Mothproof coating for wooden artworks

A technology for handicrafts and coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problem of no shielding effect, and achieve the effect of high processing efficiency, convenient operation, and preventing pests from invading the surface and interior of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

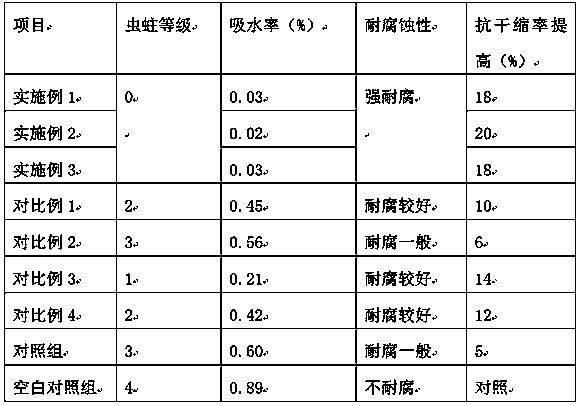

Examples

Embodiment 1

[0016] An anti-moth coating suitable for wooden handicrafts, which is made of the following components in parts by weight: 60 parts of styrene-acrylic emulsion, 18 parts of melamine resin, 14 parts of anatase titanium dioxide, and 5.0 parts of metal-organic hybrid functional complex , 2.0 parts of surfactants, 0.5 parts of thickeners, 0.10 parts of wetting agents, 0.06 parts of defoamers, 0.03 parts of fungicides, and 30 parts of water; the preparation method of the metal-organic hybrid functional complex comprises the following steps :

[0017] (1) Weigh 5.5 ml of butyl titanate and add it to 10 ml of absolute ethanol, stir and disperse evenly to obtain A solution, weigh 1.5 g of acetic acid and 2.5 g of o-phenylenediamine and dissolve in 8 ml of pre-prepared hydrochloric acid solution In, obtain B solution;

[0018] (2) Slowly add solution B to solution A drop by drop, and keep stirring, heat to 85°C under stirring, reflux for 5 hours, cool to 40°C after the reaction, pour ...

Embodiment 2

[0024] An anti-moth coating suitable for wooden handicrafts, which is made of the following components in parts by weight: 65 parts of styrene-acrylic emulsion, 19 parts of melamine resin, 15 parts of anatase titanium dioxide, and 5.5 parts of metal-organic hybrid functional complex , 2.2 parts of surfactants, 0.6 parts of thickeners, 0.11 parts of wetting agents, 0.07 parts of defoamers, 0.04 parts of antifungal agents, and 35 parts of water; the preparation method of the metal-organic hybrid functional complex comprises the following steps :

[0025] (1) Weigh 5.8 ml of butyl titanate and add it to 11 ml of absolute ethanol, stir and disperse evenly to obtain A solution, weigh 1.6 g of acetic acid and 2.55 g of o-phenylenediamine and dissolve in 9 ml of pre-prepared hydrochloric acid solution In, obtain B solution;

[0026] (2) Slowly add solution B to solution A drop by drop, and keep stirring, heat to 88°C under stirring, reflux for 5.5 hours, cool to 42°C after the react...

Embodiment 3

[0032] An anti-moth coating suitable for wooden handicrafts, which is made of the following components in parts by weight: 70 parts of styrene-acrylic emulsion, 20 parts of melamine resin, 16 parts of anatase titanium dioxide, and 6.0 parts of metal-organic hybrid functional complex , 2.5 parts of surfactants, 0.7 parts of thickeners, 0.12 parts of wetting agents, 0.08 parts of defoamers, 0.05 parts of antifungal agents, and 40 parts of water; the preparation method of the metal-organic hybrid functional complex comprises the following steps :

[0033] (1) Weigh 6.0 ml of butyl titanate and add it to 12 ml of absolute ethanol, stir and disperse evenly to obtain A solution, weigh 1.8 g of acetic acid and 2.6 g of o-phenylenediamine and dissolve in 10 ml of pre-prepared hydrochloric acid solution In, obtain B solution;

[0034] (2) Slowly add solution B to solution A drop by drop, and keep stirring, heat to 90°C under stirring, reflux for 6 hours, cool to 45°C after the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com