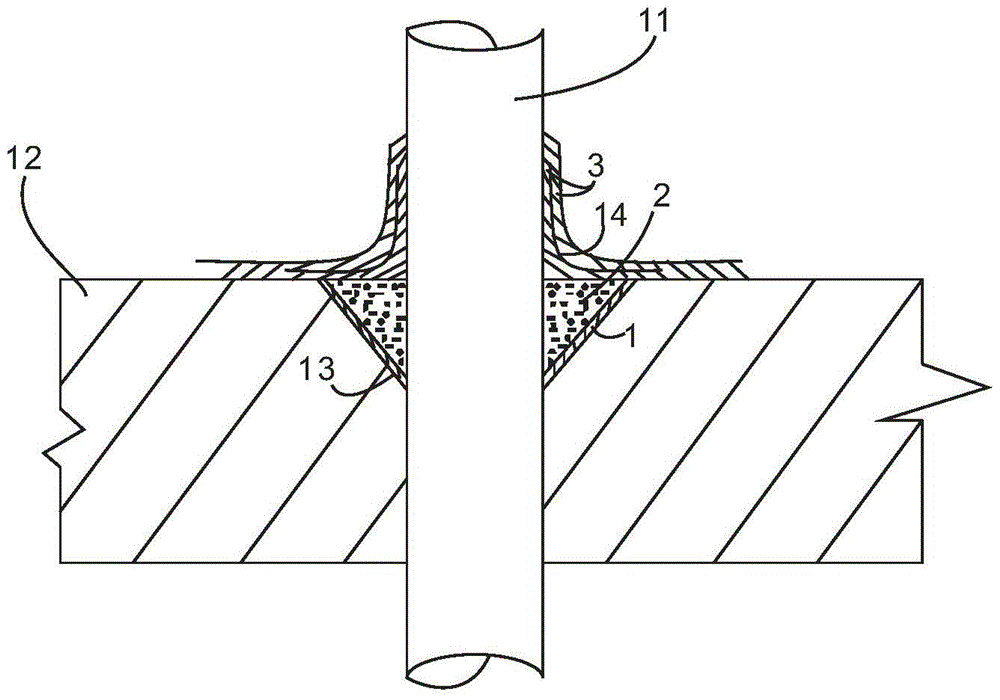

Home decoration toilet pipe-side floor drain treatment process

InactiveCN104481018AGood waterproof effectGood adhesionSewerage structuresBuilding insulationsEmulsionPulp and paper industry

The invention provides a home decoration toilet pipe-side floor drain treatment process. The treatment process comprises the steps of S1, digging out a groove in the concrete floor around the root of a pipeline, removing residue in the groove and cleaning the groove by use of water, S2, coating the groove with an interface waterproof agent once or twice under the condition of moist, S3, evenly mixing a multifunctional emulsion with quick-setting cement in the weight ratio of (0.3-0.5): 1 into a paste, applying the paste into the groove, and compacting and trowelling, S4, after the filler in the groove is solidified, coating the root and the four sides of the pipeline with a secondary pipe fixation waterproof glue. According to the home decoration toilet pipe-side floor drain treatment process, at least three waterproof layers, namely the interface waterproof agent layer, the mixed layer of the multifunctional emulsion and the quick-setting cement, and the waterproof layer of the pipe fixation waterproof glue are provided. Due to triple waterproofing operations, the waterproof effect is excellent and the service life is long.

Owner:厦门顶巢建筑科技有限公司

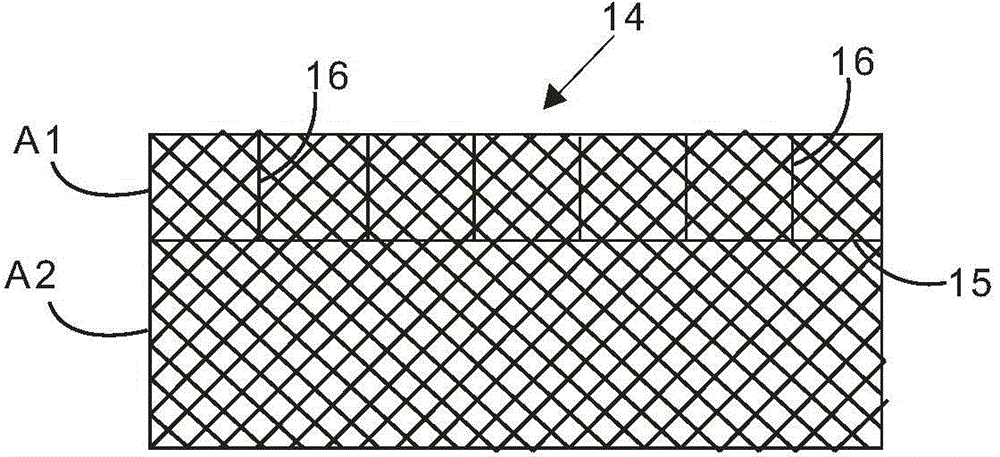

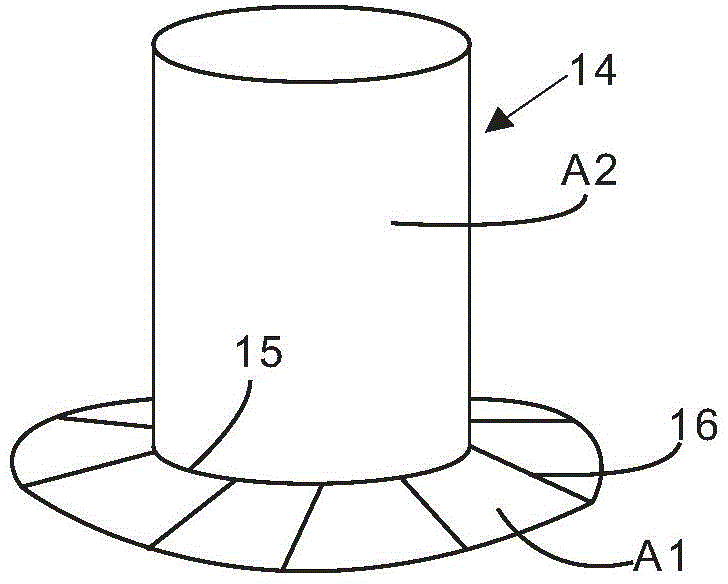

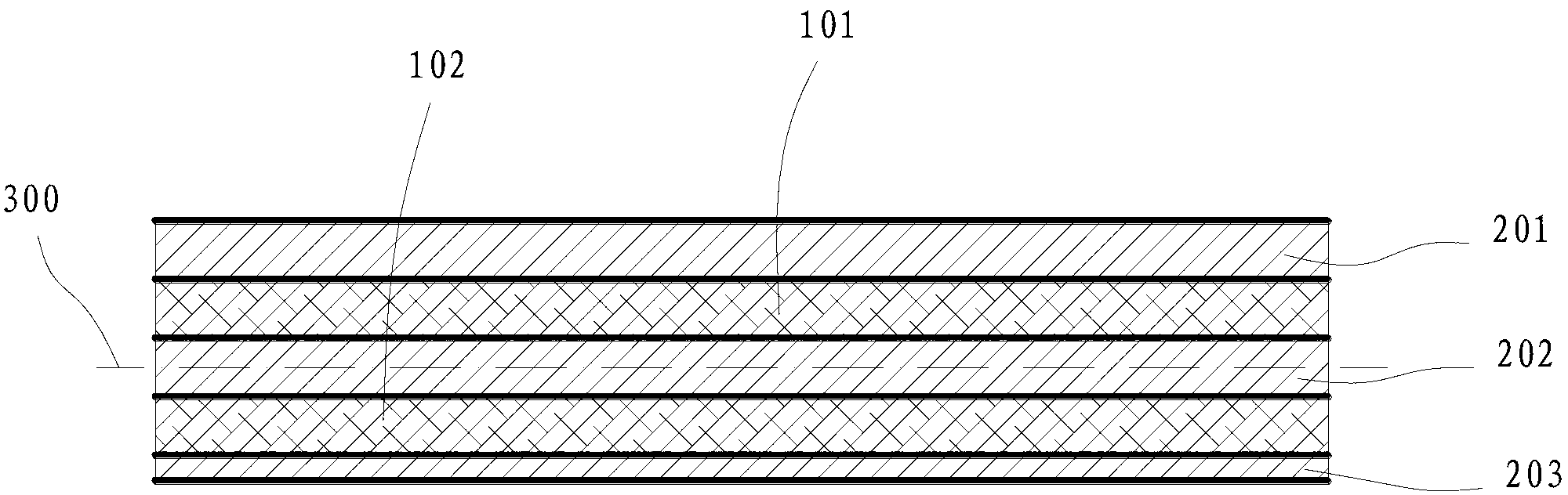

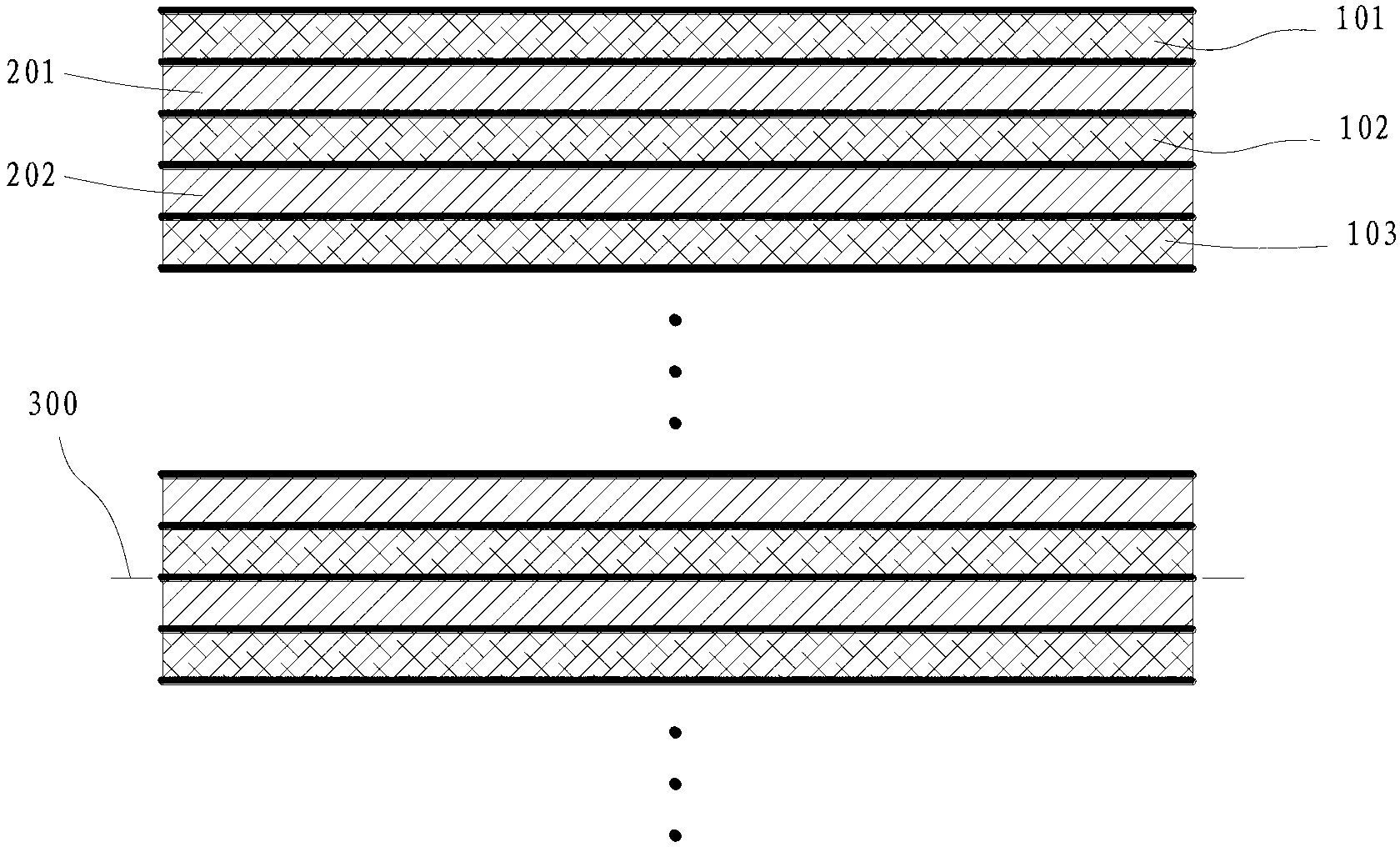

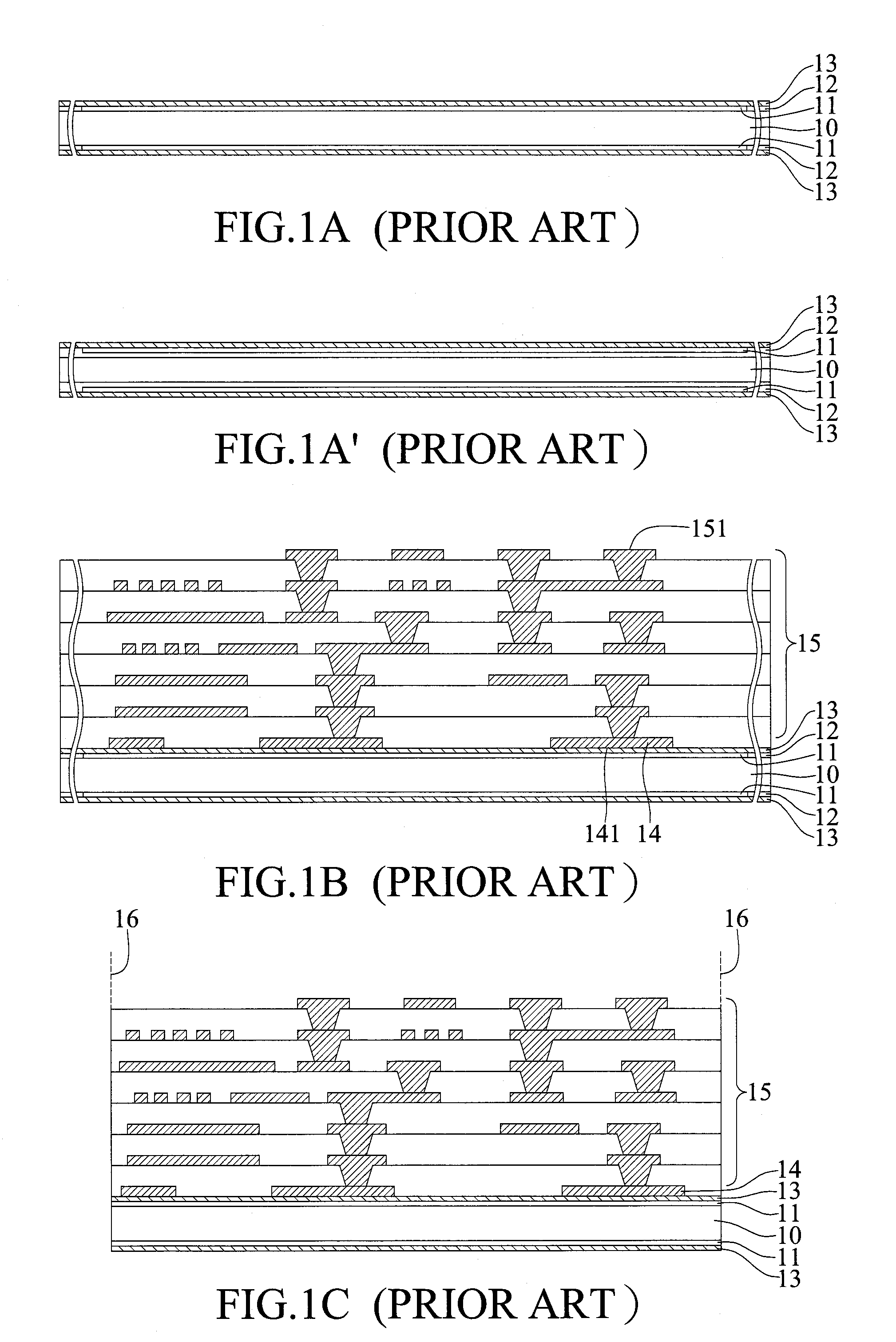

Method for restraining warping of asymmetric printed circuit board

ActiveCN103327745AOffset stressImprove production pass rateLayered productsPrinted circuit manufactureThermal expansionEngineering

The invention discloses a method for restraining warping of an asymmetric printed circuit board. According to the method for restraining the warping of the asymmetric printed circuit board, when the thicknesses of two core boards which are arranged on the corresponding positions of the two sides of a symmetrical mirror plane of the multi-layer printed circuit board are not equal, two prepregs with different thicknesses are arranged on the corresponding positions of the two sides of the symmetric mirror plane. When the thicknesses of the two core boards which are arranged on the corresponding positions of the two sides of the symmetrical mirror plane of the multi-layer printed circuit board are not equal, different kinds of thermal expansion will be generated, stress generated on one side of the symmetrical mirror plane and stress generated on the other side of the symmetrical mirror plane in the process of lamination and shrinking of resin are not equal, and therefore the warping of the printed circuit board is caused. The two prepregs with different thicknesses are arranged on the corresponding positions of the symmetric mirror plane, the prepregs generate stress, the direction of the stress generated by the prepregs is opposite to the direction of the warping of the core board, and therefore the stress generated by the core boards is counteracted. Therefore, the effect of restraining the warping is achieved, the production qualified rate of the printed circuit board is improved, the production cost is reduced, and the production cycle is shortened.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH

Frame baffle for fixing electromagnetic casting magnetic field-aided generator

The invention relates to a frame baffle for fixing an electromagnetic casting magnetic field-aided generator. Upper and lower sides of the frame baffle are provided with symmetrical fabrication holes or unsymmetrical fabrication holes, wherein the aim that the upper side is provided with the fabrication holes is for an incoming cable, a cooling water pipe and a fixing bolt to pass through; and the aim that the lower side is provided with the fabrication holes is to counteract nonuniform warp and deformation caused by a thermal stress, namely symmetrical sides of a slot and a hole of the frame baffle are provided with the corresponding fabrication holes for counteracting expansion and distortion caused by the thermal stress to eliminate the great-degree warp and deformation caused by opening the fabrication holes only on the single side. The nonuniform thermal stress deformation and warp of the frame baffle caused by heating are avoided by regulating and optimizing the positions and the number of the fabrication holes of the frame baffle so as to prolong the service life of the baffle from a plurality of weeks to more than one year and greatly reduce the consumption of auxiliary materials; and because the serious thermal stress warp is eliminated, the service life of a packing frame of a casting mold is greatly improved.

Owner:苏州有色金属研究院有限公司

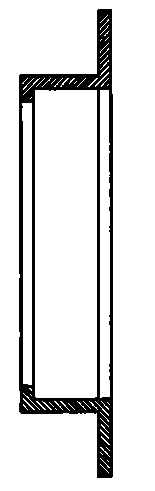

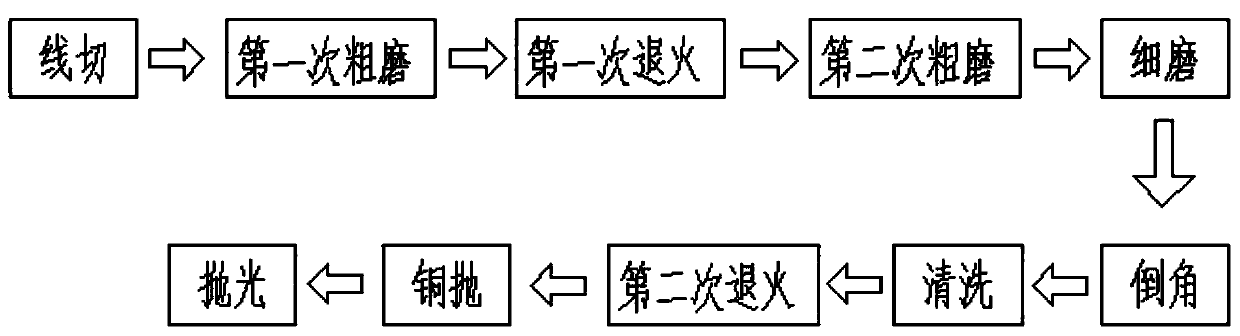

Manufacturing process of high-performance substrate

ActiveCN110744732AImprove flatnessReduce stress responsePolycrystalline material growthAfter-treatment detailsSuperfine grindingSapphire substrate

The invention discloses a manufacturing process of a high-performance substrate. The manufacturing process of the high-performance substrate comprises the following steps of line cutting, first coarsegrinding, first annealing, second coarse grinding, fine grinding, chamfering, cleaning, second annealing, copper polishing and polishing, wherein a superfine grinding machine is adopted, double-sidedfine grinding and thinning are carried out on a sapphire substrate. Warp is controlled to be 15 micrometres after the fine grinding is carried out, and Bow is controlled to be 4 micrometres or within; and after the scheme is adopted, the manufacturing process of the high-performance substrate reduces maximally the deformation influence of stress on the fine grinding, so that the substrate can obtain higher flatness and lower stress reaction in the fine grinding.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

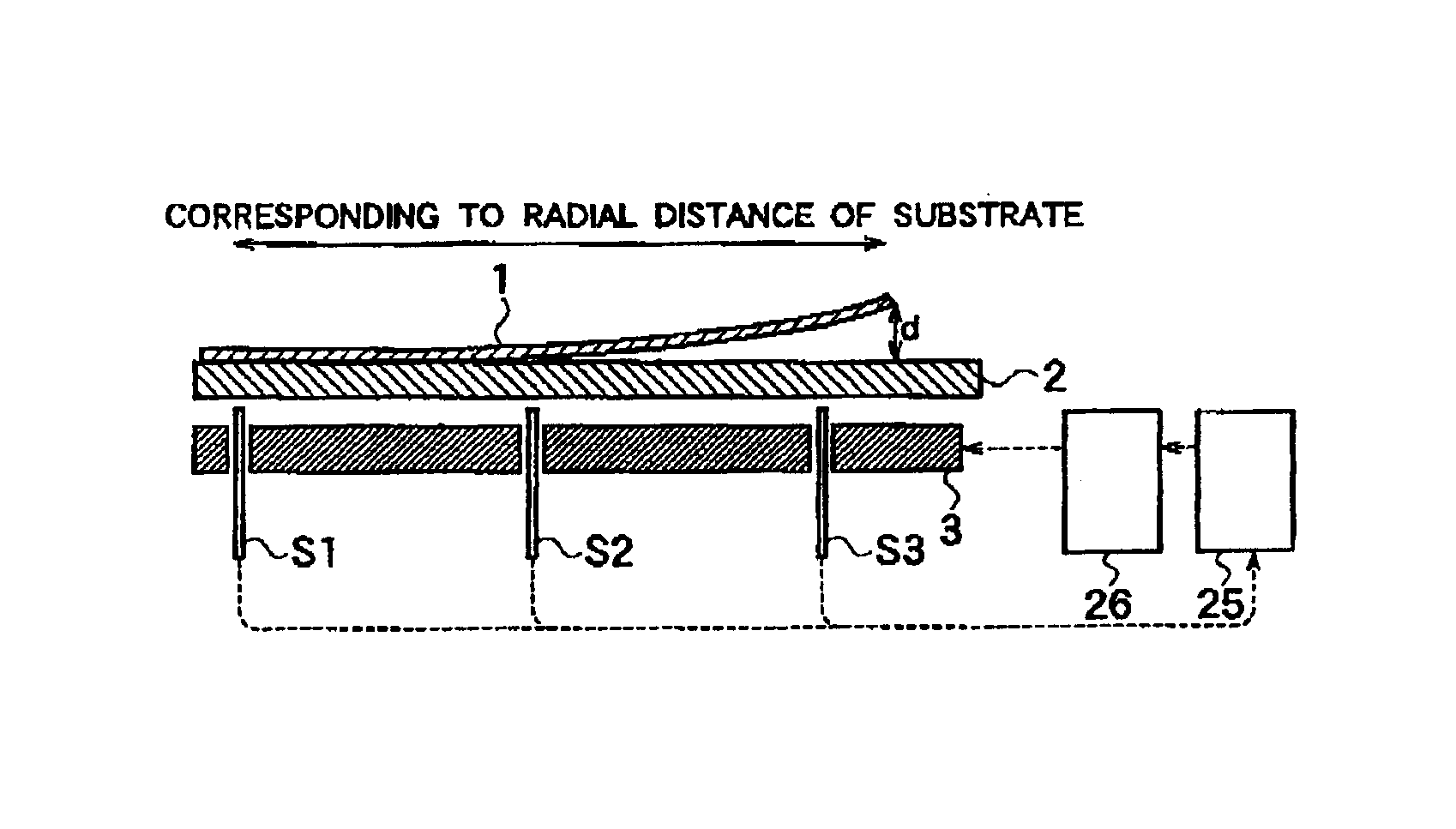

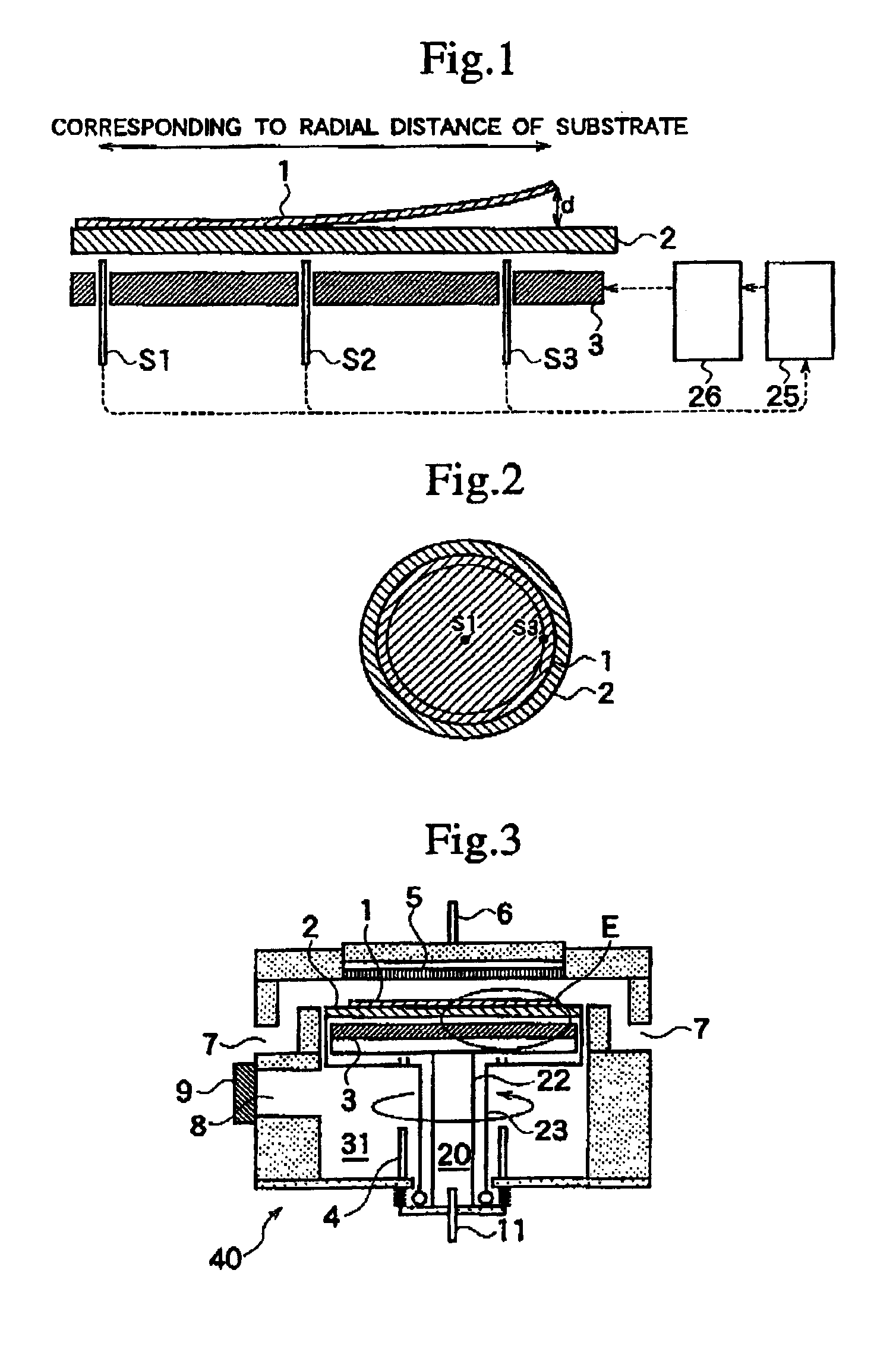

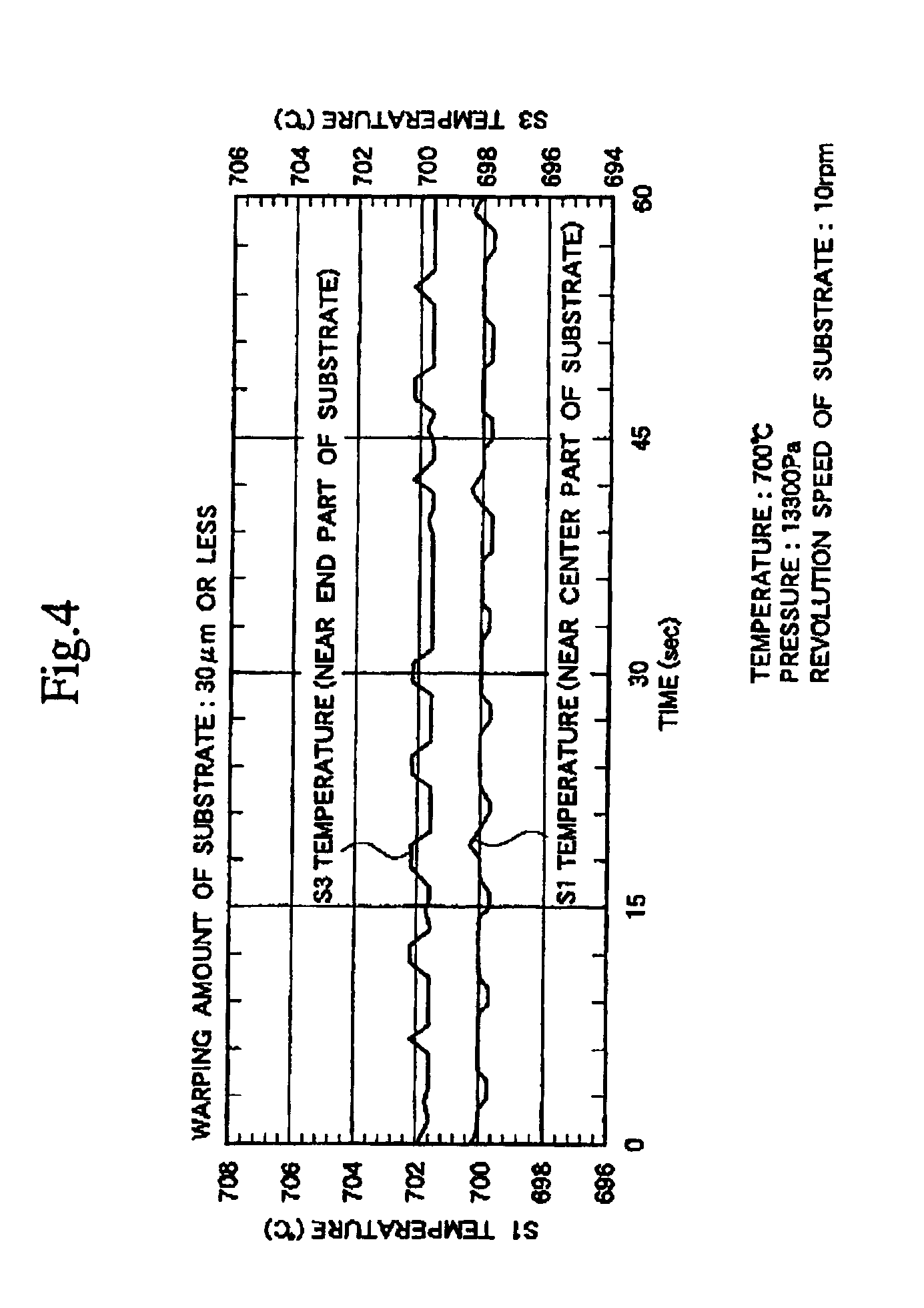

Substrate processing apparatus and method for manufacturing semiconductor device

InactiveUS6863734B2Offset stress generatedAvoid generation of unnecessary stressDrying solid materials with heatSemiconductor/solid-state device testing/measurementElectrical resistance and conductanceIn plane

By indirectly monitoring a warping amount of a substrate, it is possible to examine causes easily when substrate processing such as deposition is performed with nonuniform in-plane temperature of the substrate and a defect in a substrate characteristic, for example in uniformity of a film thickness, is caused. In a substrate processing apparatus for processing a substrate, a substrate holding body for holding the substrate on its surface and a resistance heater for heating the substrate through the substrate holding body are provided. Radiation thermometers for measuring temperature of the substrate holding body, which has a correlation with a warping amount of the substrate, from its rear surface side are provided to the resistance heater. The substrate holding body is provided to be rotatable with respect to the radiation thermometers so that temperature information of the substrate holding body in a circumferential direction can be obtained. A calculator as a monitor for monitoring the warping amount of the substrate having a correlation with the temperature of the substrate holding body, based on the measured values of the radiation thermometers, is provided. A command for correcting the warping amount is sent to a control means, based on the warping amount determined by the calculator, to control the resistance heater, as necessary.

Owner:KOKUSA ELECTRIC CO LTD

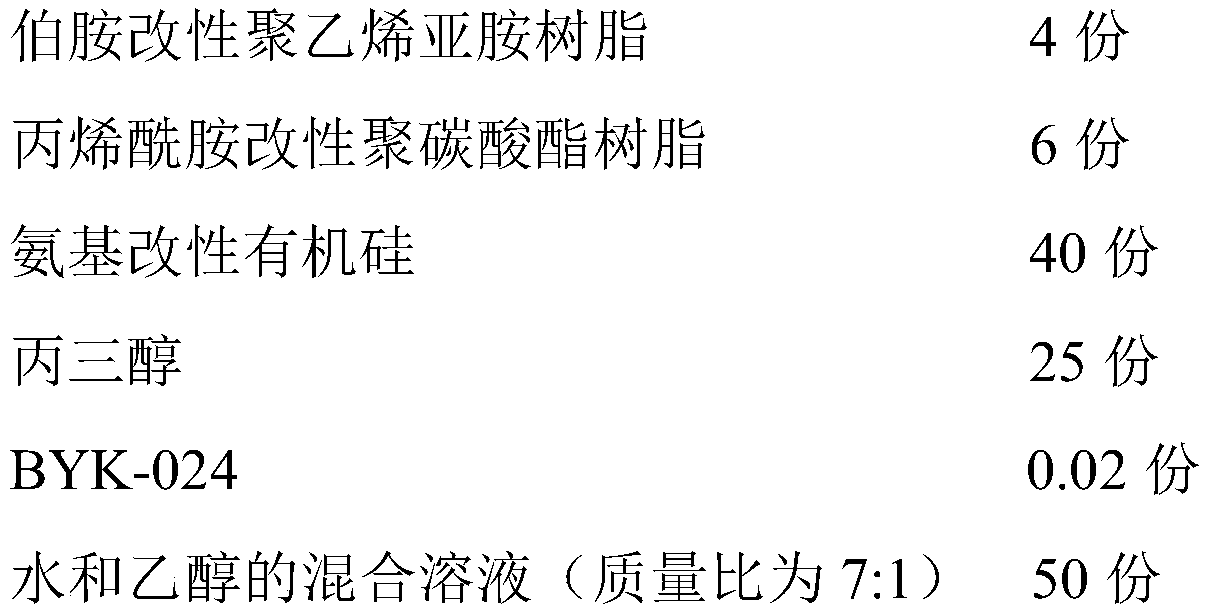

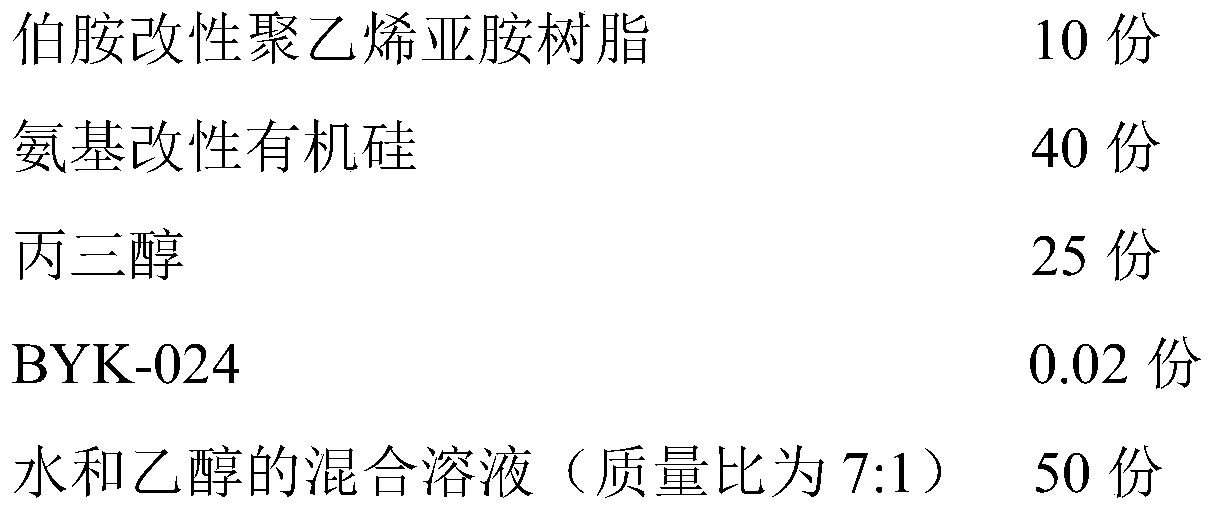

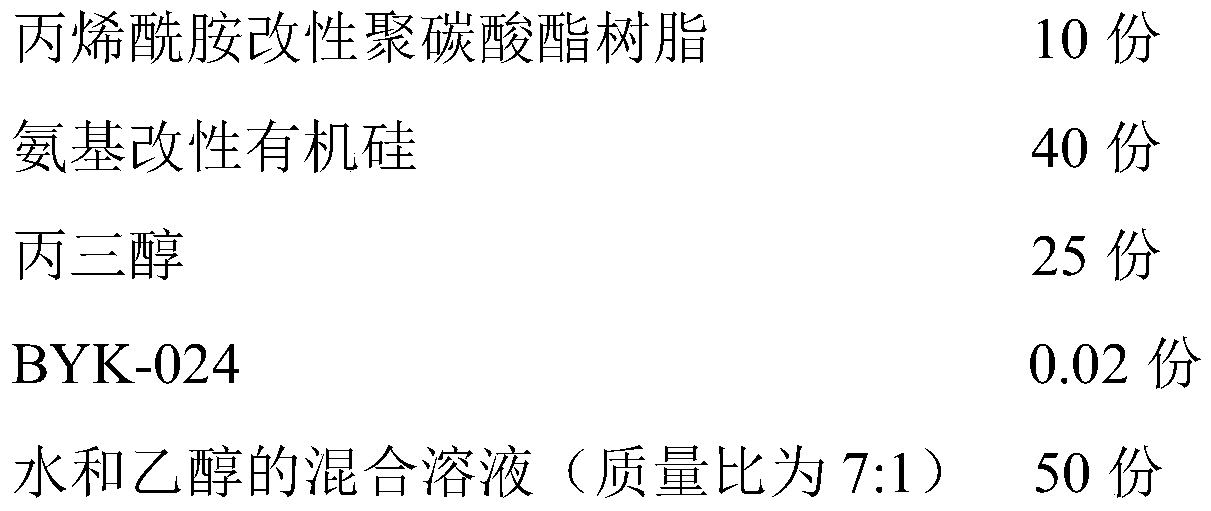

Back coating material for tipping paper for cigarettes, tipping paper for cigarettes, and preparation method of tipping paper

ActiveCN110644280ALow flatnessEasy to slideSurface covering paperNon-fibrous pulp additionPolymer sciencePolycarbonate

The invention relates to a back coating material for tipping paper for cigarettes. The back coating material comprises, by weight, 1-10 parts of a resin, 10-50 parts of a softener and 5-25 parts of awater-retaining agent; and the resin is primary amine modified polyethyleneimine and / or acrylamide modified polycarbonate, and the softener is amino modified organosilicon. The invention also relatesto the tipping paper for cigarettes. The invention further relates to a preparation method of the tipping paper for cigarettes.

Owner:ANHUI GENUINE PAPER PACKING

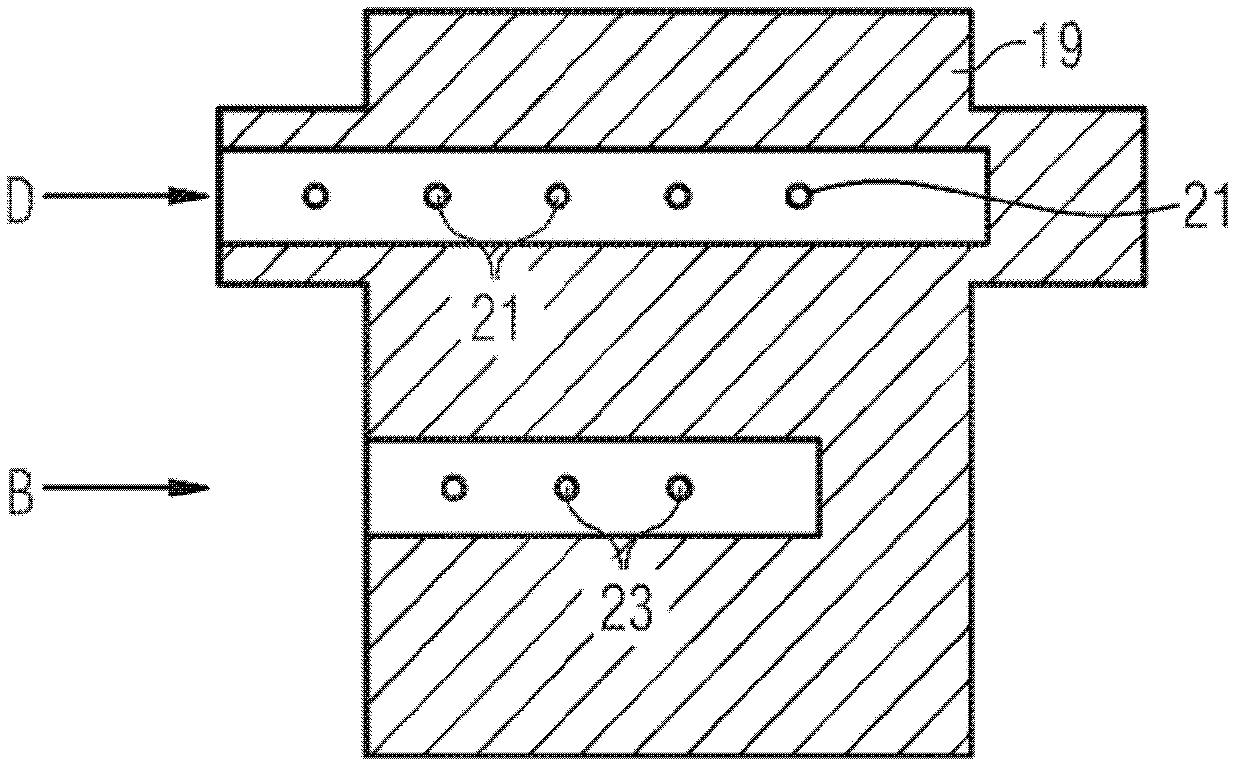

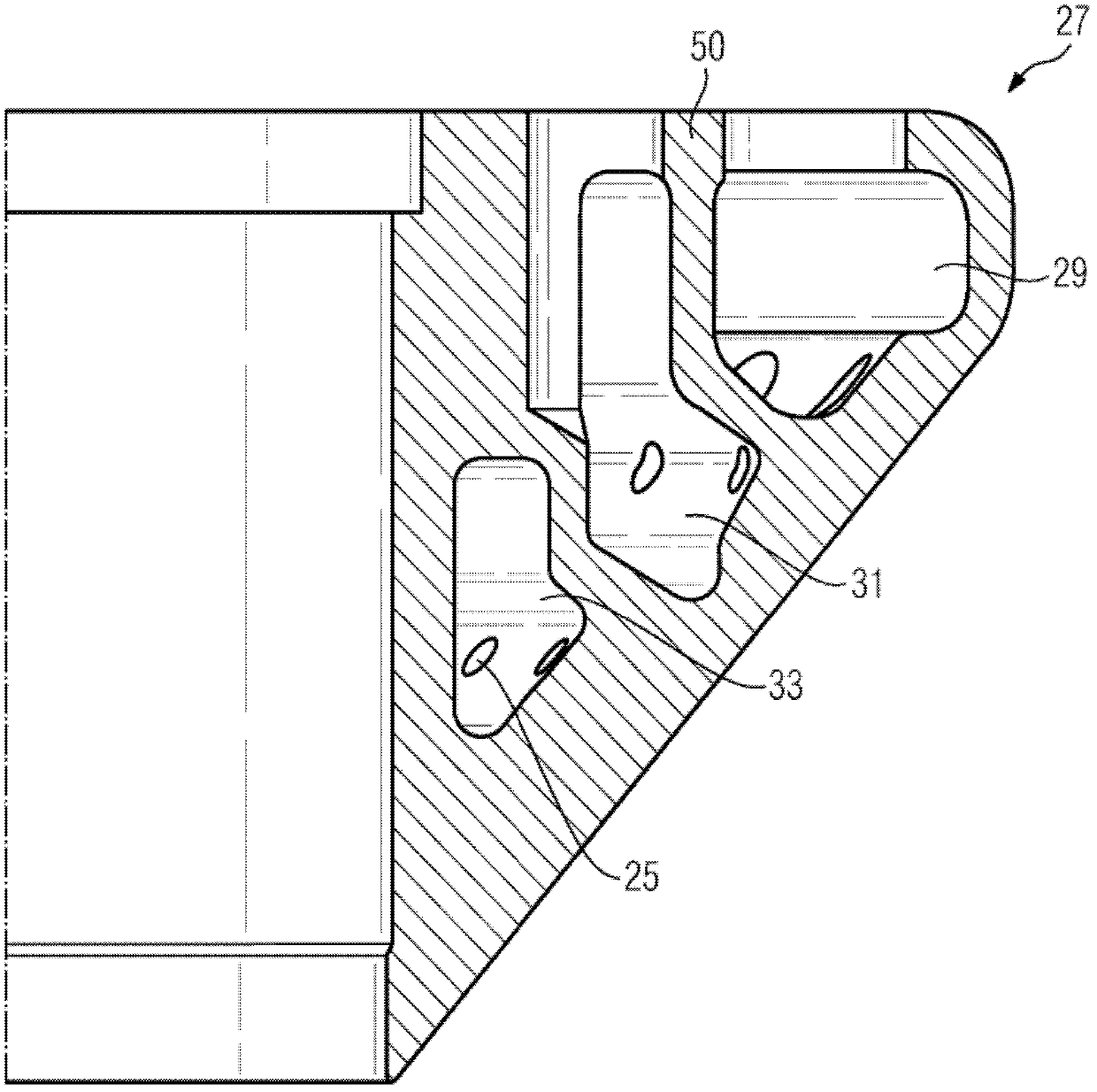

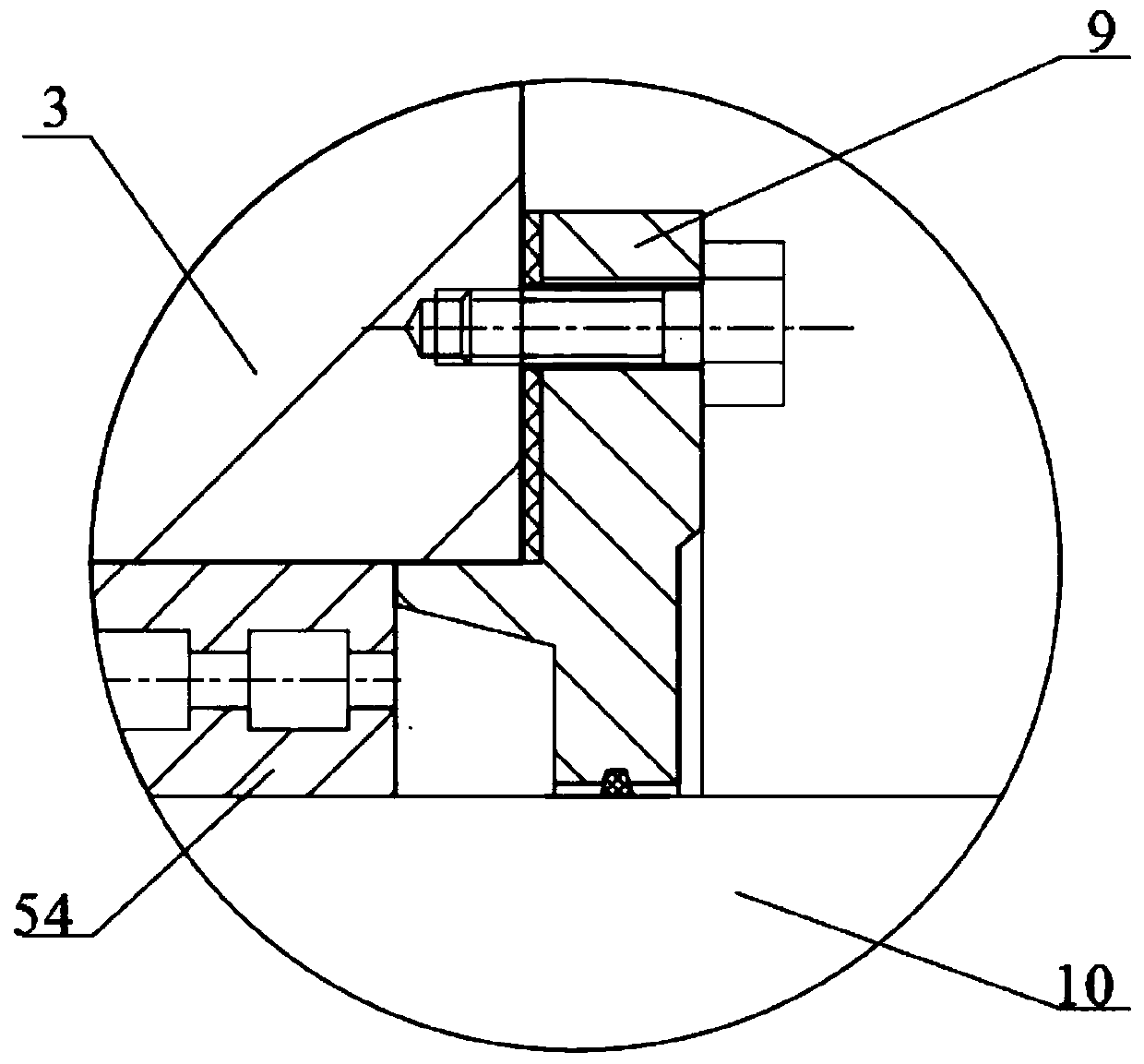

Burner, in particular for gas turbines

InactiveCN102597631AEasy to useExtended service lifeContinuous combustion chamberCombustorDistributor

The invention relates to a burner comprising a central fuel supply arrangement (27), an annular air channel (18) surrounding said central fuel supply arrangement (27), for supplying combustion air and swirl blades which are arranged in the annular air channel (17), comprising first fuel nozzles (21) for introducing an essentially gaseous fuel into the combustion air, and second fuel nozzles (23) for introducing an essentially gaseous fuel into the combustion air. The first fuel nozzles (21) are supplied by a fuel distributor supply in the fuel supply arrangement (27), and the second fuel nozzles (23) are supplied by a fuel distributor channel (31) in the fuel supply arrangement (27). The fuel distributor supply comprises a supply pipe (55) which is connected downstream of the swirl blade (19), and an annular attachment (60). The supply pipe (55) is connected downstream of the annular attachment (60) and said annular attachment (60) is mounted upstream of the fuel distributor channel (31) when seen in the direction of flow. The invention also relates to a gas turbine comprising said type of burner.

Owner:SIEMENS AG

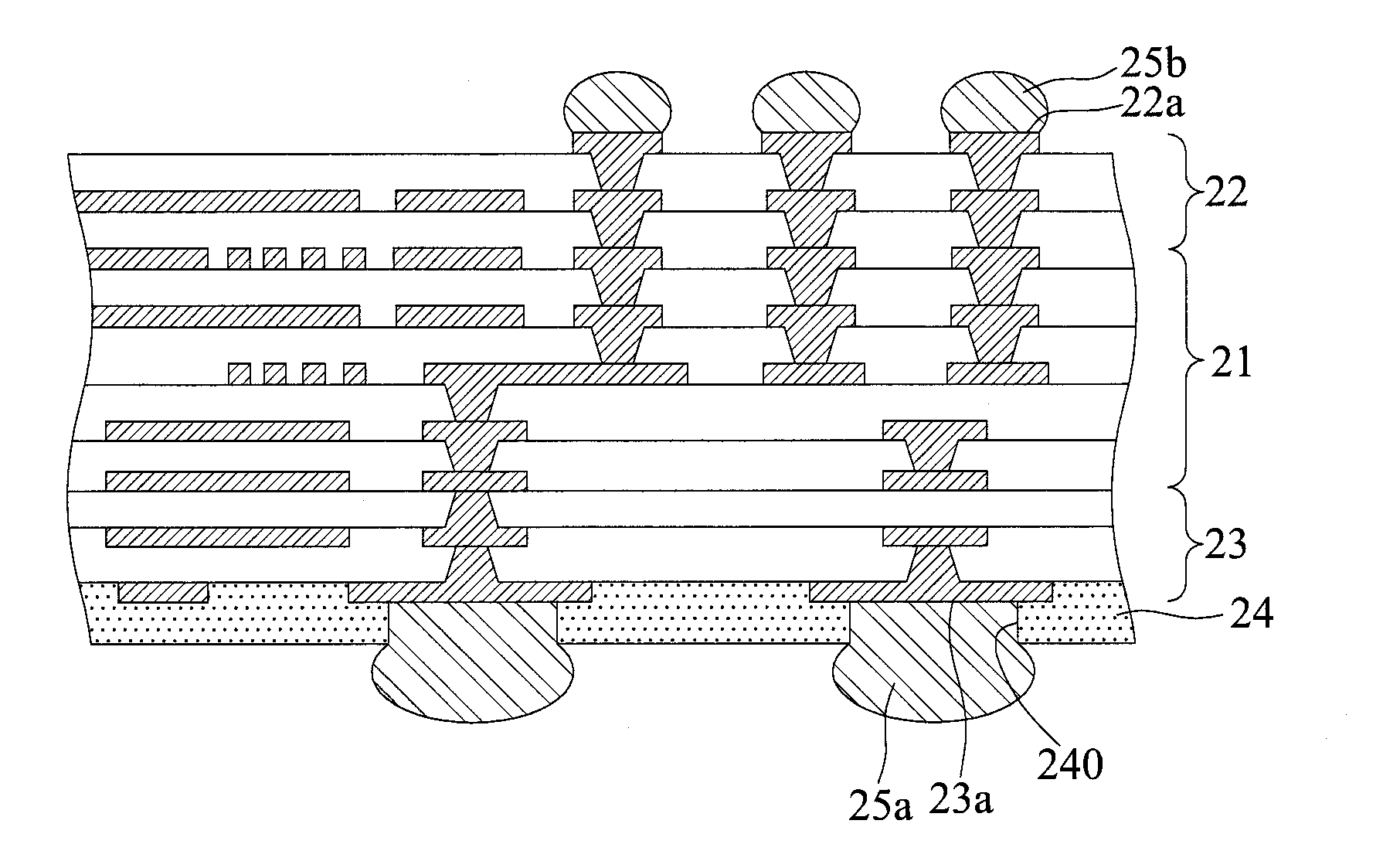

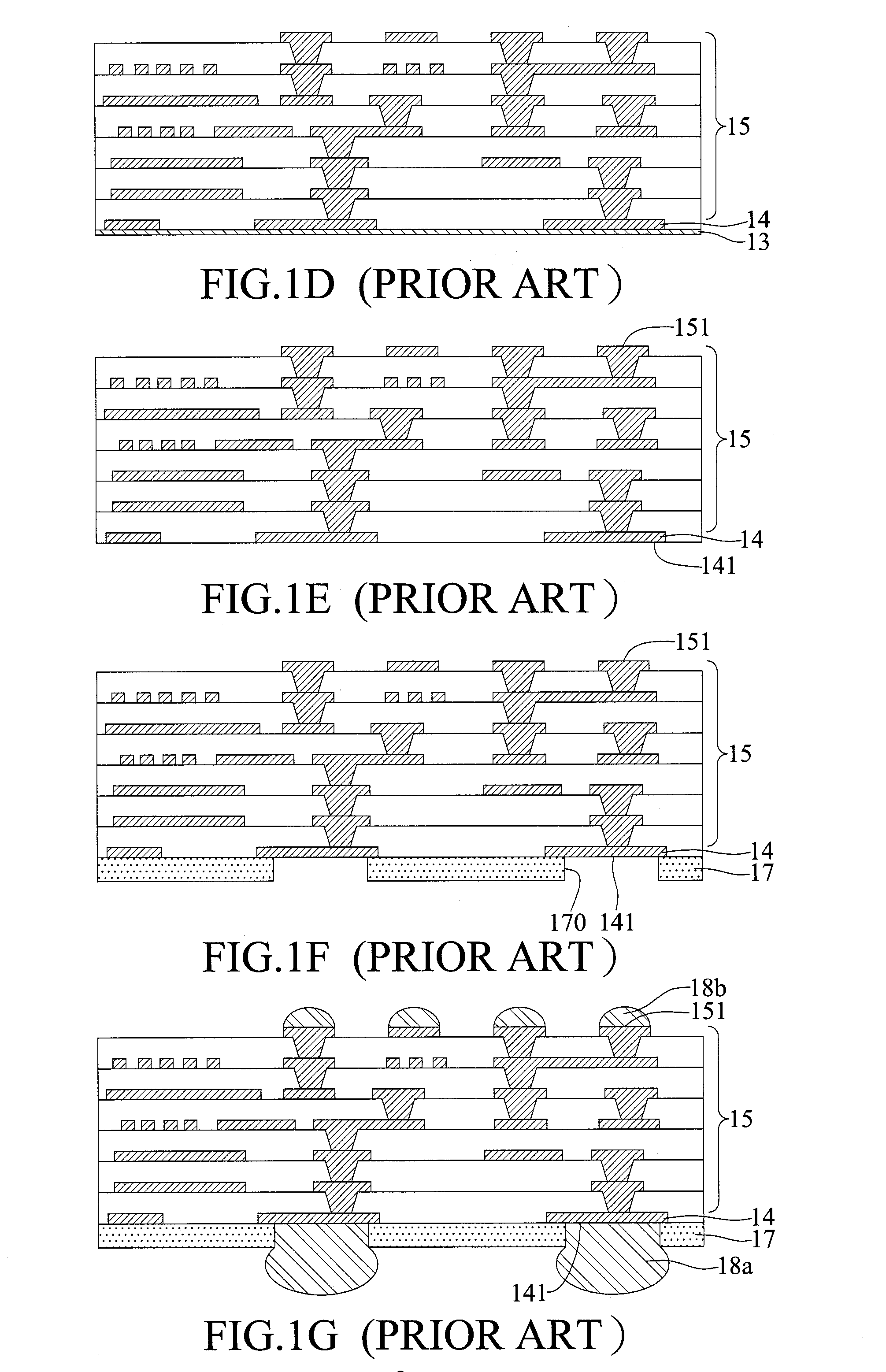

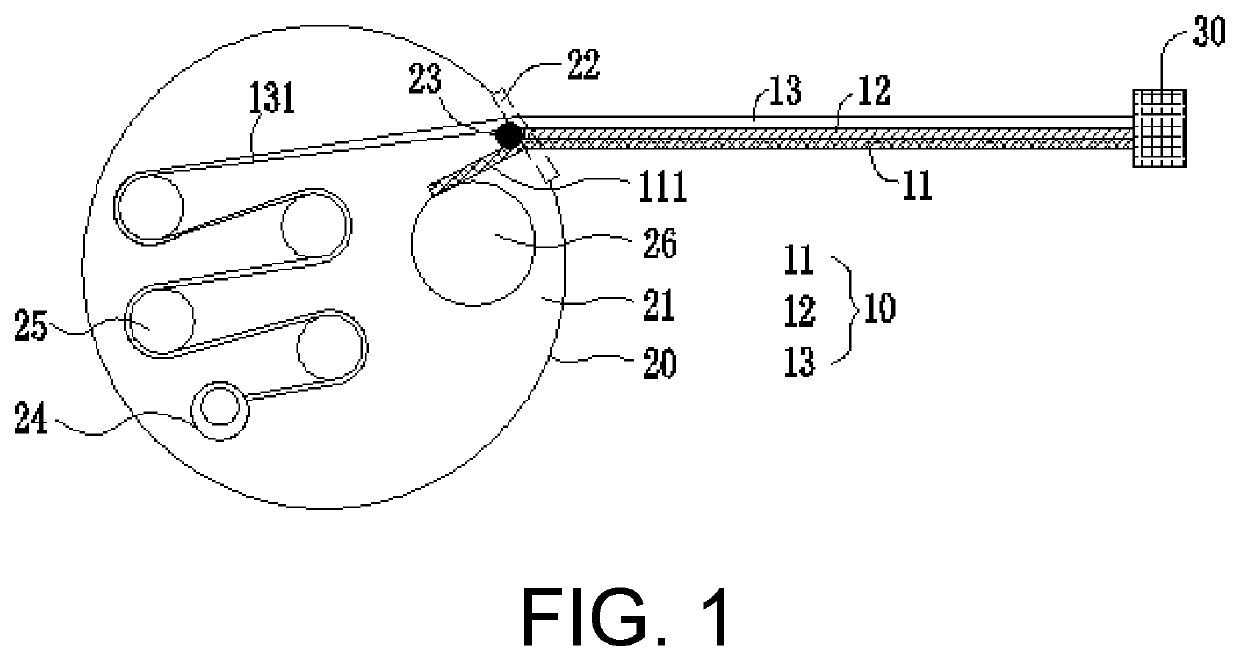

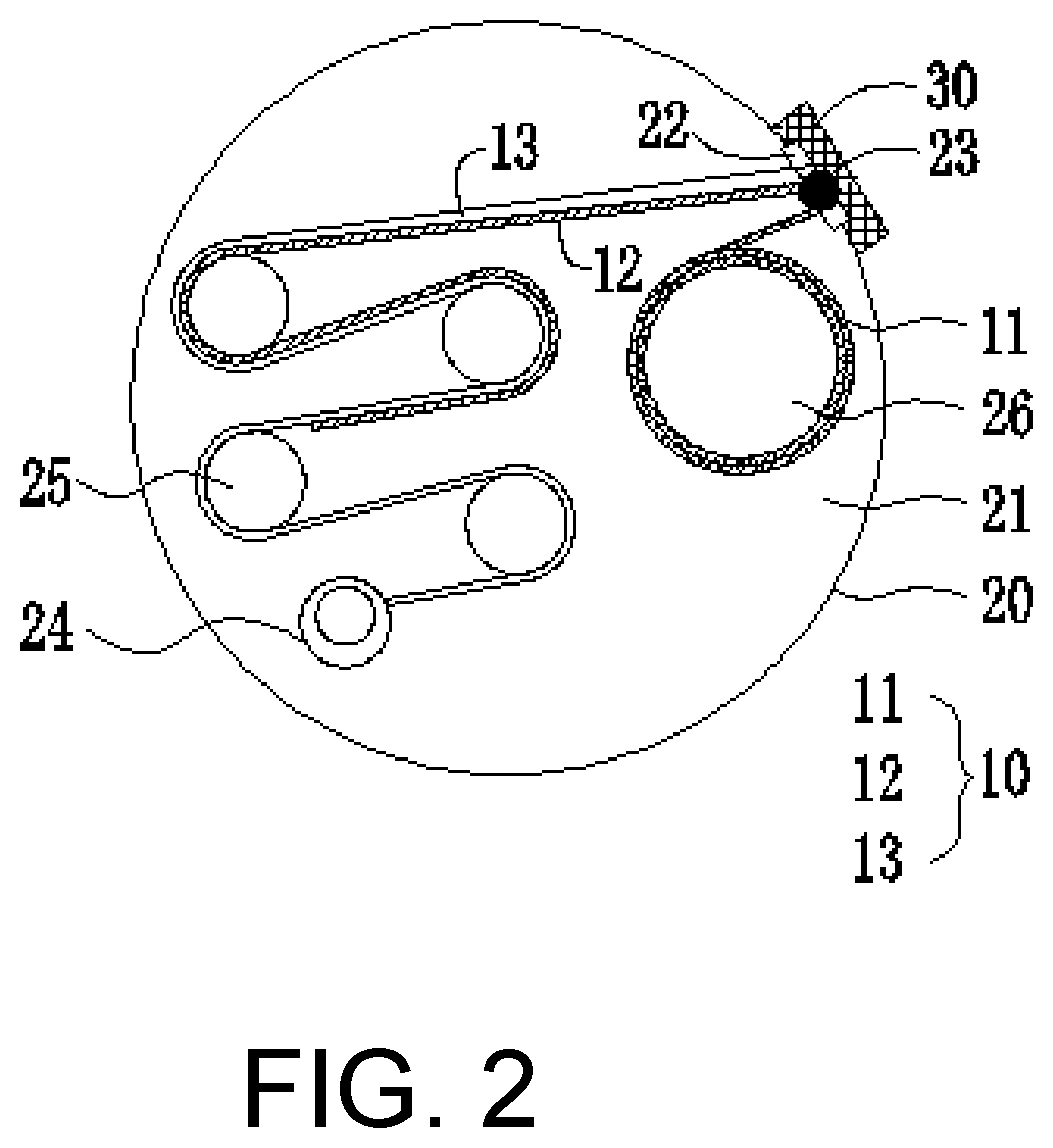

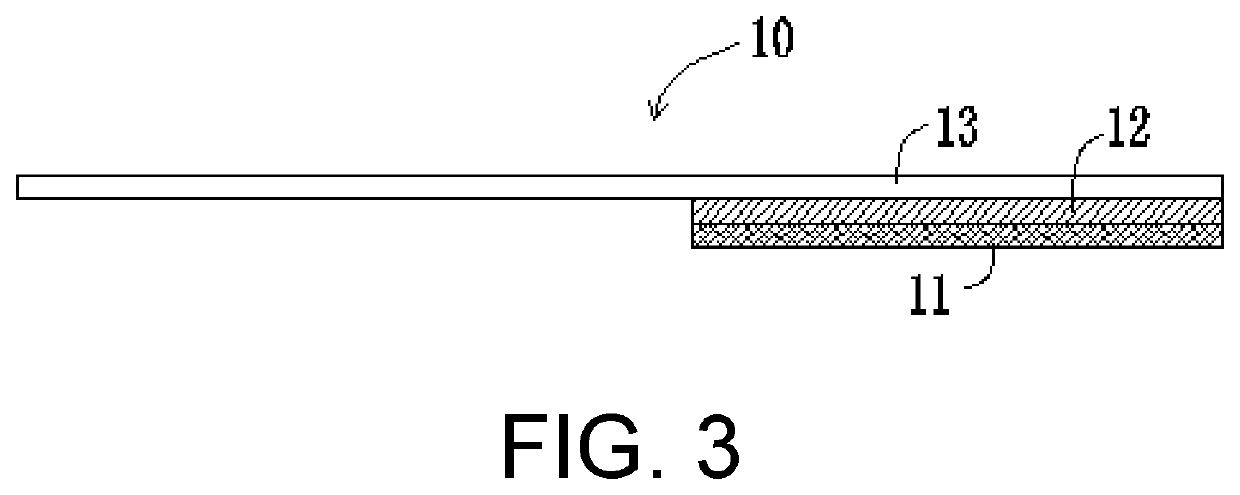

Carrier and method for fabricating coreless packaging substrate

ActiveUS20130335928A1Improve production yieldReduce manufacturing costSemiconductor/solid-state device detailsPrinted circuits stress/warp reductionElectrical and Electronics engineering

Owner:UNIMICRON TECH CORP

Refrigerator

InactiveCN103148655AEasy to manufactureReduce manufacturing costLighting and heating apparatusDomestic refrigeratorsRefrigerator carHigh density

The invention discloses a refrigerator, which comprises a refrigerator body and a door body, wherein a refrigeration room is arranged in the refrigerator body, in addition, the refrigerator body comprises a refrigerator case, a refrigerator liner and a foaming layer, the foaming layer is positioned in a foaming space between the refrigerator case and the refrigerator liner, the refrigerator case is provided with a top cover plate, the top cover plate comprises a top cover frame and a high-density plate, the high-density plate is fixedly arranged on the lower surface of the top cover frame for shielding a center hole of the top cover frame, and the door body is arranged on the refrigerator body and is used for opening and closing the refrigeration room. The refrigerator according to the embodiment of the invention has the advantages that the manufacture is easy, the deformation cannot easily occur, the finished product rate is high, the cost is low, and the like.

Owner:HEFEI HUALING CO LTD

Laminated battery cell and lithium ion battery

InactiveCN112271299ALow densitySolve the problem of curl breakageFinal product manufactureElectrode carriers/collectorsStructural engineeringLithium-ion battery

The invention provides a laminated battery cell and a lithium ion battery. The laminated battery cell comprises positive plates and negative plates, the positive plates and the negative plates are alternately laminated, and a diaphragm is arranged between every two adjacent pole pieces; each pole piece positioned on the outermost side comprises a current collector, an active layer and a coating, the active layer is positioned on one side, close to the interior of the battery cell, of the current collector, the coating is positioned on one side, far away from the interior of the battery cell, of the current collector, and a heat conduction material and / or a flame-retardant material are / is arranged in the coating. According to the invention, the problems of consumption of active lithium on the outermost layer of the laminated structure and reduction of the first effect and the capacity are solved, the problem of rolling damage caused by rolling stress of a single-sided coating pole pieceis also solved, more importantly, the heat conduction material and / or the flame retardant material can improve the safety performance of the laminated core, such as heat dissipation and flame retardance, and the safety and the practicability of the battery cell are greatly improved.

Owner:ZHUHAI COSMX POWER CO LTD

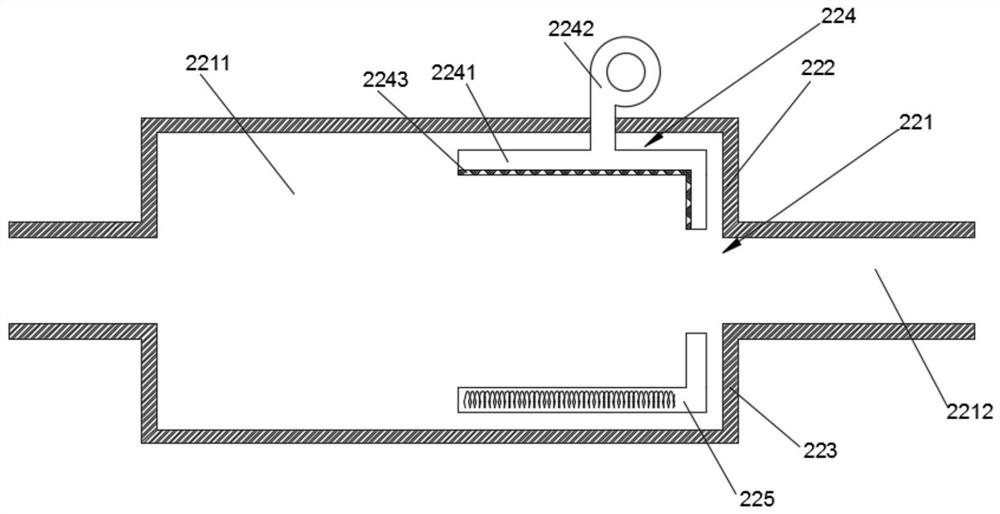

Flexible display device

ActiveUS11170671B1Occupies spaceRisk of separationDigital data processing detailsIdentification meansEngineeringFlexible display

The present invention provides a flexible display device including: a display module; an accommodating casing defined with a hollow cavity, an open channel defined in the accommodating casing, a chain lock disposed in the open channel, a resilient member, a first roller, and a second roller disposed in the hollow cavity, the resilient member forming a pre-pulling on the display module; the chain lock disassembling the display module into a first assembly and a second assembly to be rolled up on the first roller and the second roller respectively, and configured to combine the first assembly and the second assembly into the display module.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Steel structure including pre-stressing brackets for improving load-carrying capacity and serviceability

ActiveUS20130097947A1Improve carrying capacityIncreased prestressing effectGirdersJoistsPre stressPre stressing

A steel structure including pre-stressing brackets for improving load-carrying capacity and serviceability comprises: a steel girder; a plurality of connecting brackets connected to the bottom surface of the steel girder spaced and apart from one; and a cover plate connected to the bottom surfaces of the connecting brackets. Since the cover plate is installed regardless of the connecting portion of the steel girder, pre-stressing section can be consecutively formed therefore pre-stress effect is improved. Moreover, since the connecting brackets space the cover plate a constant distance from the steel girder, the moment of inertia is increased so the span of a bridge might be increased.

Owner:YOOHO DEV & CONSTR +1

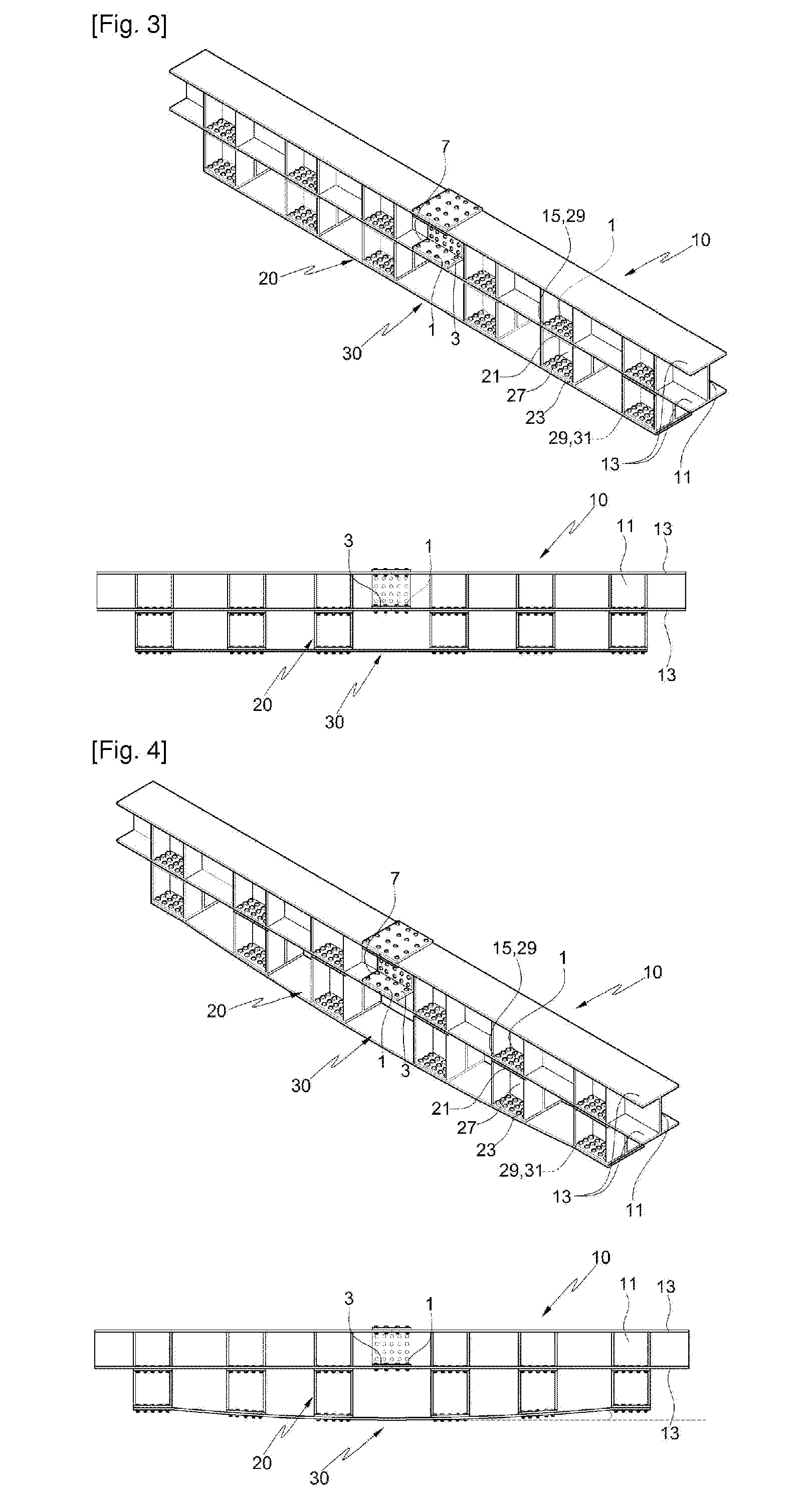

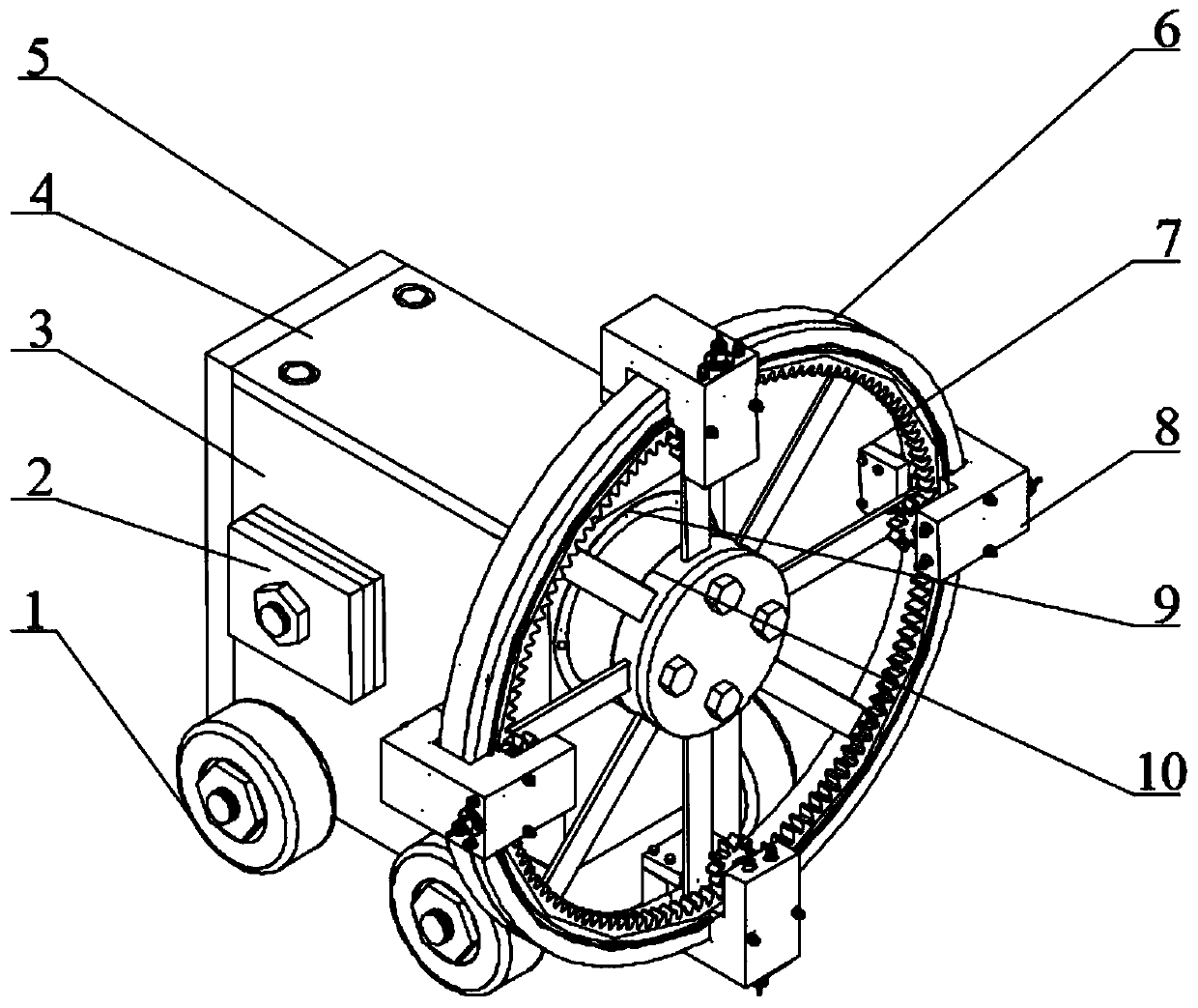

Dismantling robot for residual refractory brick in rotary kiln and dismantling method

ActiveCN109780871ARealize demolition workReduce labor intensityLinings repairManipulatorBrickControl system

The invention discloses a dismantling robot for a residual refractory brick in a rotary kiln and a dismantling method, and belongs to the technical field of industrial robots. The robot comprises a bearing moving system, a displacement system, a locking system, a feeding system, a feedback system and a control system. According to the dismantling robot, four feeding boxes are mounted on a machineframe, and the dismantling of the residual refractory brick is completed by using the coordination work of all systems; and the dismantling robot is a very typical electro-mechanical integrated system, technologies such as mechanical, electronic, control and sensing are integrated, the robot meets the relevant requirements of the cleaning of the residual refractory brick of the rotary kiln, the cleaning operation of the residual refractory brick can be completed efficiently, meanwhile, a kiln body is not damaged, and the automation and intelligence of the dismantling of the residual refractorybrick are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

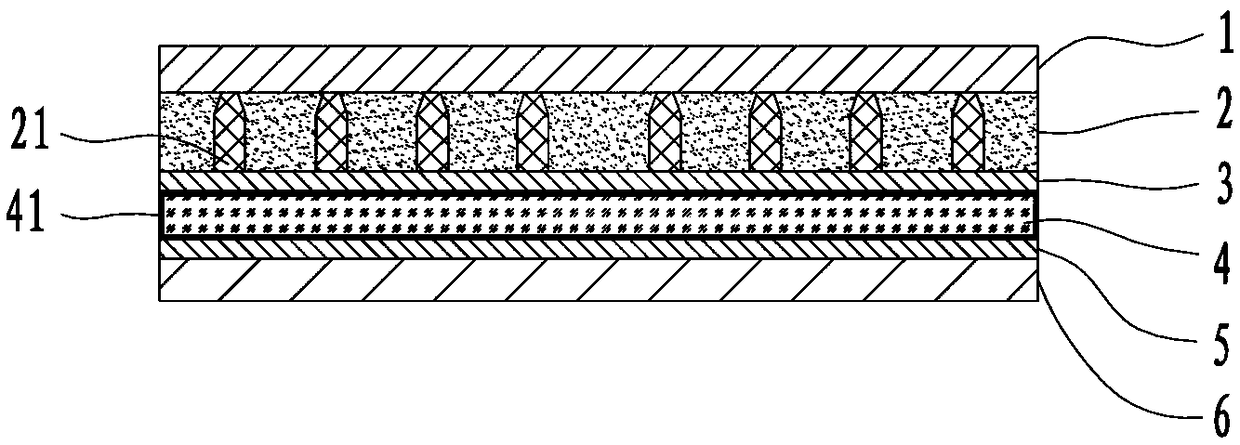

Conductive foam suitable for electromagnetic shielding

ActiveCN108882664AGuaranteed electromagnetic shielding performanceImprove conductivityMagnetic/electric field screeningAlloy thin filmCarbon nanotube

The invention discloses conductive foam suitable for electromagnetic shielding. The conductive foam sequentially comprises an outer protection layer, a foam layer, a first pasting layer, a metal foillayer and a second pasting layer, wherein the layers are combined to form the conductive foam, a nickel-titanium alloy thin film is formed on each of an upper surface and a lower surface of the metalfoil layer, leakage holes are formed in the foam layer and are filled with carbon nanotubes, the carbon nanotubes are porous spongy carbon nanotube block-shaped materials, first surfaces of the nickel-titanium alloy thin films are connected with the foam layer and the carbon nanotubes in the foam layer by the first pasting layer, and second surfaces of the nickel-titanium alloy thin films are connected with the second pasting layer. In the conductive foam provided by the invention, relatively excellent integral shielding performance and conductive performance can be provided for electronic equipment in a closed and narrow space with poor cooling performance.

Owner:XIAMEN BEACONING PRECISION IND CO LTD

Manufacture method for insulated gate bipolar transistor (IGBT) device

InactiveCN103035520AOffset stressImprove warpageSemiconductor/solid-state device manufacturingEngineeringSilicon

The invention discloses a manufacture method for an insulated gate bipolar transistor (IGBT) device. Before a metal layer of an IGBT separation device deposits, a film with positive stress is formed at the back of a silicone wafer of a formed device structure. The manufacture method can effectively offset stress of the metal layer, improves warping degree of the silicon wafer and enables follow-up photoetching and etching on the metal layer to be constructed normally.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

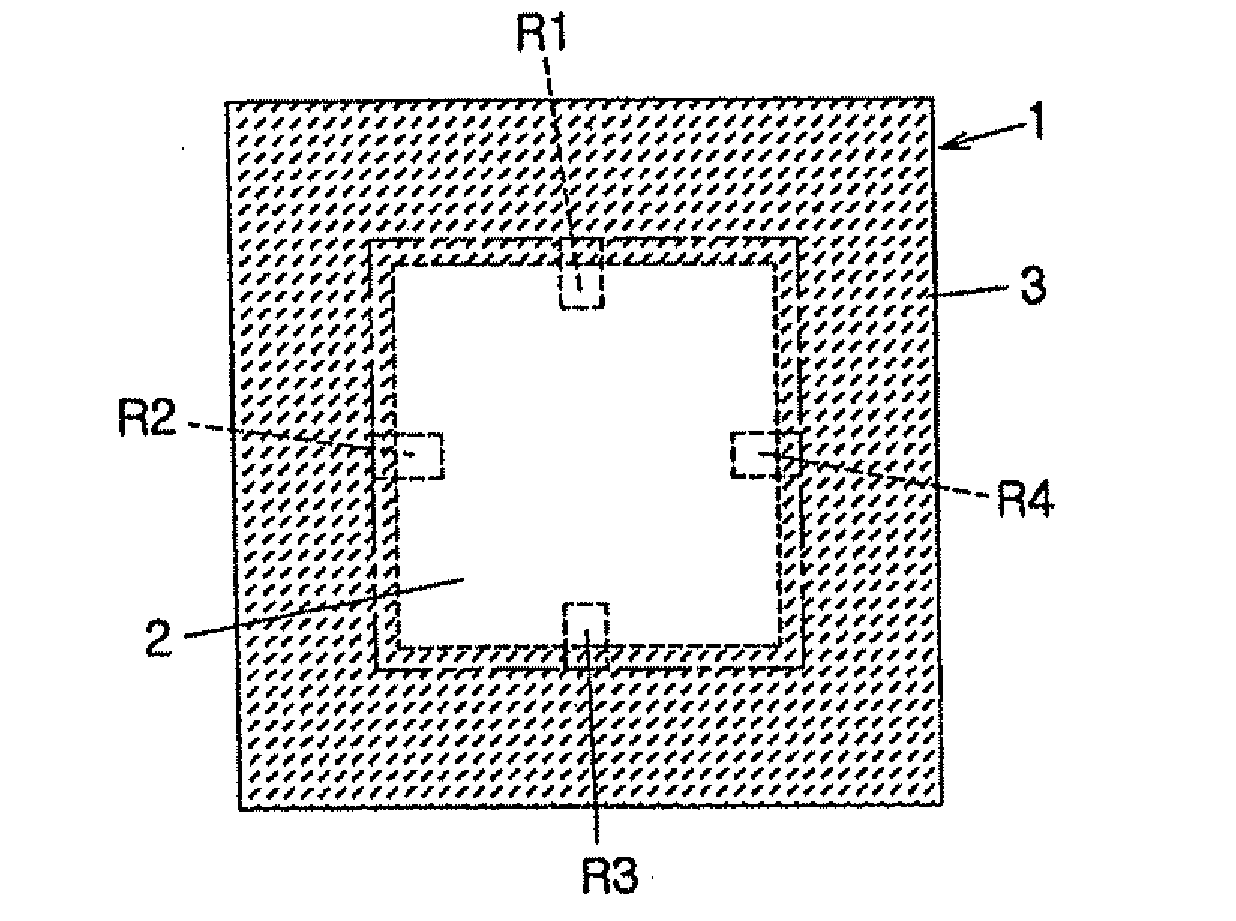

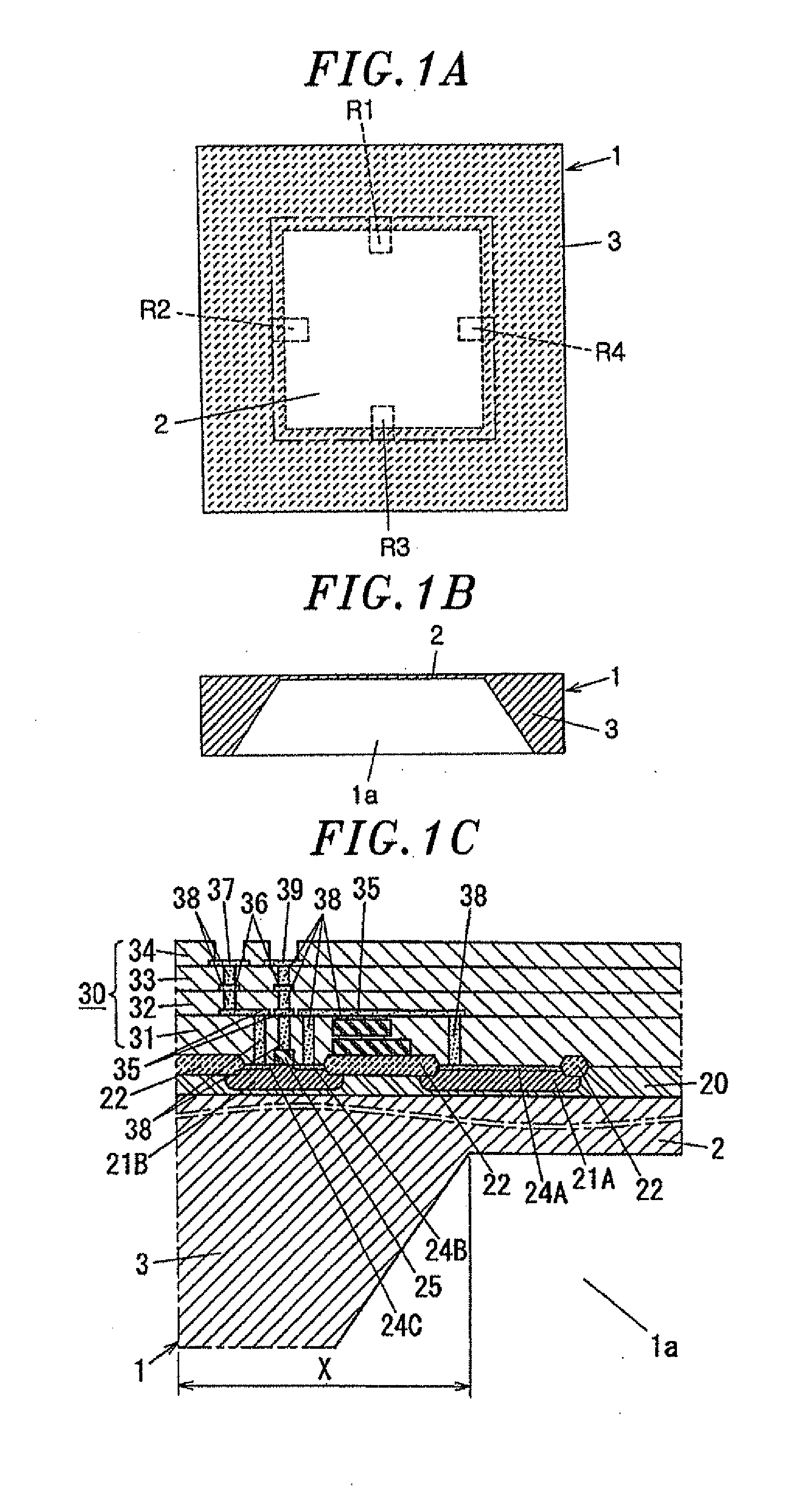

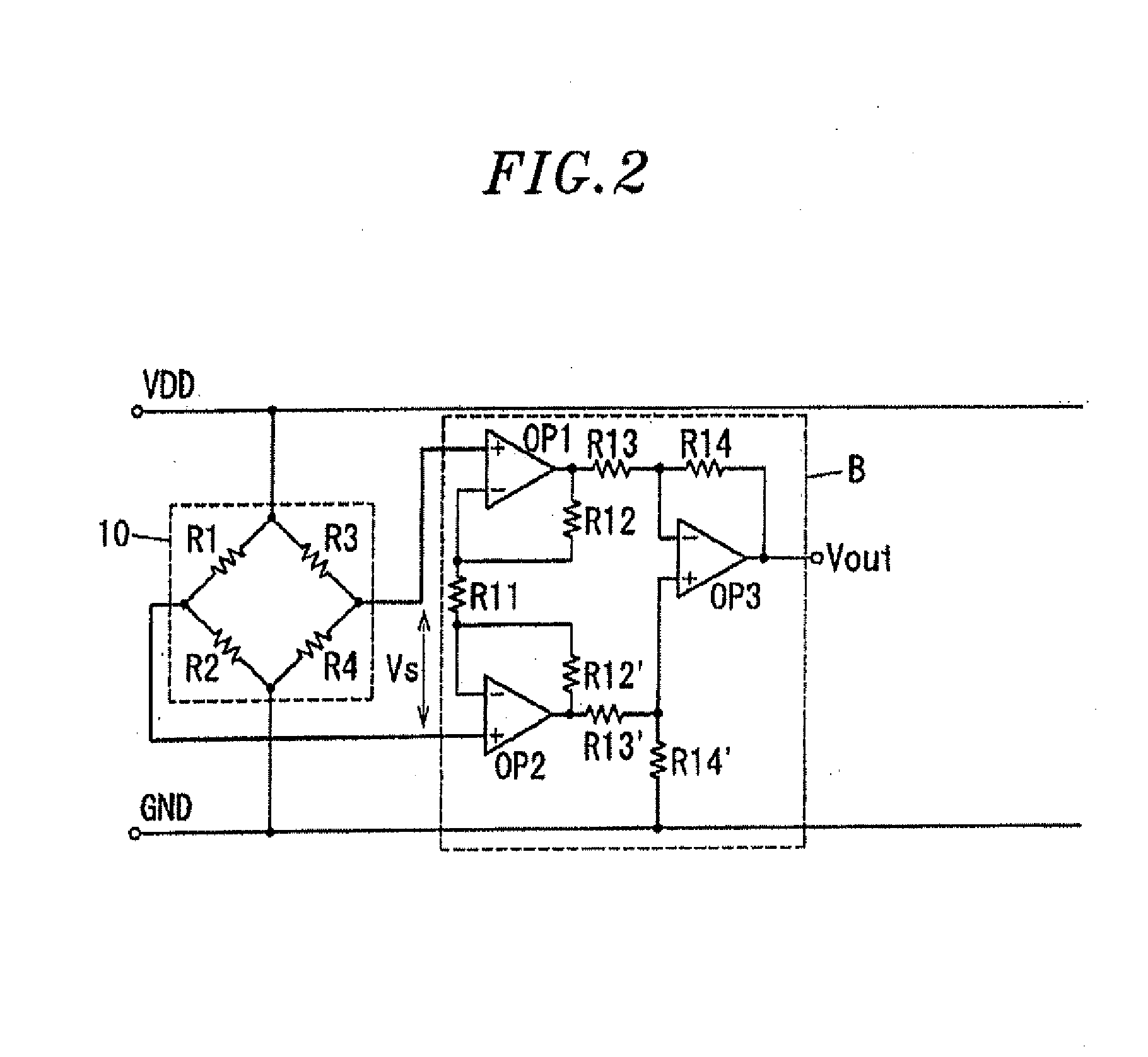

Pressure sensor

InactiveUS20120285254A1Reduce spacingImprove performanceTransistorFluid pressure measurement using ohmic-resistance variationCMOSDiffusion

A pressure sensor includes: a pressure conversion unit and a signal processing circuit installed in a semiconductor substrate. The pressure conversion unit includes: a diaphragm formed by partially thinning the semiconductor substrate; and a plurality of piezo resistive elements formed on a surface of the diaphragm. The signal processing circuit is constituted by a complementary metal-oxide semiconductor (CMOS) integrated circuit formed in a p-type conductive region disposed around the diaphragm on the surface of the semiconductor substrate, and the piezo resistive elements are provided by forming an n-type conductive region in the p-type conductive region on the surface of the diaphragm by diffusion of n-type impurities and diffusing p-type impurities in the n-type conductive region.

Owner:NIIMURA YUICHI +3

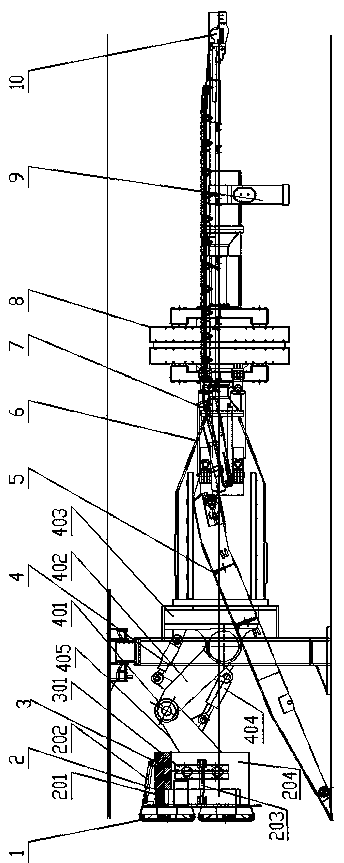

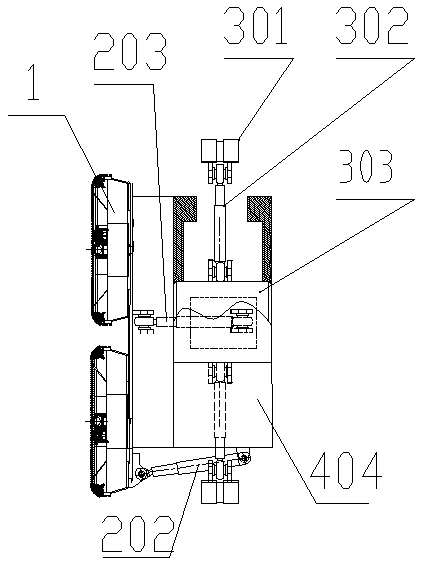

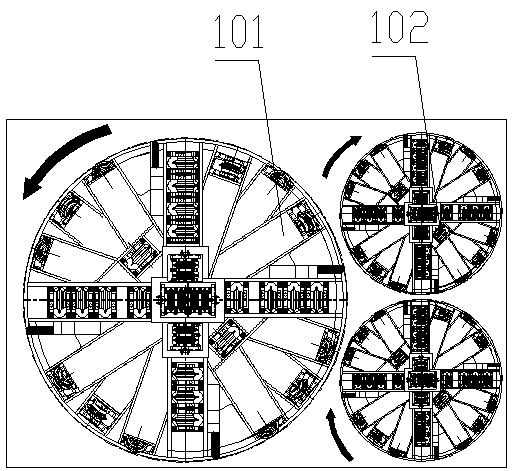

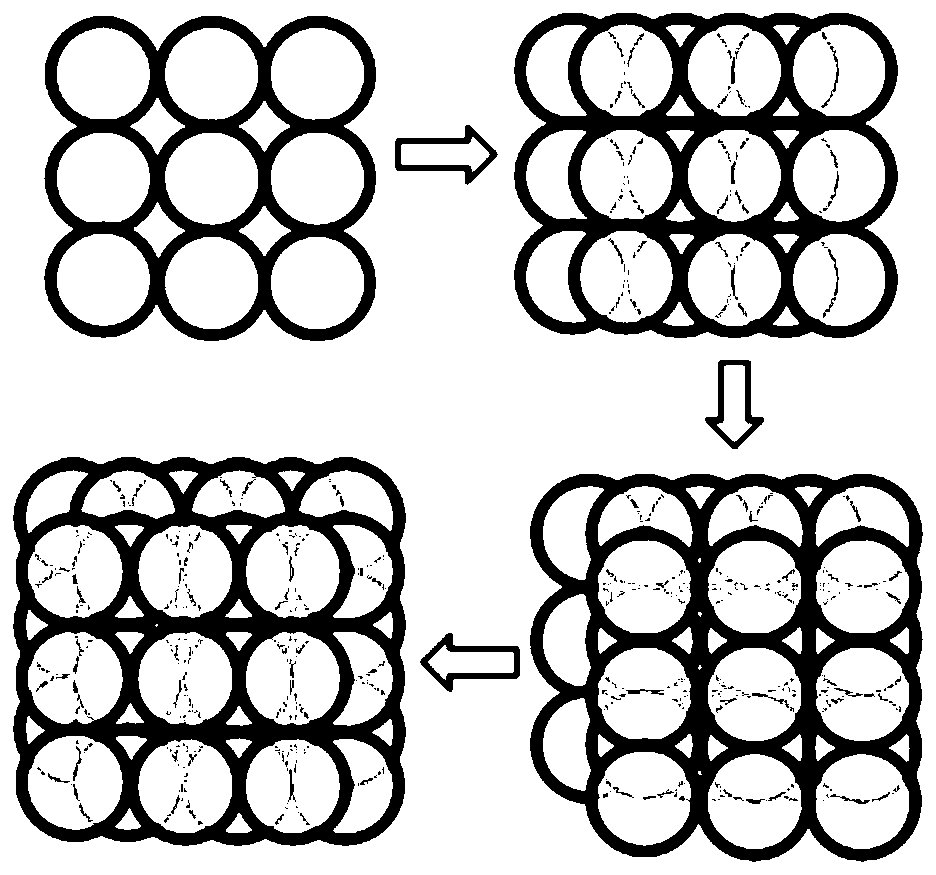

Robot-supported flexible arm tunnel boring machine (Robot-TBM) with multiple cutters boring tunnels with arbitrary cross sections

The invention discloses a robot-supported flexible arm tunnel boring machine (Robot-TBM) with multiple cutters boring tunnels with arbitrary cross sections, so as to meet the boring needs of diversified tunnel cross sections at present and make up for the single shortcomings of cross section boring by the existing tunnel boring machine. The robot-supported flexible arm tunnel boring machine (Robot-TBM) with multiple cutters boring tunnels with arbitrary cross sections comprises a cutter system and a main beam, wherein the rear part of the main beam is connected with the front part of a rear support shoe through a thrust cylinder, and the rear part of the rear support shoe is connected with a rear support; the front part of the main beam is connected with the cutter system through a robot;and the cutter system comprises at least three cutters. Due to the combined cutter system structure with multiple cutter moments coupled, the stress generated during working can be offset, the structure is optimized, and the cost is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

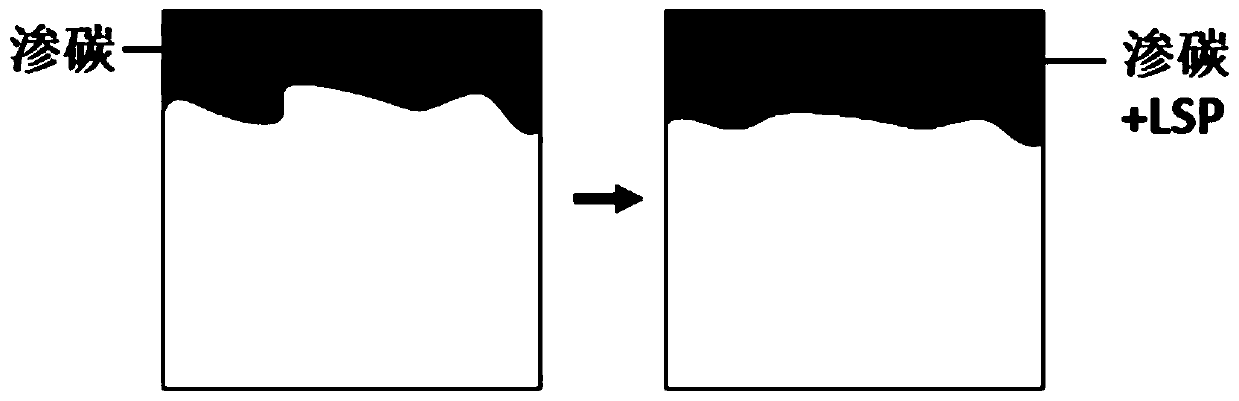

Compound technique capable of improving wear resistance and fatigue resistance of engine gear

InactiveCN111041406AImproved wear/fatigue resistanceImprove reliabilitySolid state diffusion coatingFurnace typesLight spotGear wheel

The invention discloses a compound technique capable of improving the wear resistance and fatigue resistance of an engine gear. According to the structural form of the gear, a machining path for carburization-laser shock peening is designed, and the machining demands of different positions are met. The compound technique specifically comprises the steps of 1, adopting a gas carburization technology for conducting carburization treatment on the surface of the gear; 2, conducting quenching and tempering treatment on the gear obtained after carburization treatment in step 1; 3, conducting laser shock peening treatment on the gear obtained after quenching and tempering treatment in step 2, and determining parameters of laser shock peening such as the laser wavelength, pulse width, power density, shock frequency and shock angle according to the features of materials adopted by the gear, wherein during laser shock peening treatment, the diameter of light spots is 2.4 mm, and the overlap rateof the light spots is 50%. By means of the compound technique, the technological advantages of carburization and laser shock peening are comprehensively utilized, the surface hardness and residual compressive stress of the aeroengine transmission gear are effectively increased, thus the wear resistance and fatigue performance are improved, and the requirement of industrial application is met.

Owner:XI AN JIAOTONG UNIV +1

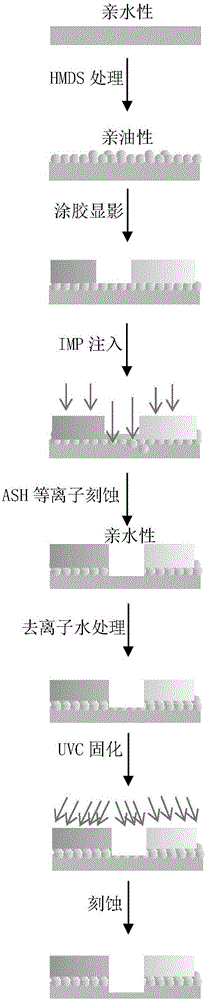

Method for preventing peeling of photoresist

The invention discloses a method for preventing peeling of a photoresist. The method is used after an ion implantation process and before an etching process, and specifically comprises the following steps: 1) carrying out treatment on a silicon substrate surface, so that the silicon substrate surface not coated with the photoresist is changed to be hydrophilic; 2) treating the silicon substrate surface by employing water, so that a silicon substrate not coated with the photoresist absorbs the water and is expanded; and 3) carrying out curing treatment on the photoresist. According to the method disclosed by the invention, after the ion implantation, through firstly treating the silicon substrate surface by employing an ASH plasma so that the exposed silicon substrate surface is changed to be hydrophilic, and then treating the silicon substrate surface by employing the water so that the exposed silicon substrate absorbs the water and is expanded, a stress produced by colloid shrinkage when UVC is cured is offset; and thus, the photoresist, when being etched, is prevented from occurring the peeling with the silicon substrate, and the etching is guaranteed to obtain good graphics.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

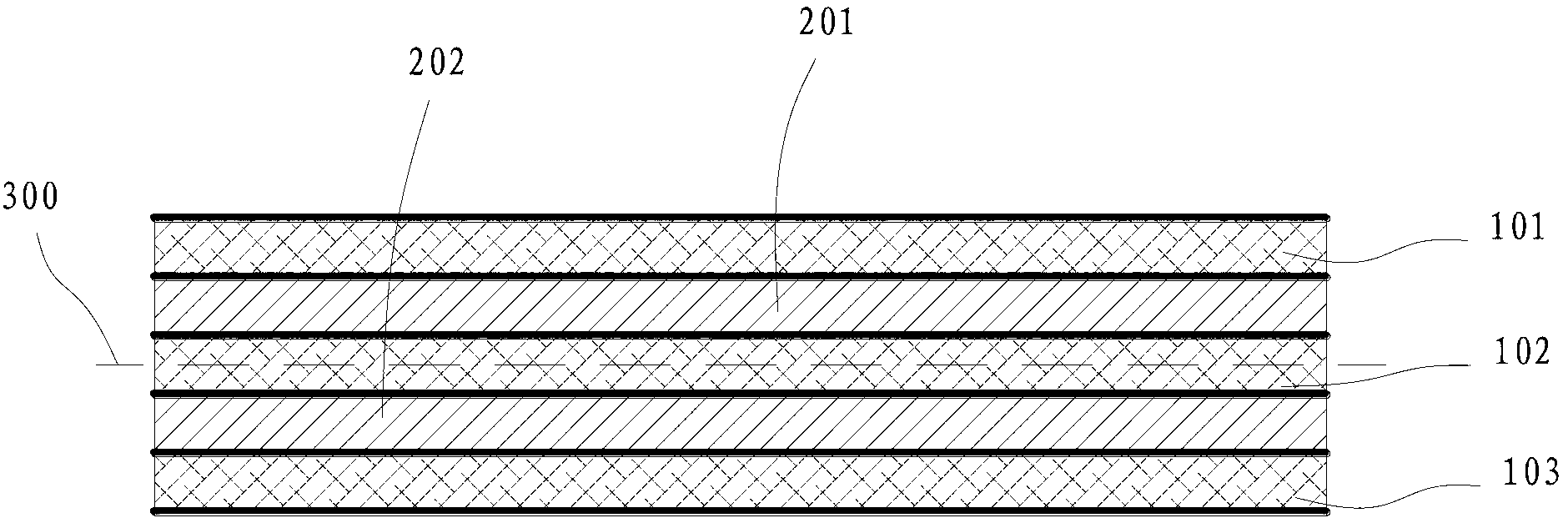

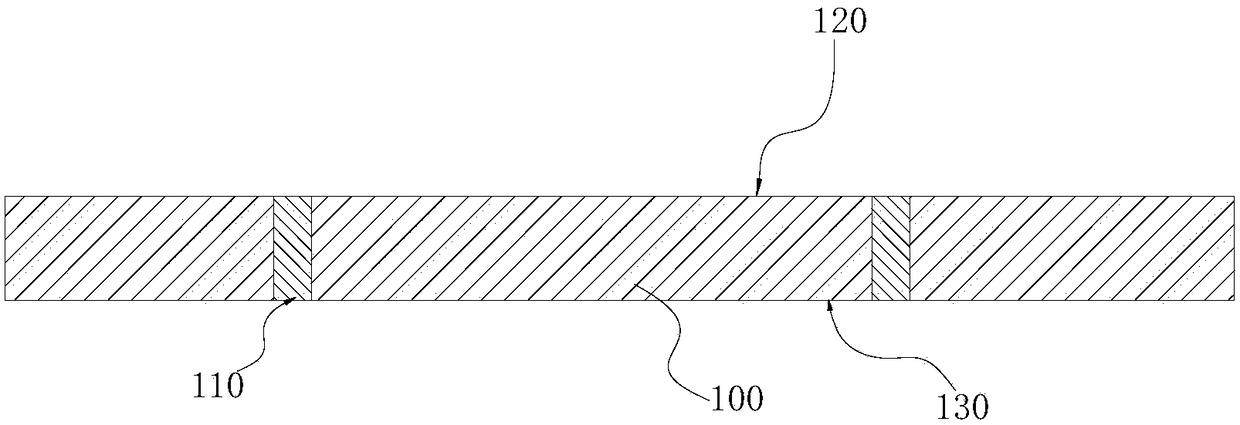

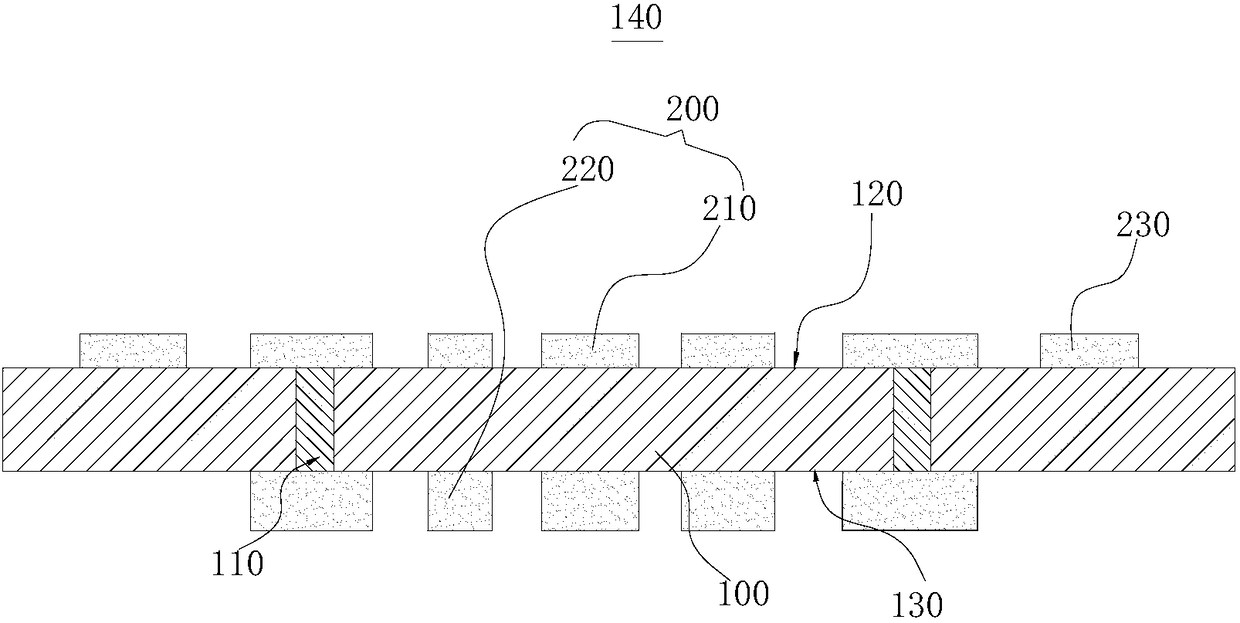

Ceramic substrate and manufacturing method thereof

InactiveCN109427596AIncreasing the thicknessImprove warpageSemiconductor/solid-state device detailsSolid-state devicesCeramic metalCeramic substrate

The invention relates to a ceramic substrate and a manufacturing method thereof. The manufacturing method comprises the steps of printing a first metal layer on a first surface of the ceramic substrate having a conduction hole, and printing a second metal layer on a second surface opposite to the first surface, so that a conductive circuit is formed, a pad area is formed on the first surface, anda thickness of the second metal layer is greater than a thickness of the first metal layer; printing a welding flux layer on the first surface; attaching an encapsulation frame on the welding flux layer; and sintering, under a vacuum condition, a ceramic metal lining plate attached with the encapsulation frame. According to the ceramic substrate and the manufacturing method thereof, the residual stress caused by an asymmetric structure of a full plate is effectively reduced, and thus the warping degree of the ceramic substrate is effectively improved, and a rear-end client is convenient to perform work such as chip full-plate encapsulation and finished product cutting; and therefore, the product yield and efficiency are improved.

Owner:ZHEJIANG TC CERAMIC ELECTRONICS

The treatment process of pipe side floor drain in home decoration bathroom

InactiveCN104481018BImprove waterproof performanceGood adhesionSewerage structuresBuilding insulationsEmulsionPulp and paper industry

The invention provides a home decoration toilet pipe-side floor drain treatment process. The treatment process comprises the steps of S1, digging out a groove in the concrete floor around the root of a pipeline, removing residue in the groove and cleaning the groove by use of water, S2, coating the groove with an interface waterproof agent once or twice under the condition of moist, S3, evenly mixing a multifunctional emulsion with quick-setting cement in the weight ratio of (0.3-0.5): 1 into a paste, applying the paste into the groove, and compacting and trowelling, S4, after the filler in the groove is solidified, coating the root and the four sides of the pipeline with a secondary pipe fixation waterproof glue. According to the home decoration toilet pipe-side floor drain treatment process, at least three waterproof layers, namely the interface waterproof agent layer, the mixed layer of the multifunctional emulsion and the quick-setting cement, and the waterproof layer of the pipe fixation waterproof glue are provided. Due to triple waterproofing operations, the waterproof effect is excellent and the service life is long.

Owner:厦门顶巢建筑科技有限公司

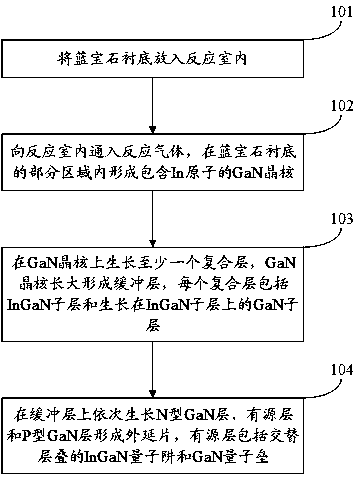

Growth method of light-emitting diode epitaxial wafer and light-emitting diode epitaxial wafer

ActiveCN111430515APromote formationIncrease in sizeSemiconductor devicesLattice mismatchQuantum well

The invention provides a growth method of a light emitting diode epitaxial wafer and the light emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The growth method comprises the following steps: putting a sapphire substrate into a reaction chamber; introducing a reaction gas into the reaction chamber, and forming a GaN crystal nucleus containing In atoms in a partial region of the sapphire substrate; at least one composite layer grows on the GaN crystal nucleus, the GaN crystal nucleus grows to form a buffer layer, and each composite layer comprises an InGaNsub-layer and a GaN sub-layer growing on the InGaN sub-layer; and sequentially growing an N-type GaN layer, an active layer and a P-type GaN layer on the buffer layer to form an epitaxial wafer, wherein the active layer comprises InGaN quantum wells and GaN quantum barriers which are alternately stacked. By forming the GaN crystal nucleus which is large in size and stable, stress generated by lattice mismatch between the sapphire substrate and the GaN-based material is effectively counteracted.

Owner:HC SEMITEK SUZHOU

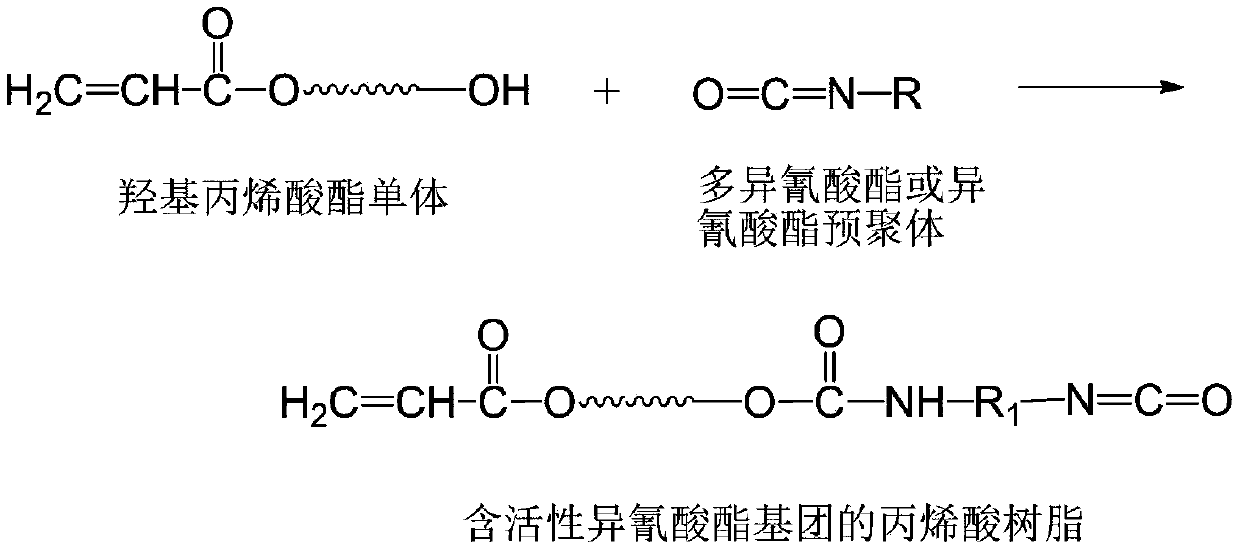

Double-curing one-component bamboo wood waterproof coating and application thereof

InactiveCN109852113AImprove ductilityImprove toughnessPolyurea/polyurethane coatingsPolyether coatingsAcrylic resinReactive diluent

The invention discloses a double-curing one-component bamboo wood waterproof coating. The coating comprises the following components, in parts by weight: 30-98 parts of acrylic resin containing activeisocyanate groups, 0-60 parts of a reactive diluent, 0.5-10 parts of a photoinitiator, and 0.1-2 parts of a water removing agent. The invention also provides an application of the above double-curingone-component bamboo wood waterproof coating. The waterproof coating provided by the invention can be widely applied to waterproof treatment of wood products such as wood floors, wood furniture and veneer and bamboo products, has a simple production process and rapid curing, does not contain volatile organic compounds, is environmentally friendly and safe, and has firm combination with wood and excellent waterproof and anti-cracking effects.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Convex point structure of semiconductor wafer

ActiveCN105633034AAvoid failureOffset stressSemiconductor/solid-state device detailsSolid-state devicesWaferEngineering physics

The invention provides a convex point structure of a semiconductor wafer. The convex point structure comprises a wafer, a regenerative passivation layer formed on the upper surface of the wafer, a polymer material layer formed on the lower surface of the wafer and back adhesive layers formed on all exposed surfaces of the polymer material layer. Compared with the prior art, the forming method for the convex point structure of the semiconductor wafer, provided by the invention, has the advantages that the wafer warppage can be reduced, and thus, the fabrication of processes such as test, printing and ball implantation before cutting is facilitated.

Owner:NANTONG FUJITSU MICROELECTRONICS

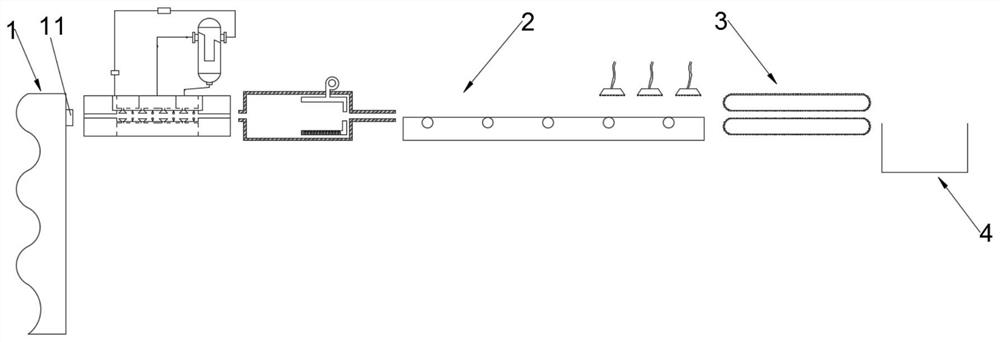

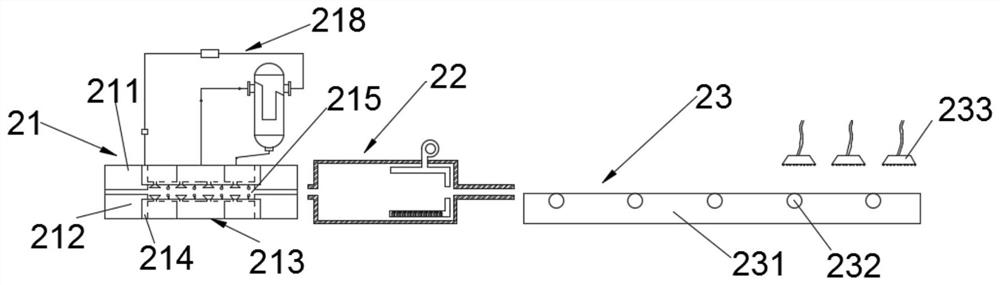

Foamed decorating plate production device and method

ActiveCN111605157ASmooth rollingThere will be no problems such as deformationFlat articlesMechanical engineeringCooling water temperature

The embodiments of the invention disclose a foamed decorating plate production device and method. The foamed decorating plate production device comprises a discharging part, a segmented cooling part,a flattening part and a receiving part, wherein the discharging part comprises an extrusion die head for extruding a material body into a template prototype; and the segmented cooling part at least comprises an indirect cooling structure, a temperature rising structure and a blowing cooling structure which are sequentially arranged in the conveying direction. The production method comprises the steps that raw materials are mixed, heated and then cooled; after being subjected to extrusion molding, the mixed raw materials are cooled by a contact cooling structure, then sent into the temperaturerising structure to be reheated and then cooled by the blowing cooling structure; after being flattened by the flattening part, the cooled template prototype is pulled into the receiving part for cutting and receiving; the temperature of cooling water in the contact cooling structure is 40-60 DEG C; and in the reheating process, the temperature in the temperature rising structure is 80-85 DEG C. The effects that shrinkage deformation is avoided, the effectiveness of the cooling process is ensured, the physical and chemical properties are improved, and the product quality is improved are realized

Owner:山东宜居新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com