Patents

Literature

48results about How to "Good anti-moth effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

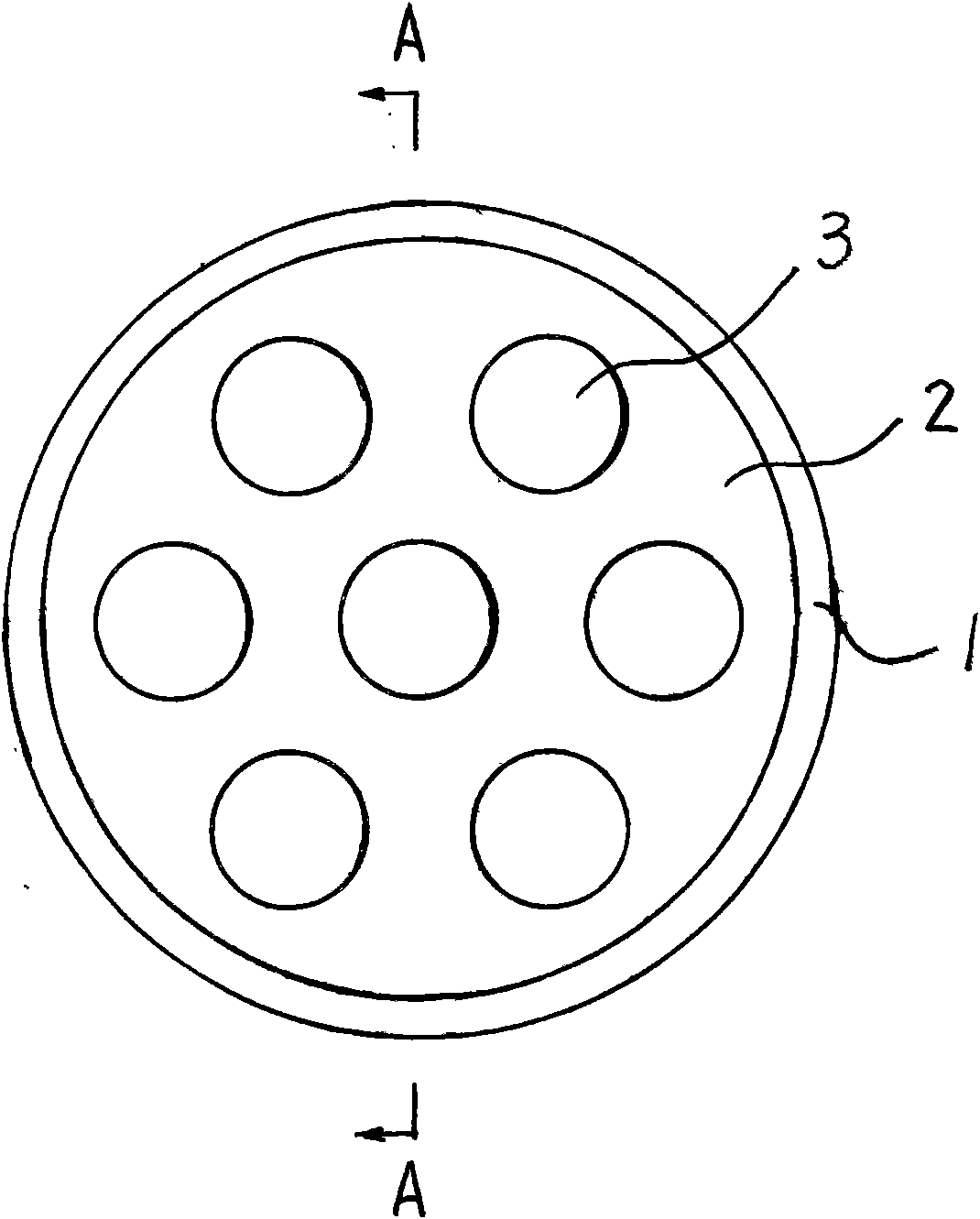

Toothpaste tube

InactiveCN101618775AReduce wasteEasy to cleanFlexible containersPliable tubular containersBrush toothToothpaste

The invention provides a toothpaste tube, which relates to the technical field of toothpaste tubes and is used for containing toothpaste. The toothpaste tube comprises a toothpaste tube body and a toothpaste tube nozzle (1) and is characterized in that the end part of the toothpaste tube nozzle (1) is provided with a nozzle sealing sheet (2) for sealing the tube nozzle and the nozzle sealing sheet (2) has a small hole (3). When the toothpaste tube is used, the toothpaste passes through the toothpaste tube nozzle (1) and then is extruded out from the small hole (3) of the nozzle sealing sheet (2) to form a thin cylinder body. Waste is reduced when a user brushes teeth, and the cleaning and mothproof effects are enhanced.

Owner:吴正德

Mildew and moth resistant woodenware paint

InactiveCN104341990AHigh hardnessGood flexibilityAntifouling/underwater paintsPaints with biocidesLacquerPliability

The invention discloses a woodenware paint for effectively resisting mildews and moths. The paint comprises 30-40 parts of aqueous polyurethane resin, 30-35 parts of an acrylic emulsion, 0.2-1 part of a dispersant, 2-5 parts of a film forming assistant, 0.2-1 part of an antifoaming agent, 0.3-0.5 parts of a wetting and leveling agent, 0.2-0.8 parts of a slipping agent, 2-4 parts of a delustering agent, 0.5-1.5 parts of a thickening agent, 2-3 parts of activated carbon, 0.3-0.8 parts of a nanosilver solution and 1-2 parts of mothproof nanopowder. The mildew and moth resistant woodenware paint has the advantages of waterproof property, fast drying, high hardness, good flexibility, good mothproof effect by using natural camphor extracts, realization of excellent broad spectrum sterilization effect and bacterium propagation prevention due to the nanosilver solution, realization of moisture absorption, smell removal, mildew prevention and moisture prevention by using the activated carbon, naturalness and environmental protection.

Owner:XUZHOU JUYEXIANG FURNITURE

Manufacturing method for mothproof writing brush

The invention discloses a manufacturing method for a mothproof writing brush. Pure natural plants are adopted, water boiled through camphorwood and camphorwood chips serve as a natural mothproofing agent to be used for conducting the mothproof treatment on the writing brush. In the whole treatment process, only a small amount of carrageen needs to be added to serve as a bonding agent, no chemical agent needs to be added, and insecticide and other harmful chemical substances are replaced to achieve insect prevention and mothproofing. A brush head can be placed for a long time, the mothproof effect is very good, and the manufacturing method is particularly suitable for storage of brush heads obtained after large-batch production. The problems existing in the industry all the time are solved. The cost is low, the mothproof effect is good, pollution will not be caused, or harm to the health of a user will not be caused. Brush bristles are not damaged, and the quality of the manufactured writing brush, especially Huzhou writing brushes is guaranteed; and during using, only the brush head needs to be scattered firstly, residual wood powder can automatically fall down, the writing effect cannot be affected, the ink absorbing amount is increased instead during ink dipping, and ink is more uniform during writing.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Fire-retardant, anticorrosive and mothproof coating for restoring ancient timberwork building

InactiveCN107236441AHigh refractorinessImprove anti-corrosion performanceFireproof paintsAntifouling/underwater paintsPolymer solutionEthyl acetate

The invention discloses a fire-retardant, anticorrosive and mothproof coating for restoring an ancient timberwork building. The fire-retardant, anticorrosive and mothproof coating is prepared from the following main components: a wetting agent, a defoaming agent, a film forming agent, an inorganic dispersant, a pigment, filler, an orange peel agent, petroleum asphalt, a cosolvent, cerium oxide, an organosilicon polymer solution, ethyl acetate and water. The fire-retardant, anticorrosive and mothproof coating for restoring the ancient timberwork building, disclosed by the invention, has the advantages of low cost, wide sources of raw materials and excellent fire-retardant, anticorrosive and mothproof effects; in addition, after the ancient timberwork building is restored, cracks on the surface of the ancient building and special vicissitude sense endowed by time still can be kept, and further a sense of repairing the old as old is obtained; the fire-retardant, anticorrosive and mothproof coating is an environment-friendly and safe novel building material.

Owner:DALIAN NATIONALITIES UNIVERSITY

Mildew-proof and mothproof coating for ancient wooden buildings in humid environments in middle and lower reaches of Yangtze River and preparation method of mildew-proof and mothproof coating

ActiveCN104910796AIncrease crosslink densityStrong adhesionFireproof paintsAntifouling/underwater paintsDimethyl methylphosphonateMildew

The invention provides a mildew-proof and mothproof coating for ancient wooden buildings in humid environments in middle and lower reaches of Yangtze River and a preparation method of the mildew-proof and mothproof coating. The mildew-proof and mothproof coating is composed of two components A and B in the mass ratio of 1: 2; the component A is prepared from the following components in parts by weight: 90-120 parts of acrylate-polyurethane water dispersion, 0.5-1.5 parts of thixotropic agent and 5-20 parts of deionized water; the component B is prepared from the following components in parts by weight: 2-8 parts of propylene glycol methyl ether acetate, 0.5-5 parts of dispersant, 0.2-0.8 part of antifoaming agent, 10-30 parts of deionized water, 10-40 parts of super fine talc powder, 10-40 parts of kaolin, 10-30 parts of iron oxide red, 0.8-1.2 parts of dimethyl methylphosphonate, 10-20 parts of nano-silver oxide mildew-proofing agent and 4-8 parts of vegetable moth-proofing agent; and the invention also discloses a preparation method of the coating. The coating has the functions of waterproofing, fire resistance, mildew resistance and moth resistance, and is green and environment-friendly.

Owner:JIANGSU UNIV OF TECH

Method for preparing insect-resistant damp-proof wood veneer

InactiveCN109135179AIncrease elasticityImprove toughnessPlastic/resin/waxes insulatorsWood treatment detailsAdhesiveNano al2o3

The invention discloses a method for preparing insect-resistant damp-proof wood veneer. The method includes steps of A, grinding pine bark to obtain pine powder; B, grinding beech shavings to obtain beech powder; C, placing the pine powder and the beech powder into stirring barrels, uniformly mixing the pine powder and the beech powder with each other to obtain first mixtures, adding distilled water into the first mixtures, stirring the distilled water and the first mixtures, and sequentially adding camphor wood powder, mica powder, nanometer aluminum oxide powder and glass fibers into the distilled water and the first mixtures in stirring procedures to obtain second mixtures; D, sequentially adding flame retardants, adhesive and drying agents into the stirring barrels, stirring the flameretardants, the adhesive, the drying agents and the second mixtures and filling the stirring barrels with nitrogen in stirring procedures; E, pouring materials obtained at the step D into molds, carrying out compression molding by the aid of molding machines and carrying out mold release to obtain wood veneer semi-finished products; F, placing the wood veneer semi-finished products obtained at thestep E into drying ovens and carrying out drying treatment to obtain wood veneer finished products. The method has the advantage that excellent insect-resistant effects and excellent damp-proof effects can be realized by the insect-resistant damp-proof wood veneer prepared by the aid of the method.

Owner:湖州韵高木业有限公司

Worm-expelling mold-proof and environmentally-friendly composite board and preparation method thereof

ActiveCN104708699AImprove mildew resistanceGood anti-moth effectFlat articlesDomestic articlesEucalyptus oilAdditive ingredient

The invention discloses a worm-expelling mold-proof and environmentally-friendly composite board. The worm-expelling mold-proof and environmentally-friendly composite board is characterized by being made of, by weight, 5-10 parts of camphorwood powder, 5-10 parts of elm bark powder, 20-30 parts of manioc waste, 3-5 parts of purple perilla powder, 10-15 parts of kieselguhr, 0.5-1 part of eucalyptus oil, 0.5-1 part of litsea cubeba oil, 0.5-1 part of sodium diacetate, 1-2 parts of sodium humate, 1-2 parts of zinc oxide, 3-5 parts of magnesium stearate and 10-20 parts of bonding accessory ingredient. The worm-expelling mold-proof and environmentally-friendly composite board has good worm-expelling, mold-proof and mothproof functions, and can clean indoor air, the intensity and toughness are good, the property is stable, the texture is even, and the using performance is good; the source of the raw materials is wide, and the composite board is economic, practical, toxic free, harmless, environmentally friendly, and suitable for being applied to indoor environment.

Owner:安徽忠盛新型装饰材料有限公司

Fully-carbonized formaldehyde-free multilayer solid wood composite floor base plate and preparation method thereof

InactiveCN107053372AGood dimensional stabilityAvoid deformationOther plywood/veneer working apparatusWood treatment detailsSolid woodWood veneer

The invention discloses a fully-carbonized formaldehyde-free multilayer solid wood composite floor base plate and a preparation method thereof. The method comprises the steps that fully-carbonized wood veneer is stacked through formaldehyde-free glue, and the fully-carbonized formaldehyde-free multilayer solid wood composite floor base plate is obtained through hot-pressing gluing or cold-pressing gluing. The fully-carbonized formaldehyde-free multilayer solid wood composite floor base plate is good in stability, not prone to get deformed, resistant to decay, high in gluing strength and environment-friendly, the service life of the multilayer solid wood composite floor is prolonged, the economical efficiency of use by a customer is improved, the fully-carbonized formaldehyde-free multilayer solid wood composite floor base plate is completely suitable for being paved for geothermal heating, and the application range of the multilayer solid wood composite floor is expanded.

Owner:张宏伟

Modified attapulgite paper filler and preparation method thereof

ActiveCN104195880AHigh activityGood dispersionInorganic compound additionMelamine formaldehyde resinStearate

The invention relates to a modified attapulgite paper filler. The modified attapulgite paper filler is prepared from the following raw materials in parts by weight: 3-5 parts of nanometer bentonite, 0.8-1.2 parts of sodium carbonate, 3-4 parts of styrene-butadiene emulsion, 3-5 parts of Camphora officinarum bark, 1-1.5 parts of dry alkyd resin, 1-1.3 parts of melamino-formaldehyde resin, 2-3 parts of electric mountain powder, 1-1.6 parts of microcrystalline cellulose, 0.4-0.6 part of sodium laurate, 2-3 parts of colloidal silicon dioxide, 1-2 parts of carbomer, 0.5-0.8 part of ceteth-n sterate, 100-120 parts of attapulgite, a proper amount of water, 5-10 parts of assistants, and 20-25 parts of a 2-3% hydrochloric acid solution. The attapulgite modification method can well remove impurities in the attapulgite, so as to improve the activity, the dispersibility and the suspension property of the attapulgite, improve the using effect of the attapulgite in papermaking and enable paper to be soft and difficult to fracture; and the Camphora officinarum bark is added to improve the mothproof performance of the paper.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

Application of plant stemona mothproofing agent on wool products

InactiveCN103103749AGood anti-moth effectNon-toxicBiocideAnimal repellantsAluminium sulfateAcetic acid

The invention relates to an application method of a plant stemona mothproofing agent on wool products. The method is characterized by comprising the following specific steps of: carrying out pretreatment on the wool products; mixing the wool products after treatment, a plant stemona mothproofing agent aqueous solution and 1-5% of aluminum sulfate, adjusting the bath ratio to be 1: (15-60) with water, adjusting the pH value of the solution to be 4-7 with acetic acid or sodium carbonate, raising the temperature to 40 DEG C from room temperature, raising the temperature to 80-100 DEG C at a heating rate of 1-3 DEG C per minute when at the temperature of 40 DEG C, preserving the temperature for 40-80 minutes, then reducing the temperature to 60 DEG C, washing for 15-45 minutes with 0.5% of 105 neutral soaping agent, and finally rinsing till purification with clear water and drying to obtain mothproofing wool products. The wool products after treatment are good in mothproofing effect, and the mothproofing indexes thereof achieve 1A level and are qualified through the detection of national quality supervision and inspection center (Shanghai) of wool textile products.

Owner:DONGHUA UNIV +1

Low-cost fireproof coating for restoration of ancient wooden structures

InactiveCN110698978AEasy to useFully in-depthFireproof paintsAntifouling/underwater paintsEthyl acetateHYDROGENATED COCONUT OIL

The invention discloses a low-cost fireproof coating for restoration of ancient wooden structures. The coating comprises the following ingredients: a wetting agent, a defoaming agent, a film-forming agent, an inorganic dispersant, a pigment, filler, hydrogenated coconut oil, petroleum asphalt, a co-solvent, a penetrant, an organic silicon polymer solution, ethyl acetate and water. As a recycled refractory material is used as the filler, the coating is not only low in price, but also very good in fire and corrosion resistance; the use amount of the petroleum asphalt is increased, and due to increase of the amount of infiltration, asphalt is integrated with wood, and thus an effect of permanent moth-proof can be achieved generally; after application, a woody surface has a special vicissitudefeeling along with time; to strengthen the infiltration effect of the petroleum asphalt, a combination of the co-solvent and the penetrant is used, and then a good infiltration effect can be achieved; due to addition of the hydrogenated coconut oil which is capable of retarding film formation and improving the infiltration effect, the petroleum asphalt can penetrate fully and evenly into the interior of the wood.

Owner:湖州市南浔联谊喷涂厂

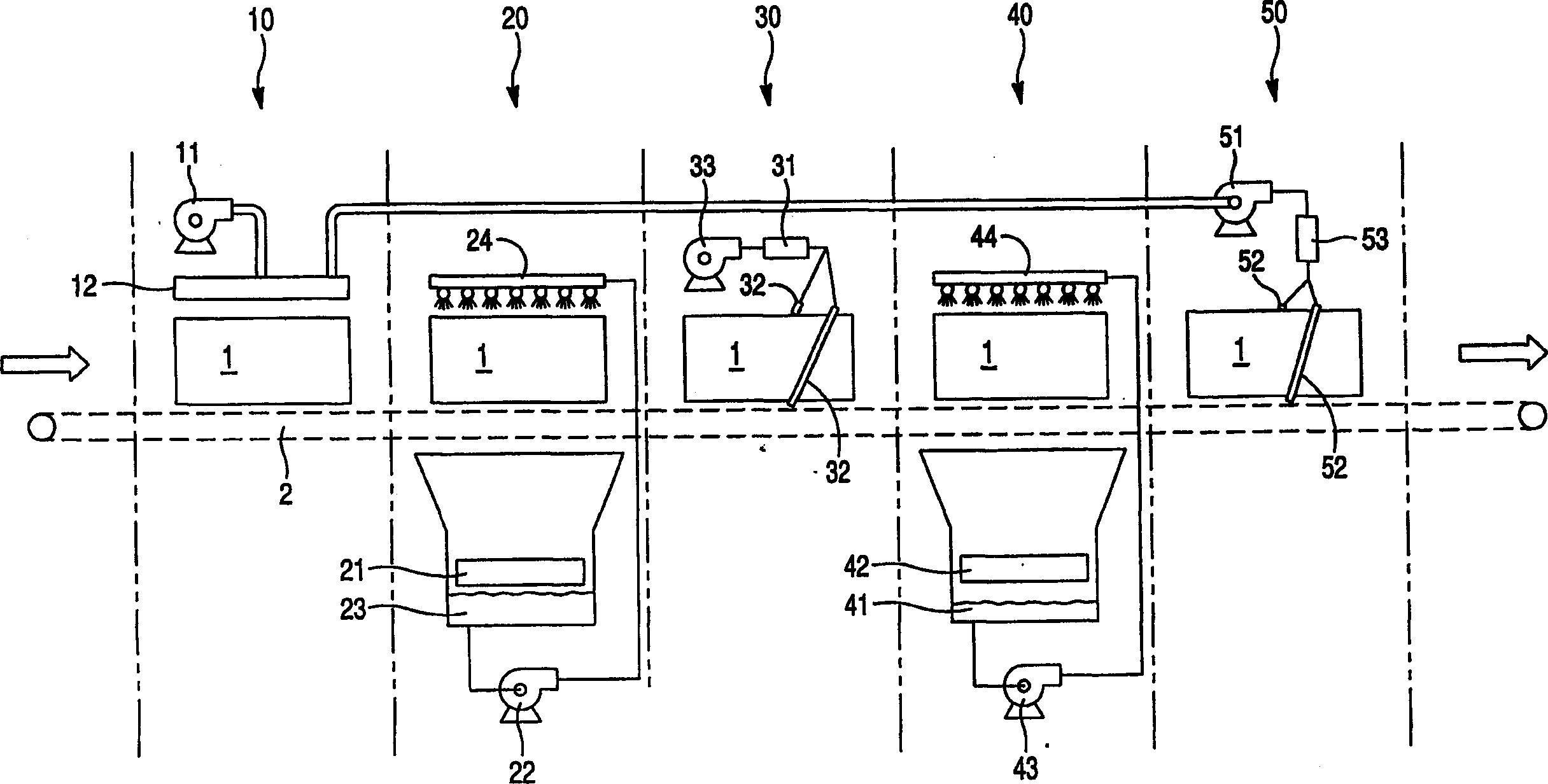

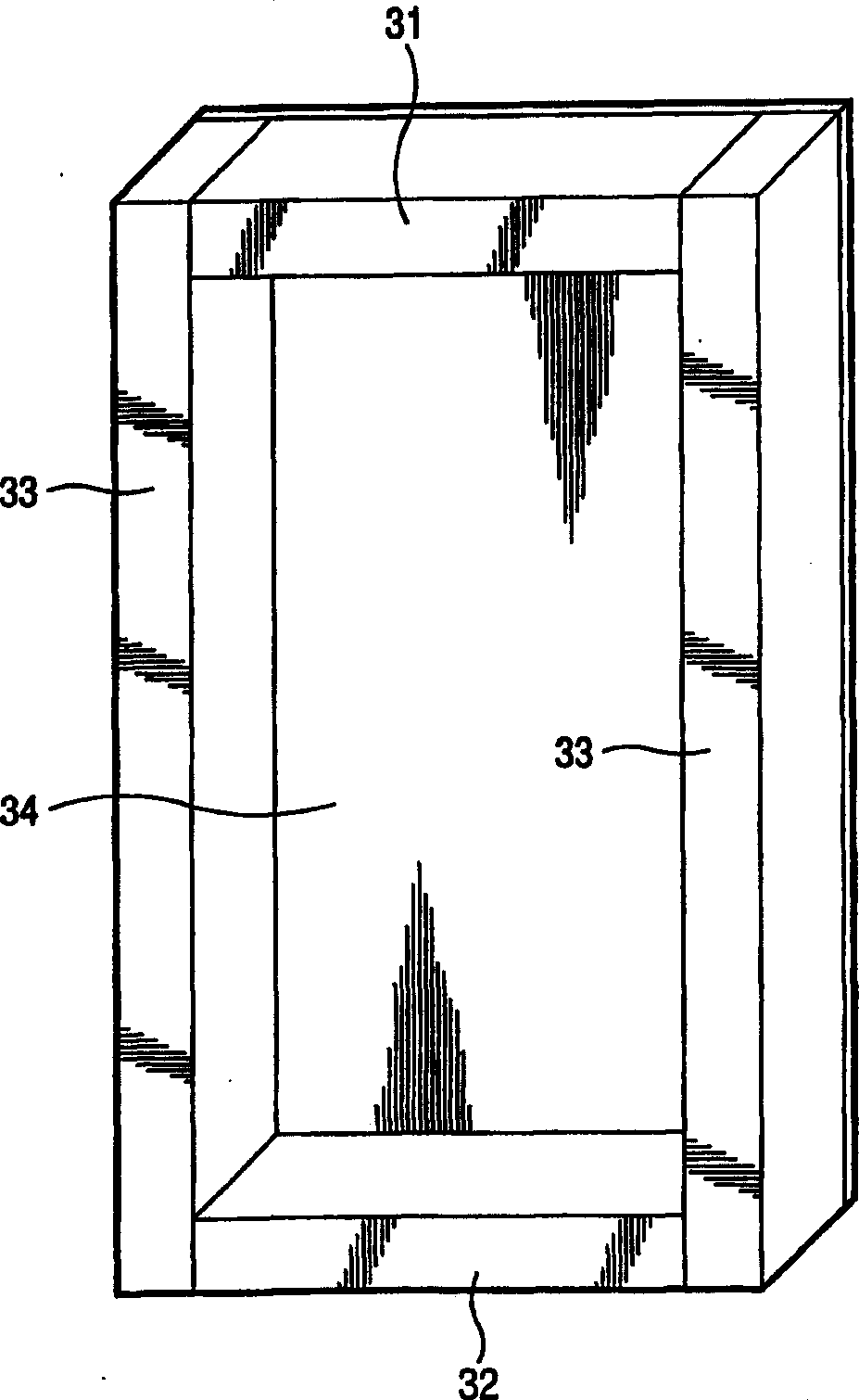

Resin impregnated substrate, method of mfg. and system therefor

The disclosed invention relates to polyisocyanate-impregnated lignocellulosic substrates having improved strength, water resistance and appearance, and also to methods and systems for producing such substrates. The polyisocyanate-impregnated lignocellulosic substrate are produced by impregnating a lignocellulosic substrate with an isocyanate resin, followed by polymerization of the isocyanate resin by applying a heated liquid to the impregnated substrate.

Owner:HOUSTON ADVANCED RESEARCH CENTER

Processing method of high-luminosity mothproof coated paper

InactiveCN110886135AImprove printing glossNo reduction in printing glossCoatings with pigmentsSpecial paperPolyvinyl alcoholNano al2o3

The invention relates to a processing method of high-luminosity mothproof coated paper, and belongs to the technical field of coated paper processing. The technical problem that the printing luminosity and the ink absorbency of coated paper in the prior art cannot be improved at the same time is solved. Processing of the high-luminosity mothproof coated paper is achieved through the following three steps: preparing raw material paper, preparing a coating liquid and preparing the coated paper, and the coating liquid is prepared from a sizing material, starch modified polyvinyl formal, talcum powder, titanium dioxide, calcium carbonate, turpentine oil, Artemisia argyi-tea tree mixed extract, nanometer aluminum oxide, microcrystalline cellulose, a dispersant and auxiliary agents. The starch modified polyvinyl formal, nanometer aluminum oxide and microcrystalline cellulose are added into the coating liquid, so the printing luminosity and the ink absorbency of the coated paper are improved;and the mutual synergistic effects of the turpentine oil and the Artemisia argyi-tea tree mixed extract improve the mothproof property and the practicability of the coated paper.

Owner:友元办公联盟(天津)股份有限公司

Anti-moth detergent for wool fabric and preparation method of anti-moth detergent

ActiveCN103451033AGood anti-moth effectNot easy to mildewNon-ionic surface-active compoundsDetergent compounding agentsAmmonium sulfateChemistry

The invention relates to an anti-moth detergent for a wool fabric and a preparation method of the anti-moth detergent. The detergent comprises the following components in parts by mass: 8-20 parts of sodium alkylarysulfonate, 2-6 parts of ammonium laureth sulfate, 0.6-2.5 parts of tetramethrin, 1.5-6 parts of benzalkonium chloride, 5-15 parts of fatty alcohol-polyoxyethylene ether, 0.05-0.15 part of kathon, 2.5-7 parts of industrial alcohol, 0.2-2 parts of essence, 1.7-4.3 parts of urea, and 55-80 parts of deionized water. The detergent not only can be used for washing the wool fabric effectively, but also has a good anti-moth effect.

Owner:FABLED ENVIRONMENTAL PROTECTION TECH SUZHOU CO LTD

Preparation method of paperboard antibacterial moistureproof agent

InactiveCN105926351APrevent moisture absorptionGood anti-mildew and anti-mite effectPaper/cardboardCoatingsEmulsionMicrocrystalline wax

The invention discloses a preparation method of a paperboard antibacterial moistureproof agent. The preparation method comprises dissolving turpentine in a dispersant to obtain a turpentine solution, mixing modified alkyd resin, microcrystalline wax, methylsilicone oil and Vaseline, heating the mixture at a temperature of 30-70 DEG C along with stirring to obtain a mixture, mixing the mixture, the turpentine solution and an emulsifier, stirring the mixture, heating the mixture to a temperature of 120-170 DEG C, adding 1N of a sodium hydroxide solution into the mixed solution, continuously heating the mixture for 10-30min, carrying out stirring emulsification, cooling the emulsion to the room temperature, dropwisely adding tea tree oil into the emulsion along with stirring and carrying out uniform stirring. The preparation method has simple processes and is free of special equipment. The paperboard antibacterial moistureproof agent has good moistureproof, anti-bacterium and anti-moth performances, is safe in use, does not pollute the environment and is suitable as a moistureproof agent in a carton package and especially as a carton moistureproof agent in a food package.

Owner:JURONG DINGSHENG CARTON PACKING

Moth-proof finishing method for cotton fabric

InactiveCN105603722AEasy to operateGood anti-moth effectBiochemical treatment with wool-protecting/anti-moth agentsVegetal fibresZinc Acetate DihydrateDiamine

The invention discloses a moth-proof finishing method for cotton fabric. The method comprises the following steps: adding water to a finishing agent to prepare a water solution; spaying the water solution on the surface of fabric by a high-pressure spraying process; and finally drying the surface, wherein the finishing agent is prepared from the following components in parts by weight: 22-26 parts of polyoxyethylene diamine, 8-10 parts of sodium polystyrenesulfonate, 18 parts of phenol, 5-10 parts of vinyl versatate, 3-6 parts of butanol, 22-24 parts of ethylene glycol, 3-6 parts of benzyltrimethylammonium chloride, 5-8 parts of glycerinum, 10-14 parts of vinyltrimethoxysilane, 3-6 parts of chitosan, 3-6 parts of talcum powder, 3-7 parts of didecyl dimethyl ammonium chloride and 1-2 parts of zinc acetate. The finishing method is convenient to operate and environmentally friendly; the finished cotton fabric is good in moth-proof effect and lasting and stable in effect; and the problem of poor moth-proof finishing fastness of the cotton fabric is effectively solved.

Owner:HUZHOU XINCHUANG SILK

Water-based bamboo and wood cultural relic protective coating and preparation and application methods thereof

InactiveCN105038567AImprove mildew resistanceGood anti-moth effectFireproof paintsAntifouling/underwater paintsEnvironmental resistanceWater based

The invention discloses a water-based bamboo and wood cultural relic protective coating. The coating is formed by a first component and a second component in a mass ratio of (1 to 1)-(1 to 2), wherein the first component comprises the following components in parts by weight: 90-120 parts of acrylic polyurethane aqueous dispersion, 0.5-1.5 parts of thickening agent and 5-20 parts of water; the second component comprises the following components in parts by weight: 2-8 parts of propylene glycol monomethyl ether acetate, 0.5-5 parts of dispersing agent, 0.2-0.8 part of defoaming agent, 10-30 parts of water, 2-8 parts of flame retardant, 10-20 parts of mould inhibitor and 4-8 parts of plant mothproofing agent. The invention also discloses preparation and application methods of the water-based bamboo and wood cultural relic protective coating. The water-based bamboo and wood cultural relic protective coating forms a fireproof, waterproof, mouldproof and mothproof coat on the surfaces of bamboo and wood cultural relics and is environment-friendly and does not pollute the cultural relics.

Owner:JIANGSU UNIV OF TECH

A kind of manufacturing method of anti-moth brush

The invention discloses a manufacturing method for a mothproof writing brush. Pure natural plants are adopted, water boiled through camphorwood and camphorwood chips serve as a natural mothproofing agent to be used for conducting the mothproof treatment on the writing brush. In the whole treatment process, only a small amount of carrageen needs to be added to serve as a bonding agent, no chemical agent needs to be added, and insecticide and other harmful chemical substances are replaced to achieve insect prevention and mothproofing. A brush head can be placed for a long time, the mothproof effect is very good, and the manufacturing method is particularly suitable for storage of brush heads obtained after large-batch production. The problems existing in the industry all the time are solved. The cost is low, the mothproof effect is good, pollution will not be caused, or harm to the health of a user will not be caused. Brush bristles are not damaged, and the quality of the manufactured writing brush, especially Huzhou writing brushes is guaranteed; and during using, only the brush head needs to be scattered firstly, residual wood powder can automatically fall down, the writing effect cannot be affected, the ink absorbing amount is increased instead during ink dipping, and ink is more uniform during writing.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Method for mothproof finish of wool fabrics

InactiveCN105755811AGood anti-moth effectSolve the problem of poor fastness of anti-moth finishingTextile treatment by spraying/projectingAnimal fibresPolyethylene glycolHigh pressure

The invention discloses a method for mothproof finish of wool fabrics.The method includes steps: adding water into a finish agent to obtain a water solution, spraying the water solution to the fabric surface by means of high-pressure spraying, and drying.The finish agent is prepared from, by weight, 13-20 parts of propylene glycol, 8-11 parts of sodium citrate, 3-10 parts of acetofenate, 3-6 parts of diphenol propane, 5-8 parts of soap powder, 2-6 parts of starch ether, 4-7 parts of xylene, 2-6 parts of potassium oxalate, 2-6 parts of light calcium carbonate, 3-7 parts of benzyltrimethylamine chloride, 1-5 parts of polyethylene glycol fatty acid serving as a dispersing agent and 20-30 parts of water.The method is convenient to implement and environment friendly, the wool fabrics are excellent in mothproof effect after finishing and long and stable in effect lasting, and accordingly the problem of poor mothproof finish fastness of the wool fabrics is effectively solved.

Owner:HUZHOU HONGXIN SILK FACTORY

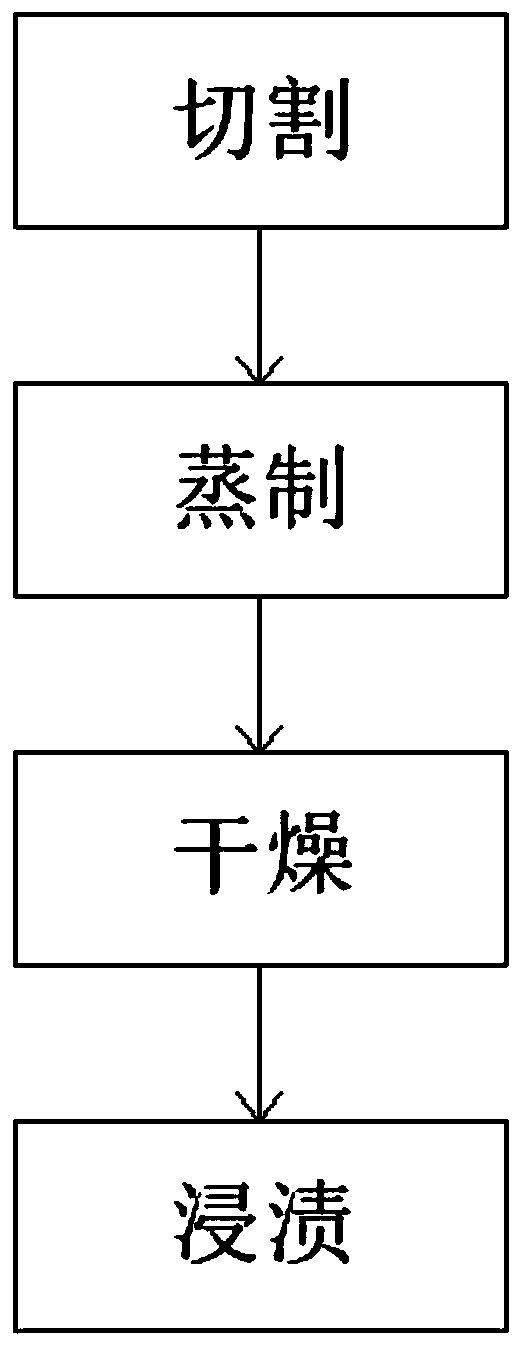

Anti-cracking and mothproof treatment process for wood used for pet houses

InactiveCN110815463AReduce lossesReduce brittlenessWood treatment detailsPressure impregnationFiberFreeze-drying

The invention discloses an anti-cracking and mothproof treatment process for wood used for pet houses. The anti-cracking and mothproof treatment process comprises the following steps: (1) cutting; cutting the wood into plates with required shapes according to requirements; (2) steaming; steaming the plates in steam for 20-25 minutes, taking out the plates, and naturally cooling the plates to 35-40DEG C to obtain steamed plates; (3) drying: putting the plates in a refrigerating chamber at the temperature of -20 DEG C to -25 DEG C for freeze drying until the water content is 20%-22% to obtain dried plates; and (4) impregnation. The treatment process is simple; storage and using are convenient; the wood is placed in steam for high-temperature heating, so that infectious microbes inside and on wood surfaces are killed, mildewing and worm damage are inhibited, loss caused by wood cracking and worm damage is reduced; the temperature is reduced after instantaneous high temperature treatment,so that wood fiber structures can be loosened, the wood softness is improved, the wood cracking phenomenon is reduced; the wood is subjected to dipping treatment, and a treatment liquid is tightly combined with wood fibers, so that the anti-cracking and mothproof properties of wood are greatly improved.

Owner:福建龙兴九源科技股份有限公司

Method for preparing attapulgite paper filler

InactiveCN106948214AImprove anti-moth performanceEasy to prepareWax additionPaper/cardboardChemistrySurface modification

The invention discloses a method for preparing an attapulgite paper filler and relates to the technical field of attapulgite. The method comprises the steps: (1) pretreating the attapulgite; (2) preparing an attapulgite primary finished product; (3) carrying out water vapor modifying treatment; (4) carrying out surface modification treatment; (5) preparing slurry; and (6) carrying out spray drying. According to the method, the attapulgite serves as a main raw material. The attapulgite is subjected to modifying treatment twice, and filler additives are added, so that the anti-moth performance, strength and toughness of paper can be improved, and the paper is resistant to writing; and furthermore, the attapulgite paper filler is simple to prepare and convenient to preserve.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

Anti-moth leather fabric

InactiveCN105383109AGood anti-moth effectIncrease warmthSynthetic resin layered productsPolyesterEngineering

The present invention discloses an anti-moth leather fabric, which comprises four parts such as a front anti-moth layer, a leather layer, a rear anti-moth layer, and a binder, wherein the front anti-moth layer is adhered on the upper side of the leather layer through the binder, the rear anti-moth layer is adhered on the lower side of the leather layer through the binder, the front anti-moth layer is a polyacrylonitrile fiber and flax blended fabric, the leather layer is buttermilk skin, the rear anti-moth layer is a spandex and polyester blended fabric, and the binder is an epoxy glue. With the technical scheme of the present invention, the anti-moth performance and the warm keeping performance of the leather can be improved.

Owner:JIANGSU JIUSAIMA FASHION CO LTD

Mothproof coating for wooden artworks

InactiveCN108976927ASolve the difficult to degradeImprove shielding effectAnti-corrosive paintsCell cavityChemistry

The invention relates to the technical field of processing of wooden artworks, and discloses a mothproof coating for wooden artworks. The mothproof coating has the advantages that a metal-organic hybrid functional complex is used as a mothproof material and added into the coating, so that the problem of invasion of moths is solved, the water is well blocked from entering the wood via capillary tubes of cell cavities, and the waterproof and anti-corrosive effects are realized; the good shielding function is realized, the moths are prevented from invading the surface and interior of the wood, and the mothproof, anti-corrosive, beautifying and anti-aging effects are realized; a series of problems due to improper mothproof treatment of the wood in the existing wooden artwork processing methodare solved; the good lyophobic and mothproof properties are realized, the mothproof effect is good, and the processing efficiency is high; the operation is convenient, the safety and reliability are realized, the service life is long, and the like; the problem of difficulty in degrading of waste liquid after use of the existing mothproof treatment agent is solved, and the mothproof coating is a technical scheme which is suitable for being popularized and applied.

Owner:安徽嘉美工艺品有限公司

Mothproof non-woven cloth material for saline-alkali land and preparation method thereof

ActiveCN106245229AGood thermal stabilityGood flame retardancyFlame-proof filament manufactureNon-woven fabricsAmmonium polyphosphatePolypropylene

The invention discloses a mothproof non-woven cloth material for a saline-alkali land and a preparation method thereof. The mothproof non-woven cloth material for the saline-alkali land is prepared from the following components in parts by mass: 80 to 100 parts of polypropylene resin, 5 to 7 parts of ammonium polyphosphate, 15 to 18 parts of ABS (Acrylonitrile Butadiene Styrene) resin, 8 to 12 parts of an antioxidant, 14 to 20 parts of calcium oxide, 8 to 10 parts of zinc borate, 1 to 2 parts of jojoba oil, 6 to 9 parts of shaddock peel, 1 to 2 parts of sodium pentachlorophenate, 2 to 3 parts of cortex acanthopanacis, and 1 to 2 parts of wrinkled gianthyssop herb. The mothproof non-woven cloth material for the saline-alkali land has the advantages of high thermal stability, good flame retardance and good heat resistance and high strength; the calcium oxide is added into the formula, so that the saline-alkaline resistance of the material is improved; the mothproof effect of the material can be improved by adding the jojoba oil, the shaddock peel and the like; the strength and the corrosion resistance of the material can be improved by adding auxiliary agents into the material; the mothproof non-woven cloth is applicable to the places, such as the saline-alkali land, with high salinity and alkalinity, and good saline-alkaline resistance and a good mothproof effect are achieved.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Halogen-free environmentally friendly fire retardant with good wood fire retardation performance

InactiveCN104650604AGood flame retardancyImprove anti-corrosion performanceDodecylsulfonic acidBisphenol A

The invention discloses a halogen-free environmentally friendly fire retardant with good wood fire retardation performance. The halogen-free environmentally friendly fire retardant comprises, by mass, 20-50% of ammonium polyphosphate, 10-25% of boric acid, 5-20% of bisphenol A-bis(diphenylphosphate) oligopolymer, 2-15% of nanometer zinc borate, 3-8% of sodium molybdate, 2-6% of sodium dodecyl sulfonate and 0.1-1% of pentaerythritol. Compared with present fire retardants, the halogen-free environmentally friendly fire retardant prepared through the steps of adding nanometer zinc borate and sodium molybdate to main flame retardation raw materials comprising ammonium polyphosphate, boric acid and bisphenol A-bis(diphenylphosphate) oligopolymer as smoke inhibitors, adding sodium dodecyl sulfonate as a surfactant and pentaerythritol as a charring agent has the advantages of very good fire retardation and smoke inhibition performances, no halogen, environmental protection, good corrosion and moth resistance, safe and convenient use, and simple preparation method.

Owner:高天红

Processing method of antibacterial mothproof coated paper

InactiveCN110886128AImprove anti-mold and anti-bacterial propertiesGood anti-moth effectNatural cellulose pulp/paperPaper coatingBiotechnologyTurpentine Oil

The invention relates to a processing method of an antibacterial mothproof coated paper, and belongs to the technical field of coated paper processing. The technical problem of poor mildew-proof and mothproof performances of coated papers in the prior art is solved. The antibacterial mothproof coated paper is processed through three steps of preparing raw material paper, preparing a coating liquidand preparing the coated paper, and the coating liquid is prepared from a sizing material, starch, talcum powder, titanium dioxide, calcium carbonate, turpentine oil, a wormwood-tea tree mixed extract, a mildew-proof bactericide, a dispersing agent and additives. The mildew-proof bactericide, the turpentine oil and the wormwood-tea tree mixed extract are added into the coating liquid to improve the mildew-proof and antibacterial properties of the coated paper, and the mutual synergistic effects of the turpentine oil and the wormwood-tea tree mixed extract improve the mothproof property of thecoated paper, so that the storage condition and the storage cost of the coated paper are reduced, and the storage time of the coated paper is prolonged.

Owner:友元办公联盟(天津)股份有限公司

Mothproof finishing method for wool fabric

InactiveCN107938352AGood anti-moth effectThe effect is long-lasting and stableAnimal fibresEngineeringPre treatment

The invention discloses a mothproof finishing method for wool fabrics. The mothproof finishing method comprises the following steps: firstly, performing water washing pretreatment on a wool fabric soas to remove impurities in the wool fabric; secondly, soaking the wool fabric after water washing treatment into a finishing agent, and performing two-padding two-rolling treatment, wherein the rolling percentage is 30-45%; prebaking the wool fabric after padding and rolling treatment for 5-8 minutes; finally baking the wool fabric after prebaking treatment for 3-5 minutes at 110-150 DEG C, so asto obtain a finished product. The invention provides the mothproof finishing method for wool fabrics, the method is convenient to operate and green and environmental-friendly, the wool fabric finishedby using the method is good in mothproof effect and long-lasting and stable in effect, and the problem that a wool fabric is relatively poor in mothproof finishing fastness is effectively solved.

Owner:SUZHOU EMBROIDERY COLORFUL WORLD EMBROIDERY CRAFT CO LTD

Mothproof and easy-to-finish composite filament and garment fabric

InactiveCN110129940AEasy to organizeConvenient careBiochemical fibre treatmentGrip property fibresPolyethylene glycolAnimal fiber

The invention discloses a mothproof and easy-to-finish composite filament and garment fabric. The composite filament comprises animal fiber and synthetic fiber, a coating formed by a finishing agent is formed on the surface of at least one of the animal fiber and the synthesis fiber, the finishing agent comprises a component A and a component B, in parts by weight, the component A comprises 10-30parts of polyethylene glycol, 0.5-3 parts of a catalyst, 5-10 parts of isocyanate and 30-100 parts of hydroxyalkyl silicone oil; the component B comprises 80-200 parts of a mixed extract of Chinese gall, radix sophorae flavescentis and herba taraxaci; the mass ratio of the component A to the component B is 1:(2-10). The composite filament is better in flexibility, easy to maintain and long in mothproof effect and has bacteriostatic and antibacterial effect.

Owner:上海恋轩实业有限公司

Anti-tooth decay mouthwash

InactiveCN109528575AGood anti-moth effectImprove antibacterial propertiesAntibacterial agentsCosmetic preparationsLicorice rootsSodium fluoride

The invention discloses an anti-tooth decay mouthwash prepared from, by mass, 15-20 parts of sodium fluoride, 6-9 parts of anhydrous calcium hydrophosphate, 5-7 parts of ethanol, 11-13 parts of honeysuckle extract liquid, 5-7 parts of dandelion extract liquid, 10-14 parts of metronidazole, 3-5 parts of borneol, 3-7 parts of methyl sorbitol, 4-6 parts of licorice roots, 6-8 parts of artemisia apiacea, 7-10 parts of folium isatidis, 5-6 parts of stevia rebaudiana, and 35-40 parts of water. The mouthwash has good anti-tooth decay effect, strong sterilization and antibacterial capability, and caneliminate inflammation and relieve pain, remove bad breath and keep refreshing breath.

Owner:位书奎

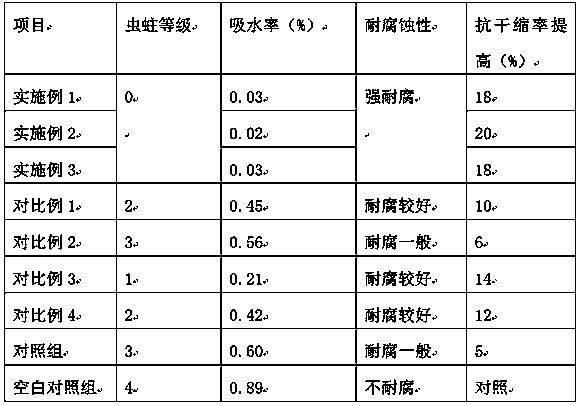

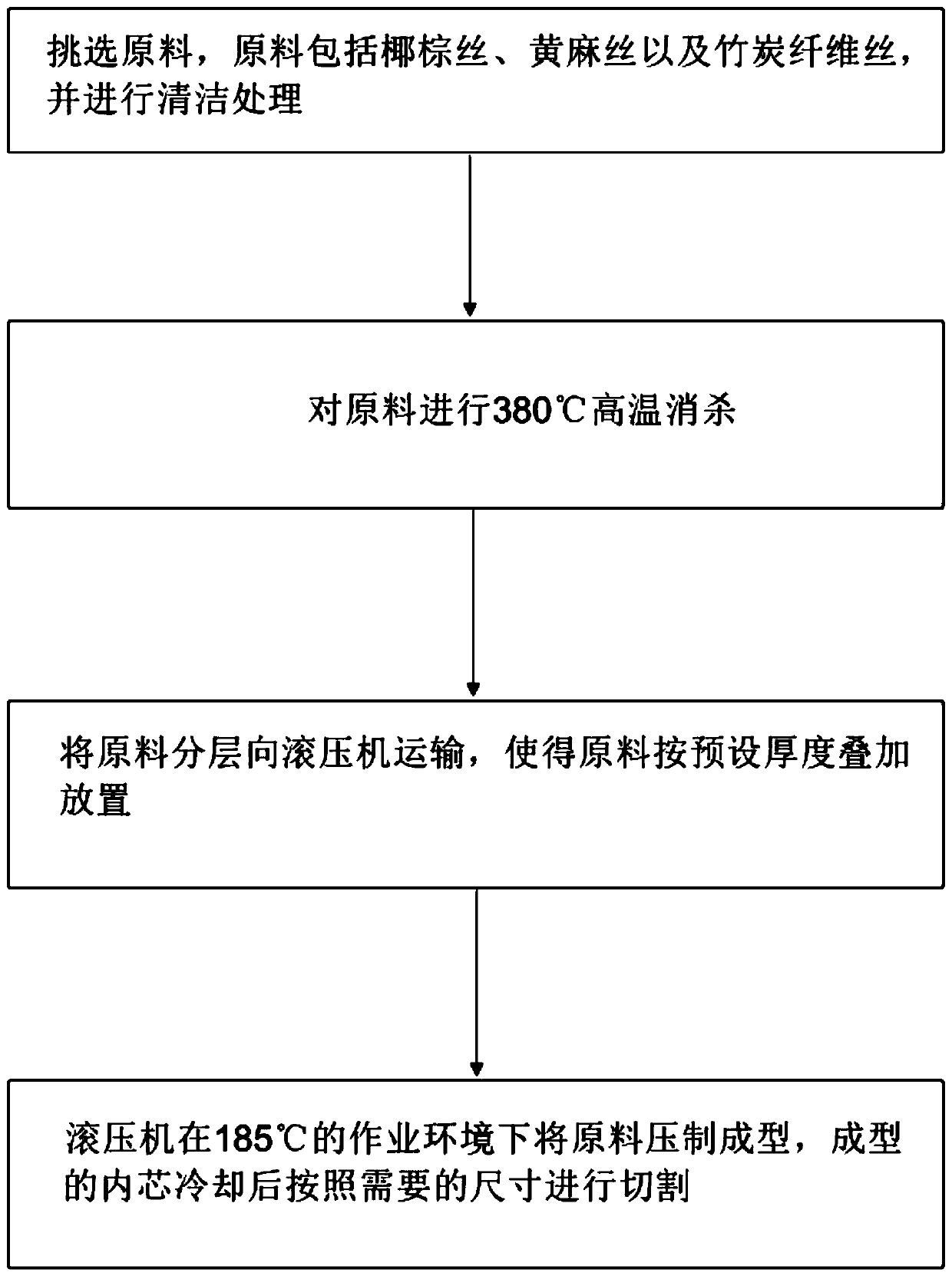

Manufacturing process of plant fiber inner core

InactiveCN111466748AGood anti-moth effectImprove moisture resistanceStuffed mattressesSpring mattressesYarnPlant fibre

The invention discloses a manufacturing process of a plant fiber inner core. The manufacturing process comprises the following steps of obtaining coconut palm yarns , jute yarns and bamboo charcoal fiber yarns, and cleaning the coconut palm yarns, the jute yarns and the bamboo charcoal fiber yarns; putting the cleaned coconut yarns, jute yarns and bamboo charcoal fiber yarns into an environment with the temperature of 300-420 DEG C for disinfection; transporting the sterilized coconut yarns, jute yarns and bamboo charcoal fiber yarns to a roller press in a layered manner, and pressing the coconut yarns, jute yarns and bamboo charcoal fiber yarns together to form an inner core after the thickness reaches a preset thickness; and cutting the formed inner core into the required size. The manufacturing process is advantaged in that the jute yarns and the bamboo charcoal fiber yarns are arranged so that the moth-proof capability and the moisture-proof capability of the inner core can be improved, the coconut yarns have high toughness and are not prone to deformation, high-temperature sterilization can guarantee safety of the raw materials, the biological characteristics of raw materialscan be removed, a moth-proof purpose is achieved, multiple layers of materials can be better combined together in a pressing mode, and the inner core is not prone to deformation.

Owner:雷林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com