A kind of degradable food packaging material and preparation method thereof

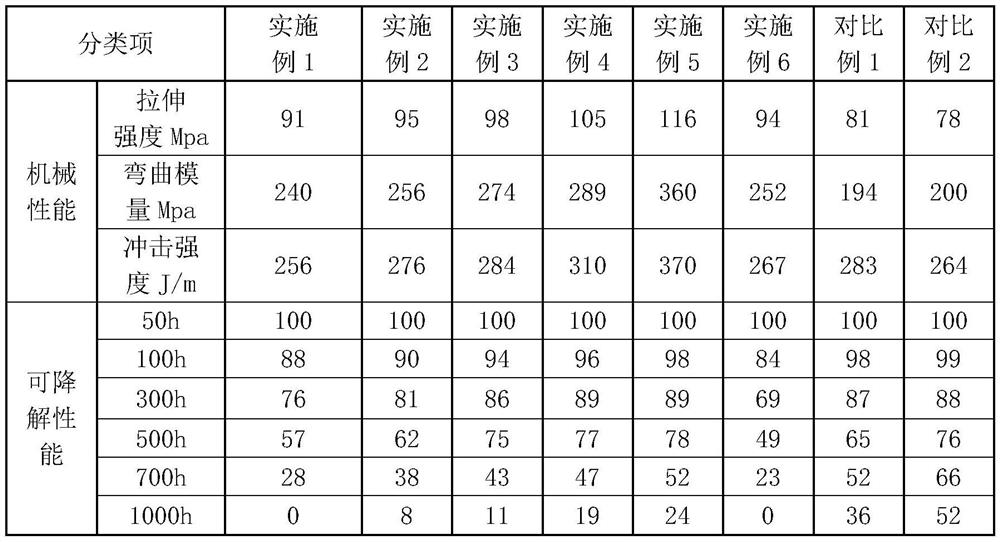

A technology for food packaging and composite fillers, applied in the field of food packaging materials, can solve the problems of difficult biodegradation and low mechanical strength of food packaging materials, and achieve the effects of solving low mechanical strength, strengthening mechanical properties, and solving difficult degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

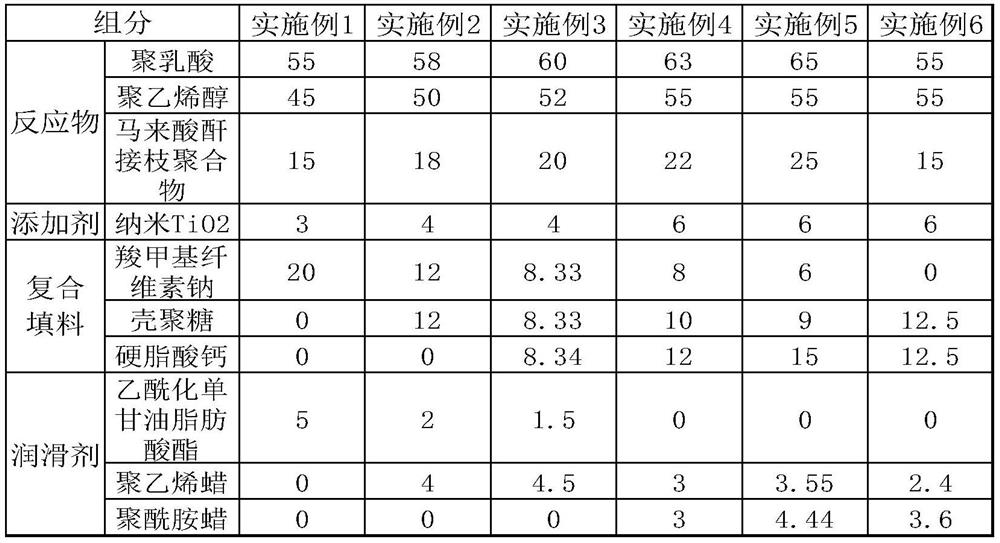

[0024] Embodiment 1: This embodiment provides a food packaging material, which is prepared according to the method for preparing food packaging materials, and the specific steps are as follows:

[0025] (1) Weigh 55 parts of polylactic acid, 45 parts of polyvinyl alcohol, 15 parts of maleic anhydride grafted compatibilizer, 5 parts of lubricant, 20 parts of composite filler and 3 parts of nano-titanium dioxide by weight and add them to the batching container , wherein the composite filler is sodium carboxymethyl cellulose, and the lubricant is acetylated monoglyceride fatty acid ester. Stir evenly at 80°C to 90°C. During the preparation of material Ⅰ, the stirring speed is 300r / min, and then Cool to below 80°C to obtain preliminary mixed material I;

[0026] (2) Put material I into a twin-screw extruder, melt, extrude strands, cool, and pelletize. The temperature in the twin-screw extruder is 120°C to 125°C to obtain pellets II for manufacturing food packaging materials .

...

Embodiment 2

[0028] Embodiment 2: This embodiment provides a food packaging material, which is prepared according to the method for preparing food packaging materials, and the specific steps are as follows:

[0029] (1) Weigh 58 parts of polylactic acid, 50 parts of polyvinyl alcohol, 18 parts of maleic anhydride grafted compatibilizer, 6 parts of lubricant, 24 parts of composite filler and 4 parts of nano-titanium dioxide by weight and add them to the batching container , wherein the composite filler is sodium carboxymethylcellulose and chitosan with a mass ratio of 1:1, the lubricant is acetylated monoglyceride fatty acid ester and polyethylene wax with a mass ratio of 1:2; at 80°C Stir evenly at ~100°C. During the preparation of material I, the stirring speed is 350r / min, and then cool to below 80°C to obtain the preliminary mixed material I;

[0030] (2) Put material I into a twin-screw extruder, melt, extrude strands, cool, and pelletize. The temperature in the twin-screw extruder is ...

Embodiment 3

[0032] Embodiment 3: This embodiment provides a food packaging material, which is prepared according to the above-mentioned method for preparing food packaging materials, and the specific steps are as follows:

[0033] (1) Weigh 60 parts of polylactic acid, 52 parts of polyvinyl alcohol, 20 parts of maleic anhydride grafted compatibilizer, 6 parts of lubricant, 25 parts of composite filler and 4 parts of nano-titanium dioxide by weight and add them to the batching container , wherein the composite filler is sodium carboxymethylcellulose, chitosan, calcium stearate and its mass ratio is 2:2:2, and the lubricant is acetylated monoglyceride fatty acid ester and polyethylene wax and its mass ratio is 1:3; Stir evenly under the condition of 90℃~115℃. During the preparation of material Ⅰ, the stirring speed is 380r / min, and then cool to below 80℃ to obtain the preliminary mixed material Ⅰ;

[0034] (2) Add material I into a twin-screw extruder, melt, extrude strands, cool, and pelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com