Mildew-proof treatment agent for bamboo

An anti-mildew treatment agent, bamboo technology, applied in the direction of reed/straw treatment, impregnated wood, wood impregnation, etc., can solve the problems of decreased anti-mildew effect, short maintenance time, etc., to improve long-term effect, maintain long life, reduce draining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

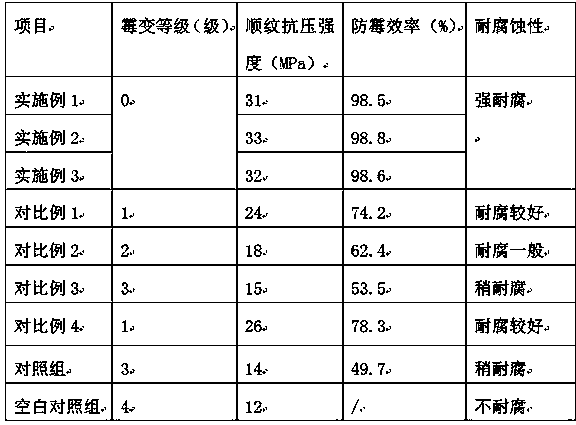

Examples

Embodiment 1

[0018] A kind of mildew-resistant treatment agent for bamboo, made of the following components in parts by weight: 2.5 parts of carboxymethyl cellulose, 4.0 parts of acetic acid, 1.2 parts of nonylphenol polyoxyethylene ether, 3.0 parts of sorbitan ester, oxidized 1.0 parts of copper, 0.8 parts of activated nano-zinc oxide, 5.0 parts of sodium silicate, 40 parts of ethanol, and 860 parts of deionized water. The preparation method of the activated nano-zinc oxide comprises the following steps:

[0019] (1) Weigh 0.65 grams of zinc acetate and add it to 20 milliliters of dodecaphosphotungstic acid ethanol solution, stir and mix evenly, add 0.03 grams of pyridoxine, ultrasonicate for 25 minutes, and then use concentrated ammonia water to adjust the pH of the system between 8.2-8.5 between;

[0020] (2) Disperse the mixed material evenly and transfer it to a Teflon high pressure vessel with a volume of 50 ml. Set the reaction temperature to 125°C and the reaction time to 36 hours....

Embodiment 2

[0028] A kind of mildew-resistant treatment agent for bamboo, made of the following components in parts by weight: 2.8 parts of carboxymethyl cellulose, 4.5 parts of acetic acid, 1.3 parts of nonylphenol polyoxyethylene ether, 3.5 parts of sorbitan ester, oxidation 1.1 parts of copper, 0.85 parts of activated nano zinc oxide, 5.5 parts of sodium silicate, 45 parts of ethanol, and 880 parts of deionized water. The preparation method of the activated nano zinc oxide comprises the following steps:

[0029] (1) Weigh 0.68 g of zinc acetate and add it to 22 ml of dodecaphosphotungstic acid ethanol solution, stir and mix evenly, add 0.035 g of pyridoxine, ultrasonicate for 28 minutes, and then use concentrated ammonia water to adjust the pH of the system between 8.2-8.5 between;

[0030] (2) Disperse the mixed material evenly and transfer it to a Teflon high pressure vessel with a volume of 50 ml. Set the reaction temperature to 130°C and the reaction time to 38 hours. After the rea...

Embodiment 3

[0038]A kind of mildew-resistant treatment agent for bamboo, made of the following components in parts by weight: 3.0 parts of carboxymethyl cellulose, 5.0 parts of acetic acid, 1.4 parts of nonylphenol polyoxyethylene ether, 4.0 parts of sorbitan ester, oxidation 1.2 parts of copper, 0.9 parts of activated nano zinc oxide, 6.0 parts of sodium silicate, 50 parts of ethanol, and 900 parts of deionized water. The preparation method of the activated nano zinc oxide comprises the following steps:

[0039] (1) Weigh 0.70 g of zinc acetate and add it to 25 ml of dodecaphosphotungstic acid ethanol solution, stir and mix evenly, add 0.04 g of pyridoxine, ultrasonicate for 30 minutes, and then use concentrated ammonia water to adjust the pH of the system between 8.2-8.5 between;

[0040] (2) Disperse the mixed material evenly and transfer it to a Teflon high pressure vessel with a volume of 50 ml. Set the reaction temperature to 135°C and the reaction time to 40 hours. After the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com