Vapor axial deposition apparatus and vapor axial deposition method

A vapor-phase axial deposition, vertical axis technology, used in glass deposition furnaces, glass manufacturing equipment, glass production, etc., can solve the problem of difficulty in maintaining focus, not fully considering the overall temperature distribution of soot preforms, and reducing the quality of soot preforms. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. It should be noted that the same reference numerals are used to designate the same elements even though they are illustrated in different drawings. And, in the following description, a detailed description of well-known functions and structures incorporated herein will be omitted when it may obscure the subject matter of the present invention.

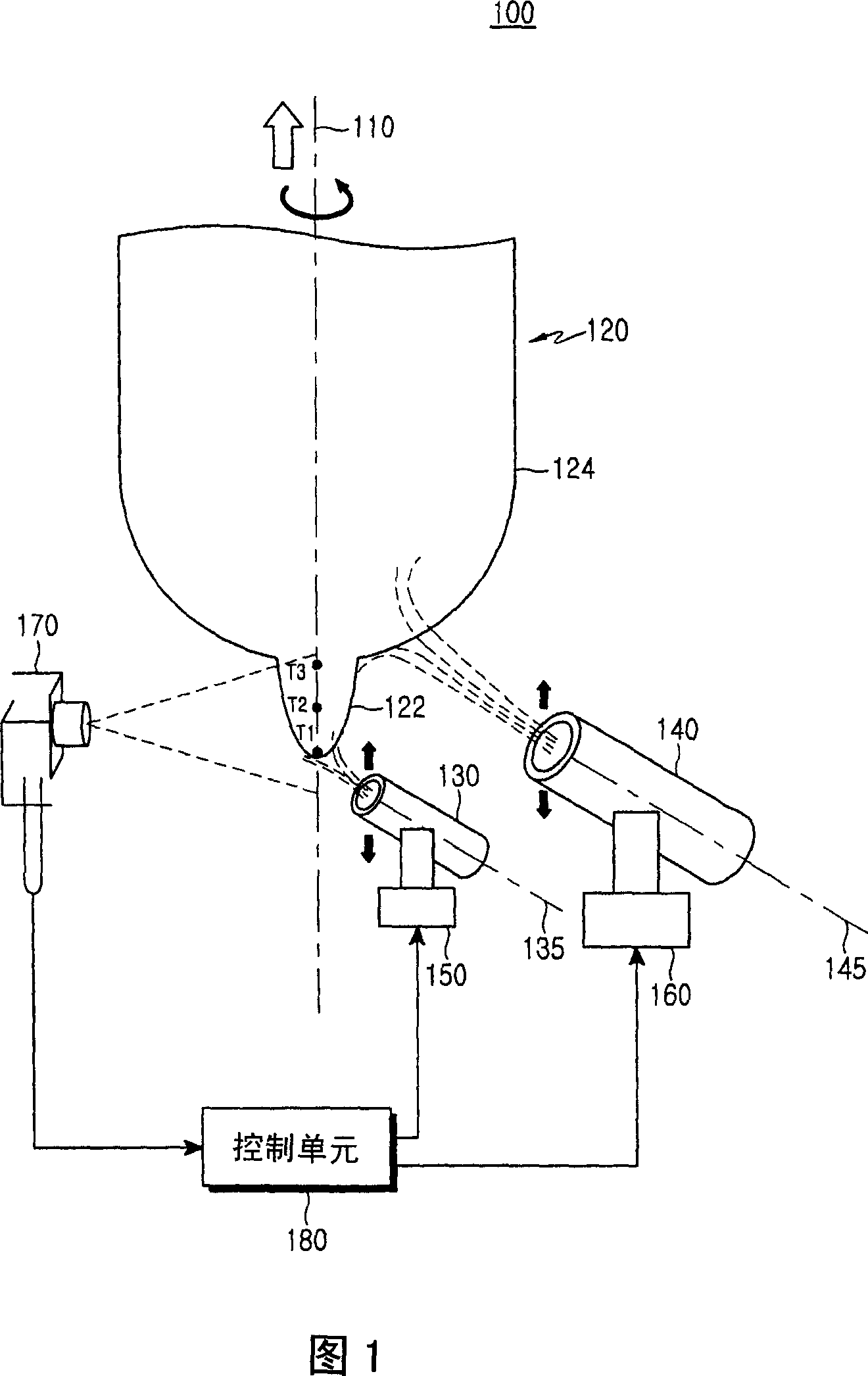

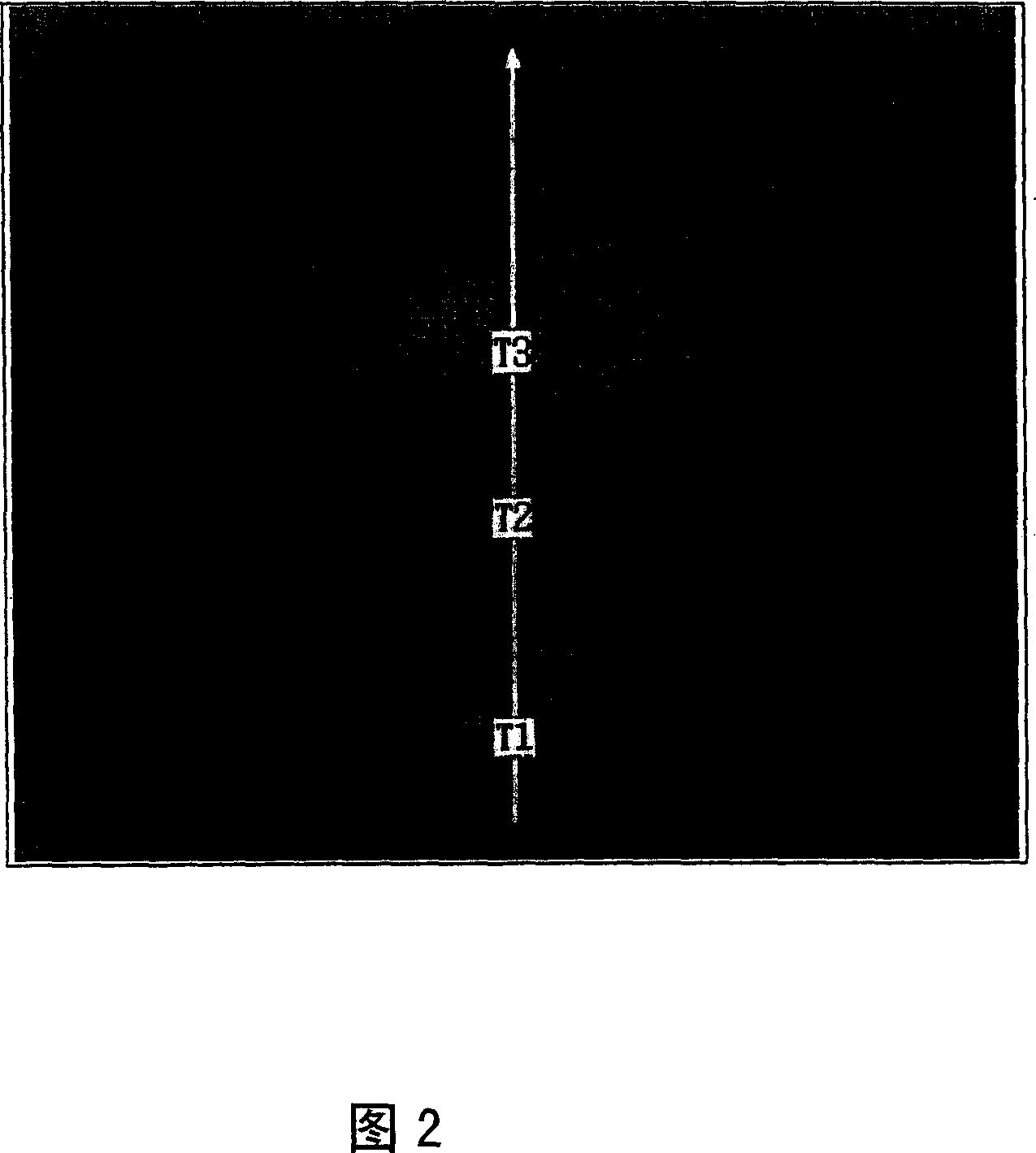

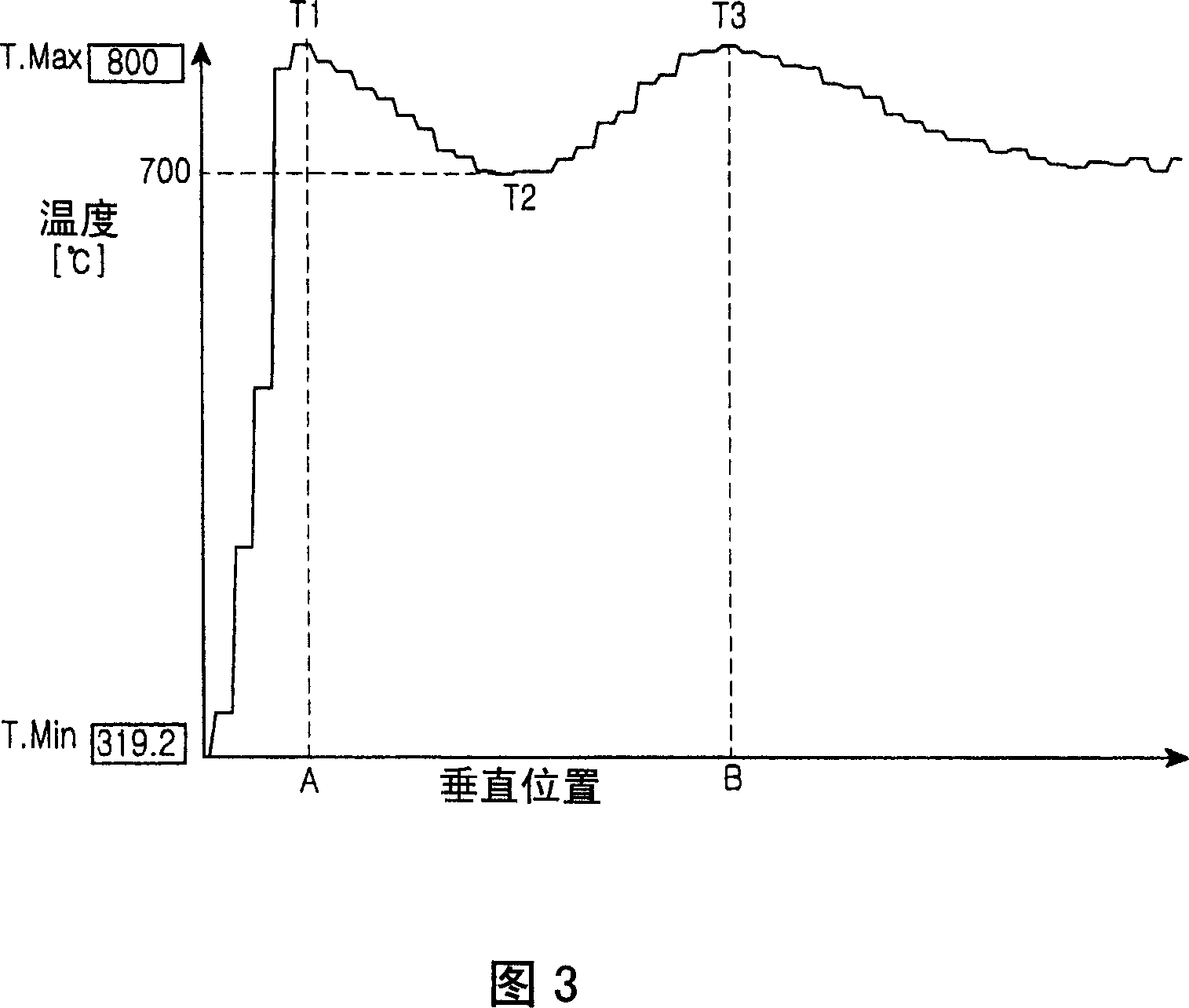

[0018] Fig. 1 illustrates a vapor phase axial deposition apparatus according to a preferred embodiment of the present invention. The vapor phase axial deposition apparatus 100 includes: first and second torches 130, 140 for generating and depositing soot; first and second tables 150, 160 for tilting the first and second torches, respectively; temperature measurement A unit 170, a temperature measuring unit 170 for detecting the temperature distribution of the end of the soot preform along the vertical axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com