Last stage rotor blade of steam turbine

A technology of steam turbine and moving blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

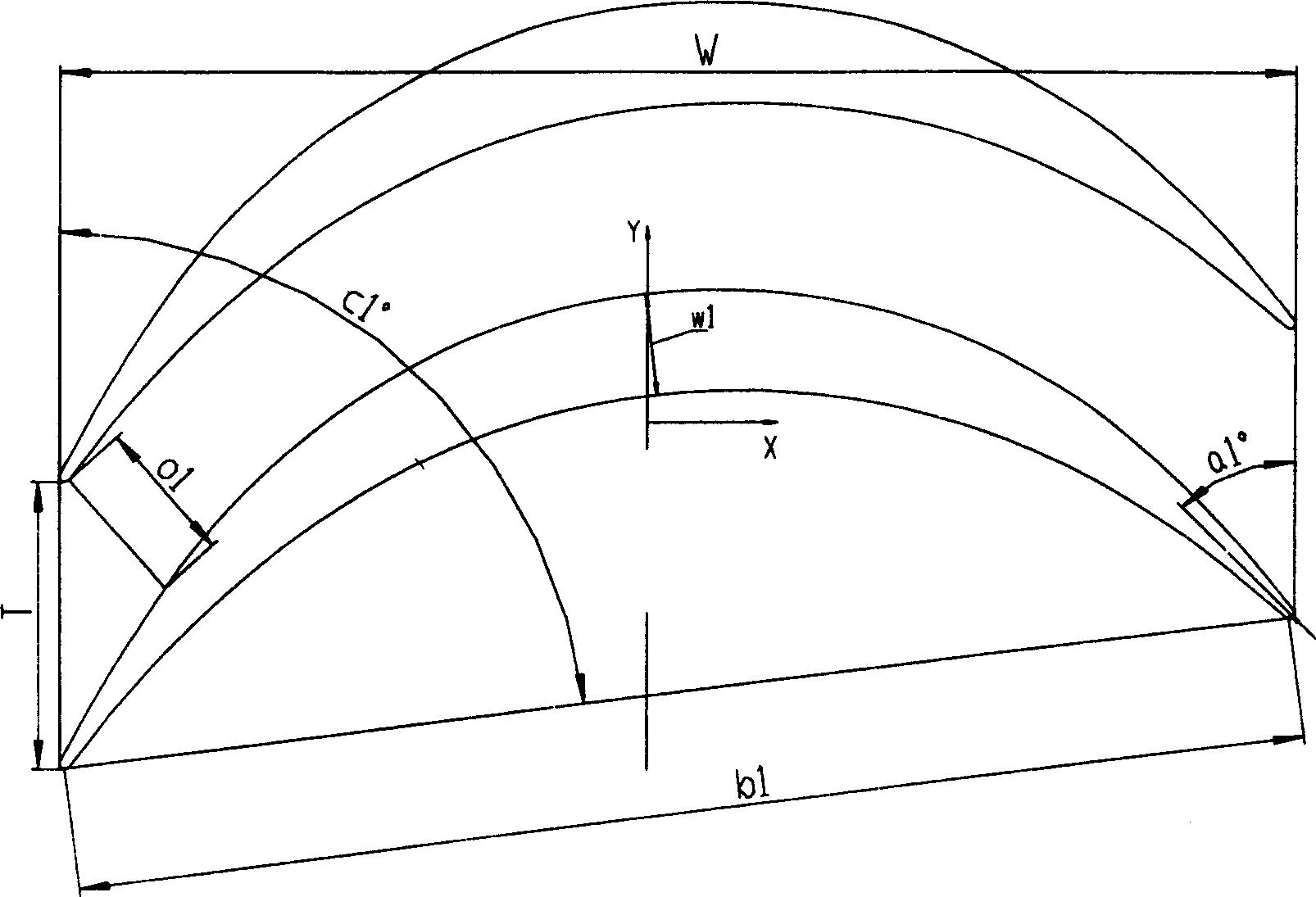

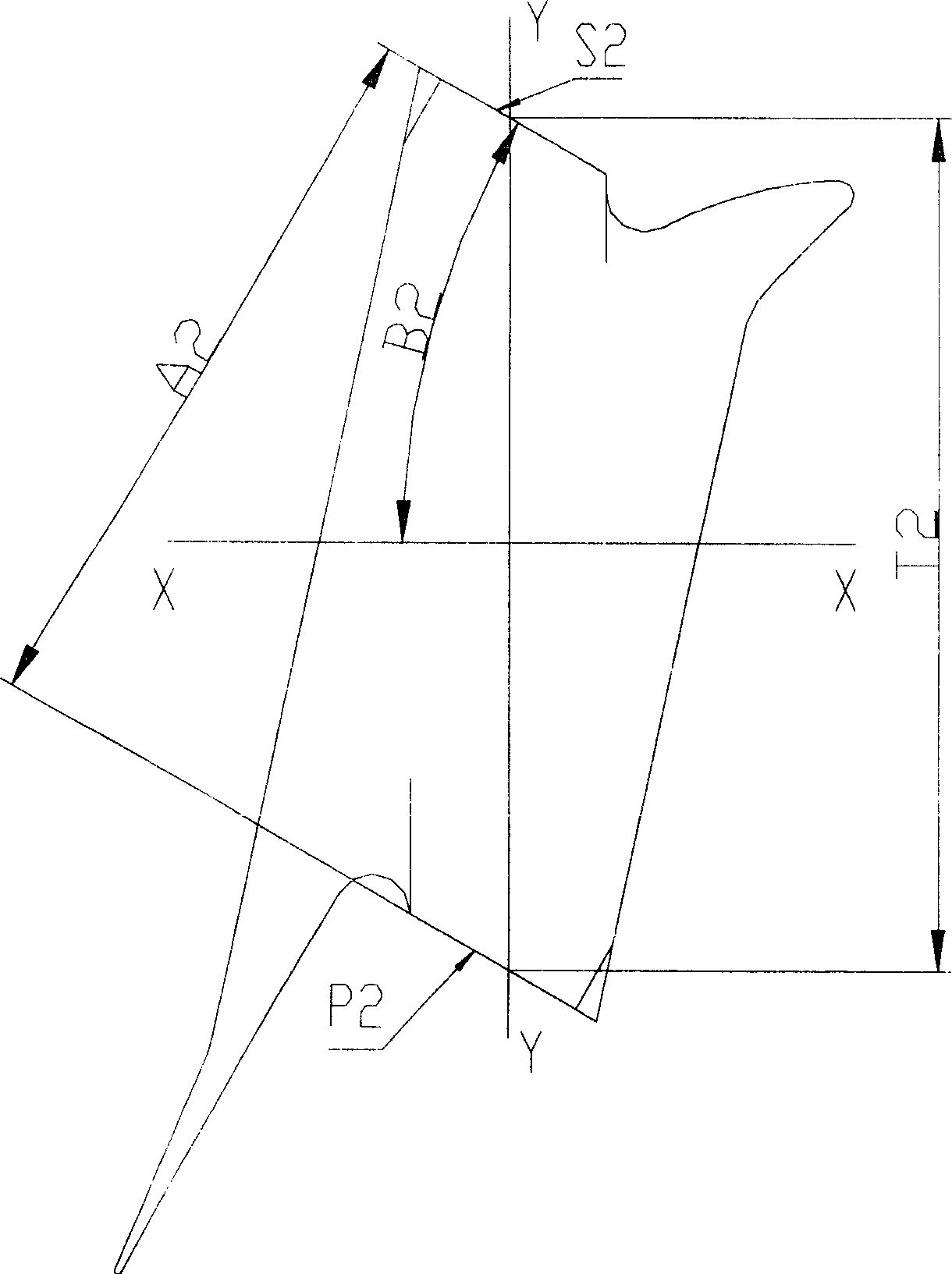

[0026] Now take the 1200mm moving blade used for 4F-1000MW class steam turbine as an example to describe the present invention in detail.

[0027] The design back pressure of the steam turbine is 5.0Kpa. Within this design back pressure range, the air passage height of the final moving blade (that is, the effective height of the blade, and the length of the blade body part) H of the final plan is 1200mm. The root diameter (that is, the diameter of the circle where the root section of the blade body is located after the blade is installed on the rotor, which is also the diameter of the rotor rim) Dr is 1905mm, and its annular area is greater than 11.6m 2 , based on the root diameter Dr and leaf height H, the flow of the low-pressure module is designed. The design principle is that the last three stages of the low-voltage are used as a building block to carry out flow-matching design. stream module. Given the low-pressure inlet pressure, enthalpy, flow rate and back pressure, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com