Trench-type super-junction device layout structure and manufacturing method thereof

A technology of layout structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as device failure, and achieve the effect of avoiding wafer warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

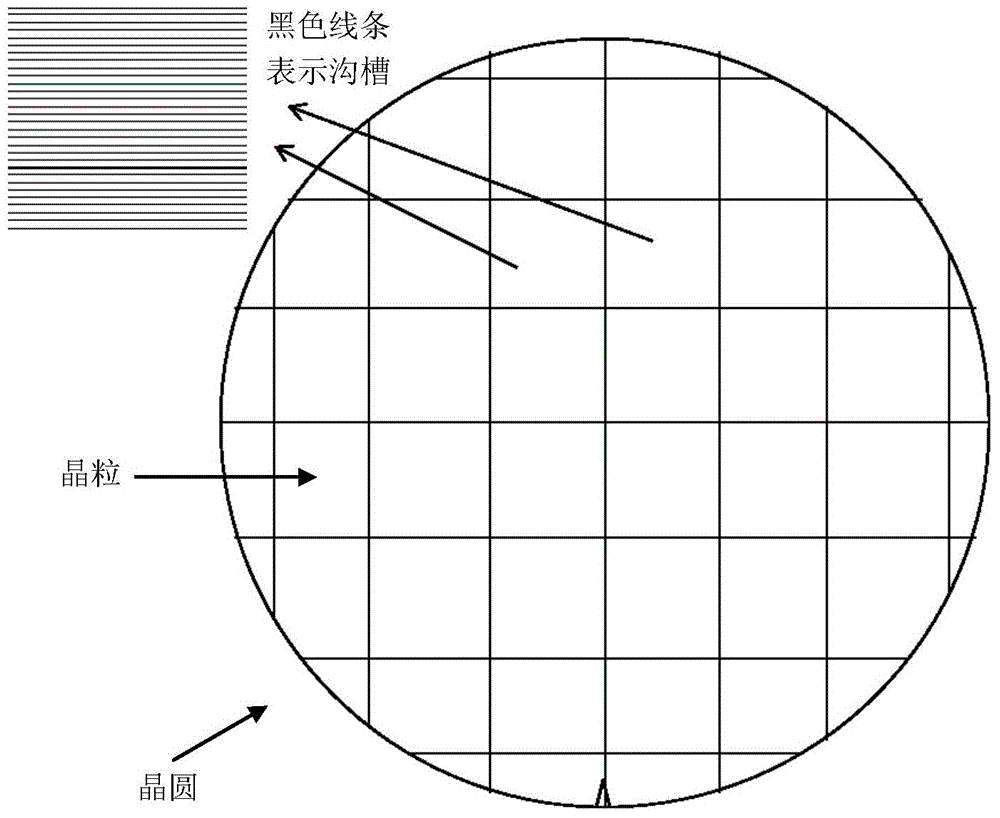

[0018] see Figure 4a , which is Embodiment 1 of the present application. In each die there are multiple trenches for forming pillars, all indicated by black lines. Adjacent and parallel grooves form a plurality of square groove arrays, and the groove arrays are approximately the same size. The arrangement directions of two adjacent groove arrays are perpendicular to each other no matter in the horizontal direction or in the vertical direction.

[0019] see Figure 4b , which is the second embodiment of the present application. It differs from Embodiment 1 only in that the shape of the groove array is either square or rectangular, and the size of the groove array is different.

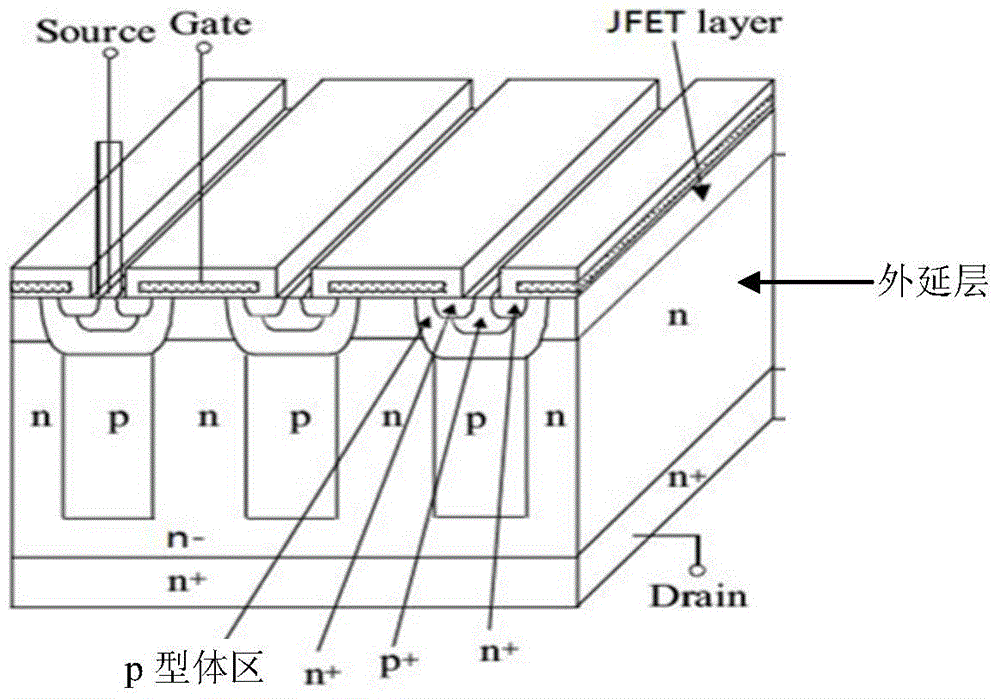

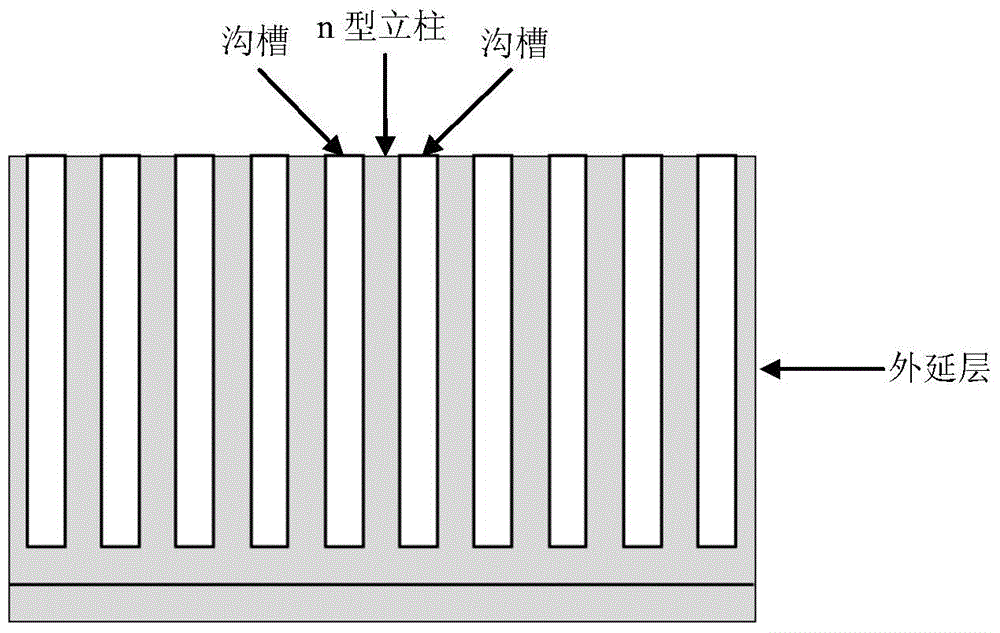

[0020] Since the present application has an array of trenches perpendicular to each other in a crystal grain, the manufacturing process of the layout structure of this special trench-type super junction device is as follows: Figure 5a to Figure 5c As shown, take the manufacture of super junction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com