Biodegradable PTT slice and preparation method thereof

A biodegradation and slicing technology, which is applied in the manufacture of rayon, single-component polyester rayon, chemical characteristics of fibers, etc., can solve problems such as difficult biodegradation, and achieve the effect of reducing environmental pressure and improving hydrophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

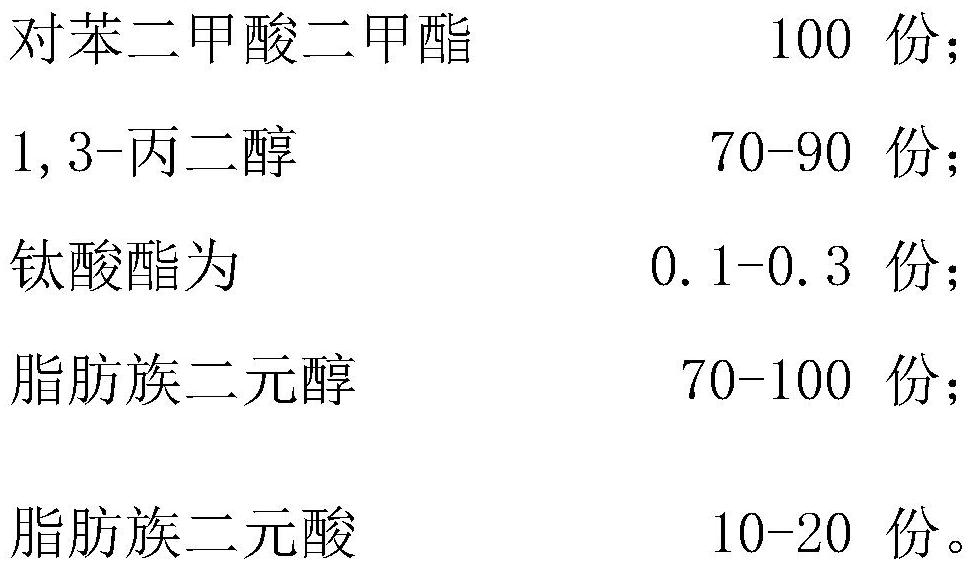

[0035] A biodegradable PTT slice, the biodegradable PTT slice is made of raw materials comprising the following parts by weight:

[0036]

[0037] The inventor has found through a large number of tests: in this embodiment, at first, when using the addition amount of each component described in the present invention, the reaction speed can be made to reach a relative maximum value, and the reaction can be carried out more completely at the same time, and finally obtained High-quality polyester chips can be degraded to the maximum extent, so that the raw materials can be fully utilized and the cost can be reduced. If the amount added is not within the set range, not only the mechanical properties of the obtained polyester will not meet the standards, but also it will not be biodegradable, resulting in complex processes, increased by-products, and waste of resources.

[0038] The preparation method of the biodegradable PTT slice comprises the following steps:

[0039] 1) Unde...

Embodiment 2

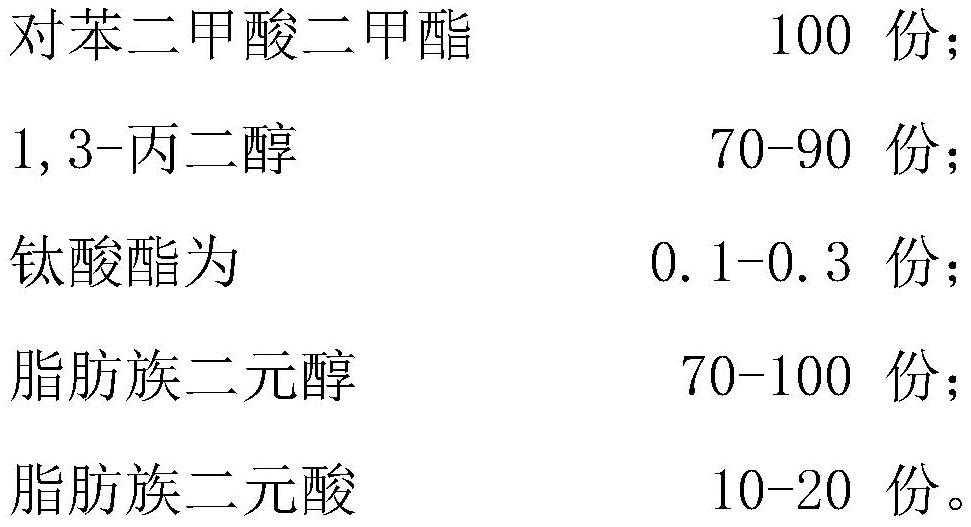

[0051] A biodegradable PTT slice, the biodegradable PTT slice is made of raw materials comprising the following parts by weight:

[0052]

[0053] The preparation method of the biodegradable PTT slice comprises the following steps:

[0054] 1) Under the catalysis of titanate, dimethyl terephthalate and 1,3-propanediol are transesterified at 180°C to 190°C to obtain a transesterification product;

[0055] 2) Mixing the transesterification reaction product prepared in step 1) with biodegradable additives, catalysts, and thermal stabilizers to carry out polycondensation reaction.

[0056] In step 1), the titanate is isopropyl titanate.

[0057] In step 1), the methanol vapor generated by the transesterification reaction is separated and processed through distillation, and the generated methanol flows into a methanol receiving tank.

[0058] In step 2), the reaction conditions of the polycondensation reaction are:

[0059] First raise the temperature to 270°C-285°C in a non-...

Embodiment 3

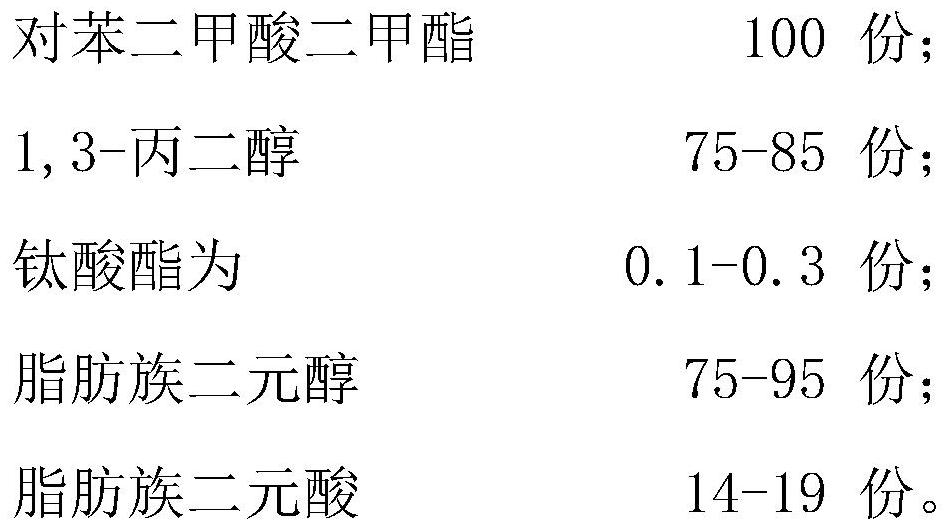

[0066] (1) Take the following raw materials:

[0067] 100kg of dimethyl terephthalate, 75kg of 1,3-propanediol, 85kg of aliphatic dibasic alcohol, 12kg of aliphatic dibasic acid, and 0.25kg of isopropyl titanate.

[0068] The aliphatic dibasic alcohol is ethylene glycol and hexanediol, and the weight ratio of the two is 3:1; the aliphatic dibasic acid is succinic acid and adipic acid, and the weight ratio of the two is 2:1.

[0069] (2) transesterification reaction

[0070] Add dimethyl terephthalate, 1,3-propanediol, and isopropyl titanate into the reaction kettle, gradually raise the temperature to 180°C~190°C, and start the transesterification reaction. During the transesterification process, methanol vapor is formed. The distillation tower is separated, and the methanol vapor at the top of the tower flows into the methanol receiving tank after being condensed. When the temperature at the top of the distillation tower drops, the transesterification reaction ends.

[0071]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com