Home decoration toilet pipe-side floor drain treatment process

A treatment process and toilet technology, applied to water supply devices, waterway systems, drainage structures, etc., can solve the problems of filling mortar and pipe edge falling off, frequent pipe edge vibration, poor adhesion, etc., to achieve long service life and excellent flexibility , excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A process for treating floor drains on the pipe side of a home improvement bathroom includes the following steps:

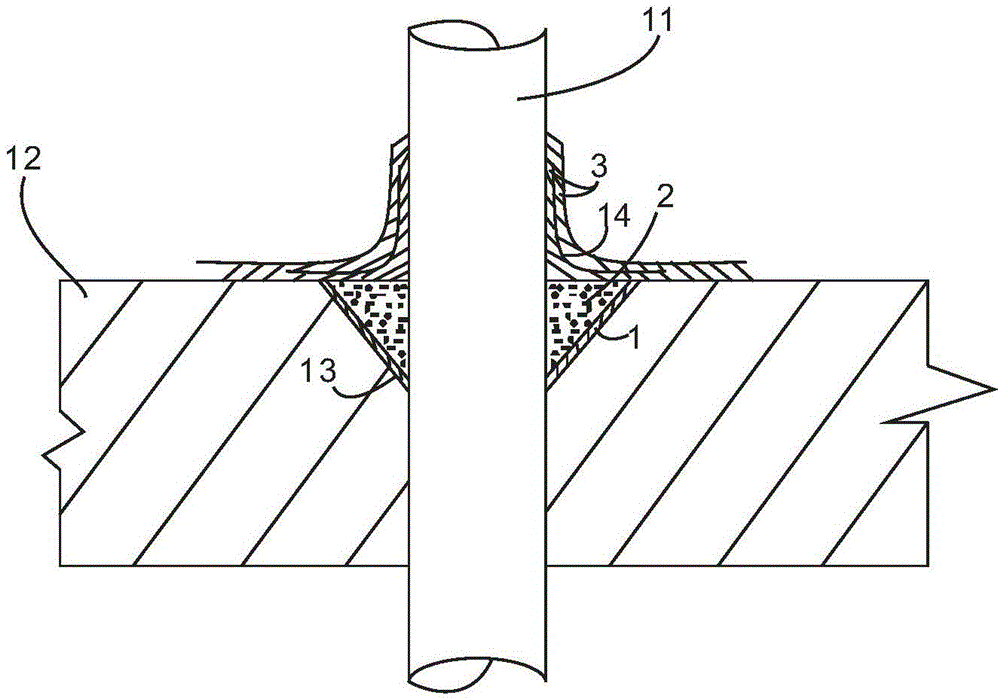

[0026] S1, reference figure 1 As shown, on the concrete floor 12 around the root of the plastic pipe 11, an inverted conical groove 13 is cut out with a chisel. The depth and width depend on the specific situation. In principle, the wider the deeper the better. But the depth generally does not exceed one-third of the thickness of the floor. Remove the scum in the tank and wash with water.

[0027] S2. Paint the groove with an interface waterproofing agent for 1-2 times under humid conditions; the interface waterproofing agent is composed of liquid and powder, and the powder is composed of the following components and mass parts: waterproof glue 370-450 Parts; 1-2 parts of defoamer; 1-2 parts of preservative; 1-2 parts of wetting agent; 550-630 parts of water; the powder consists of the following components and parts by mass: 800-1000 parts of cement; 400 parts...

Embodiment 2

[0037] Referring to Example 1, the difference from Example 1 is:

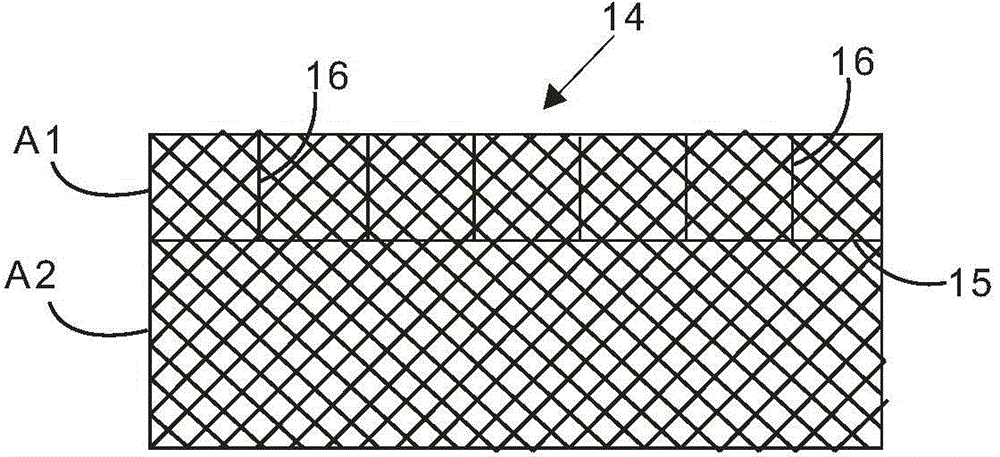

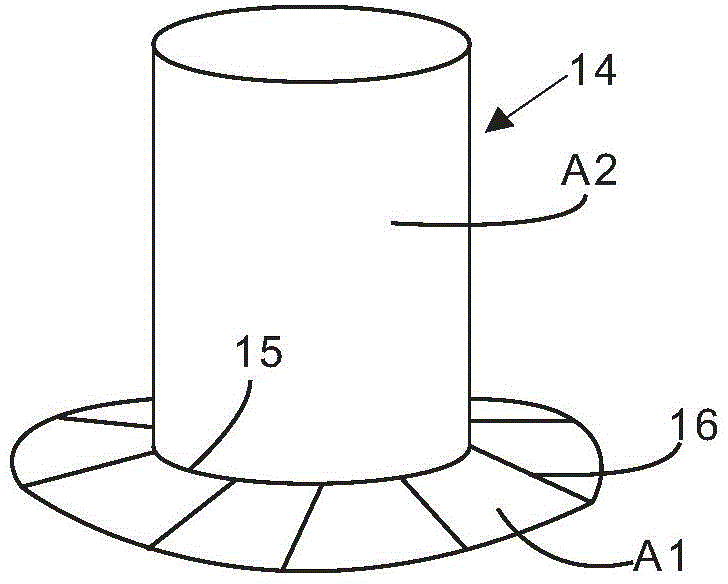

[0038] First, in S4 of Example 1, see figure 1 As shown, a polyester cloth 14 is sandwiched between the two pipe-fixed waterproof glues that are painted. That is, after applying the first pipe-fixing waterproof glue 3, put on the polyester cloth 14, and then apply the second pipe-fixing waterproof glue 3 on the polyester cloth. Among them, polyester cloth such as figure 2 As shown, it is generally a rectangular piece of cloth. The processing method is as follows: first form a crease 15 and divide it into A1 and A2 sides; then form multiple torn edges 16 perpendicular to the crease 15 at equal intervals on the A1 side; and finally Roll the A2 surface into a cylinder, and unfold the A1 surface around the crease 15 to form image 3 Shown.

[0039] Then, after S4, S5 is included, and the waterproof slurry is applied to the pipe-fixed waterproof glue. The waterproof slurry 1 is also composed of powder and liquid, whe...

Embodiment 3

[0044] Referring to Example 2, the difference from Example 2 is that in S3, the multifunctional emulsion and the quick-setting cement are mixed at a weight ratio of 0.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com