Patents

Literature

92 results about "Relative maximum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A relative maximum or minimum occurs at turning points on the curve where as the absolute minimum and maximum are the appropriate values over the entire domain of the function. In other words the absolute minimum and maximum are bounded by the domain of the function. Example:

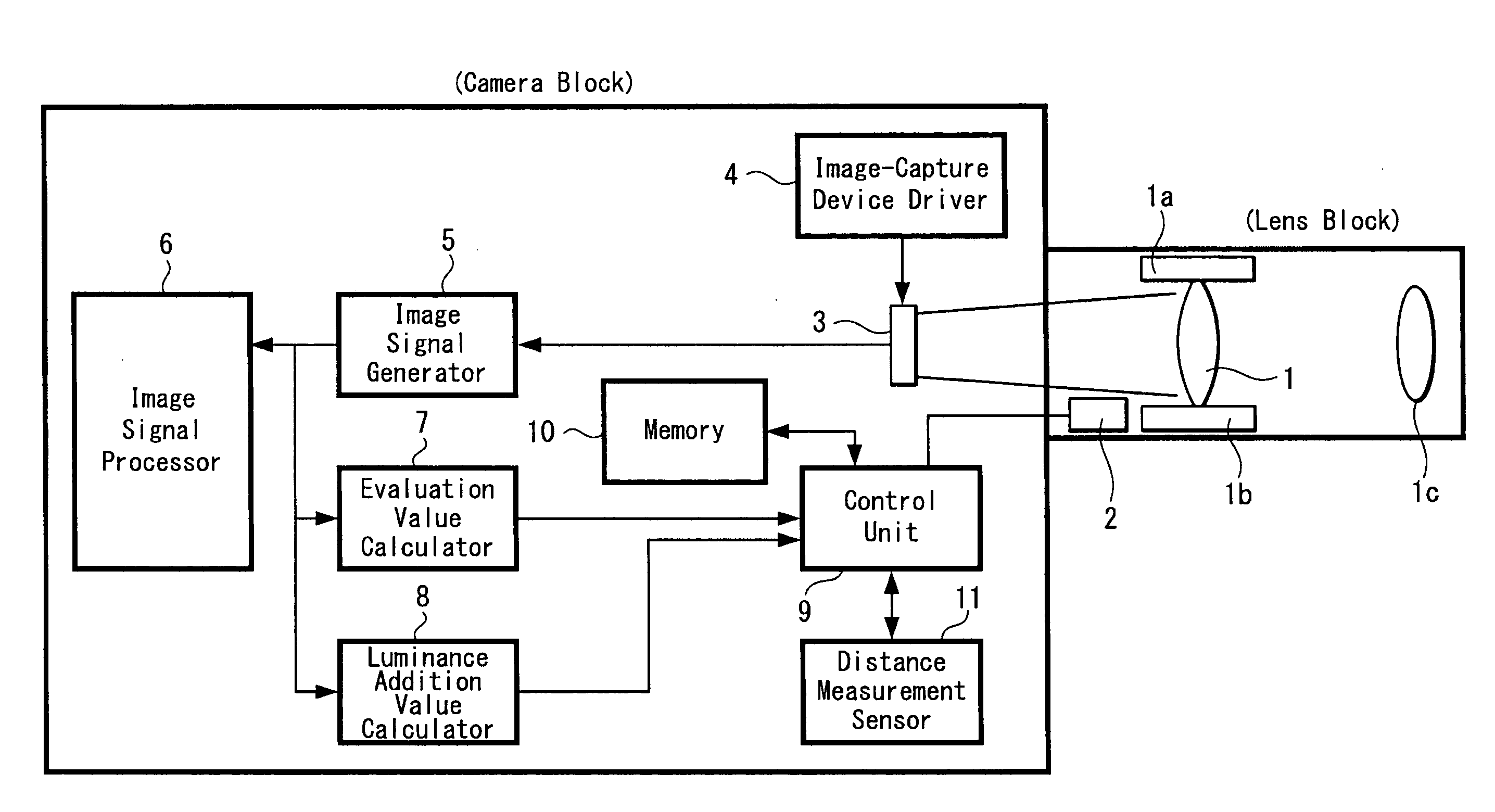

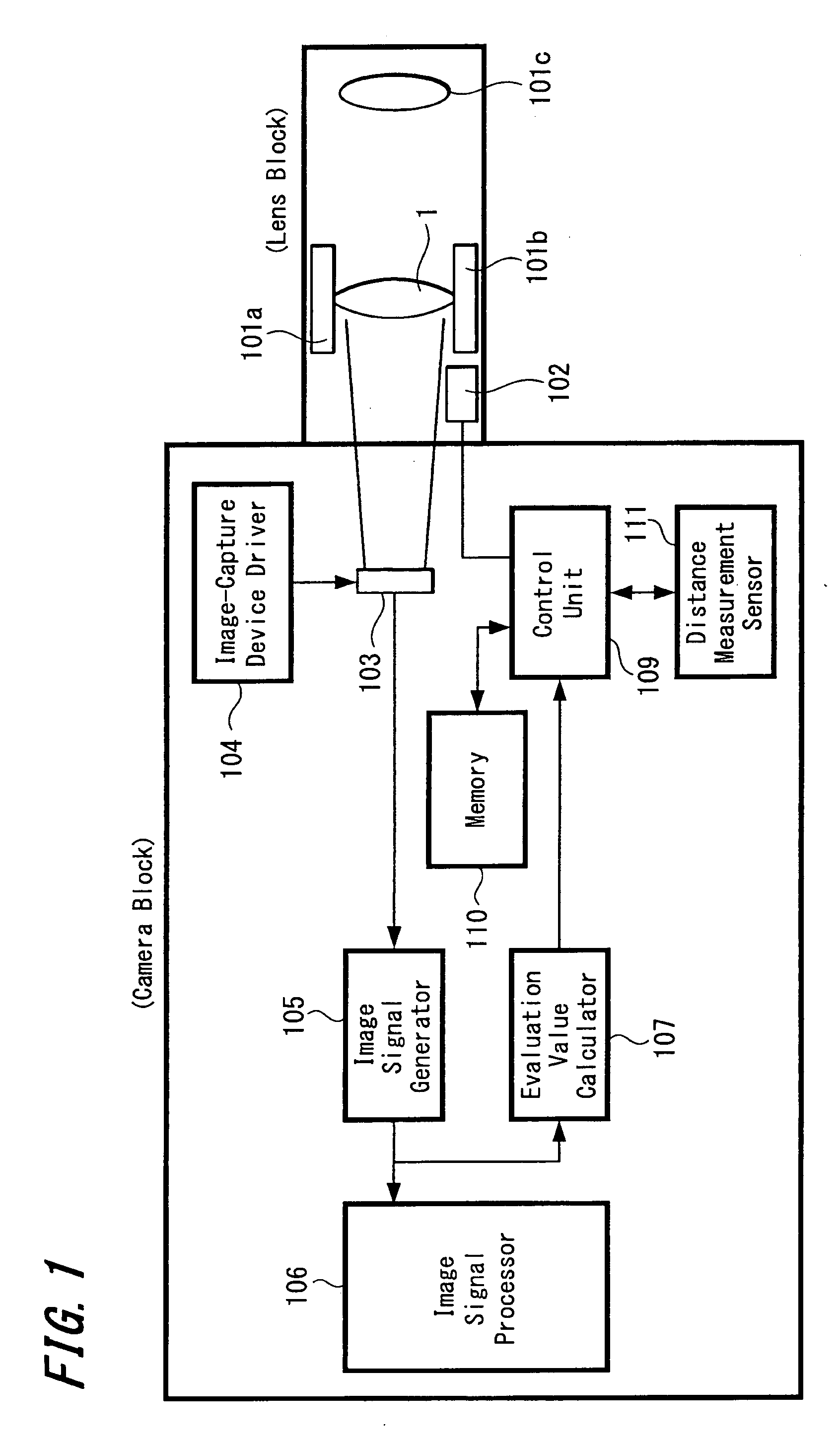

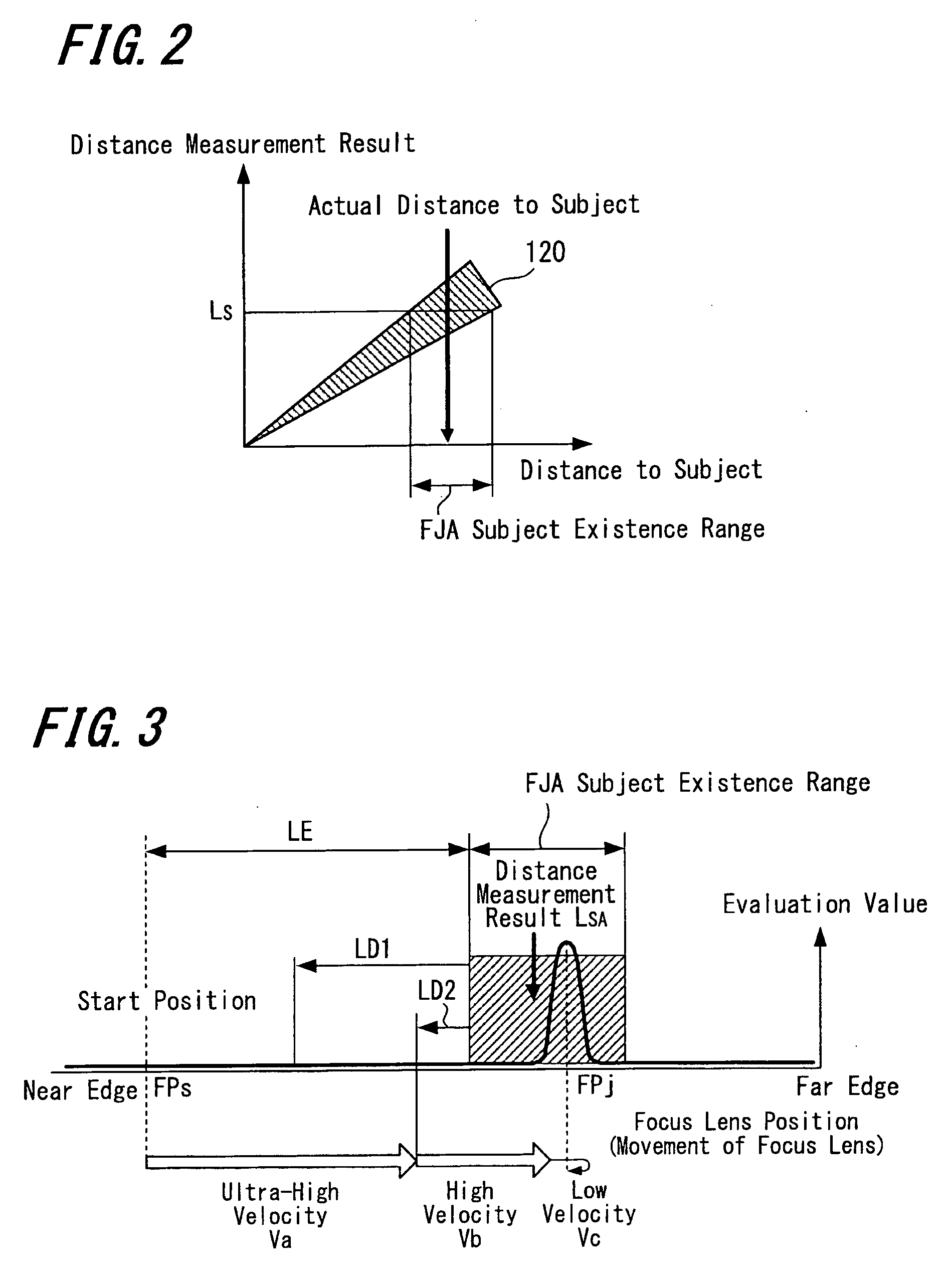

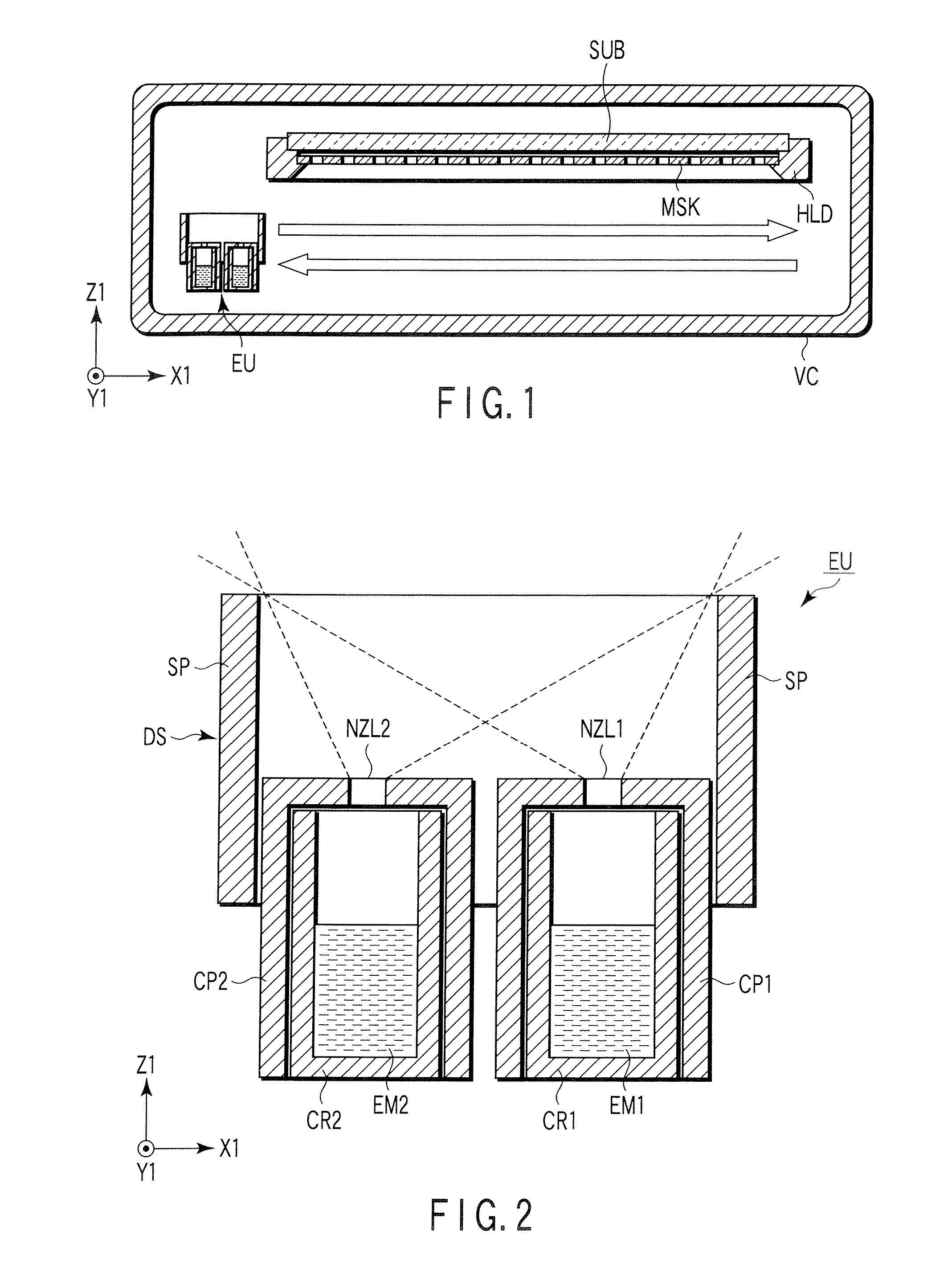

Auto-focus apparatus, image-capture apparatus, and auto-focus method

InactiveUS20080002960A1Maintain precisionSecuring searching accuracyTelevision system detailsProjector focusing arrangementRelative maximumPeak value

Disclosed is an auto-focus apparatus including an evaluation value calculator periodically calculating evaluation values using high frequency components of image signals in a specific region of a subject image, a distance measurement unit measuring a distance to a subject and output a distance measurement result, a control unit outputting instruction values based on the evaluation values and determines whether a subject image is in-focus or out-of-focus, and a storage storing the distance measurement results and lens positions. In the apparatus, after searching the peak of the evaluation values, the control unit returns the lens to the position at which the relative maximum has been detected, obtains evaluation values, stores lens positions and distance measurement results when the evaluation values satisfy a prescribed condition, and retrieves distance measurement results and lens positions when the number of times that results are stored reaches a prescribed number, and computes a correction amount.

Owner:SONY CORP

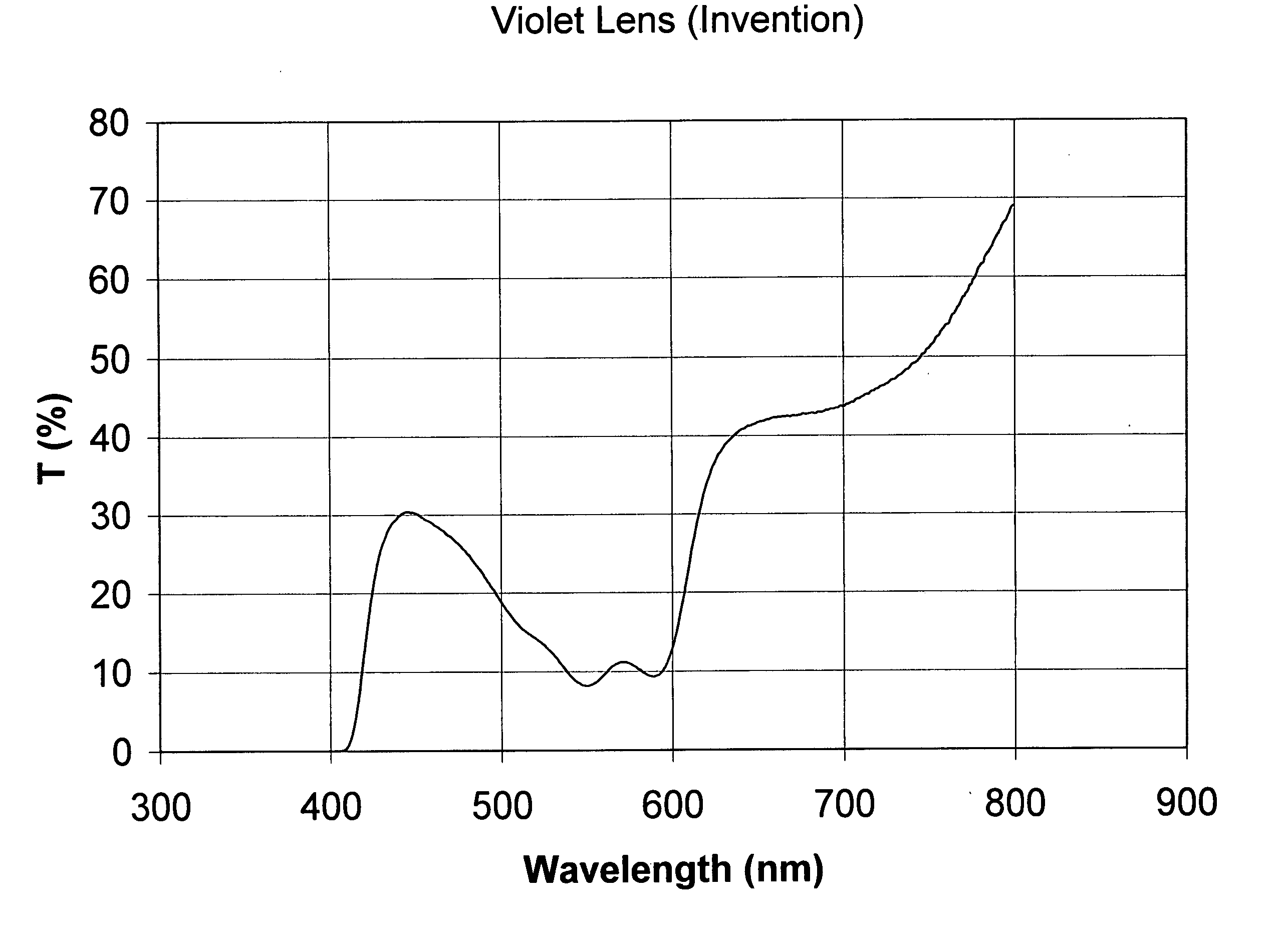

Polarized optical elements enhancing color contrast and methods for their manufacture

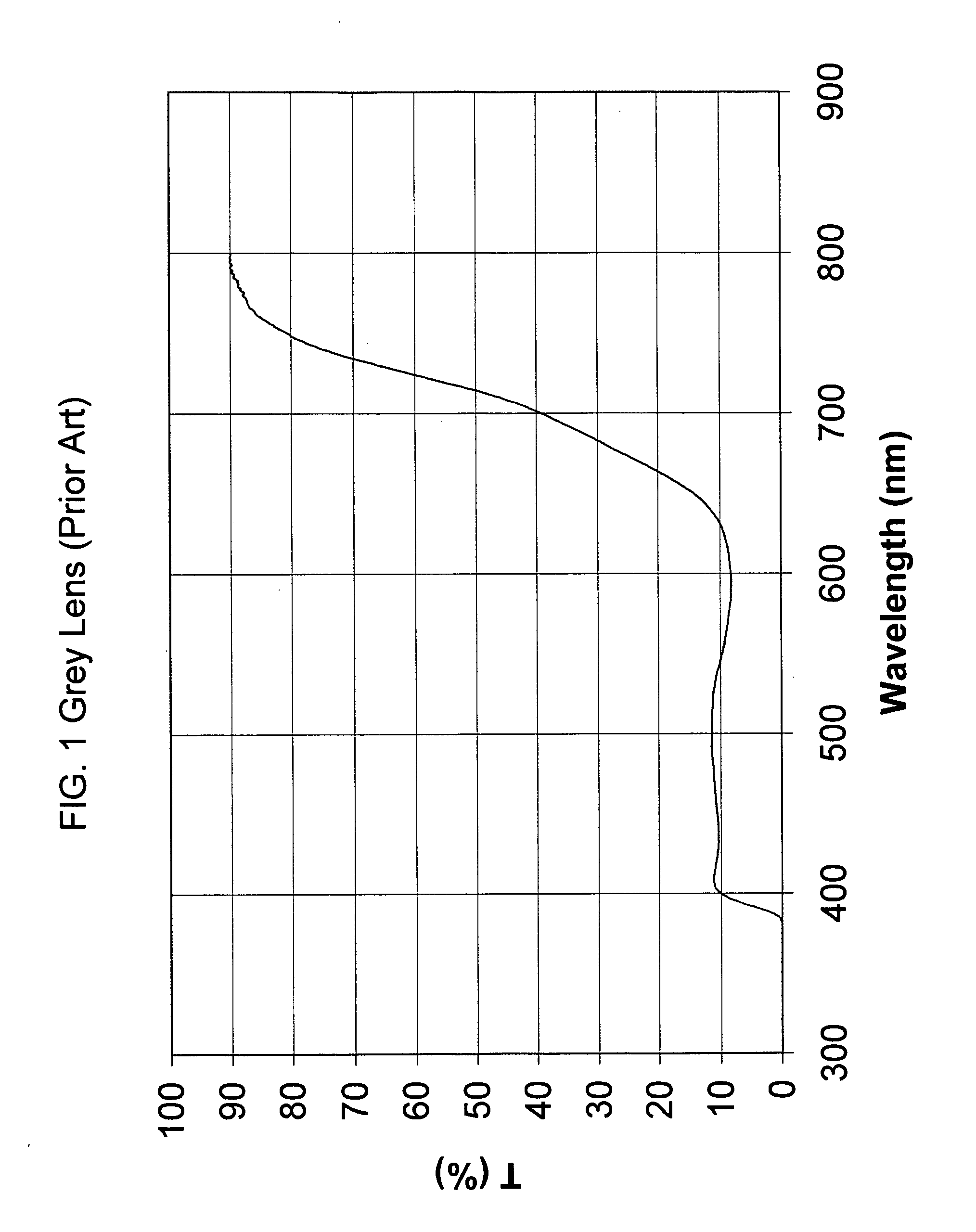

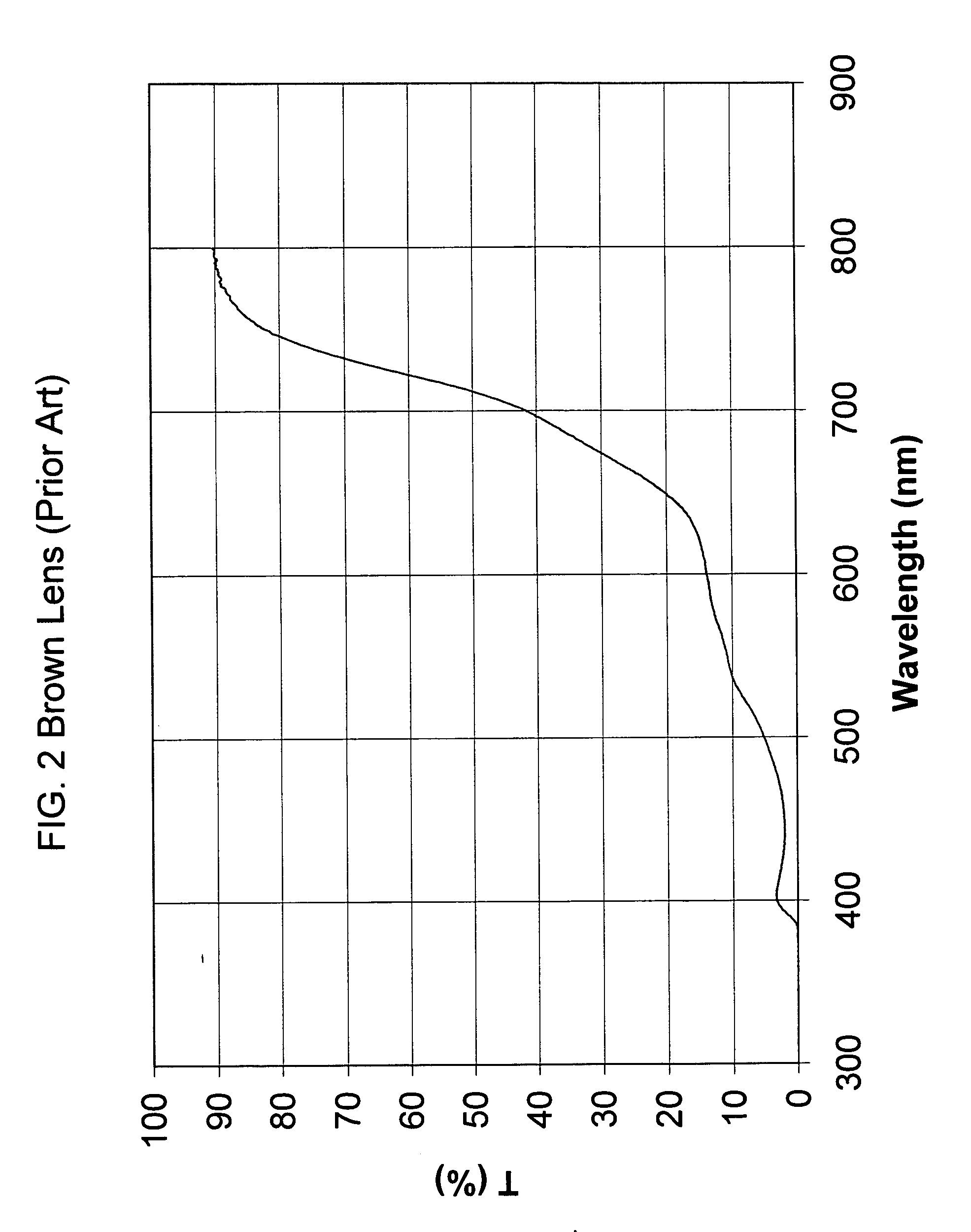

InactiveUS20060033851A1Reduce glareImprove eyesightOptical filtersNon-linear opticsInternational standardTraffic signal

Owner:INTERCAST EURO

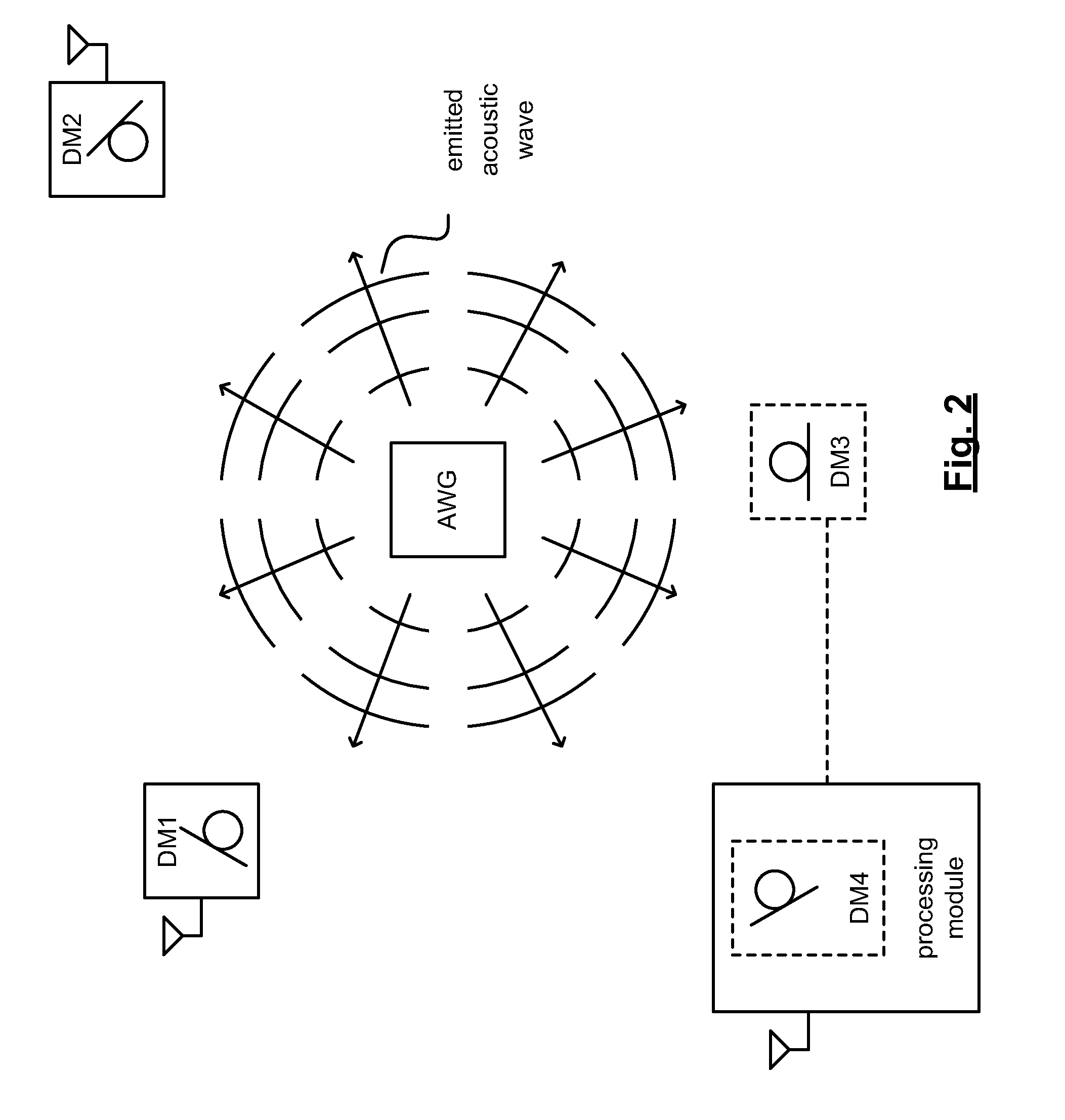

Directional microphone or microphones for position determination

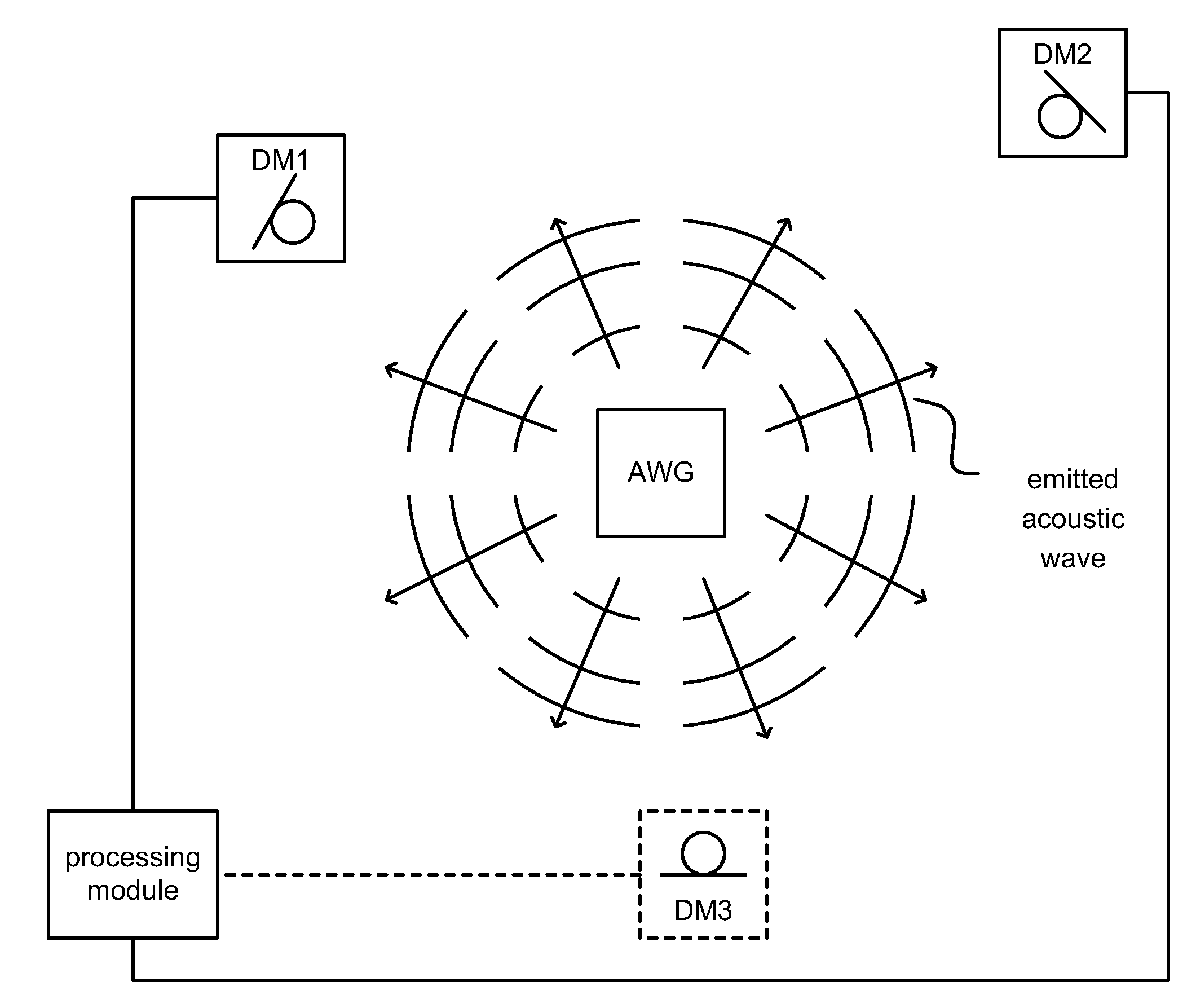

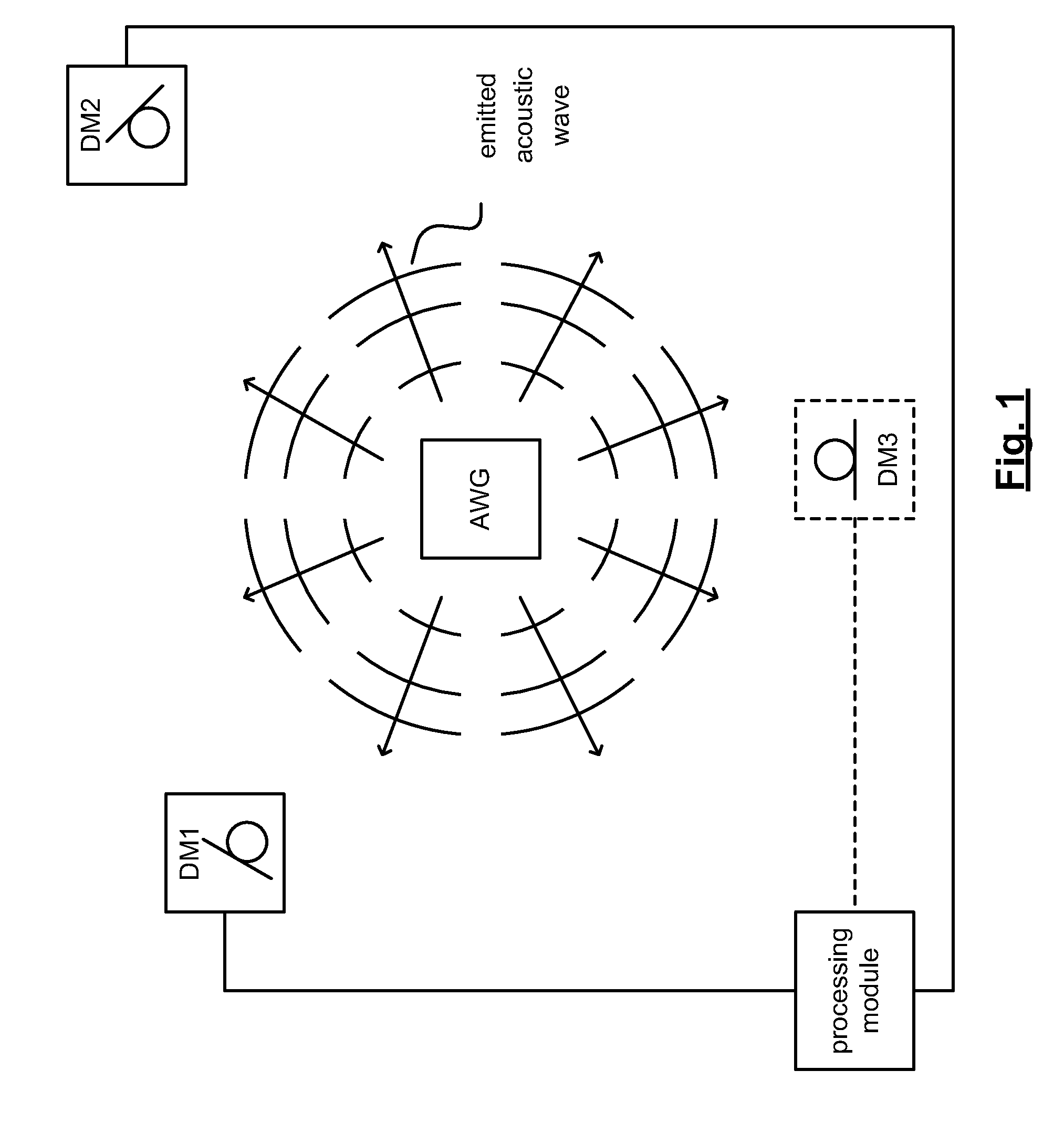

ActiveUS20080316863A1Direction finders using ultrasonic/sonic/infrasonic wavesVideo gamesSonificationProcess module

Directional microphone or microphones for position determination. One or multiple directional microphones are implemented in various locations to perform acoustic wave capture of acoustic waves associated with object (e.g., a player, a gaming object, a game controller, etc.). The generator of such acoustic waves may be co-located with the object (e.g., integrated into the object if the object is a device such as a gaming object, a game controller, etc., or integrated into clothing worn by a player such as on a hat, a jacket, etc.). The acoustic waves described herein may be generated by any number of means / devices including audio output devices, speakers, pulse wave generators, audio oscillators, etc. Moreover, such acoustic waves may be ultrasonic. A game module and / or processing module processes directional vectors associated with positions of the directional microphones when detecting relative maximum amplitude of an acoustic wave emits by an acoustic wave generator.

Owner:AVAGO TECH INT SALES PTE LTD

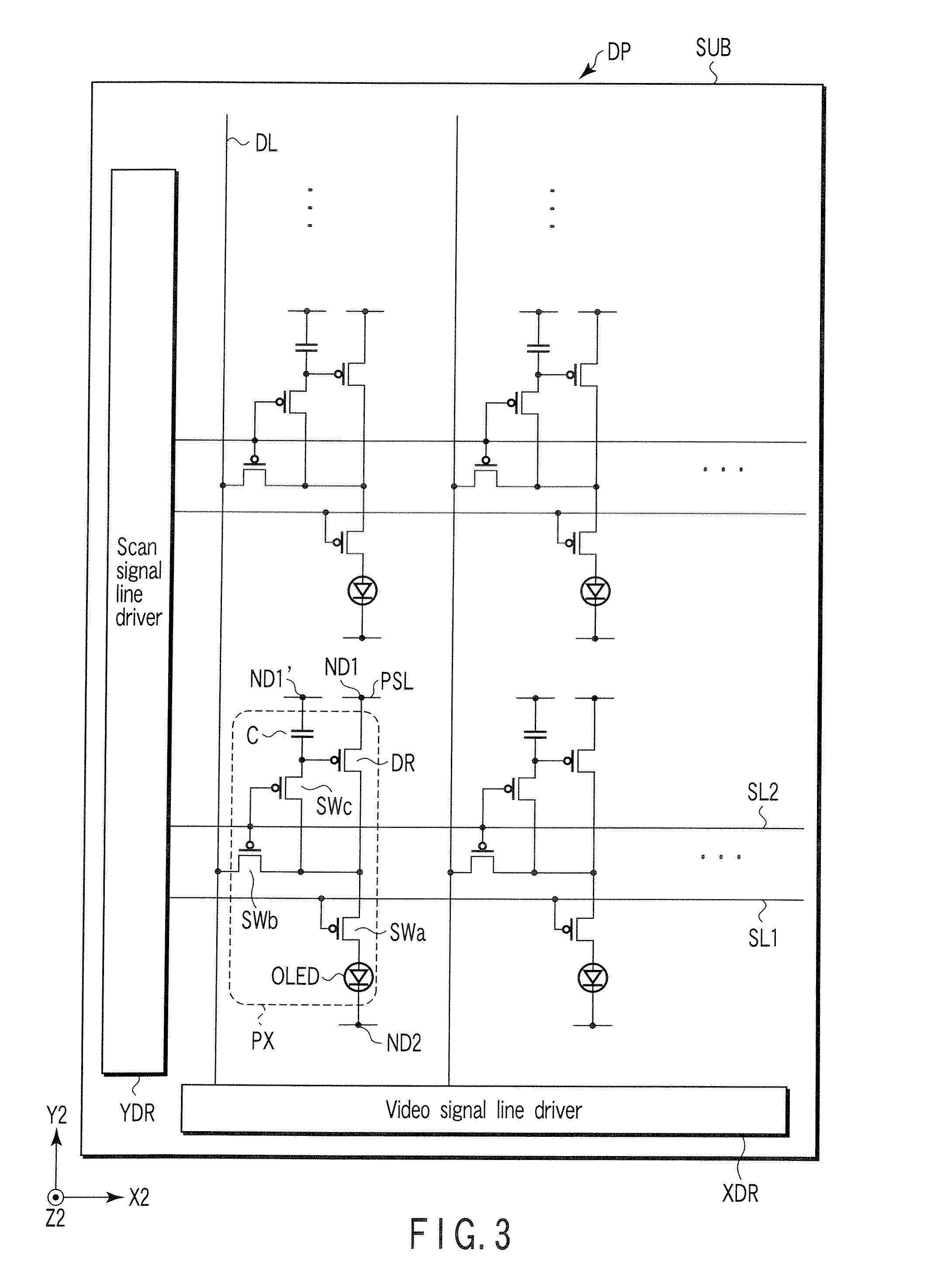

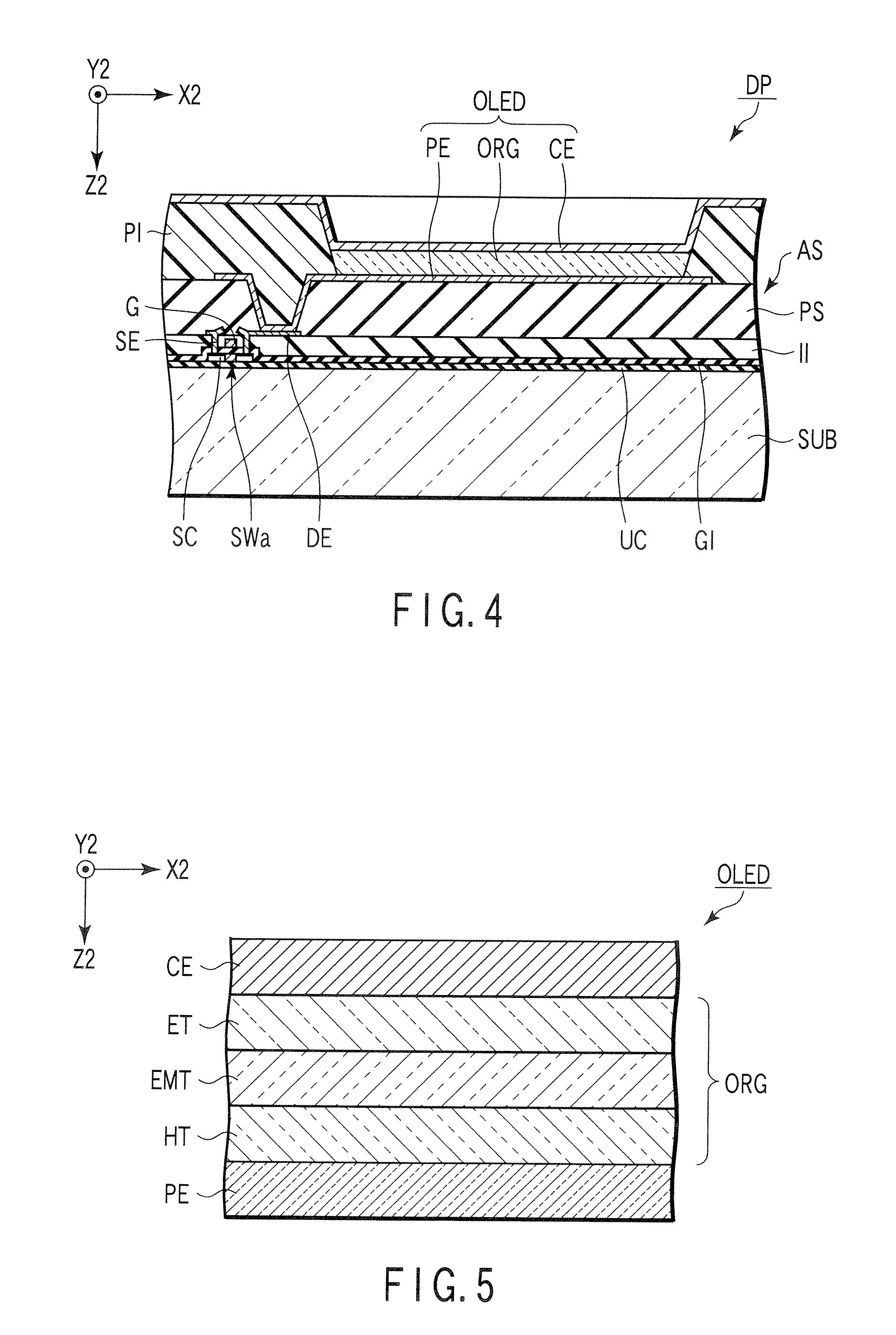

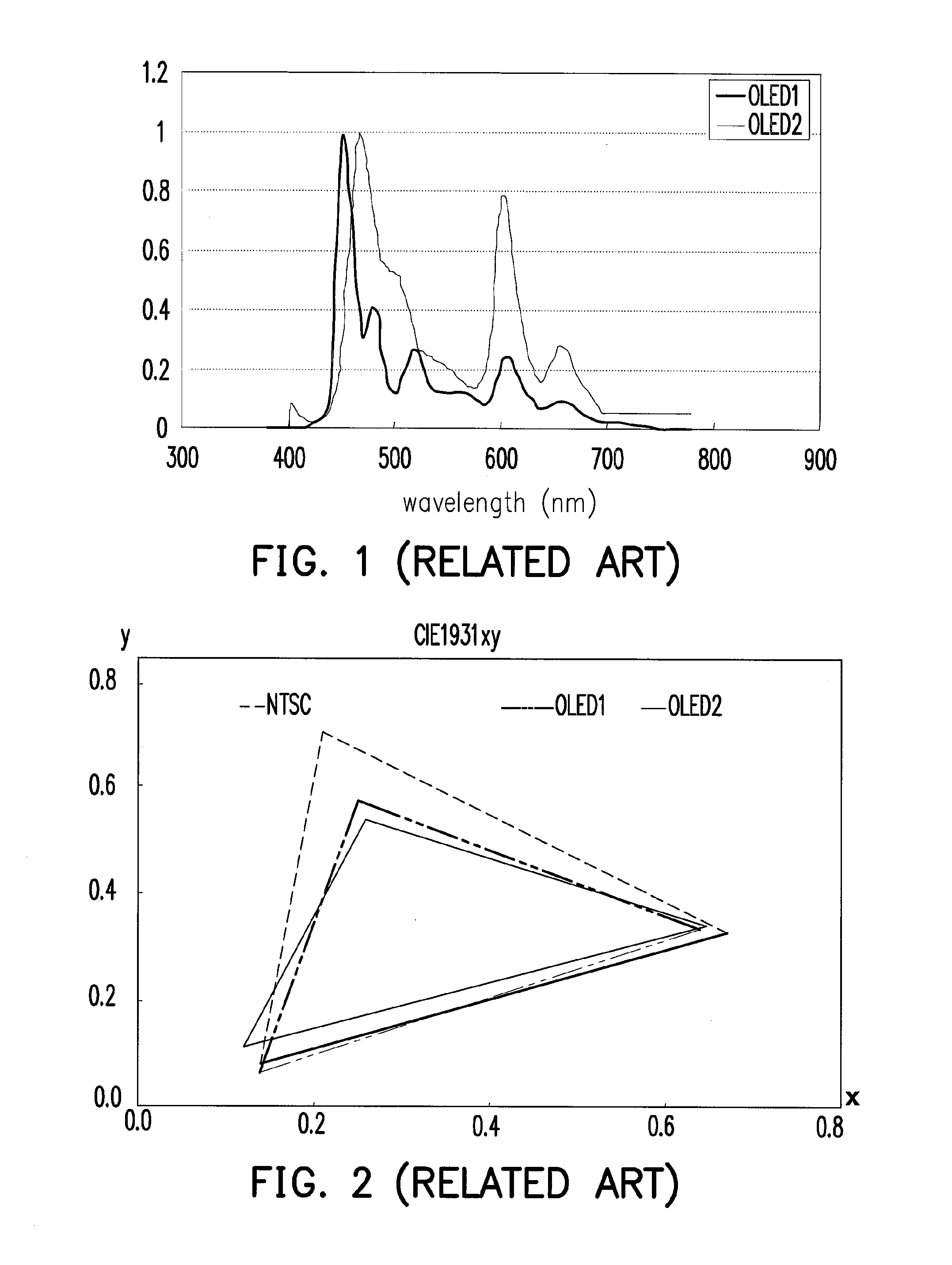

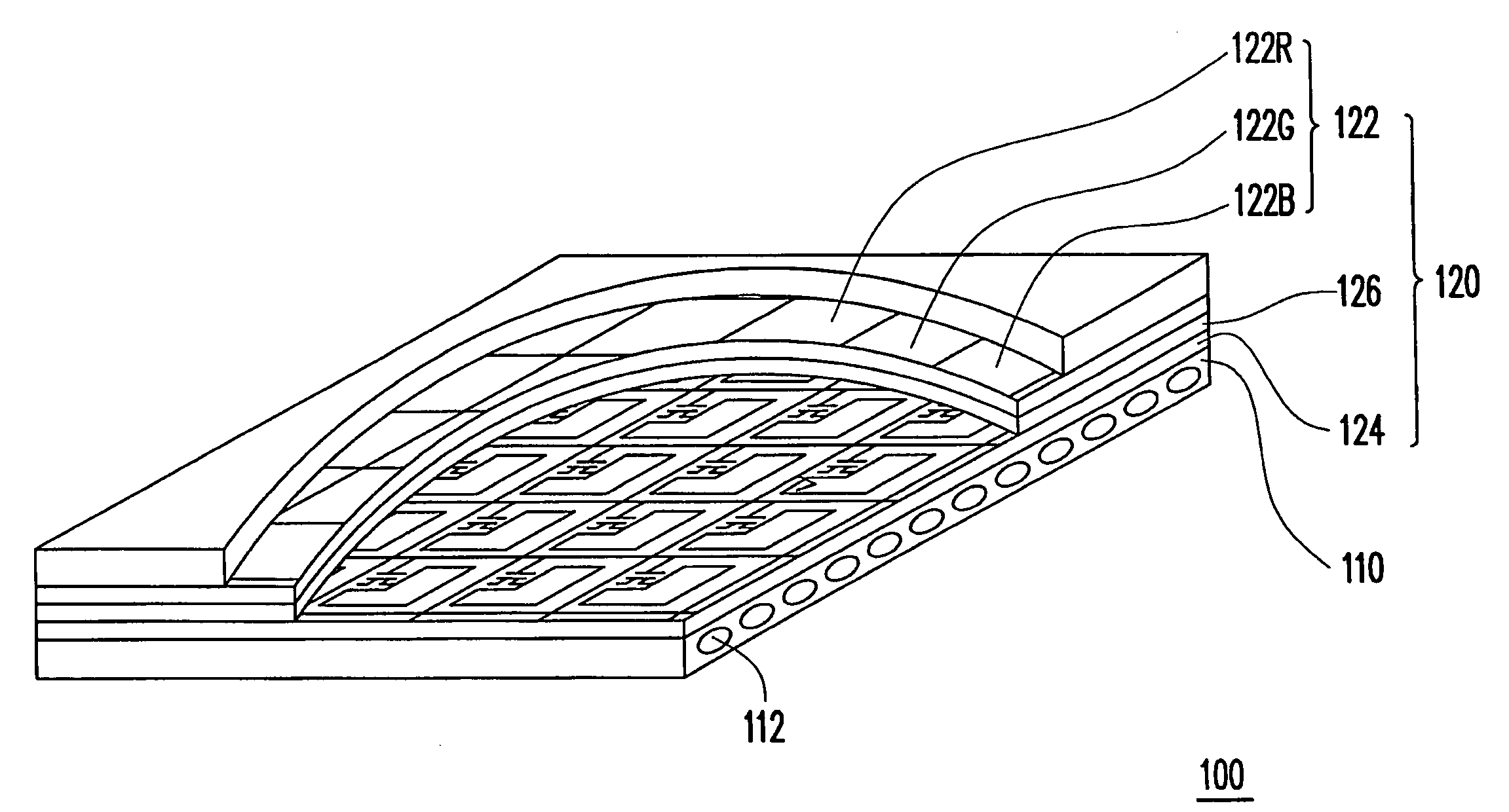

Organic el display

An organic EL element includes a pair of electrodes and an emitting layer interposed therebetween. The emitting layer is made of a mixture containing a host material and a dopant material. In the emitting layer, a concentration profile of the dopant material along a thickness direction includes at least two relative maximums or at least two relative minimums.

Owner:JAPAN DISPLAY CENTRAL CO LTD

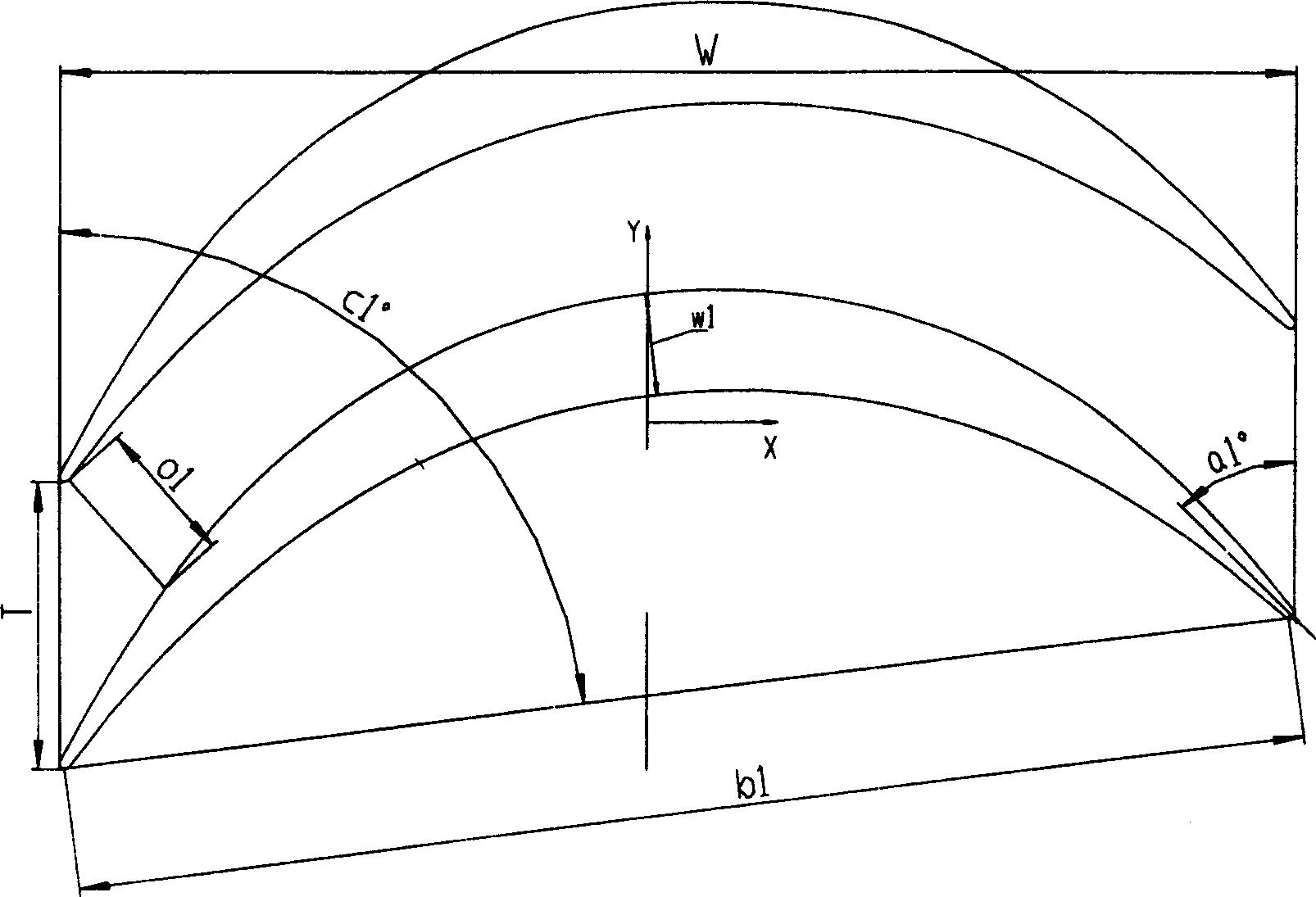

Last stage rotor blade of steam turbine

ActiveCN1730912AMeet flowReduce flow lossBlade accessoriesMachines/enginesRelative maximumRoot radius

The last stage movable blade of steam turbine features the relative blade height H monotonously increased from 0.0 to 1.0, blade body profile with assembling angle c1 monotonously decreased from 82.81 deg to 10.1 deg, inlet geometric angle a1 monotonously increased from 36.65 deg to 168.0 deg, outlet geometric angle a2 monotonously decreased from 31.4 deg to 10.6 deg, relative maximum thickness w1 monotonously decreased from 3.47 to 1.0, relative chord length b1 monotonously decreased from 1.84 to 1.0, relative cross section area S monotonously decreased from 7.98 to 1.0, and the ratio between blade height H to root radius of 0.5-0.7. The present invention is especially suitable for sub-critical and supercritical steam turbine with effective blade height not smaller than 1200 mm, power of 600-1200 MW and rotation speed of 3000 rpm.

Owner:DONGFANG TURBINE CO LTD

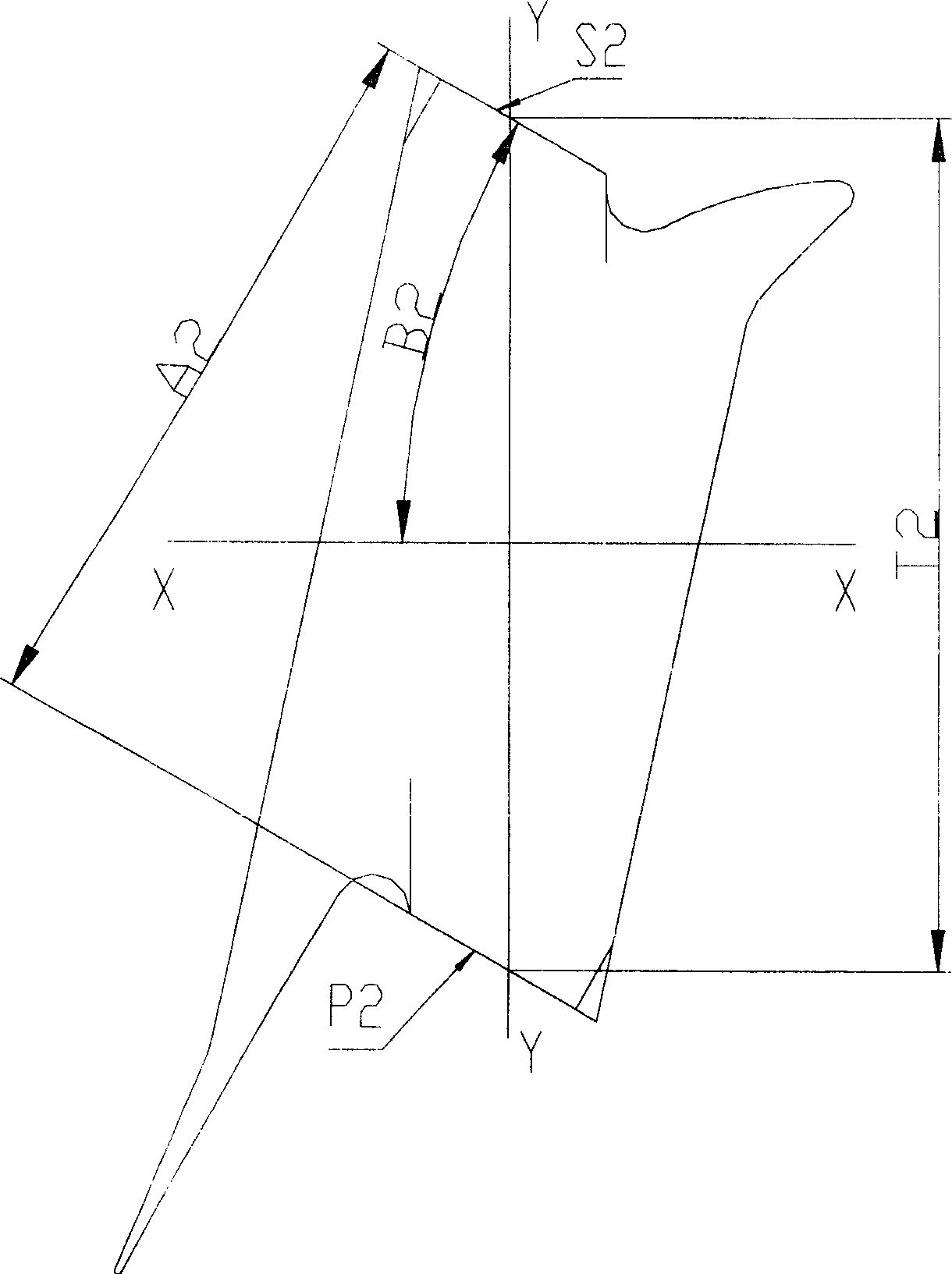

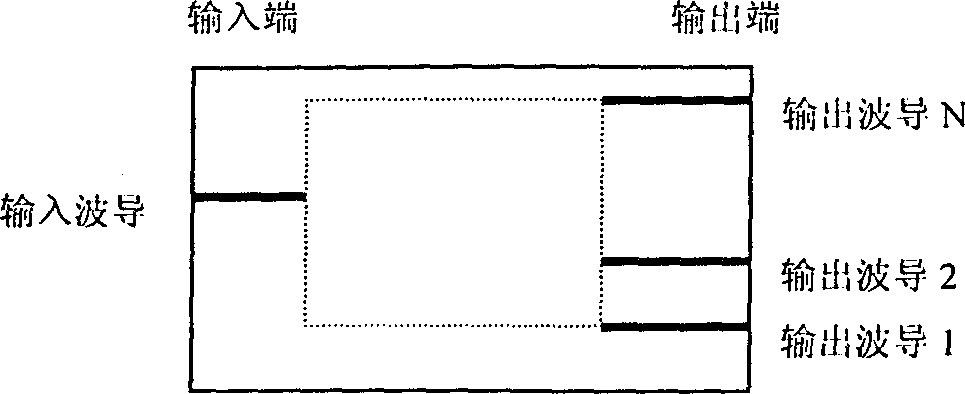

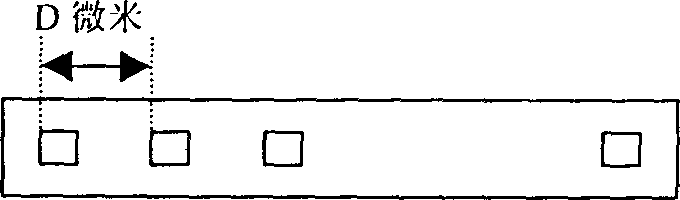

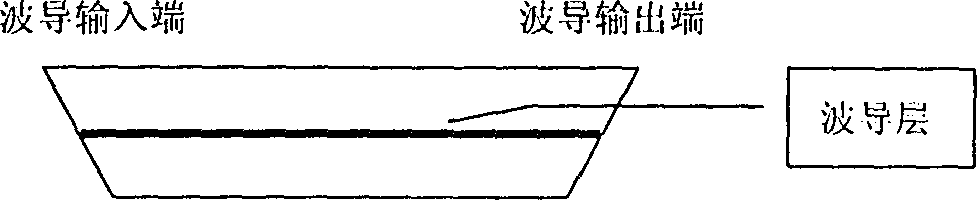

Automatic alligning method for optical waveguide device and optical fibre array

The invention relates to the method for automatically aligning the optical wave guide part with the optical fiber array, including the coarse alignment, fine alignment and the equalization of energy in each channel. The mixed type algorithm for automatic alignment is adopted in the fine alignment. The procedure of the fine alignment is as follows: With relatively great scanning range and step size, using the numerical value plot mode alignment algorithm searches the position of the relative maximum value of energy in K channel further. With relatively small scanning range and step size, usingthe numerical value plot mode alignment algorithm searches the position of the final absolute maximum value of energy in K channel. Using the fast aligning method-the rotation method searches the maximum value of energy in J channel.

Owner:GUANGXUN SCI & TECH WUHAN

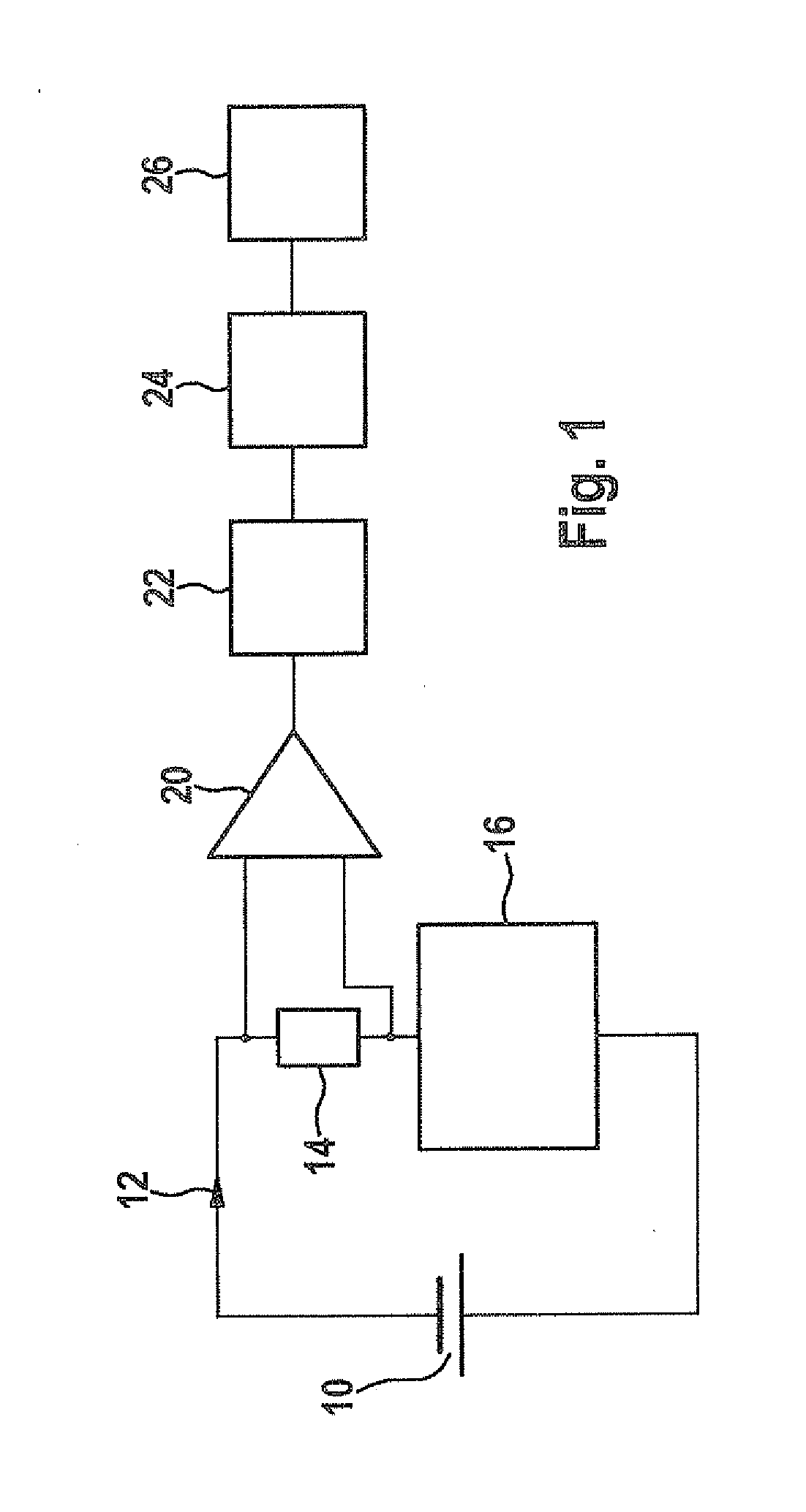

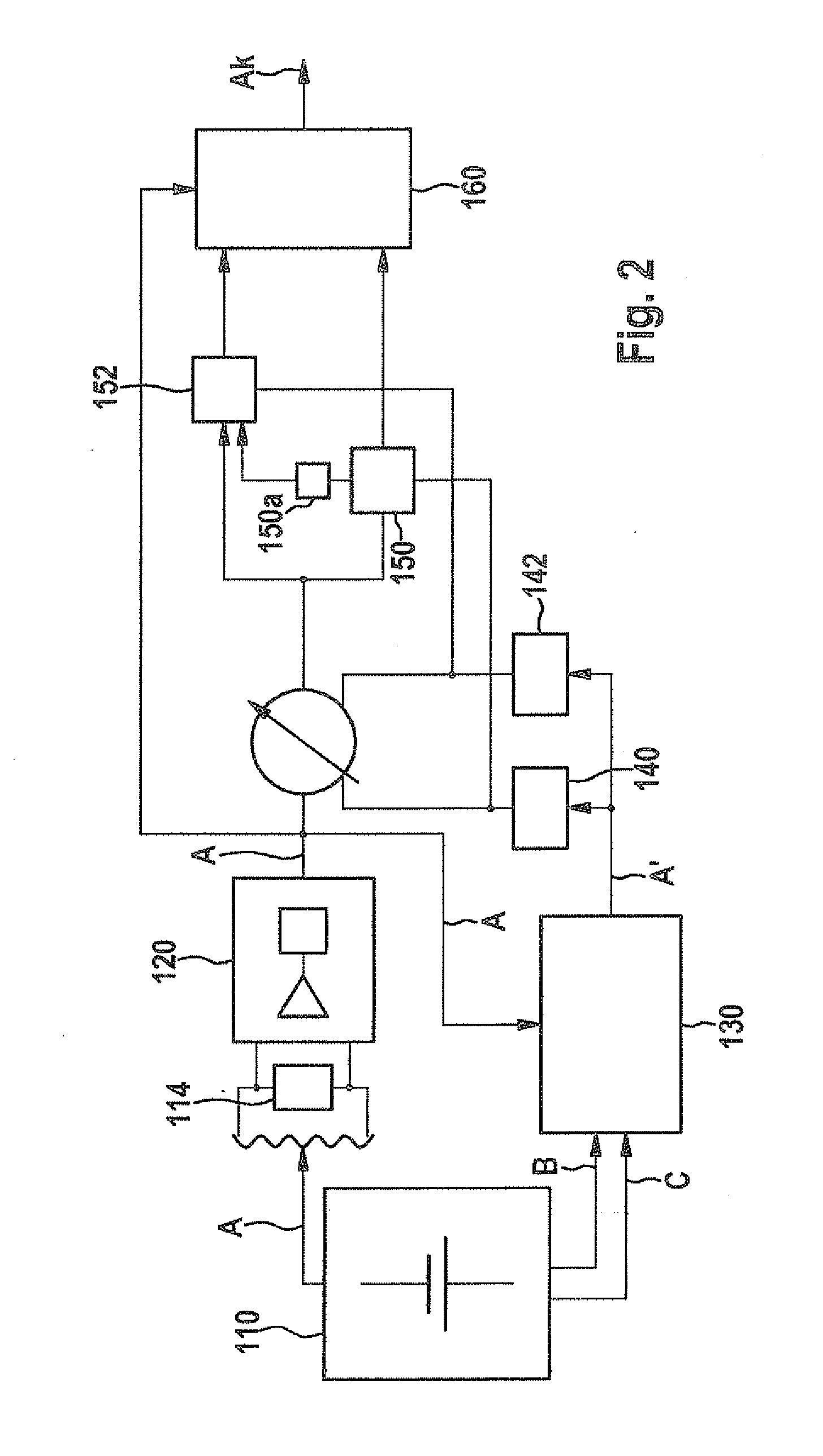

Method and device for error-compensated current measurement of an electrical accumulator

InactiveUS20120283970A1Improve Manufacturing TolerancesImprove accuracyElectrical testingCurrent measurements onlyEngineeringRelative maximum

A method for error-compensated current measurement of an electrical accumulator, including: providing a time window-related estimated charge ascertained by a model-based estimator from operating variables of the accumulator and reflecting the estimated charge that has been withdrawn from the accumulator and supplied to the accumulator within the time window; and detecting the accumulator current supplied to the accumulator and withdrawn from the accumulator during the time window, with a current detection sensor. A zero crossing point in time (estimated charge is essentially zero) and a maximum point in time (the absolute value of the estimated charge essentially has a relative maximum or has a value which is greater than a minimum charge difference) are detected. A current measurement offset error is ascertained at the zero crossing point in time by comparing the estimated charge to the detected accumulator current. The accumulator current is ascertained according to the current measurement offset error, and a current measurement scaling error is ascertained at the maximum point in time by comparing the estimated charge to the detected accumulator current. The ascertained current measurement offset error is subtracted from the comparison result thus obtained, and the accumulator current is compensated for based on the current measurement scaling error. A related device for error-compensated current measurement is also described.

Owner:ROBERT BOSCH GMBH

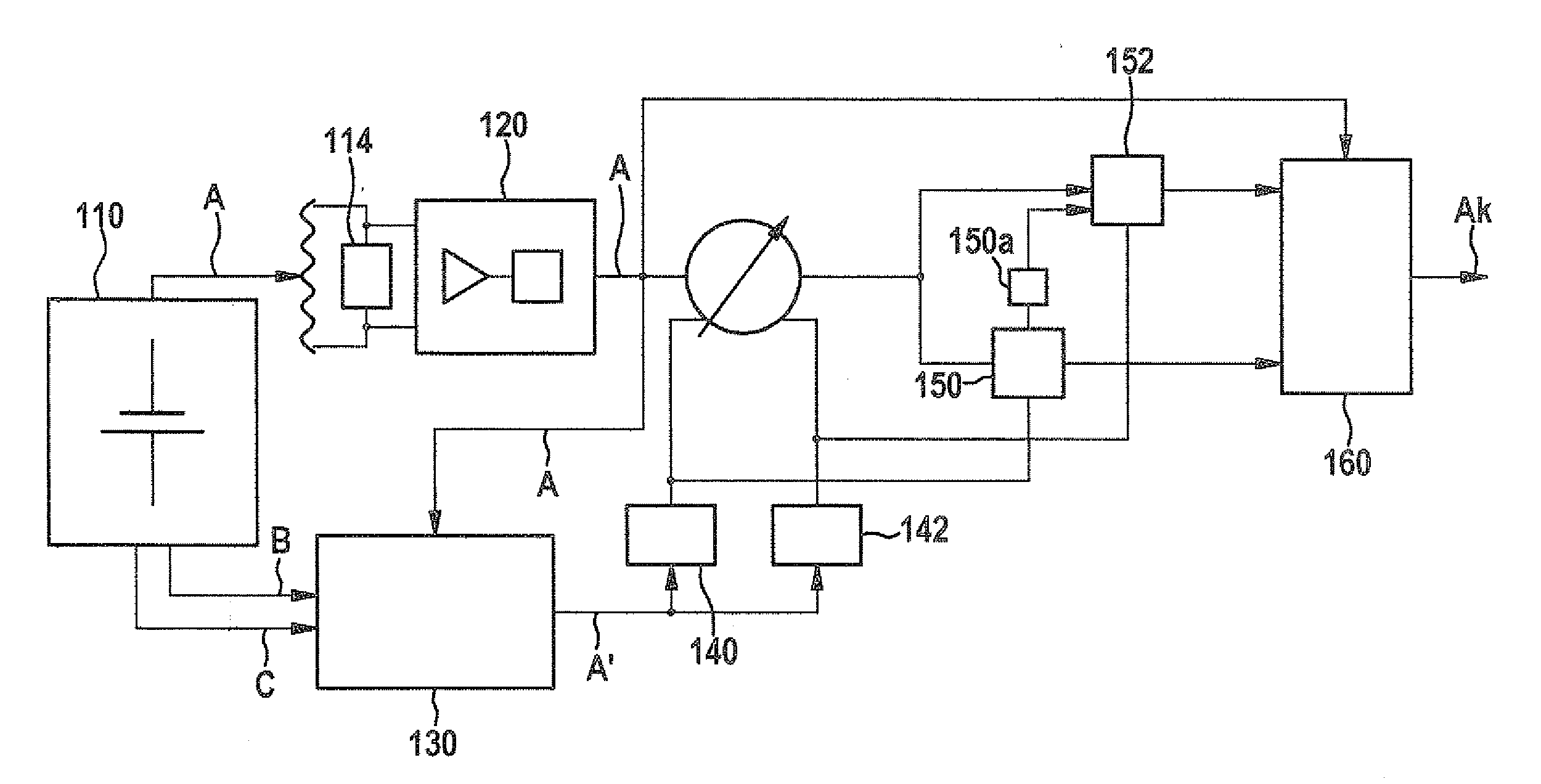

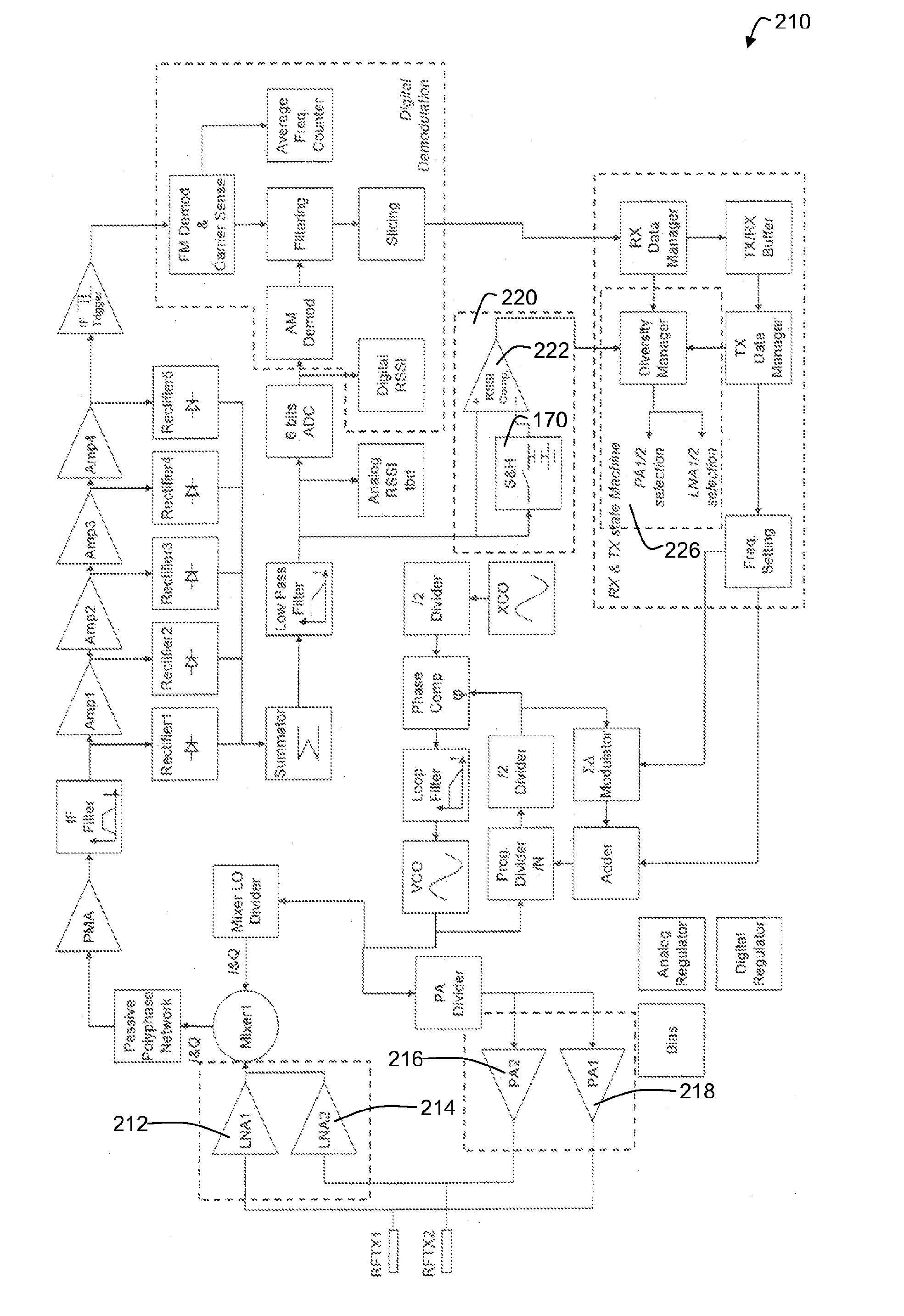

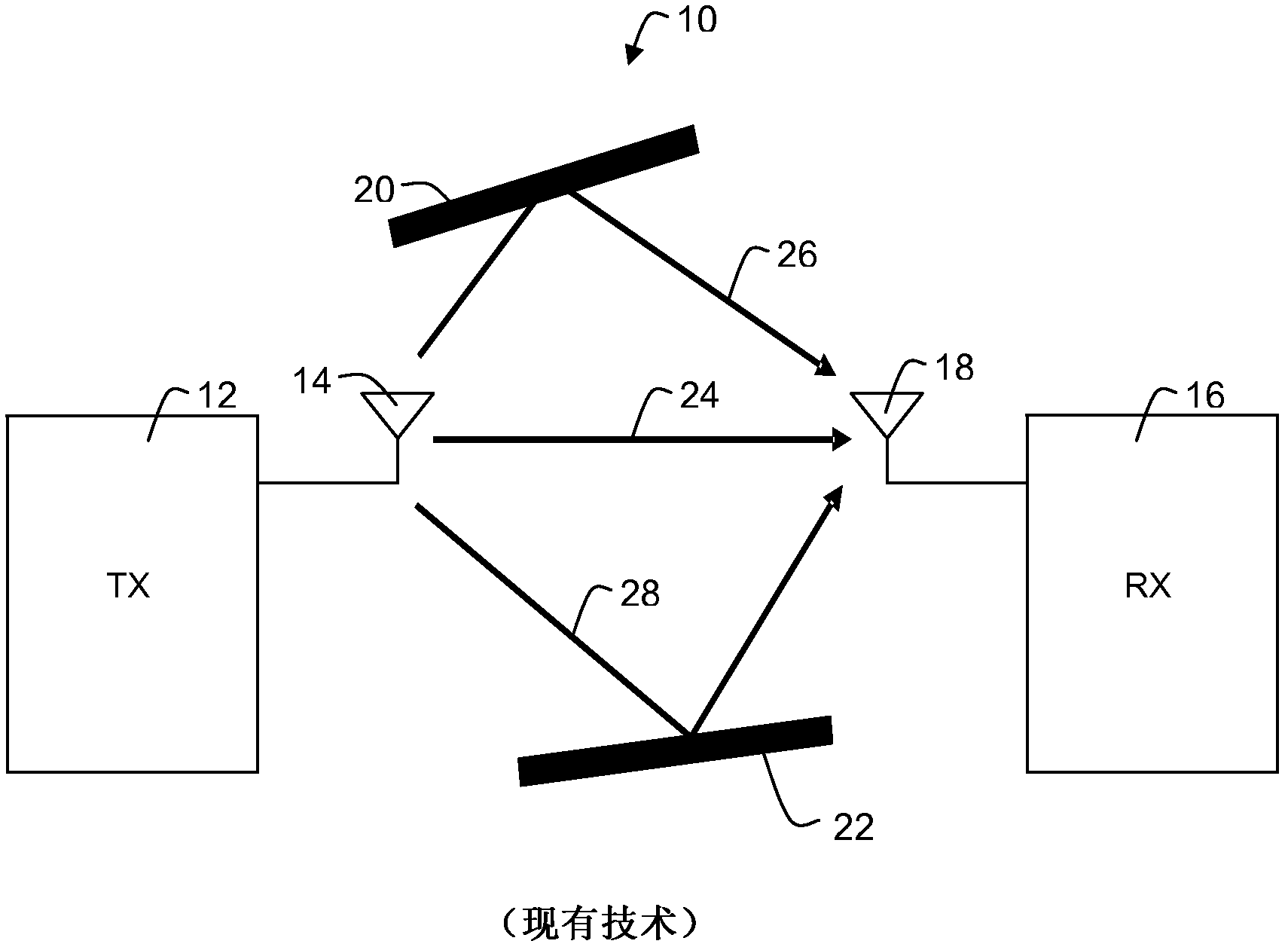

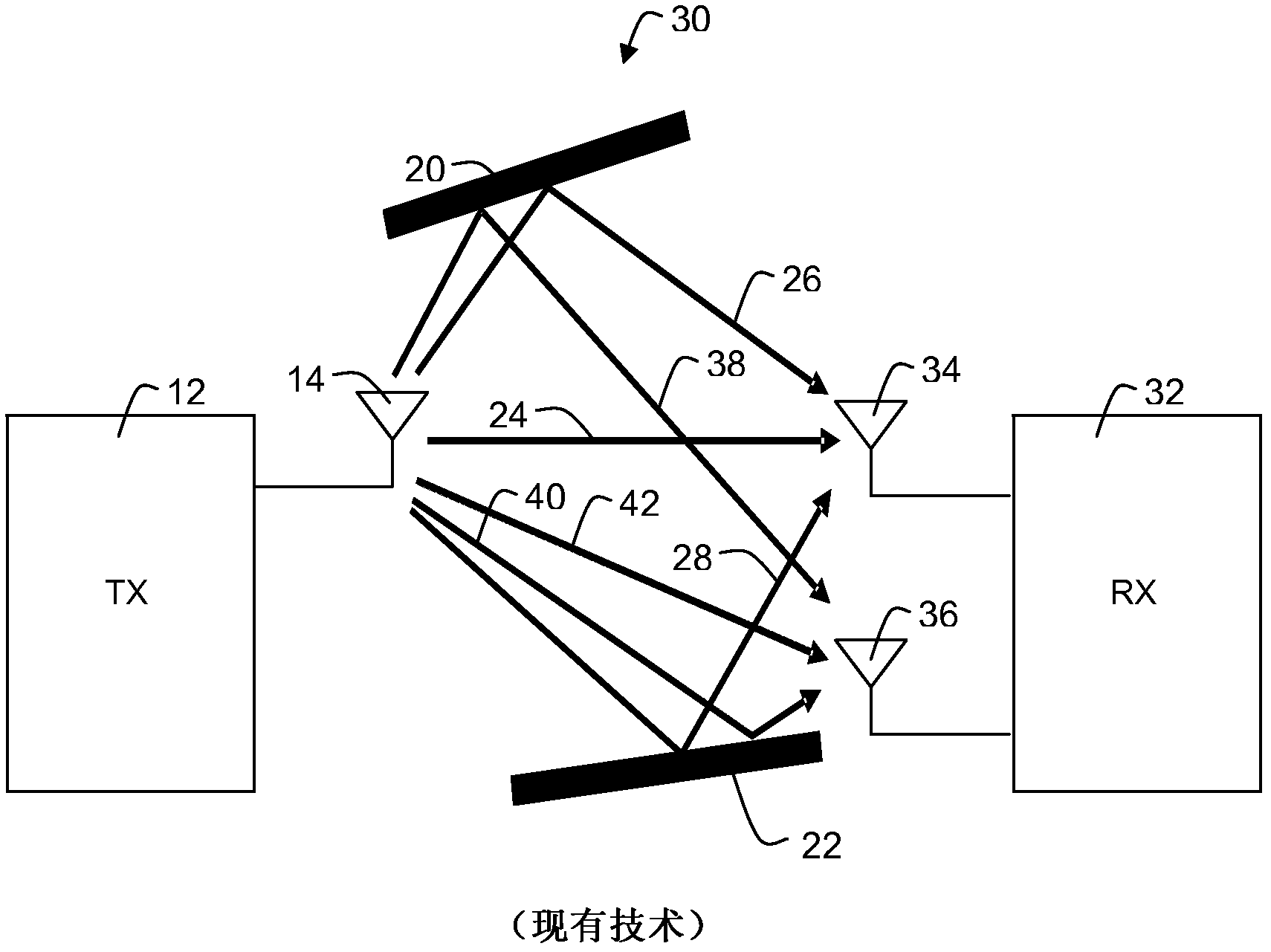

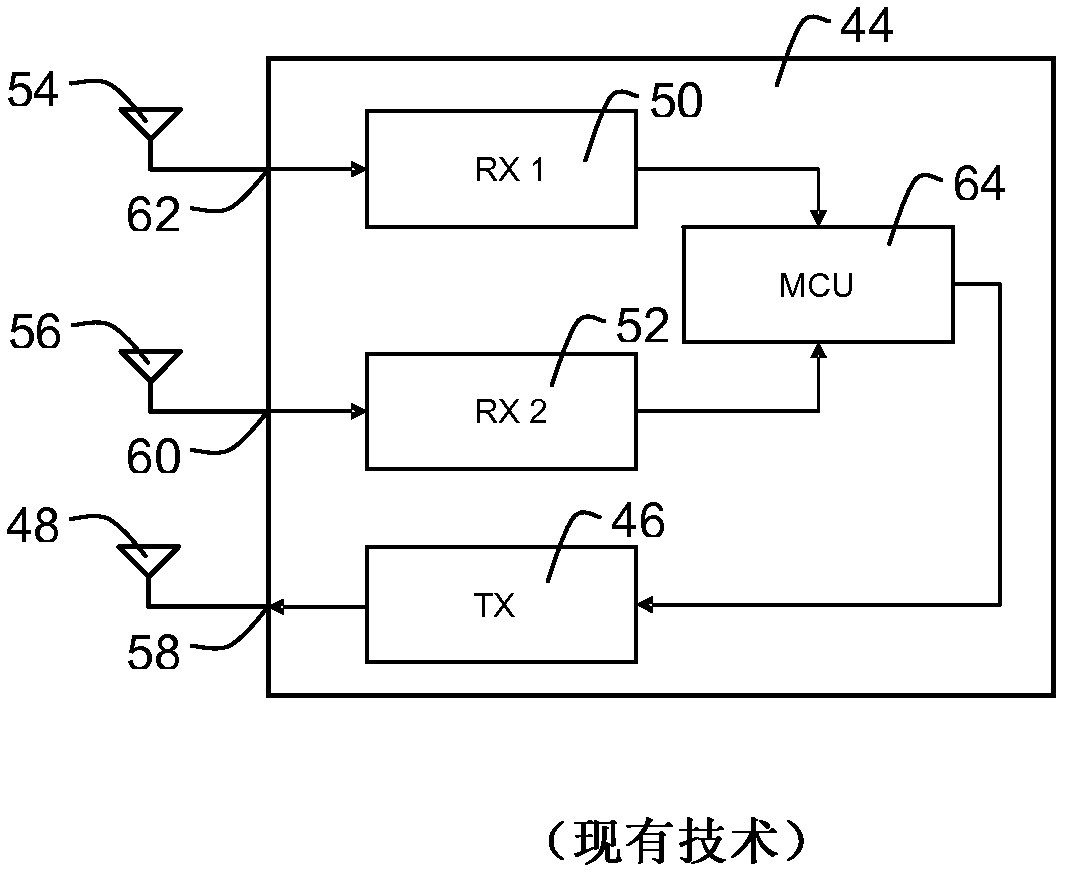

Diversity receiver and transceiver

ActiveUS20120114025A1Spatial transmit diversityDuplex signal operationTransceiverAudio power amplifier

A diversity receiver comprises a plurality of receiving paths connected to a receiver circuit. Each of the receiving paths comprises an antenna receiving a signal, connected to a matching network connected to a receive amplifier. The receiver circuit is connected to a signal level comparison circuit for providing a relative comparison value indicating one of the receiving paths receiving the signal with a relative maximum strength. The signal level comparison circuit comprises a comparator circuit connected to the receiver circuit receiving a currently received signal level, and to a logic control unit being arranged to select one of the receive paths to provide the currently received signal to the receiver circuit.

Owner:NXP USA INC

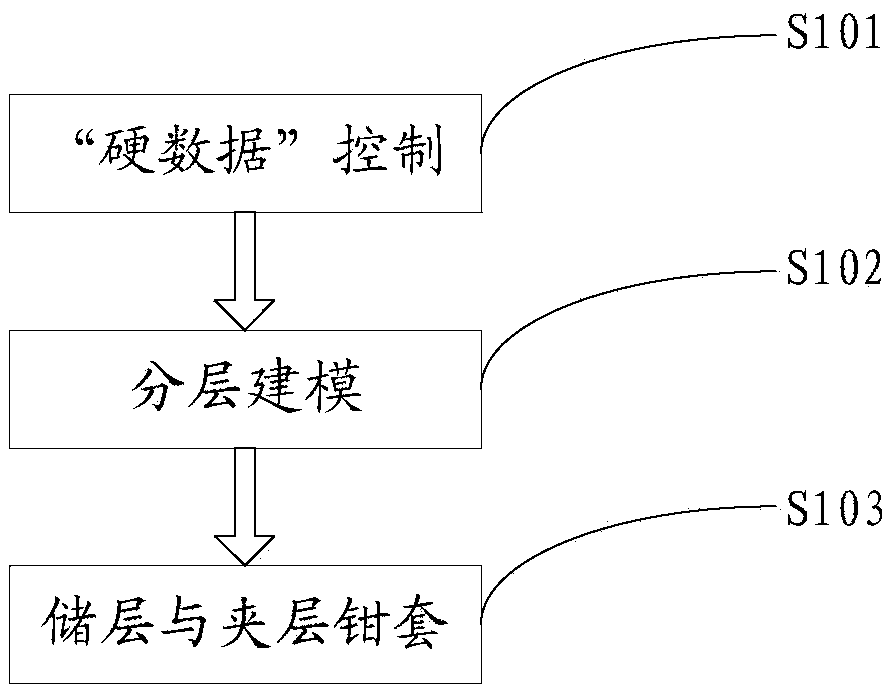

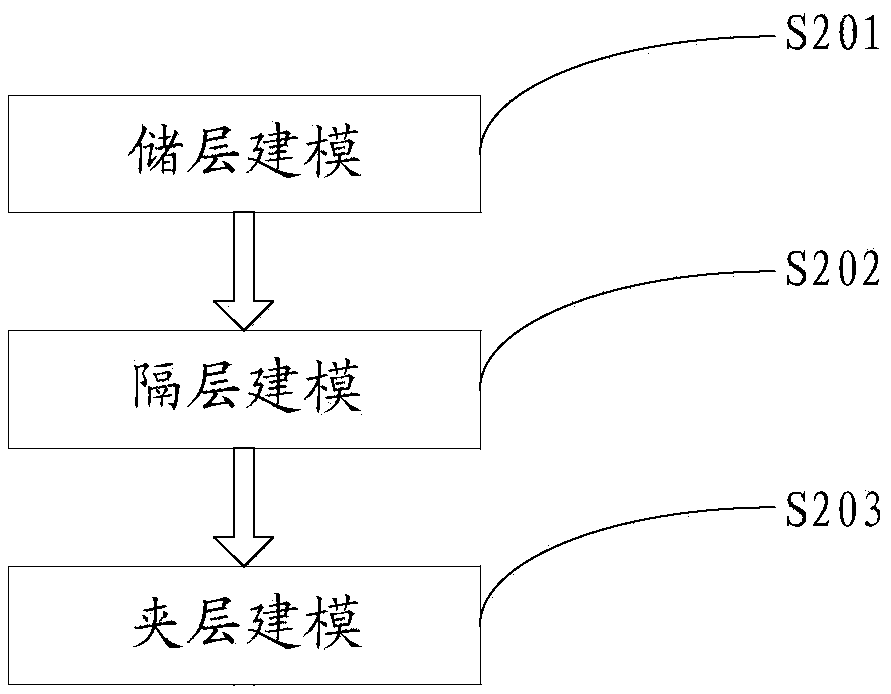

Modeling method for sand shale interbed type sedimentary body reservoir architecture

InactiveCN105373648APrecise markingImprove modeling accuracySpecial data processing applicationsData controlDemarcation point

The invention discloses a modeling method for a sand shale interbed type sedimentary body reservoir architecture. The method comprises three aspects of hard data control, layered modeling, and reservoir and interlayer nesting, wherein the layered modeling mainly comprises reservoir modeling, spacing layer modeling, and interlayer modeling. According to the modeling method, thin layer division is performed by adopting a half amplitude point based thin layer division principle, so that the defect that true thicknesses and depths of a reservoir and a spacing layer cannot be obtained in a conventional method for determining a boundary line of a thin layer based on relative maximum of natural gamma and / or positive anomaly of natural potential is overcome; and the hard data control is adopted for architecture modeling, so that a demarcation point of sand shale is accurately positioned, three-dimensional spatial distribution of single sand bodies and sub sand bodies is accurately depicted, the architecture effect is good, the precision is high, the difficulty in development is lowered, and the development benefits are increased.

Owner:SOUTHWEST PETROLEUM UNIV

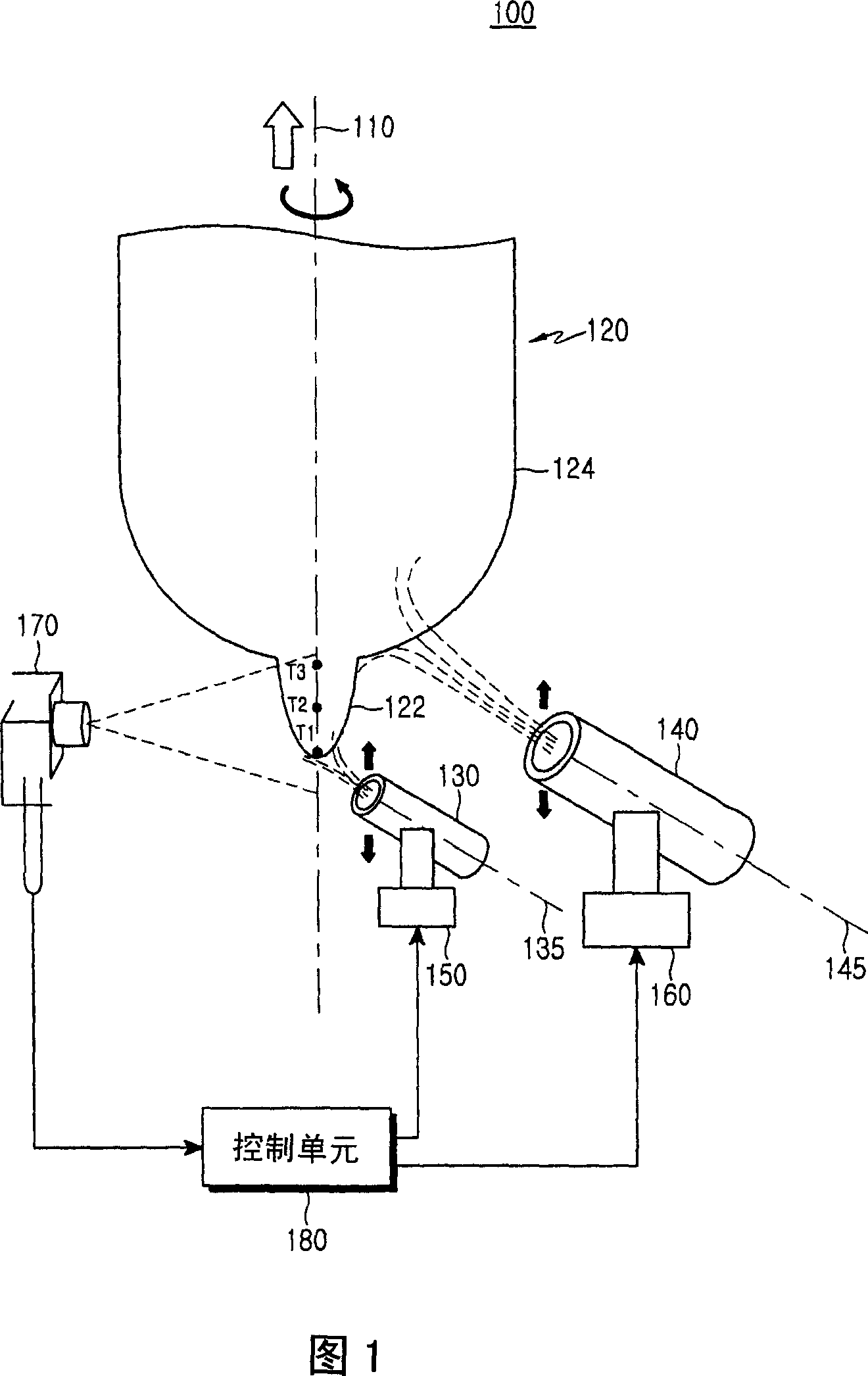

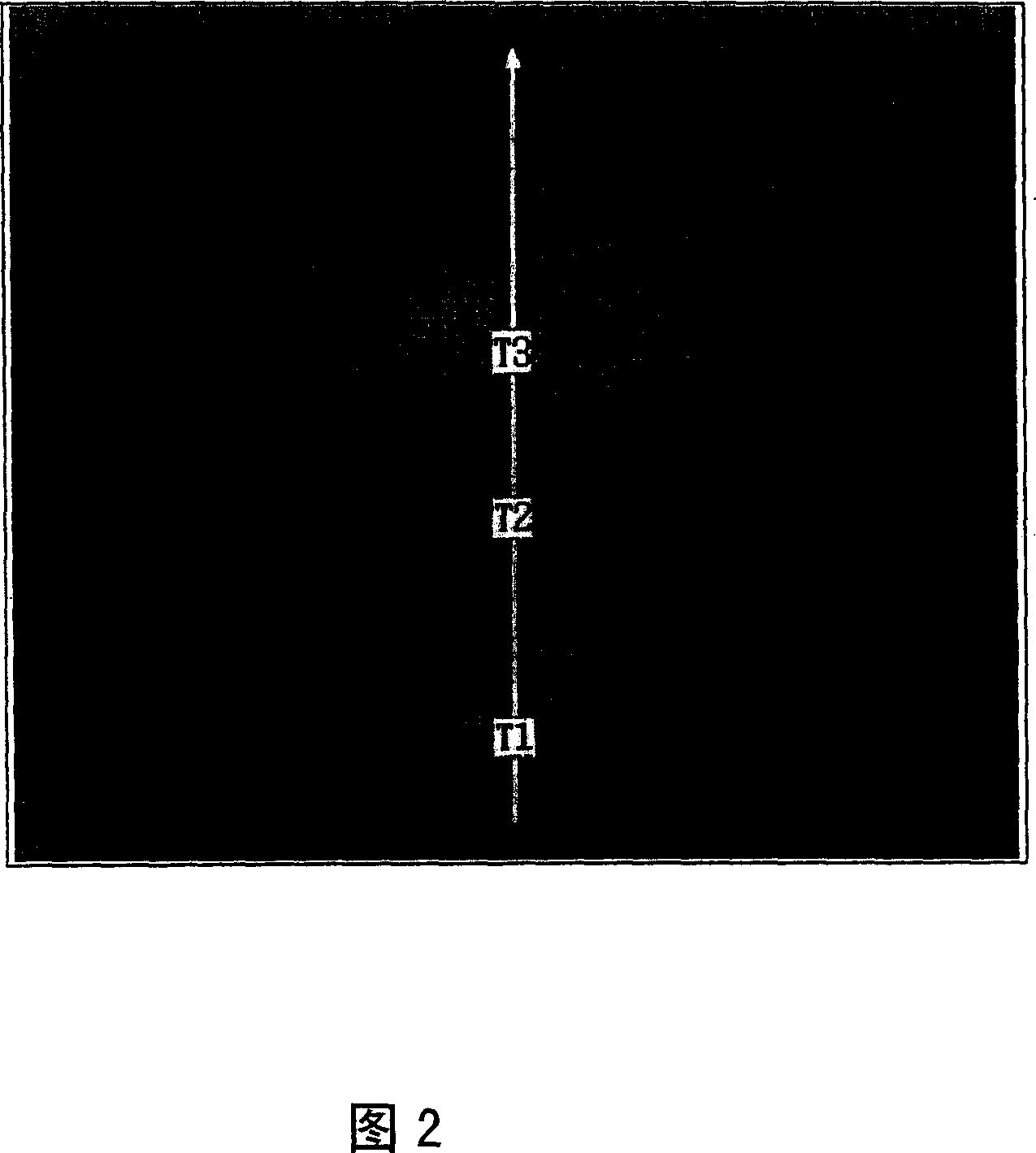

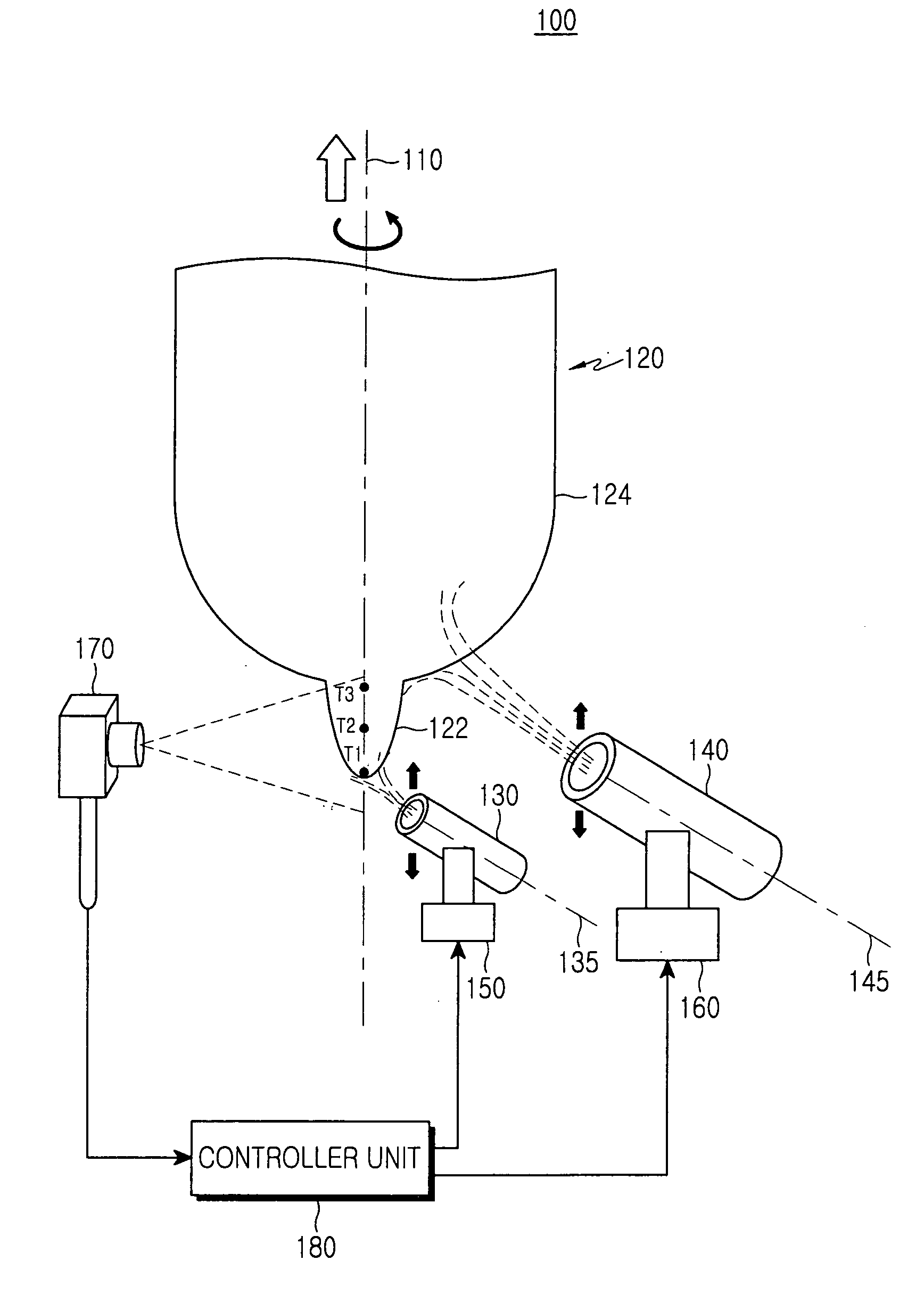

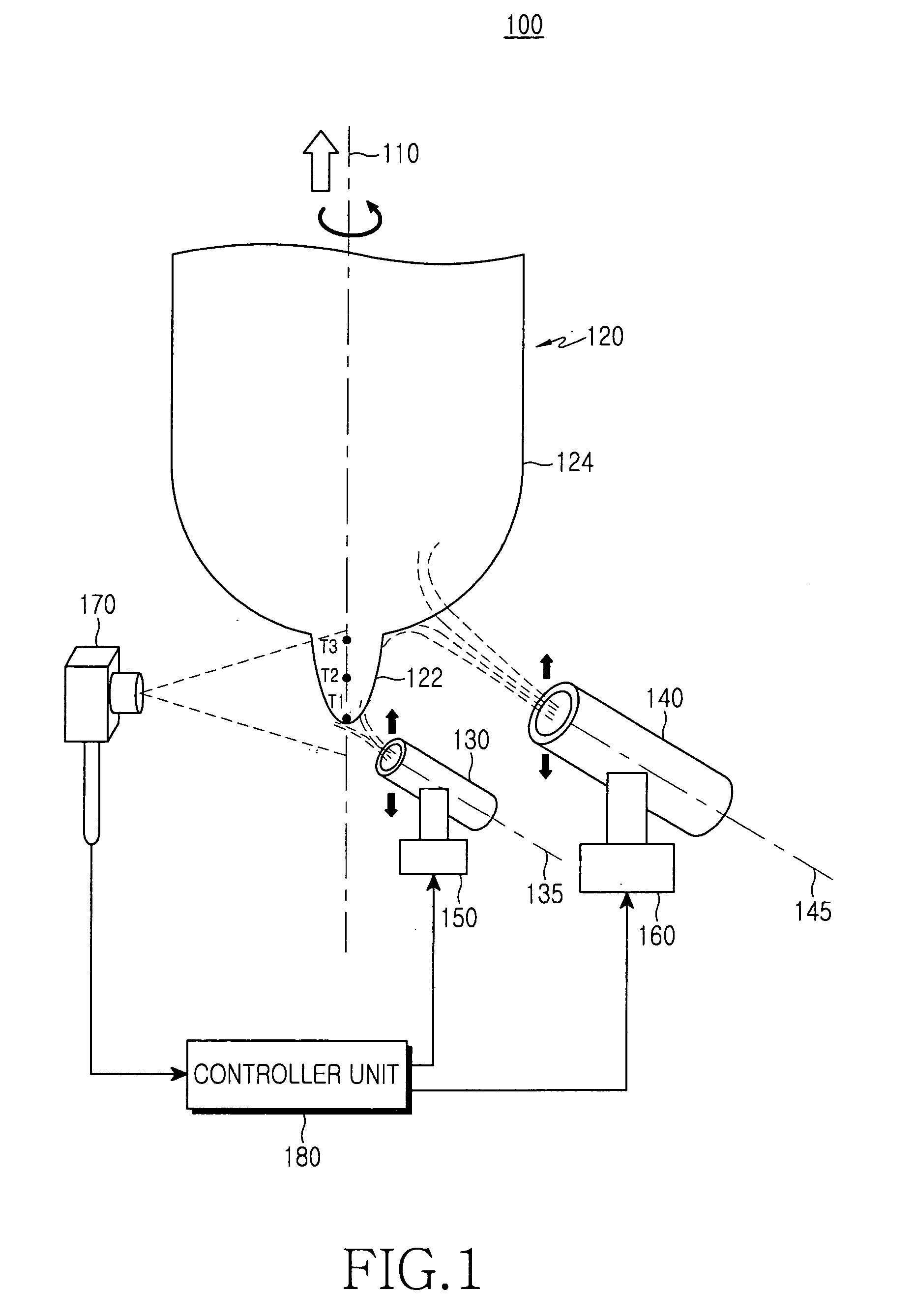

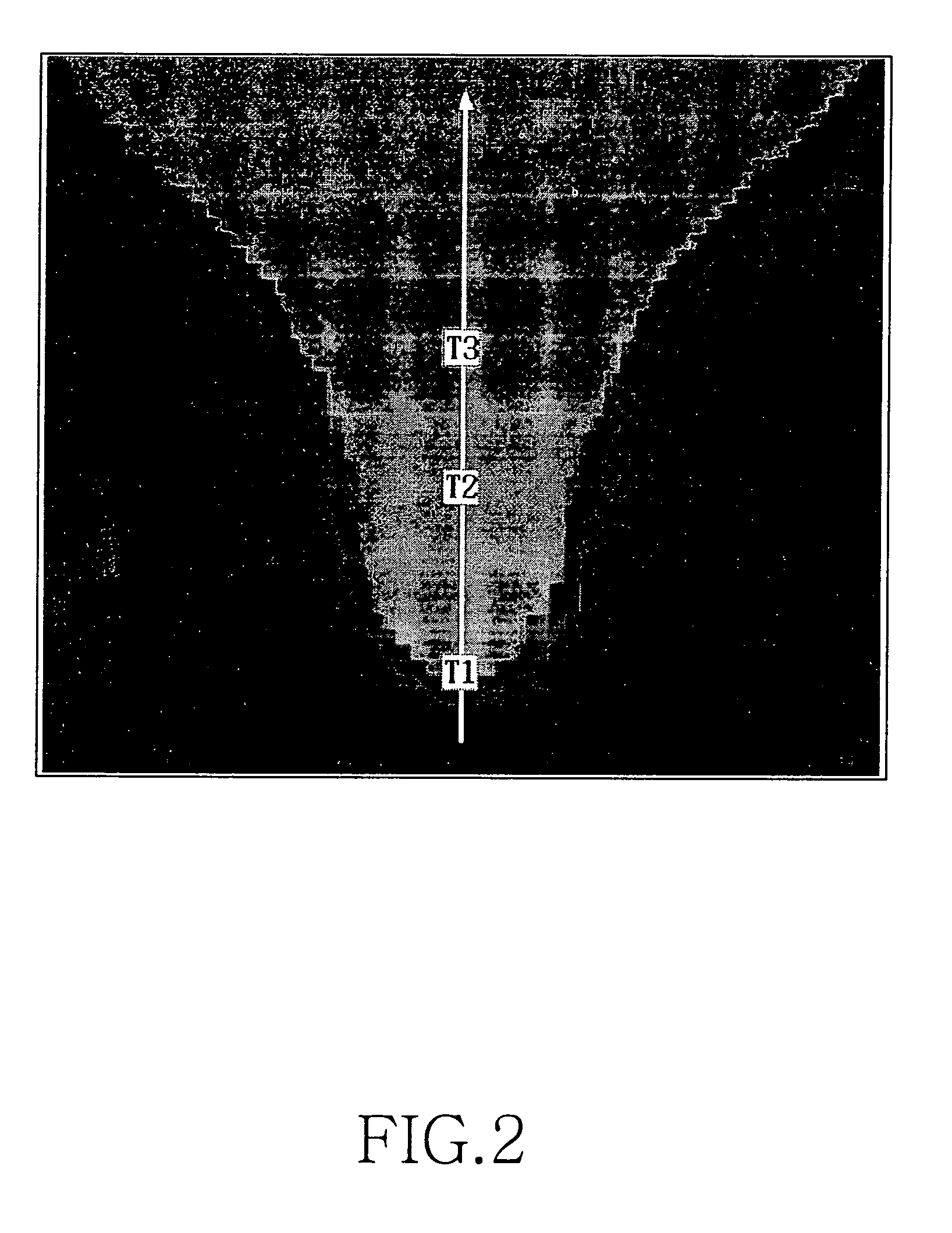

Vapor axial deposition apparatus and vapor axial deposition method

InactiveCN1951848AQuality improvementIncrease production capacityGlass deposition burnersGlass productionGas phaseEngineering

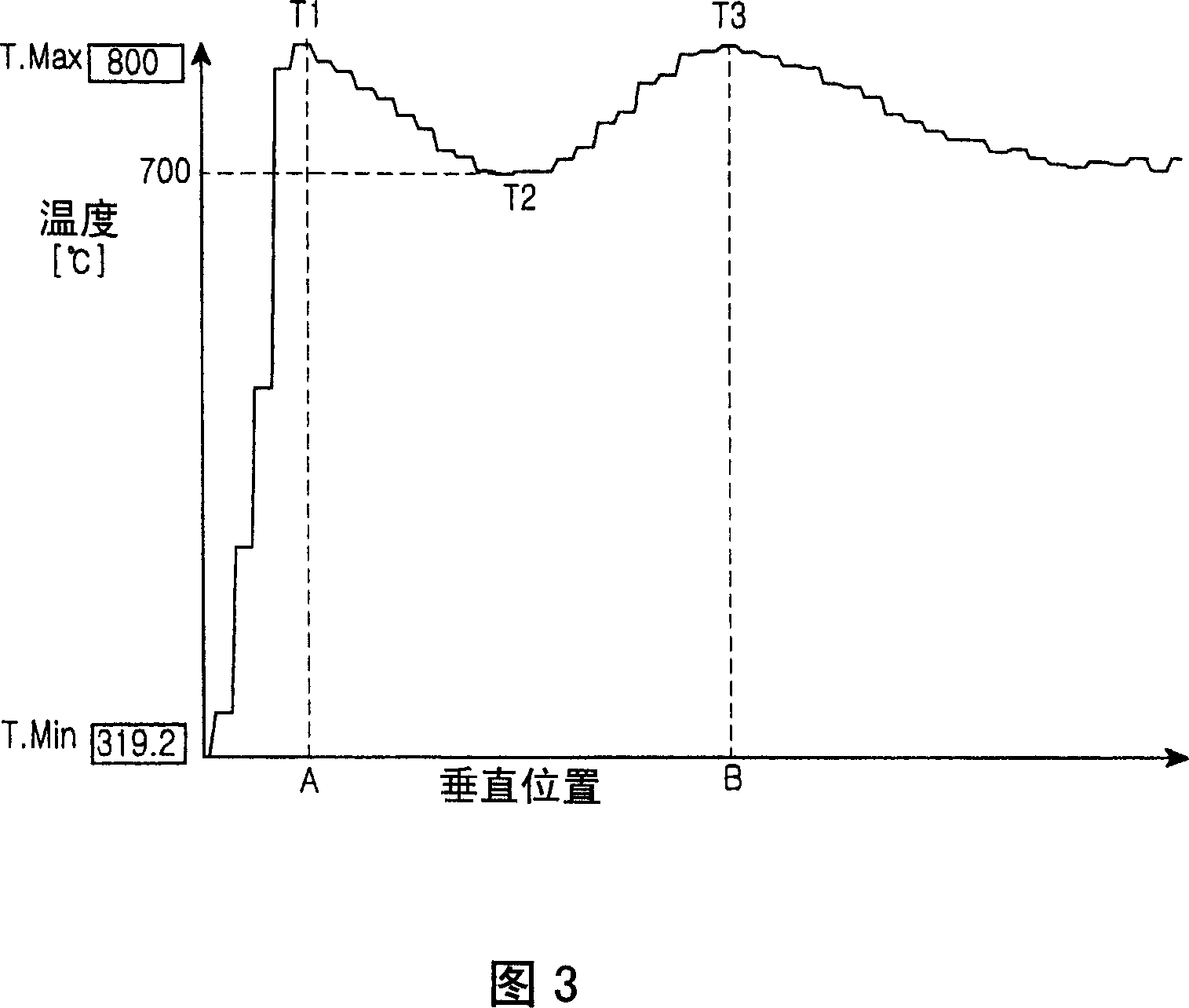

Disclosed is a vapor axial deposition apparatus. The vapor axial deposition apparatus includes a first torch, a second torch, a temperature measuring unit and a controller unit. The first torch deposits soot on a distal end of a soot preform aligned with a vertical axis to thereby grow a core. The second torch deposits soot on an outer circumferential surface of the core to thereby grow a clad. The temperature measuring unit detects the temperature distribution of an end portion of the soot preform along the vertical axis. The controller unit determines first and second relative maximum temperatures T 1 and T 3, and relative minimum temperature T 2 between T 1 and T 3 in the detected temperature distribution, and controls T 1 to be within a predetermined range and the greater one of the difference (T 1 -T 2 ) and (T 3 -T 2 ) to not exceed a predetermined temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

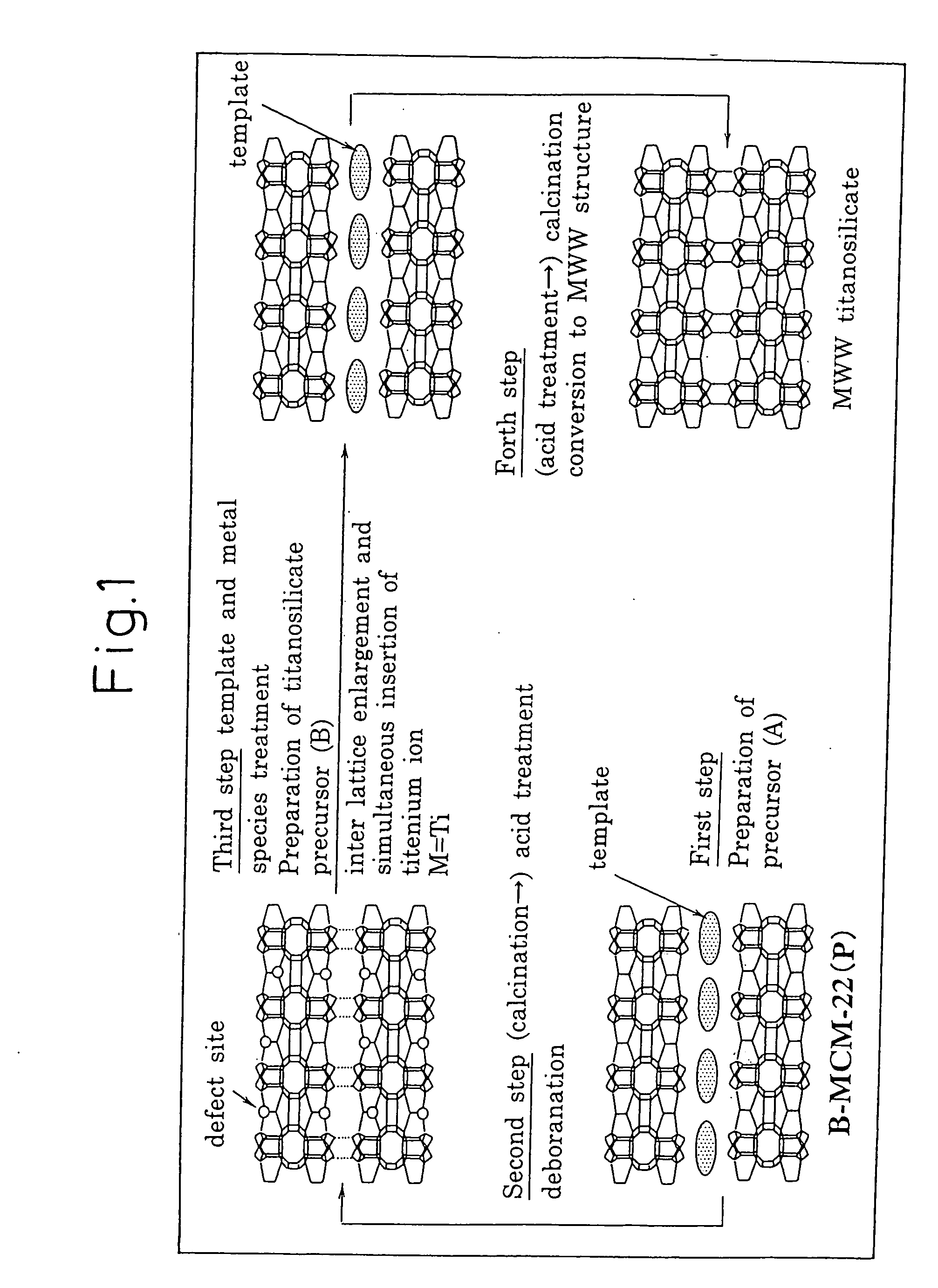

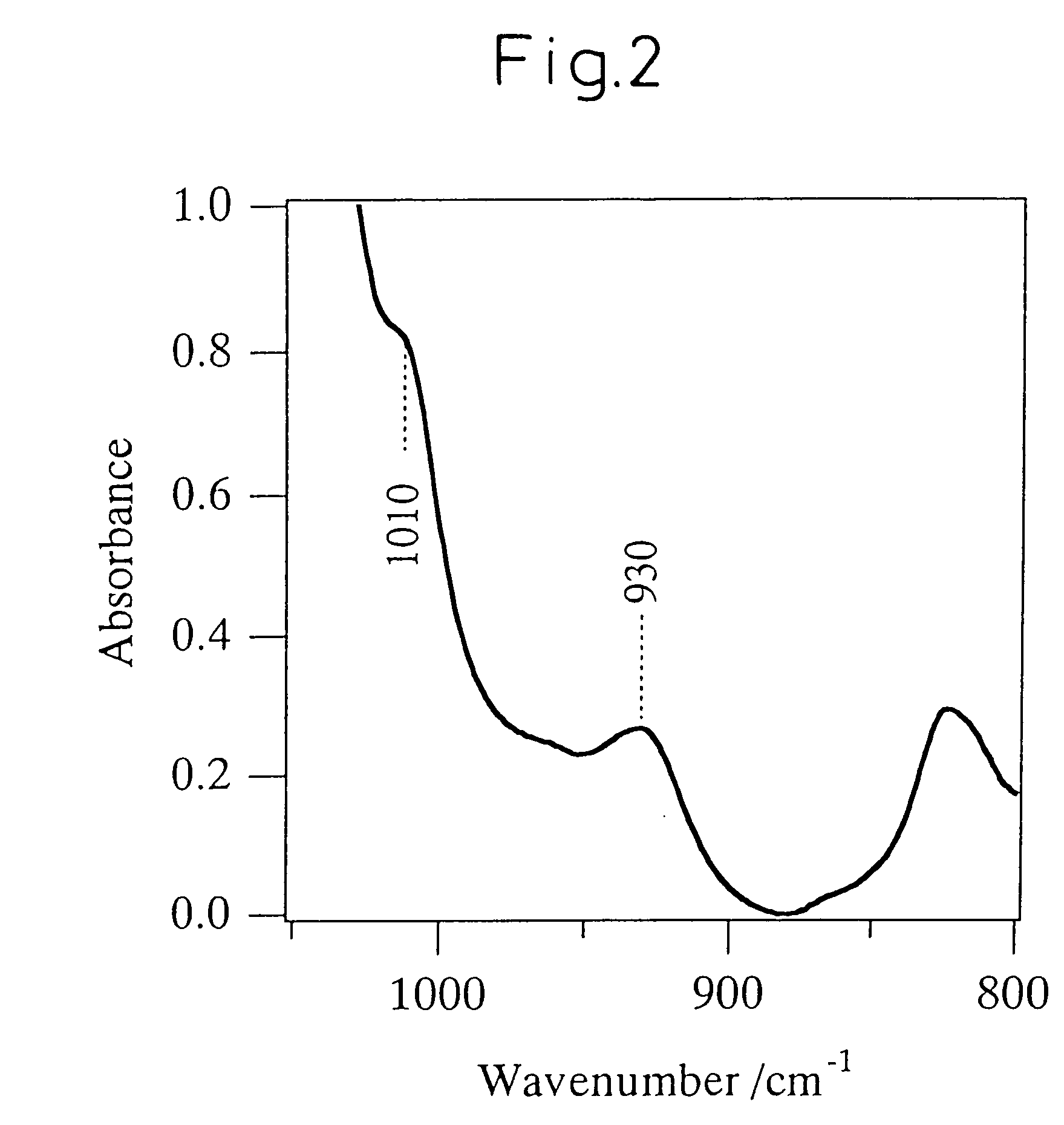

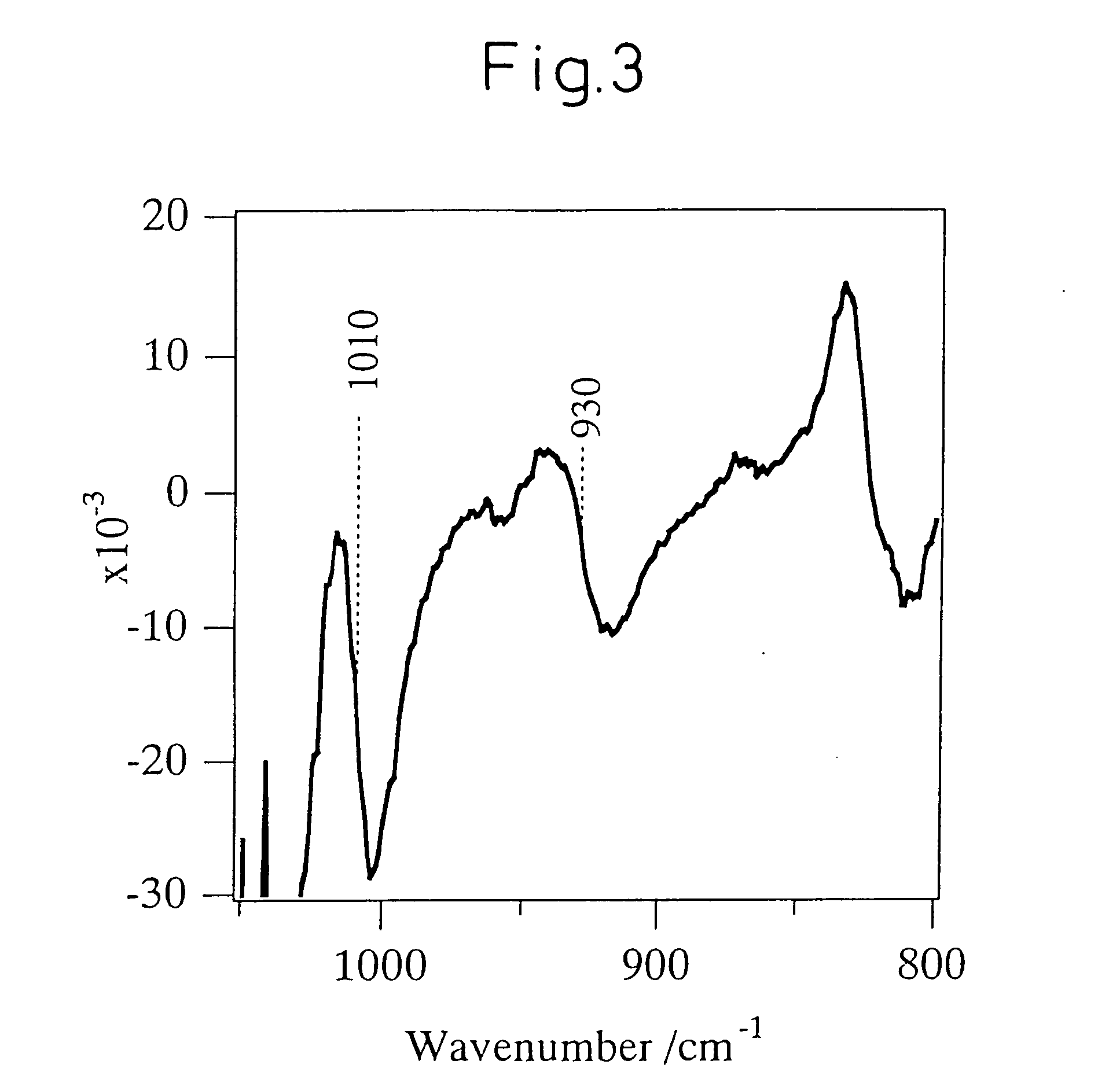

Titanosilicate, process for its production, and its use in producing oxidized compound

ActiveUS20050209091A1High selectivityEffectively actPreparation by oxidation reactionsAluminium compoundsCompound aRelative maximum

A titanosilicate represented by the following compositional formula (1), wherein in the infrared absorption spectrum measured in the dehydrated state, the absorption spectrum has an absorption band having a relative maximum value at 930±15 cm−1:xTiO2.(1−X)SiO2 Compositional Formula (1)(wherein x is from 0.0001 to 0.2).

Owner:SHOWA DENKO KK

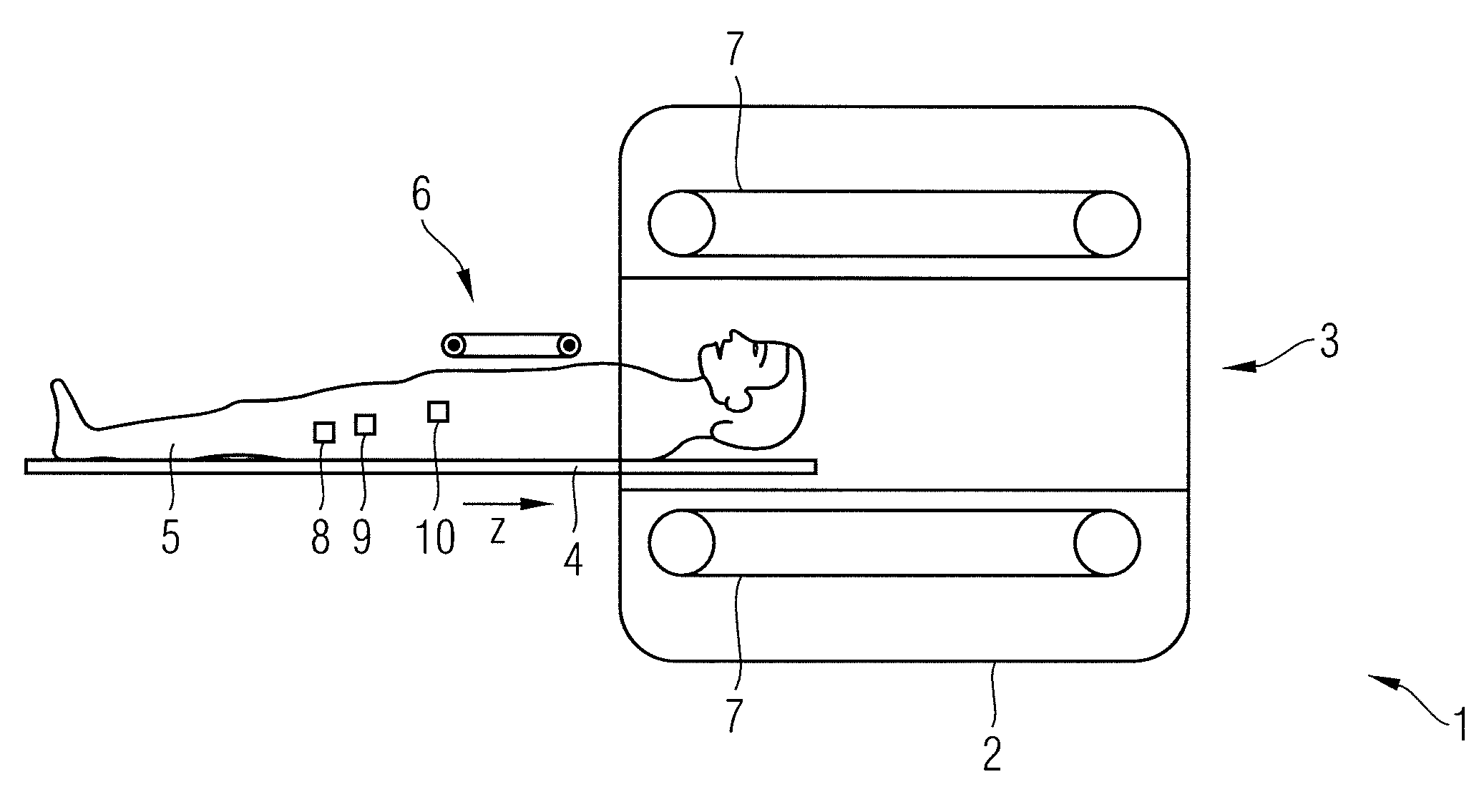

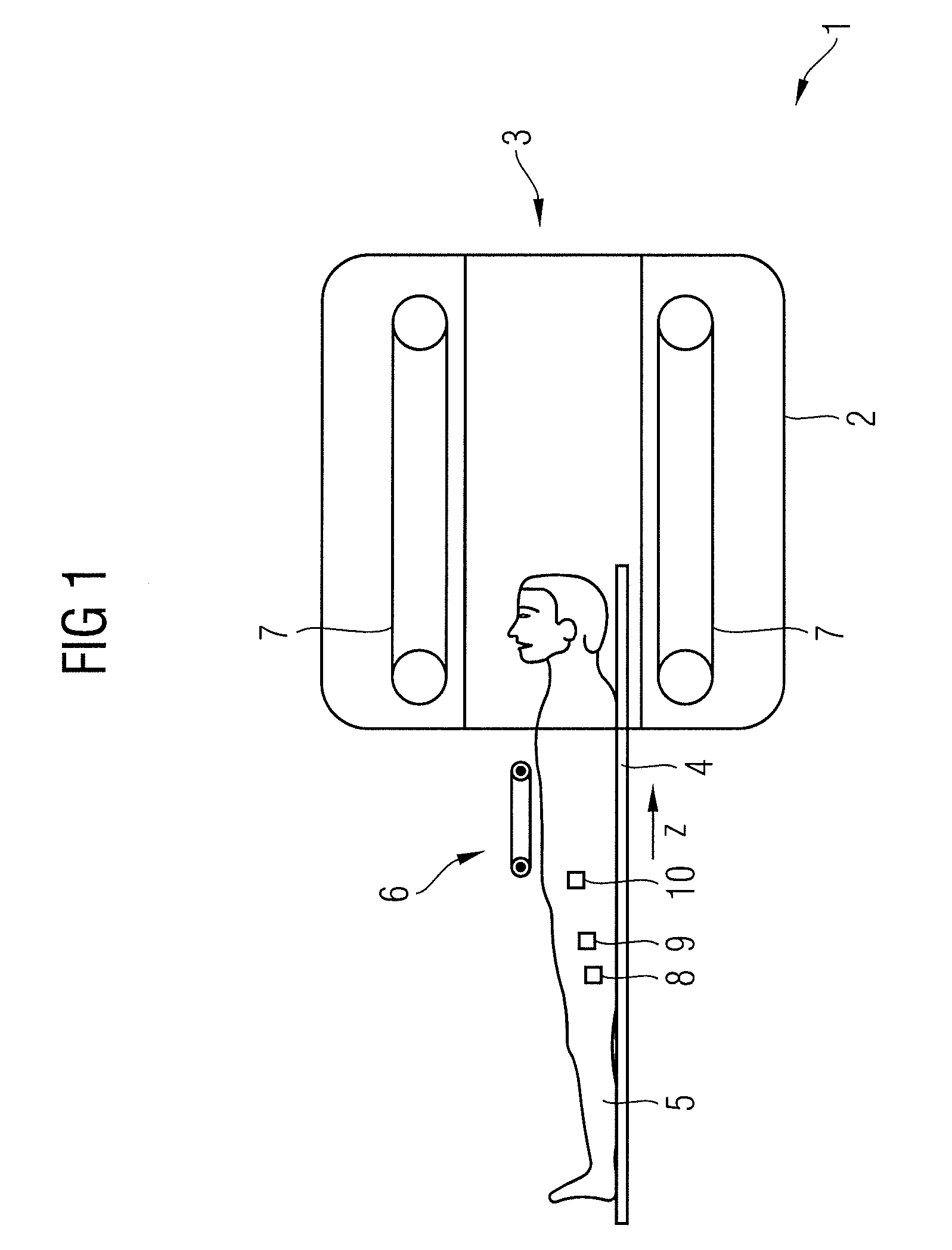

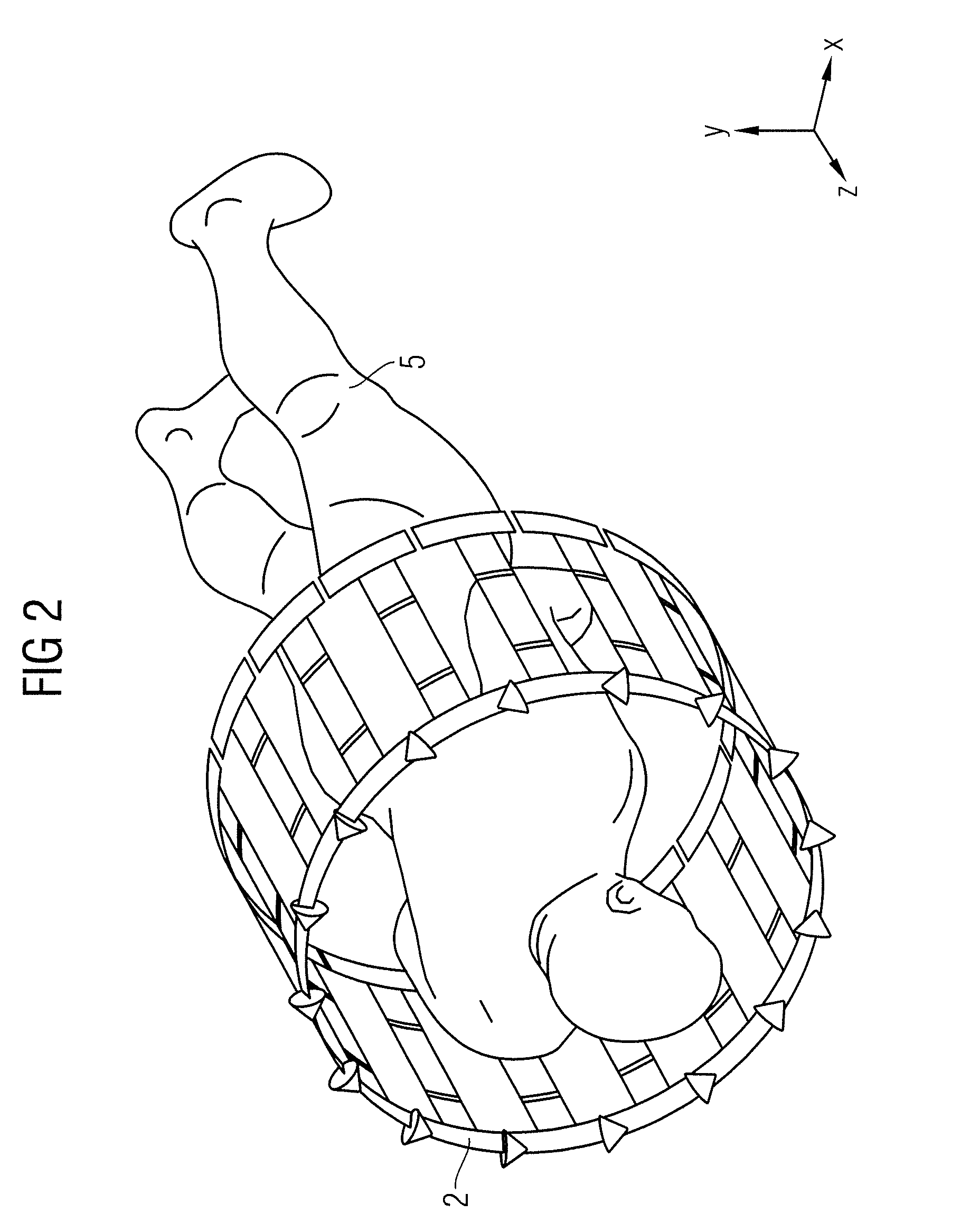

Method and device for selecting body model positions for SAR monitoring of a magnetic resonance transmit array

InactiveUS20100308825A1Efficient and fast monitoringElectric/magnetic detectionMeasurements using NMRVoxelResonance

In a method and a device for specific absorption rate monitoring in a magnetic resonance system wherein multiple transmit coils are independently charged with respective currents, a primary model point voxel and at least one auxiliary model point voxel are automatically selected from among multiple voxels that model a modeled examination subject. The primary model point voxel is that voxel in which an absolute maximum of a total field variable occurs that is produced by the respective electrical fields emitted by the transmit coils. The at least one auxiliary model point voxel is that voxel in which a relative maximum of the variable occurs. The primary model point voxel and the at least one auxiliary model point voxel are stored, and specific absorption rate monitoring of an actual examination subject in the magnetic resonance system is implemented during the acquisition of magnetic resonance data in respective voxels of the actual examination subject corresponding to the stored primary model point voxel and the stored at least one auxiliary model point voxel.

Owner:SIEMENS HEALTHCARE GMBH

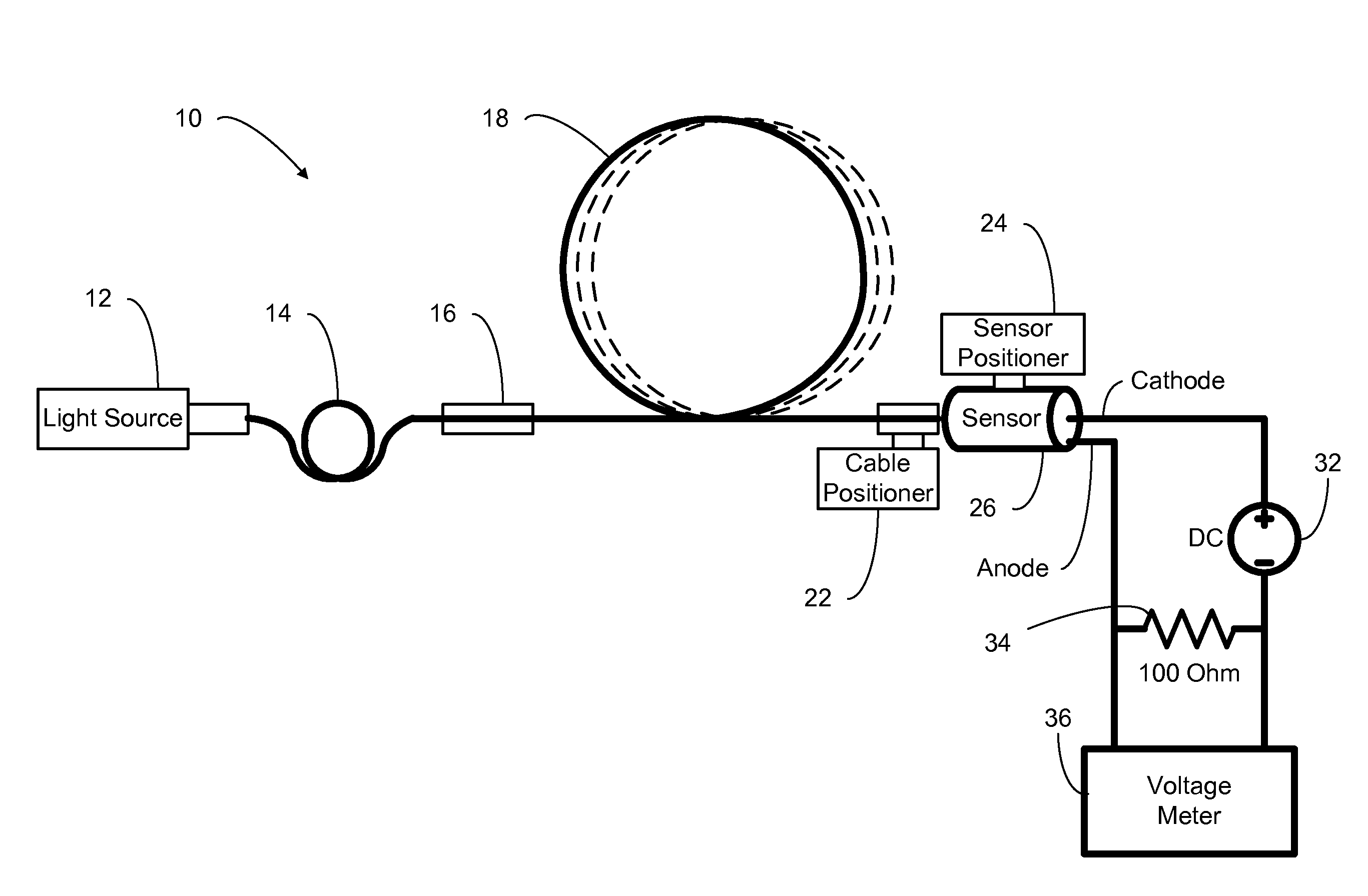

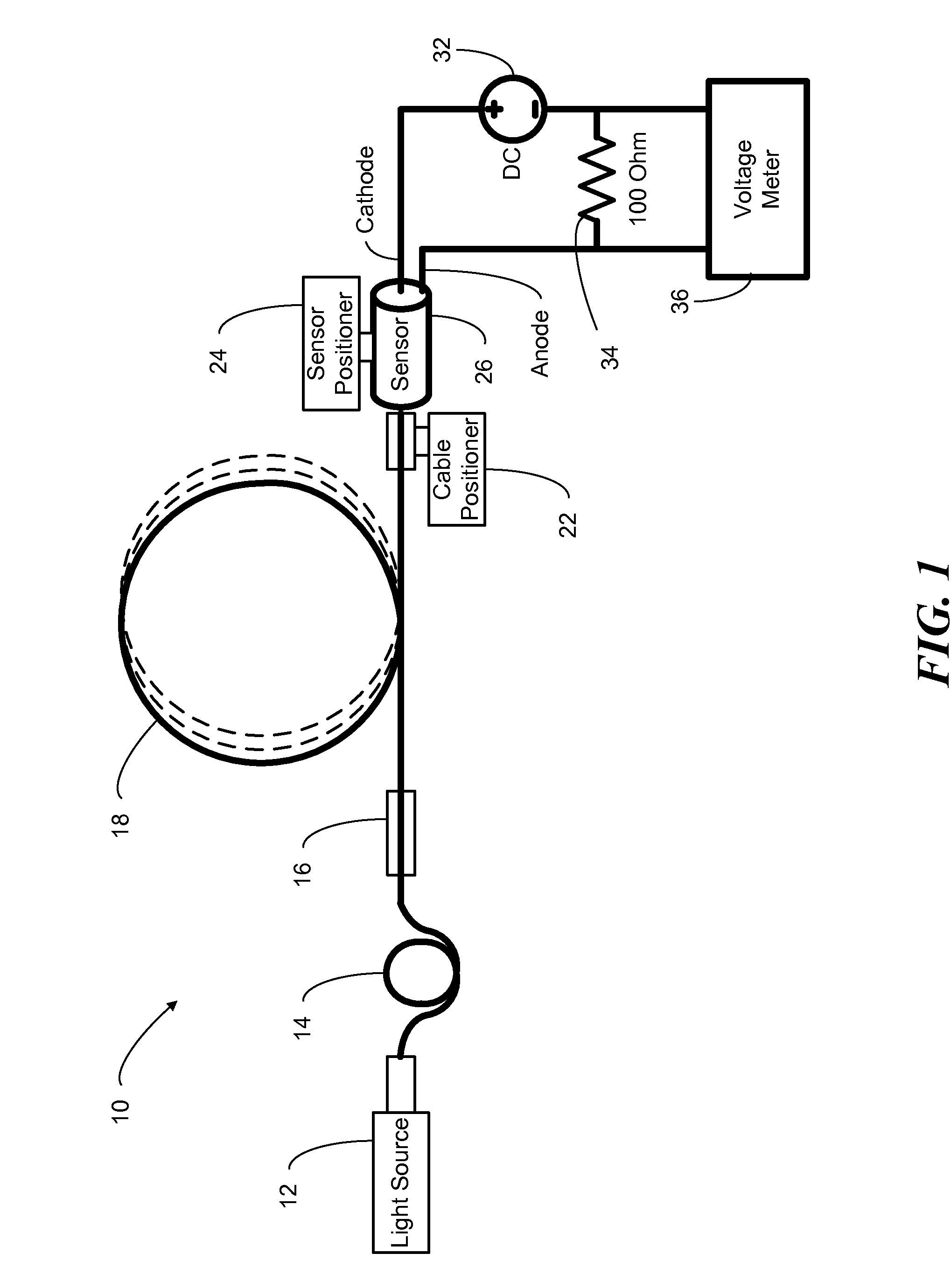

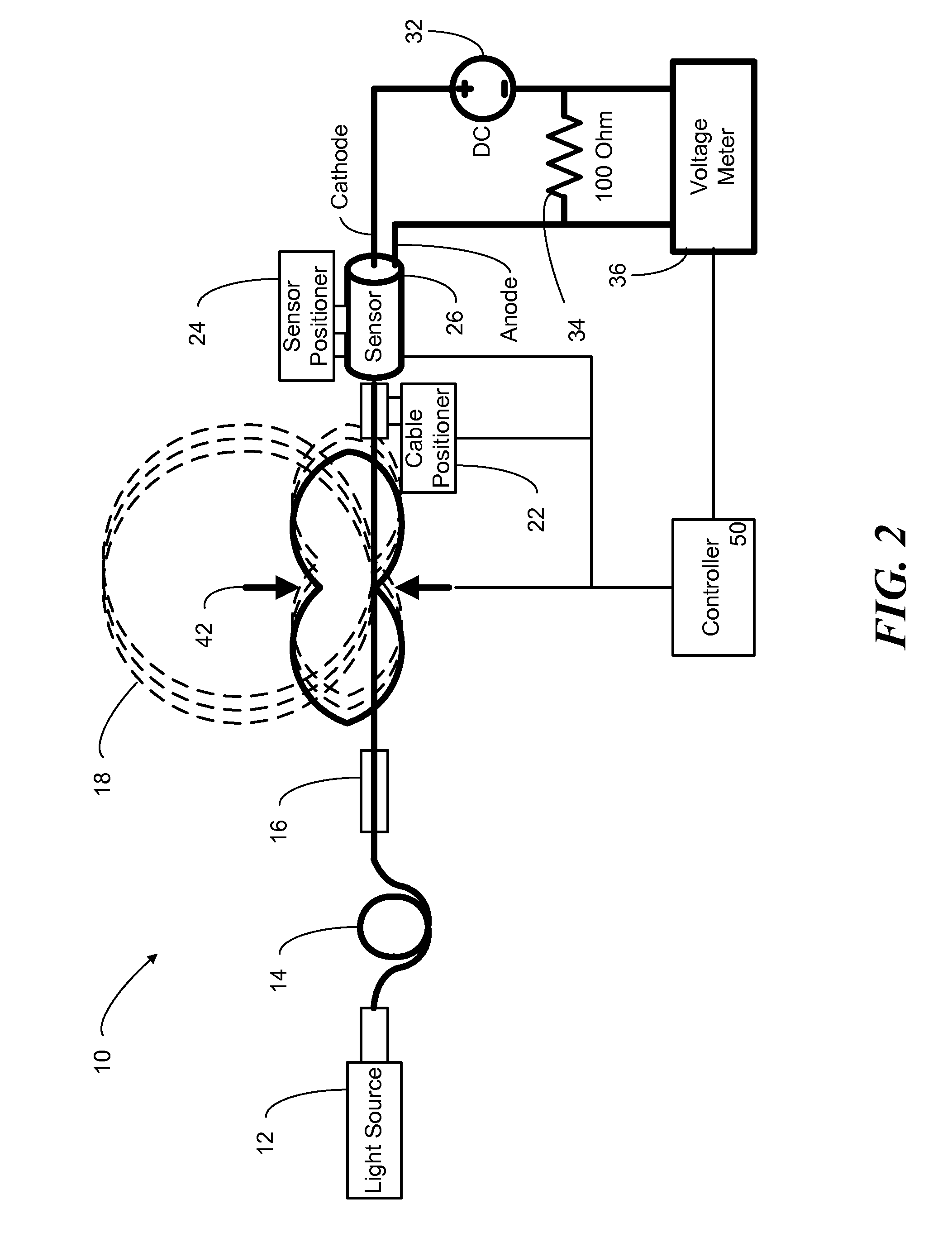

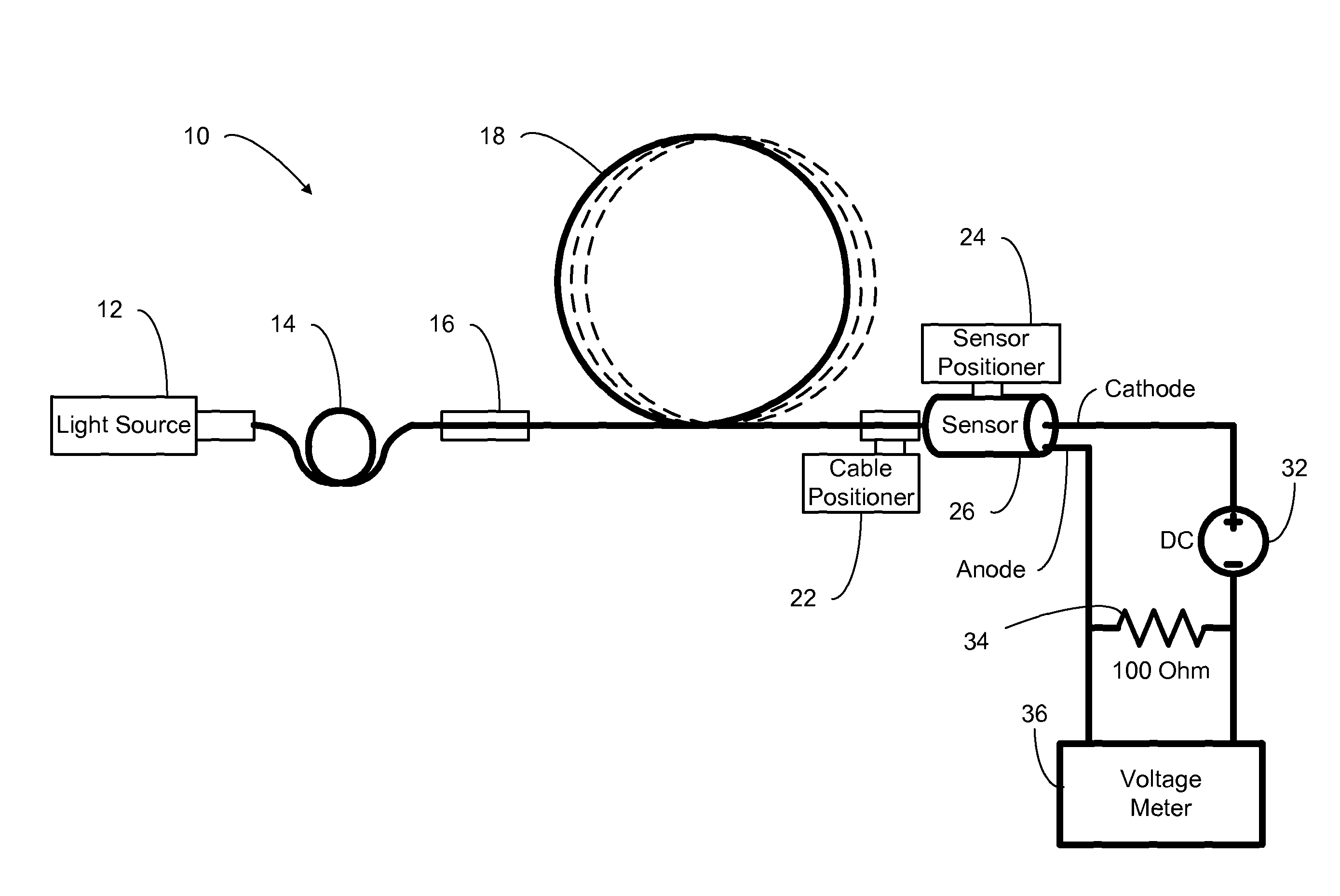

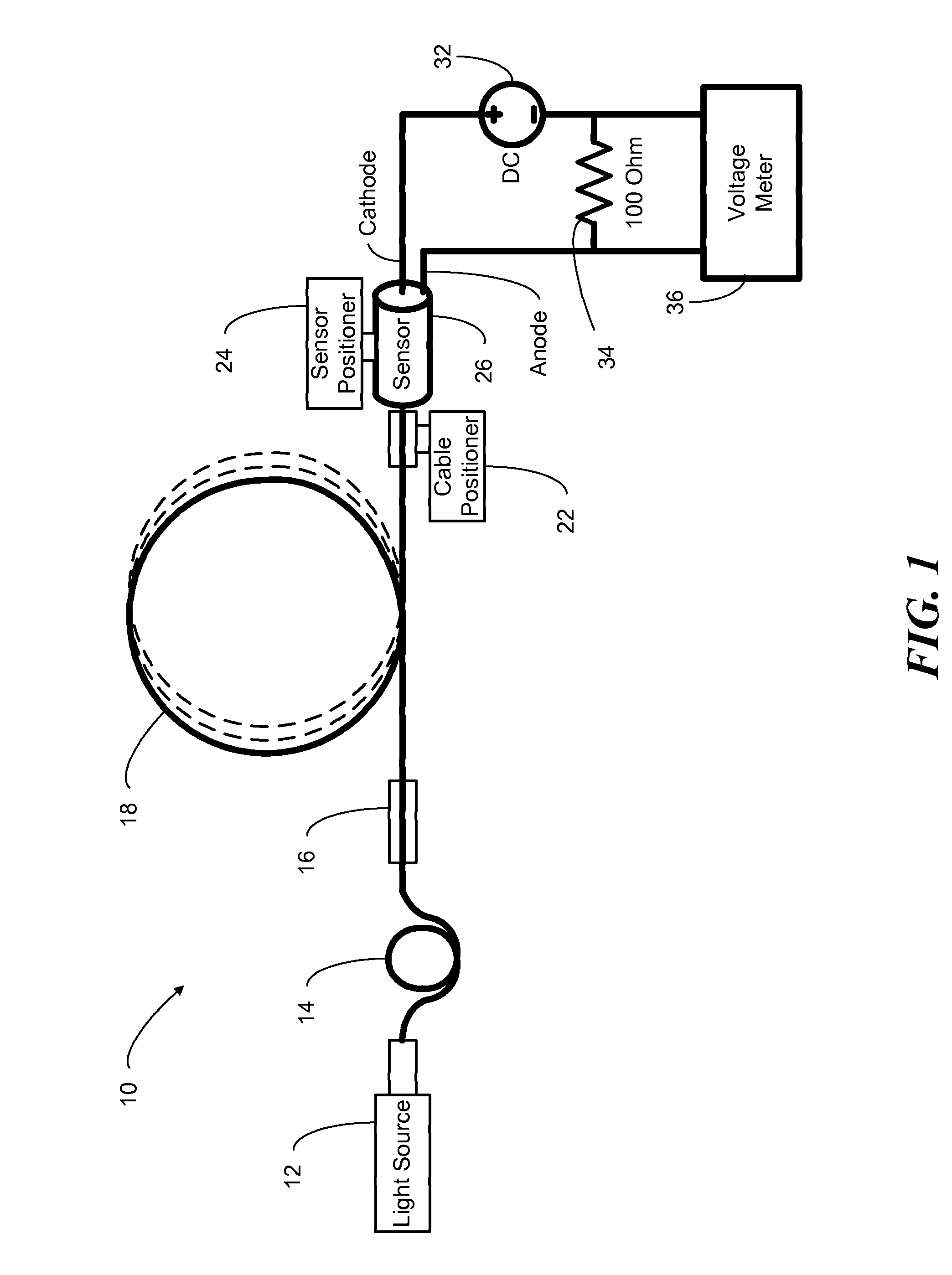

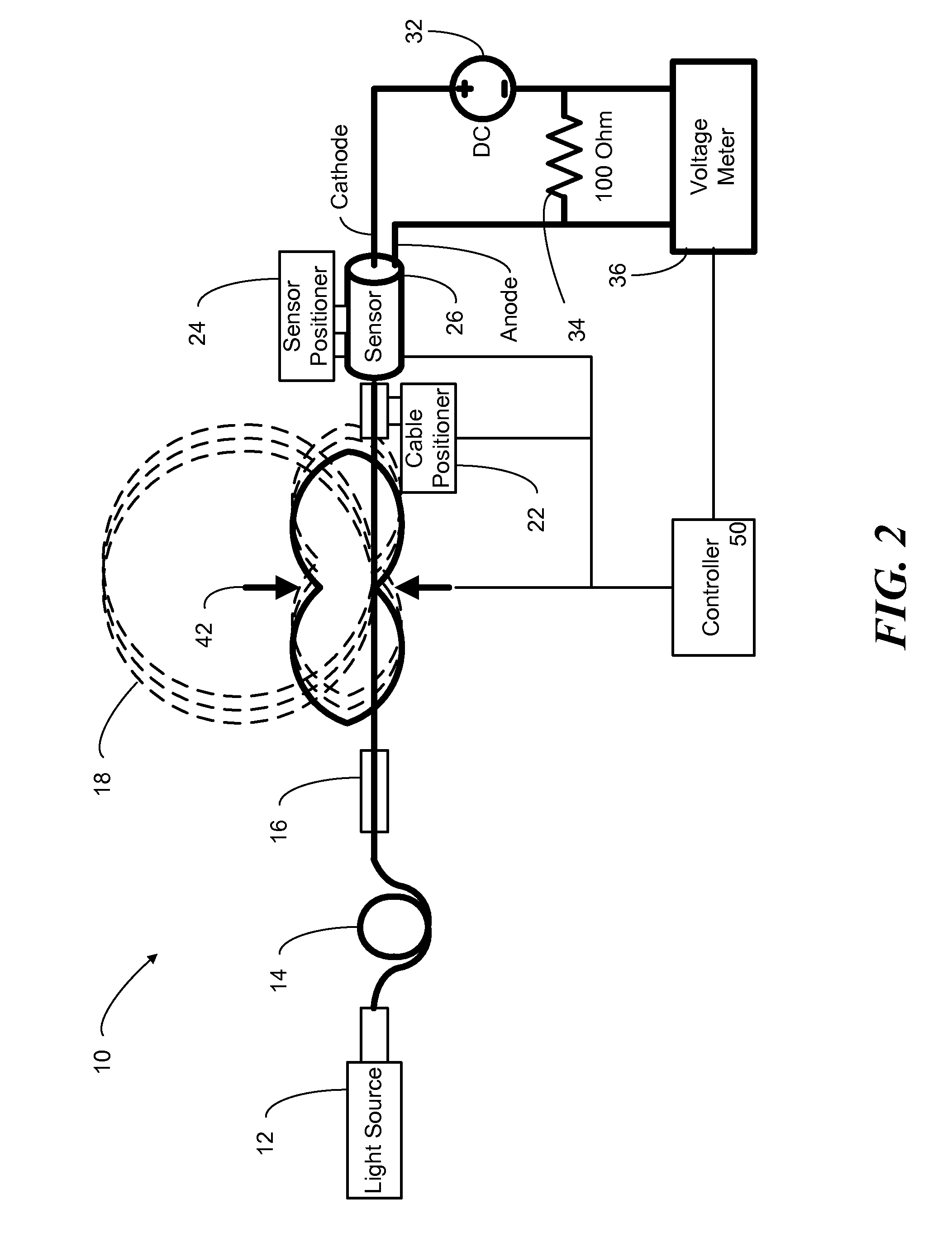

Method and System for Coupling Multimode Optical Fiber to an Optical Detector

ActiveUS20100027940A1Stable outputReduced output variationWave amplification devicesCoupling light guidesFiberShortest distance

A method for making a multimode fiber optic subassembly includes alignment of an optical detector with a fiber termination of an optical fiber. The output of the optical detector (e.g. photocurrent) can be measured from light being transmitted through the optical fiber and detected by the optical detector. The end of the optical fiber and / or the optical detector can be positioned and angularly oriented in order to obtain relative maximum or peak output of the optical detector for a given position and orientation. The output of the optical detector can be monitored while mechanically manipulating, e.g. bending, flexing, shaking and / or twisting, the optical fiber, in order to verify that the positional relationship between the end of the optical fiber and the optical detector corresponds to a position and / or orientation that provides stable output from the optical detector. If the optical detector output is not stable, the end of the multimode optical fiber and the optical detector can be moved, changing the position and / or the orientation of one or both, until the output of the optical detector is stable during manipulation. If the optical detector output is stable, the end of the multimode optical fiber is fixed to the optical detector. The resulting subassembly, a fiber optic pigtail, can be made by cutting the optical fiber a short distance from the optical detector.

Owner:CORNING OPTICAL COMM WIRELESS

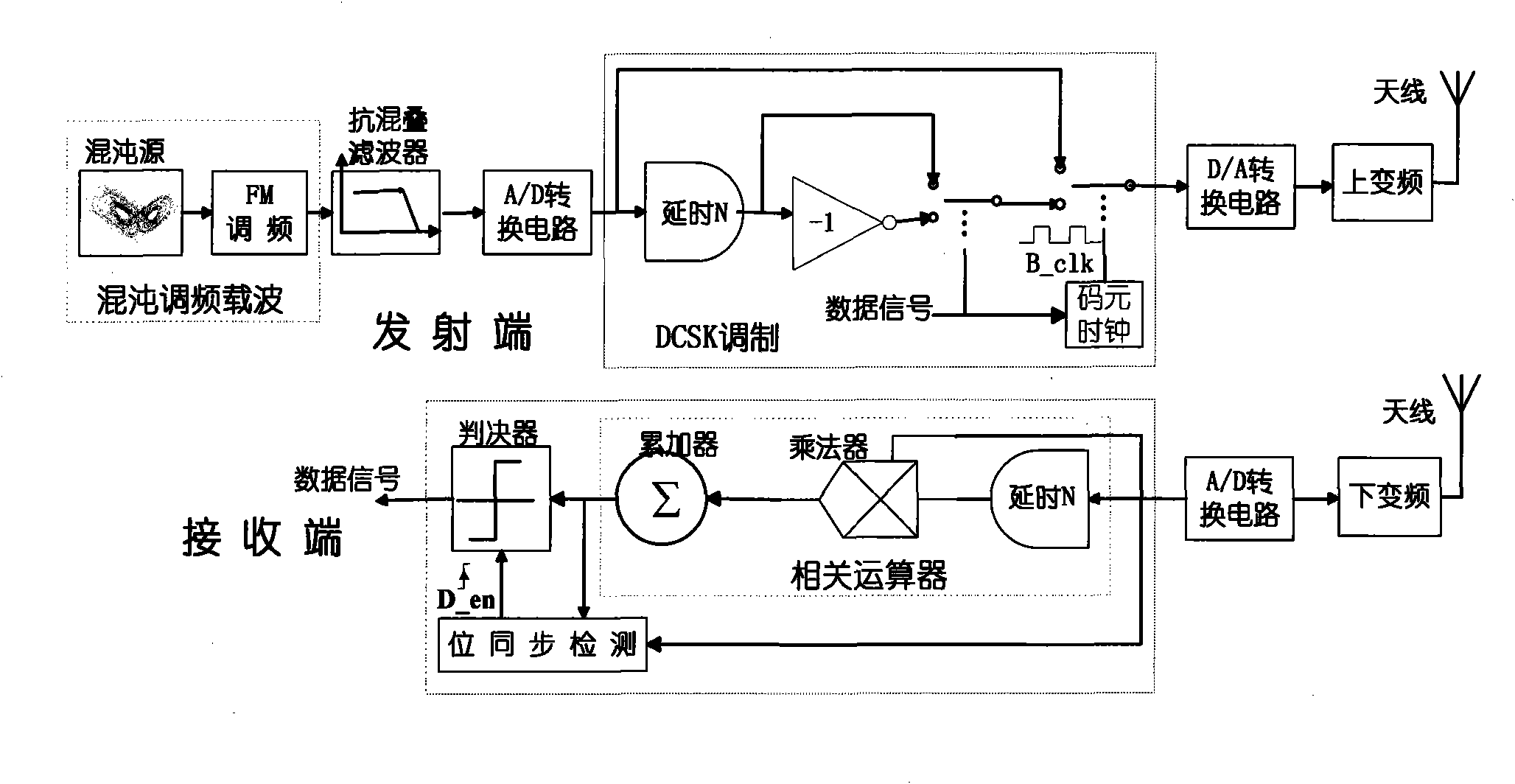

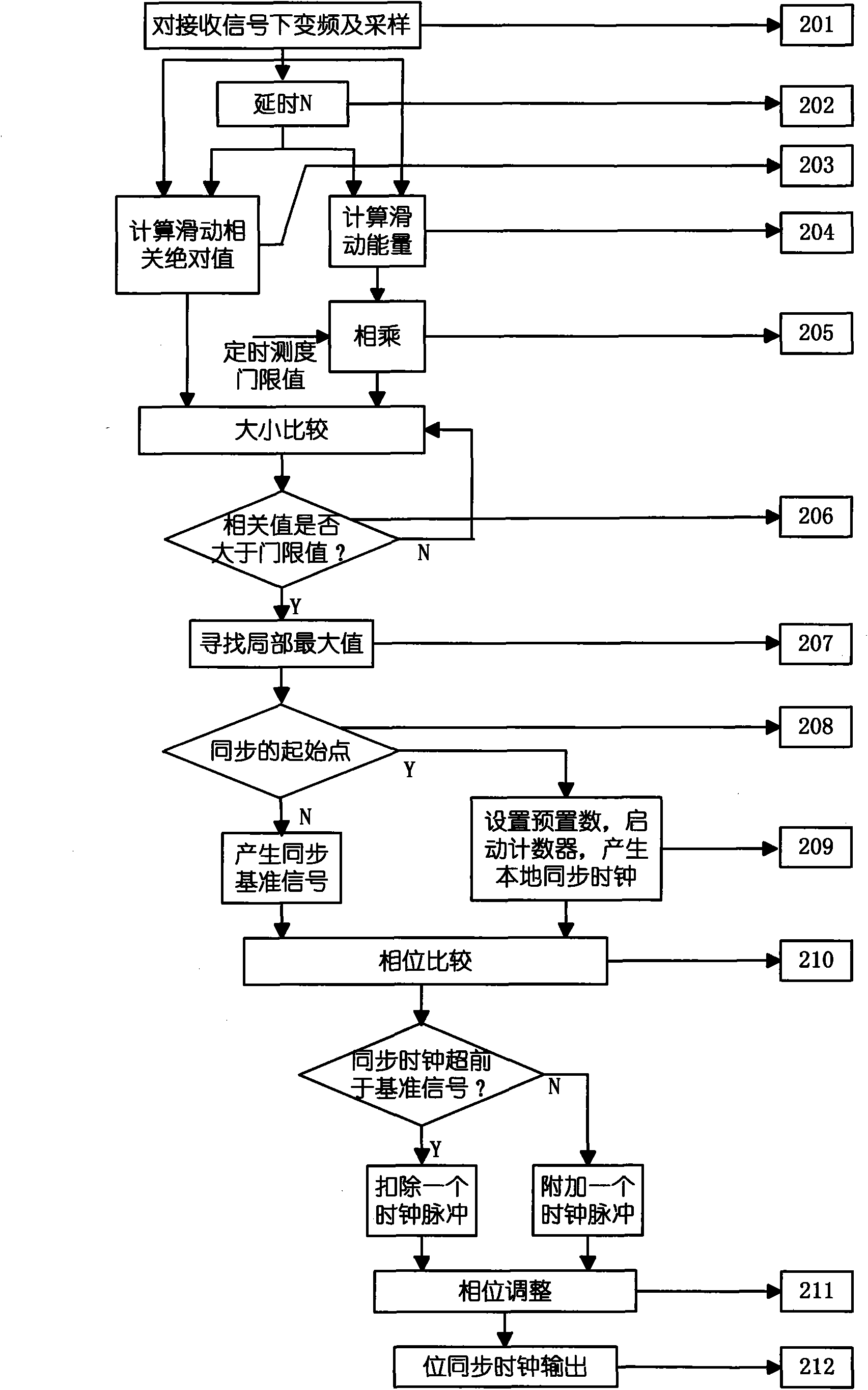

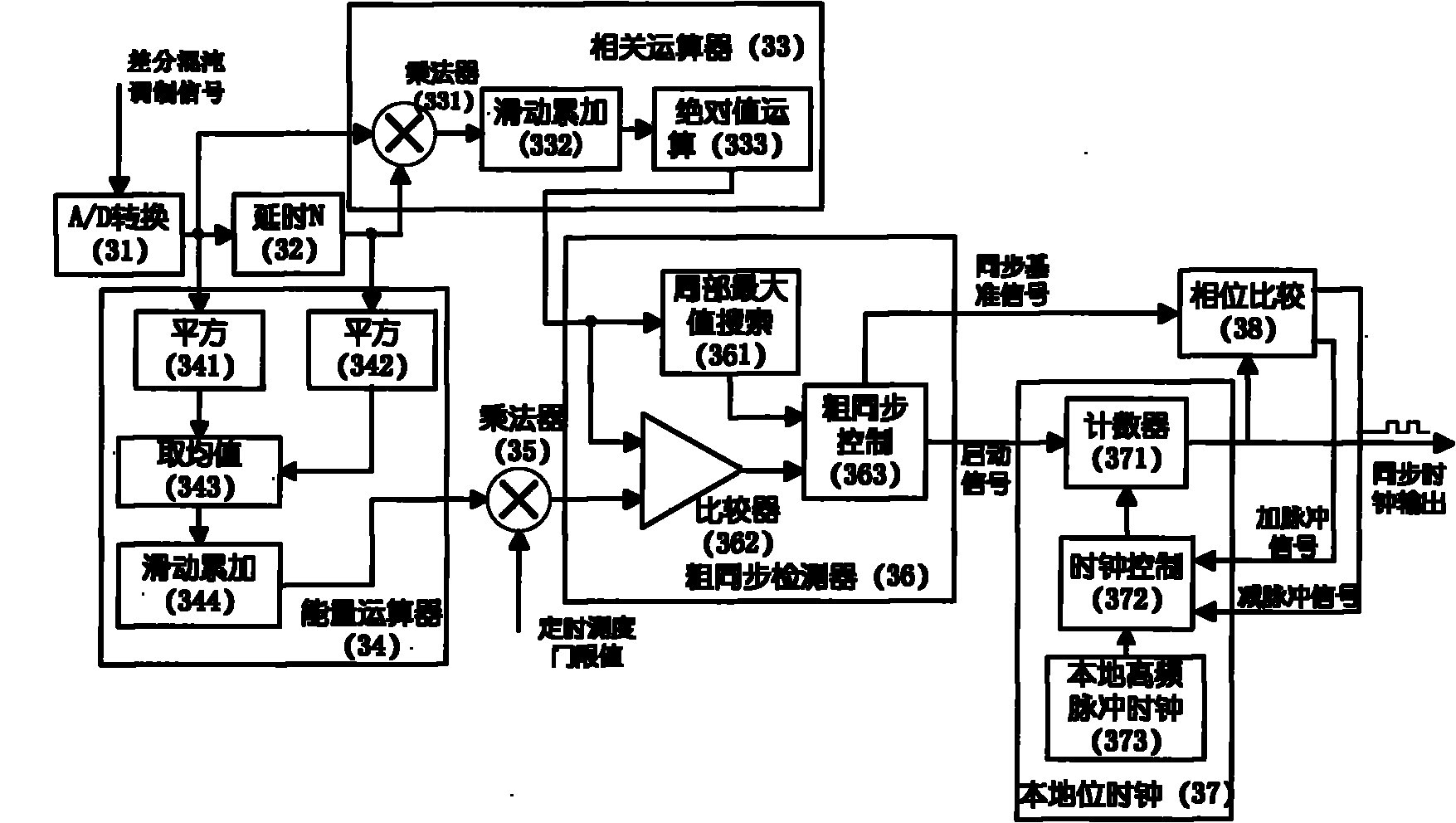

Blind estimation bit synchronization method for differential chaotic modulation communication system

InactiveCN101895380ASolve the problem that the correlation value of the received signal is not constantGood synchronizationModulated-carrier systemsTransmitter/receiver shaping networksCarrier signalPeak value

The invention discloses a blind estimation bit synchronization method for a differential chaotic modulation communication system and relates to a bit synchronization method based on the chaotic spread spectrum technology in the field of digital mobile communication. The invention provides the blind estimation bit synchronization method for the differential chaotic modulation communication system. In the blind estimation bit synchronization method, the characteristics of carrier waveform repetition and energy conservation of reference and modulation parts in a differential chaotic modulation signal are utilized, a local relative maximum value which is more than a synchronous threshold is searched and is used as an initial synchronization point of a local clock, and a digital phase-locked loop is used to perform the tracking synchronous adjustment of subsequent relative peak value, so that the establishing speed and accuracy of the bit synchronization are considered.

Owner:XIAMEN UNIV

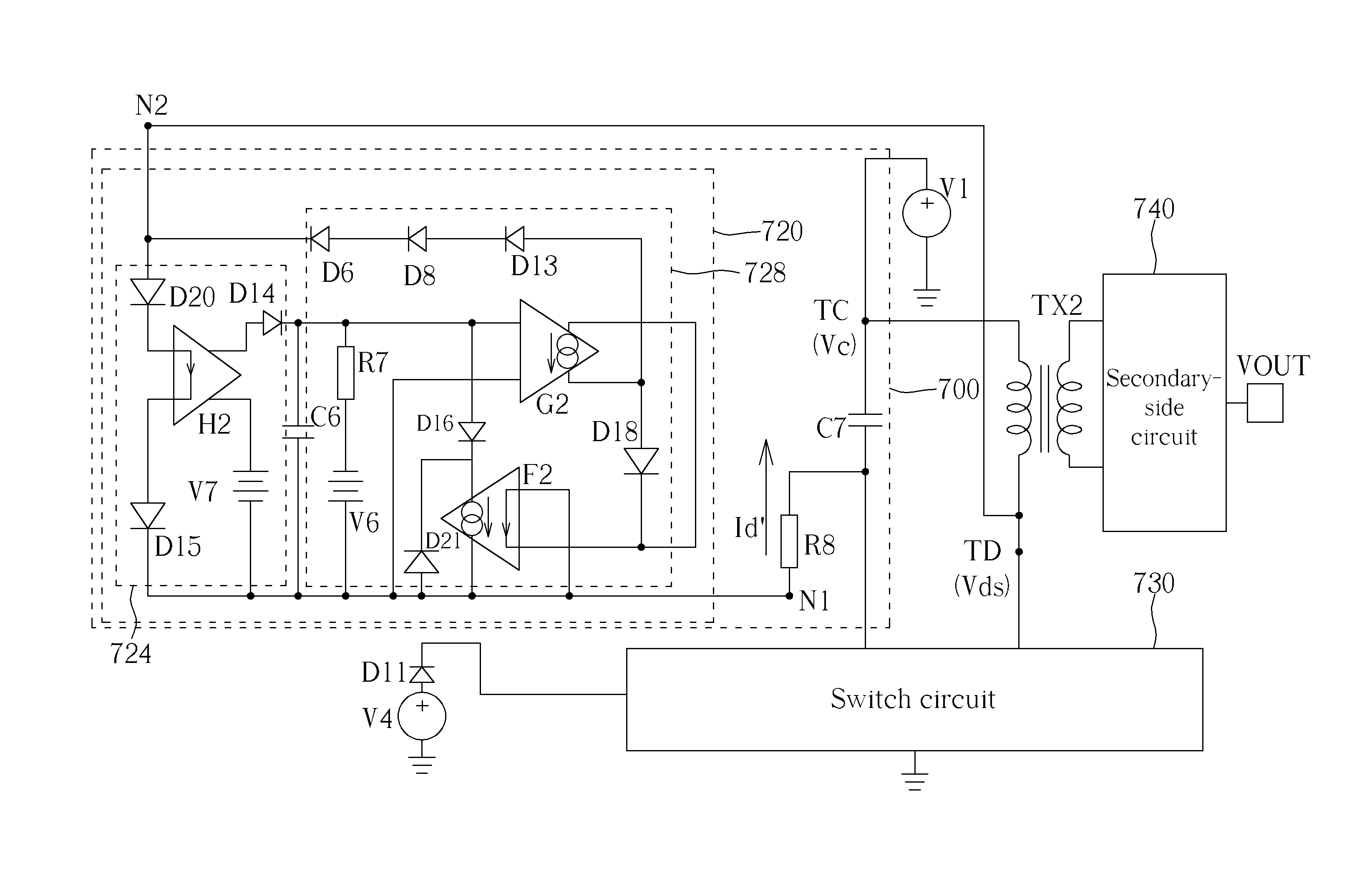

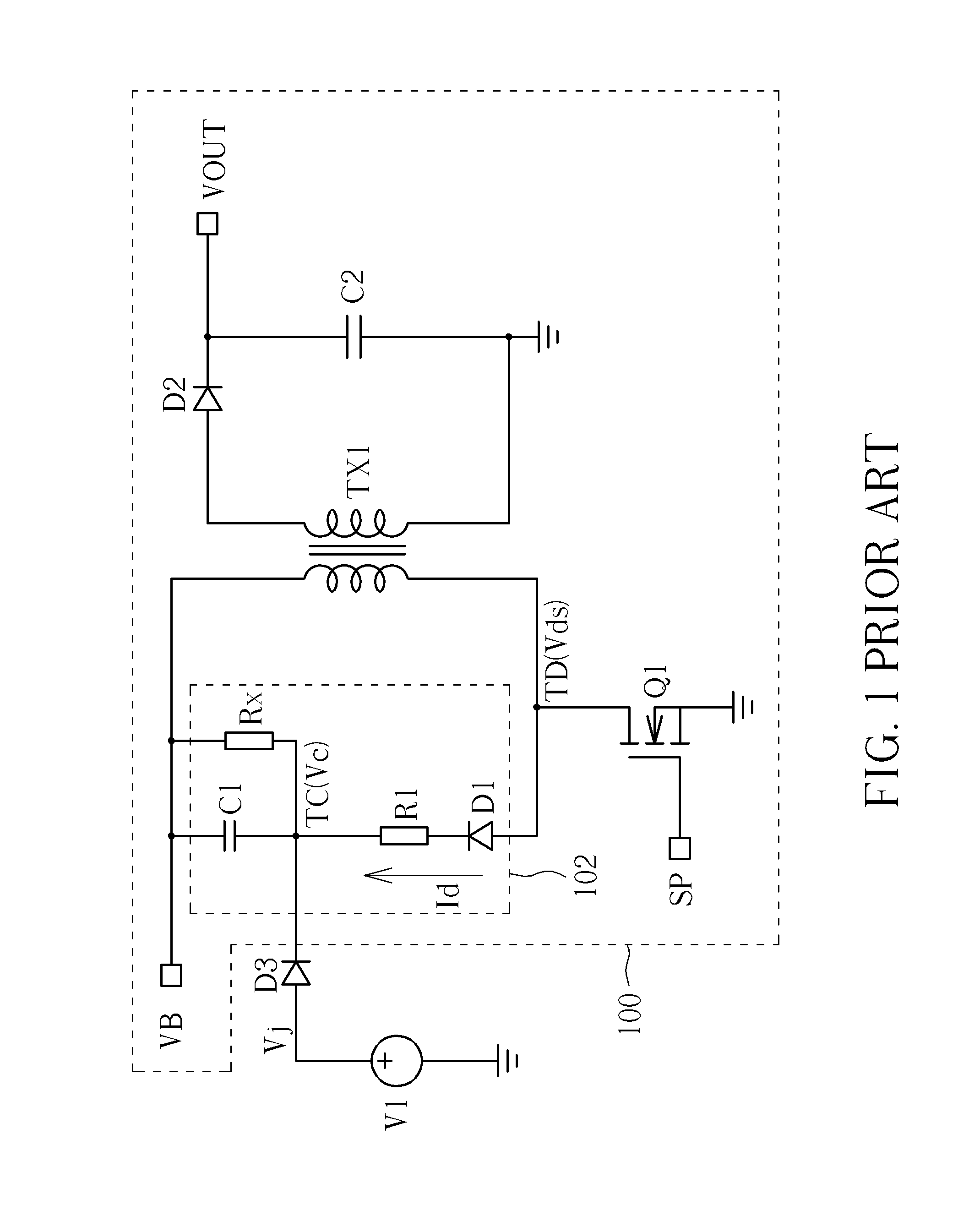

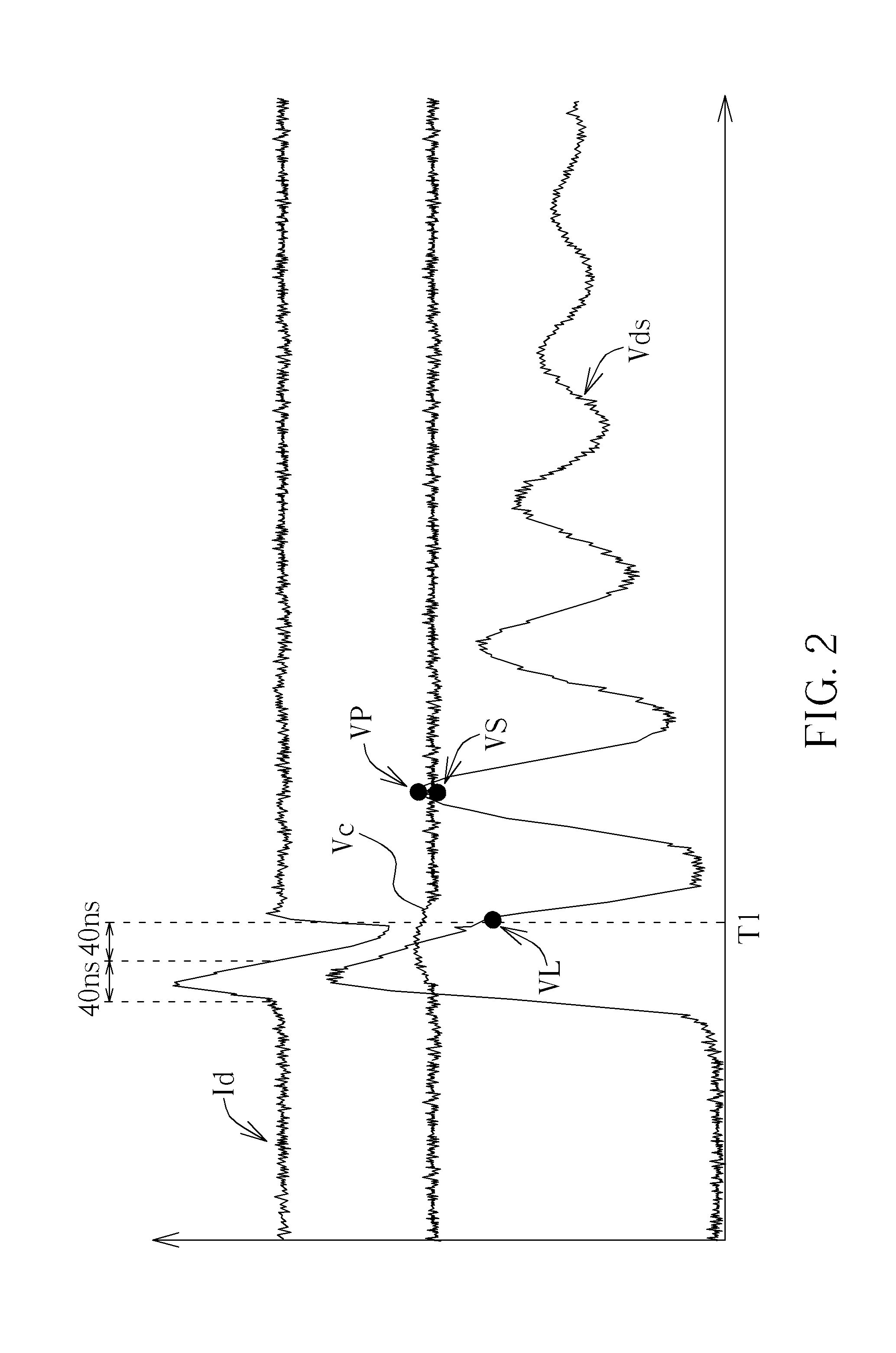

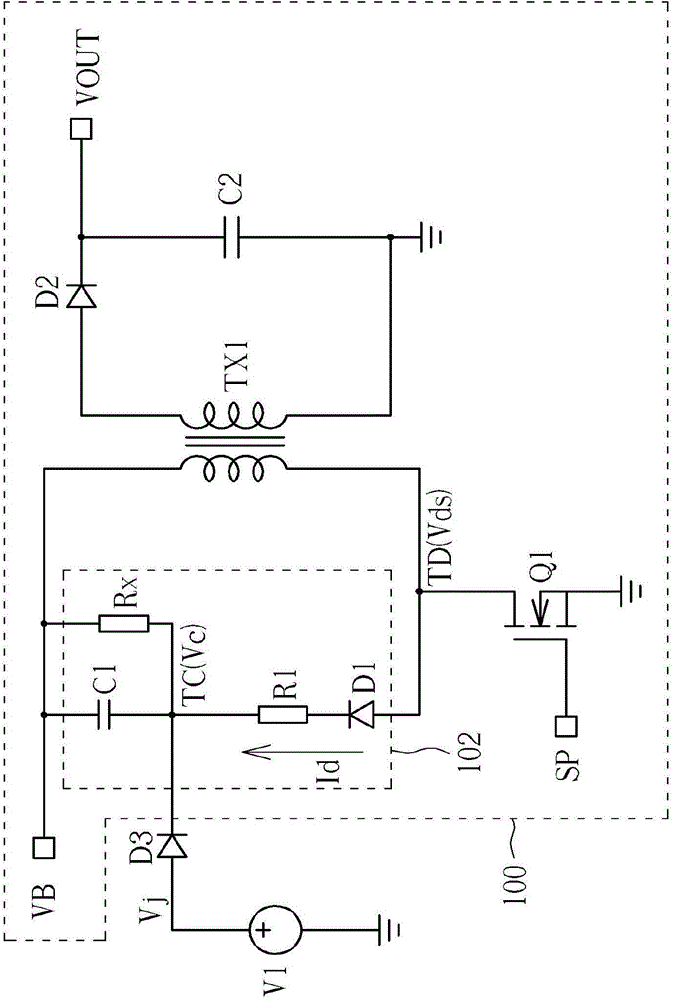

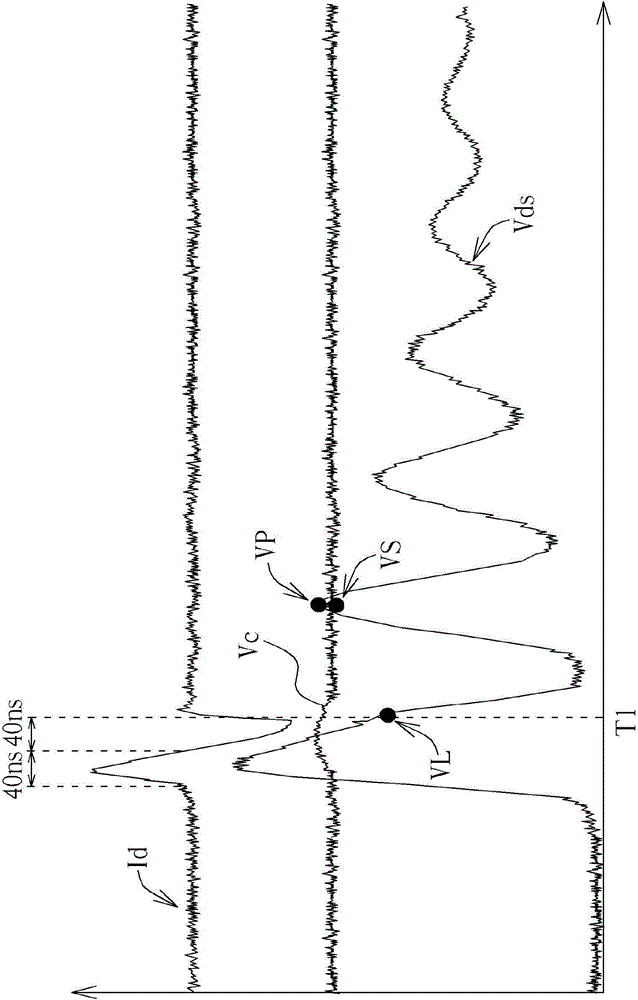

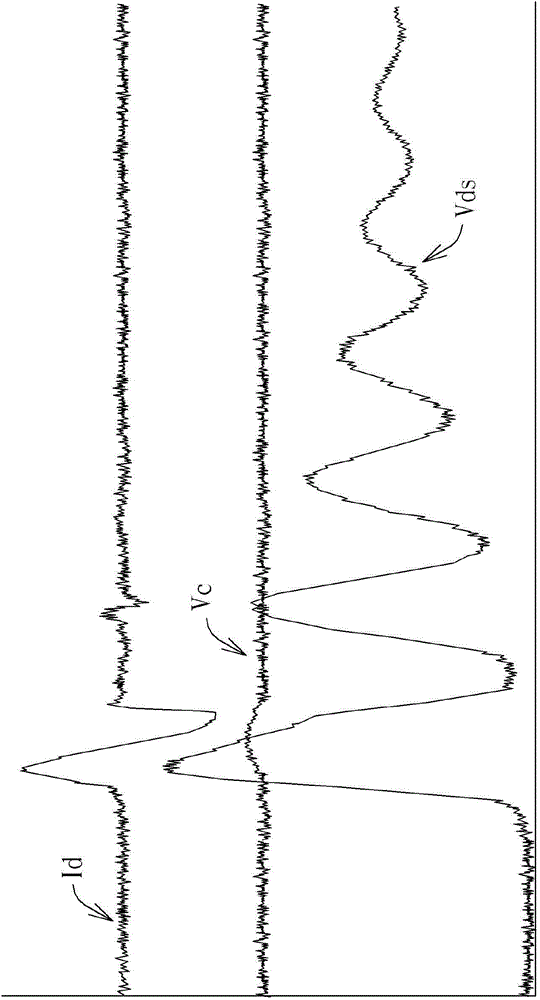

Snubber circuit and buffering method for snubber circuit

ActiveUS20150055262A1Long reverse recovery timeReducing/eliminating power lossEfficient power electronics conversionDc-dc conversionCharge currentRelative maximum

A snubber circuit includes a capacitor and a buffer device. The buffer device has a first terminal and a second terminal. The first terminal is electrically connected to the capacitor. When the buffer device operates in a first conduction mode, a charge current flows from the second terminal to the first terminal through the buffer device. When the buffer device switches from the first conduction mode to a second conduction mode, the buffer device generates a discharge current which flows from the first terminal to the second terminal through the buffer device over a specific period of time, such that after the buffer device enters the second conduction mode, a relative maximum voltage level appearing first at the second terminal is lower than a voltage level at the first terminal.

Owner:SPI ELECTRONICS

Method and system for coupling multimode optical fiber to an optical detector

ActiveUS8111959B2Stable outputReduced output variationWave amplification devicesCoupling light guidesFiberShortest distance

A method for making a multimode fiber optic subassembly includes alignment of an optical detector with a fiber termination of an optical fiber. The output of the optical detector (e.g. photocurrent) can be measured from light being transmitted through the optical fiber and detected by the optical detector. The end of the optical fiber and / or the optical detector can be positioned and angularly oriented in order to obtain relative maximum or peak output of the optical detector for a given position and orientation. The output of the optical detector can be monitored while mechanically manipulating, e.g. bending, flexing, shaking and / or twisting, the optical fiber, in order to verify that the positional relationship between the end of the optical fiber and the optical detector corresponds to a position and / or orientation that provides stable output from the optical detector. If the optical detector output is not stable, the end of the multimode optical fiber and the optical detector can be moved, changing the position and / or the orientation of one or both, until the output of the optical detector is stable during manipulation. If the optical detector output is stable, the end of the multimode optical fiber is fixed to the optical detector. The resulting subassembly, a fiber optic pigtail, can be made by cutting the optical fiber a short distance from the optical detector.

Owner:CORNING OPTICAL COMM WIRELESS

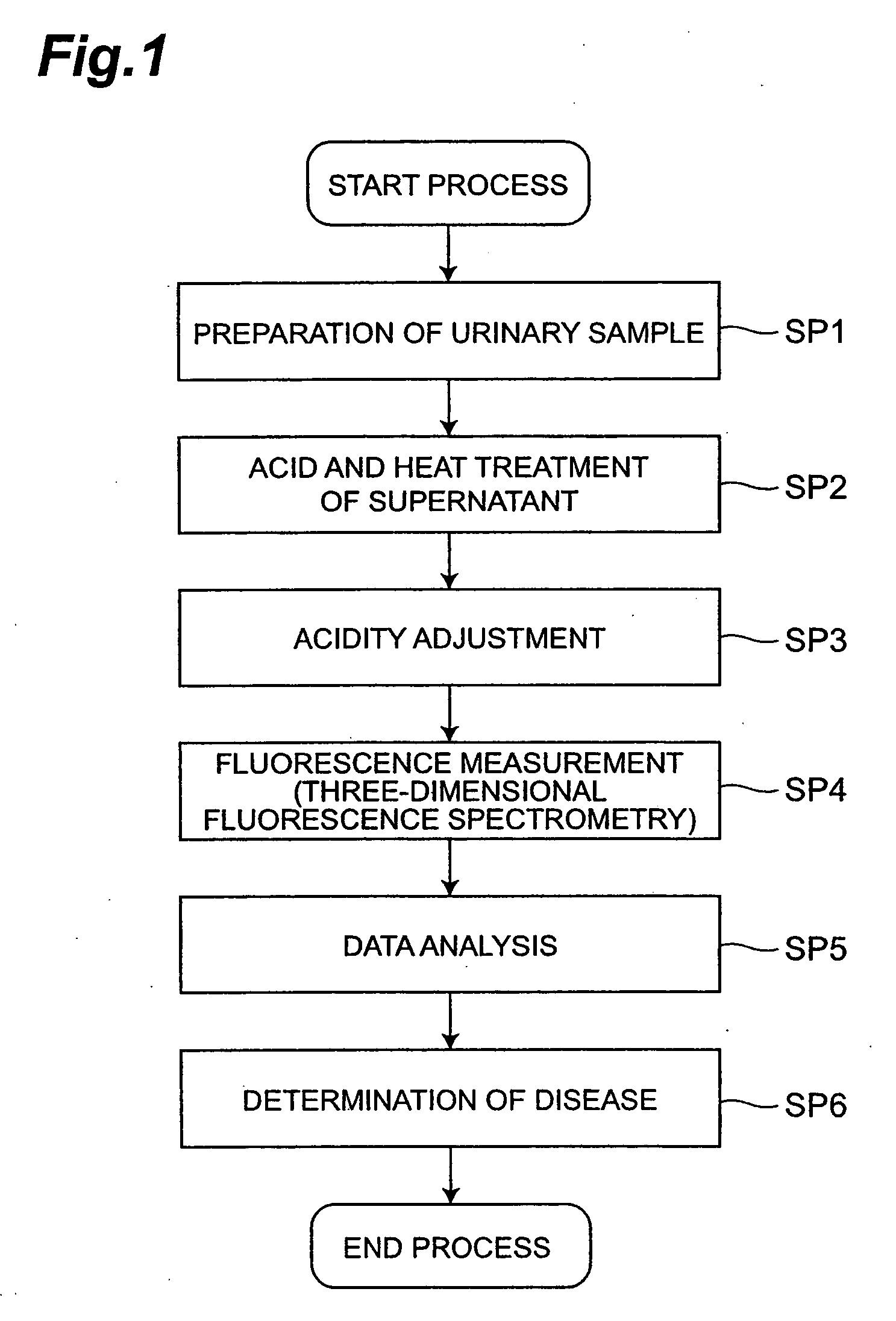

Disease determination method, data generation method for disease determination and data generation system for disease determination

InactiveUS20060234319A1High measurement accuracyEasy to determinePeptide/protein ingredientsMaterial analysis by observing effect on chemical indicatorAbnormal tissue growthRelative maximum

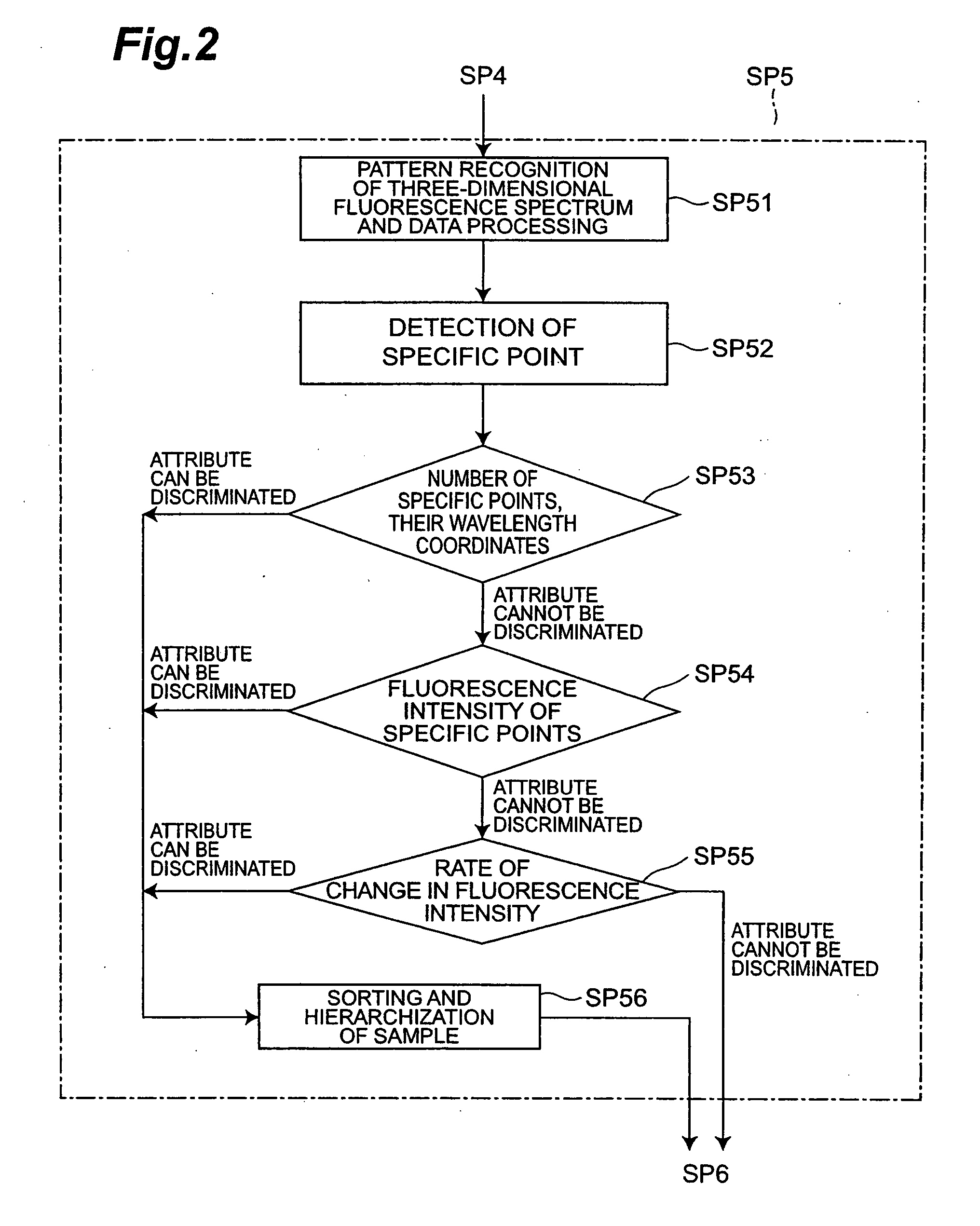

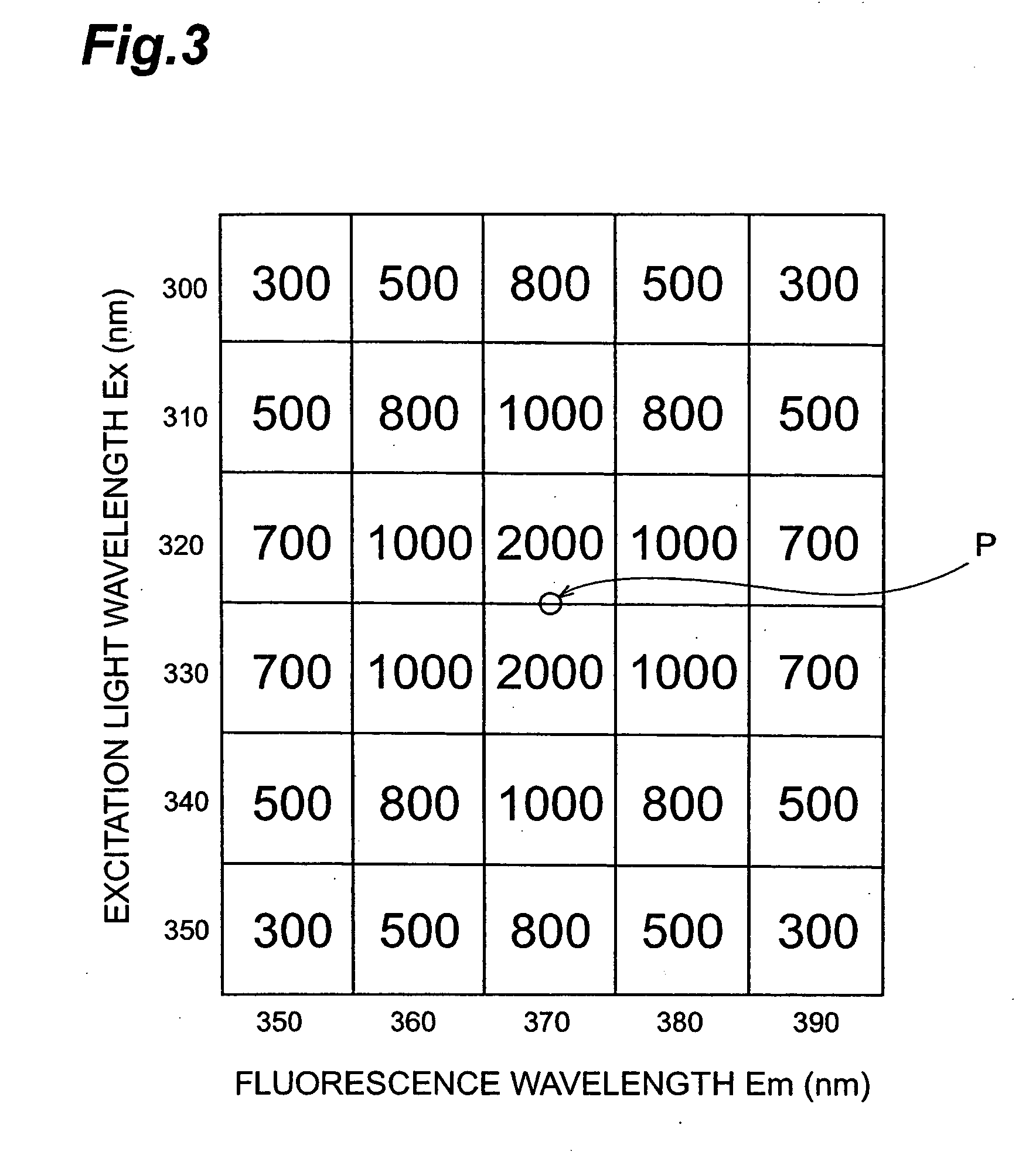

Supernatant of the urinary sample (SP1) was mixed with an acid or alkali and heated (SP2) and the sample for fluorescence assay was prepared after adjusting its acidity to alkaline (SP3). Next, using fluorometry, three-dimensional fluorescence spectrum consisted of an excitation light wavelength, fluorescence wavelength and fluorescence intensity (SP4). Then, a relative maximum peak is detected as a specific point in the three-dimensional fluorescence spectrum to specify a specific point attribute (peak number, peak position and fluorescence intensity) and then the urinary sample is sorted based on the attribute (SP5). Finally, the presence or absence of a disease such as a malignant tumor is determined based on the sorting results of the urinary sample (P6).

Owner:HAMAMATSU PHOTONICS KK

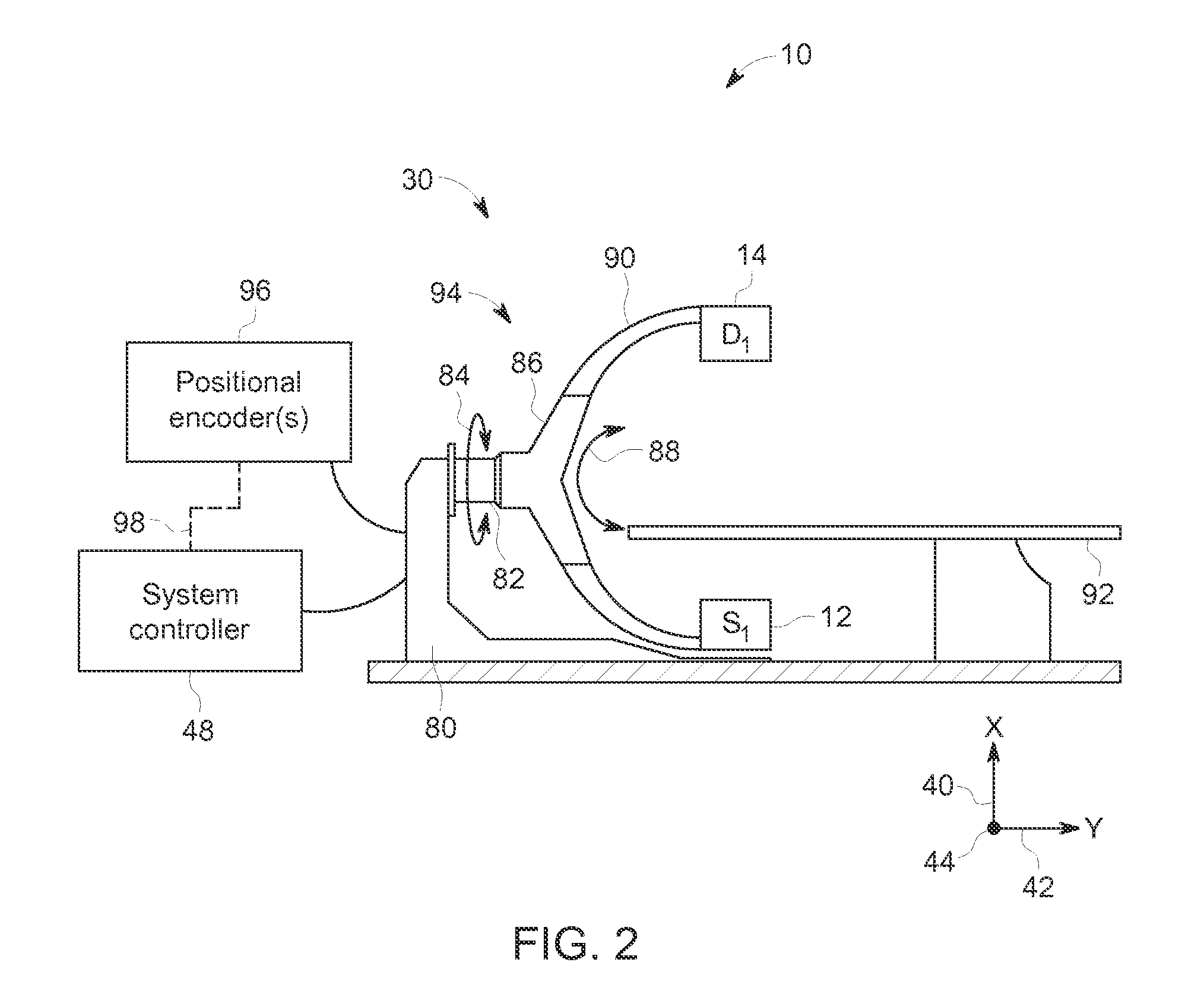

Tomographic imaging for time-sensitive applications

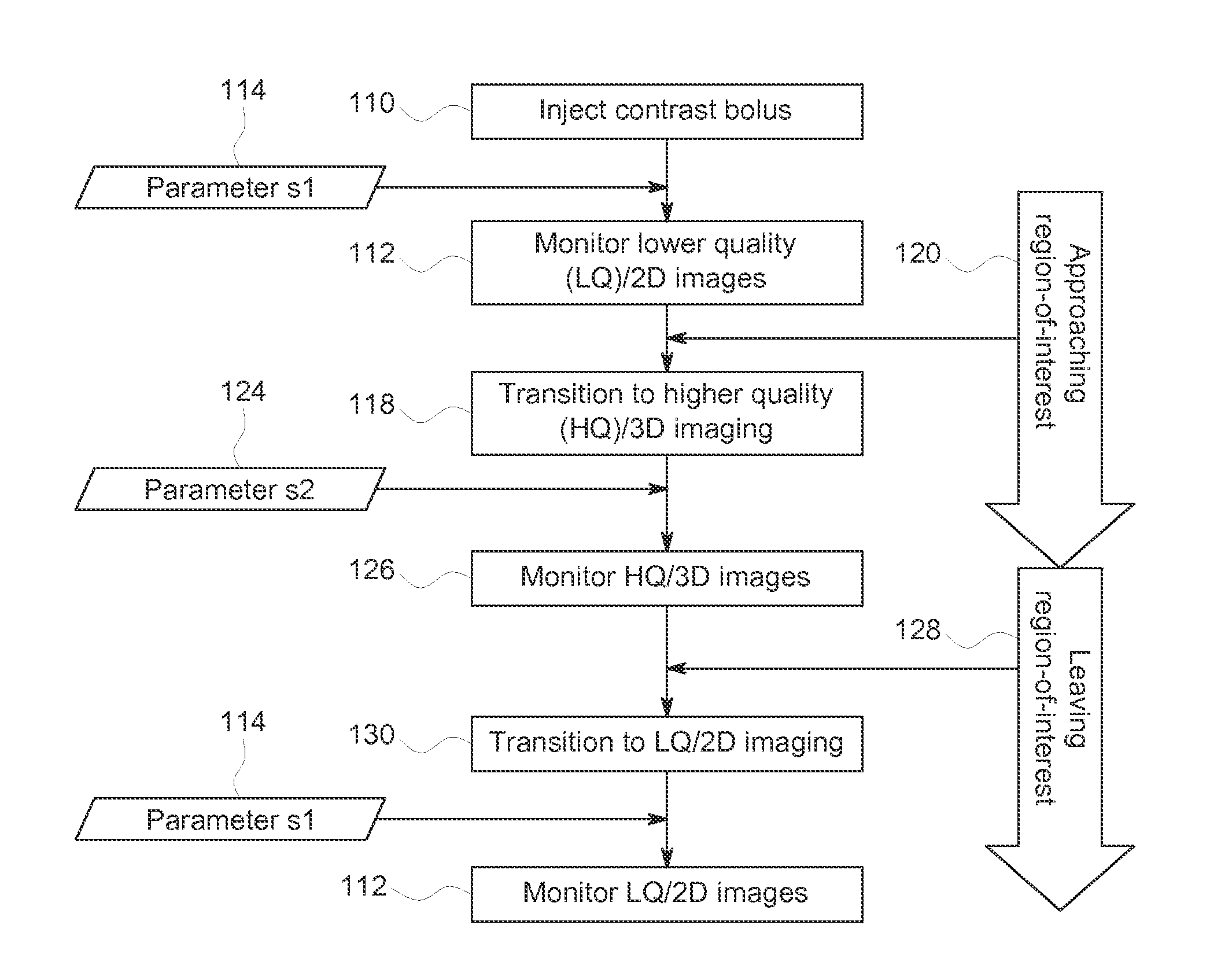

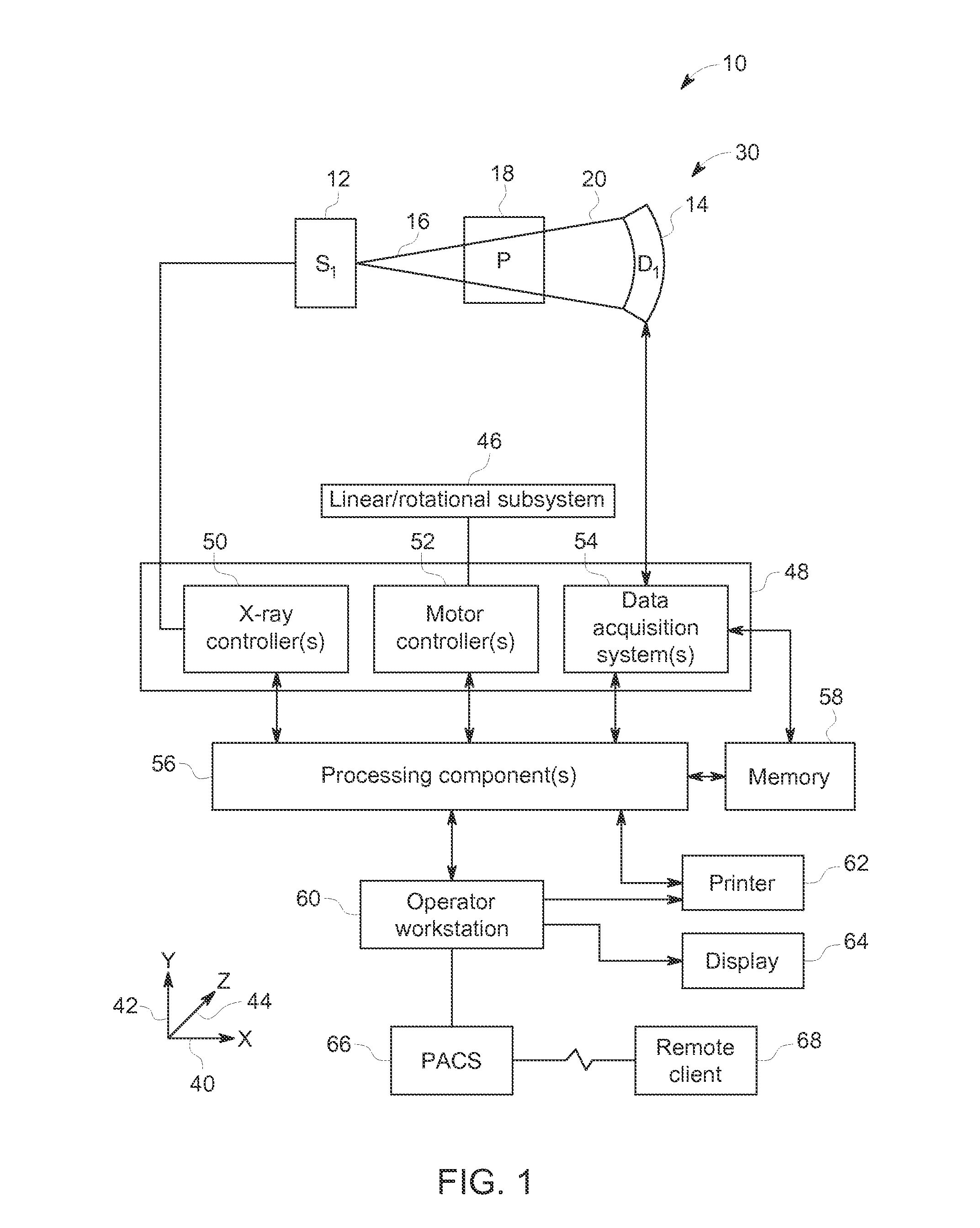

Disclosed aspects relate to the acquisition and processing of projection data using temporal characteristics of the imaged volume, such as the uptake and clearance of a contrast agent within the volume. Such temporal aspects may be used in the acquisition process, such as to differentially acquire images based on the propagation of the contrast agent. In addition, such temporal aspects may be used in the processing of projection data to generate differential projections (e.g., first or second order subtraction projections), compound projections synthesized using the absolute or relative maximum opacity values observed over time for a region of interest, or interpolated projections synthesized using observed opacity values at known or fixed time intervals and a derived peak opacity time.

Owner:GENERAL ELECTRIC CO

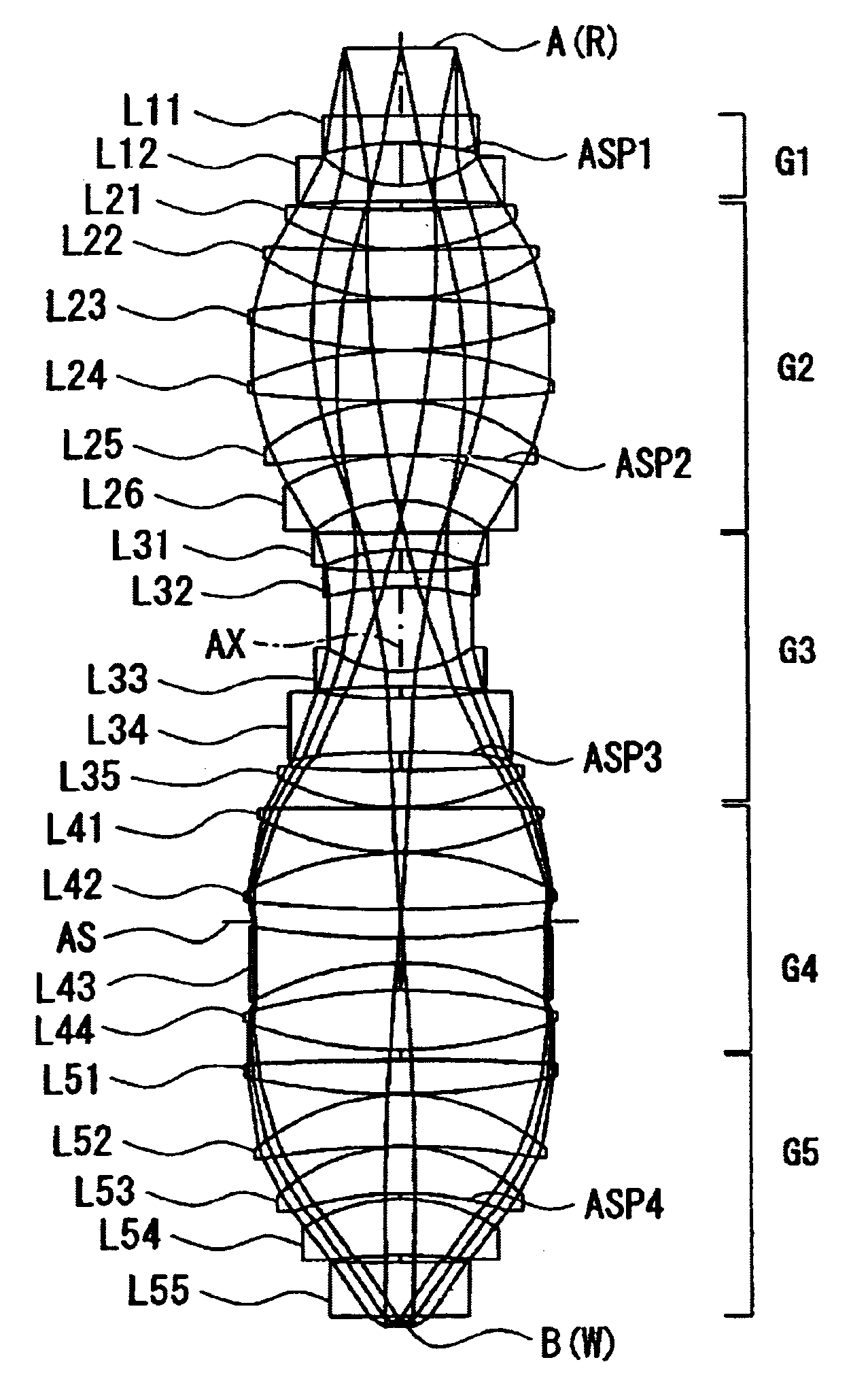

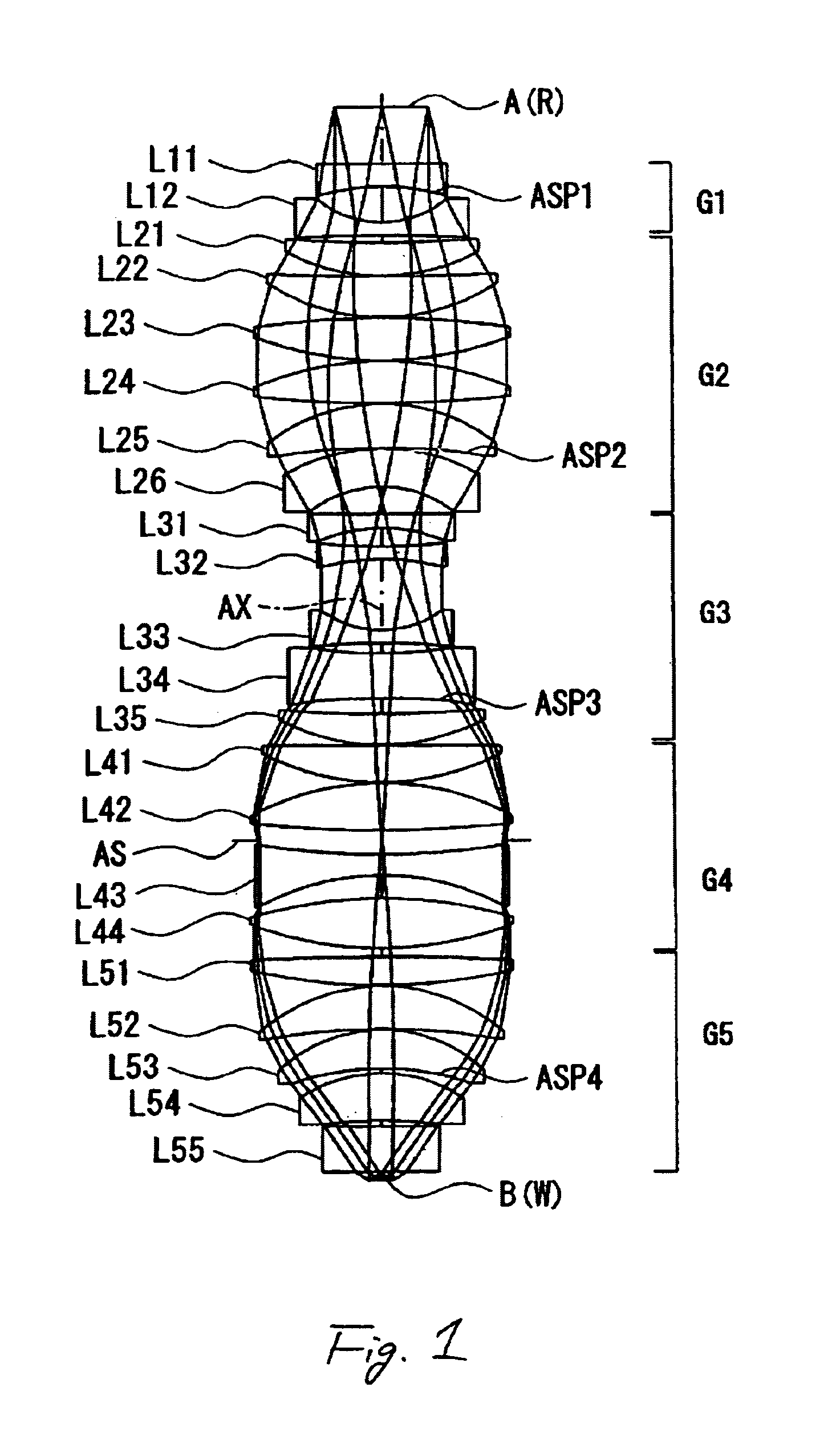

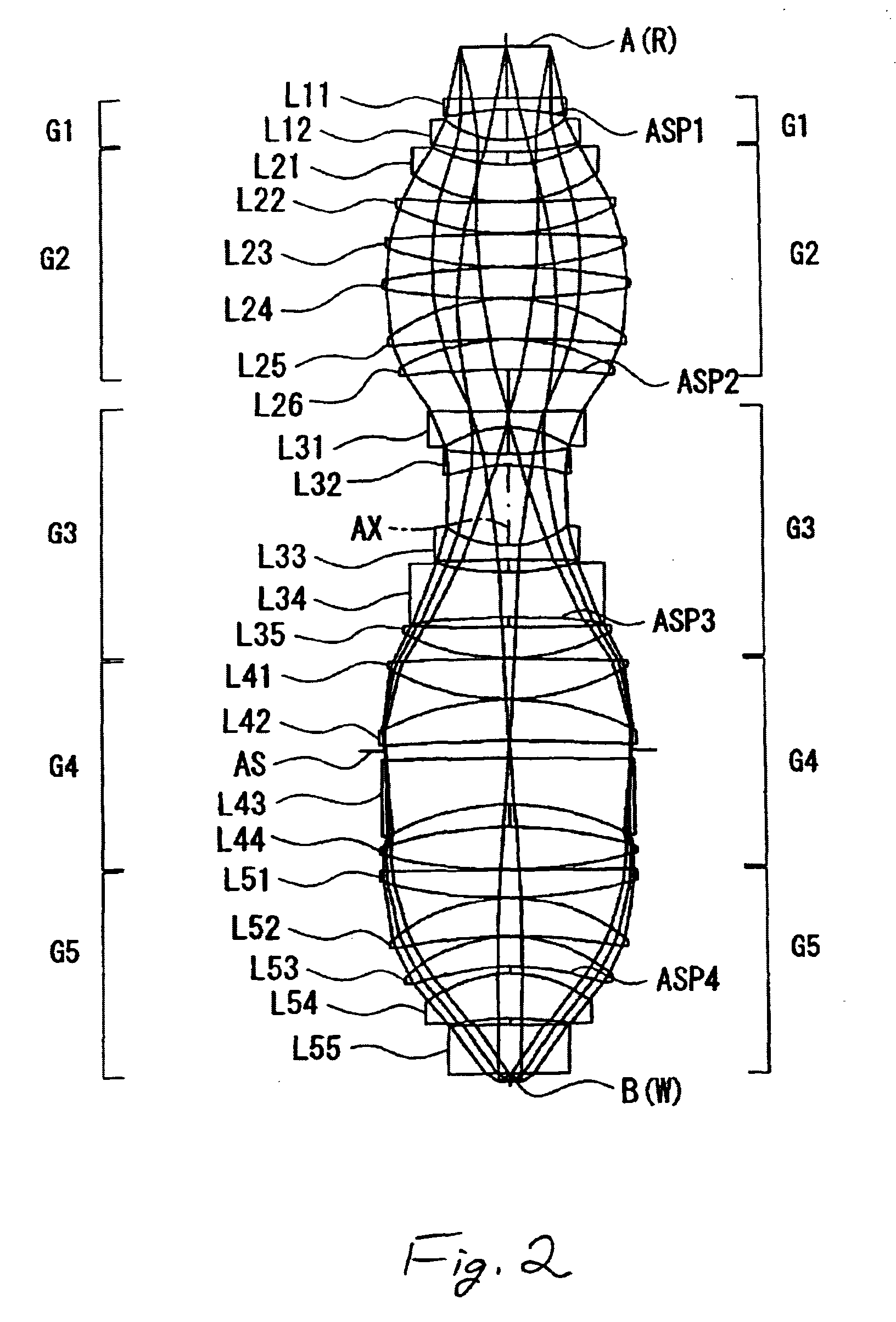

Projection optical system, a projection exposure apparatus, and a projection exposure method

InactiveUS6912094B2Improve imaging effectImprove performanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRelative maximumOptical path

A projection optical system that projects an image on a first side onto a second plane through a plurality of lenses includes the following elements in order from the first side to the second plane: a first lens group that has a negative refractive power, a second lens group that has a positive refractive power, a third lens group that has a negative refractive power, a fourth lens group that has an aperture stop in the optical path, and a fifth lens group that has a positive refractive power. A clear aperture of a lens surface or an outer diameter of a lens in the projection optical system has a relative maximum in the second lens group, a relative minimum in the third lens group, and a relative maximum in the third-fifth lens groups, and has only one significant minimum between the first side and the second plane.

Owner:NIKON CORP

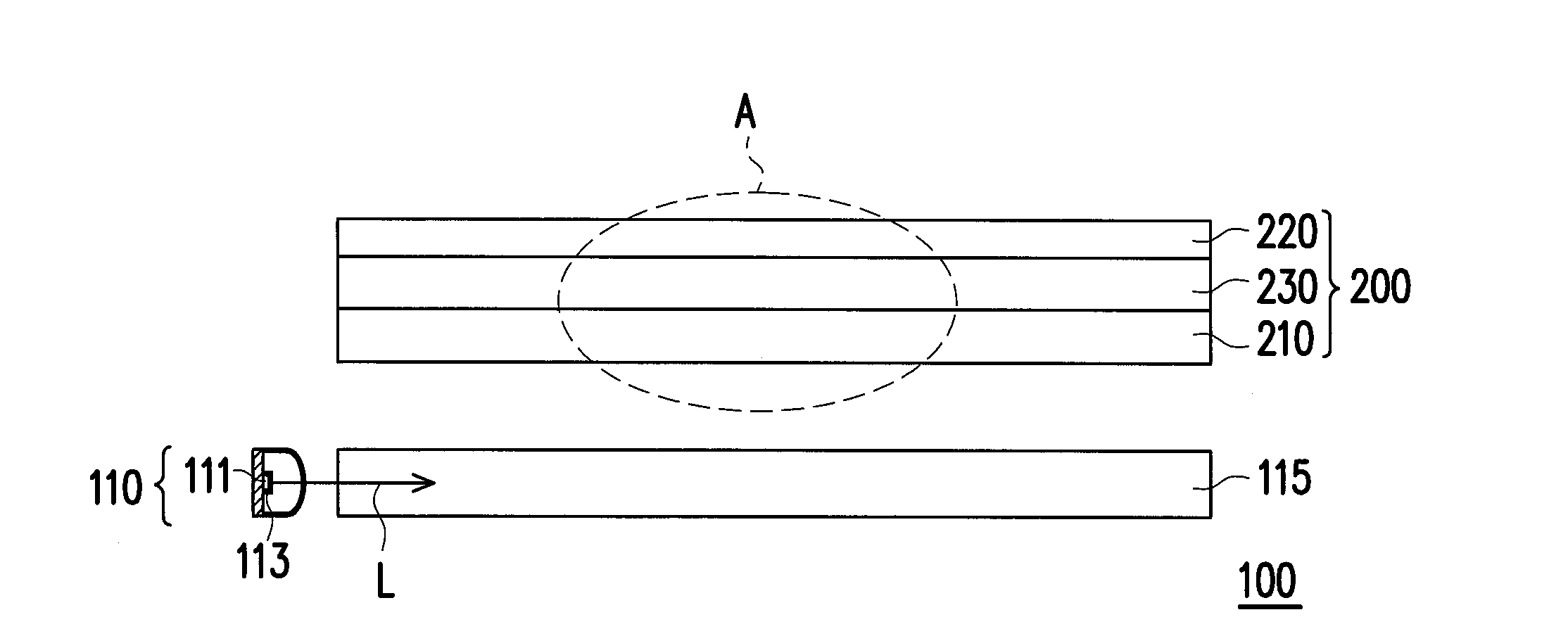

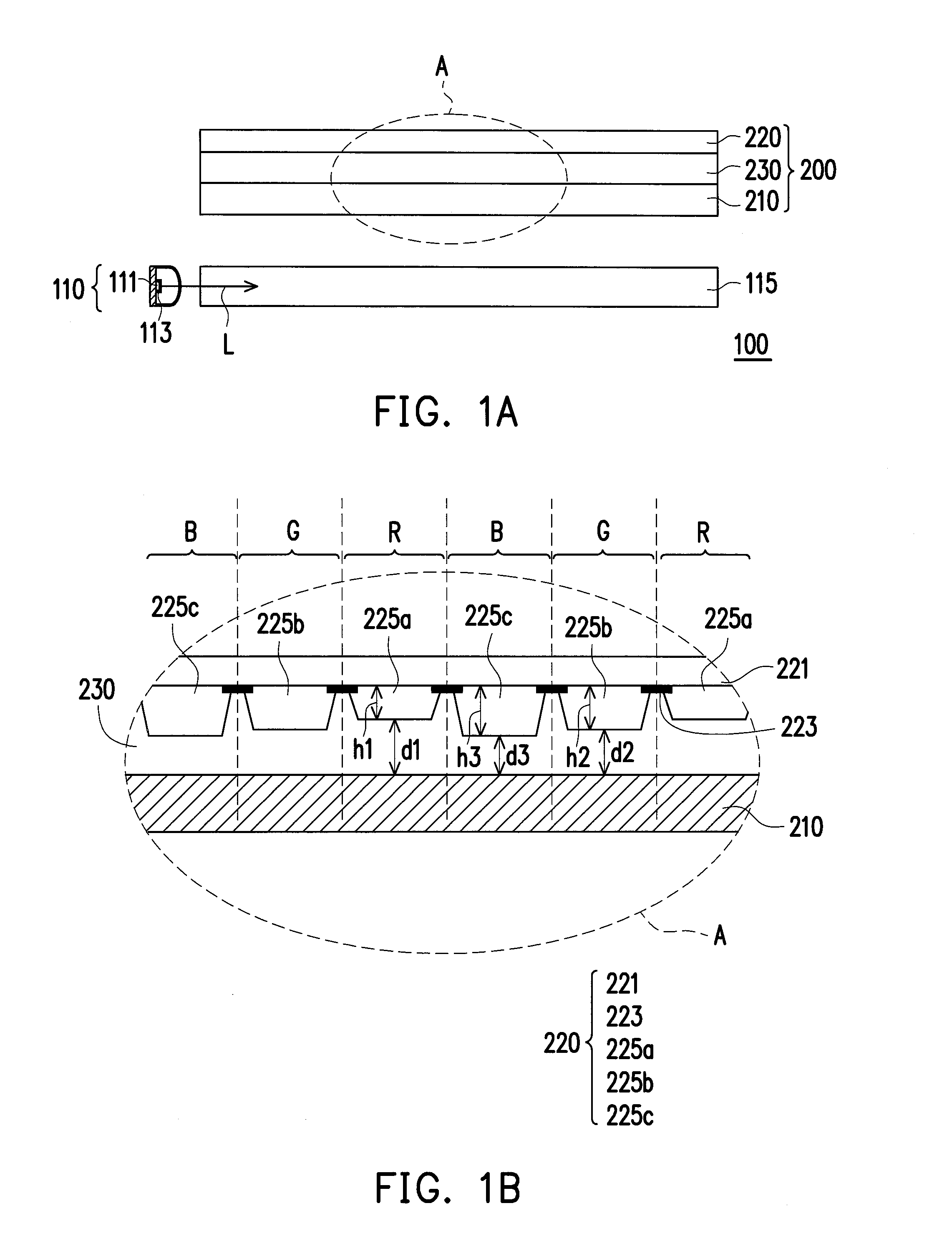

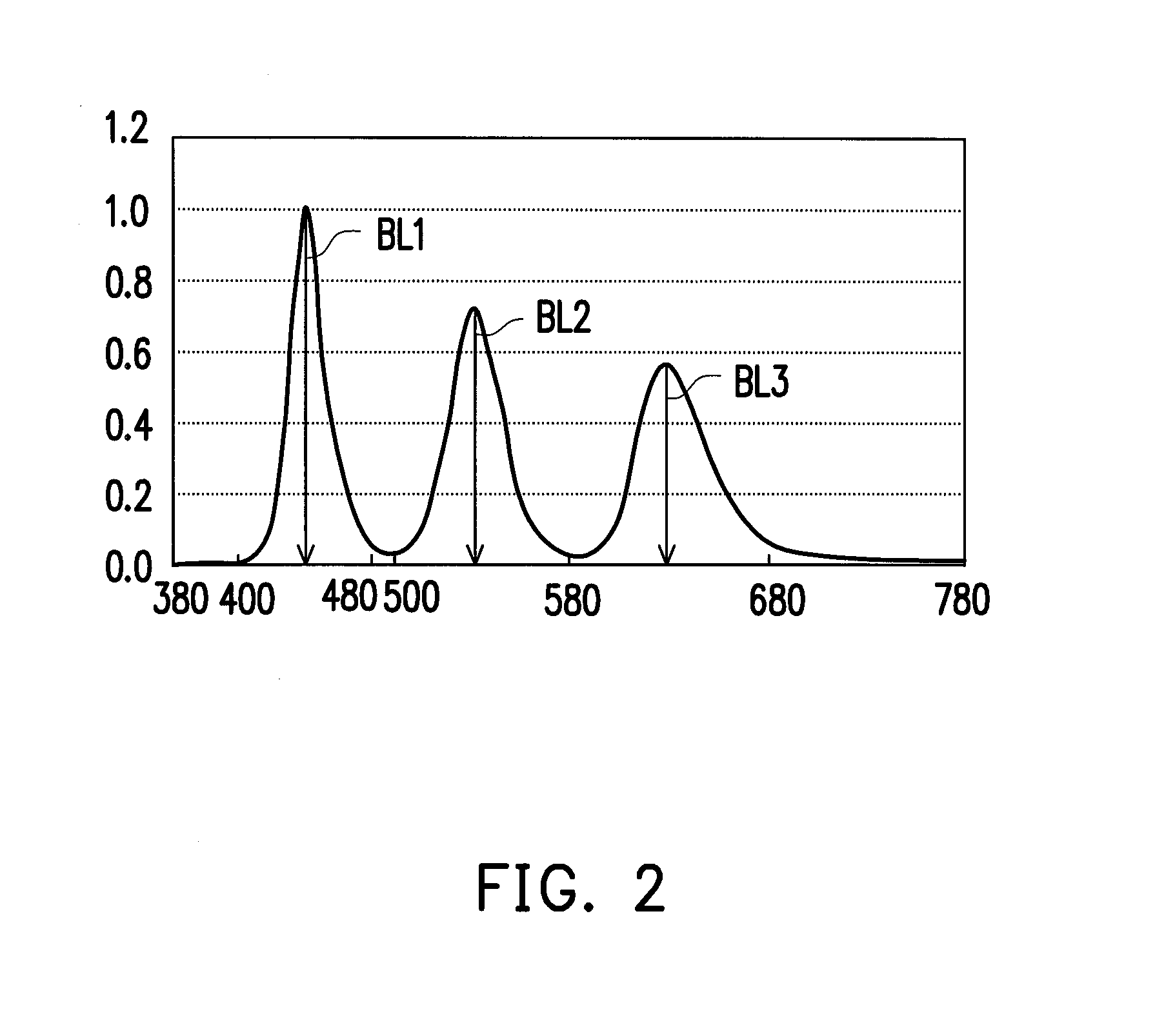

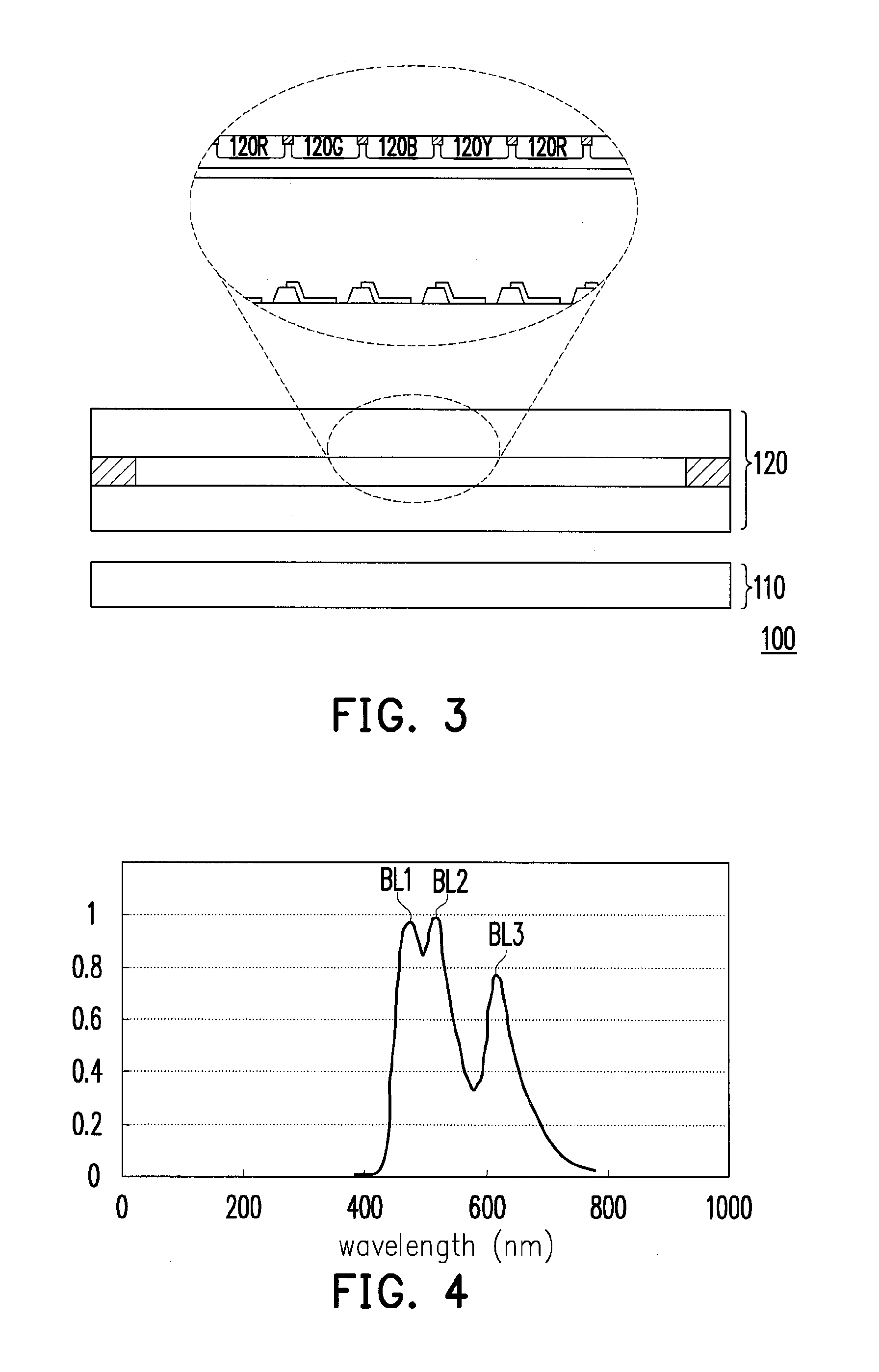

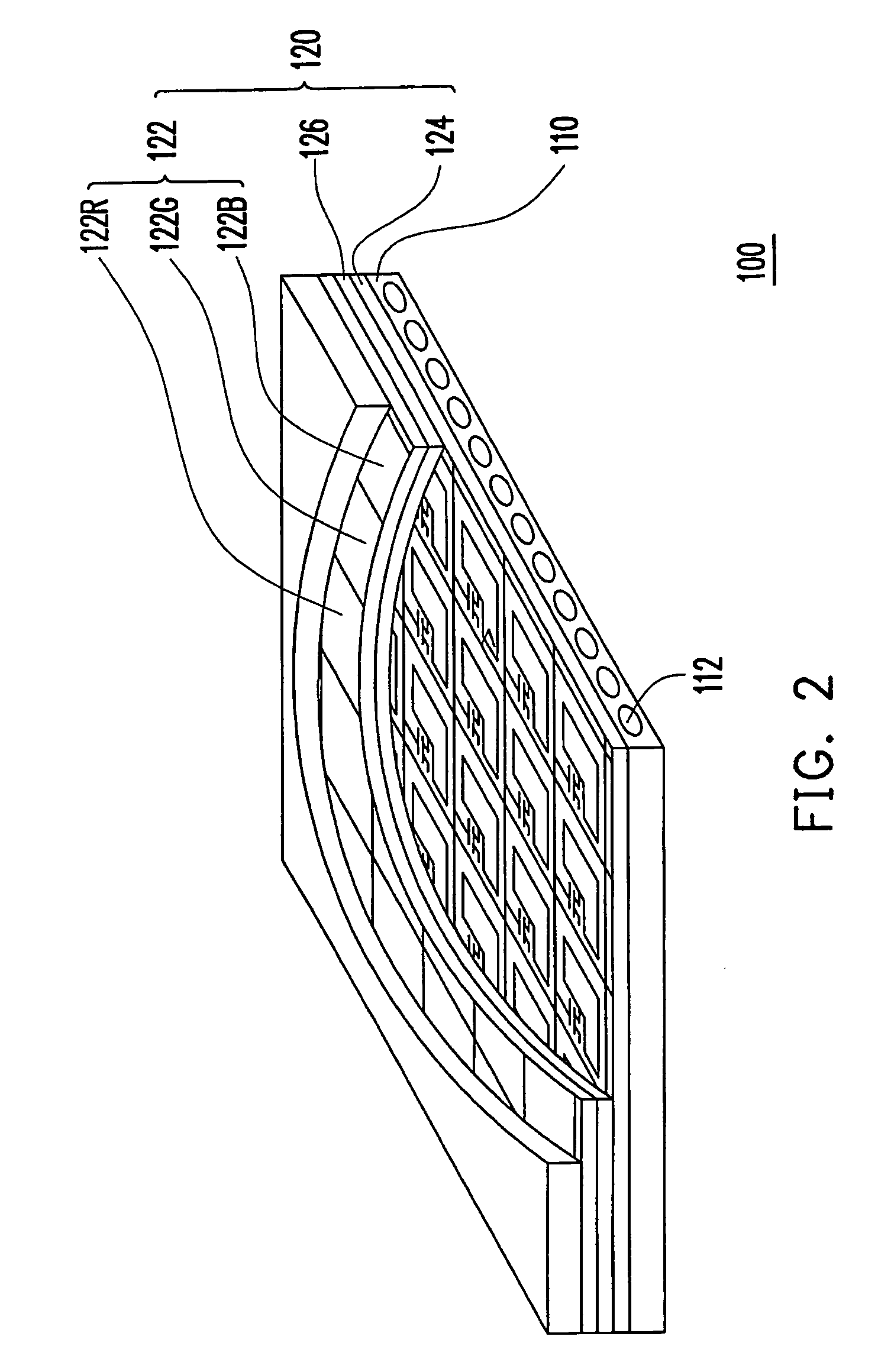

Liquid crystal panel and liquid crystal display

ActiveUS20150070624A1Good color saturationGreat color white color display performancePlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayQuantum dot

A liquid crystal panel and a liquid crystal display including the liquid crystal panel and a backlight unit are provided. The backlight unit includes an exciting light source and a quantum dot fluorescent material. An emission spectrum of the backlight unit at a wavelength from 400 nm to 500 nm, from 500 nm to 580 nm and from 580 nm to 780 nm has relative maximum brightness peaks BL1, BL2 and BL3, respectively, wherein BL2 / BL1>0.65, and BL2 / BL3>1. The liquid crystal panel is disposed above the backlight unit, and has red pixel regions, green pixels regions and blue pixel regions. A cell gap in the red pixel regions of the liquid crystal panel is bigger than a cell gap in the green pixel regions of the liquid crystal panel and a cell gap in the blue pixel regions of the liquid crystal panel.

Owner:AU OPTRONICS CORP

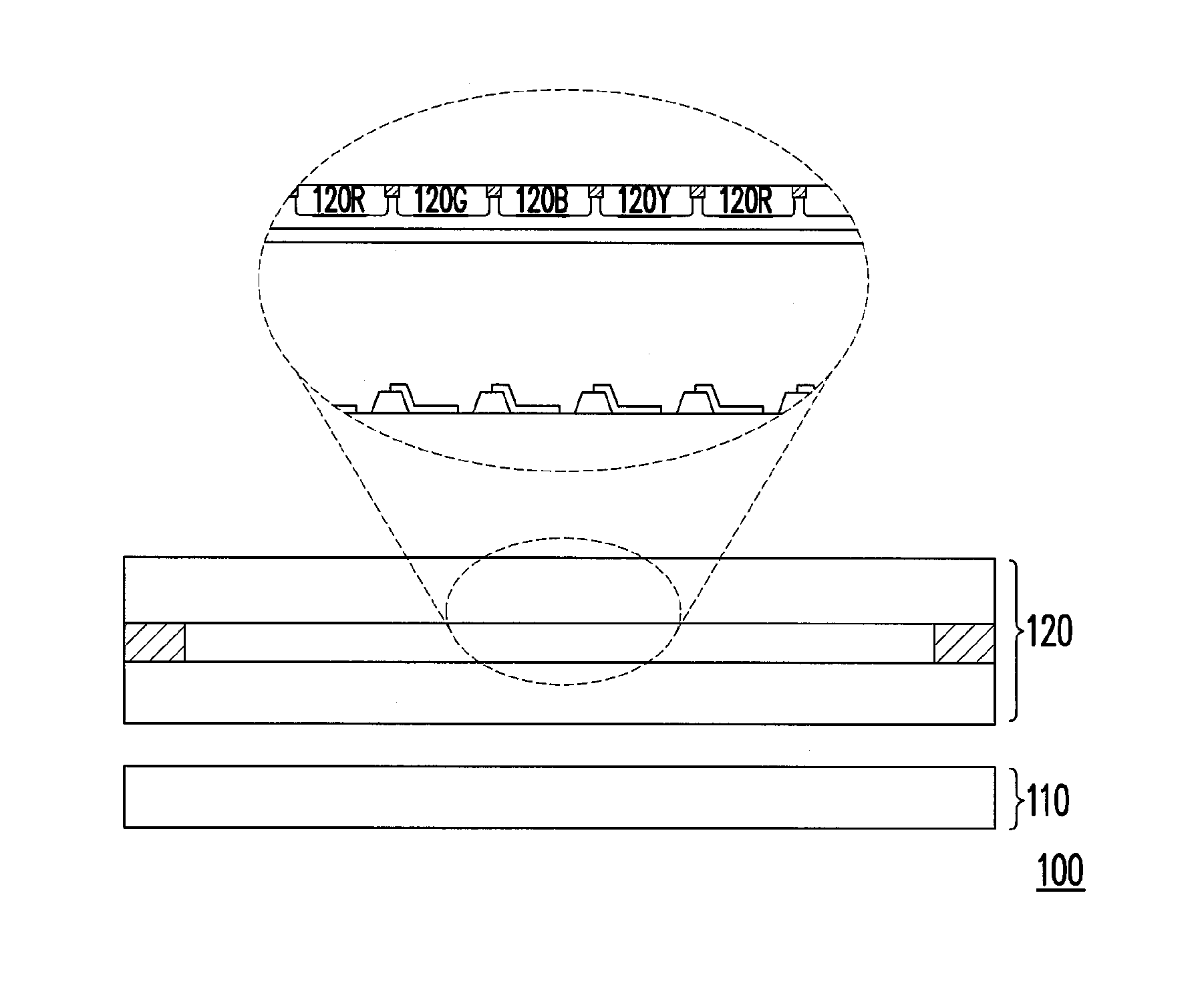

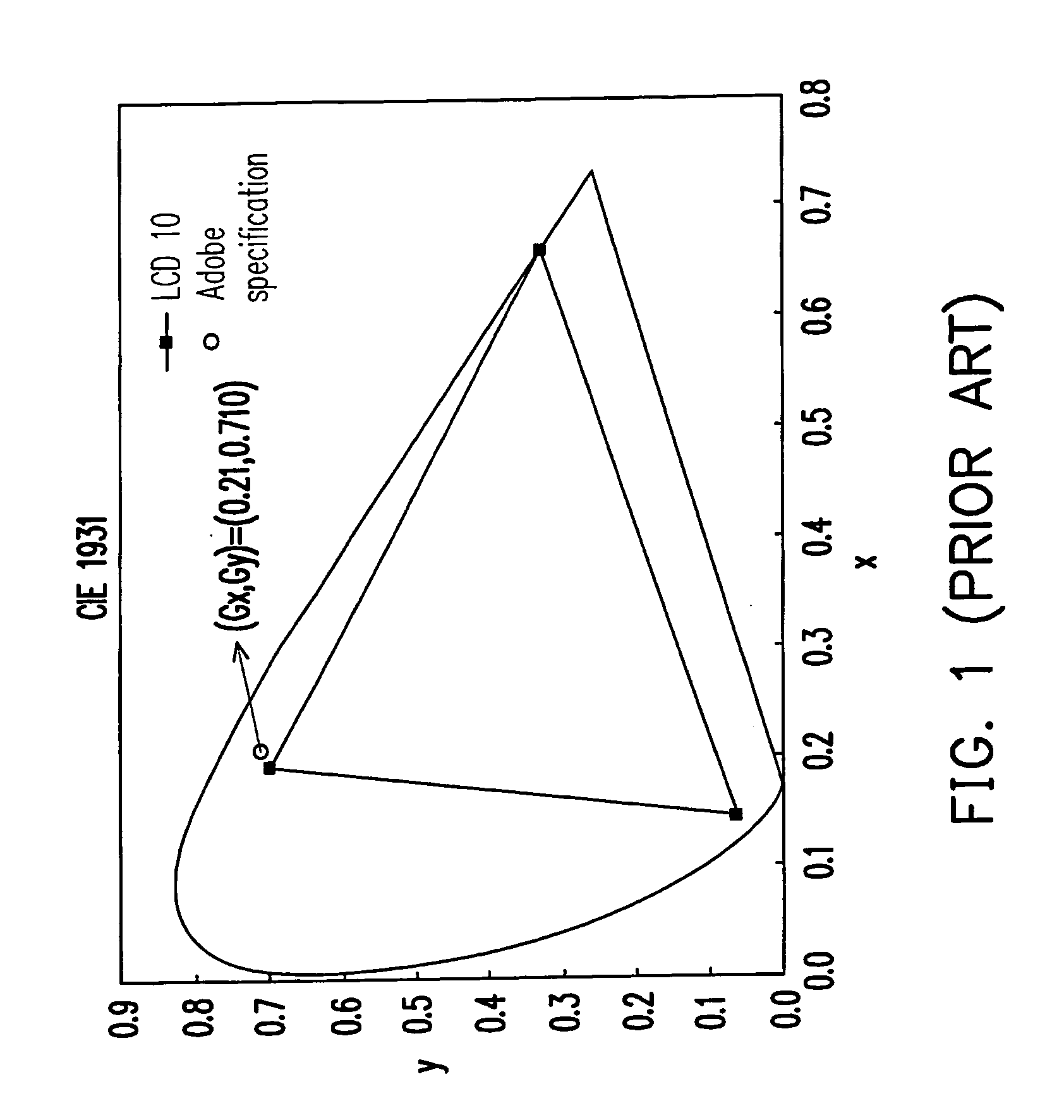

Liquid crystal display

ActiveUS20120069274A1Good color saturation and white color performanceNon-linear opticsLiquid-crystal displayRelative maximum

A liquid crystal display including a backlight unit and a liquid crystal display panel is provided. A spectrum of the backlight unit has relative maximum brightness peaks at wavelength between 460 nm to 480 nm, between 505 nm to 525 nm, and between 610 nm to 630 nm. The liquid crystal display panel is disposed above the backlight unit. The liquid crystal display panel has a red color filter layer (Rx, Ry, RY), a green color filter layer (Gx, Gy, GY), a blue color filter layer (Bx, By, BY) and a yellow color filter layer (Yx, Yy, YY), wherein under the backlight source, the red color filter layer, the green color filter layer, the blue color filter layer and the yellow color filter layer satisfy following conditions: Rx≧0.654; Ry≦0.330; Gx≦0.253; Gy≧0.605; Bx≦0.136; By≦0.146; Yx≦0.408; Yy≦0.534; 0.83≦RY / GY≦0.87; 0.86≦GY / BY≦0.92; 0.83≦BY / YY≦0.87 and 1.5≦YY / RY≦1.55.

Owner:AU OPTRONICS CORP

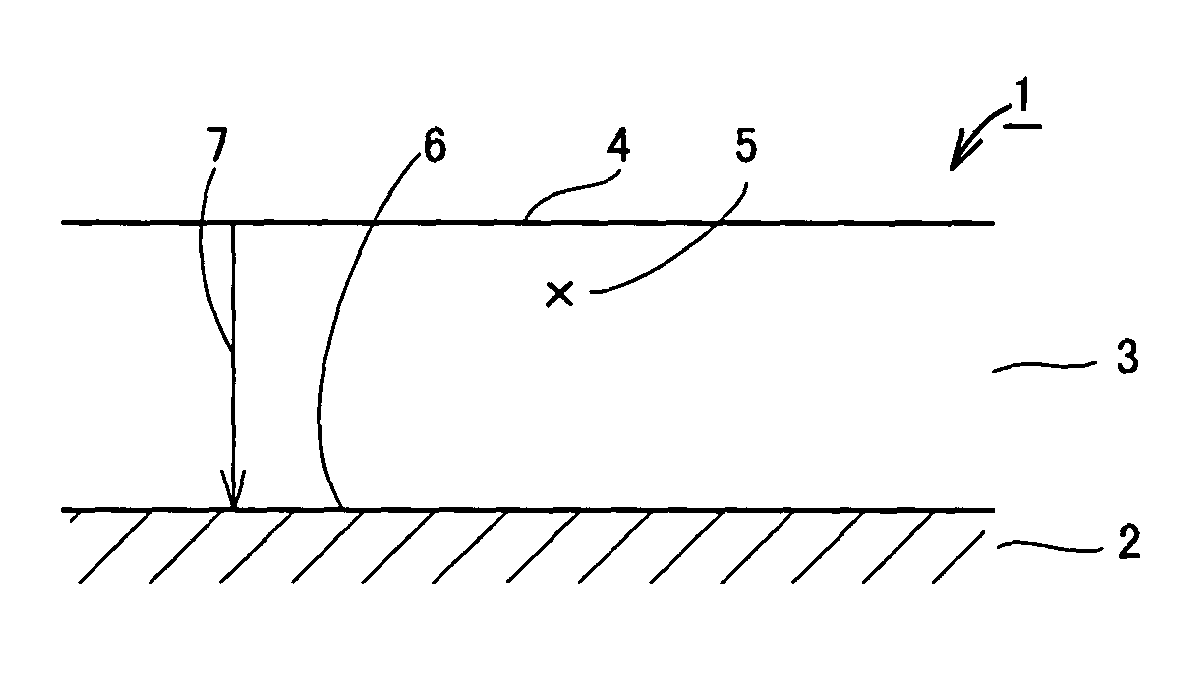

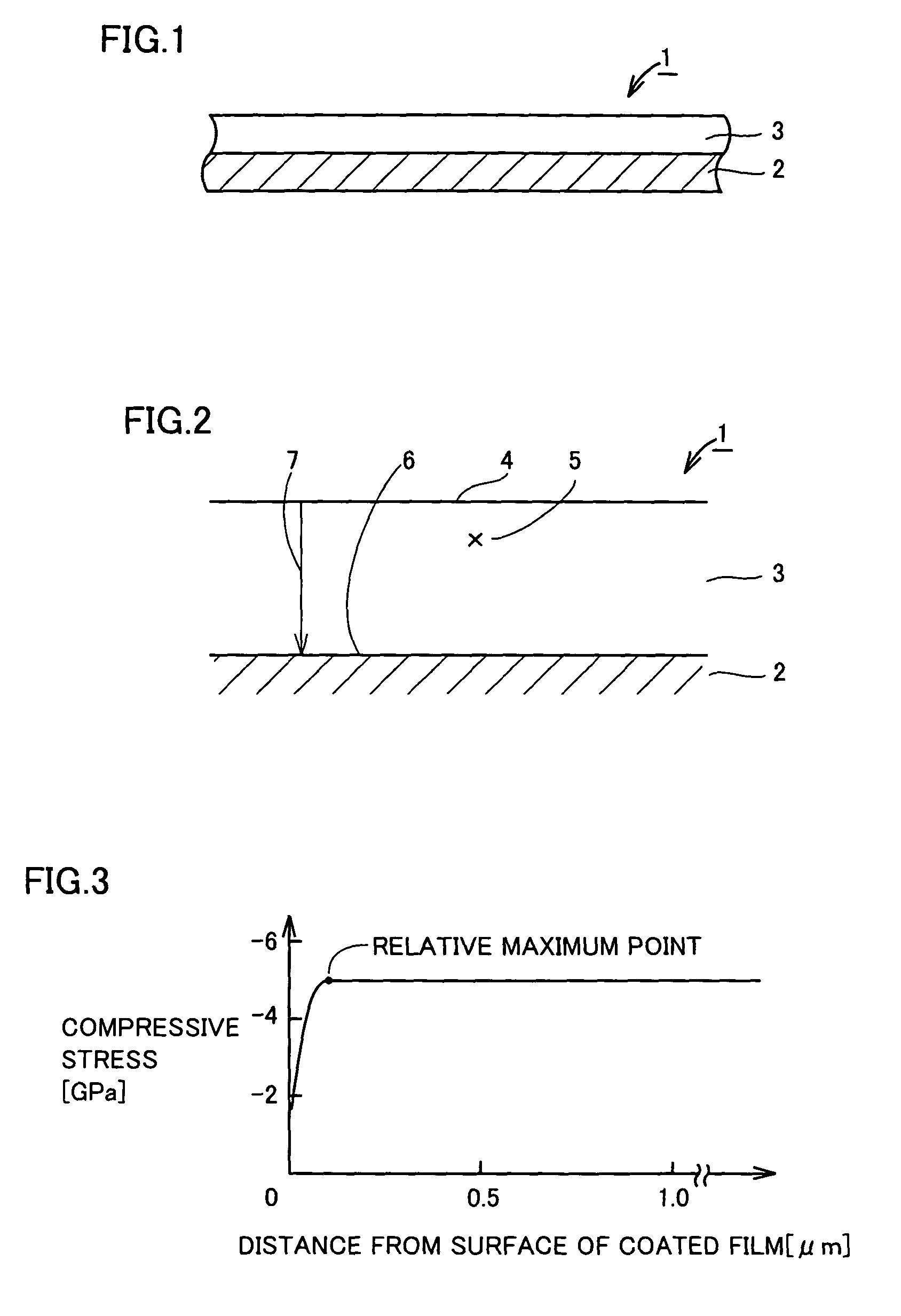

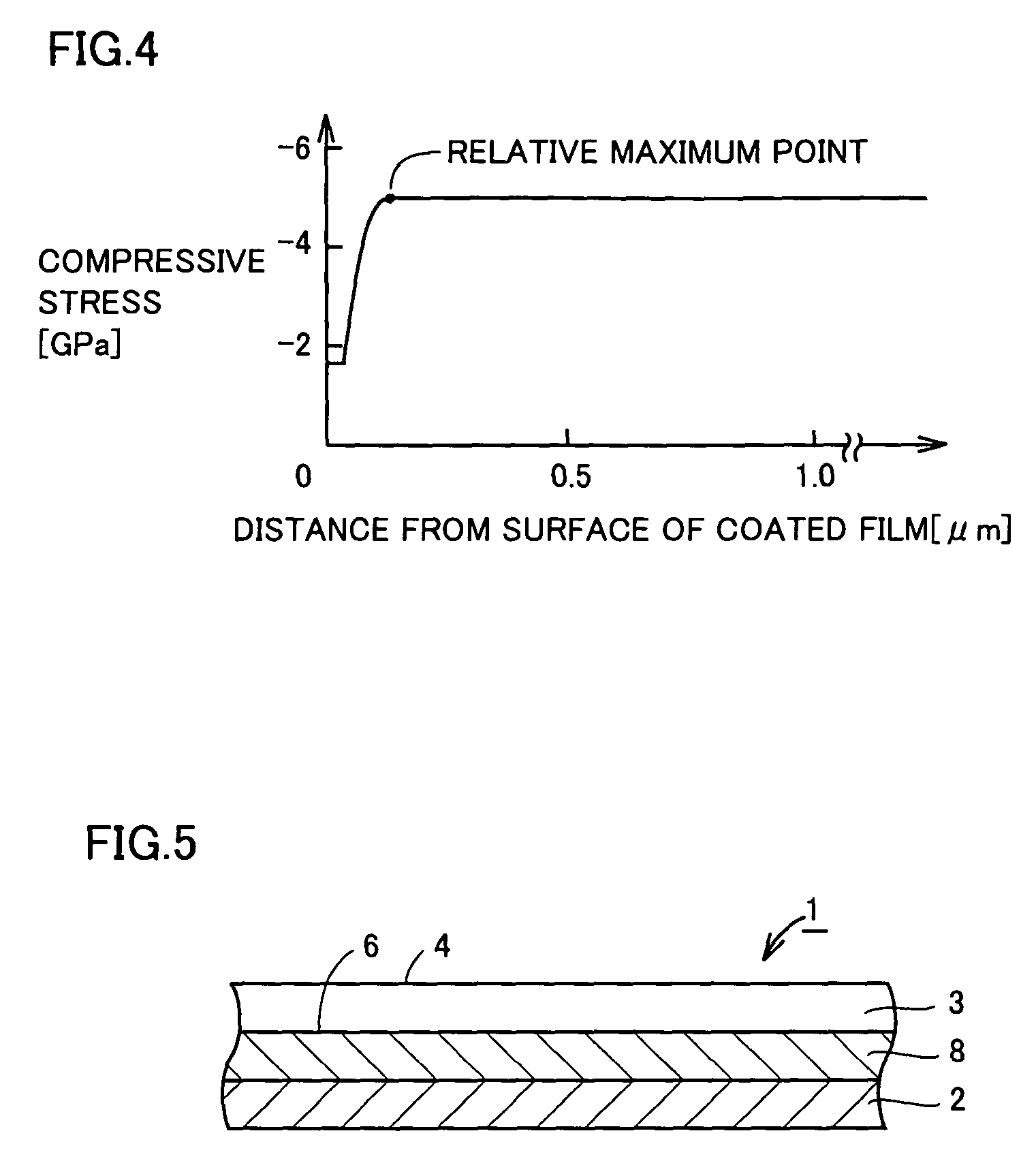

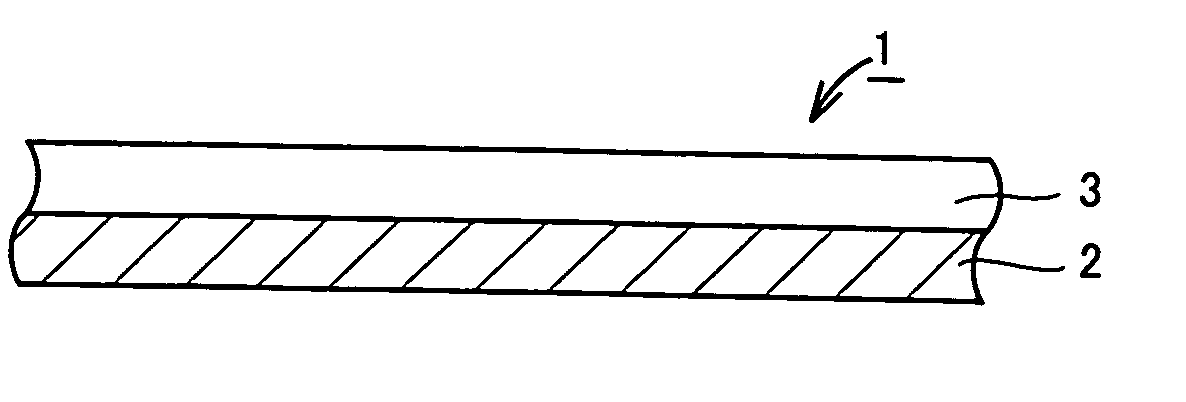

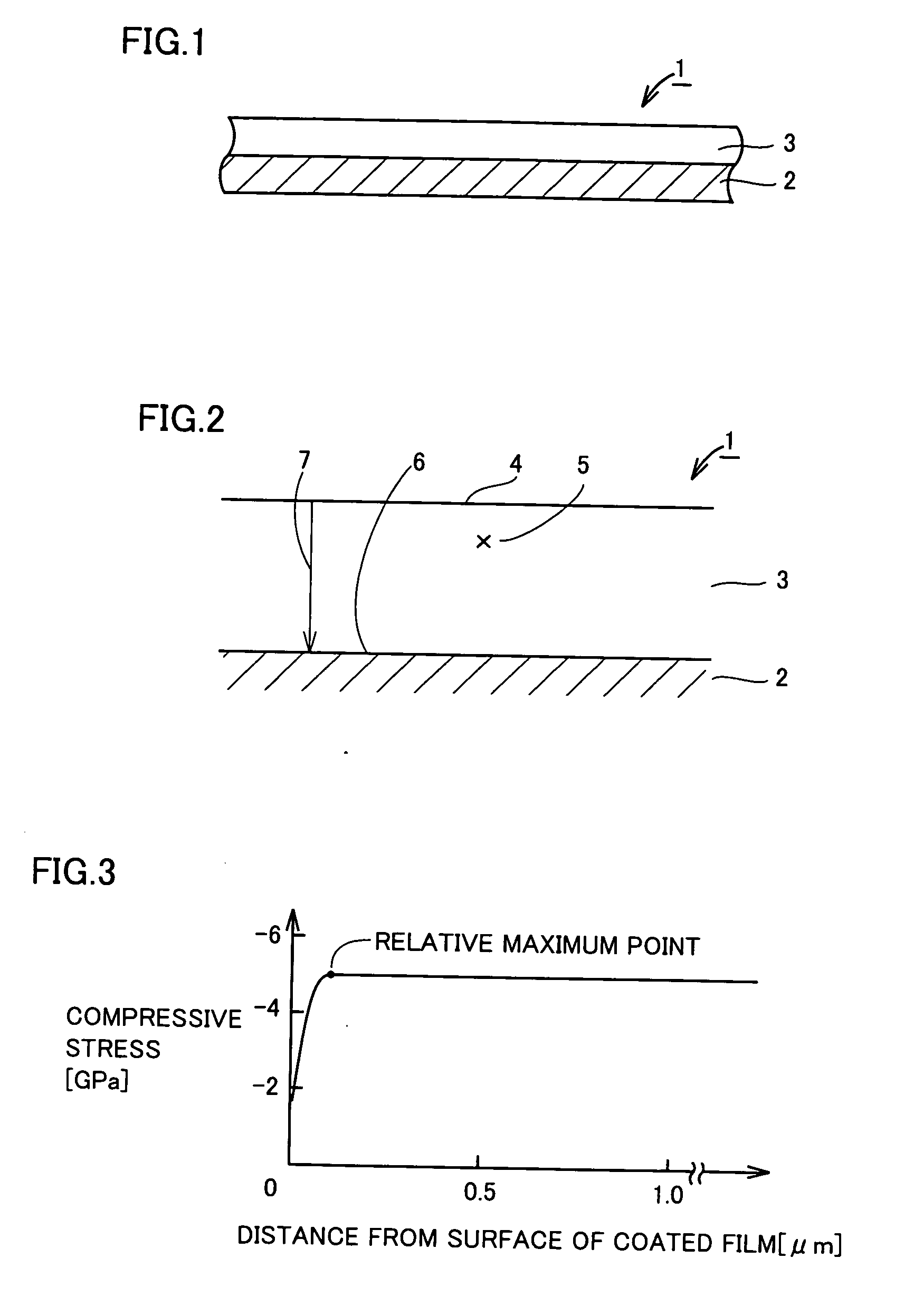

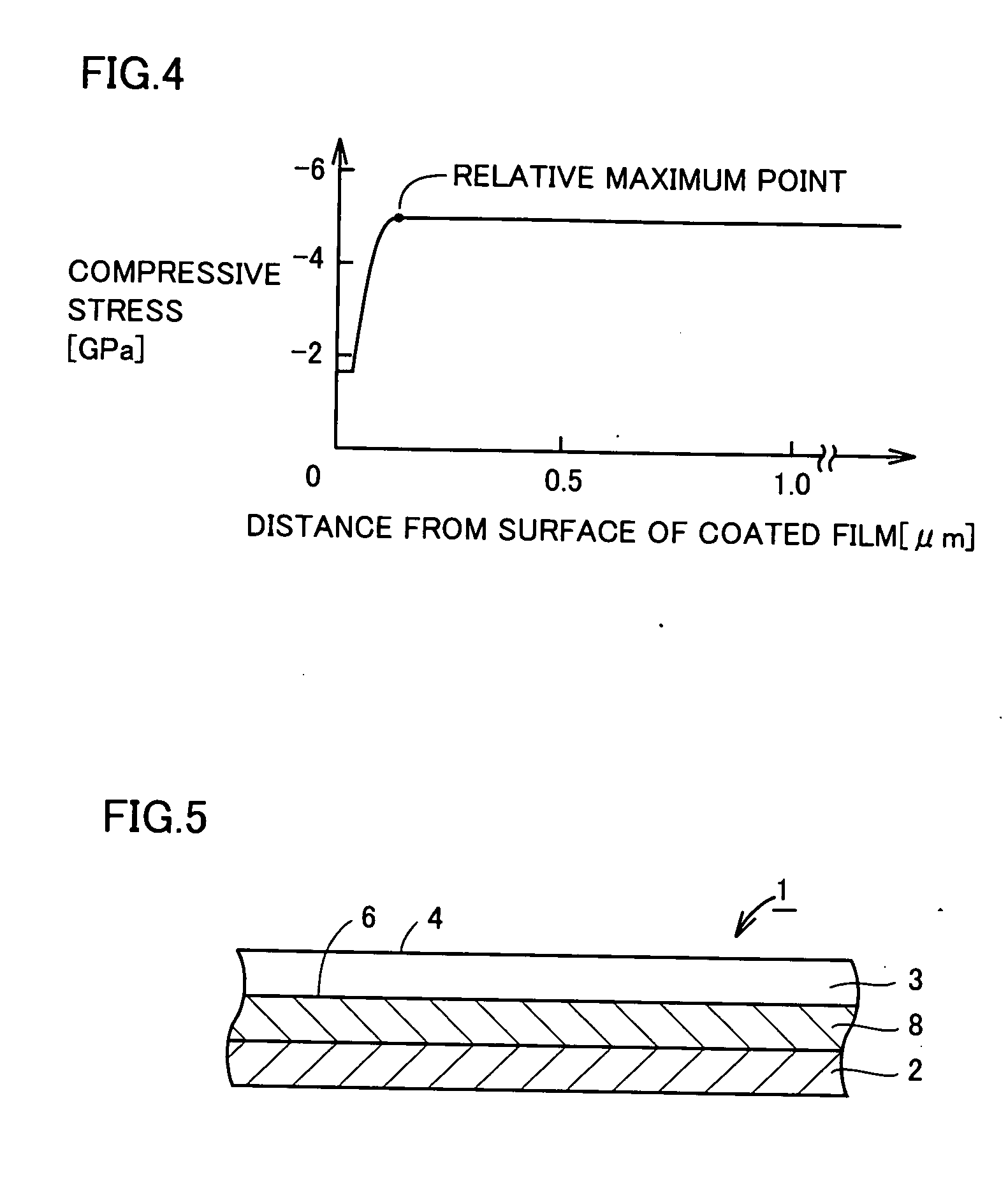

Surface-coated cutting tool with coated film having strength distribution of compressive stress

ActiveUS7758950B2Improve toughnessImprove the immunityMilling cuttersVacuum evaporation coatingRelative maximumCompressive strength

A surface-coated cutting tool according to the present invention includes a base material and a coated film formed on the base material. The coated film serves as an outermost layer on the base material and has compressive stress. The compressive stress is varied so as to have strength distribution in a direction of thickness of the coated film. The strength distribution is characterized in that the compressive stress at a surface of the coated film continuously increases from the surface of the coated film toward a first intermediate point located between the surface of the coated film and a bottom surface of the coated film and the compressive stress attains a relative maximum point at the first intermediate point.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP +1

Diversity receiver and transceiver

A diversity receiver (112) comprises a plurality of receiving paths connected to a receiver circuit (174). Each of the receiving paths comprises an antenna (114, 1 16) receiving a signal, connected to a matching network (170, 176) connected to a receive amplifier (172, 178). The receiver circuit is connected to a signal level comparison circuit for providing a relative comparison value indicating one of the receiving paths receiving the signal with a relative maximum strength. The signal level comparison circuit comprises a comparator circuit (182) connected to the receiver circuit receiving a currently received signal level, and to a logic control unit (180) being arranged to select one of the receive paths to provide the currently received signal to the receiver circuit.

Owner:NXP USA INC

Surface-coated cutting tool with coated film having strength distribution of compressive stress

ActiveUS20070184272A1Improve toughnessImprove wear resistanceMilling cuttersVacuum evaporation coatingRelative maximumCompressive strength

A surface-coated cutting tool according to the present invention includes a base material and a coated film formed on the base material. The coated film serves as an outermost layer on the base material and has compressive stress. The compressive stress is varied so as to have strength distribution in a direction of thickness of the coated film. The strength distribution is characterized in that the compressive stress at a surface of the coated film continuously increases from the surface of the coated film toward a first intermediate point located between the surface of the coated film and a bottom surface of the coated film and the compressive stress attains a relative maximum point at the first intermediate point.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP +1

Liquid crystal display

A liquid crystal display (LCD) including a backlight module and a LCD panel is provided. The backlight module has at least one white light source. BL1 and BL2 respectively represent a relative maximum brightness peak of an emission spectrum of the backlight module at a wavelength from 445 nm to 448 nm and from 510 nm to 520 nm. The LCD panel including two substrates and a liquid crystal layer sandwiched between the two substrates is disposed above the backlight module. One of the two substrates has a red filter layer, a green filter and a blue filter layer. Specially, Gx represents an x coordinate in a CIE 1931 chromaticity diagram when the green filter layer uses a CIE standard light source C, and Gx is larger than or equal to 0.286 (Gx≧20.286).

Owner:AU OPTRONICS CORP

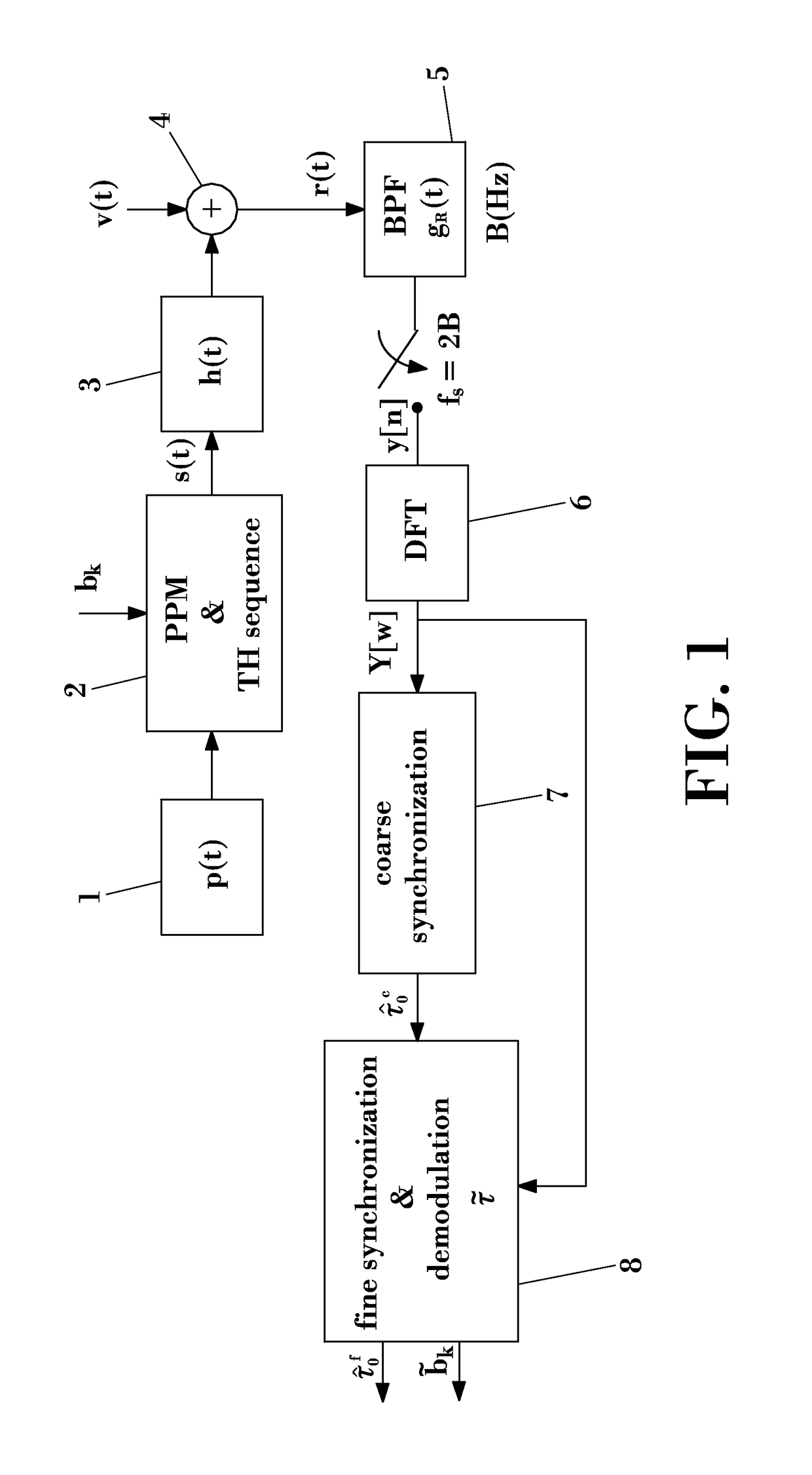

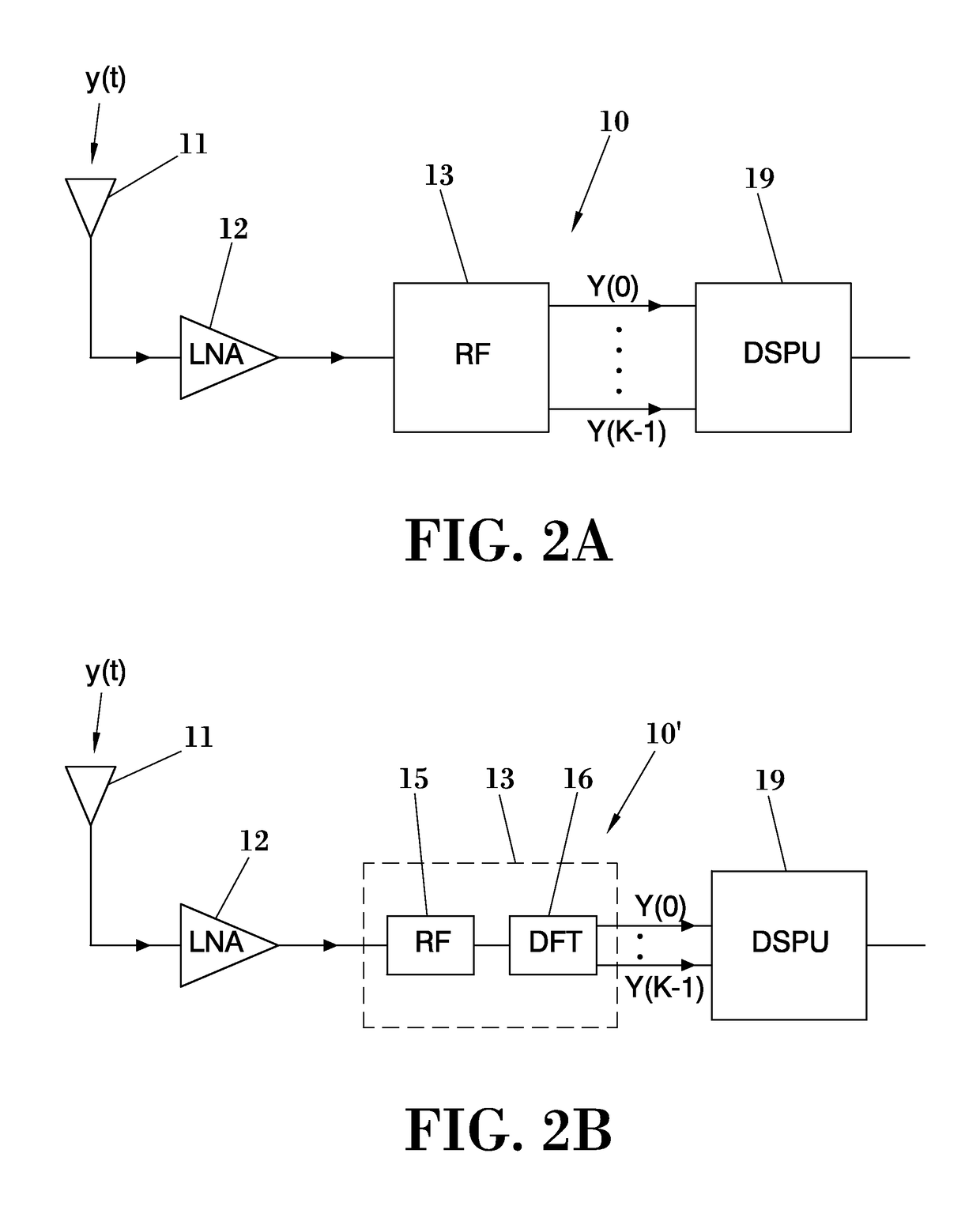

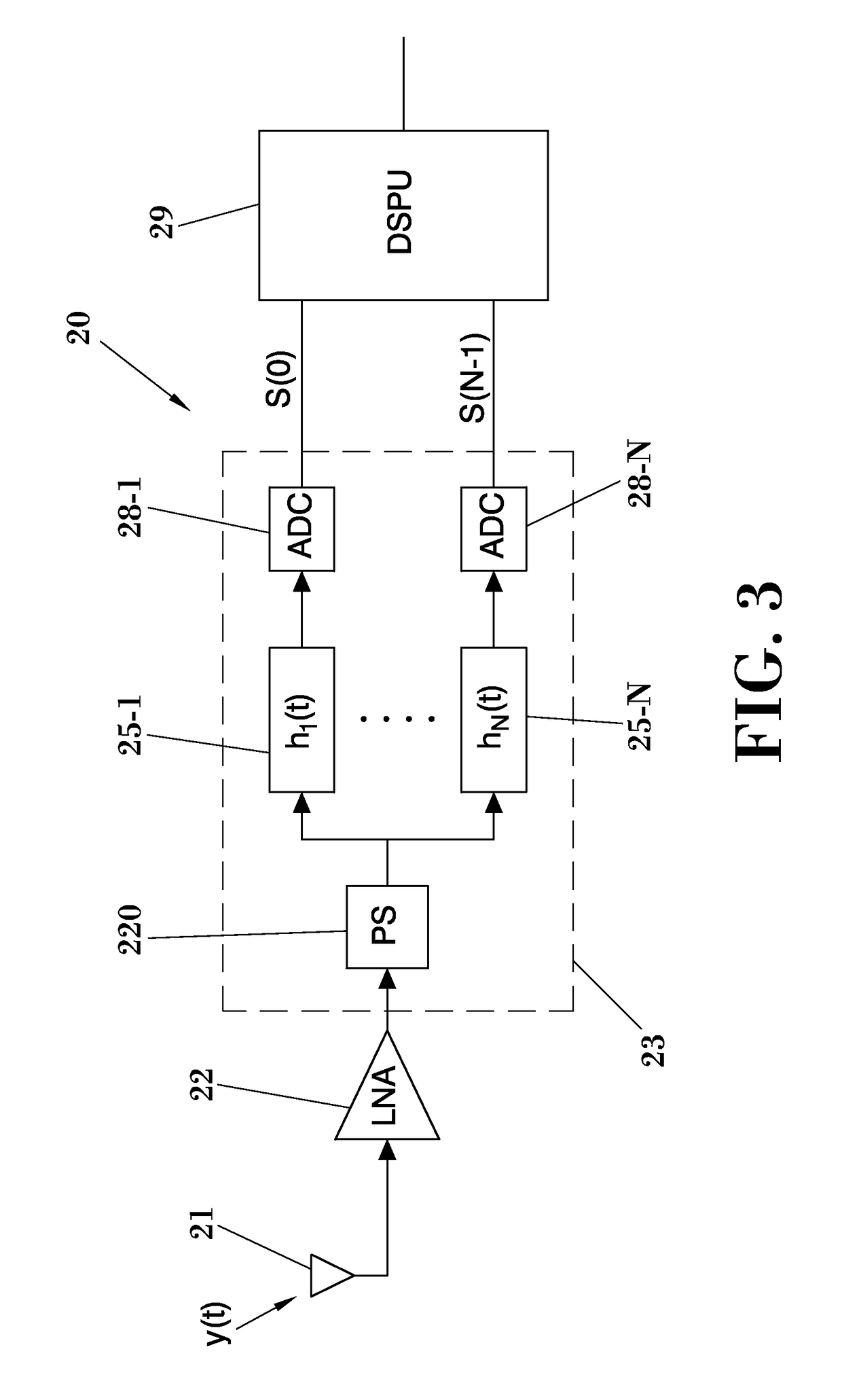

Joint demodulation and synchronization in ultra wideband systems

InactiveUS8472500B2Drawback can be solvedTime-division multiplexAmplitude-modulated carrier systemsUltra-widebandStage iib

A method of demodulating at a receiver a plurality of symbols bk comprised in a e.g. UWB, received signal y(t), said receiver having knowledge of a time hopping sequence vector c of the transmitted signal, said method comprising the step of: generating a plurality of frequency-domain samples from the received signal y(t). It further comprises the steps of: from said plurality of frequency-domain samples and said time hopping sequence vector c, applying a coarse estimation stage (7) for identifying the beginning of a first complete symbol (formula A) in an acquisition interval; applying a stage for fine estimation (8) of the time delay (formula B) of each symbol bk, wherein k denotes the k-th symbol, by searching a relative maximum at which a signal energy distribution exceeds a certain threshold Pth; from said fine estimation of the time delay (formula B) of each symbol bk, demodulating (formula C) said symbols bk.

Owner:FUNDACIO PRIVADA CENT TECNOLOGIC DE TELECOMUNICACIONS DE CATALUNYA

Snubber circuit and buffering method for snubber circuit

ActiveCN104426344AReduce/eliminate power lossLong reverse current recovery timeEfficient power electronics conversionDc-dc conversionCapacitanceElectricity

A snubber circuit includes a capacitor and a buffer device. The buffer device has a first terminal and a second terminal. The first terminal is electrically connected to the capacitor. When the buffer device operates in a first conduction mode, a charge current flows from the second terminal to the first terminal through the buffer device. When the buffer device switches from the first conduction mode to a second conduction mode, the buffer device generates a discharge current which flows from the first terminal to the second terminal through the buffer device over a specific period of time, such that after the buffer device enters the second conduction mode, a relative maximum voltage level appearing first at the second terminal is lower than a voltage level at the first terminal.

Owner:SPI ELECTRONICS

Vapor axial deposition apparatus and vapor axial deposition method

InactiveUS20070084248A1Quality improvementEase of mass productionGlass deposition burnersVertical furnacesGas phaseEngineering

Disclosed is a vapor axial deposition apparatus. The vapor axial deposition apparatus includes a first torch, a second torch, a temperature measuring unit and a controller unit. The first torch deposits soot on a distal end of a soot preform aligned with a vertical axis to thereby grow a core. The second torch deposits soot on an outer circumferential surface of the core to thereby grow a clad. The temperature measuring unit detects the temperature distribution of an end portion of the soot preform along the vertical axis. The controller unit determines first and second relative maximum temperatures T1 and T3, and relative minimum temperature T2 between T1 and T3 in the detected temperature distribution, and controls T1 to be within a predetermined range and the greater one of the difference (T1−T2) and (T3−T2) to not exceed a predetermined temperature.

Owner:SAMSUNG ELECTRONICS CO LTD +1

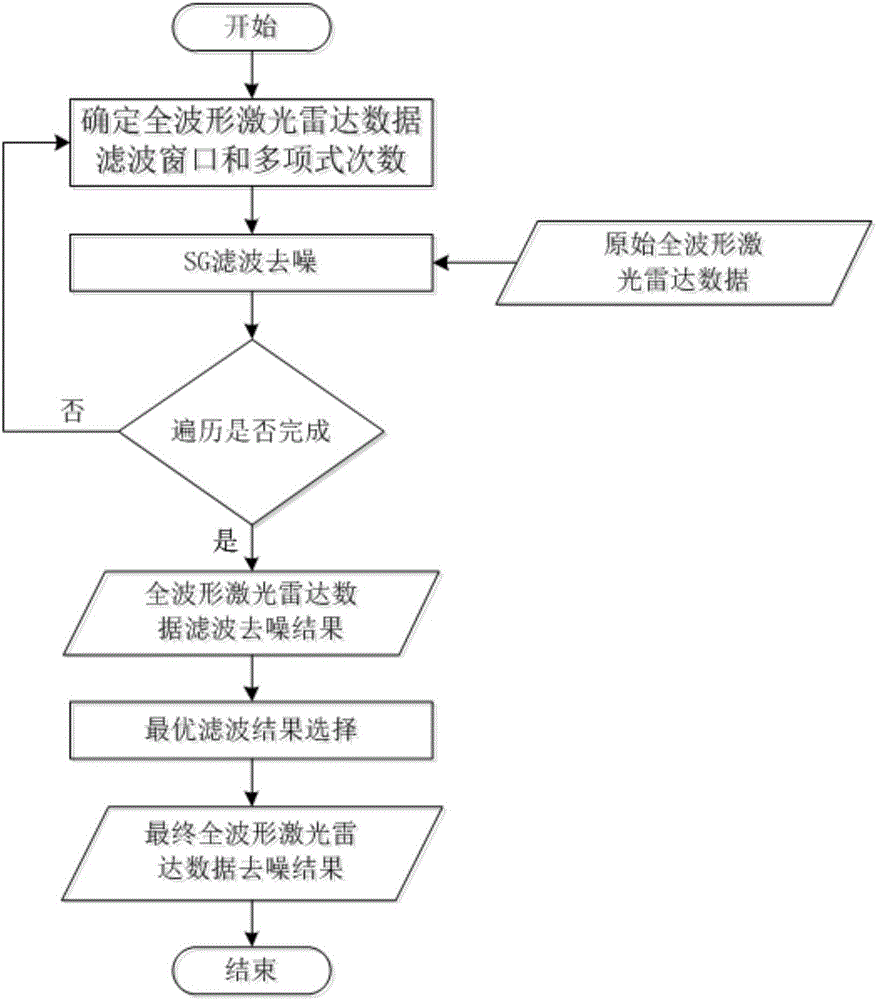

Full-waveform laser radar data denoising method for satellite laser altimeter

ActiveCN105929380AEffectively remove noiseCancel noiseElectromagnetic wave reradiationComputation complexityRadar

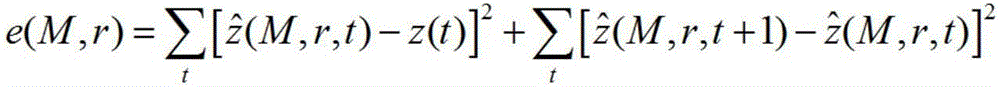

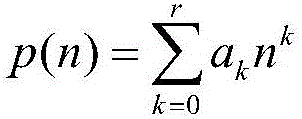

The invention discloses a full-waveform laser radar data denoising method for a satellite laser altimeter, and the method comprises the following steps: (1), determining a full-waveform laser radar data filtering window and a polynomial degree change range; (2), carrying out the sliding fitting of original full-waveform laser data through employing the least square method, solving a convolution coefficient, carrying out the convolution calculation of the original full-waveform laser data through the convolution coefficient, completing the SG filtering, and obtaining denoised original full-waveform laser data; (3), repeatedly carrying out steps (1)-(2), and carrying out the traversal of all possible combinations of the full-waveform laser radar data filtering window and polynomial degrees; (4), extracting an optimal filtering result. The method provided by the invention can effectively remove the noise of the full-waveform laser radar data, is low in calculation complexity, and can effectively maintain the relative maximum and minimum values and pulse width of the original full-waveform laser data.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

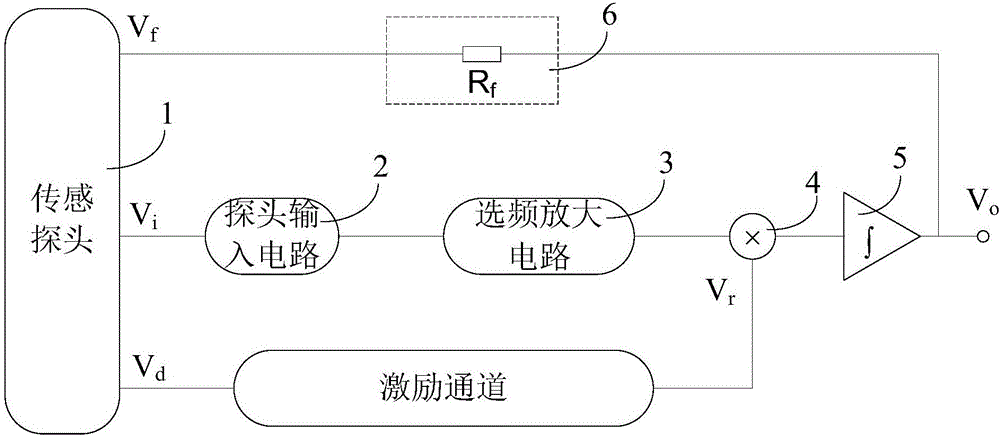

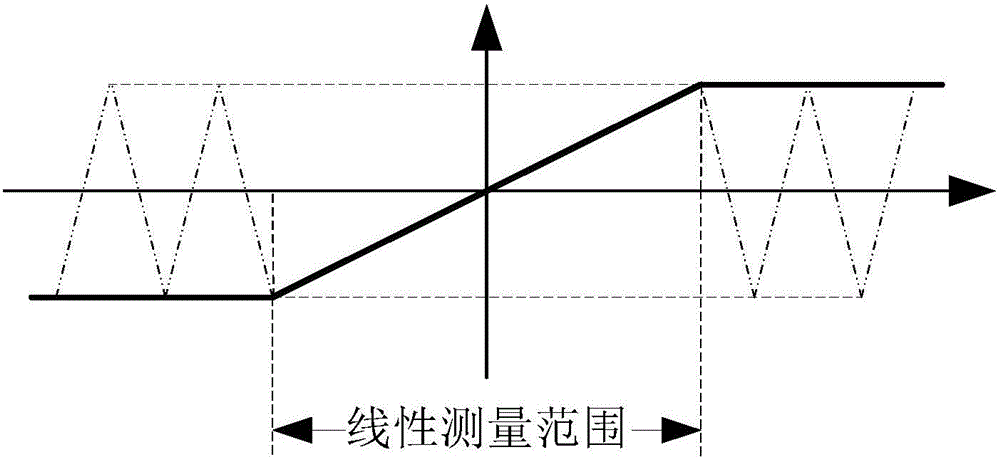

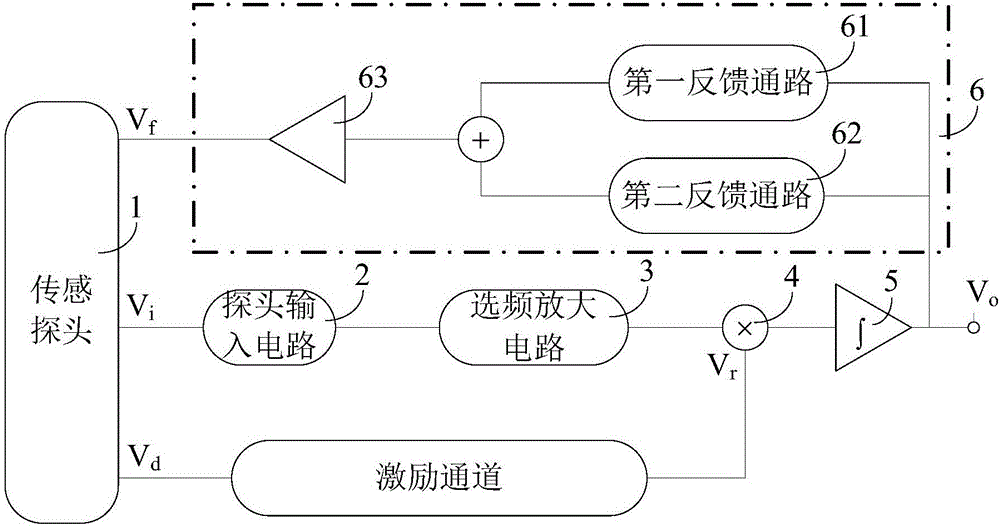

Signal detection circuit of magnetic-flux-gate magnetometer, and the magnetic-flux-gate magnetometer

ActiveCN106443805AResolve resolutionSolve the problem of allowing large signal inputElectric/magnetic detectionAcoustic wave reradiationNegative feedbackImage resolution

The invention relates to the technical field of seismic, and discloses a signal detection circuit of a magnetic-flux-gate magnetometer, and the magnetic-flux-gate magnetometer. The signal detection circuit includes a signal channel and an excitation channel, wherein the signal channel acquires a magnetic field signal from a sensing probe; the excitation channel outputs an excitation signal to the sensing probe; the signal channel includes successively connected probe input circuit, frequency selection amplification circuit, phase sensitive detection circuit, integrating circuit and feedback circuit; the feedback circuit comprises a first feedback path and a second feedback path; the first feedback path is configured as a linear feedback circuit; the second feedback path is connected with the first feedback path in parallel, and is configured as a non-linear feedback circuit; and the second feedback path works when the magnetic field signal detected by the sensing probe reaches the relative maximum measuring range for observation. The signal detection circuit of a magnetic-flux-gate magnetometer utilizes the non-linear negative feedback method, and converts different feedback branches when a small signal is input and when a large signal is input, thus solving the problem that a traditional signal detection circuit cannot give consideration to both the resolution of the signal and allowance of input of the large signal.

Owner:INST OF GEOPHYSICS CHINA EARTHQUAKE ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com