Fire path structure of a carbon roasting furnace

A carbon roasting furnace and fire channel technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of high stress on fire channel walls and guide bricks, uneven distribution of gas flow field in the fire channel, and quality deviation of roasting anodes. and other problems, to achieve the effect of reducing thermal energy loss, improving anode baking quality, and reducing anode consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described through the description of specific embodiments below, but the protection scope of the present invention is not limited by the examples. Those skilled in the art can make various modifications or improvements according to the basic concept of the invention, but as long as they do not deviate from the basic concept of the present invention, they all fall within the scope of the present invention.

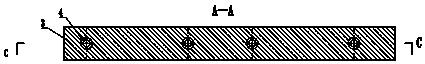

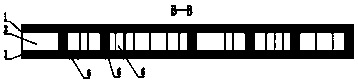

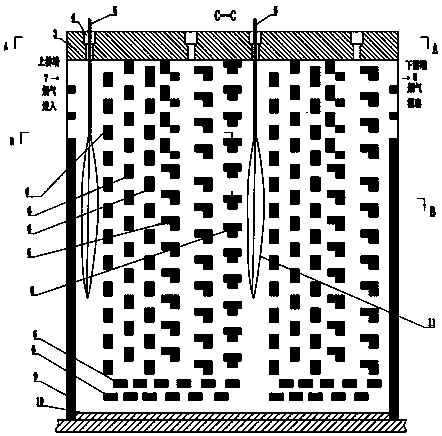

[0034] As shown in the figure, the present invention is an anode roasting furnace flue structure, including two side walls (1), two end walls (9), a cavity surrounded by a top plate (3) and a bottom plate (10), the cavity Guide bricks (6) are set inside. The roof (3) in the fireway structure is made of refractory materials, and four observation holes (4) are provided, and gas nozzles (5) can be inserted into two of the observation holes, and gas can be injected into the combustion (11). The arrangement is biased towards the upst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com