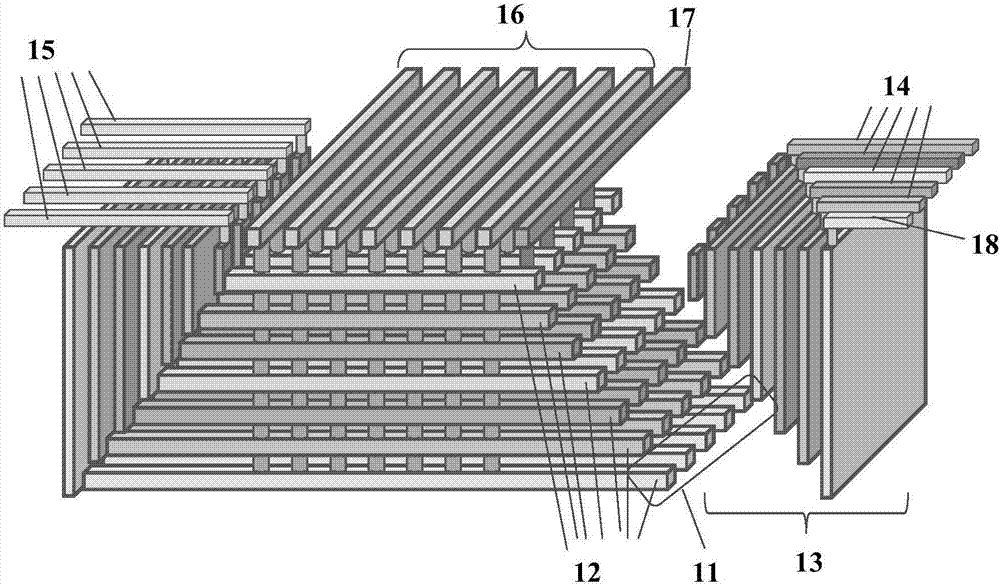

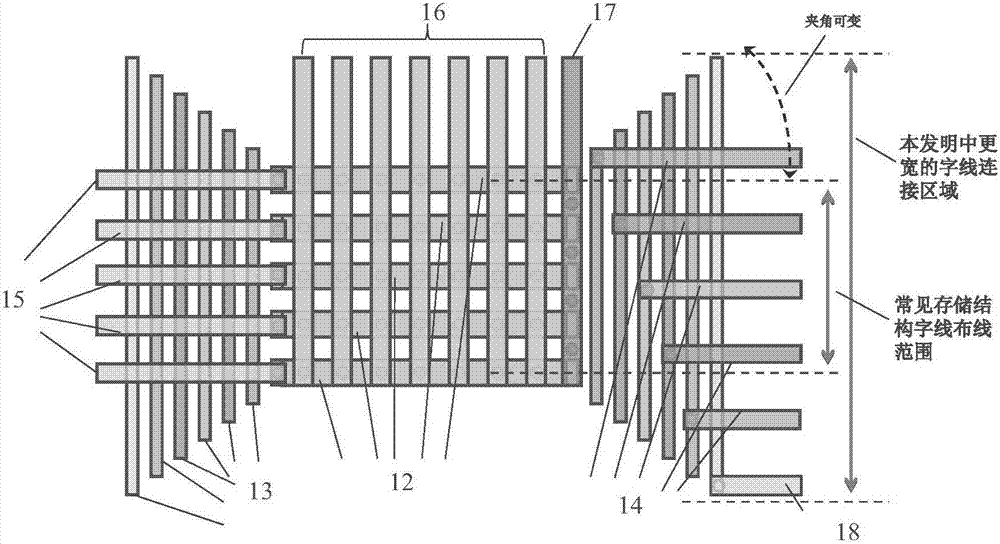

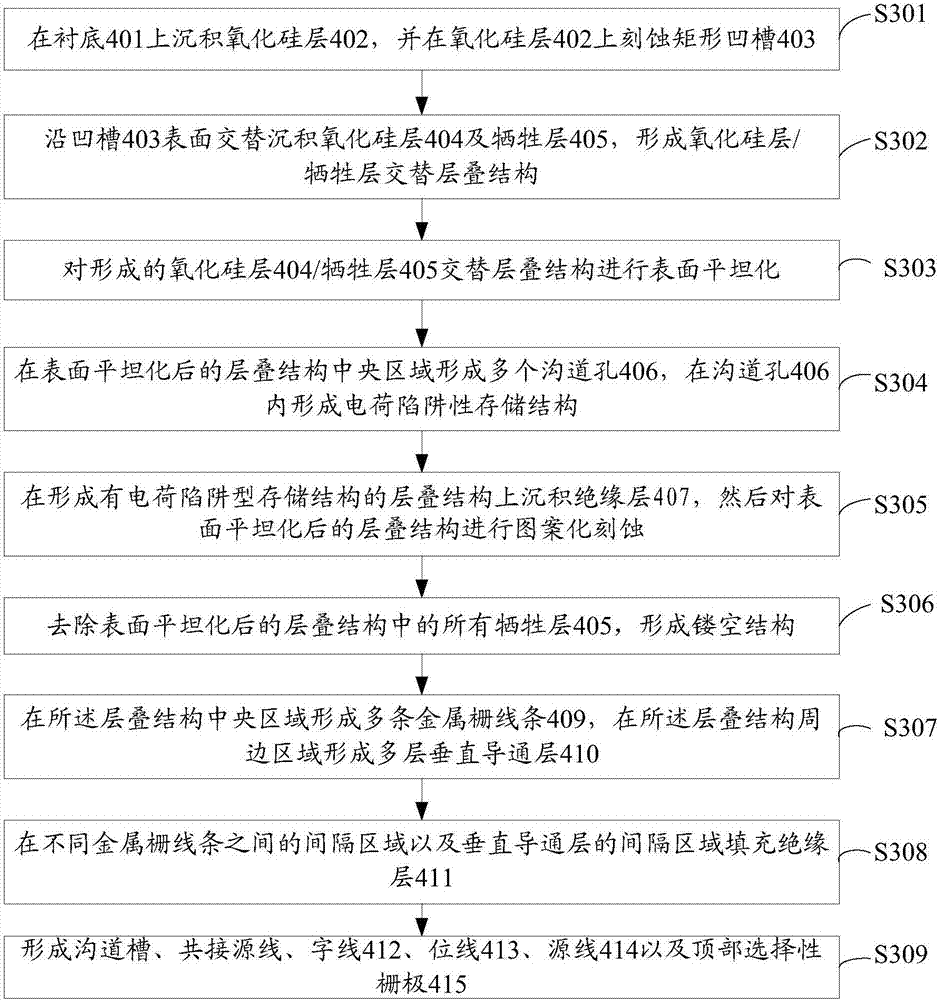

Memory structure of 3D NAND memory and method for manufacturing the same

A memory structure and memory technology, which is applied in the field of memory, can solve the problems of large degree of wafer warpage, uneven stress distribution, and reduced registration accuracy, and achieve the effects of avoiding wafer warpage and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to avoid the phenomenon that the vertical connection channels formed due to wafer warpage cannot be accurately connected with the stepped metal gate layer one by one, and thus cannot form an effective storage word line area, the application provides an integrated method of the stepped metal gate layer and the vertical connection channel. The storage structure of the formed 3D NAND memory and its preparation method. Since the metal gate and the vertical conduction layer are integrally formed, the storage structure and its preparation method can ensure that the vertical conduction layer is connected with the stepped metal gate layer one by one accurately, thereby forming an effective storage word line region.

[0048] In addition, in the embodiment of the present application, the stepped shape of the metal gate layer in the storage structure can be automatically formed during the process of film deposition. Therefore, the preparation method provided in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com