Mothproof waterproof magnesium oxide refractory slab

A refractory board, magnesium oxide technology, applied in the field of building materials, can solve the problems of affecting product quality, affecting the appearance, warping and deformation of the board, and achieving the effects of avoiding moisture absorption and returning halogen, good anti-moth effect, and good waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

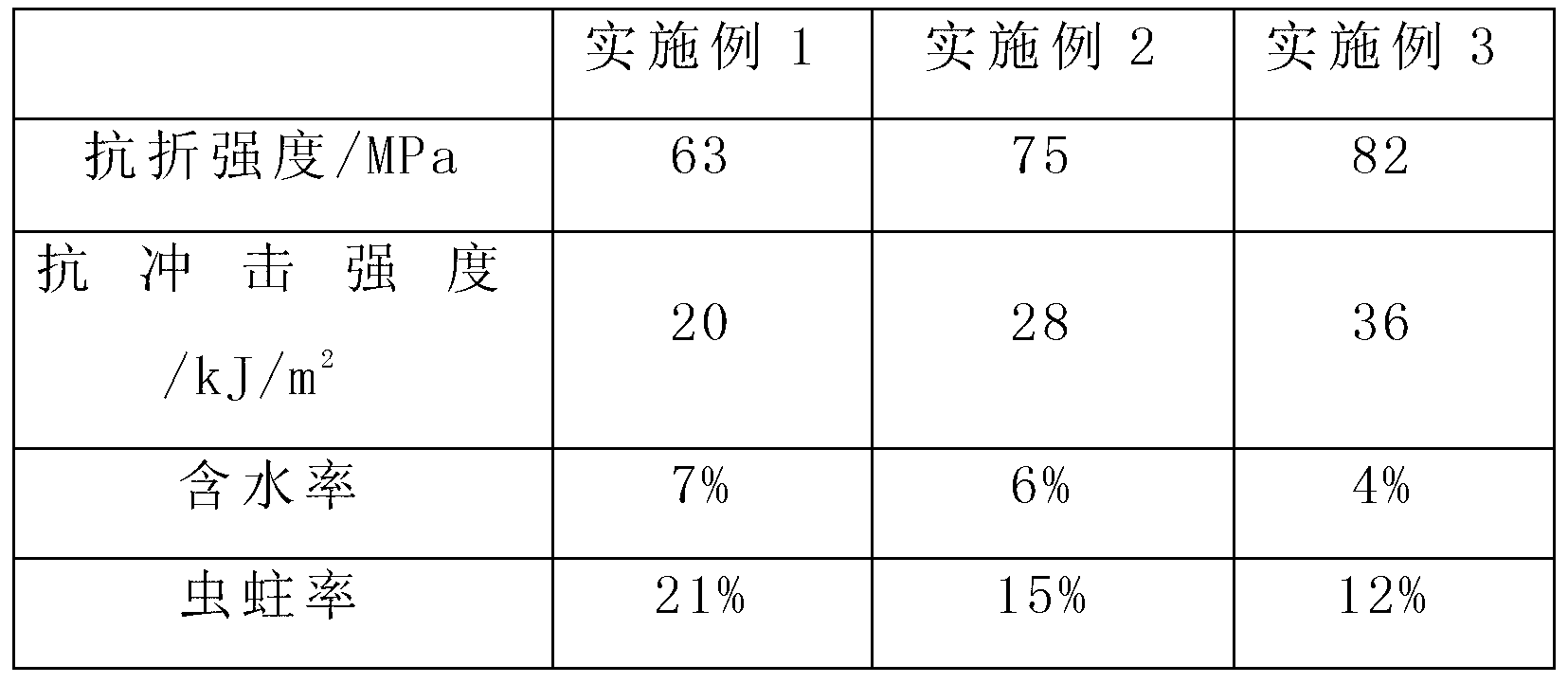

Embodiment 1

[0014] Example 1 Magnesium oxide mothproof waterproof refractory board is made by mixing the following raw materials. The weight parts of each raw material are as follows: 82 parts of light burned magnesia, 28 parts of magnesium chloride, 5 parts of perlite, 12 parts of wood chips, and 6 parts of talc. 4 parts of wollastonite powder, 6 parts of camphor, 0.2 parts of mothproof essential oil, 2 parts of neoprene latex.

Embodiment 2

[0015] Example 2 Magnesium oxide mothproof waterproof refractory board is made by mixing the following raw materials. The weight parts of each raw material are as follows: 90 parts of light burned magnesia, 32 parts of magnesium chloride, 7 parts of perlite, 15 parts of wood chips, 7 parts of talcum powder, 2 parts of wollastonite powder, 8 parts of camphor, 0.5 parts of mothproof essential oil, 3 parts of neoprene latex.

Embodiment 3

[0016] Example 3 Magnesium oxide mothproof waterproof refractory board is made by mixing the following raw materials, and the weight parts of each raw material are as follows: 75 parts of light burned magnesium oxide, 27 parts of magnesium chloride, 8 parts of perlite, 12 parts of wood chips, and 5 parts of talc. 7 parts of wollastonite powder, 2 parts of camphor, 0.9 parts of mothproof essential oil, 5 parts of neoprene latex.

[0017] The above raw materials are mixed and added to the mixing equipment, mixed evenly for 20 minutes to form a magnesium oxychloride slurry, and then mechanically rolled and formed, natural curing and consolidation, demoulding, drying, cutting and shaping to form a magnesium oxide board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com