Laminated battery cell and lithium ion battery

A lithium-ion battery and cell technology, applied in lithium batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of increasing cost and battery quality, reducing battery first efficiency and capacity, and increasing battery temperature. Achieve the effect of solving curl damage, offset stress, and reduce internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

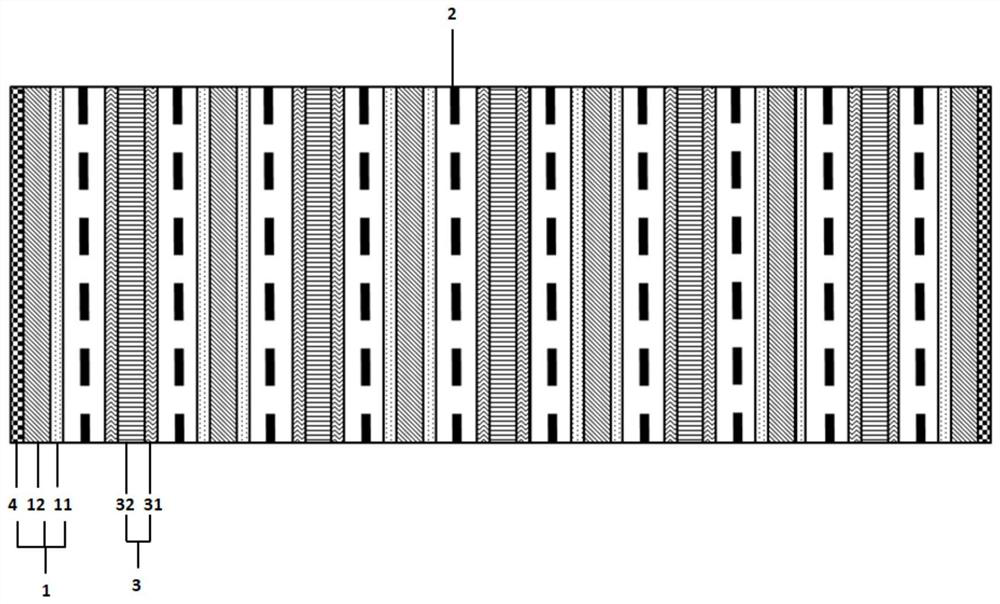

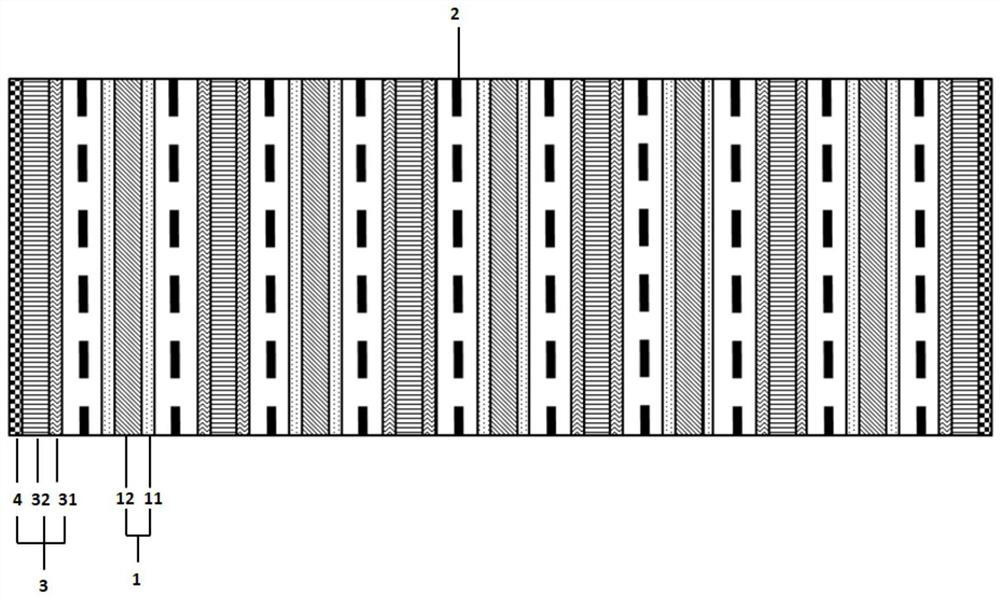

Method used

Image

Examples

Embodiment 1

[0054] (1) Prepare a positive electrode sheet P0 with one side coated with active material and one side coated with heat dissipation and flame retardant hot melt adhesive coating

[0055] The positive electrode active material ternary nickel-cobalt-manganese (NCM), binder PVDF and conductive carbon black are mixed, and a uniformly dispersed mixture is obtained by high-speed stirring. In the mixture, the solid content contained 95wt% NCM, 2wt% binder PVDF and 3wt% conductive carbon black. The mixture uses N-methylpyrrolidone as a solvent to prepare positive electrode active material slurry, and the solid content in the slurry is 70 wt%. The slurry was evenly coated on one side of the positive electrode current collector aluminum foil, and dried to obtain a single side coating of the positive electrode current collector active material of the aluminum foil, that is, the positive active layer, and the thickness of the coating was 120 μm.

Embodiment 2

[0064] (1) Prepare a negative electrode sheet N0 coated with an active material on one side and a heat-dissipating flame-retardant hot-melt adhesive coating on one side

[0065]The negative electrode active material graphite, SBR type binder, thickener sodium carboxymethyl cellulose and conductive carbon black are mixed, and the mixture is uniformly dispersed by high-speed stirring to form a mixture containing the negative electrode active material. In the mixture, the solid component contains 95wt% of graphite, 1.5wt% of sodium carboxymethylcellulose, 1.5wt% of conductive carbon black, and 2wt% of binder. Using deionized water as a solvent, a negative electrode active material slurry was prepared, and the solid content in the slurry was 50 wt%. The slurry was uniformly coated on one side of the copper foil, and dried to obtain a negative electrode sheet coated with an active material on one side, and the coating thickness was 130 μm.

[0066] Mix 60wt% EVA hot melt adhesive ...

Embodiment 3

[0072] The difference between embodiment 3 and embodiment 1 is only that: the hot melt adhesive material EVA in step (1) is replaced by polyurethane hot melt adhesive material. The rest of the steps and operation methods are the same as in Example 1, and the assembled battery is denoted as C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com