Patents

Literature

234 results about "Sub critical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

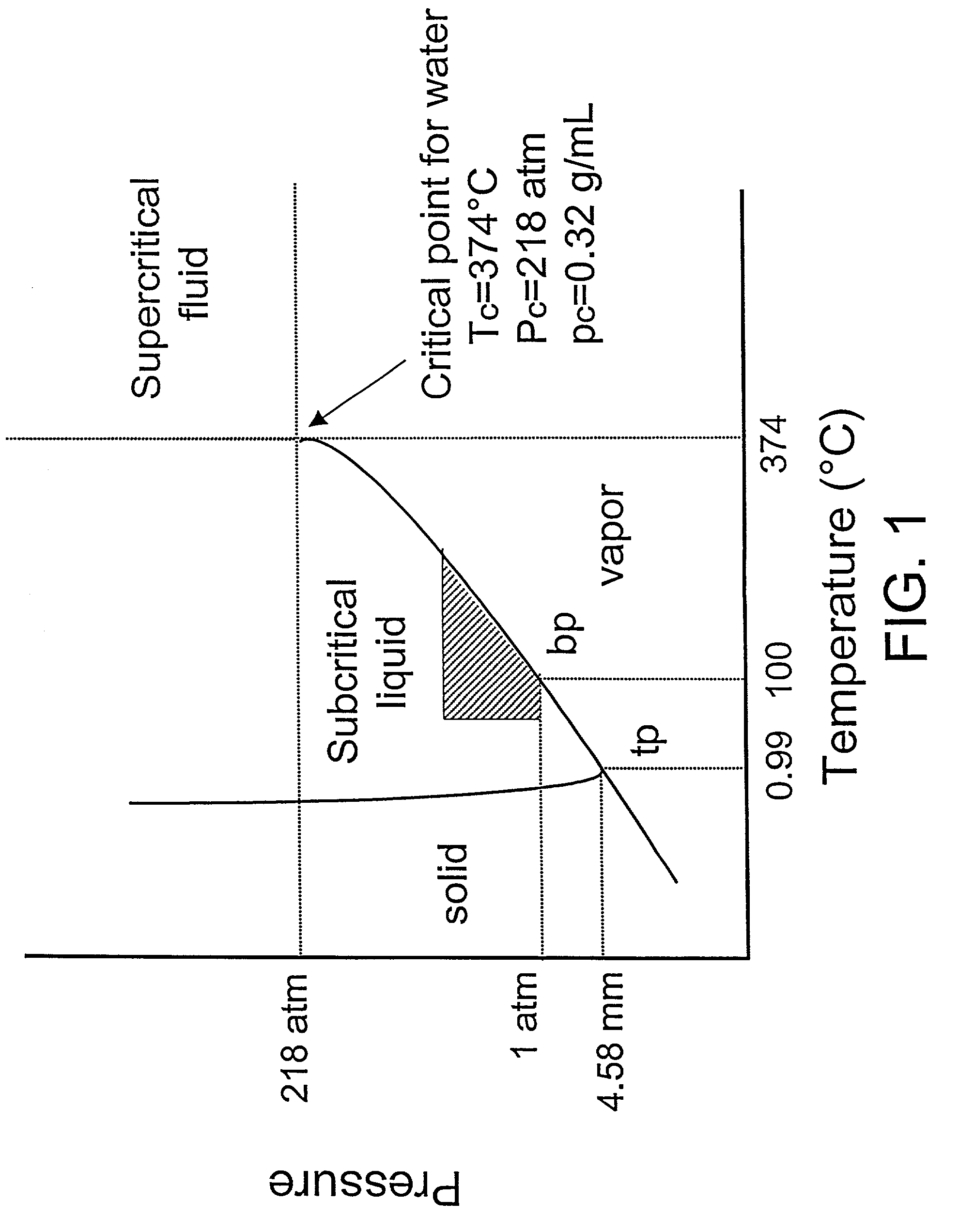

Definition of subcritical. 1 : less or lower than critical in respect to a specified factor. 2a : of insufficient size to sustain a chain reaction a subcritical mass of fissionable material.

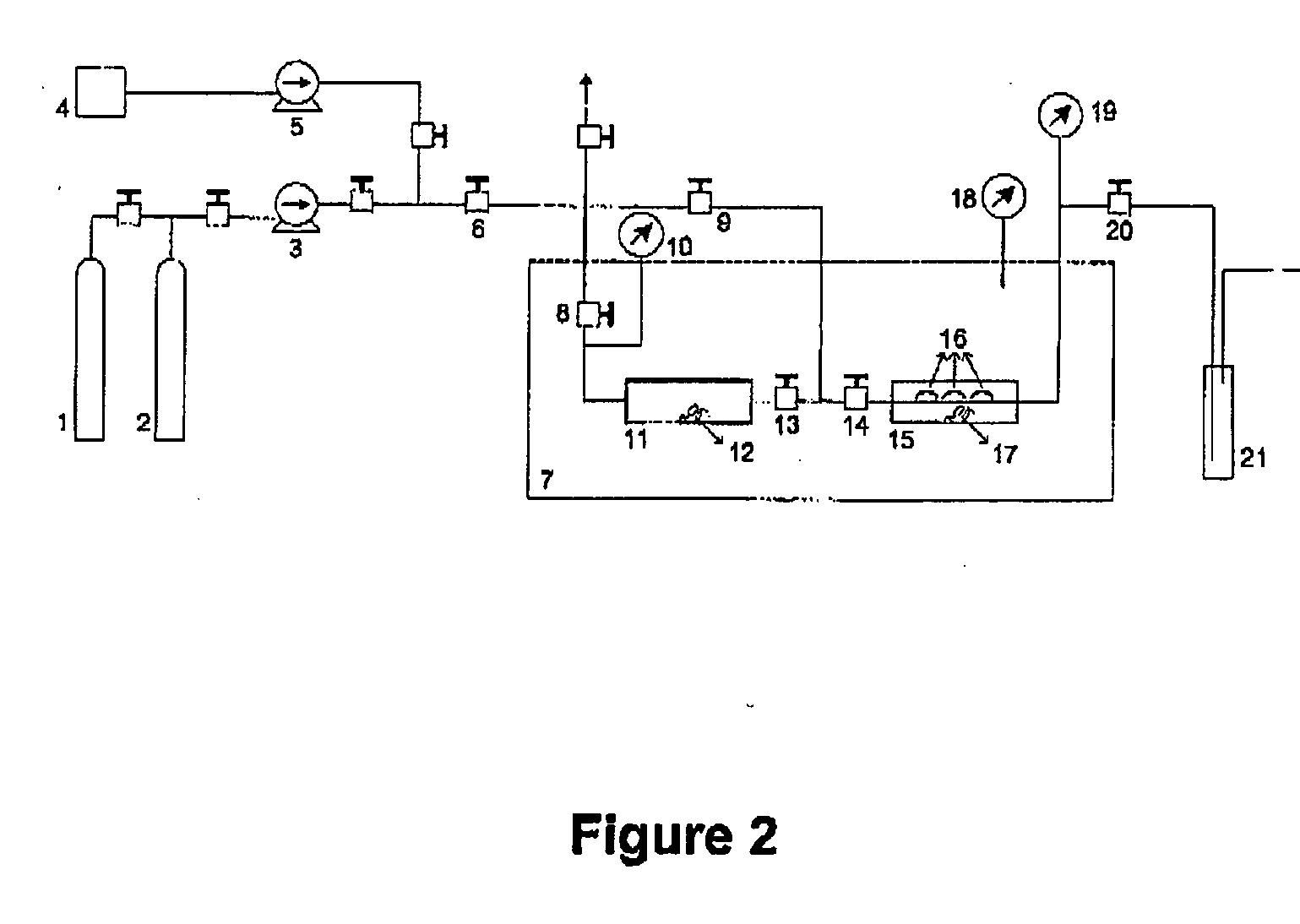

Apparatus and methods for increasing the rate of solute concentration evolution in a supercritical process chamber

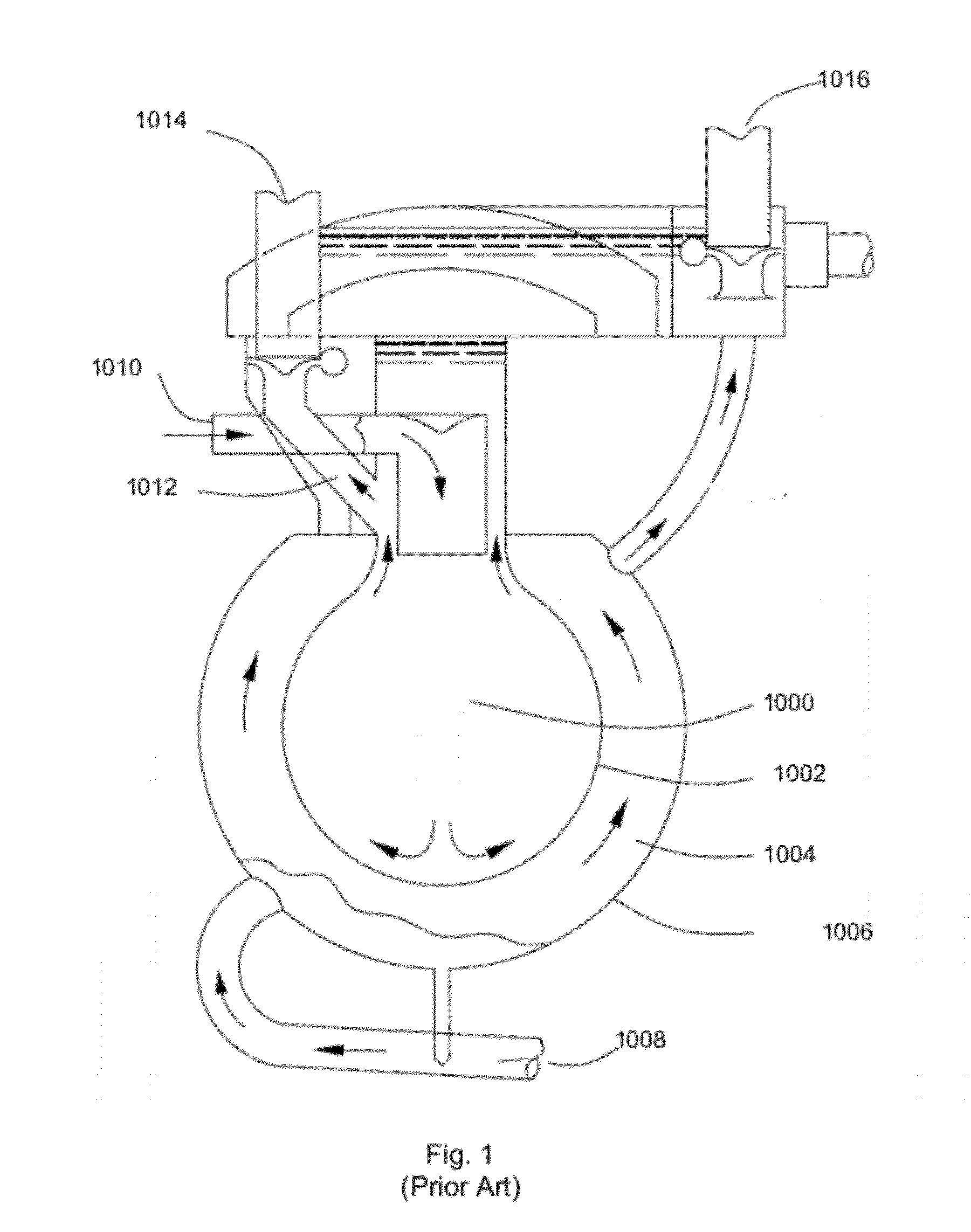

InactiveUS20080264443A1Avoid re-introductionSemiconductor/solid-state device manufacturingCleaning using liquidsChemical physicsMomentum

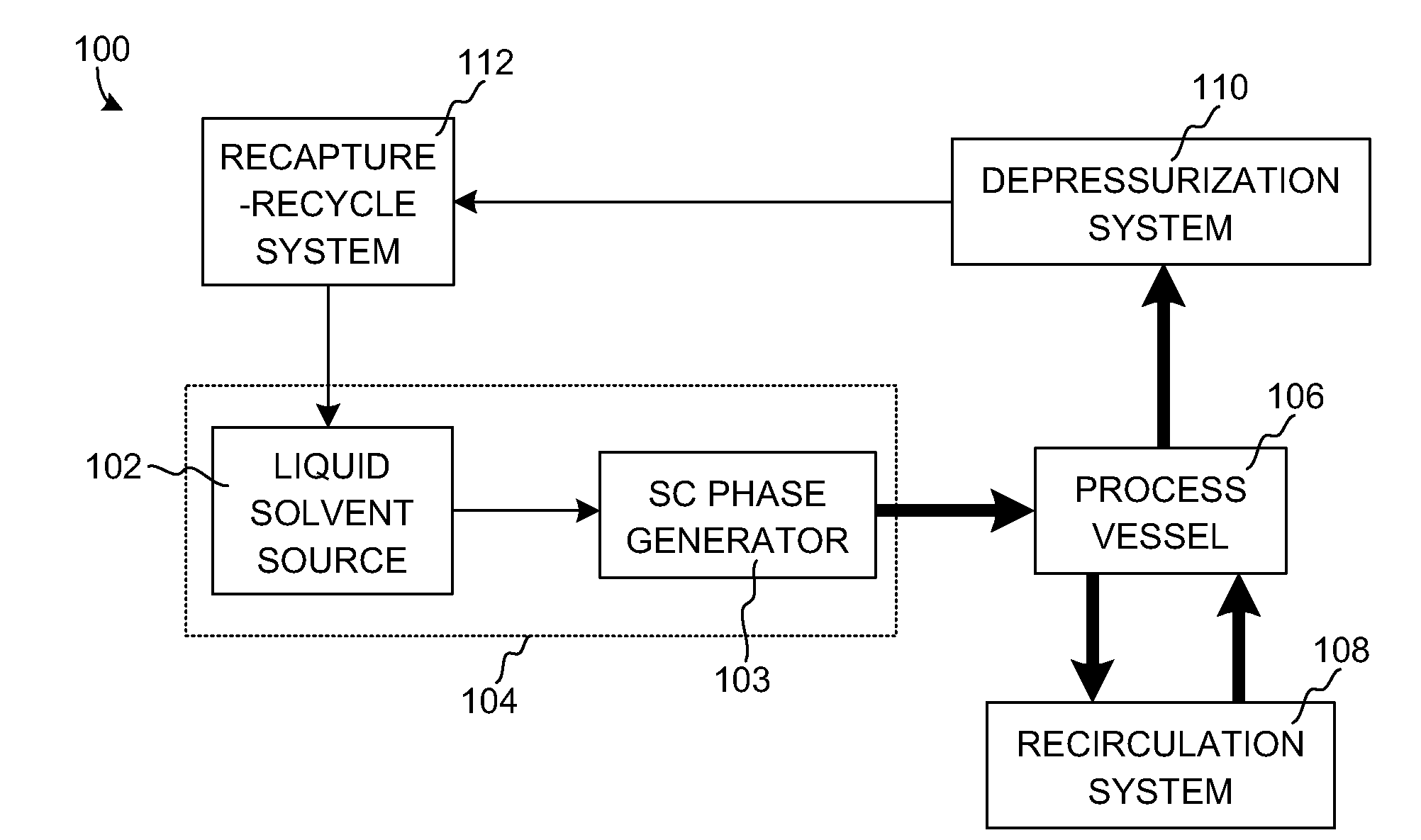

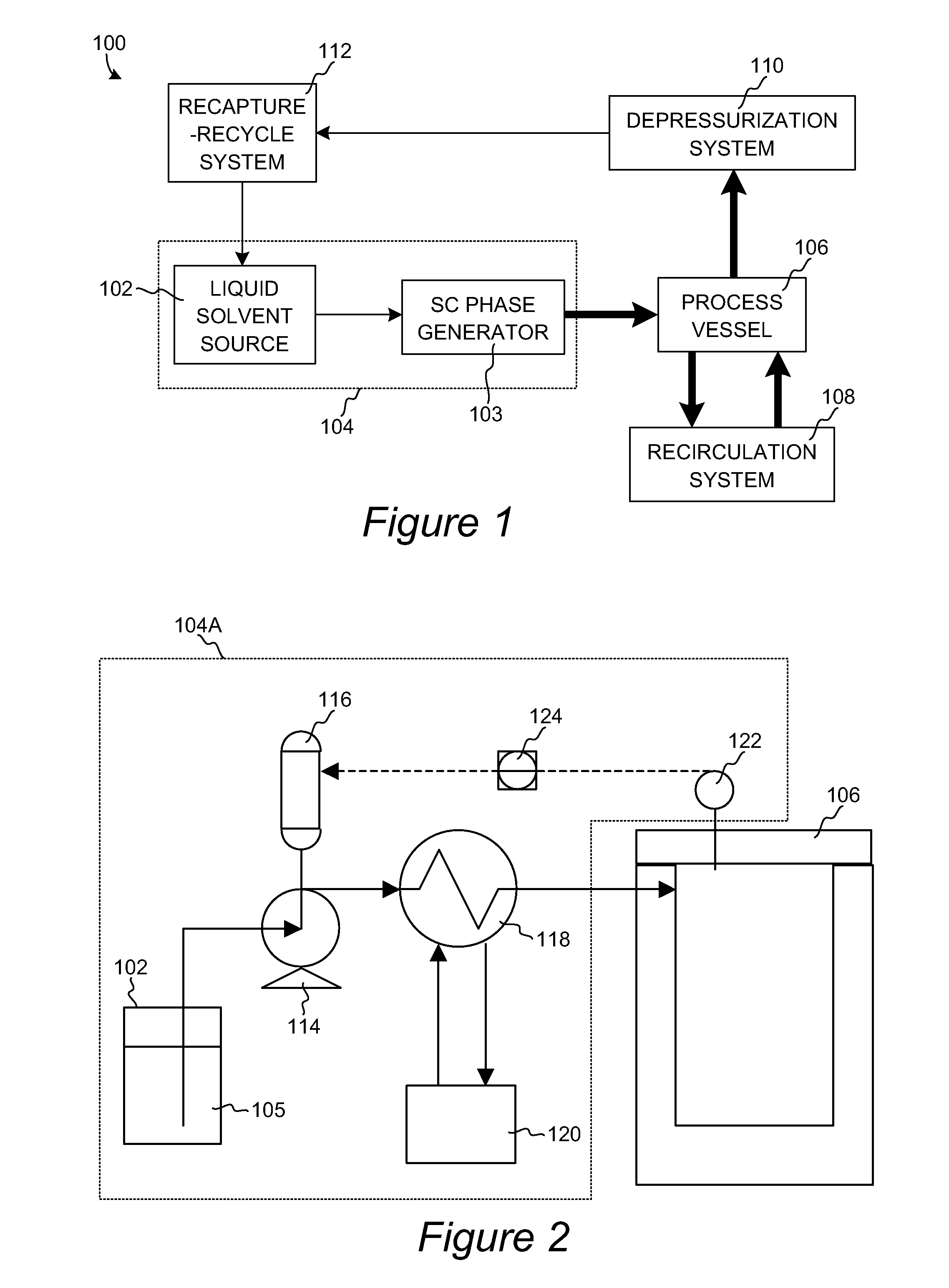

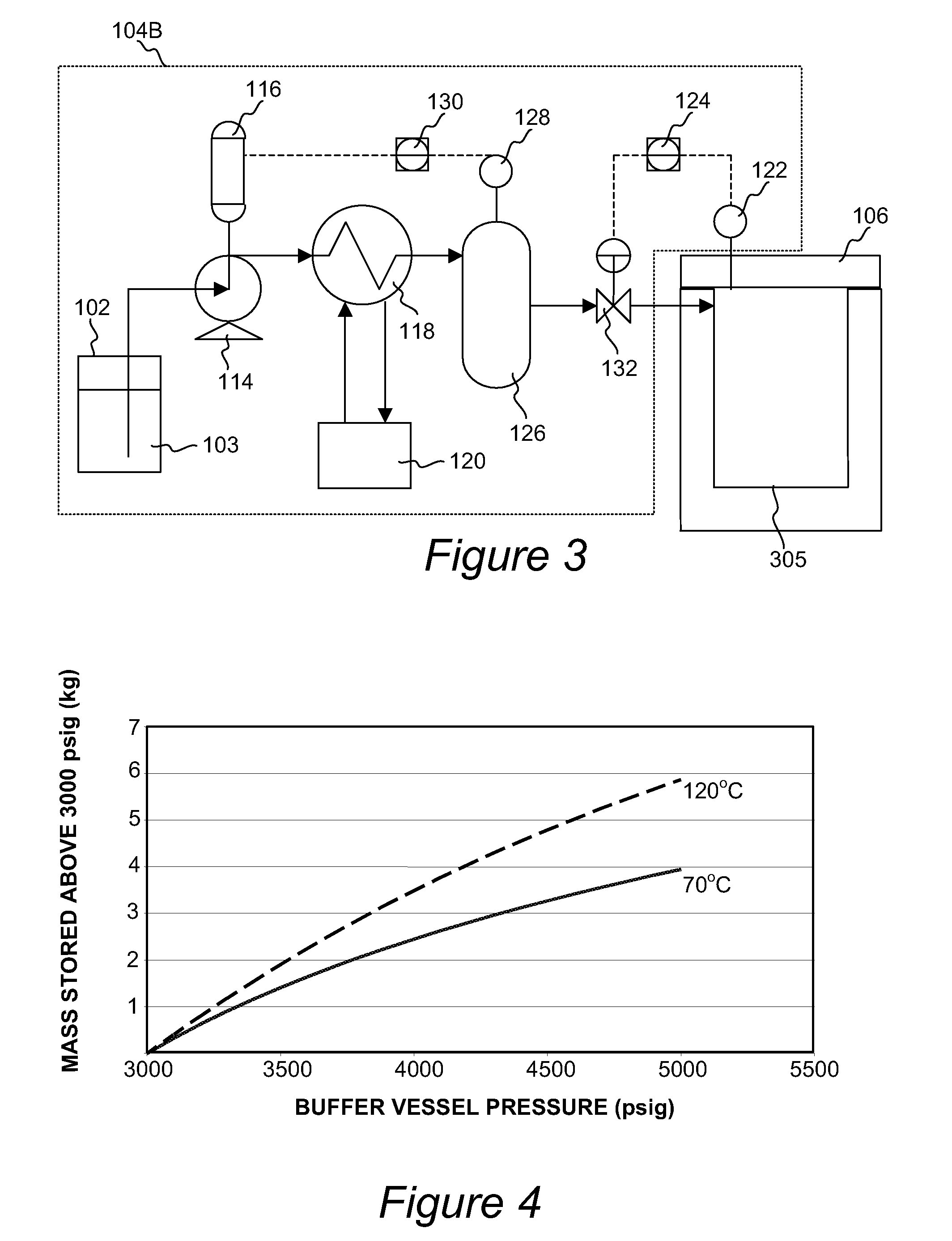

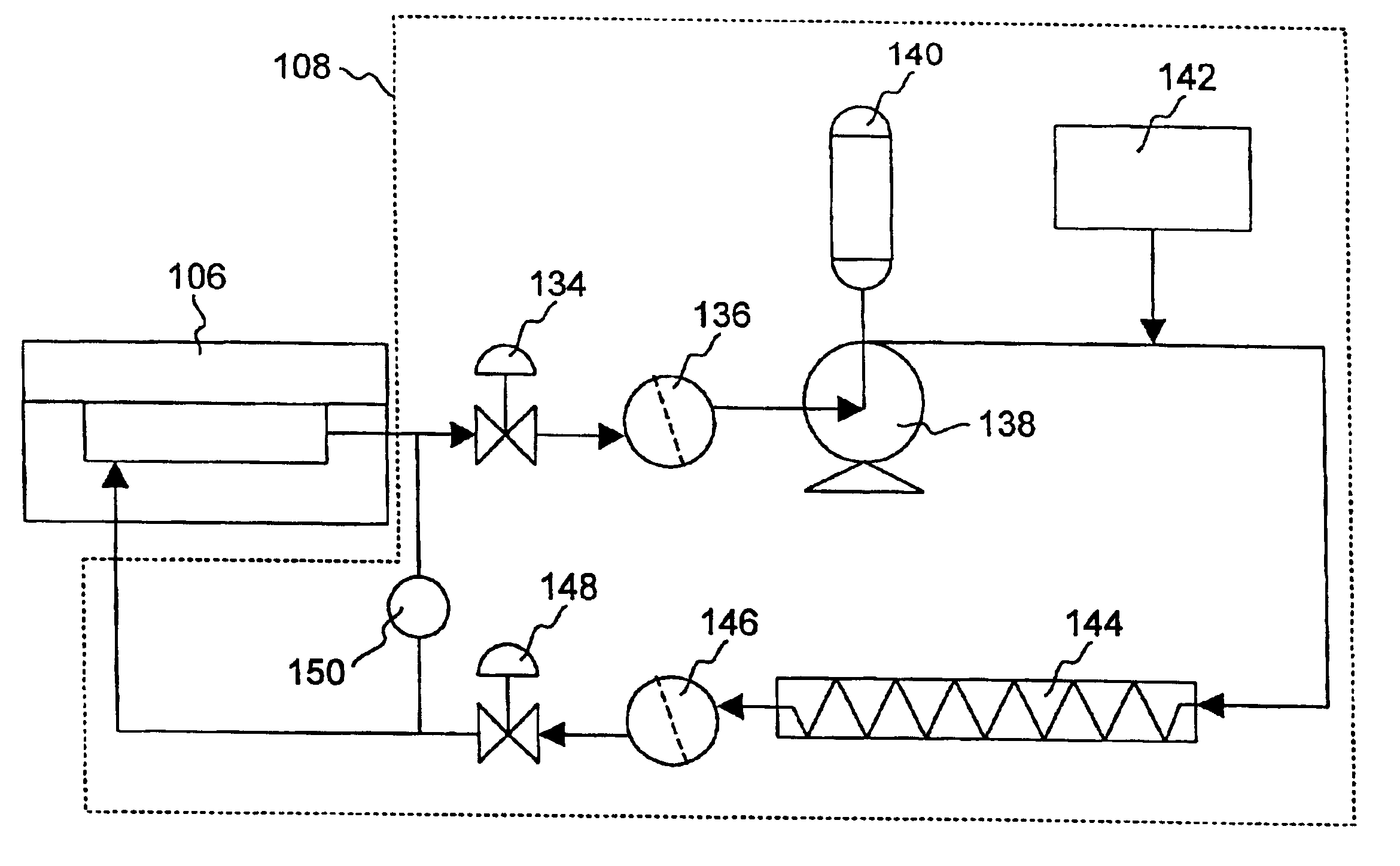

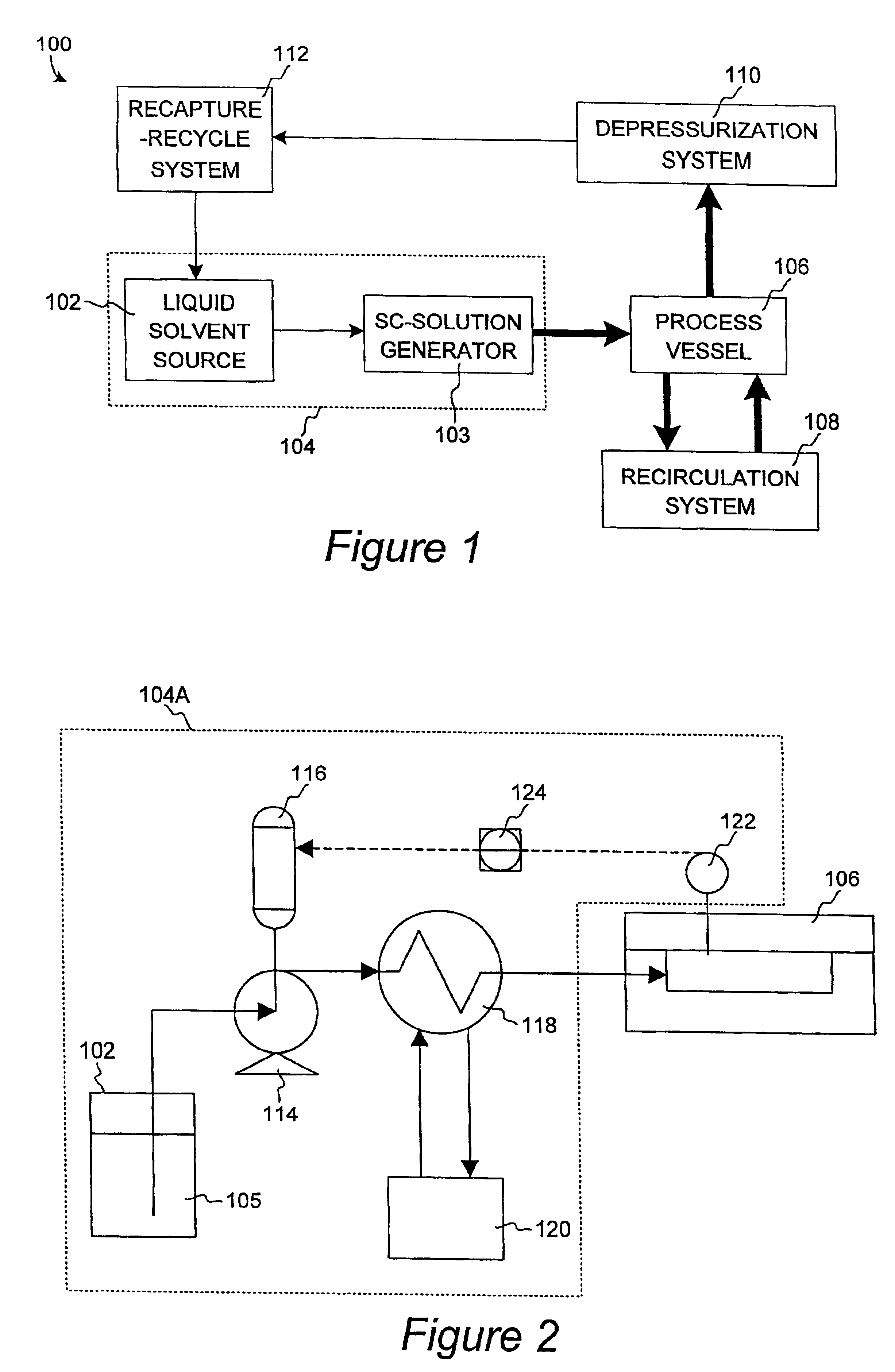

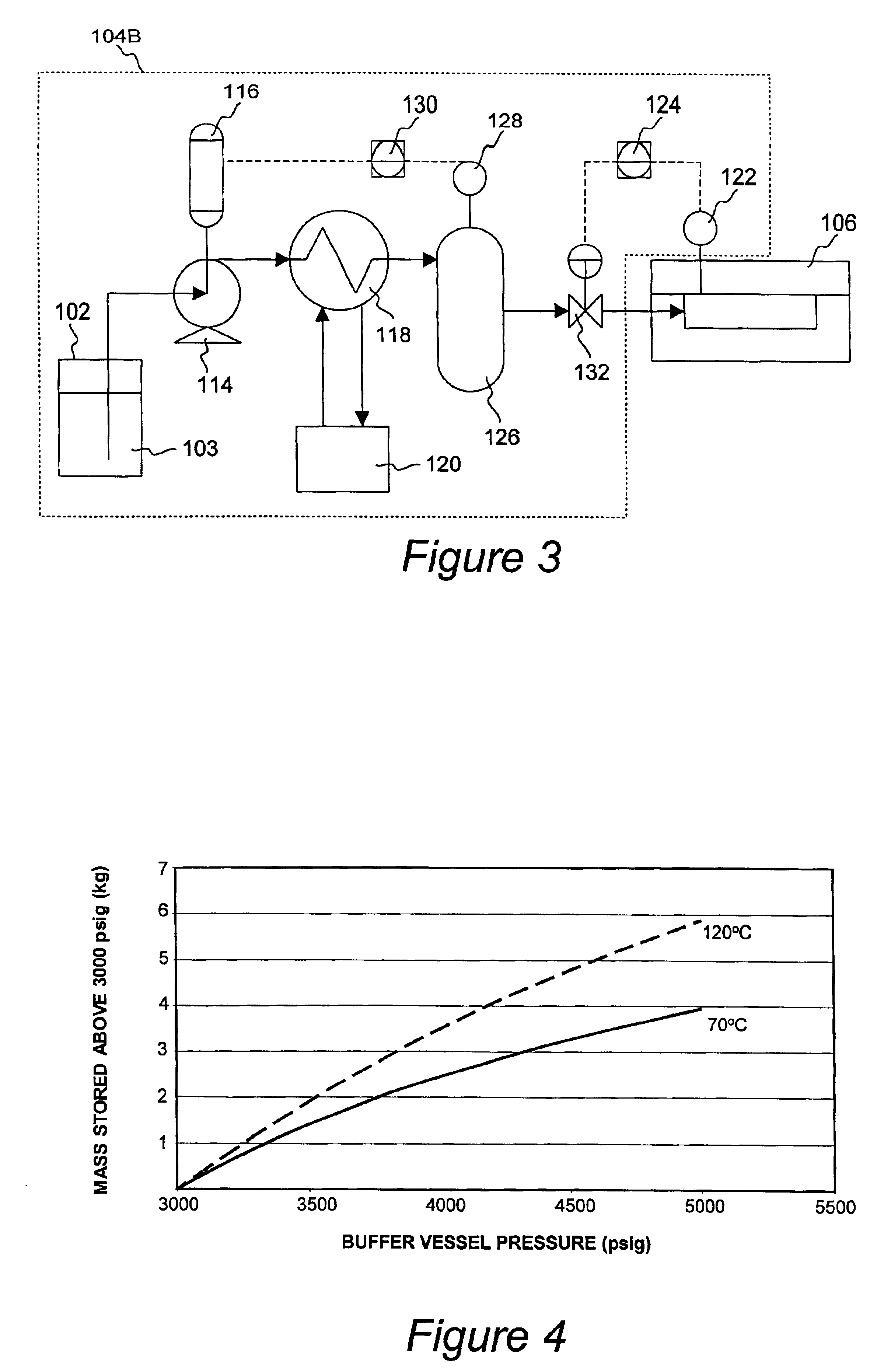

The present invention pertains to a system for processing semiconductor wafers. The processing may involve the removal of material from the wafers or deposition of material on the wafers. Various aspects of the invention include specialized pressurization, process vessel, recirculation, chemical addition, depressurization, and recapture-recycle subsystems. A solvent delivery mechanism can convert a liquid-state sub-critical solution to a supercritical processing solution and introduce it into a process vessel that contains a batch of wafers. The wafers may be rotated within the supercritical processing solution. The supercritical processing solution is preferably recirculated through the process vessel by a recirculation system. When chemical additives are added to a supercritical solvent, the momentum of the chemical additives are preferably matched to the momentum of the supercritical solvent. Additives may be added at a higher initial flow rate, then ramped down a lower flow rate, e.g., a steady-state flow rate.

Owner:NOVELLUS SYSTEMS

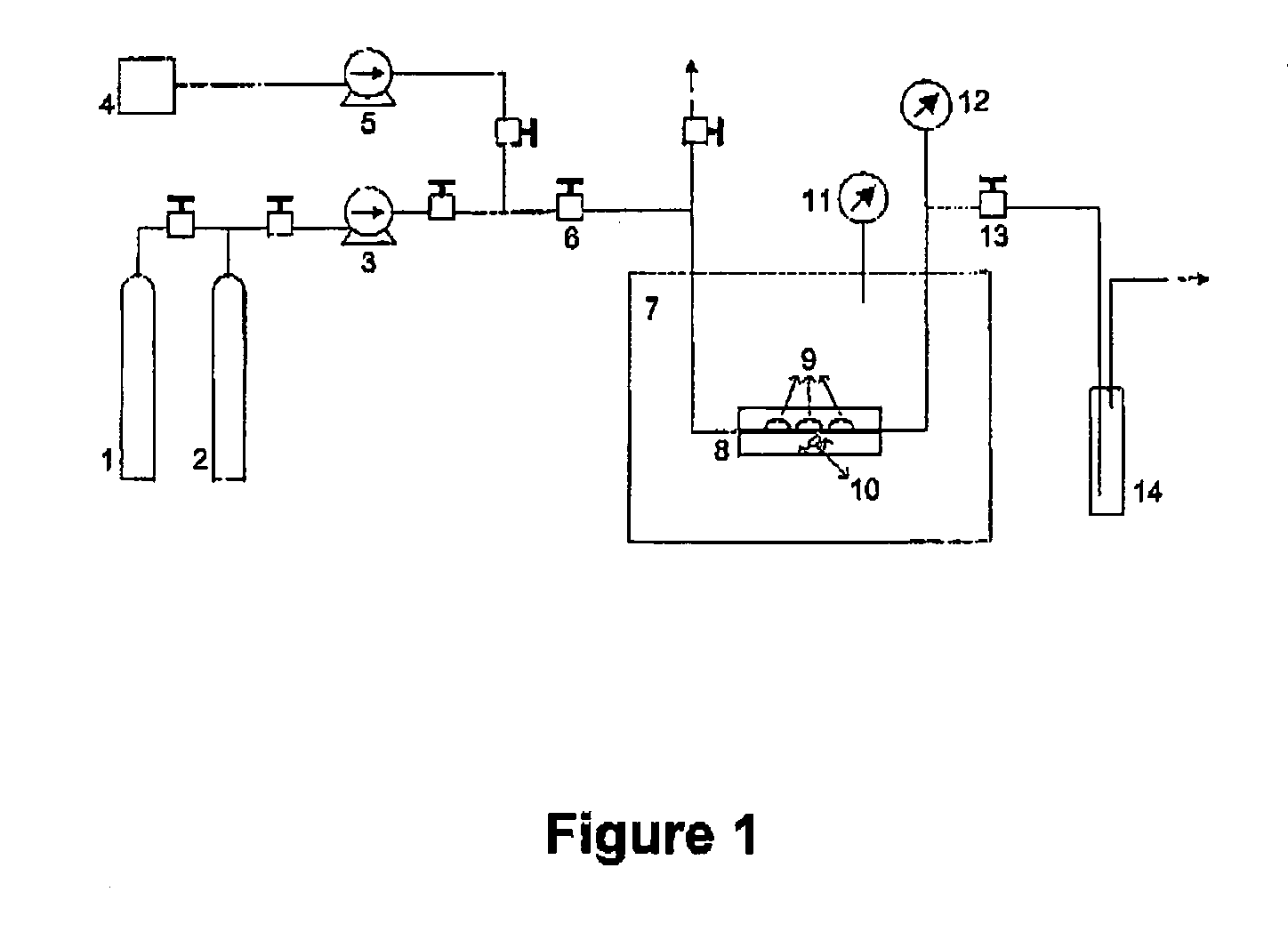

Apparatus and methods for processing semiconductor substrates using supercritical fluids

InactiveUS6848458B1Ease in introductionHigh removal rateSemiconductor/solid-state device manufacturingElectrostatic cleaningLiquid stateCompound (substance)

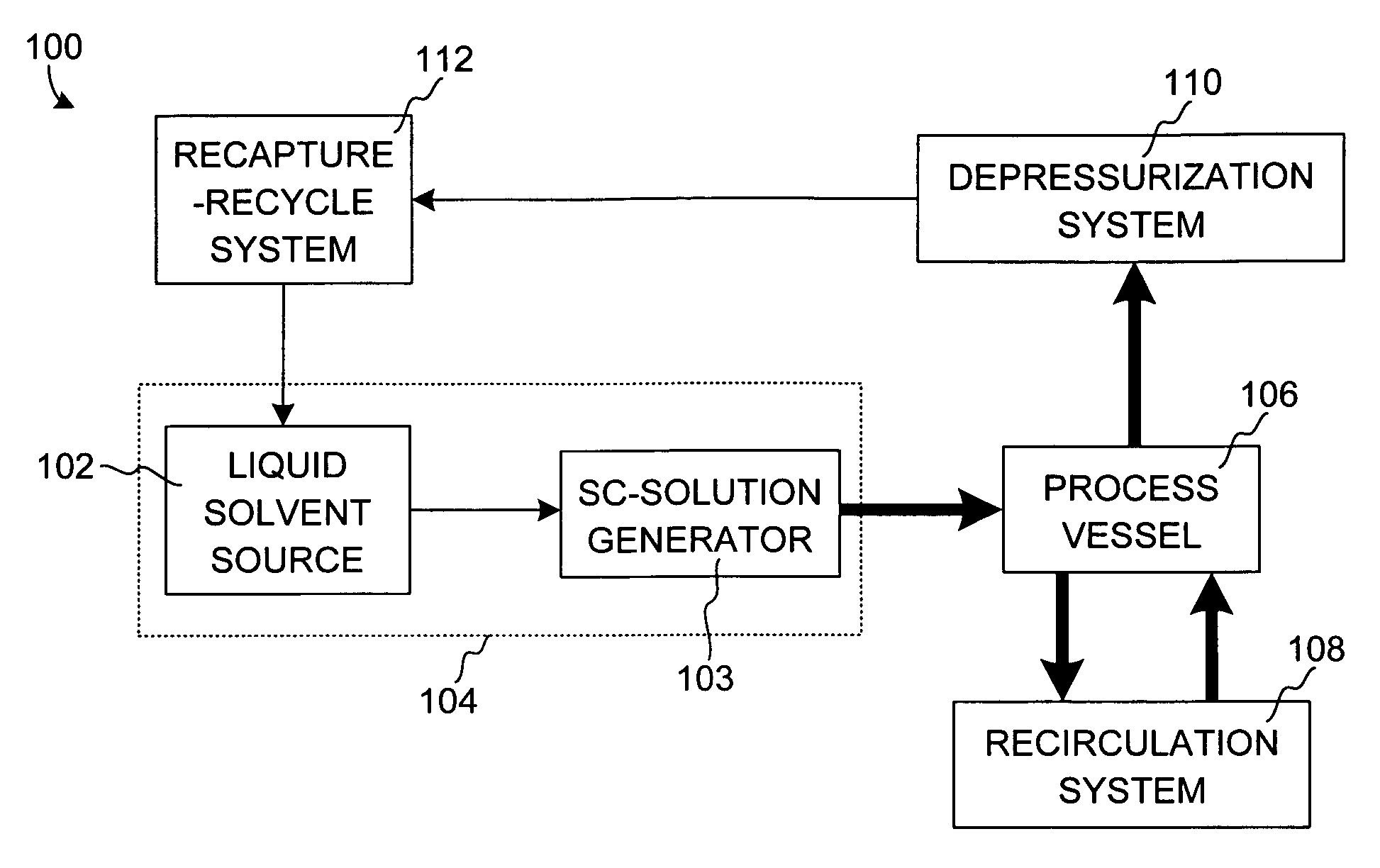

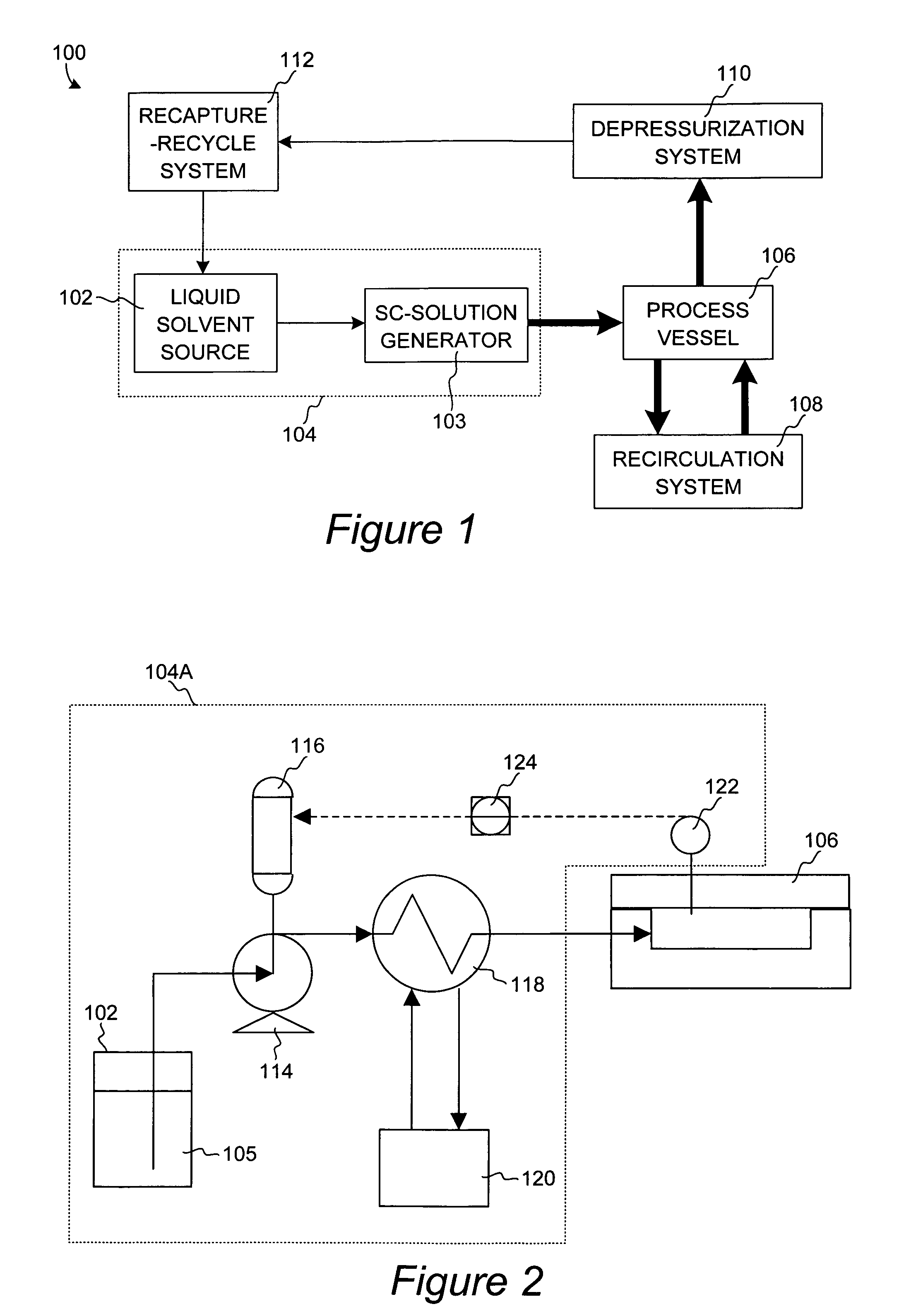

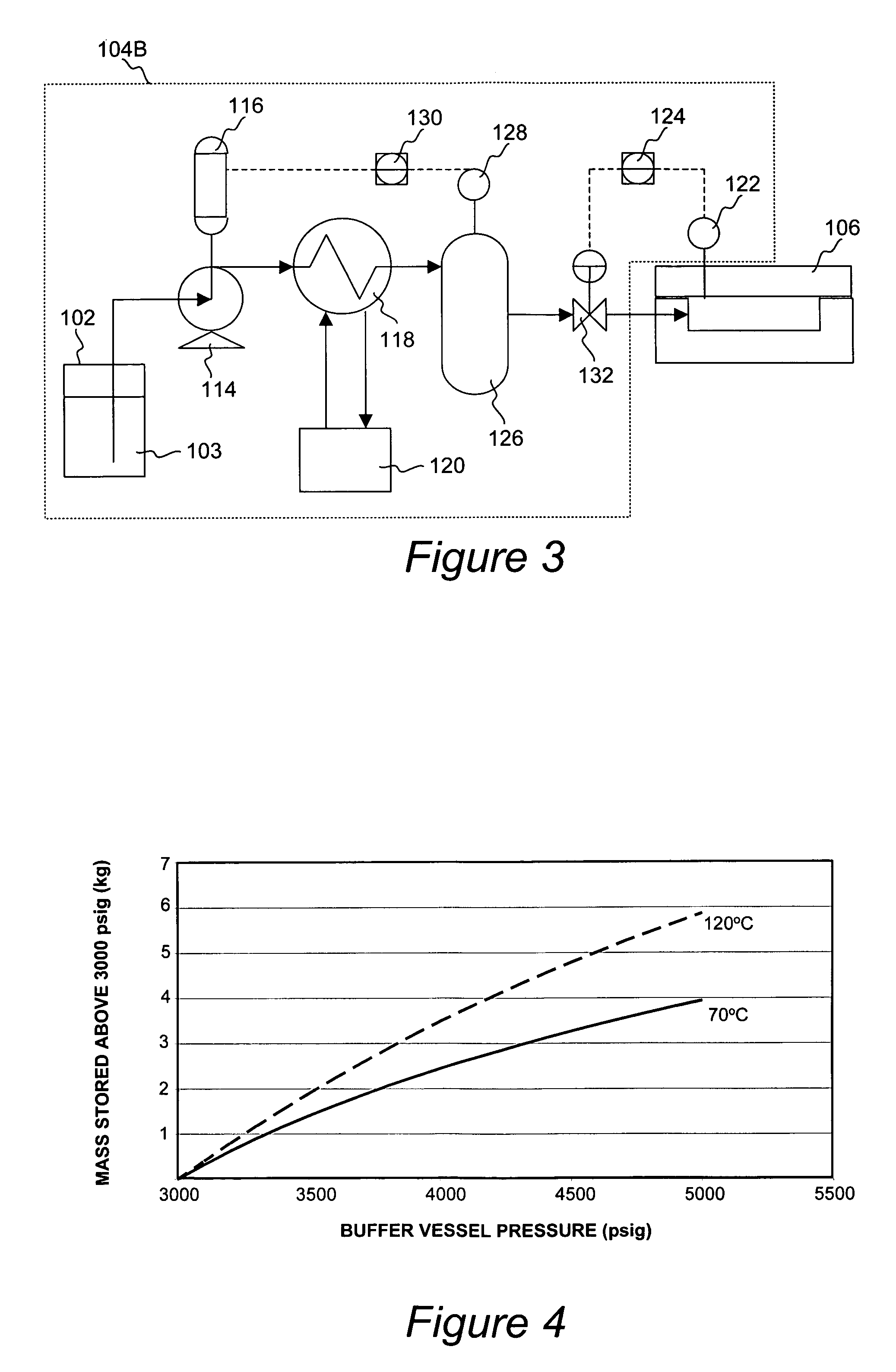

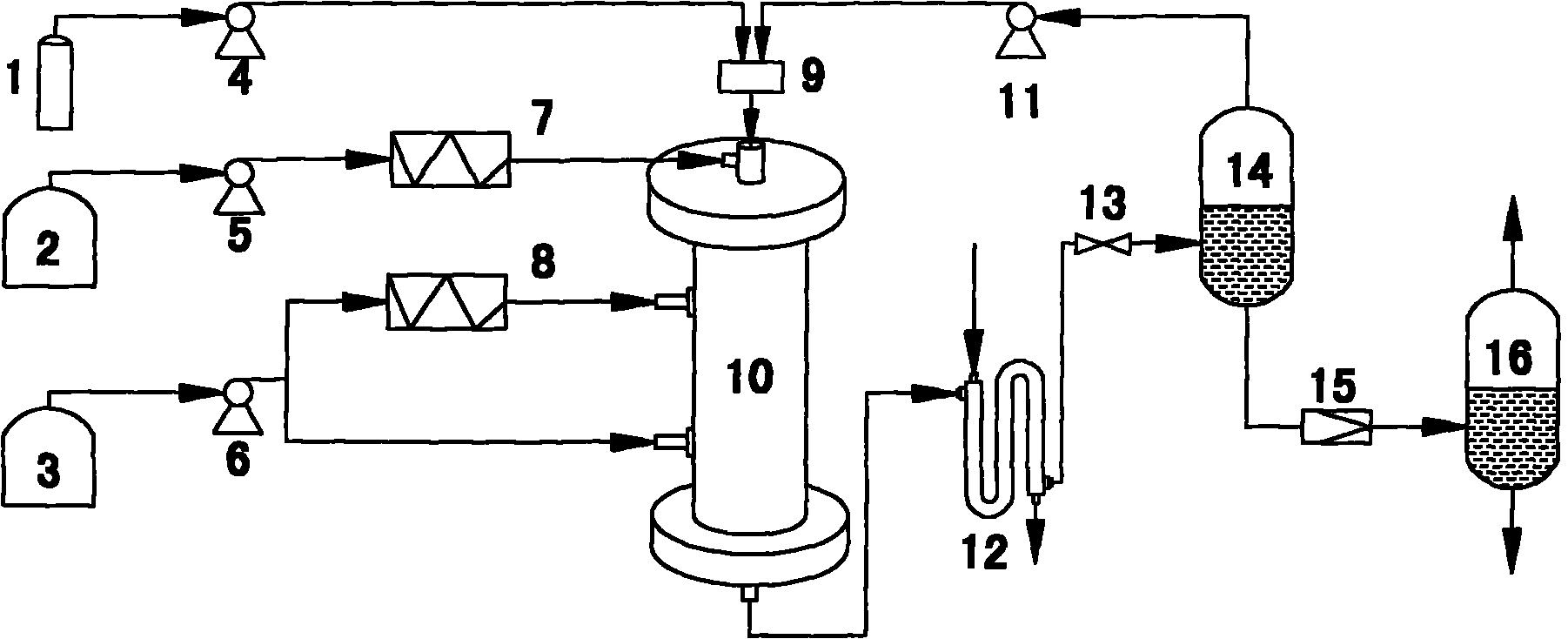

The present invention pertains to a system for cleaning wafers that includes specialized pressurization, process vessel, recirculation, chemical addition, depressurization, and recapture-recycle subsystems, as well as methods for implementing wafer cleaning using such a system. A solvent delivery mechanism converts a liquid-state sub-critical solution to a supercritical cleaning solution and introduces it into a process vessel that contains a wafer or wafers. The supercritical cleaning solution is recirculated through the process vessel by a recirculation system. An additive delivery system introduces chemical additives to the supercritical cleaning solution via the solvent delivery mechanism, the process vessel, or the recirculation system. Addition of chemical additives to the sub-critical solution may also be performed. The recirculation system provides efficient mixing of chemical additives, efficient cleaning, and process uniformity. A depressurization system provides dilution and removal of cleaning solutions under supercritical conditions. A recapture-recycle system introduces captured-purified solvents into the solvent delivery mechanism.

Owner:NOVELLUS SYSTEMS

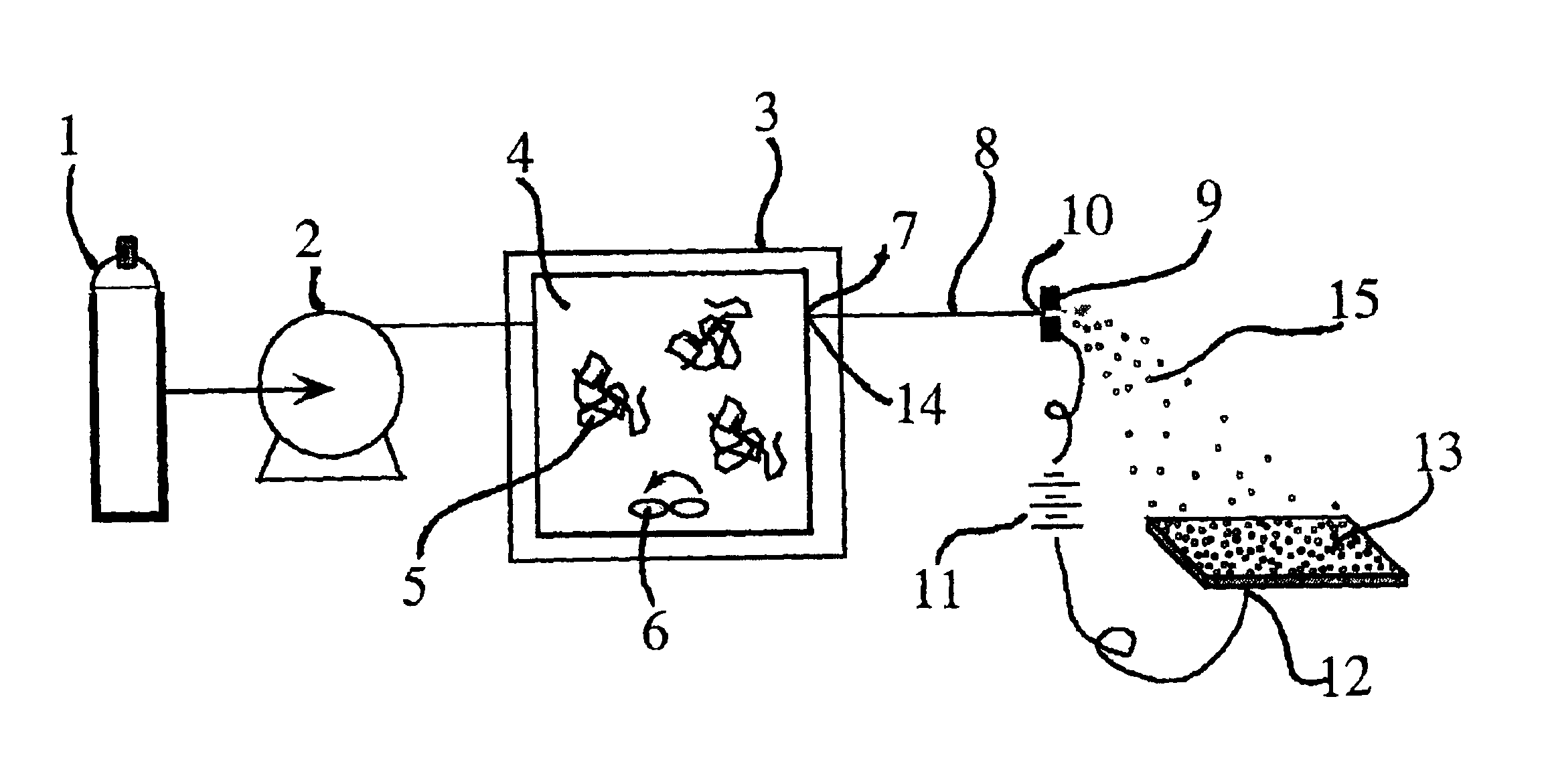

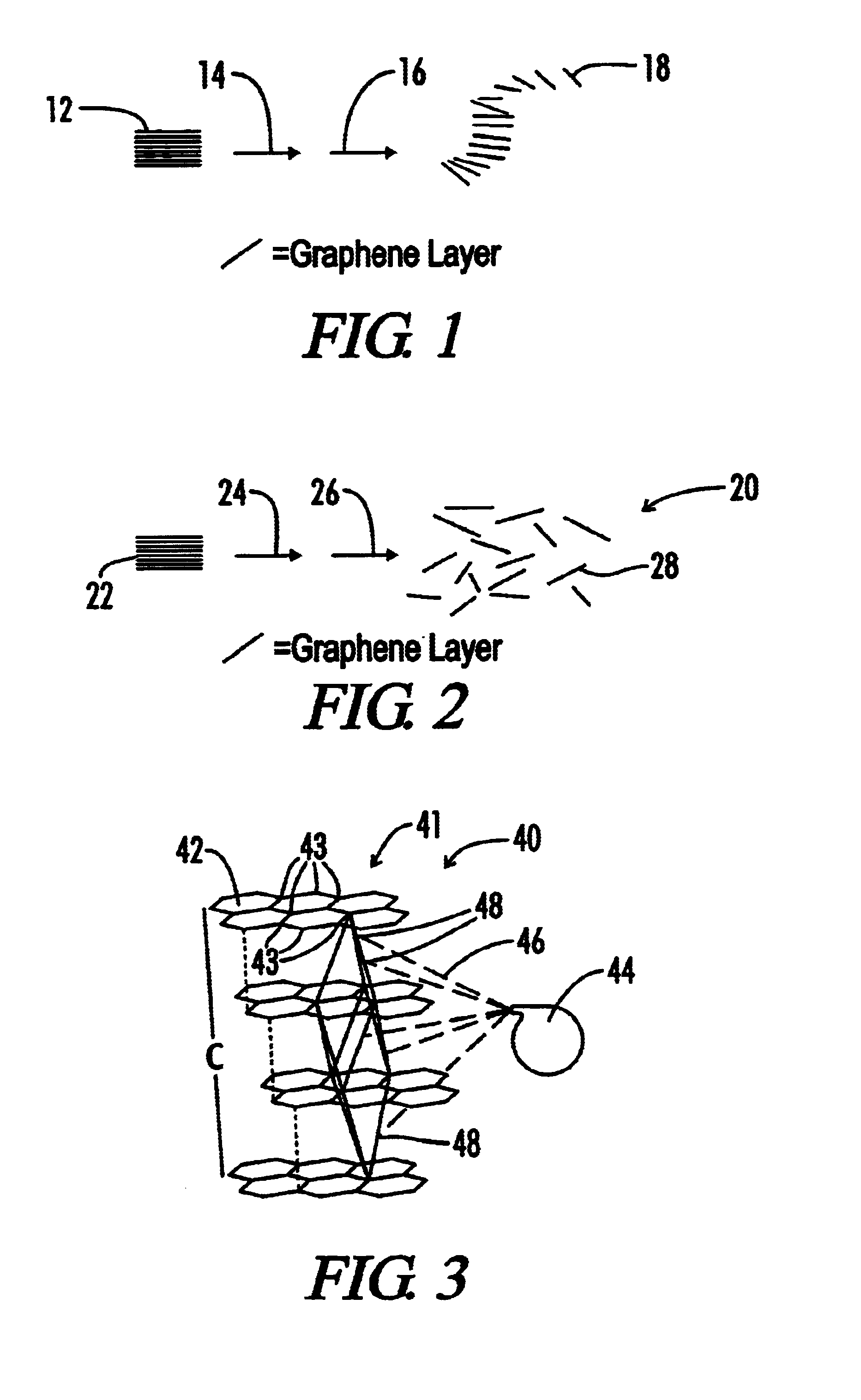

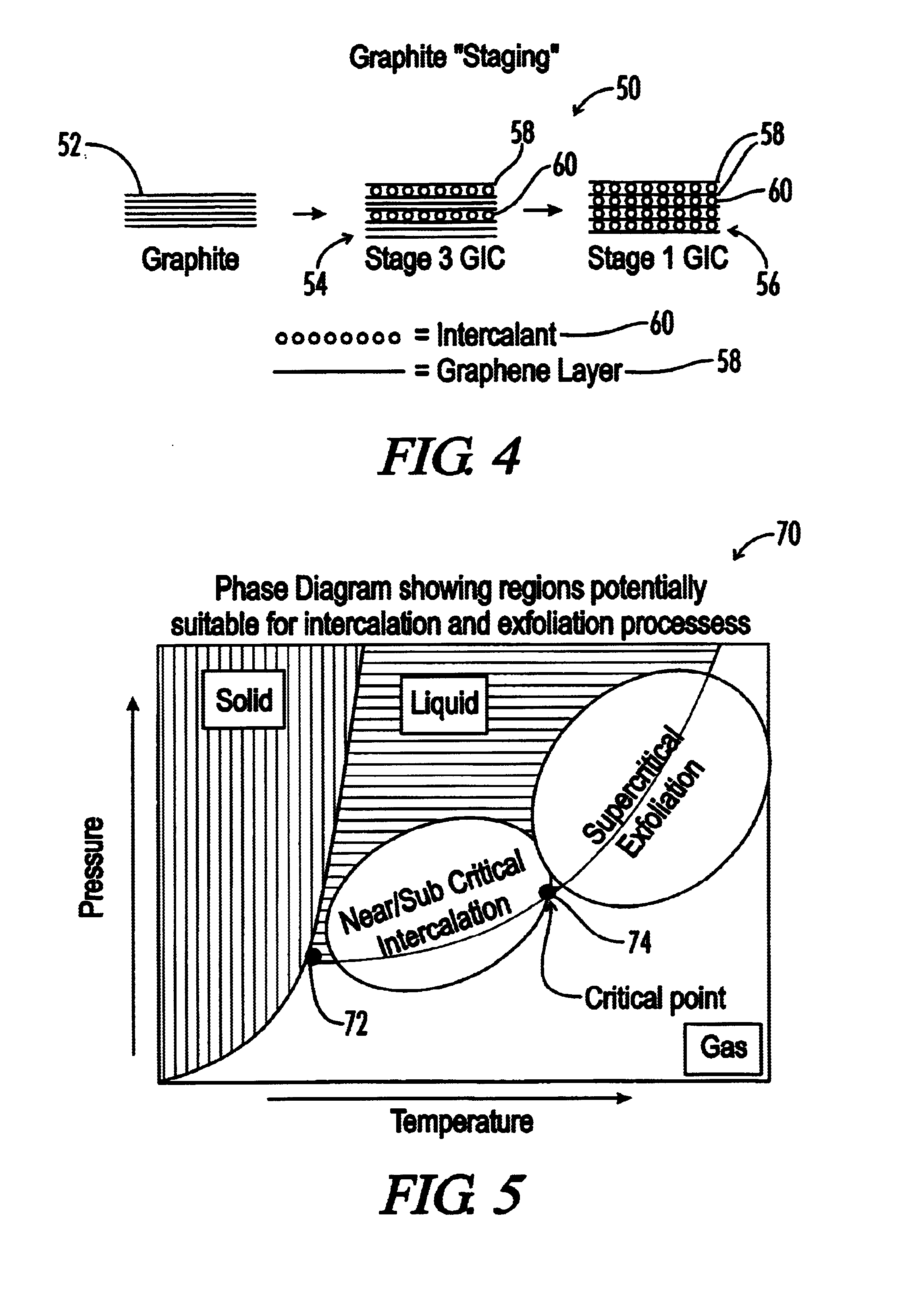

Graphite intercalation and exfoliation process

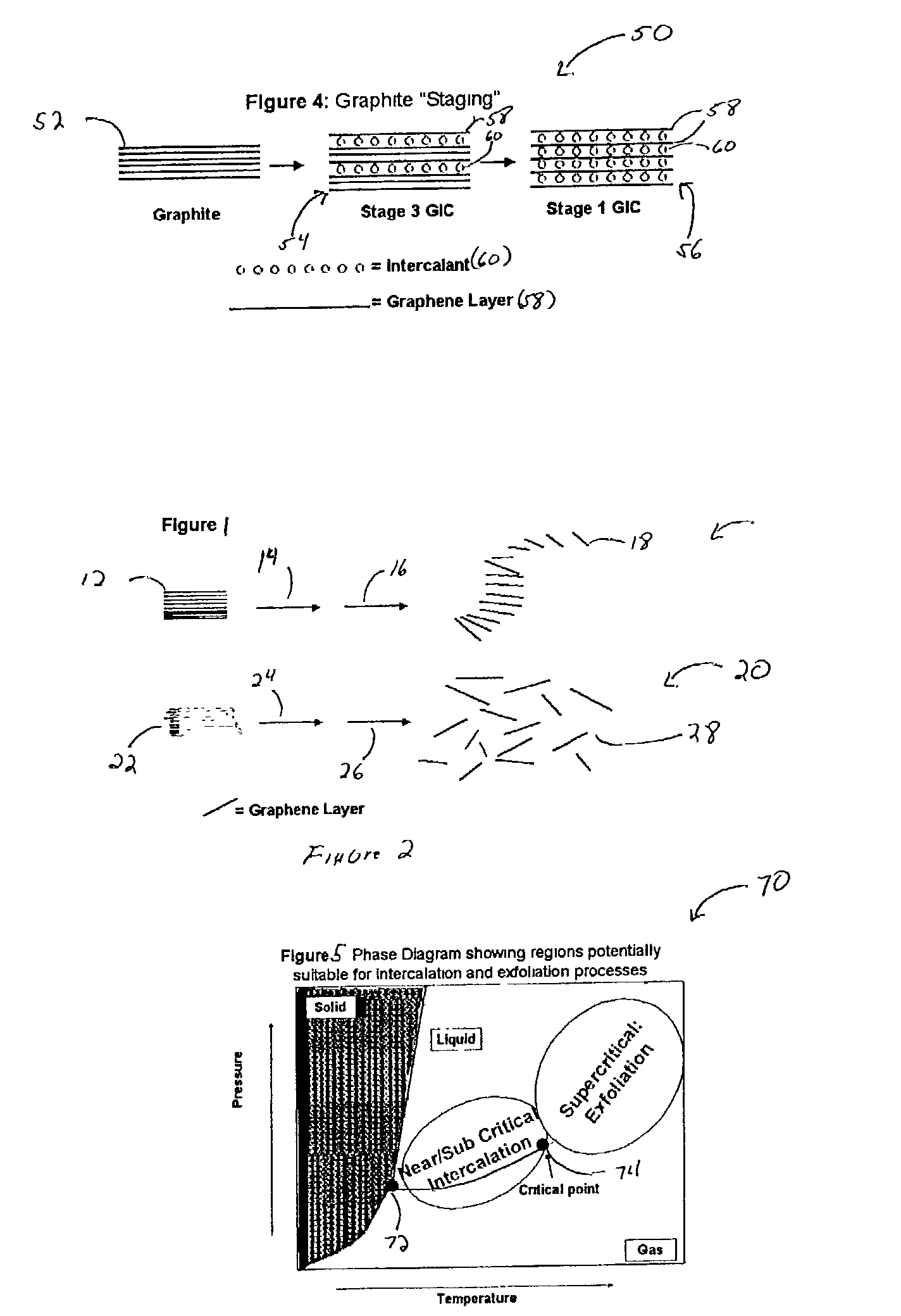

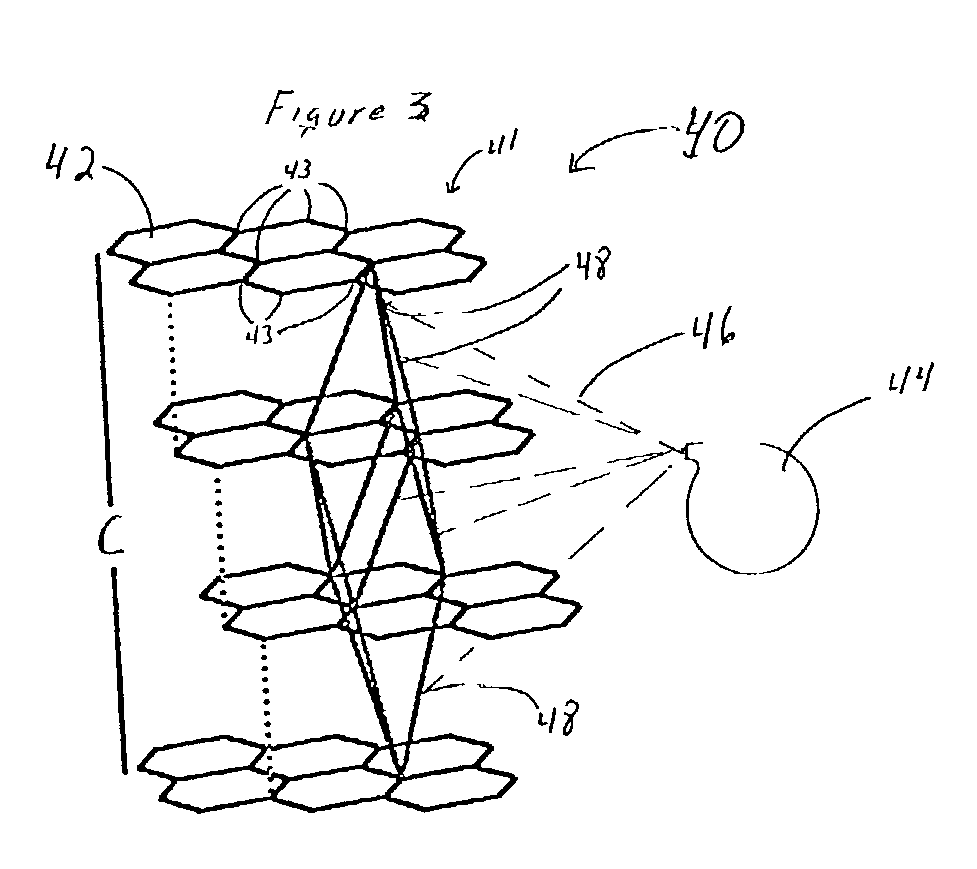

InactiveUS7105108B2Improve volume expansionReduce needMaterial nanotechnologyGraphiteConductive polymerGraphite particle

The invention relates to expanded graphite and methods of making the graphite and products that can be made from the graphite made from the inventive process. The invention includes the step of introducing a fluid into at least one of a plurality of interstices of graphite flake, wherein the fluid comprises at least one of a sub-critical point fluid, a near critical point fluid, or a supercritical fluid. The graphite flake is also intercalated with an intercalant and optionally an oxidizing agent. The invention may further include novel techniques of exfoliating the graphite. The invention may be practiced to make nano-sized graphite particles and also graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites.

Owner:GRAFTECH INT HLDG INC

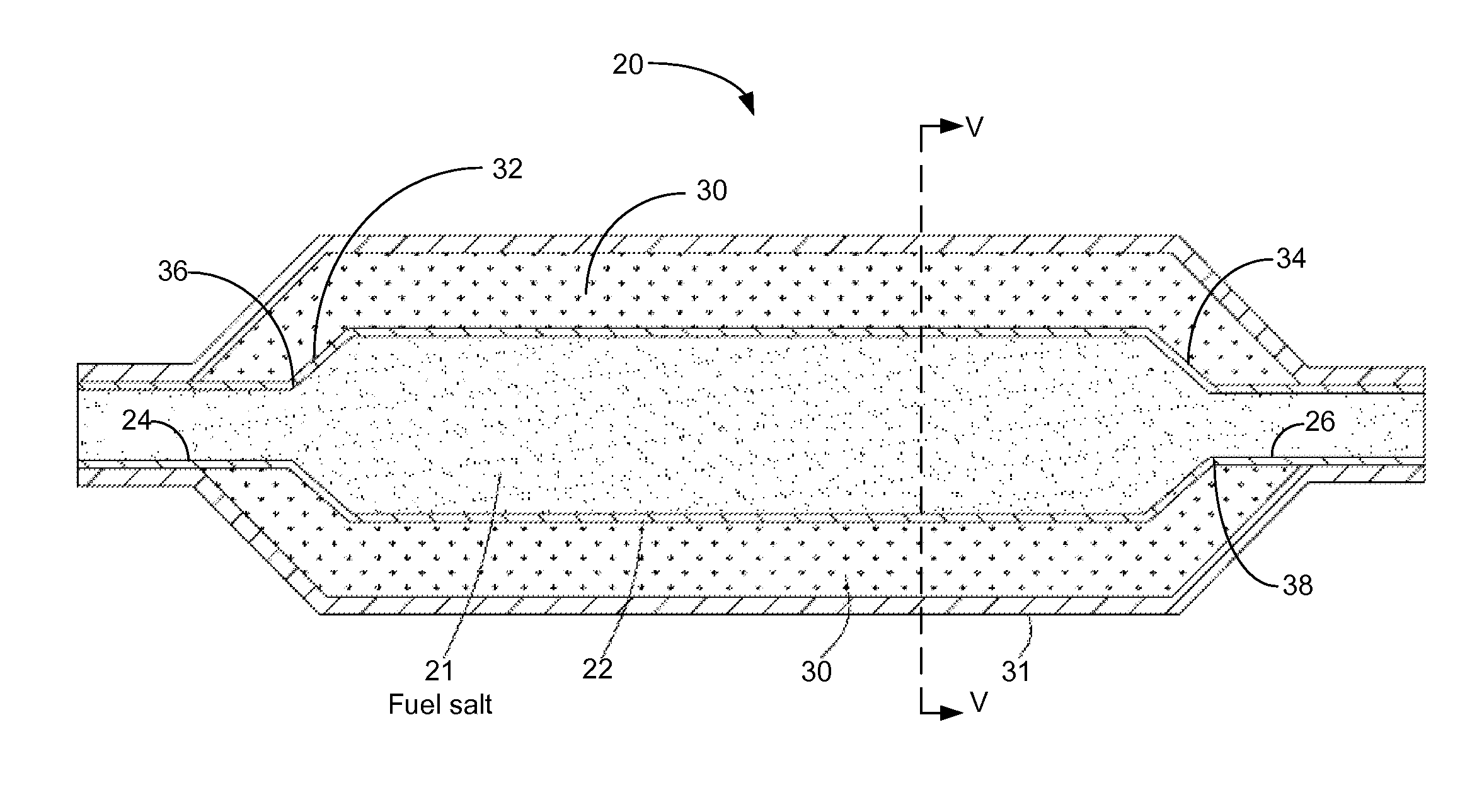

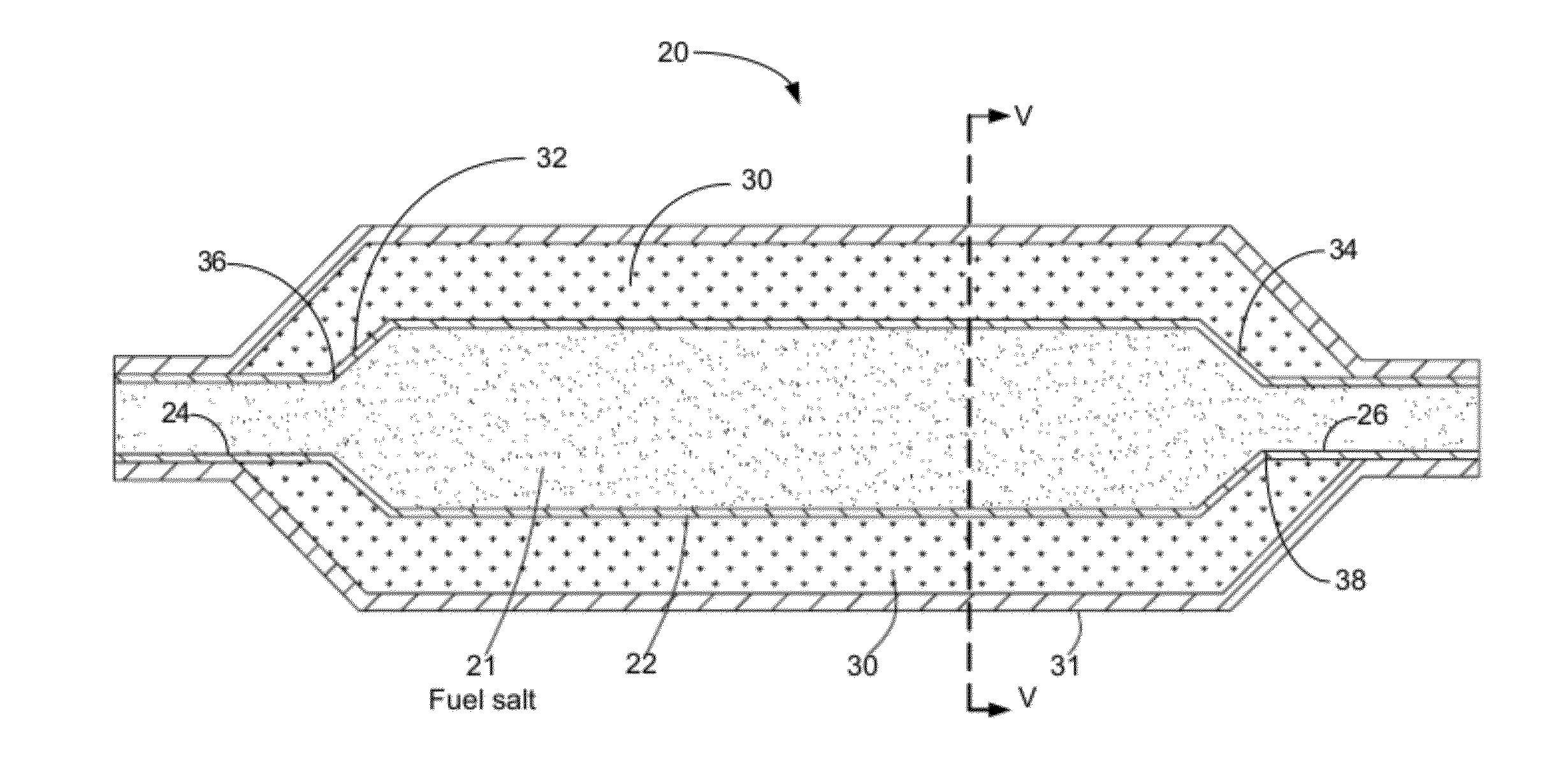

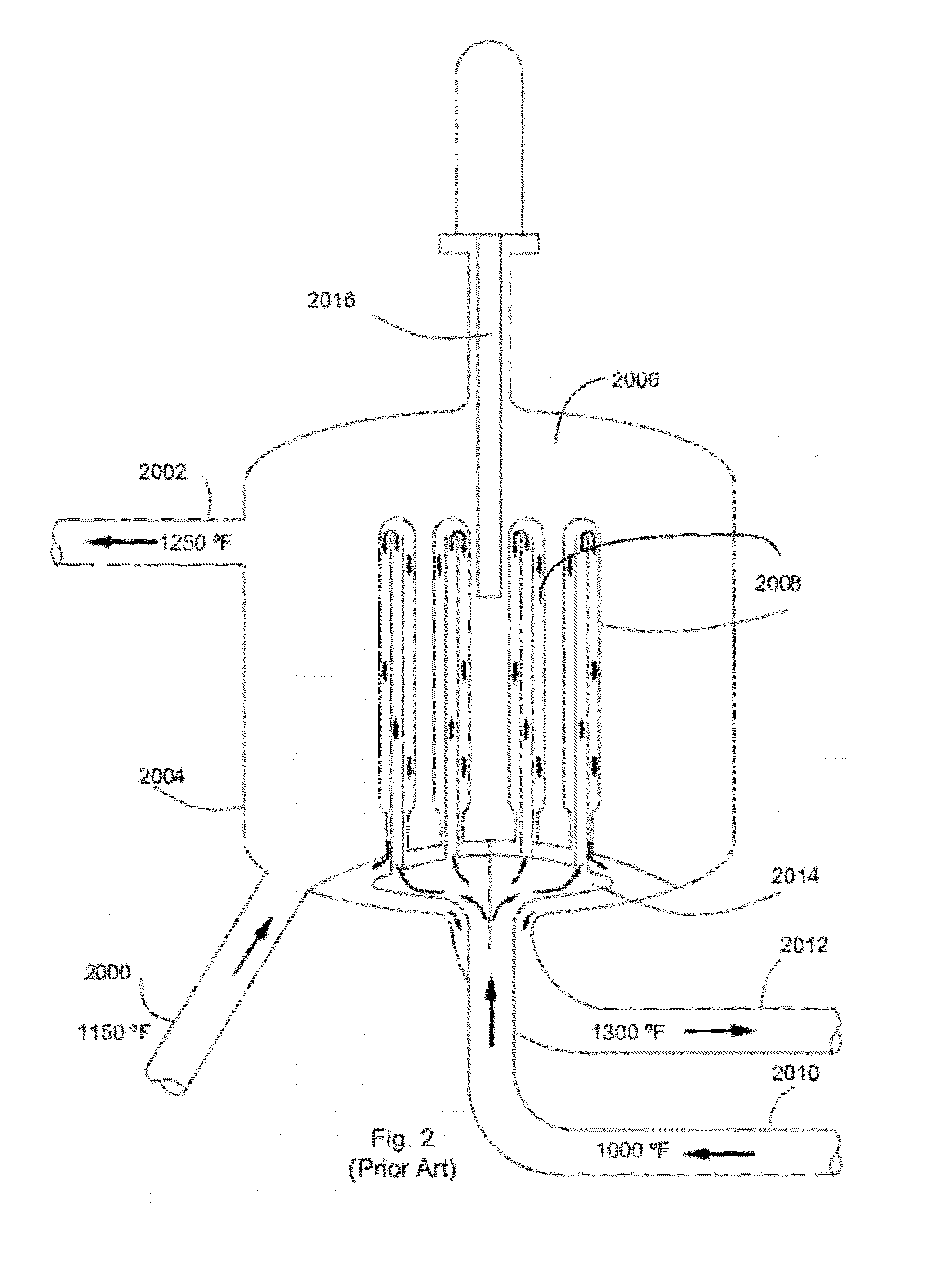

Molten salt nuclear reactor

InactiveUS20090279658A1Maximize probabilityFuel elementsNuclear energy generationBreeder reactorNuclear reactor

A molten salt breeder reactor that has fuel conduit surrounded by a fertile blanket. The fuel salt conduit has an elongated core section that allows for the generation of electrical power on a scale comparable to commercially available nuclear reactors. The geometry of the fuel conduit is such that sub-critical conditions exist near the input and output of the fuel salt conduit and the fertile blanket surrounds the input and output of the fuel salt conduit, thereby minimizing neutron losses.

Owner:OTTAWA VALLEY RES ASSOCS

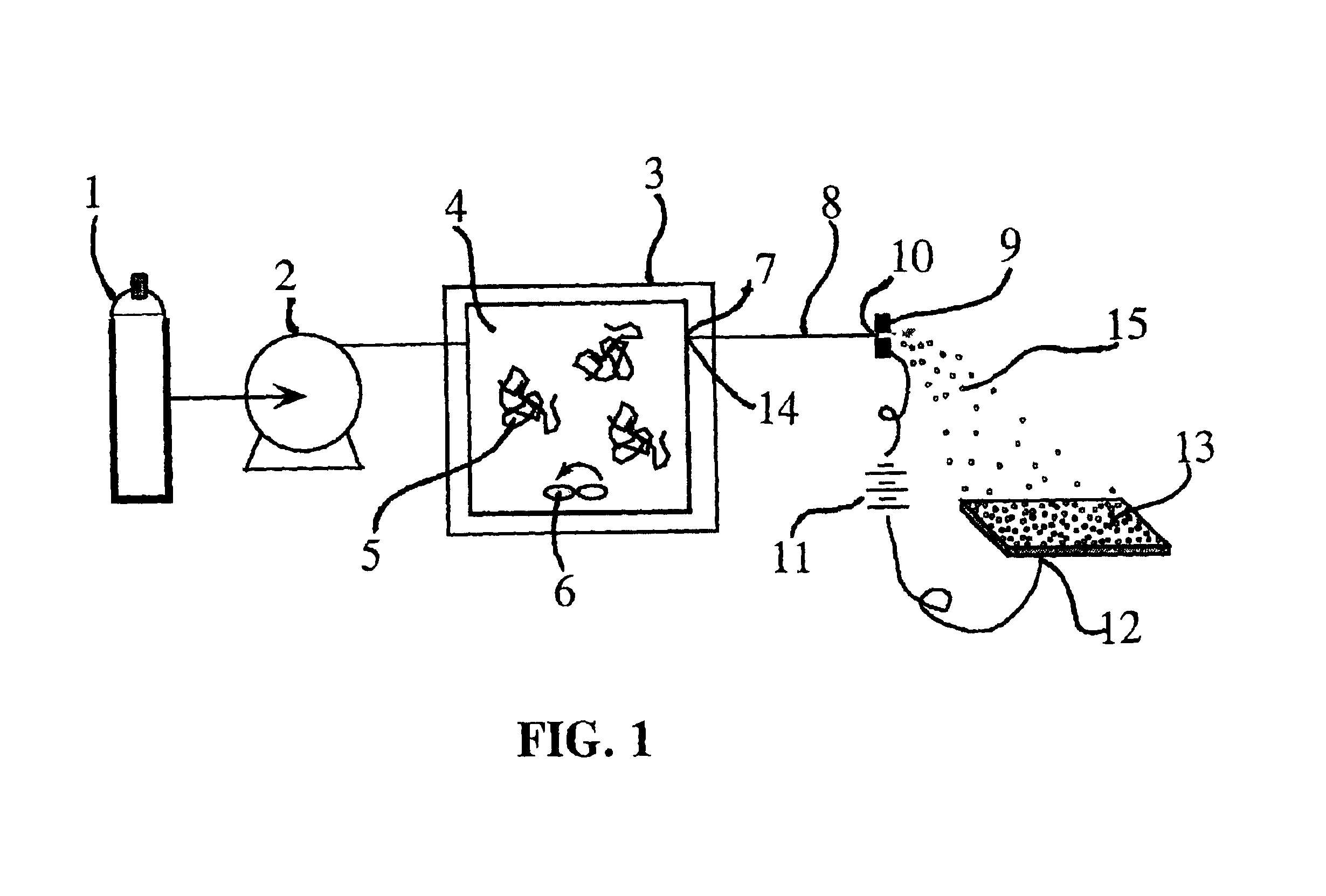

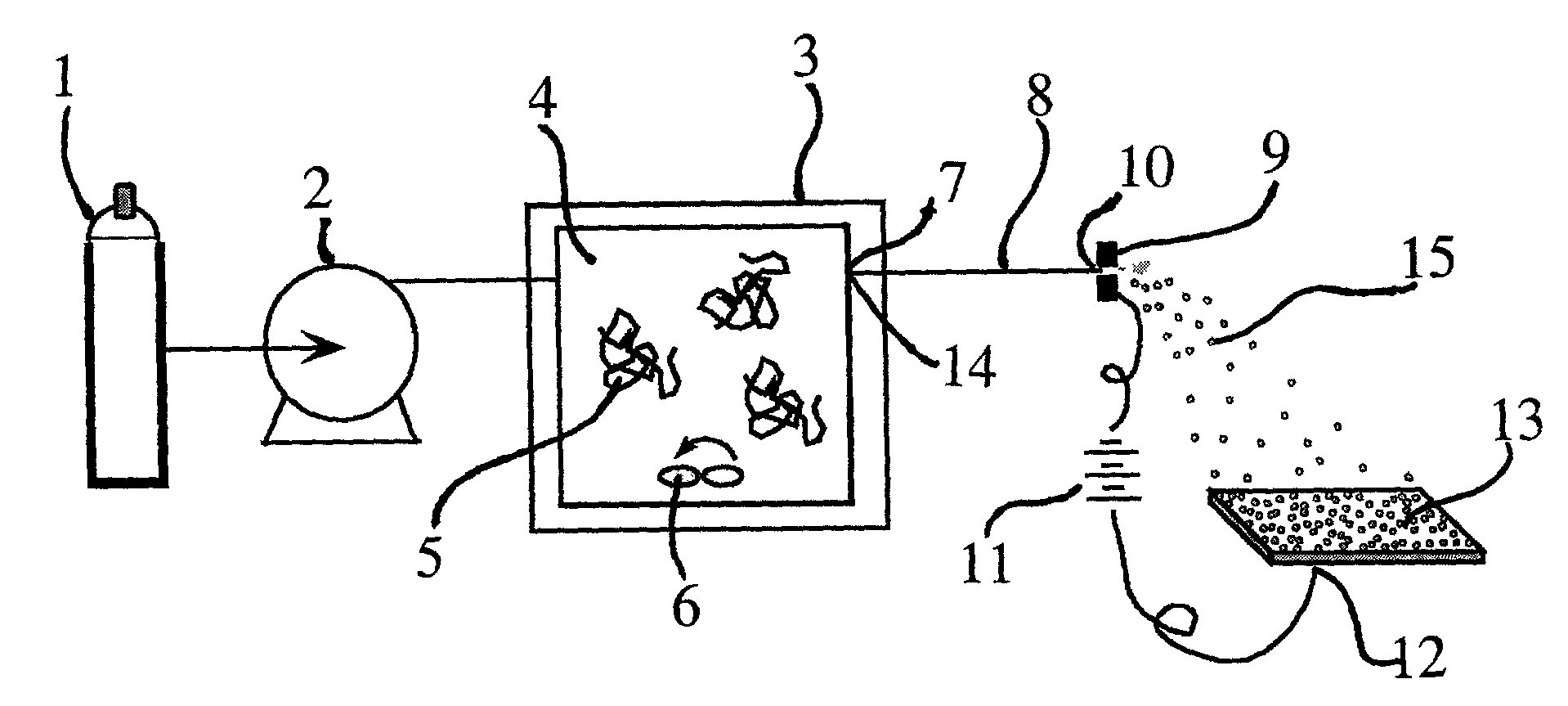

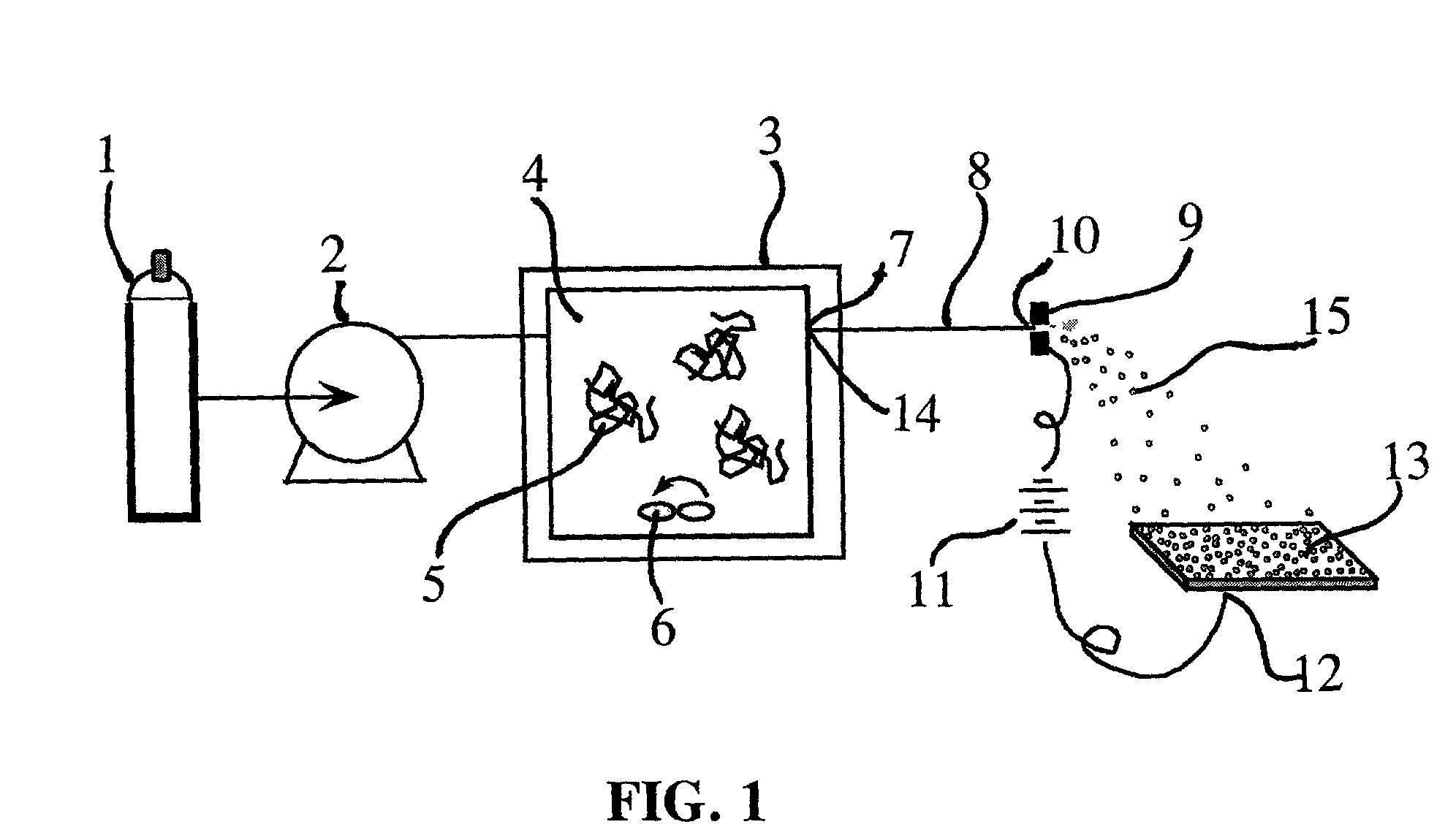

Methods for producing films using supercritical fluid

A method for forming a continuous film on a substrate surface that involves depositing particles onto a substrate surface and contacting the particle-deposited substrate surface with a supercritical fluid under conditions sufficient for forming a continuous film from the deposited particles. The particles may have a mean particle size of less 1 micron. The method may be performed by providing a pressure vessel that can contain a compressible fluid. A particle-deposited substrate is provided in the pressure vessel and the compressible fluid is maintained at a supercritical or sub-critical state sufficient for forming a film from the deposited particles. The Tg of particles may be reduced by subjecting the particles to the methods detailed in the present disclosure.

Owner:BATTELLE MEMORIAL INST

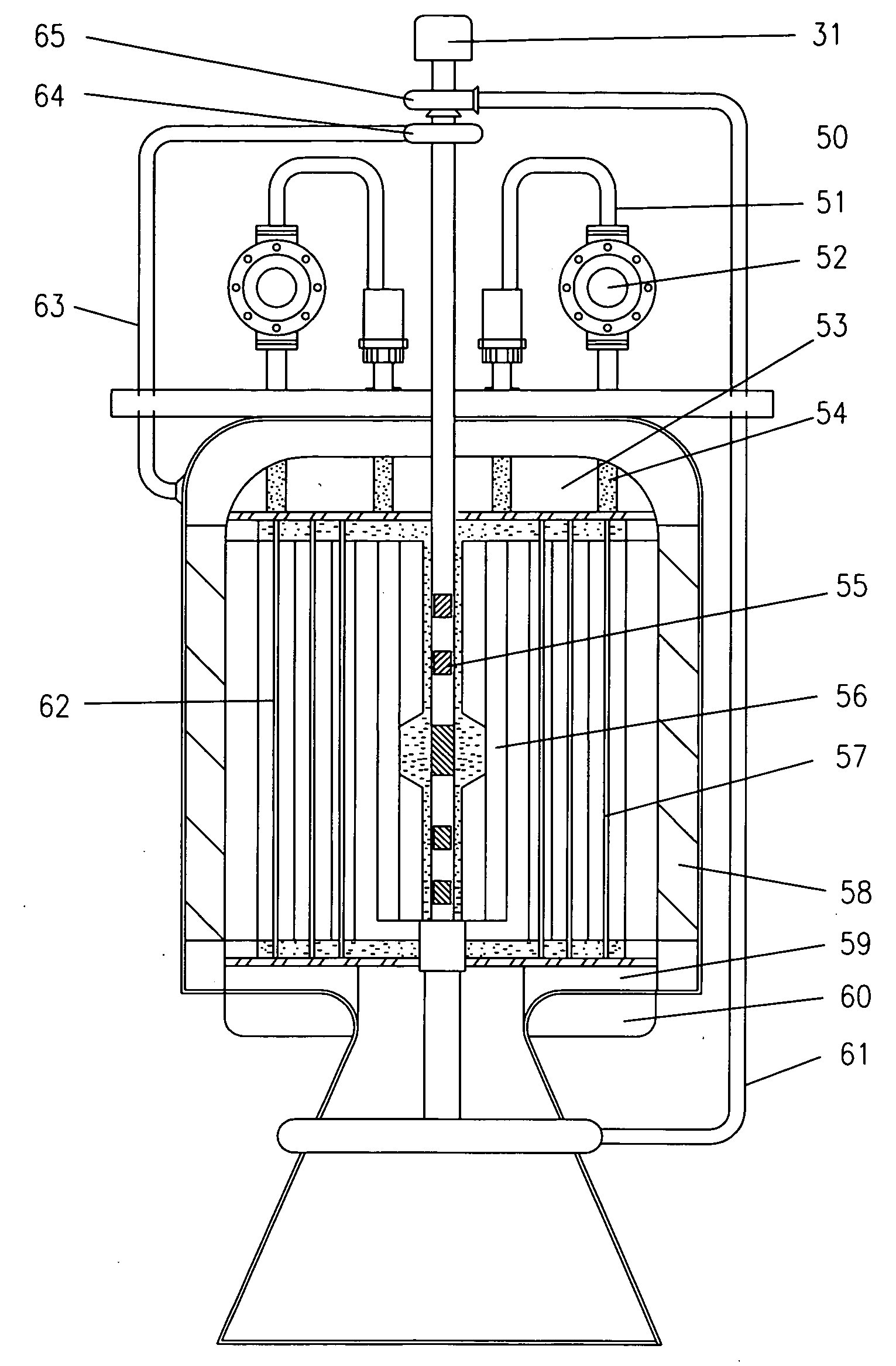

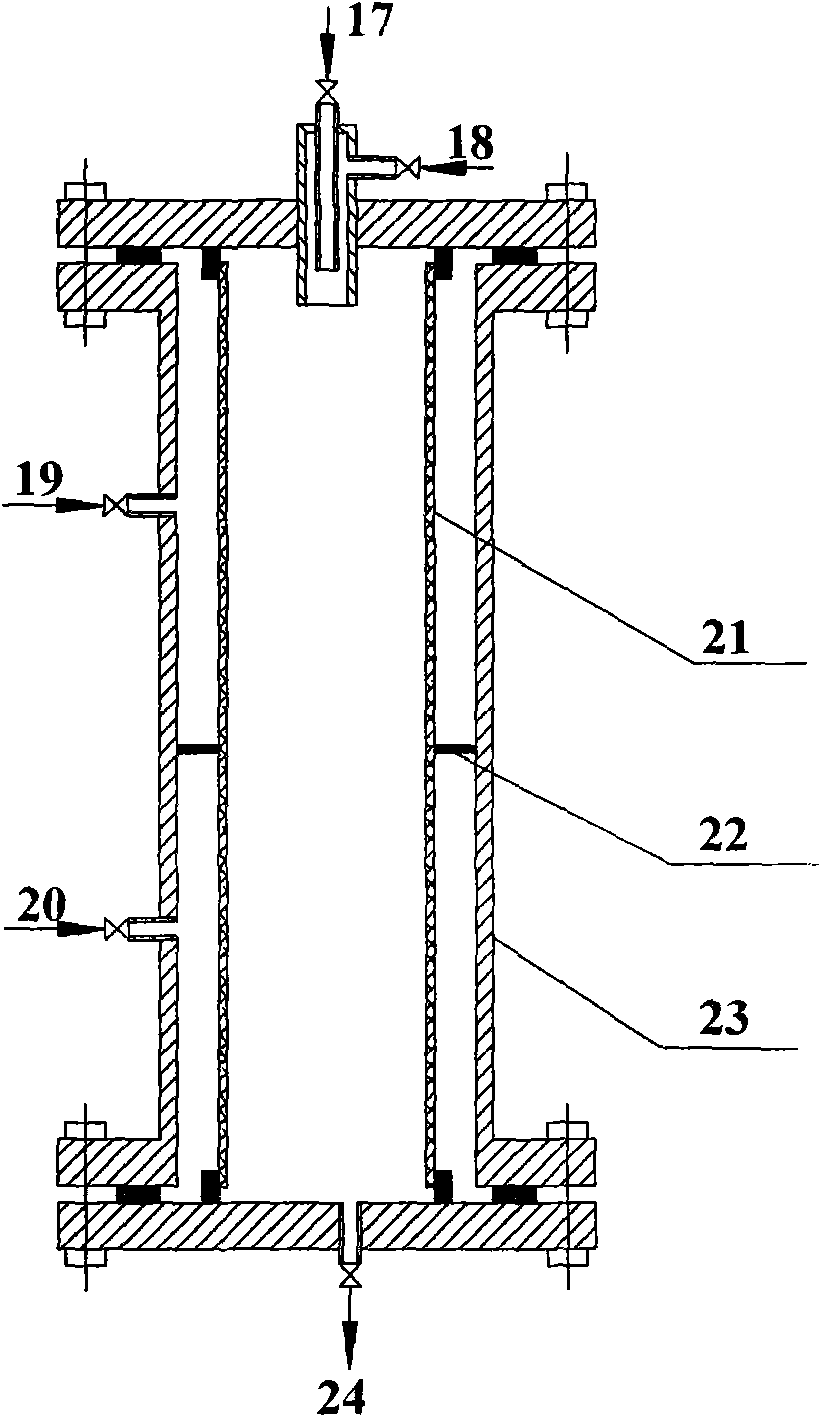

Corrosion-resisting clogging-proof overcritical water oxidization reactor

InactiveCN101164912ALarge choiceAvoid corrosionWater/sewage treatment by oxidationCentral line placementOxygen

This invention relates to a corrosion-resistance and blocking-resistance supercritical water oxidation reactor. It is composed of: a casing, a water inlet, a jacketed supporting ring and a spring ring, an annular water entrance and a water dash plate, inner cylinder of the reactor, raw material feeder, nozzle, an outlet of reactant and multi-point optical fiber online thermo-detector. In said reactor, there are a process water jacket area, supercritical water oxidation area, a sub-critical water area for dissolving inorganic salts on the bottom of the inner cylinder of the reactor. The process water jacket area is divided into two or more than two layer area by the supporting ring and the spring ring. The water, after removing oxygen and removing salts, passes through porous-wall structure enters the reaction area and forming a protective water membrance over the inner wall of the reactor. The temperature sensor and optical fiber are placed in a sleeve which is placed near the central line of the reactor. Advantages are: easy to be maintained, safety operation.

Owner:SHANDONG UNIV

Methods for producing films using supercritical fluid

A method for forming a continuous film on a substrate surface that involves depositing particles onto a substrate surface and contacting the particle-deposited substrate surface with a supercritical fluid under conditions sufficient for forming a continuous film from the deposited particles. The particles may have a mean particle size of less 1 micron. The method may be performed by providing a pressure vessel that can contain a compressible fluid. A particle-deposited substrate is provided in the pressure vessel and the compressible fluid is maintained at a supercritical or sub-critical state sufficient for forming a film from the deposited particles. The Tg of particles may be reduced by subjecting the particles to the methods detailed in the present disclosure.

Owner:BATTELLE MEMORIAL INST

Isolation of polyphenolic compounds from fruits or vegetables utilizing sub-critical water extraction

InactiveUS7208181B1Effective applicationEffective isolationBiocideAdhesive dressingsPhytochemicalDietary supplement

Anthocyanins, other flavonoids and related polyphenolic compounds are extracted from fruits or highly pigmented garden vegetables and their by-products using subcritical water with or without a secondary cosolvent. This method has the advantages of being relatively inexpensive, minimizes or totally avoids the use of objectionable solvents, and provides a facile means for supplying an ample source of concentrated phytochemicals for use in food formulation, dietary supplements and phyto-pharmaceutical applications.

Owner:US SEC AGRI

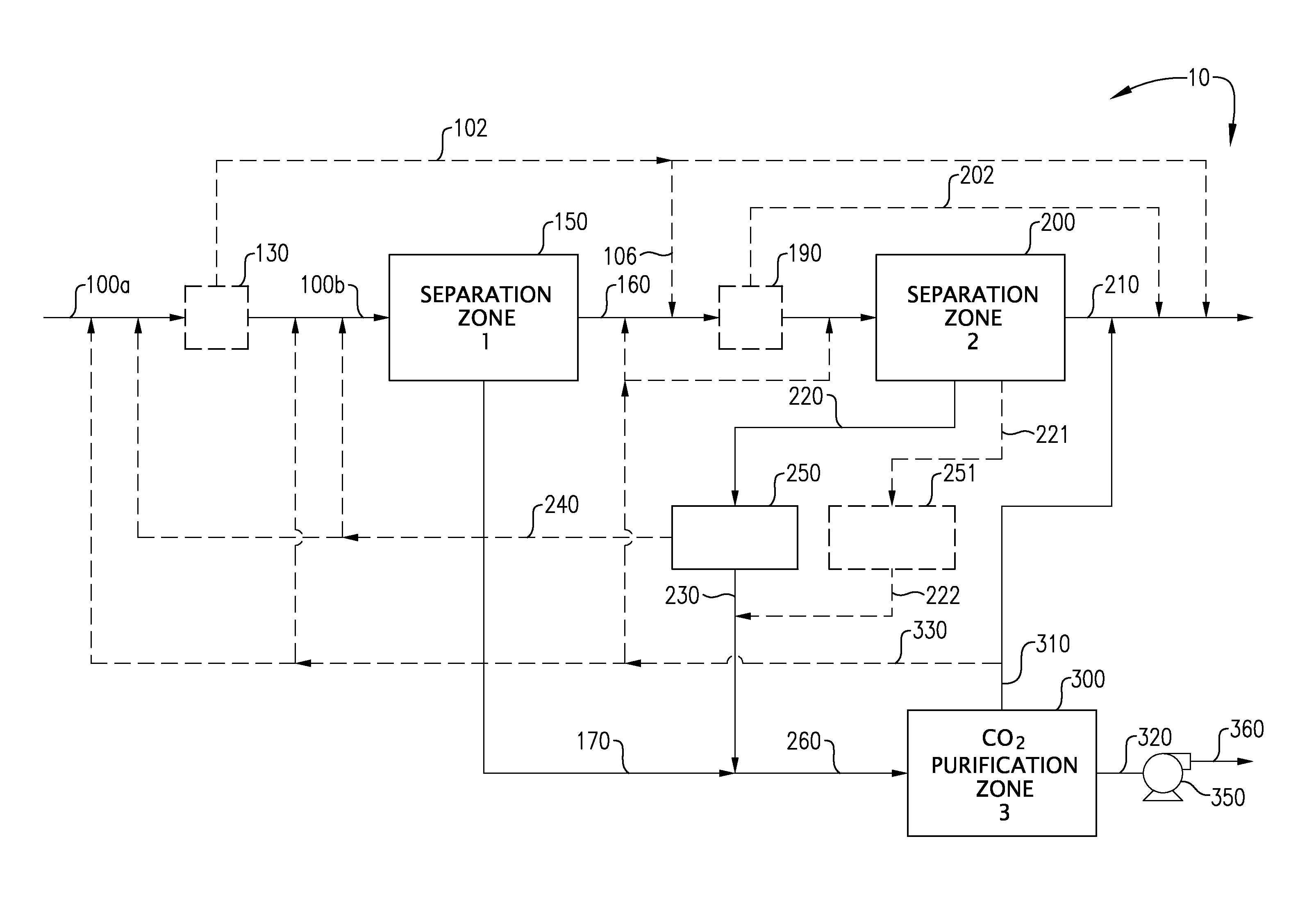

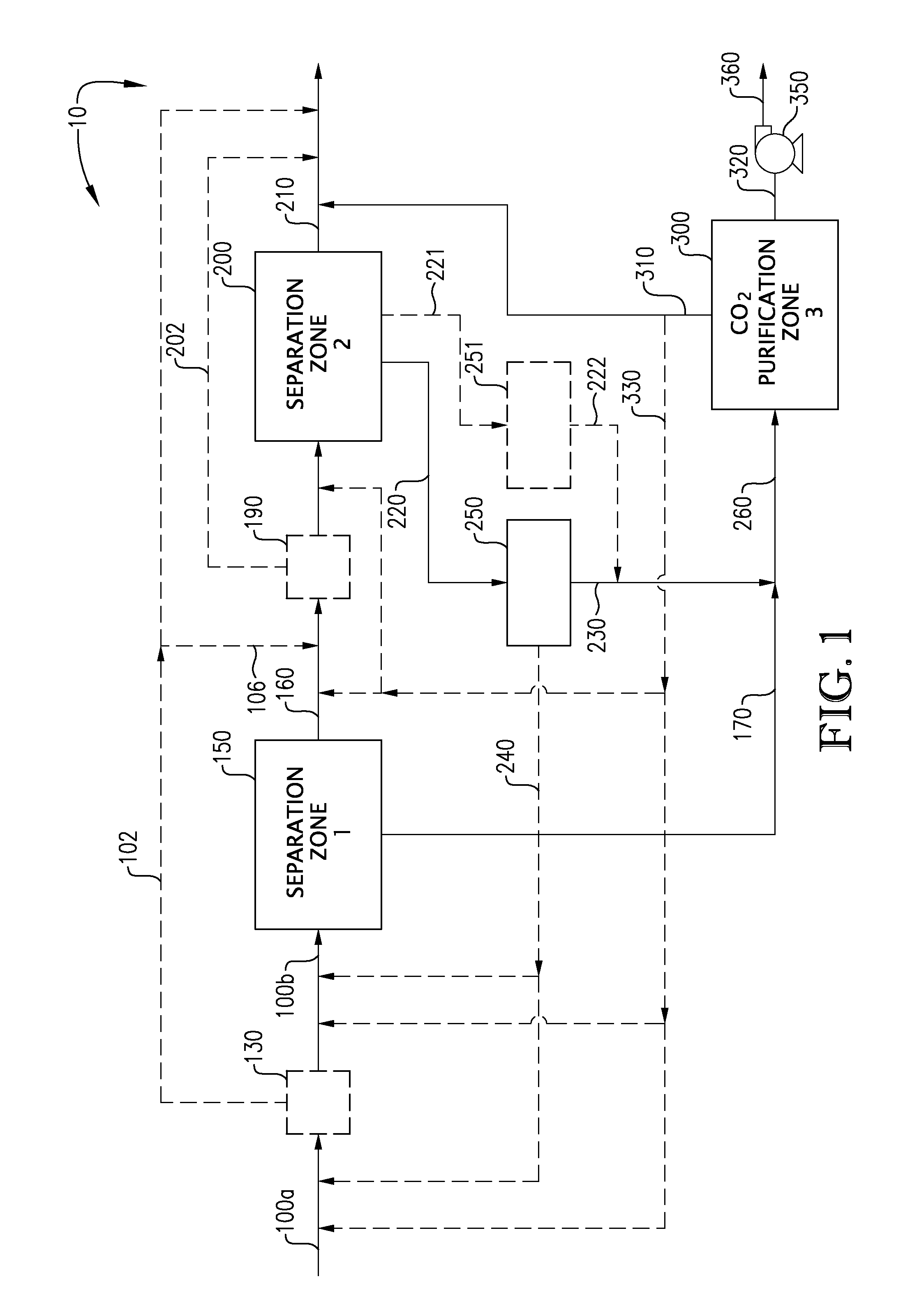

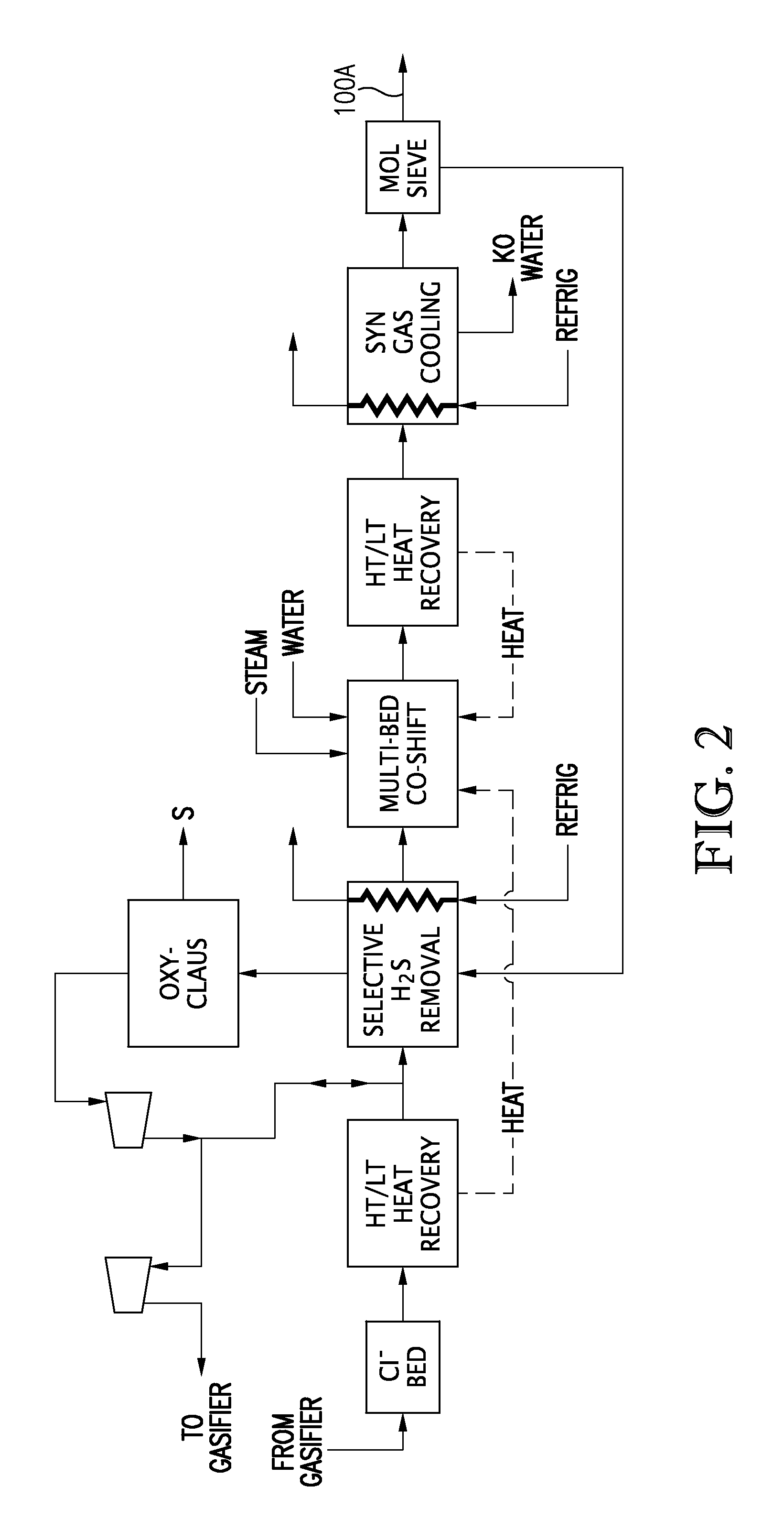

Carbon dioxide capture and liquefaction

ActiveUS20120006054A1Big advantageMinimize energy consumptionSolidificationLiquefactionLiquid stateHigh pressure

An energy-efficient method of recovering carbon dioxide (CO2) in a high-pressure liquid state from a high-pressure gas stream. The method includes cooling, condensing, and / or separating CO2 from a high-pressure gas stream in two or more separation zones and further purifying the resulting sub-critical pressure liquid CO2 streams in a third purification zone to thereby provide purified CO2. The purified liquid CO2 may be pumped to above the critical pressure for further utilization and / or sequestration for industrial or environmental purposes.

Owner:KELLER ARNOLD

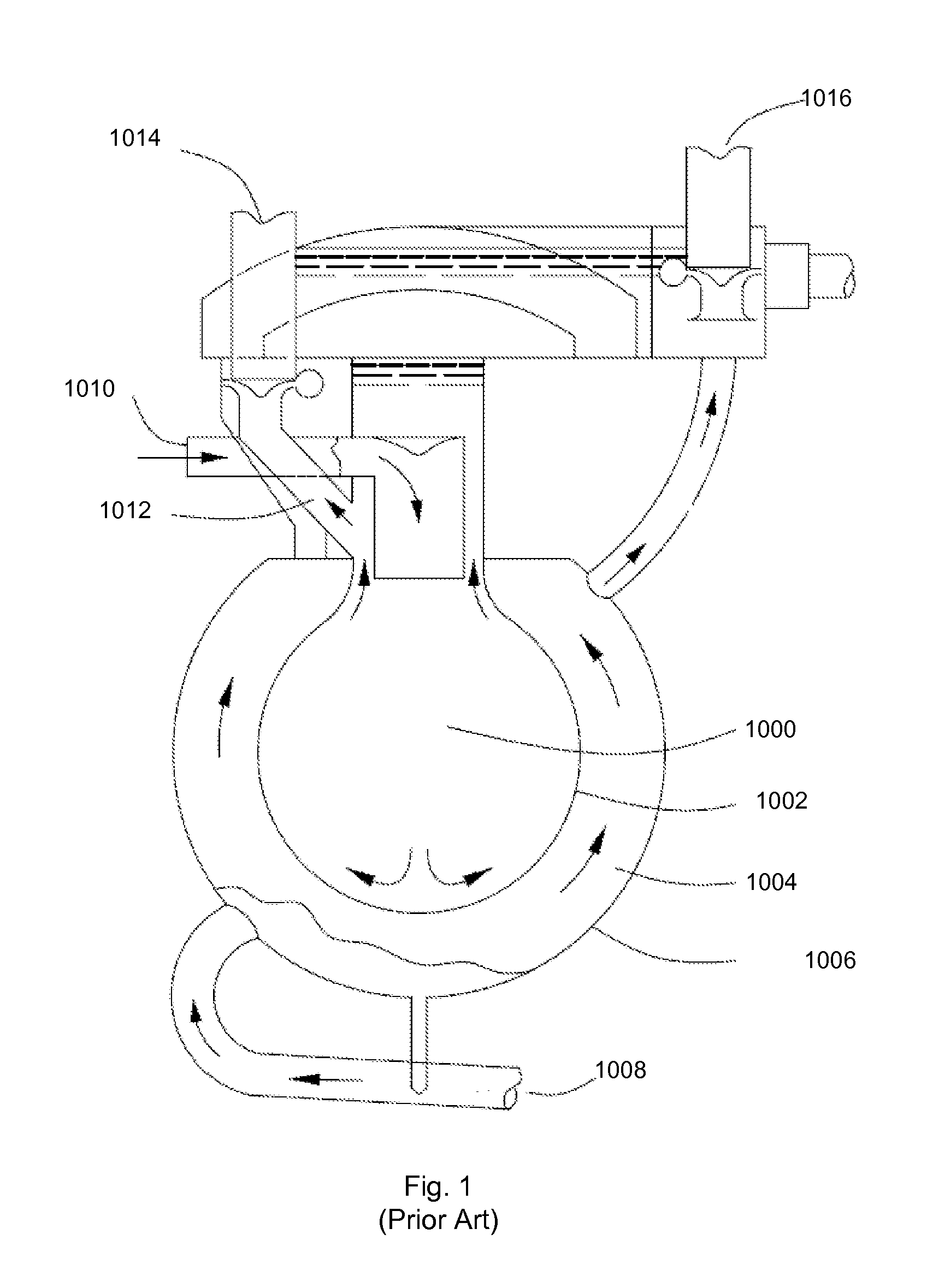

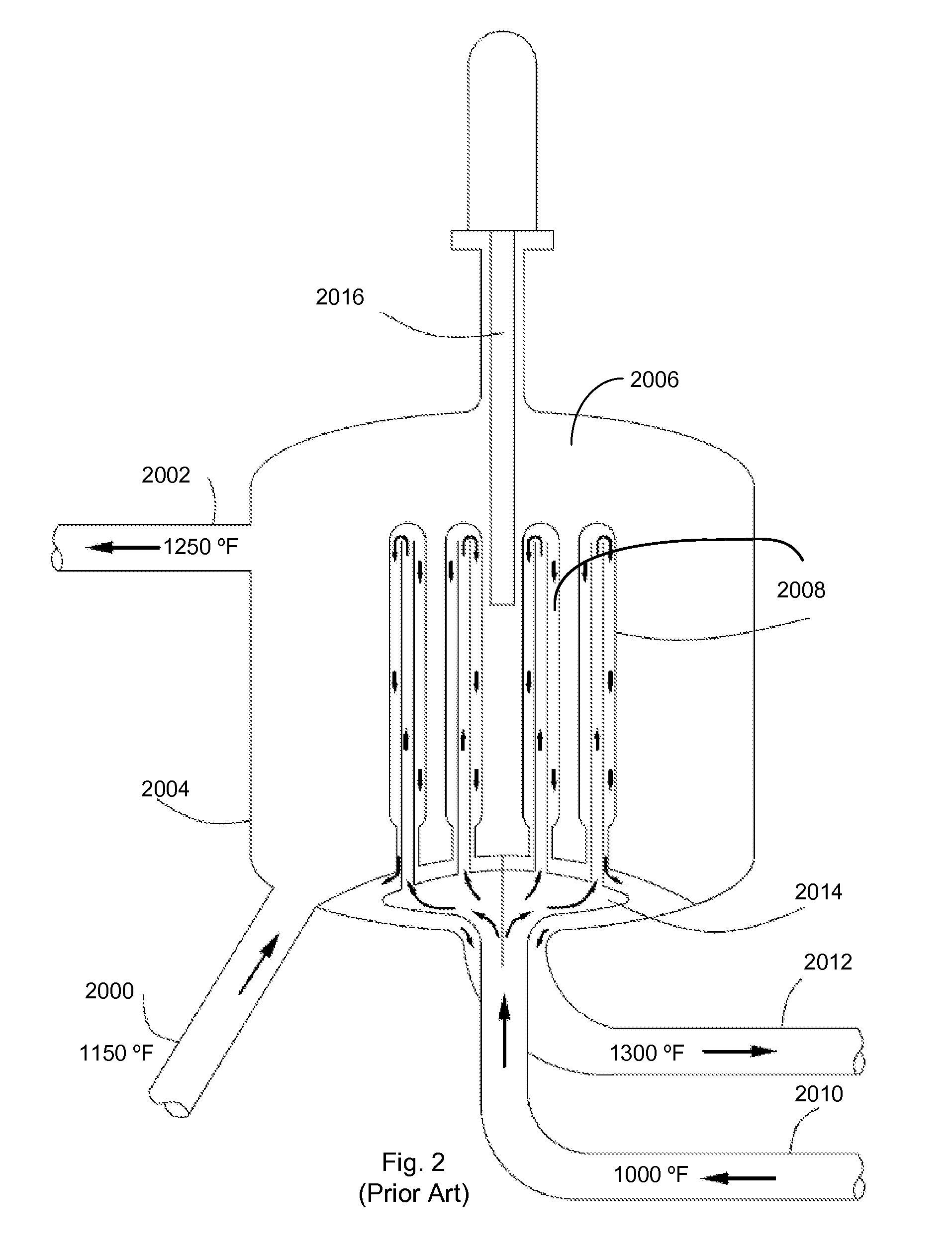

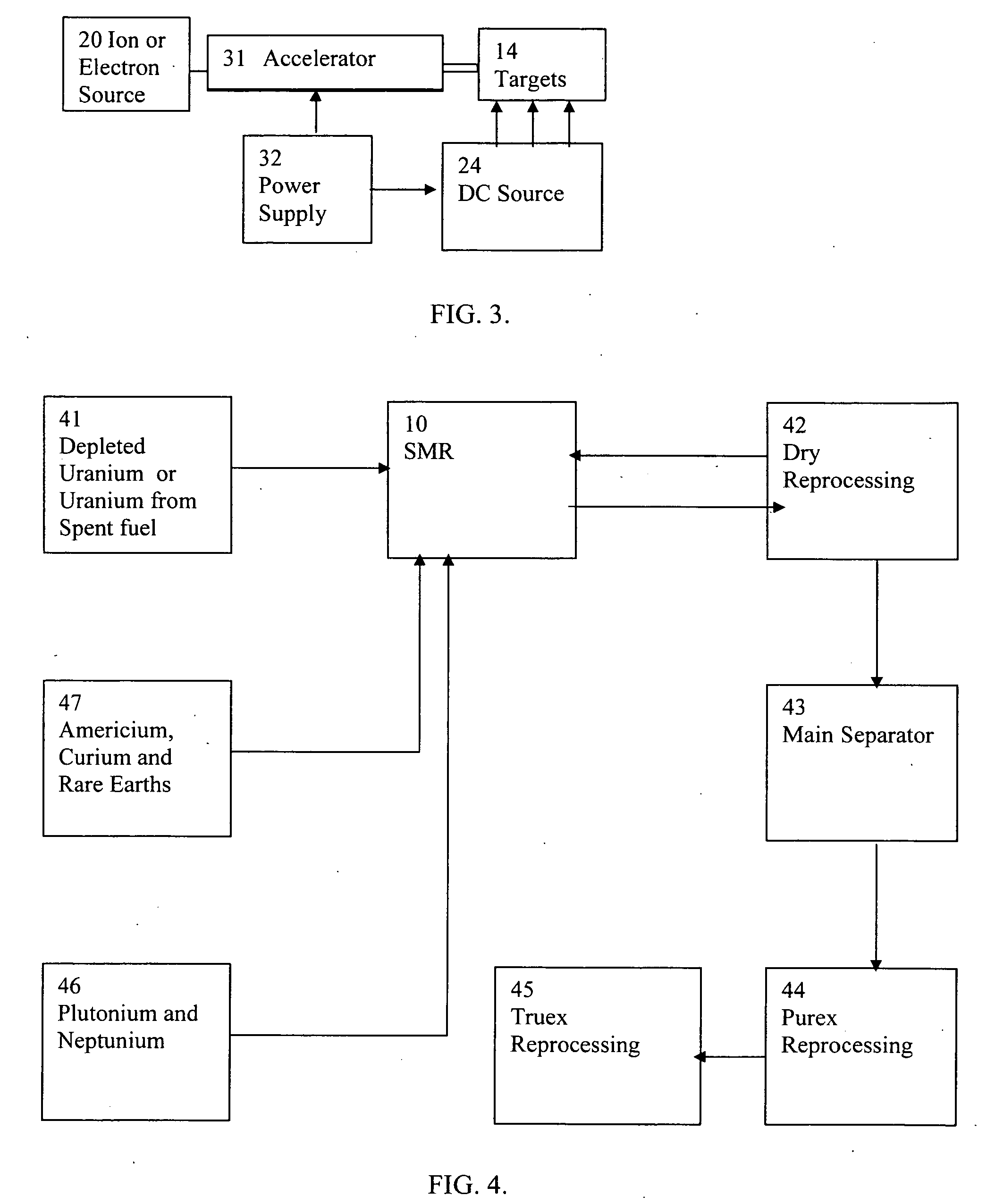

High flux sub-critical reactor for nuclear waste transmulation

InactiveUS20080232533A1Improve distributionImprove economyConversion outside reactor/acceleratorsNuclear energy generationHigh fluxPu element

A process to safely convert about 95% of the nuclear waste into a usable fuel source is disclosed. The process, involving a sub-critical power reactor and a proliferation-resistant fuel cycle, consumes depleted uranium or thorium fuel with fissionable fuel, including reactor or weapons-grade plutonium. The reactor is comprised of coaxial neutron and energy-amplifying regions separated by moderating and thermal neutron absorbing layers. Control of the water or gas-cooled reactor is provided by plutonium-helium loops with a variable volume flow rate and an external source of neutrons that quickly reacts to any fluctuations of the reactor parameters. A second embodiment of the invention is a compact sub-critical propulsion reactor utilizing fission electric cell and thermo-acoustic technology for electrical power generation.

Owner:BLANOVSKY ANATOLY

Graphite composites and methods of making such composites

InactiveUS6927250B2Improve volume expansionReduce needSpecial tyresBulk chemical productionConductive polymerPolymer composites

The invention may be practiced to make graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites. One method of making the graphite aforementioned composites includes introducing an intercalant into at least one interstice of at least one flake of natural graphite. The method also includes introducing a fluid into the at least one interstices of the flake. Preferably, the fluid comprises at least one of a sub-critical fluid, near critical point fluid, or a supercritical fluid. Furthermore the method includes blending the flake with a polymer, thereby forming a graphite-polymeric composite.

Owner:GRAFTECH INT HLDG INC

Method for preparing therapeutic ophthalmic articles using compressed fluids

The present invention describes a method for the impregnation of a drug or a drug composition into ophthalmic articles, in order to prepare drug sustained release systems mainly for the treatment of glaucoma and other eye diseases. Ophthalmic articles can be for example contact lenses. The drug or drug composition is dissolved in a compressed fluid, or mixture of compressed fluids, in a liquid, sub-critical liquid, gaseous or supercritical state. Co-solvents can be added to increase drug solubility in the compressed fluids. The mixture is subsequently contacted with the ophthalmic article. This process can be done in a single step or in a double step manner. The impregnation can be carried out in finished or semi-finished ophthalmic articles.

Owner:UNIVE DE COIMBRA +1

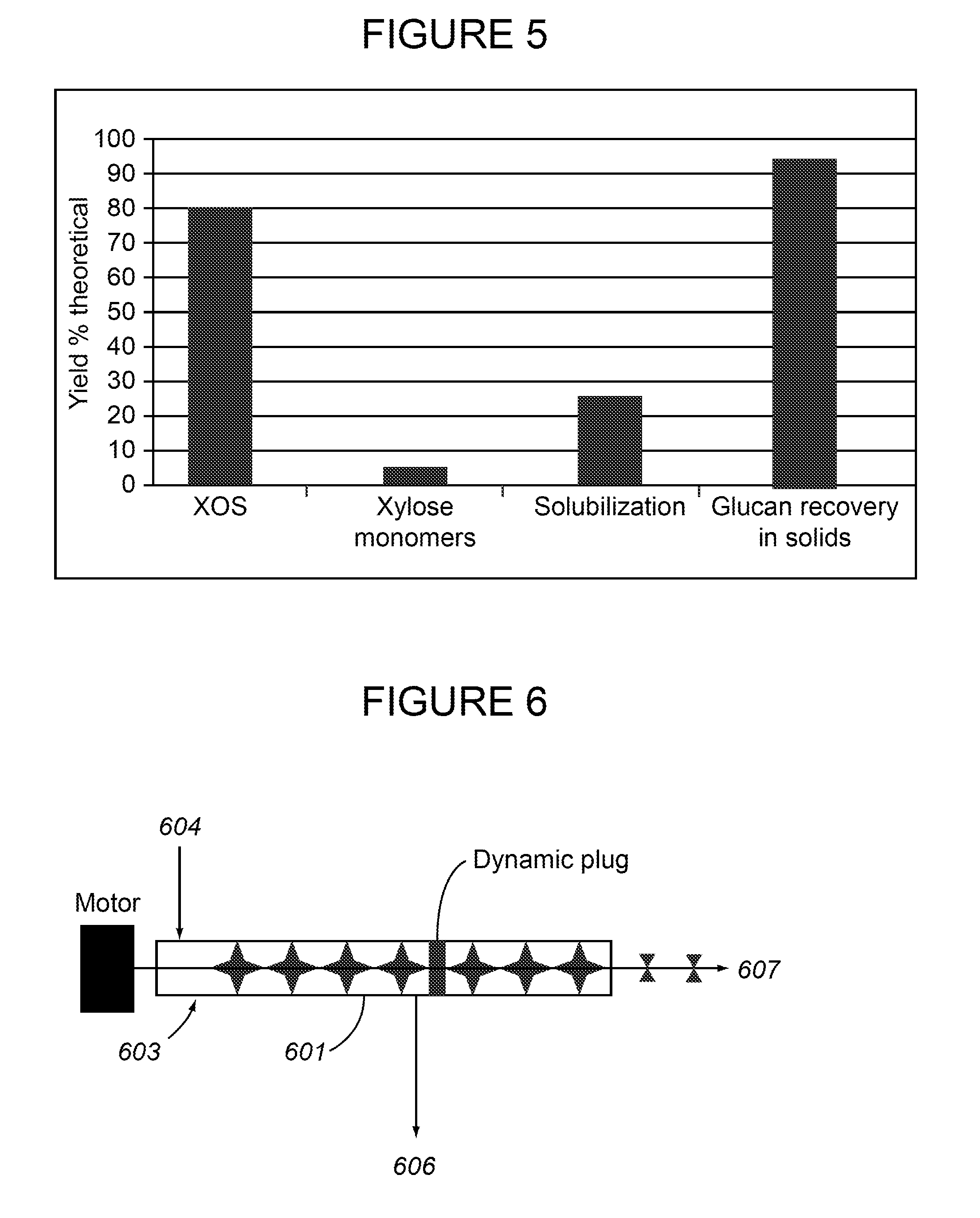

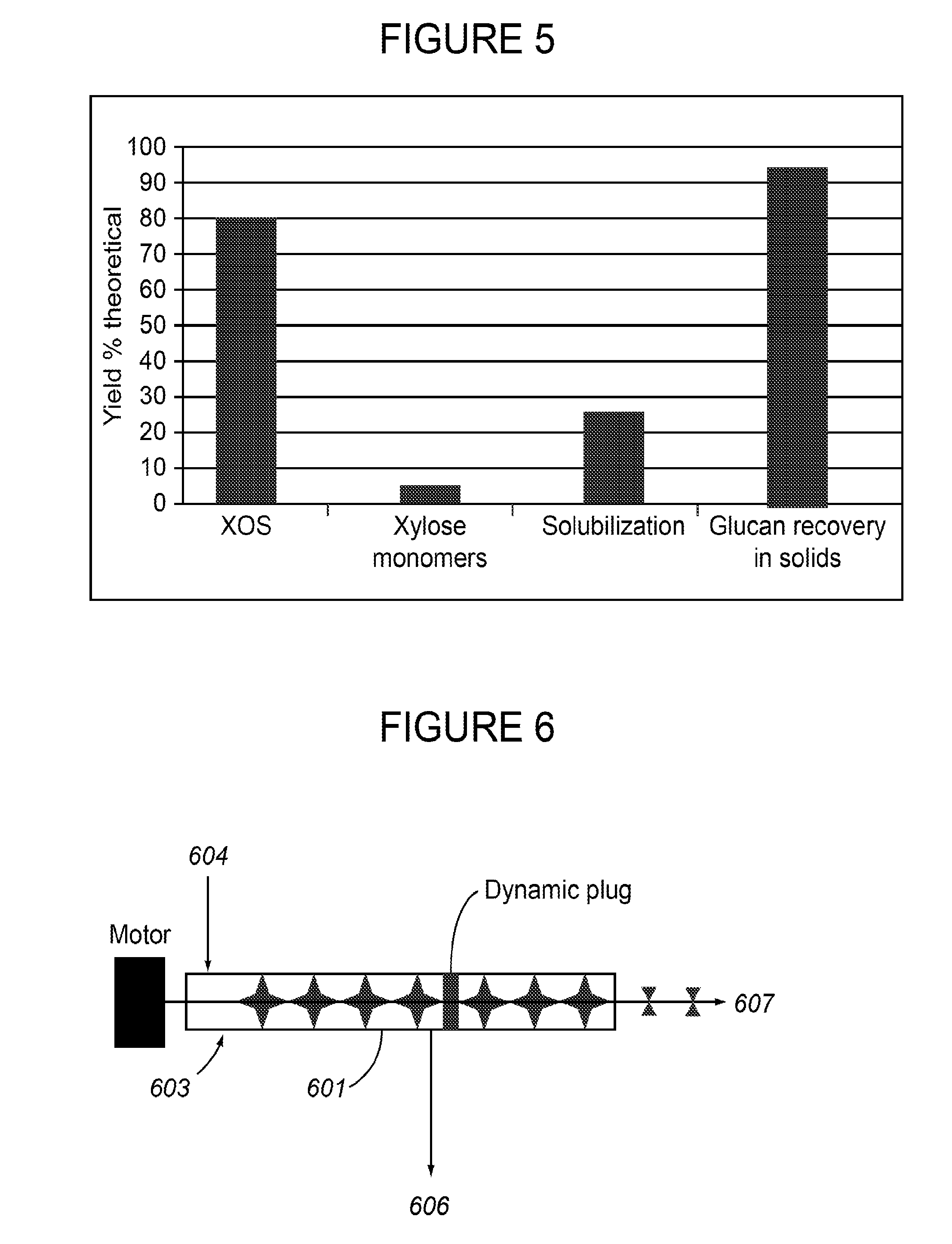

Solvo-thermal hydrolysis of xylose

ActiveUS20100048924A1Rapid coolingOrganic chemistryChemical/physical/physico-chemical processesSolventFurfural

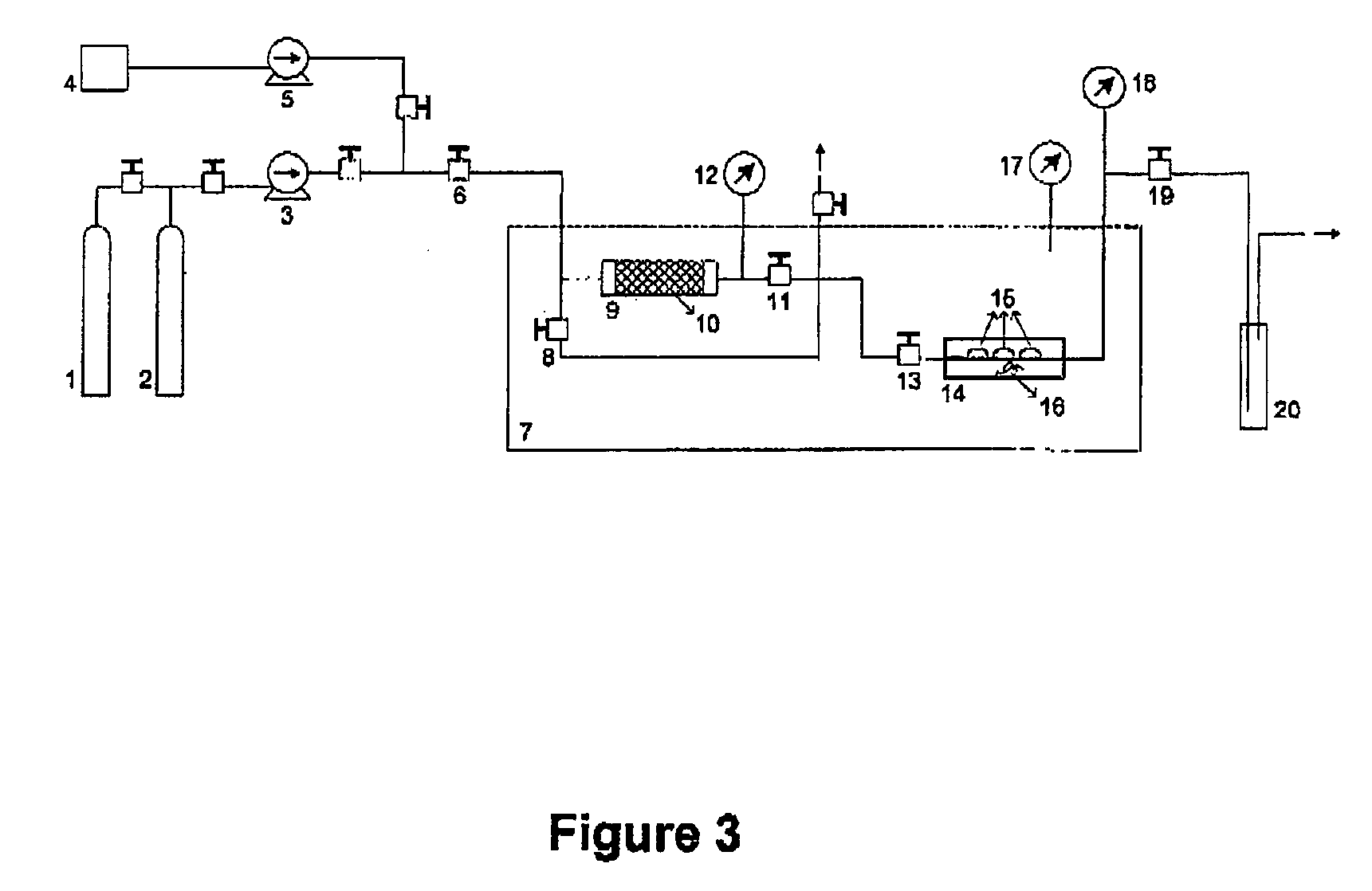

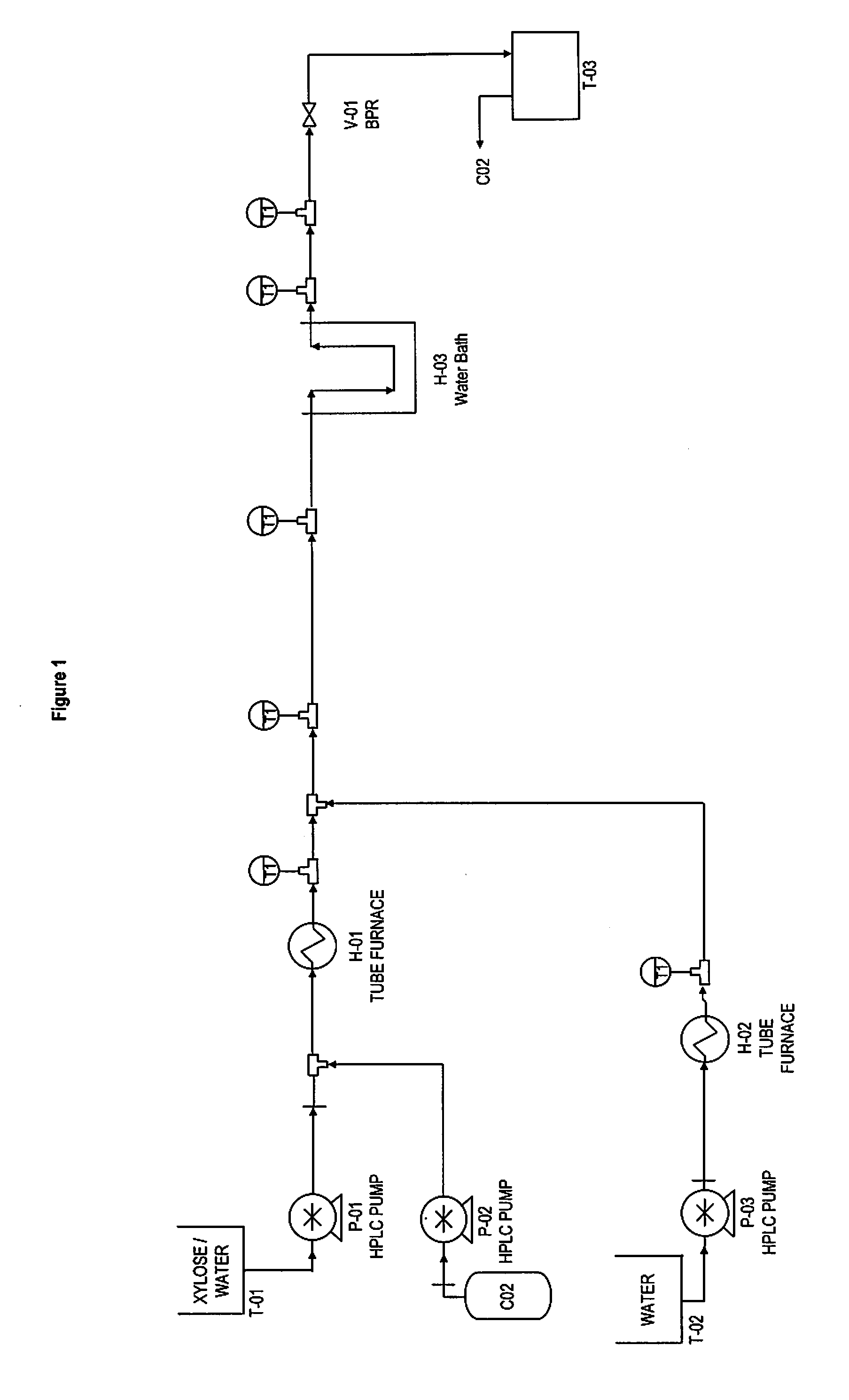

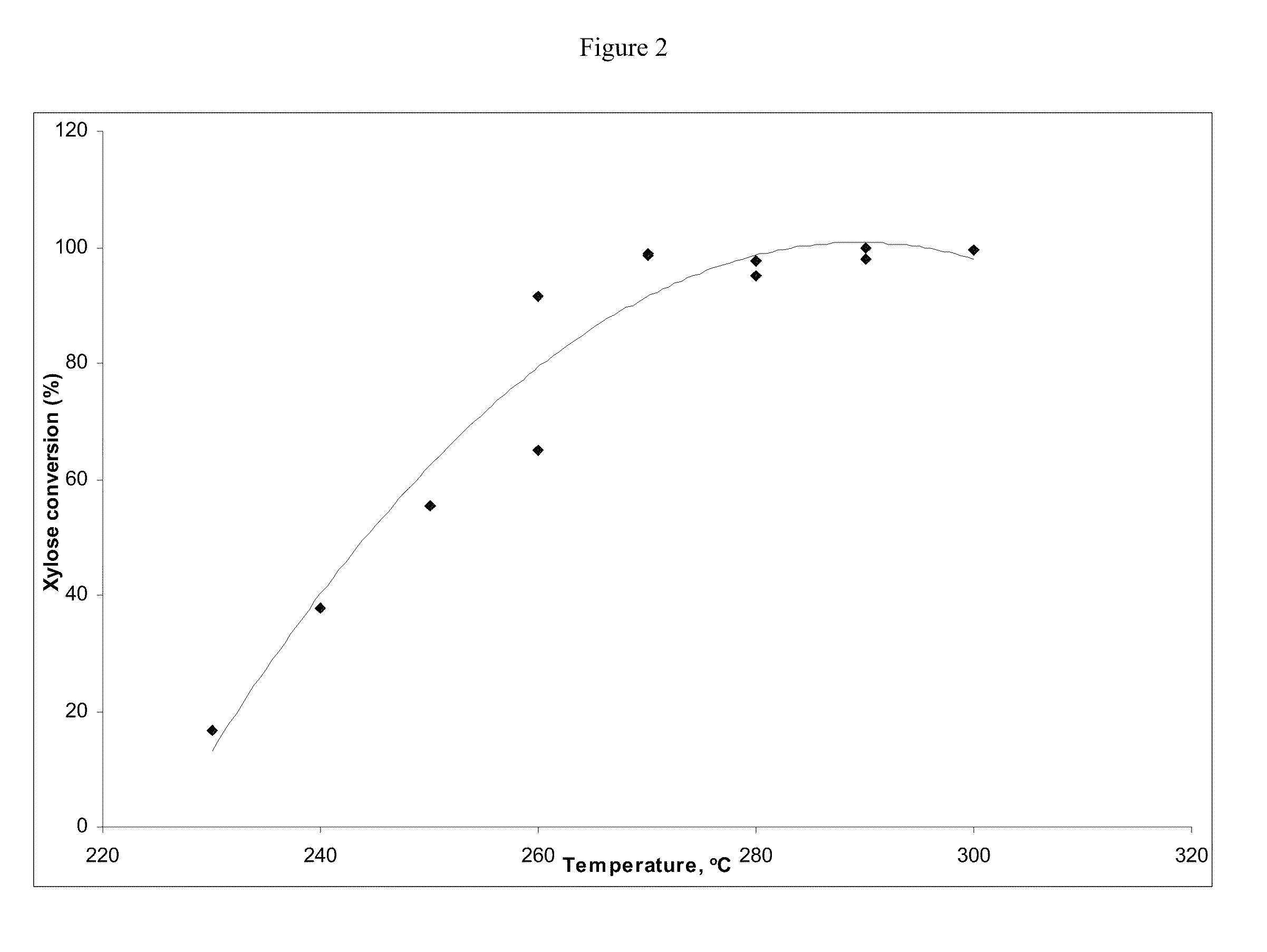

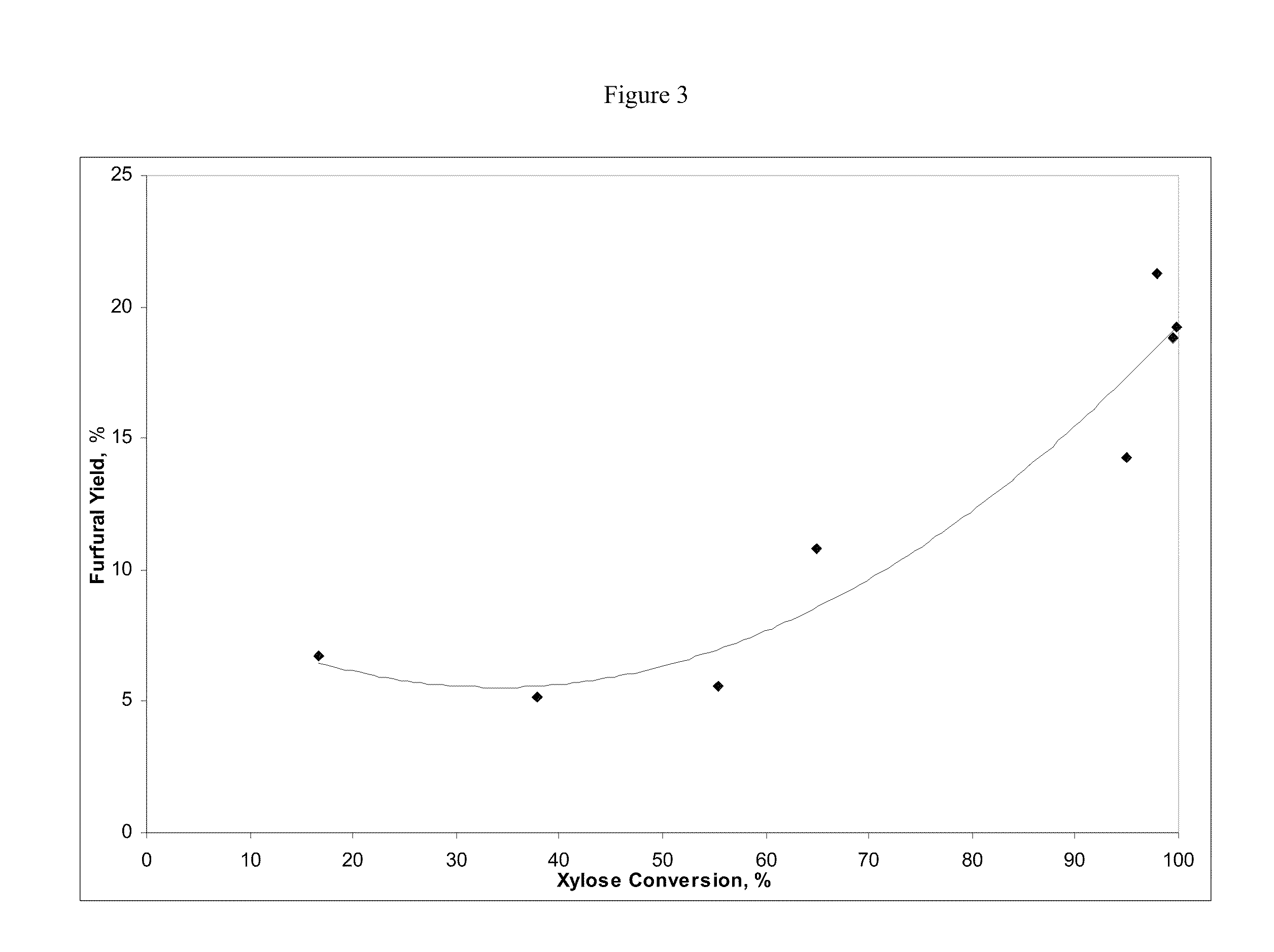

The invention relates to a process for producing furfural from xylose comprising: (a) mixing an aqueous xylose solution containing xylose oligosaccharides with sub-critical or near-critical water to form a mixture at a first temperature and a first pressure; (b) maintaining the mixture at the first temperature and the first pressure for a first time period; and (c) rapidly cooling the mixture to a second temperature and a second pressure, wherein furfural is produced by the process (d) process can also be carried out with or without mixing of carbon dioxide with aqueous xylose solution before it is mixed with sub-critical or near-critical water to form a mixture at a first temperature and pressure.

Owner:RENMATIX INC

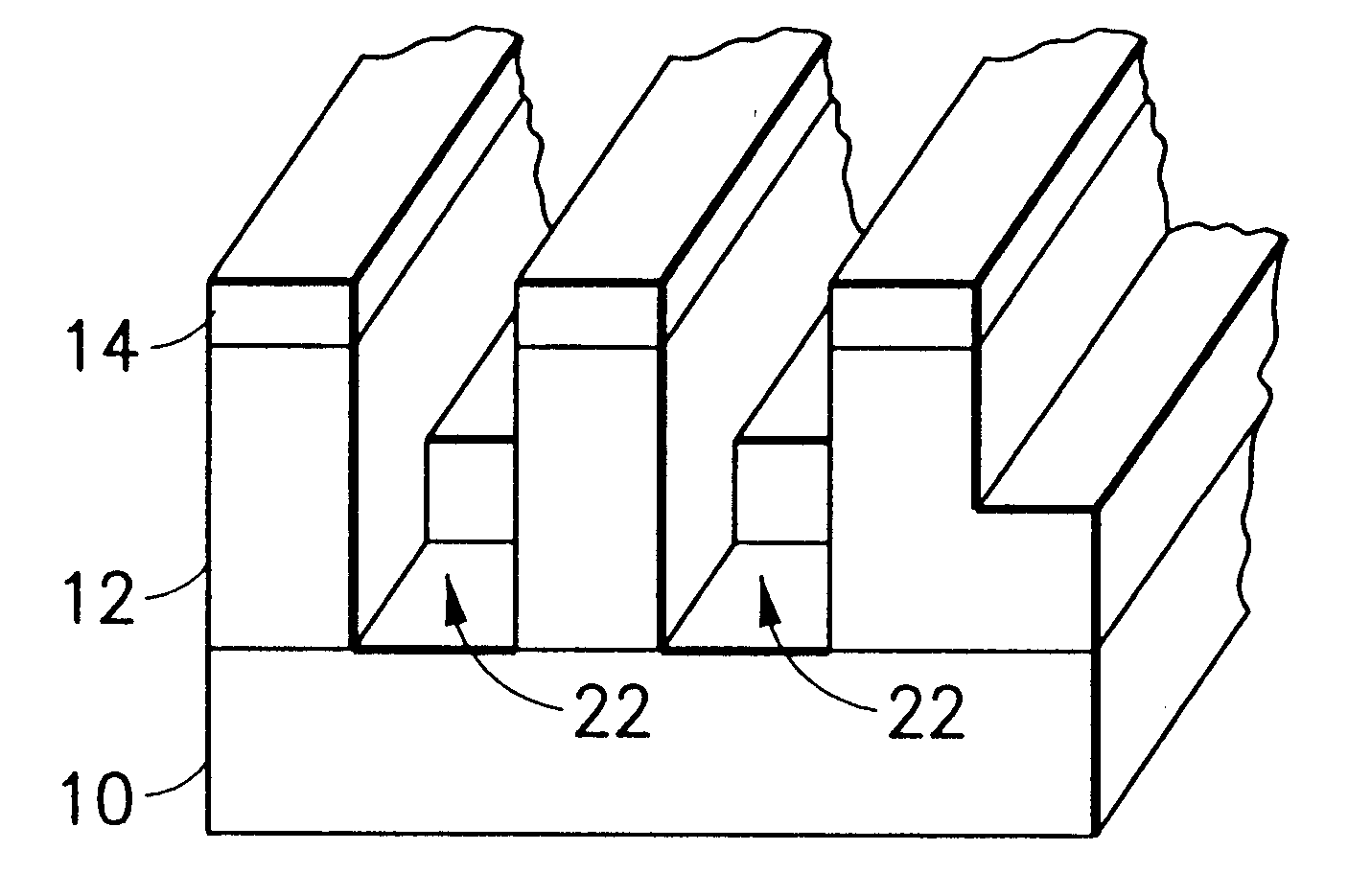

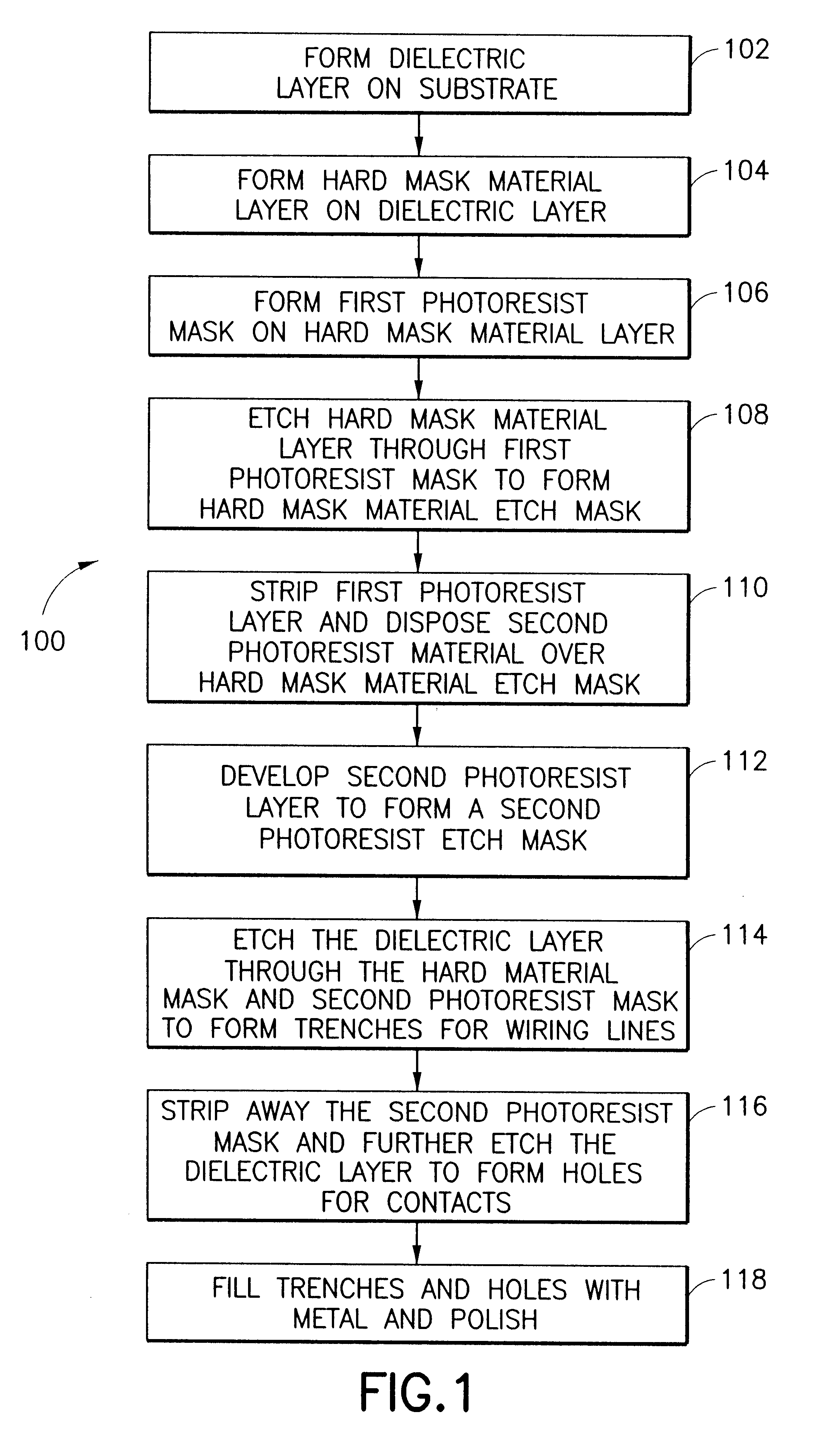

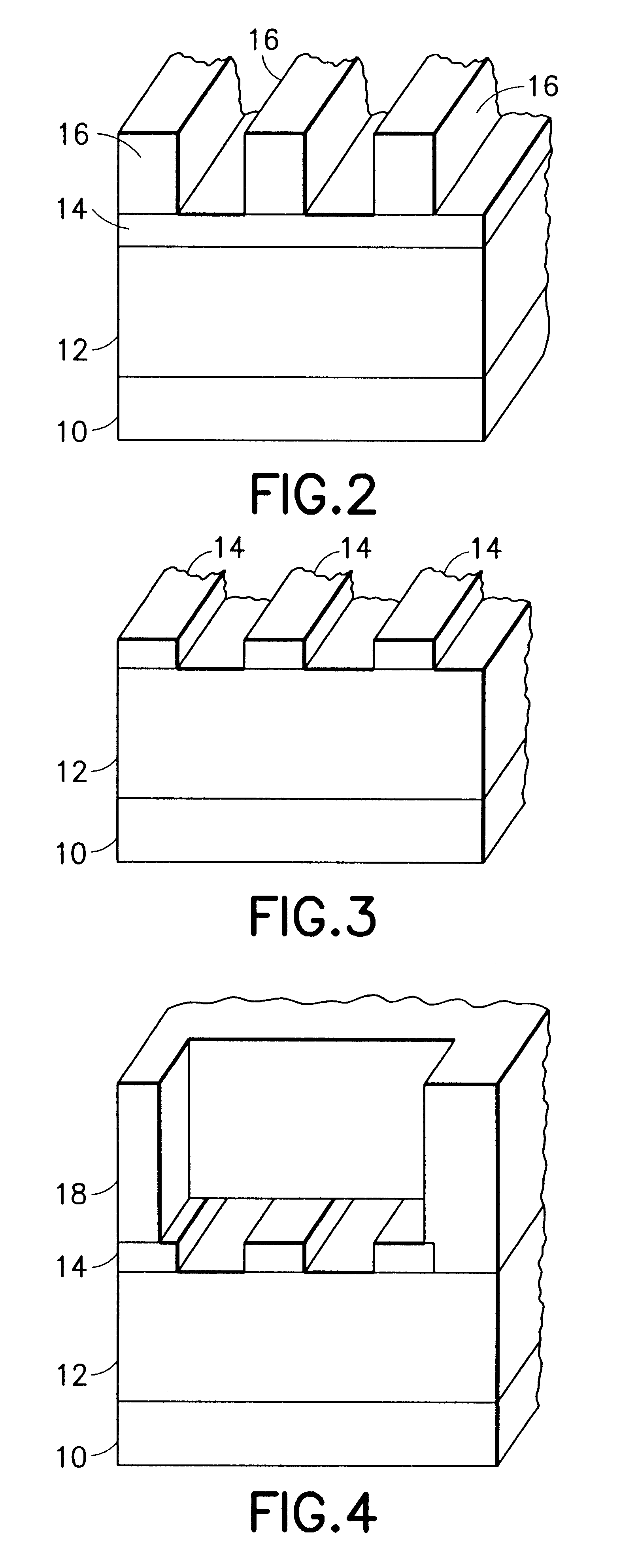

Process for self-alignment of sub-critical contacts to wiring

A method for forming contacts on an integrated circuit that are self-aligned with the wiring patterns of the integrated circuit. In the method a thicker lower layer of a first material and a thinner upper layer of a second material are formed on a substrate. The features of the metal wiring is patterned first on the upper layer. The wiring pattern trenches are etched through the thinner surface layer, and partially through the second, thicker layer. After the wiring pattern is etched, the contacts for the wiring layer are printed as line / space patterns which intersect the wiring pattern. The contact pattern is etched into the lower, thicker layer with an etch process that is selective to the upper thinner layer. The contact is only formed at the intersection point of the wiring image with the contact image, therefore the contact is self-aligned to the metal.

Owner:IBM CORP

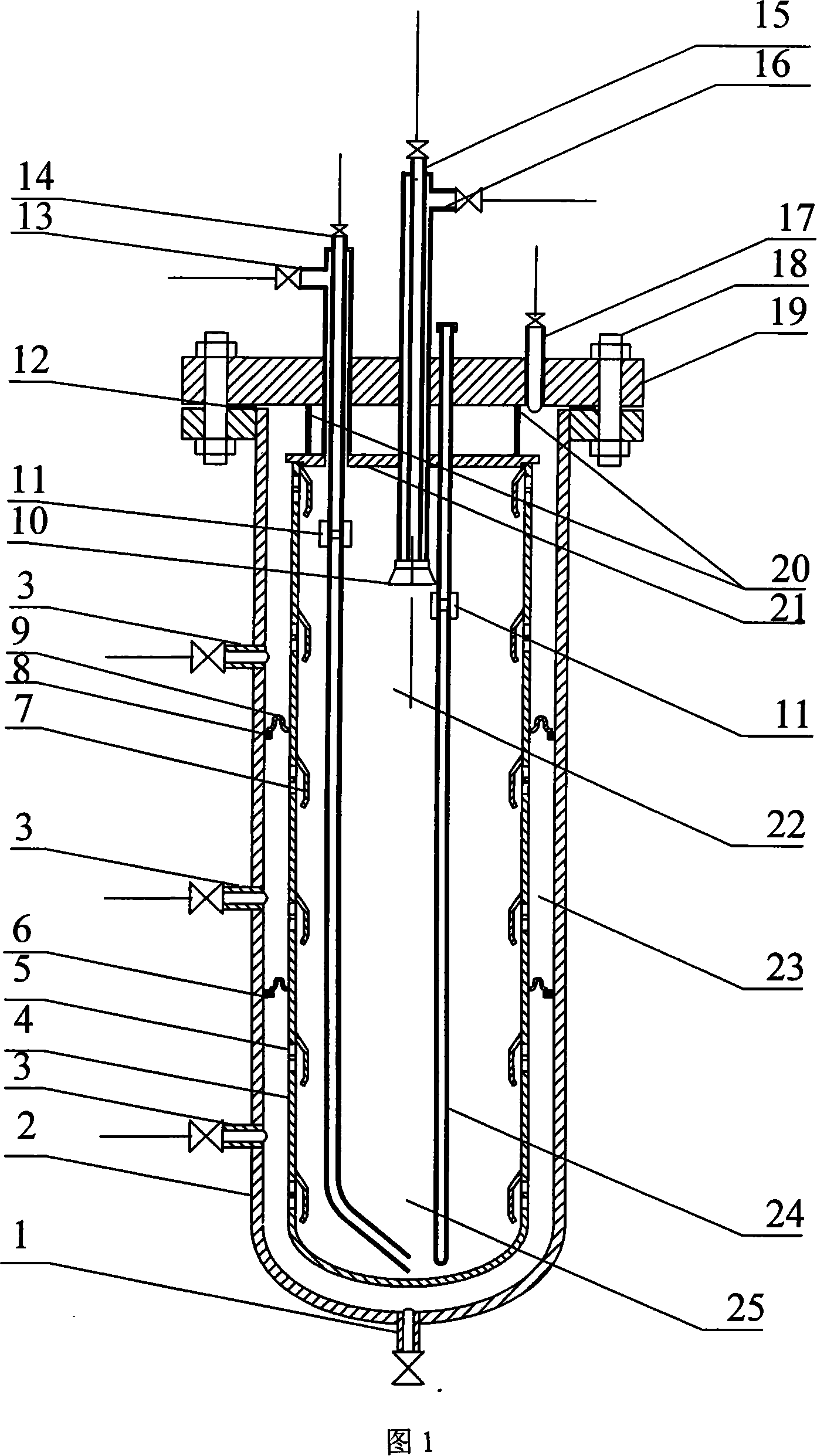

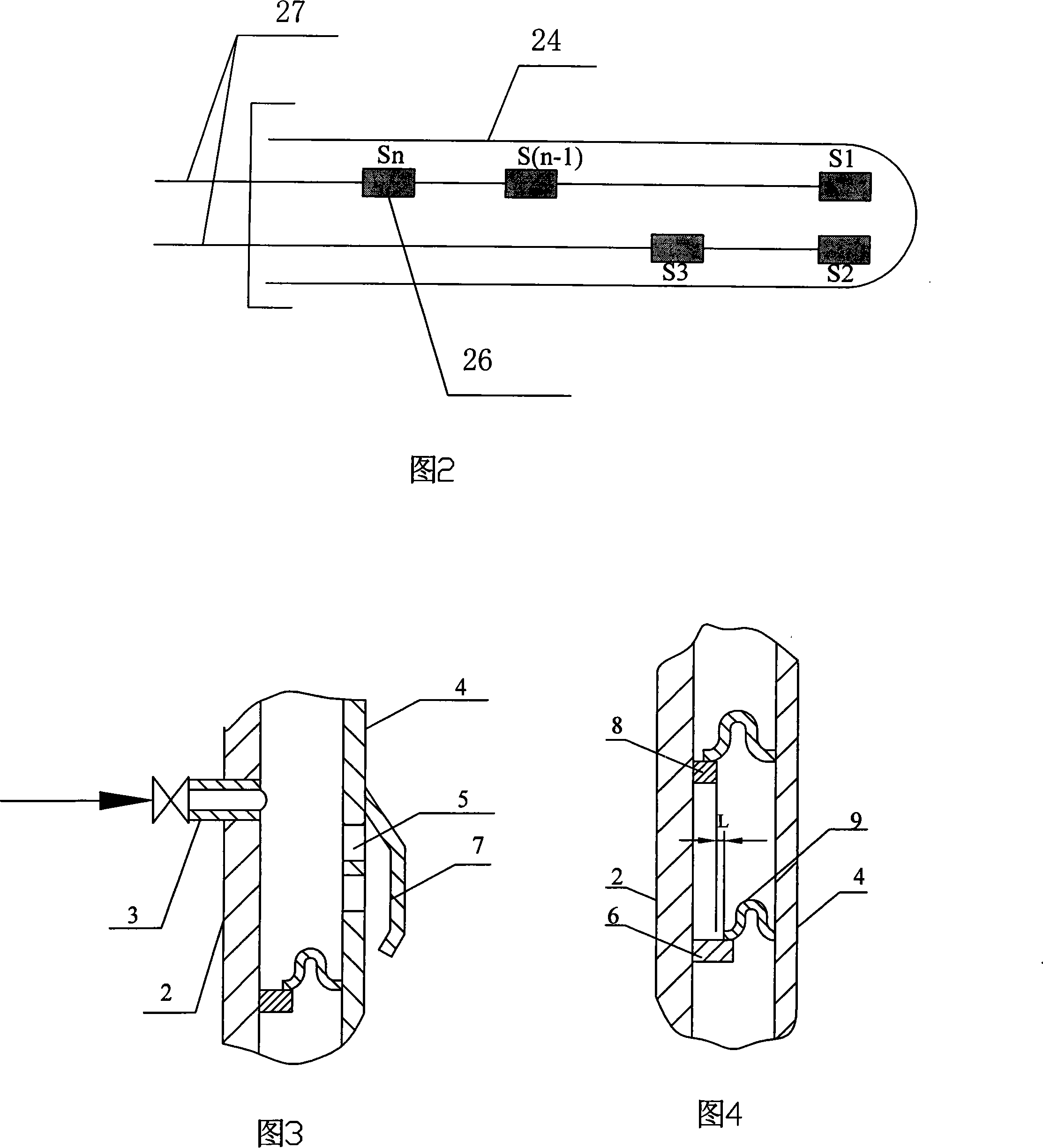

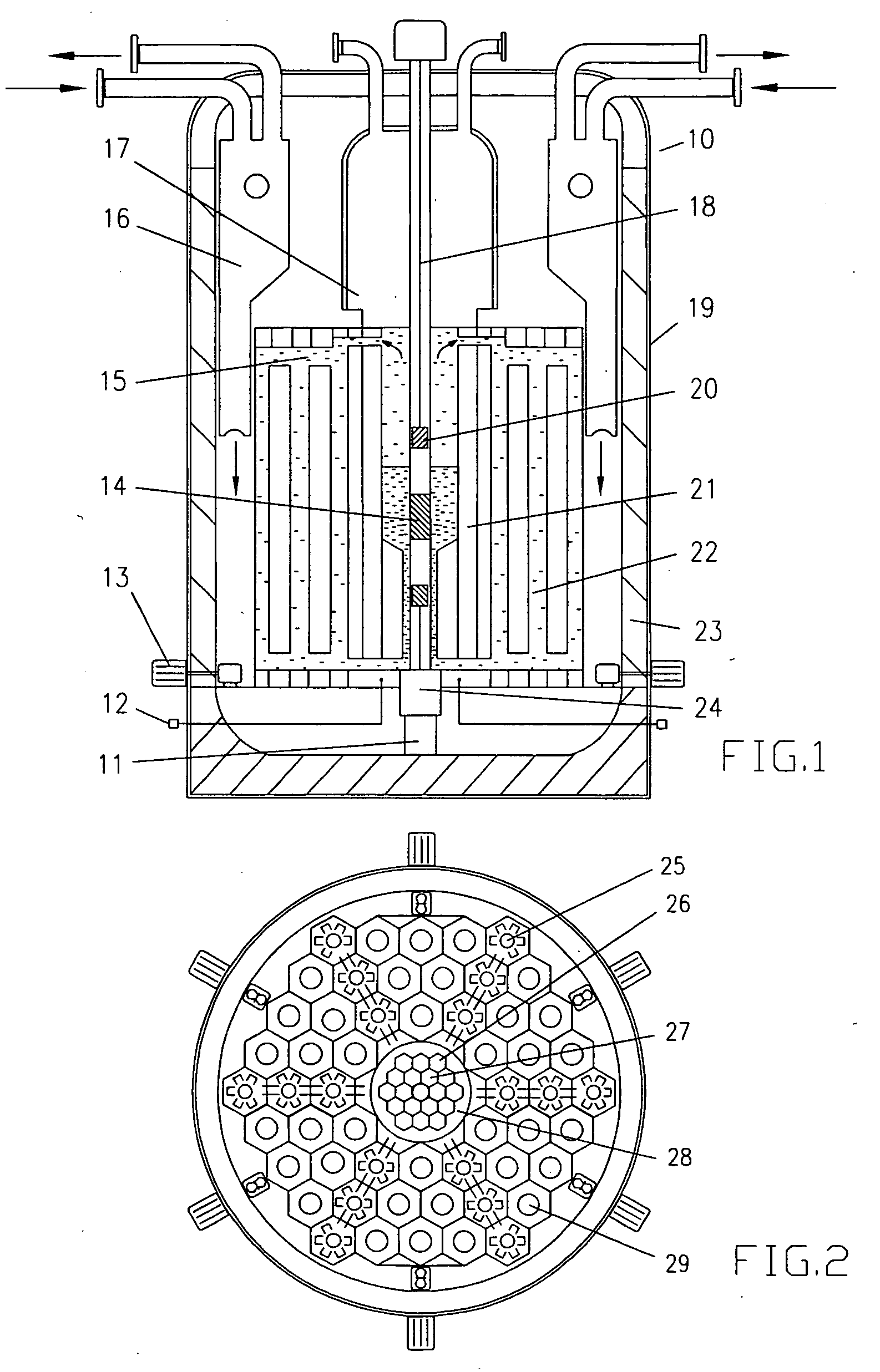

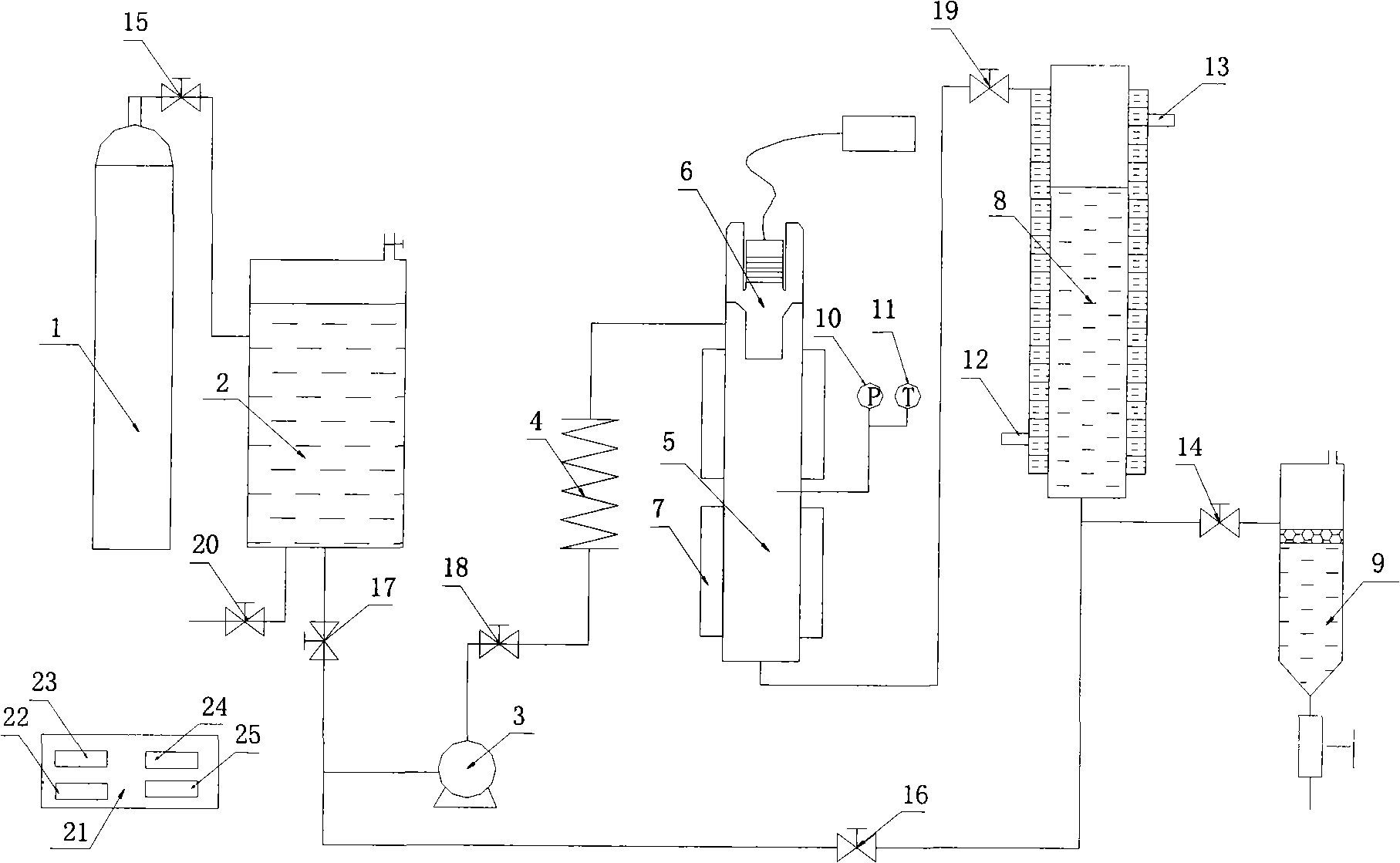

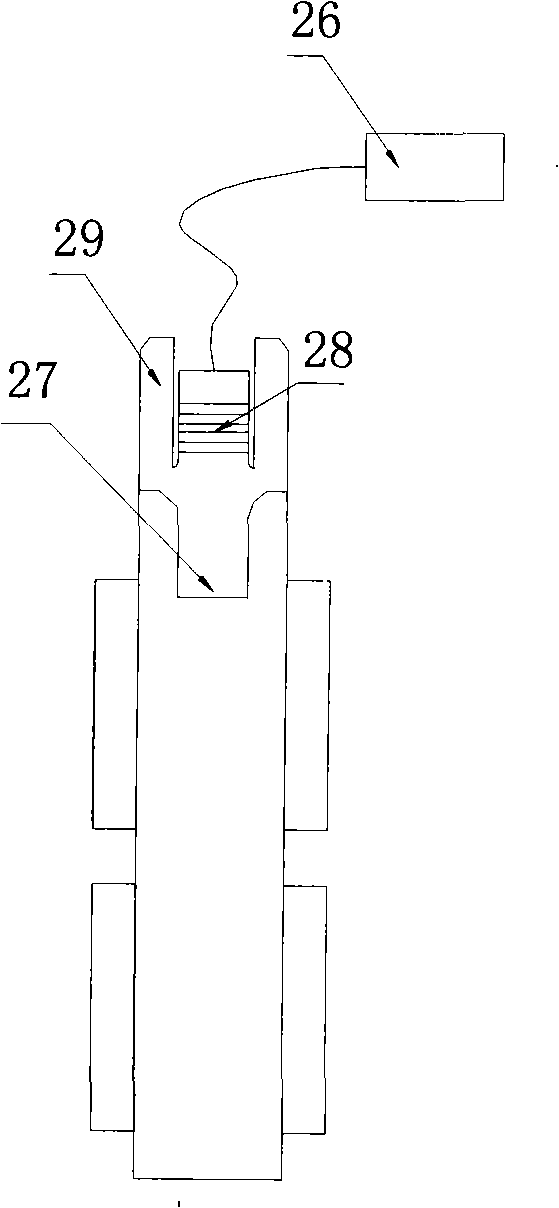

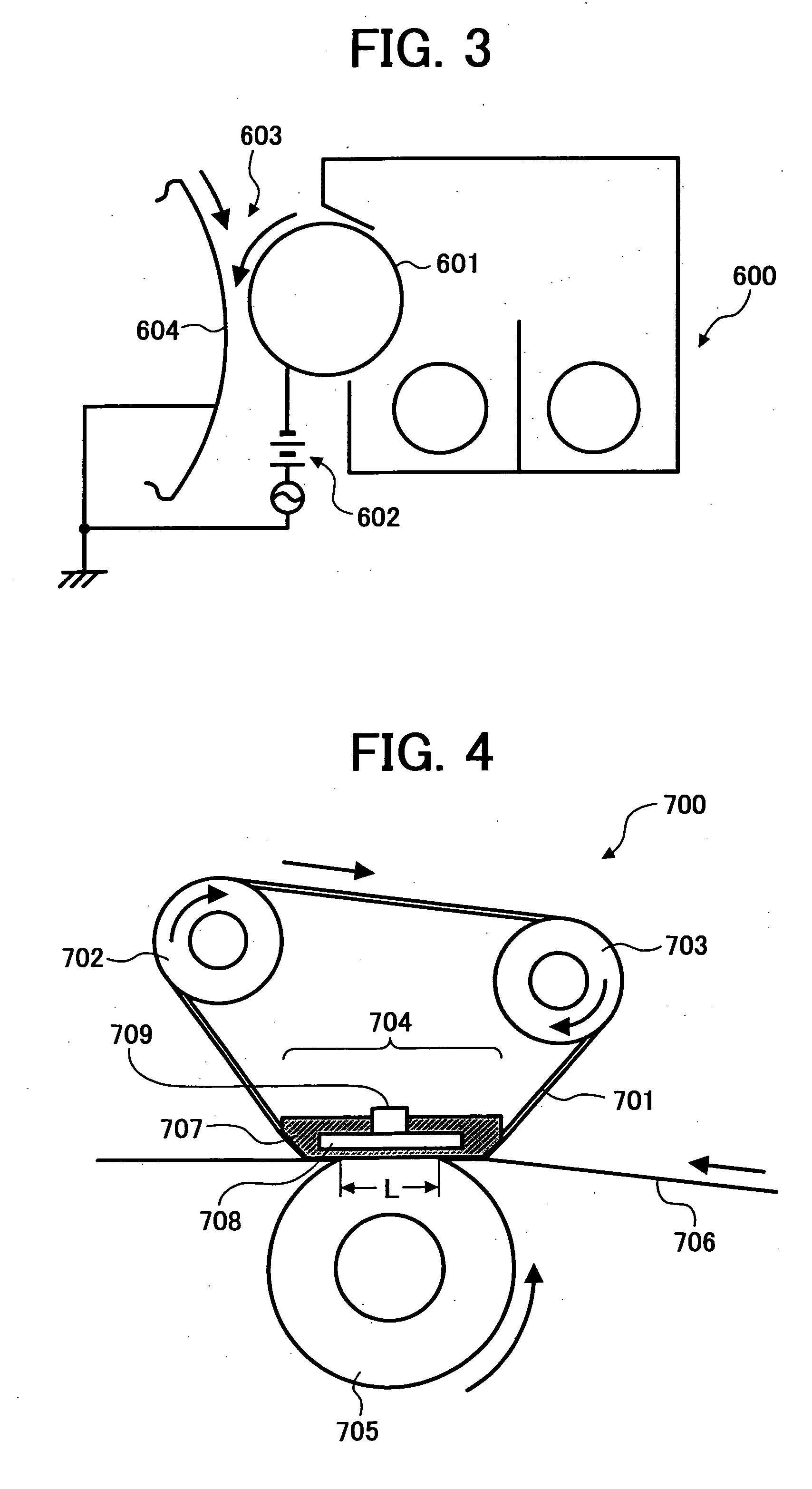

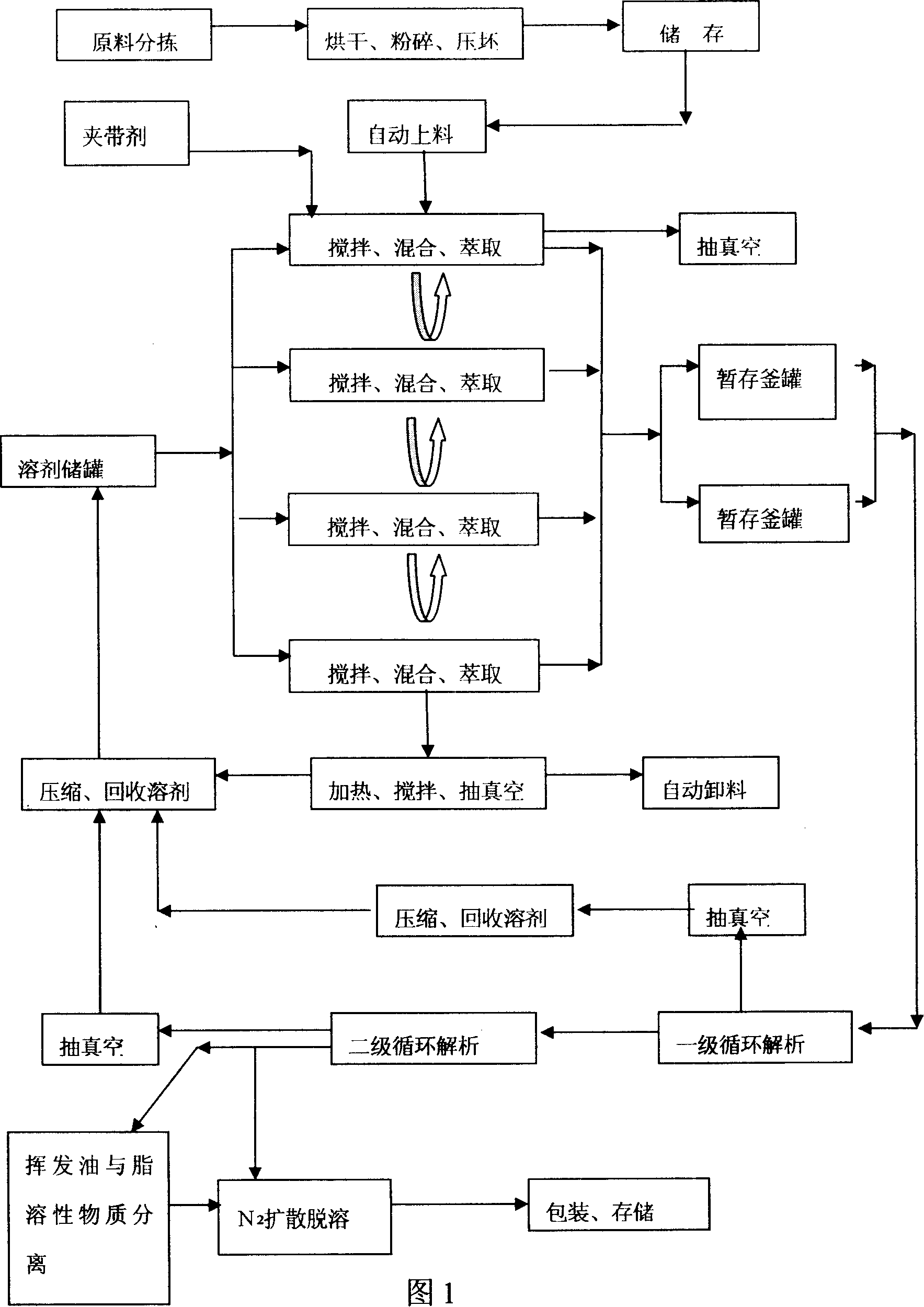

Ultrasonic reinforced subcritical water extraction method of natural product effective ingredient and device

InactiveCN101274156AHigh extraction rateReduce extraction timeEnergy based chemical/physical/physico-chemical processesSolid solvent extractionElectricityNatural product

The invention provides an extraction method and a device used for extracting ultrasonic reinforced sub-critical water of effective component of a natural outcome. The method is mainly characterized in that a pre-disposed raw material is arranged in an extraction kettle; the sub-critical water is taken as an extraction solvent to carry out the exaction under the conditions of 1 to 20MPa of extraction pressure, 50 to 500W of ultrasonic power and 20 to 80KHz of ultrasonic frequency. The method has high extraction efficiency and short extraction time. The device is mainly characterized in that the extraction kettle is provided with an ultrasonic reinforced part which comprises an ultrasonic generator and an energy changing head; the ultrasonic generator is arranged on the external surface of the extraction kettle and at the upper part of the extraction kettle; the energy changing head and the extraction kettle cover are processed into a whole; the piezoelectric ceramic wafer of the energy changing head is arranged at the upper end of the extraction kettle cover; the variable-spoke rod of the energy changing head is directly arranged in the extraction kettle by the extraction kettle cover. The device can carry out selectable exaction of the articles to be extracted by changing the extraction parameters (temperature, pressure, time, etc.), thus realizing static extraction or dynamic circulation extraction.

Owner:SOUTH CHINA UNIV OF TECH

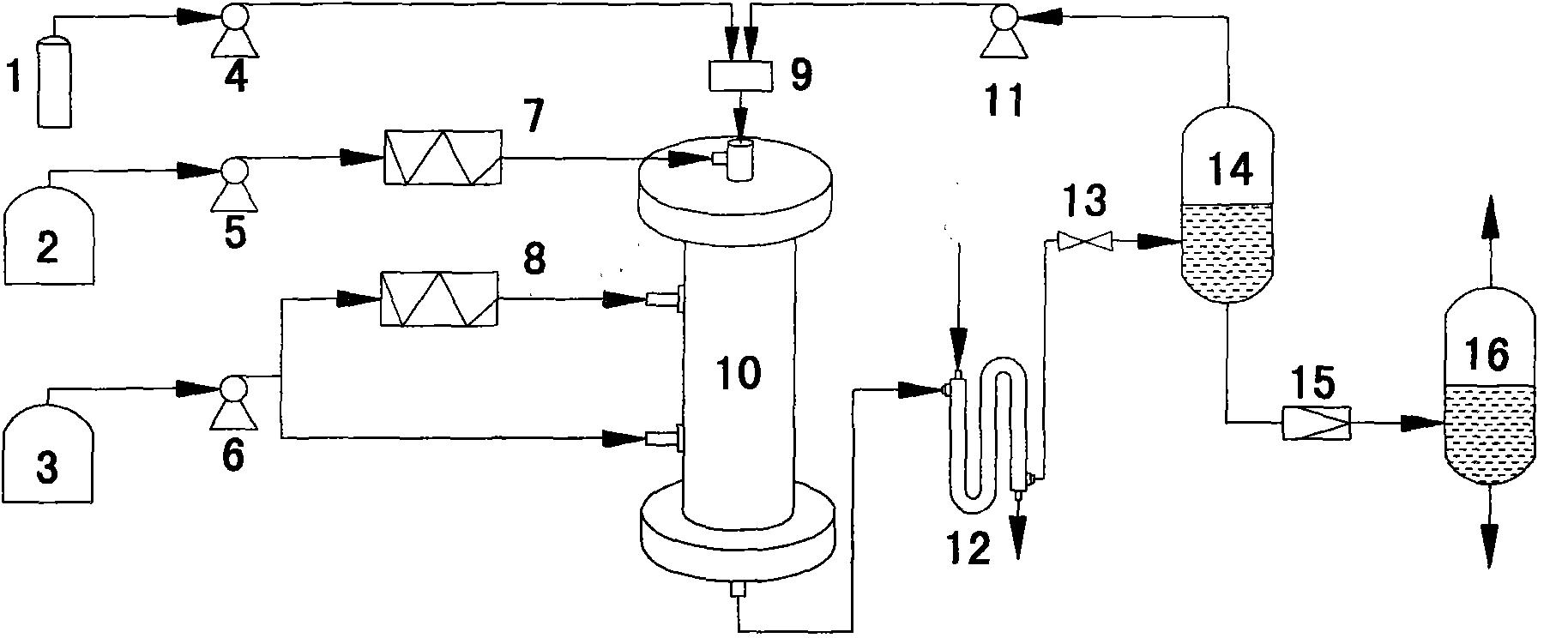

Apparatus and methods for processing semiconductor substrates using supercritical fluids

InactiveUS7503334B1Ease in introduction and removalEfficient mixingSemiconductor/solid-state device manufacturingCleaning using liquidsLiquid stateCompound (substance)

A system is provided for cleaning wafers that includes specialized pressurization, process vessel, recirculation, chemical addition, depressurization, and recapture-recycle subsystems. A solvent delivery mechanism converts a liquid-state sub-critical solution to a supercritical cleaning solution and introduces it into a process vessel that contains a wafer or wafers. The supercritical cleaning solution is recirculated through the process vessel by a recirculation system. An additive delivery system introduces chemical additives to the supercritical cleaning solution via the solvent delivery mechanism, the process vessel, or the recirculation system. Addition of chemical additives to the sub-critical solution may also be performed. The recirculation system provides efficient mixing of chemical additives, efficient cleaning, and process uniformity. A depressurization system provides dilution and removal of cleaning solutions under supercritical conditions. A recapture-recycle system introduces captured-purified solvents into the solvent delivery mechanism.

Owner:NOVELLUS SYSTEMS

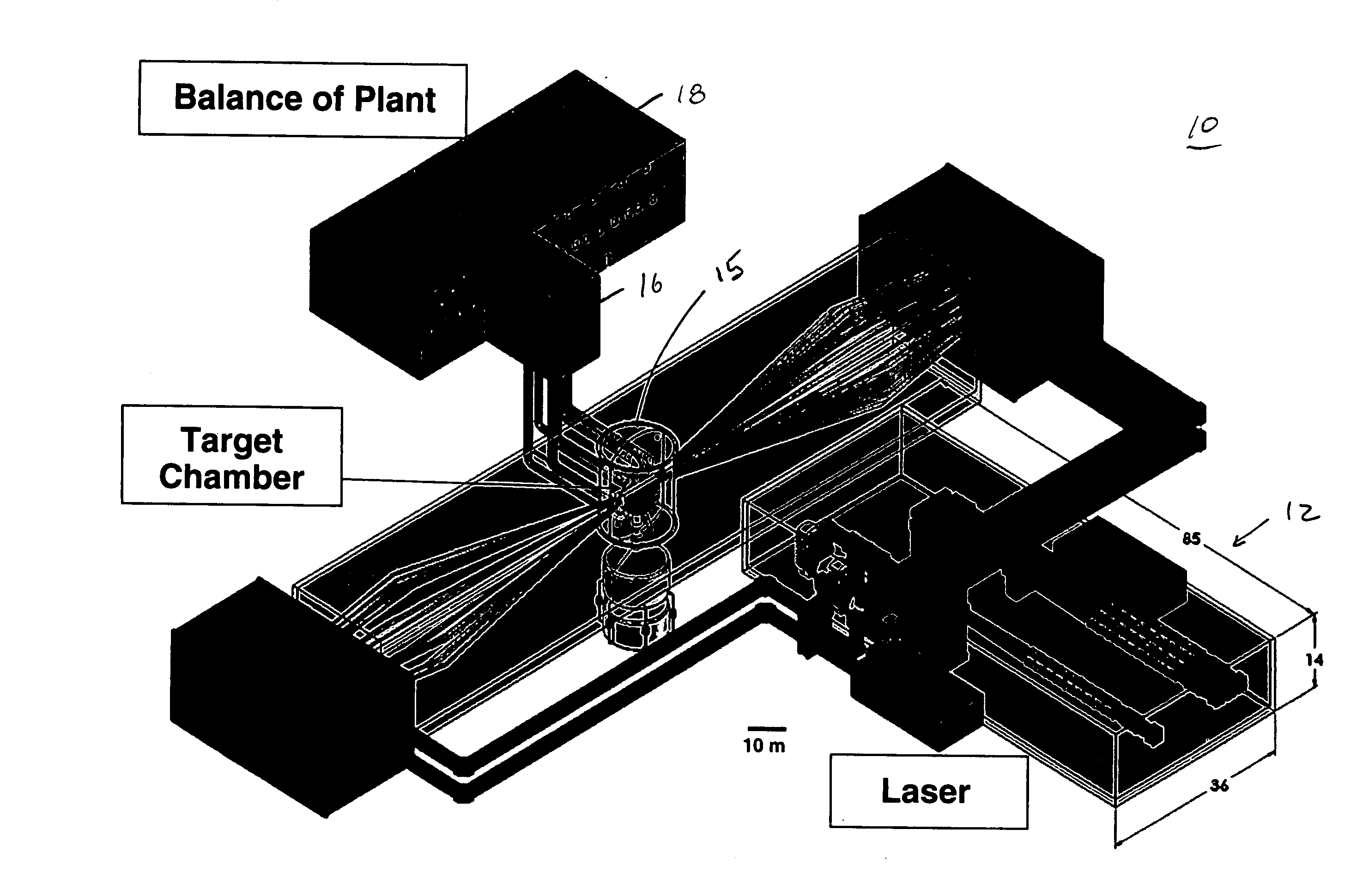

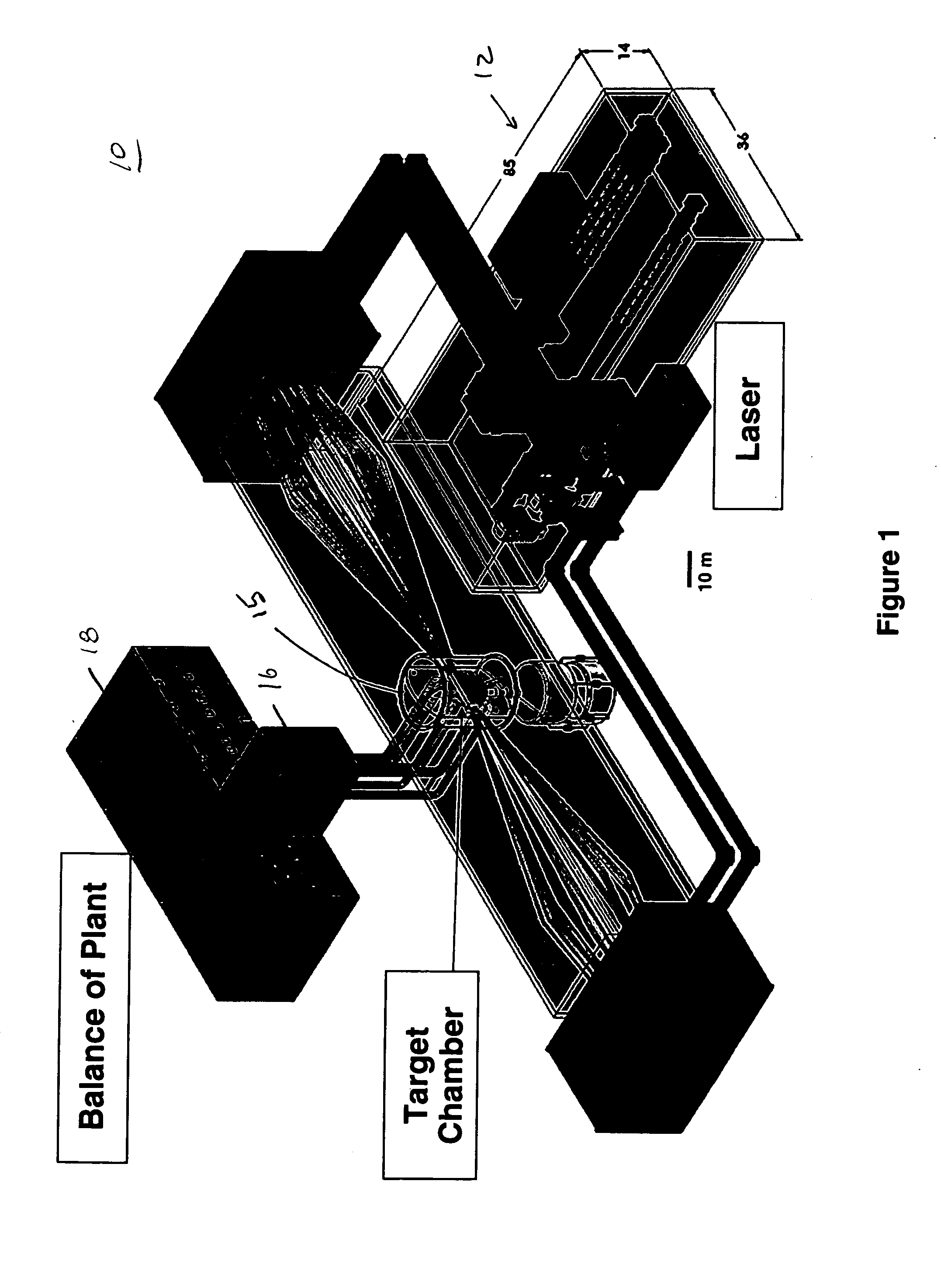

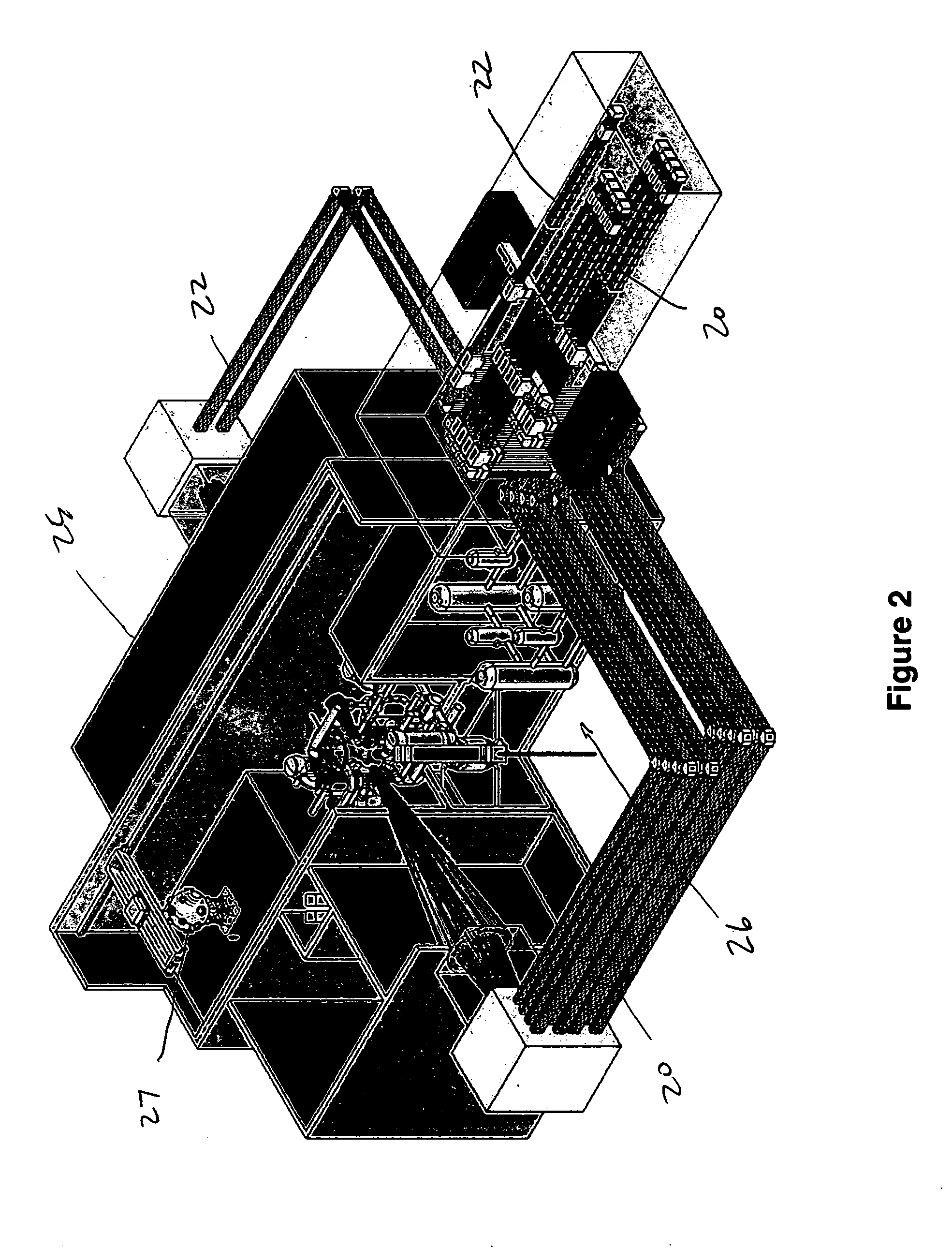

Control of a Laser Inertial Confinement Fusion-Fission Power Plant

ActiveUS20110286563A1Extended service lifeReduce spreadNuclear energy generationWaste based fuelFusion fissionEngineering

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method for improving oxygen utilization rate of supercritical water oxidation system

InactiveCN101830554AHigh oxygen utilizationLower oxygen peroxide coefficientWater/sewage treatment by oxidationRunning economyOxygen utilization rate

The invention relates to a method for improving oxygen utilization rate of a supercritical water oxidation system. The method comprises the following steps of: injecting excessive oxygen and preheated organic waste liquid from the upper part of an evaporation wall reactor, mixing the oxygen and the organic waste liquid, performing supercritical water oxidation reaction on the mixture, and injecting evaporation water from the lateral surface of the evaporation wall reactor so as to form a supercritical temperature reaction area on the upper part and a sub-critical temperature salt dissolution area on the lower part in the reactor. When the reacted rest oxygen downwards flows to the sub-critical temperature salt dissolution area from the supercritical temperature reaction area, a part of oxygen is separated out and circulated to the supercritical temperature area on the upper part of the reactor to form internal circulation utilization of the oxygen; and the reacted fluid enters a high-pressure gas-liquid separator through condensation and pressure reduction, is dissolved into sub-critical water and carries the oxygen flowing out of the reactor, is separated by the high-pressure gas-liquid separator and then is re-injected to the reactor to form external circulation utilization. The method remarkably reduces the excessive oxygen amount coefficient by improving the utilization rate of the oxygen, and improves the running economy of the supercritical water oxidation system.

Owner:SHANDONG UNIV

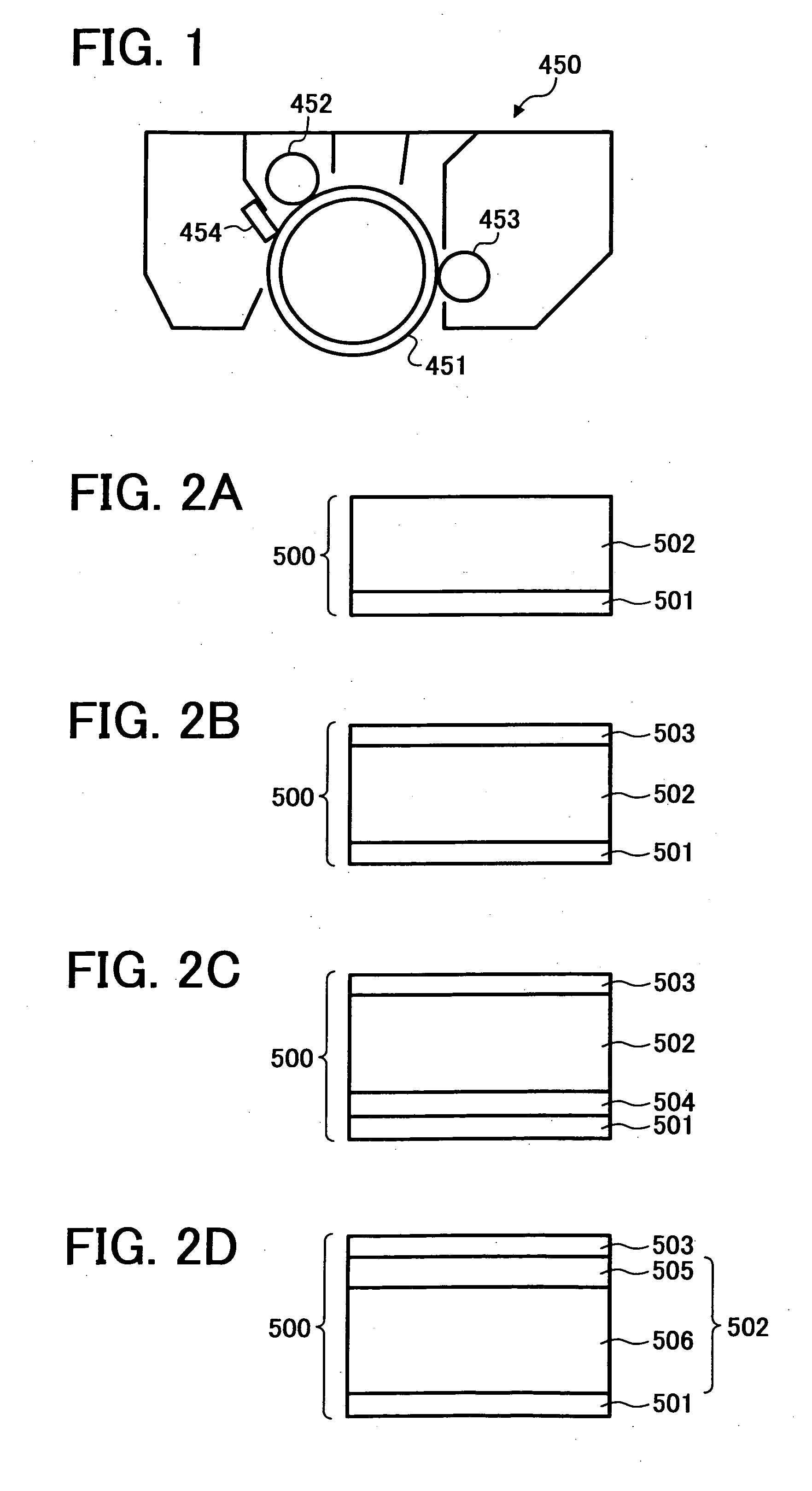

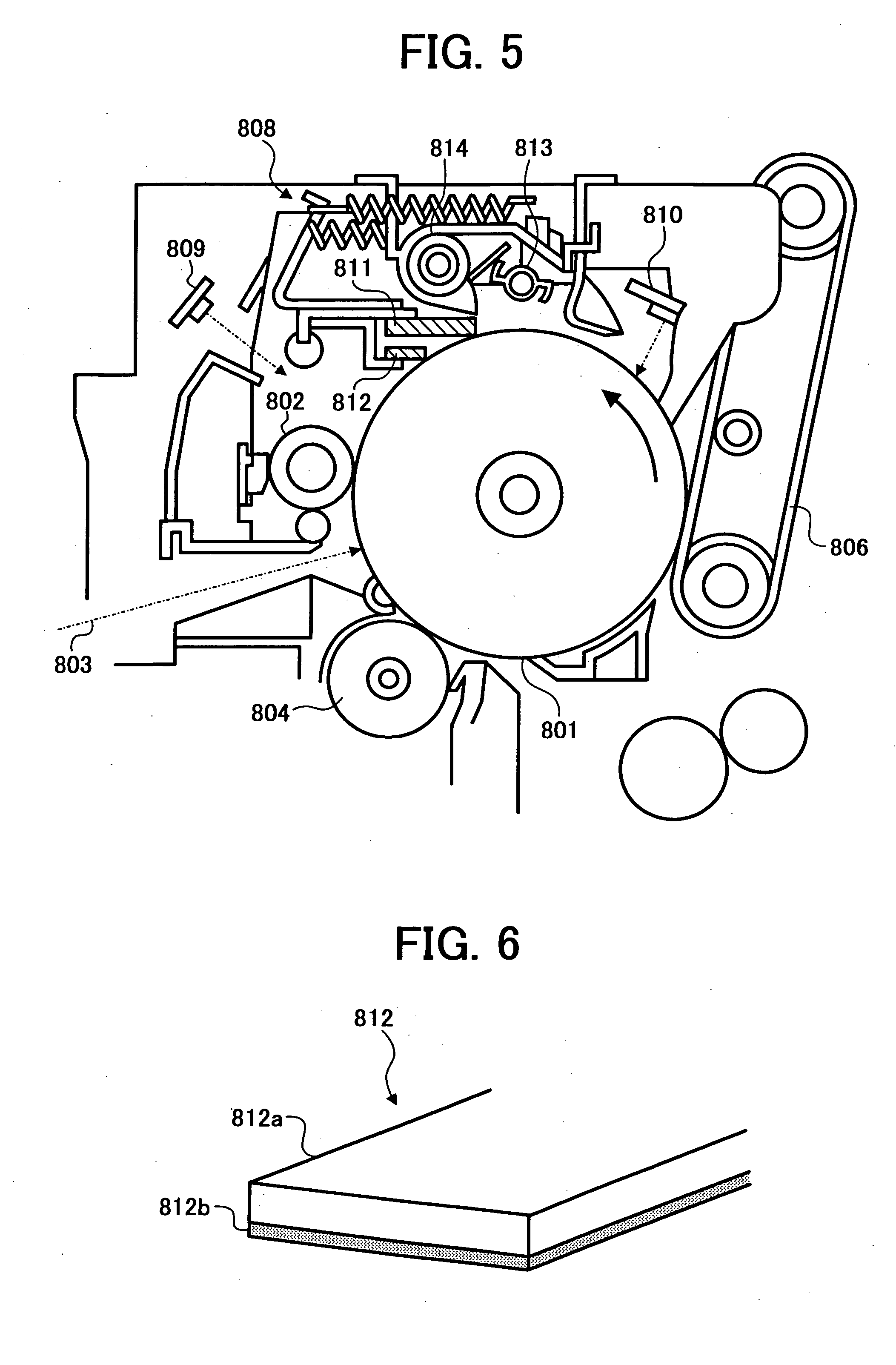

Method of preparing a toner, developer including the toner, container containing the toner, and image forming method and process cartridge using the toner

InactiveUS20050277044A1Improve chargeabilityGood fluidityDevelopersElectrographic processes using charge patternCarboxylic acidMonomer

A method including contacting a toner including: a binder resin including an unsaturated carboxylic acid derivative monomer; a vinyl polymerizing monomer; and a colorant; to a supercritical fluid or a sub-critical fluid to remove the unsaturated carboxylic acid derivative monomer.

Owner:RICOH KK

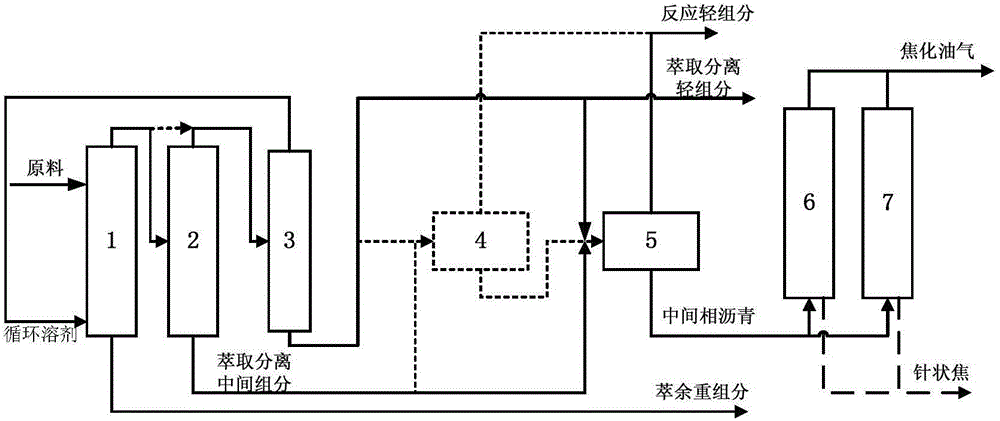

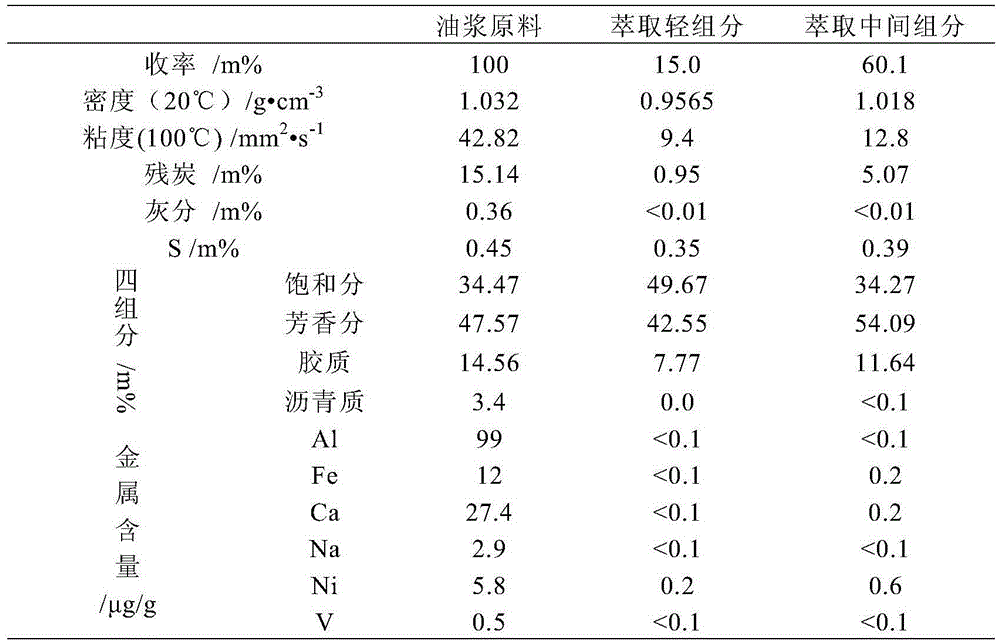

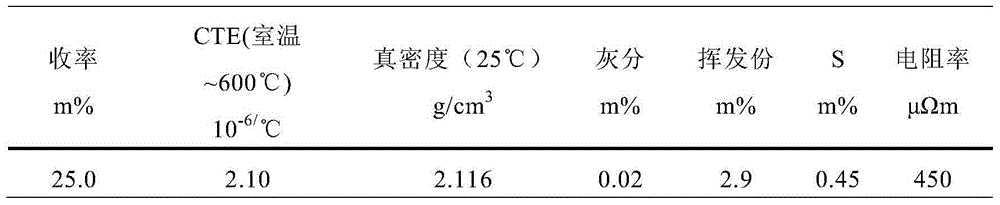

Combined method for separating fluid catalytic cracking slurry oil and preparing oil-series needle coke

ActiveCN106147835AImprove qualityEasy to industrializeTreatment with hydrotreatment processesTreatment with polymerisationHydrodesulfurizationCombined method

The invention provides a combined method for separating fluid catalytic cracking slurry oil and preparing oil-series needle coke. C3-C5 light dydrocarbon cut fraction is adopted as extraction solvent for conducting sub-critical or super-critical extraction on fluid catalytic cracking slurry oil, solvent is recovered from an obtained extraction oil phase in a super-critical mode to prepare extraction components, the extraction components serve as raw materials for preparing middle phase asphalt, and the middle phase asphalt is prepared through retrogressive reaction and then subjected to delayed coking reaction to prepare high-quality oil-series needle coke. When the sulfur content of fluid catalytic cracking slurry oil is high, extraction light components can be subjected to hydrodesulfurization treatment first, hydrogenated oil is subjected to fractionation to collect hydrogenation tail oil, the hydrogenation tail oil serves as a raw material for preparing middle phase asphalt, and then the needle coke is prepared. By means of the method, by controlling the preparation of middle phase asphalt and the coking procedure of the needle coke to be independent of each other, industrial implementation is easier, and fluid catalytic cracking slurry oil can be sufficiently used and the high-quality needle coke material can be prepared.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

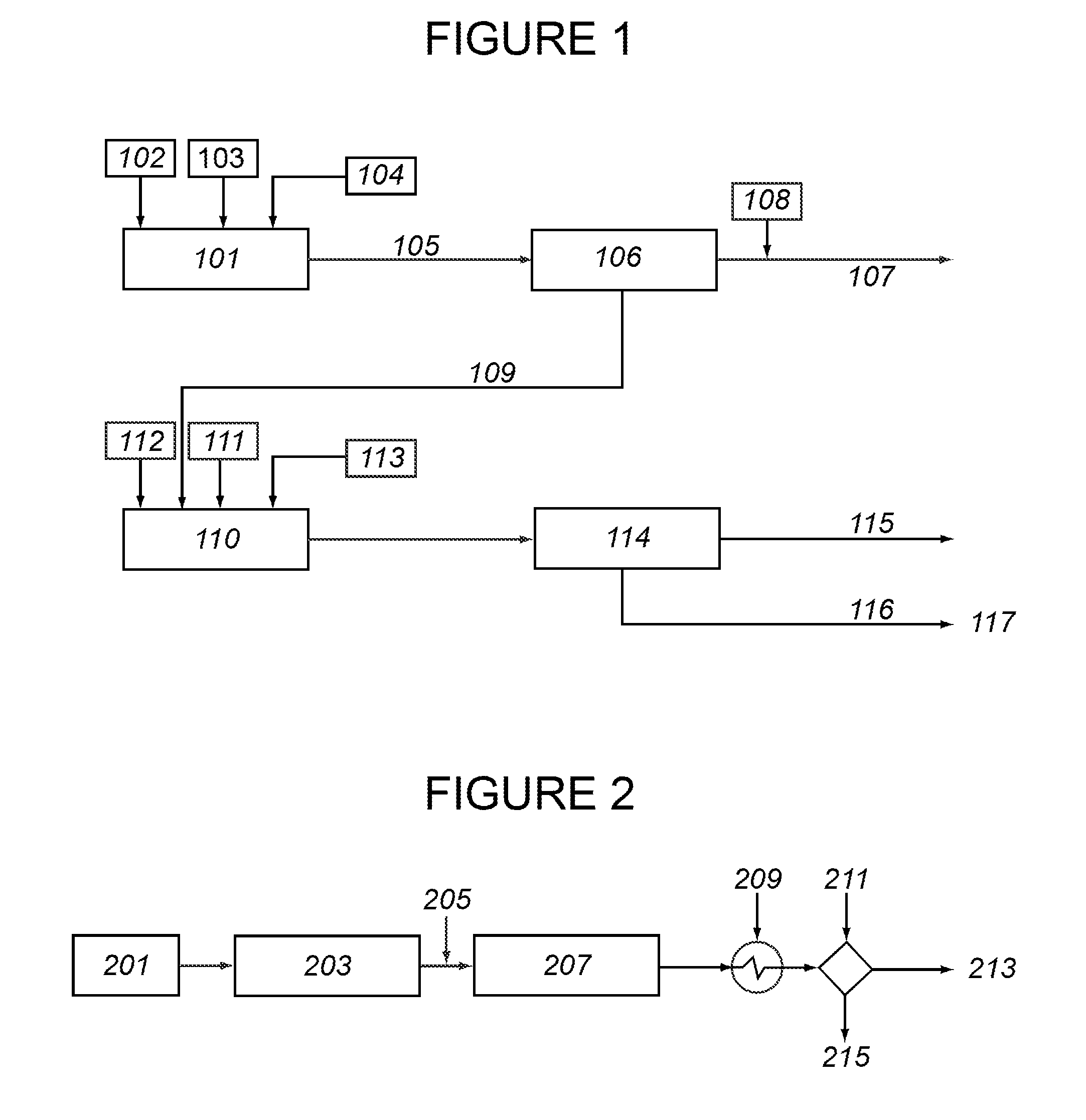

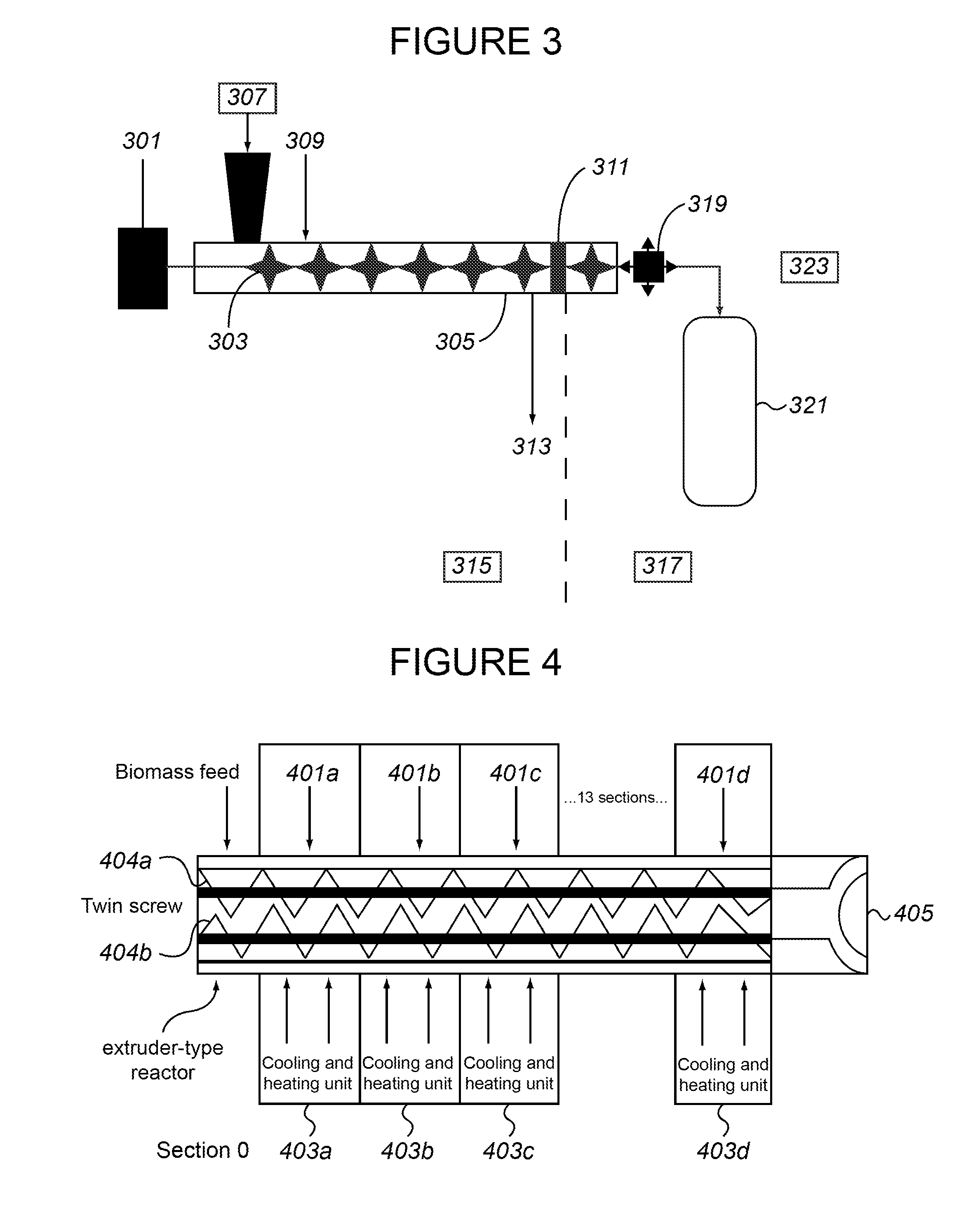

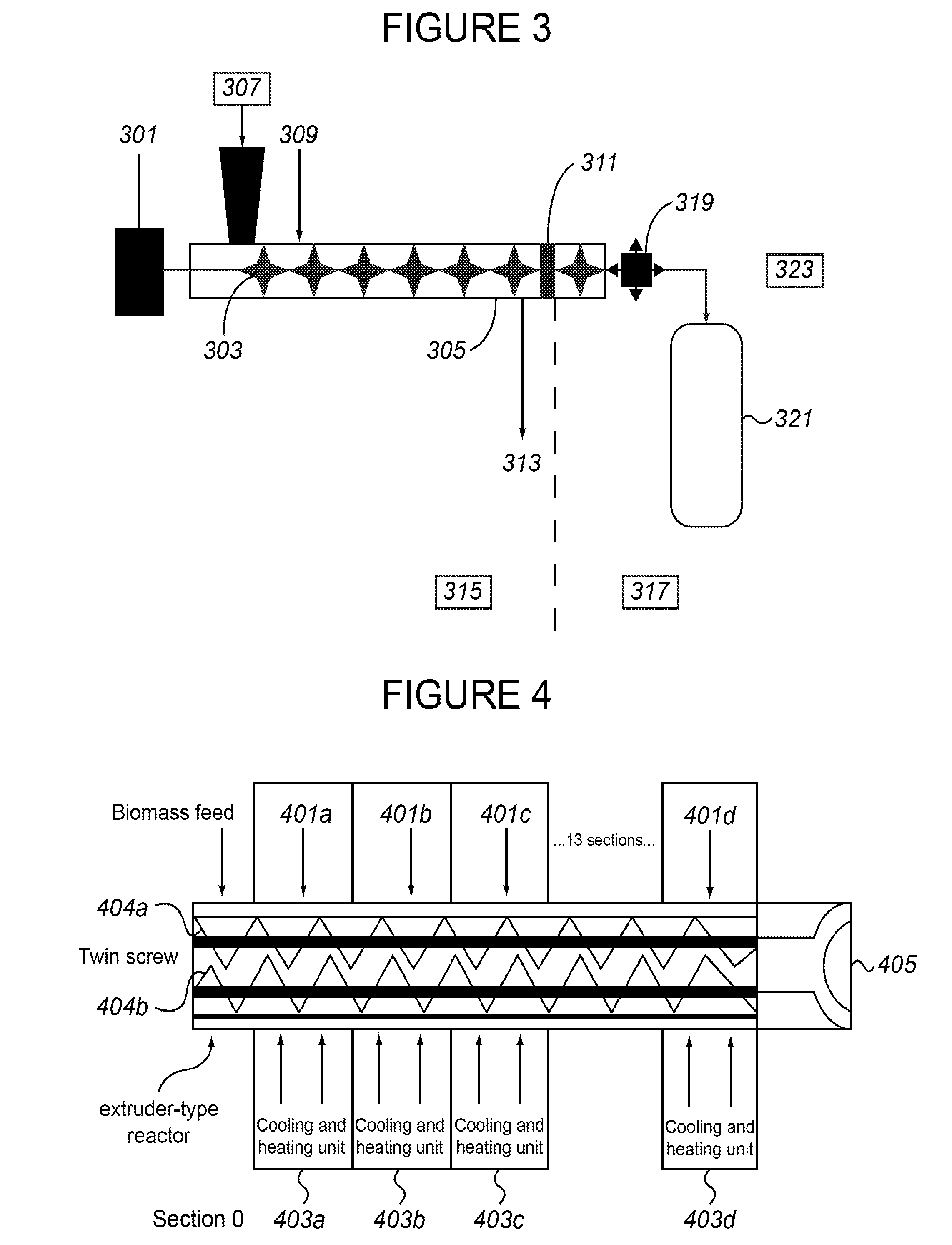

Production of fermentable sugars and lignin from biomass using supercritical fluids

Methods are disclosed for the continuous treatment of biomass comprising a pretreatment step, wherein said biomass is contacted with a first supercritical, near-critical, or sub-critical fluid to form a solid matrix and a first liquid fraction; and a hydrolysis step, wherein said solid matrix formed in said pretreatment step is contacted with a second supercritical or near-supercritical fluid to produce a second liquid fraction and a insoluble lignin-containing fraction. Also disclosed are apparatuses for the continuous conversion of biomass comprising a pretreatment reactor and a hydrolysis reactor associated with said pretreatment reactor.

Owner:RENMATIX INC

Molten salt nuclear reactor

InactiveUS20120183112A1Maximize probabilityFuel elementsConversion outside reactor/acceleratorsNuclear reactor coreBreeder reactor

A molten salt breeder reactor that has fuel conduit surrounded by a fertile blanket. The fuel salt conduit has an elongated core section that allows for the generation of electrical power on a scale comparable to commercially available nuclear reactors. The geometry of the fuel conduit is such that sub-critical conditions exist near the input and output of the fuel salt conduit and the fertile blanket surrounds the input and output of the fuel salt conduit, thereby minimizing neutron losses.

Owner:OTTAWA VALLEY RES ASSOCS

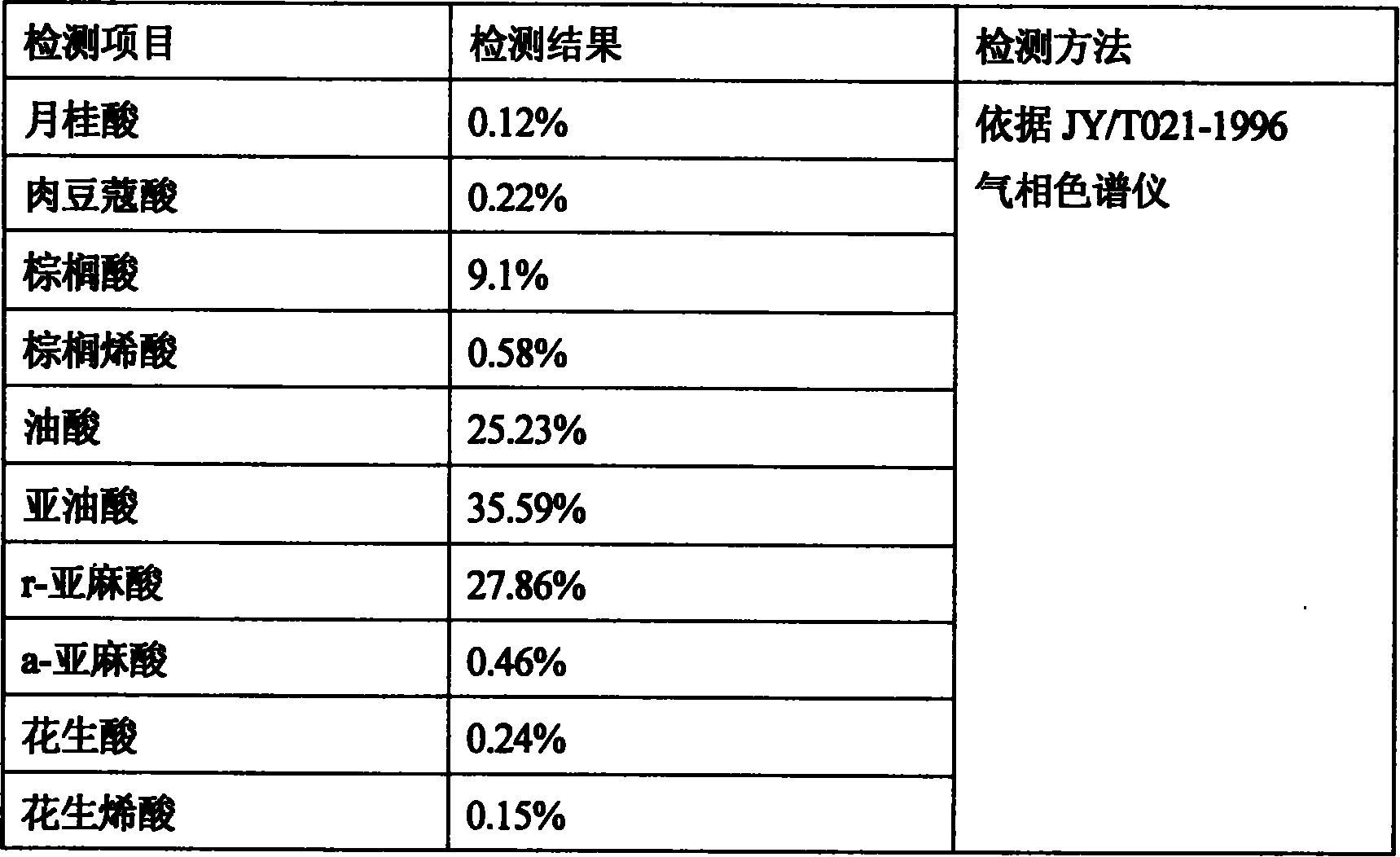

Sub-critical fluid extraction solvent and abstraction method

InactiveCN101161324AHigh extraction rateIncrease profitSolid solvent extractionSulfur hexafluorideAdditive ingredient

The present invention relates to a dissolvent with effective ingredient extracted from the plant-and-animal raw material and the extraction method thereof. One subcritical fluid extraction solvent includes an extraction solvent of a compound or composition extracted from the raw material containing compound or composition as component element, and the solvent is mainly characterized in that the liquid sulfur hexafluoride works as the extraction solvent. The invention also includes a method for extracting the subcritical fluid extraction solvent. The advantage of the invention is that the extraction and separation of the target component in the natural product are optionally executed to further increase the extraction rate of the intermediate product and the usage factor of the raw material while the unique dissolving character of the sulfur hexafluoride and the mixed solvent thereof to the liposoluble active ingredient is used. The physical features of strong dissolving capacity and low boiling point of the sulfur hexafluoride and the mixed solvent thereof are used to reduce the consumption quantity of the energy source, dissolvent of the system and the cost, and increase the market competition ability of the intermediate product.

Owner:韩延欣 +2

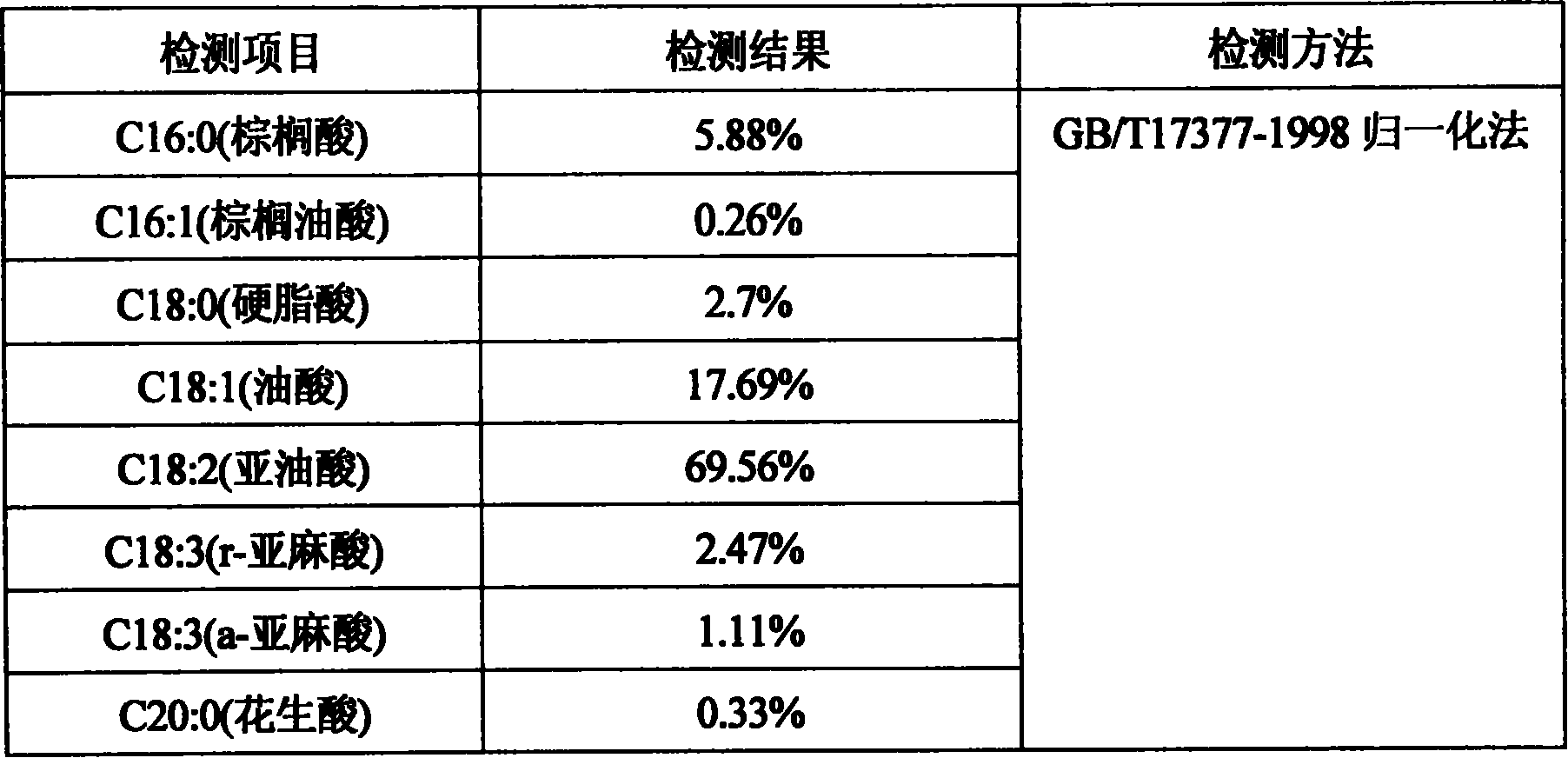

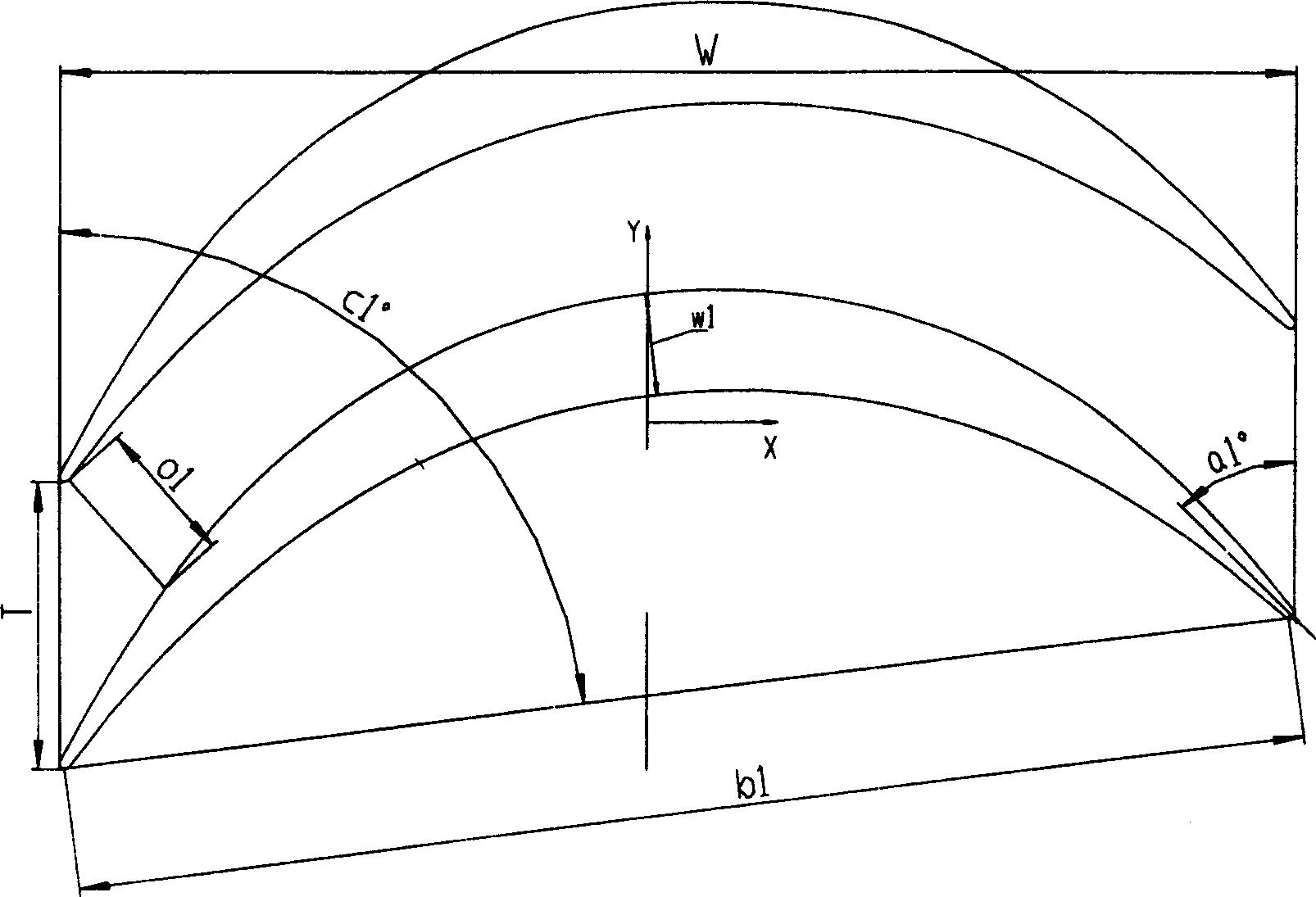

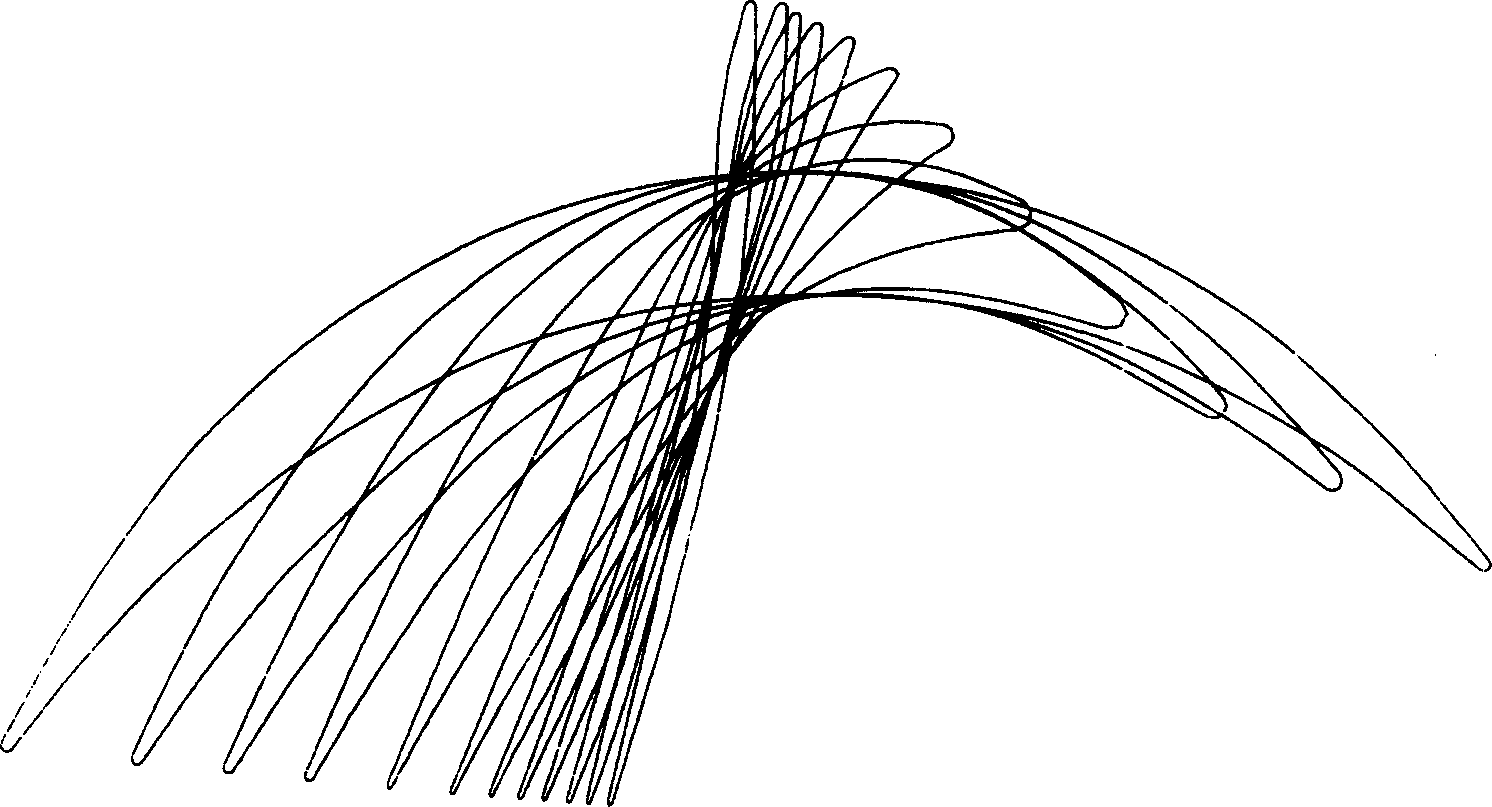

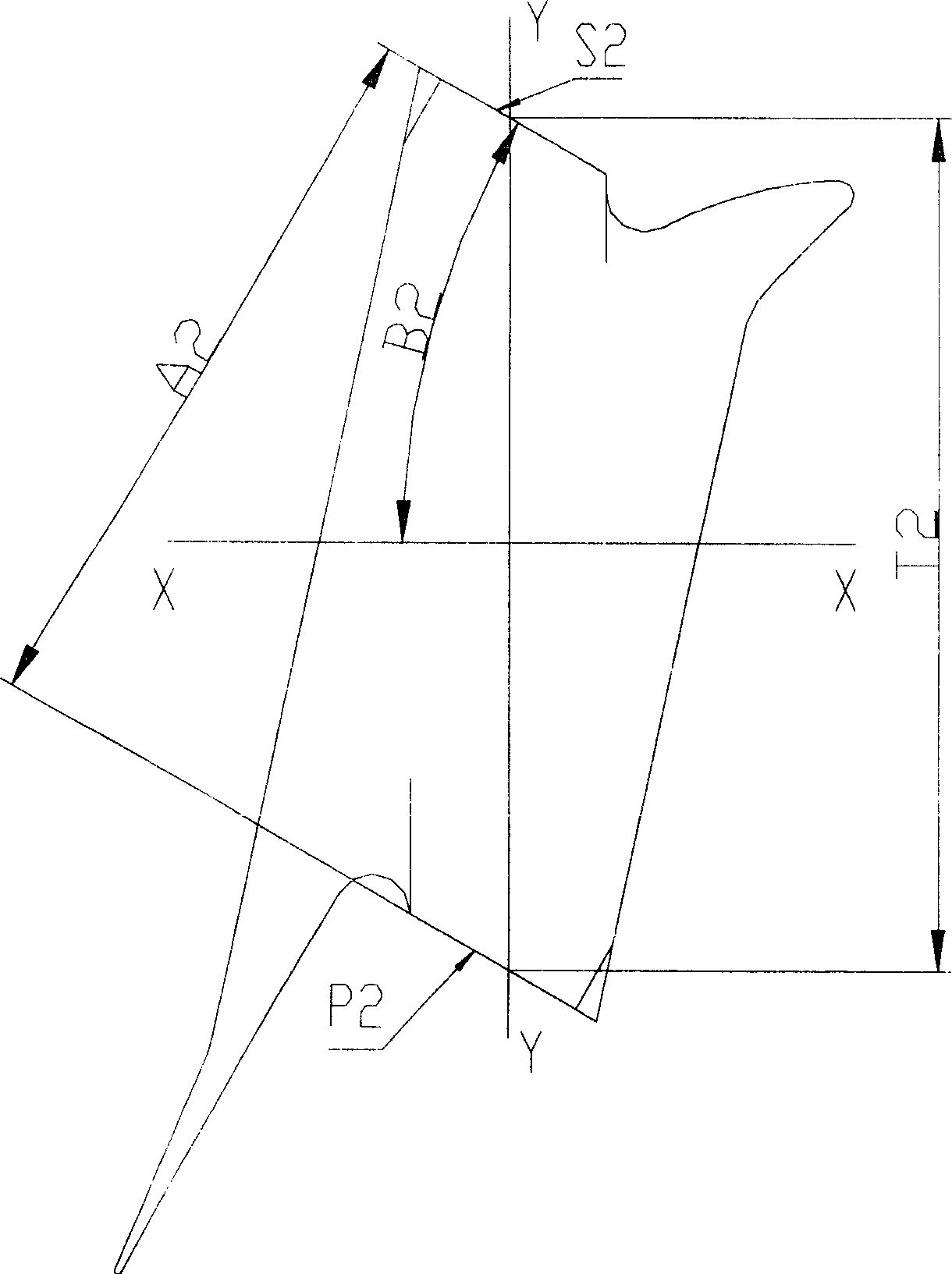

Last stage rotor blade of steam turbine

ActiveCN1730912AMeet flowReduce flow lossBlade accessoriesMachines/enginesRelative maximumRoot radius

The last stage movable blade of steam turbine features the relative blade height H monotonously increased from 0.0 to 1.0, blade body profile with assembling angle c1 monotonously decreased from 82.81 deg to 10.1 deg, inlet geometric angle a1 monotonously increased from 36.65 deg to 168.0 deg, outlet geometric angle a2 monotonously decreased from 31.4 deg to 10.6 deg, relative maximum thickness w1 monotonously decreased from 3.47 to 1.0, relative chord length b1 monotonously decreased from 1.84 to 1.0, relative cross section area S monotonously decreased from 7.98 to 1.0, and the ratio between blade height H to root radius of 0.5-0.7. The present invention is especially suitable for sub-critical and supercritical steam turbine with effective blade height not smaller than 1200 mm, power of 600-1200 MW and rotation speed of 3000 rpm.

Owner:DONGFANG TURBINE CO LTD

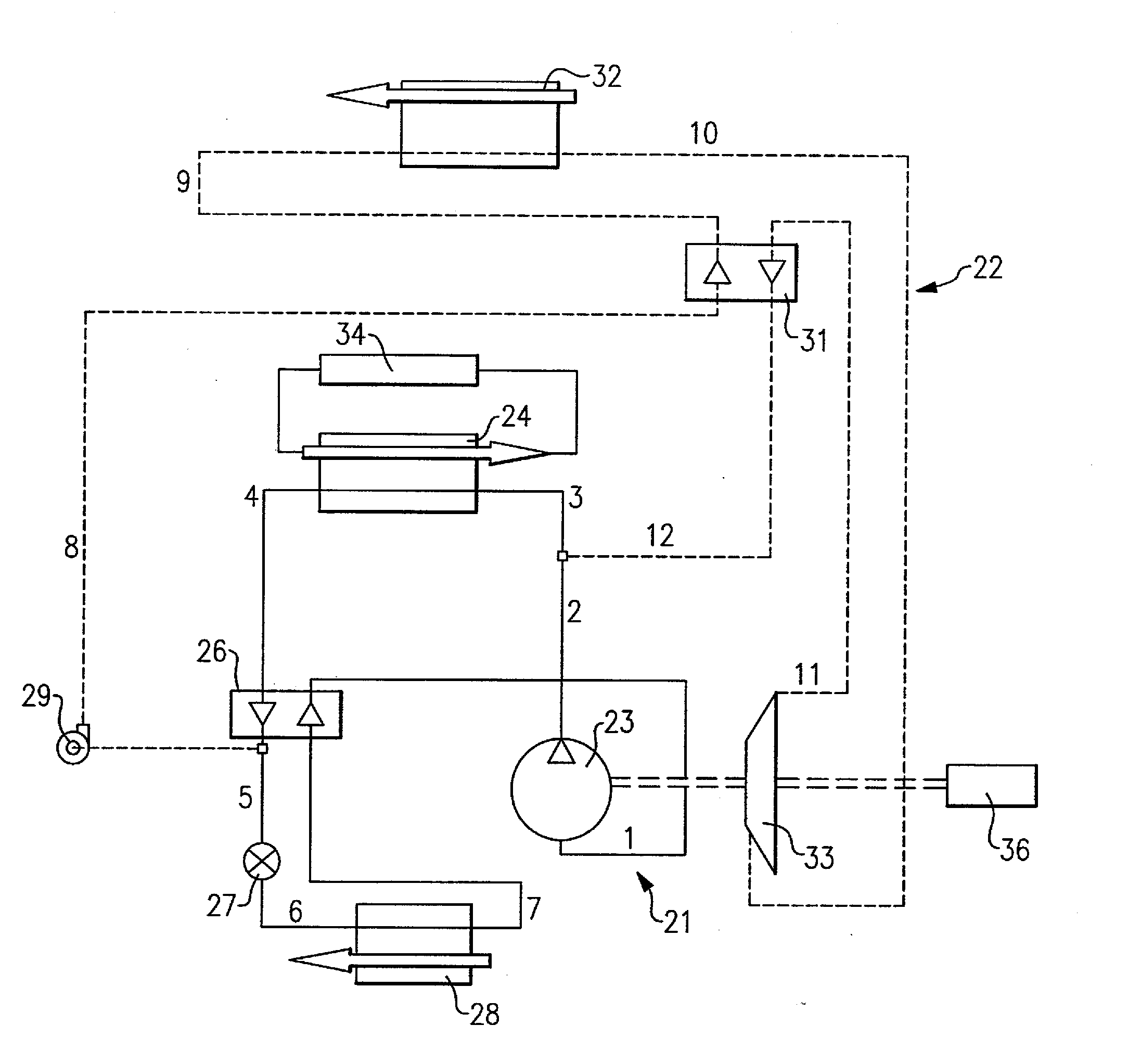

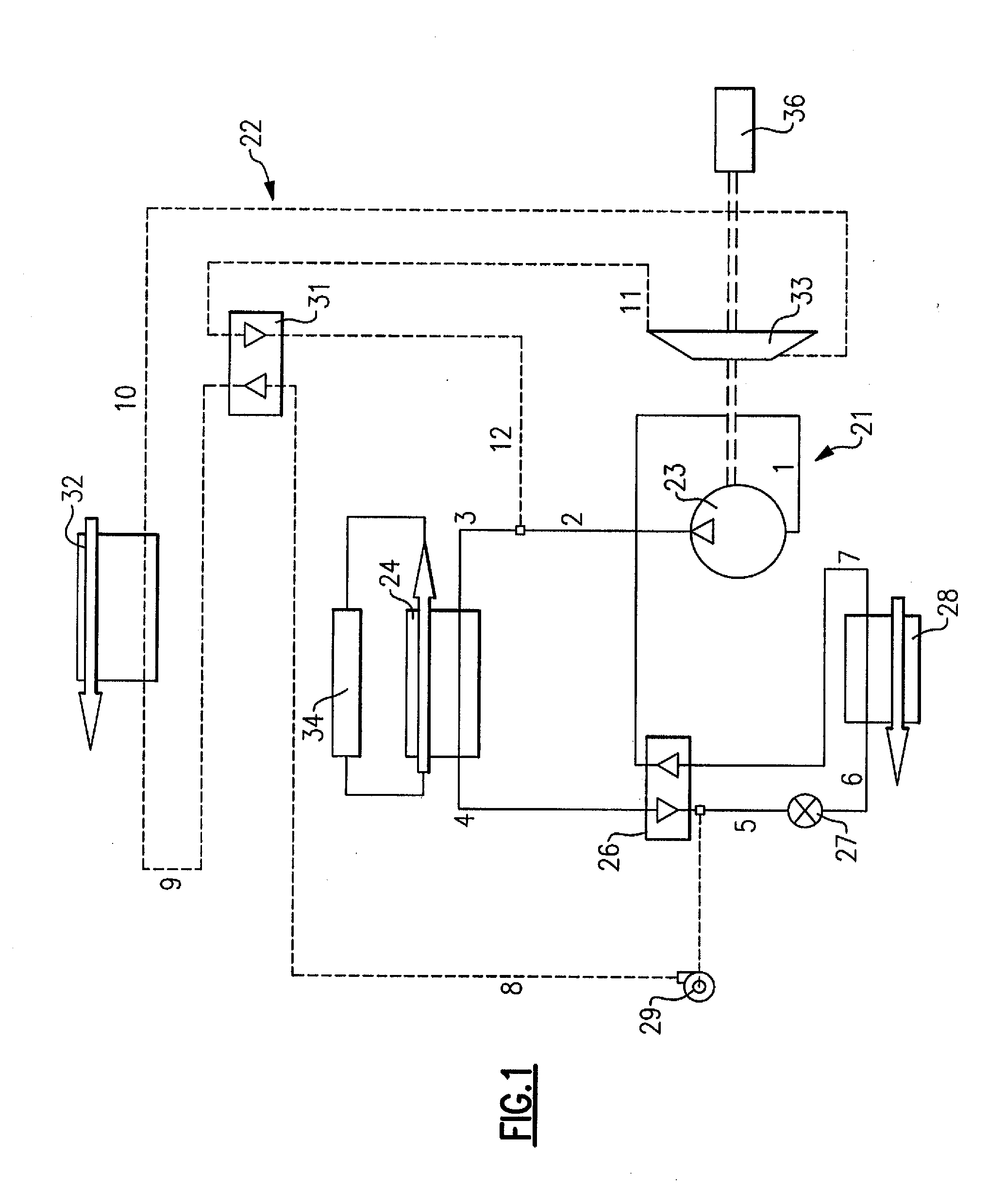

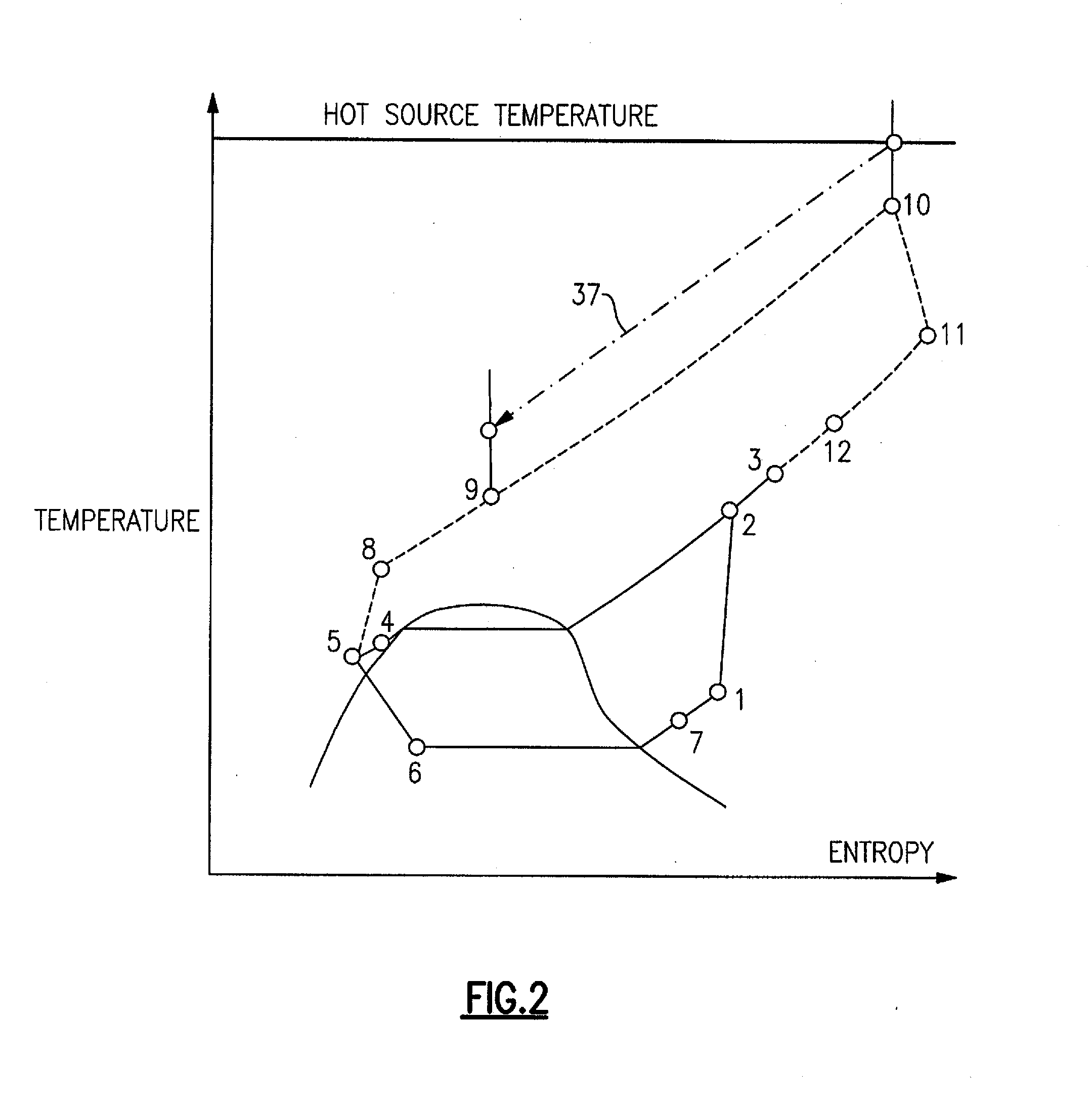

Transcritical thermally activated cooling, heating and refrigerating system

InactiveUS20120036854A1Climate change adaptationCompression machines with non-reversible cycleWorking fluidEngineering

A combined vapor compression and vapor expansion system uses a common refrigerant which enables a super-critical high pressure portion and a sub-critical low pressure portion of the vapor expansion circuit. Provision is made to combine the refrigerant flow from the vapor expander and from the compressor discharge. The outdoor heat exchanger is so sized and designed that the working fluid discharged therefrom is always in a liquid form so as to provide a liquid into the pump inlet. The pump and expander are so sized and designed that the high pressure portion of the vapor expansion circuit is always super-critical. A topping heat exchanger, liquid to suction heat exchanger, and various other design features are provided to further increase the thermodynamic efficiency of the system.

Owner:CARRIER CORP

Production of Fermentable Sugars and Lignin from Biomass Using Supercritical Fluids

ActiveUS20120291774A1Improve the level ofBiofuelsPulp by-products recoveryFermentable sugarSupercritical fluid

Methods are disclosed for the continuous treatment of biomass comprising a pretreatment step, wherein said biomass is contacted with a first supercritical, near-critical, or sub-critical fluid to form a solid matrix and a first liquid fraction; and a hydrolysis step, wherein said solid matrix formed in said pretreatment step is contacted with a second supercritical or near-supercritical fluid to produce a second liquid fraction and a insoluble lignin-containing fraction. Also disclosed are apparatuses for the continuous conversion of biomass comprising a pretreatment reactor and a hydrolysis reactor associated with said pretreatment reactor.

Owner:RENMATIX INC

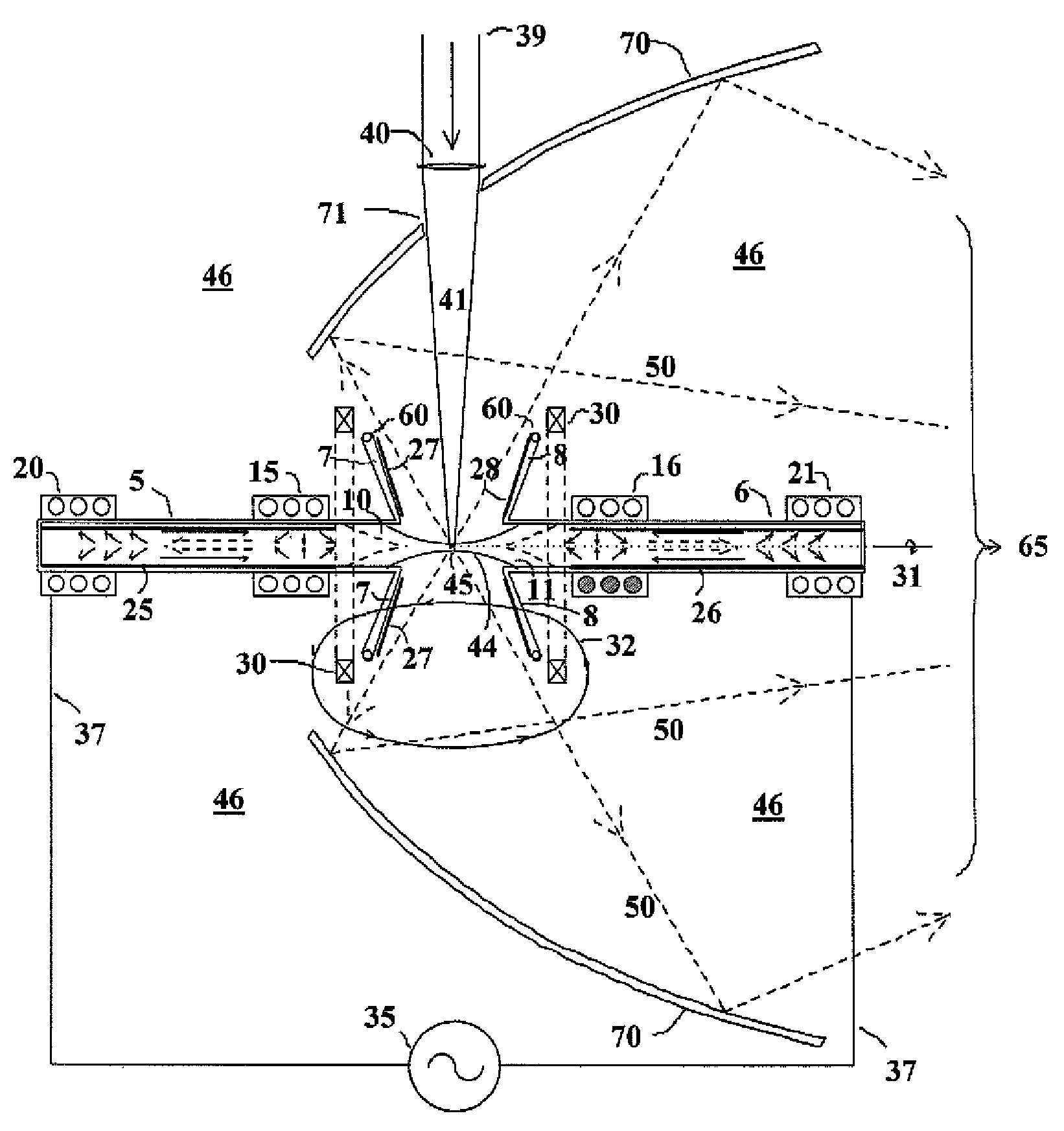

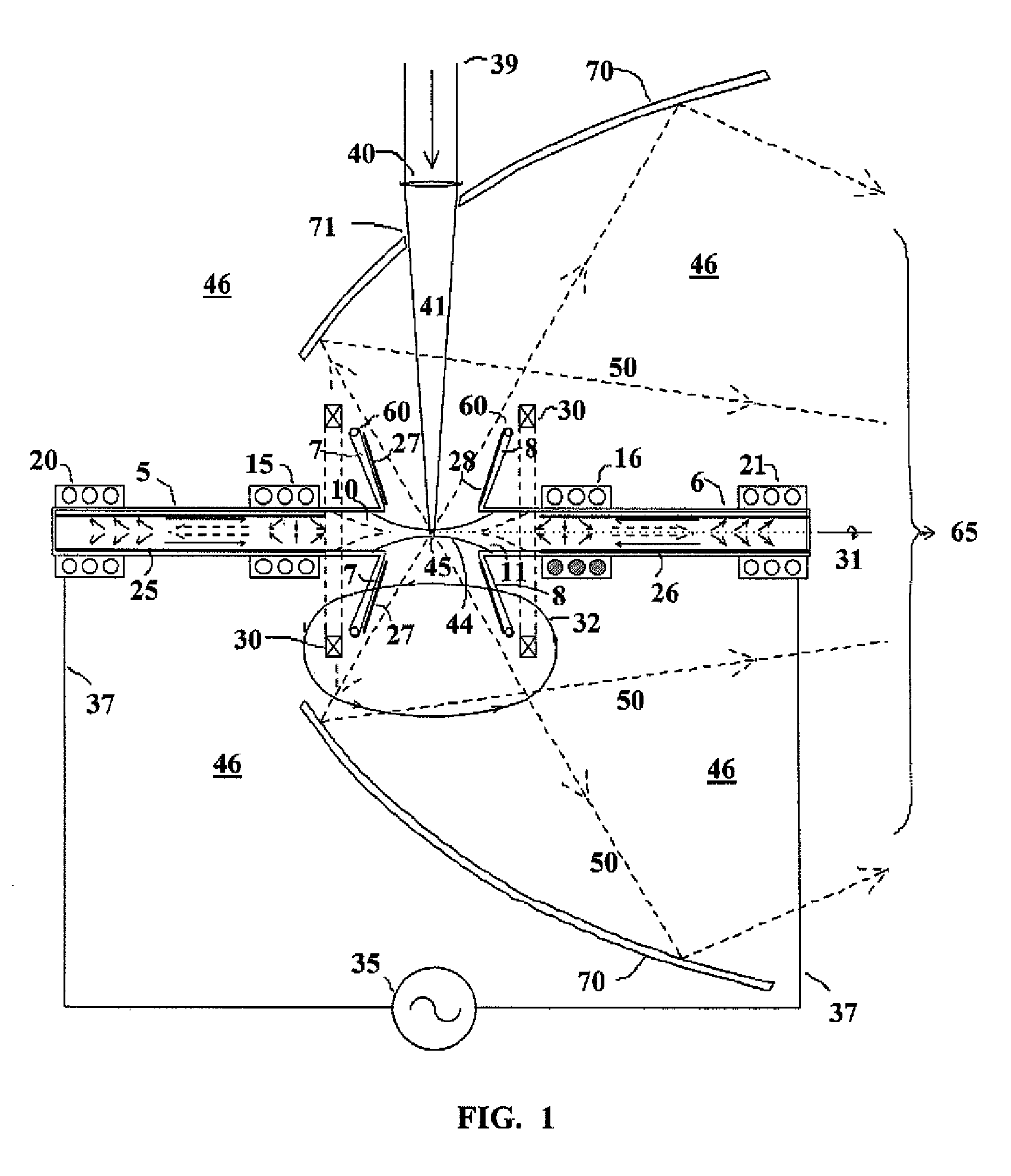

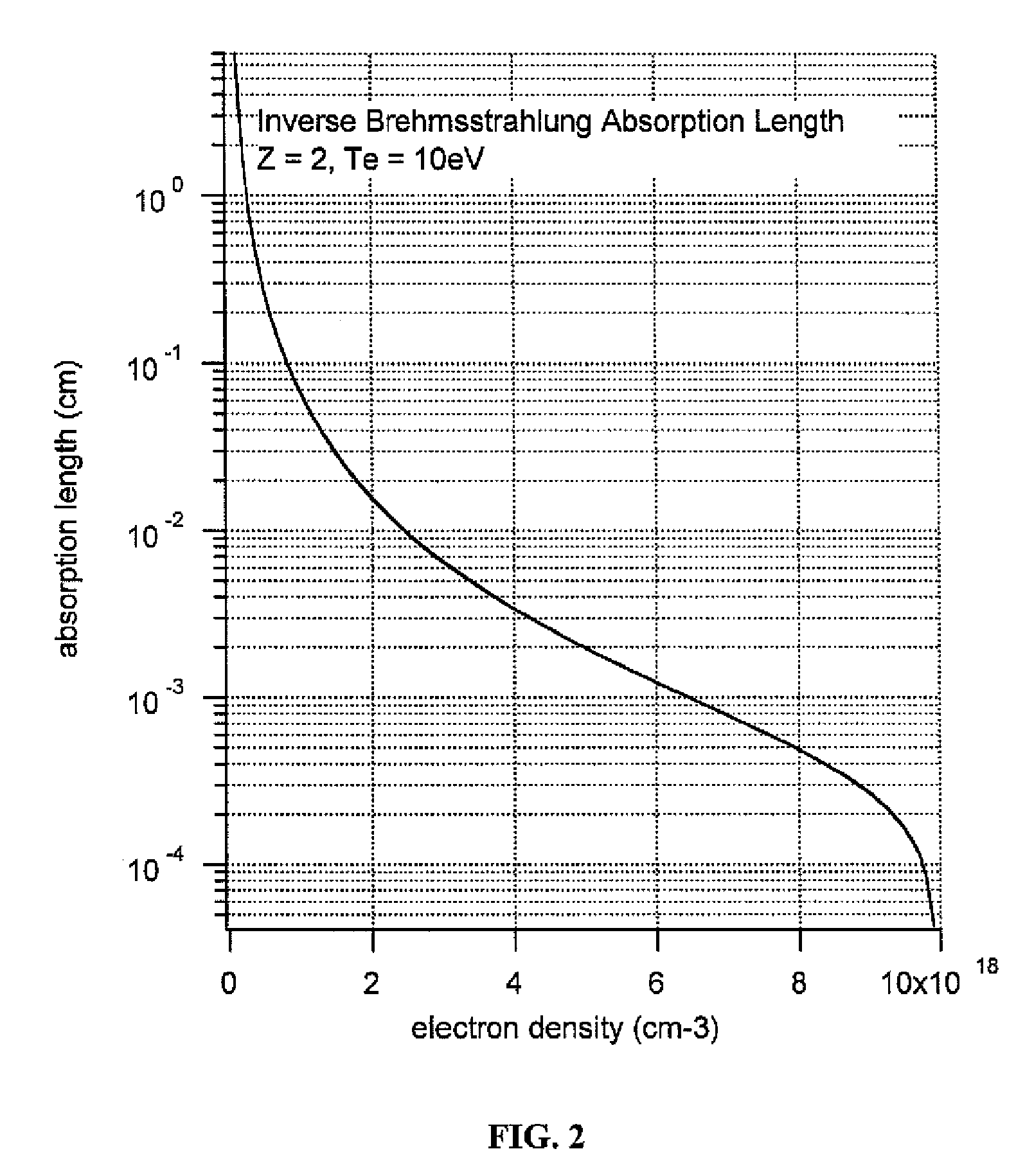

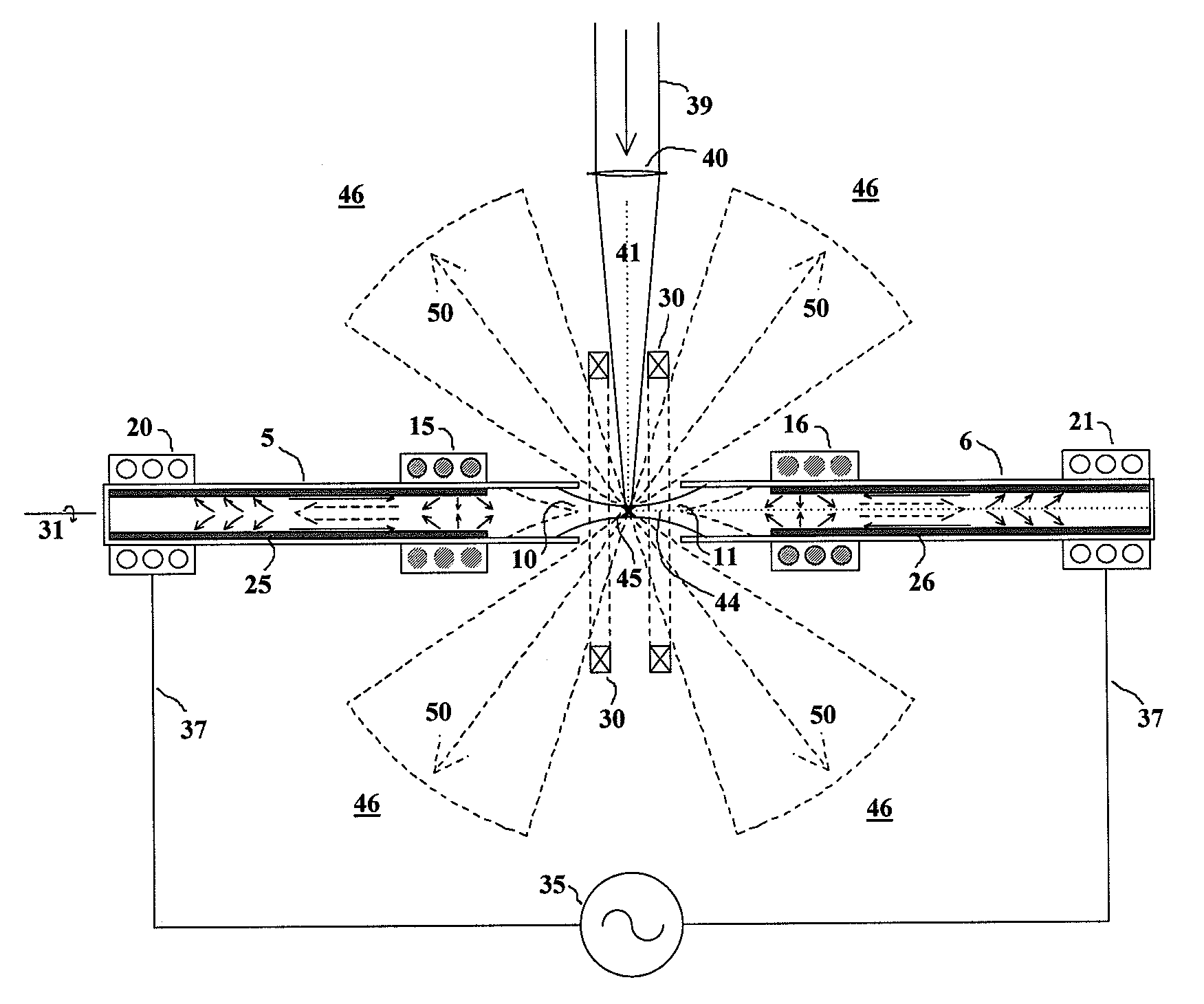

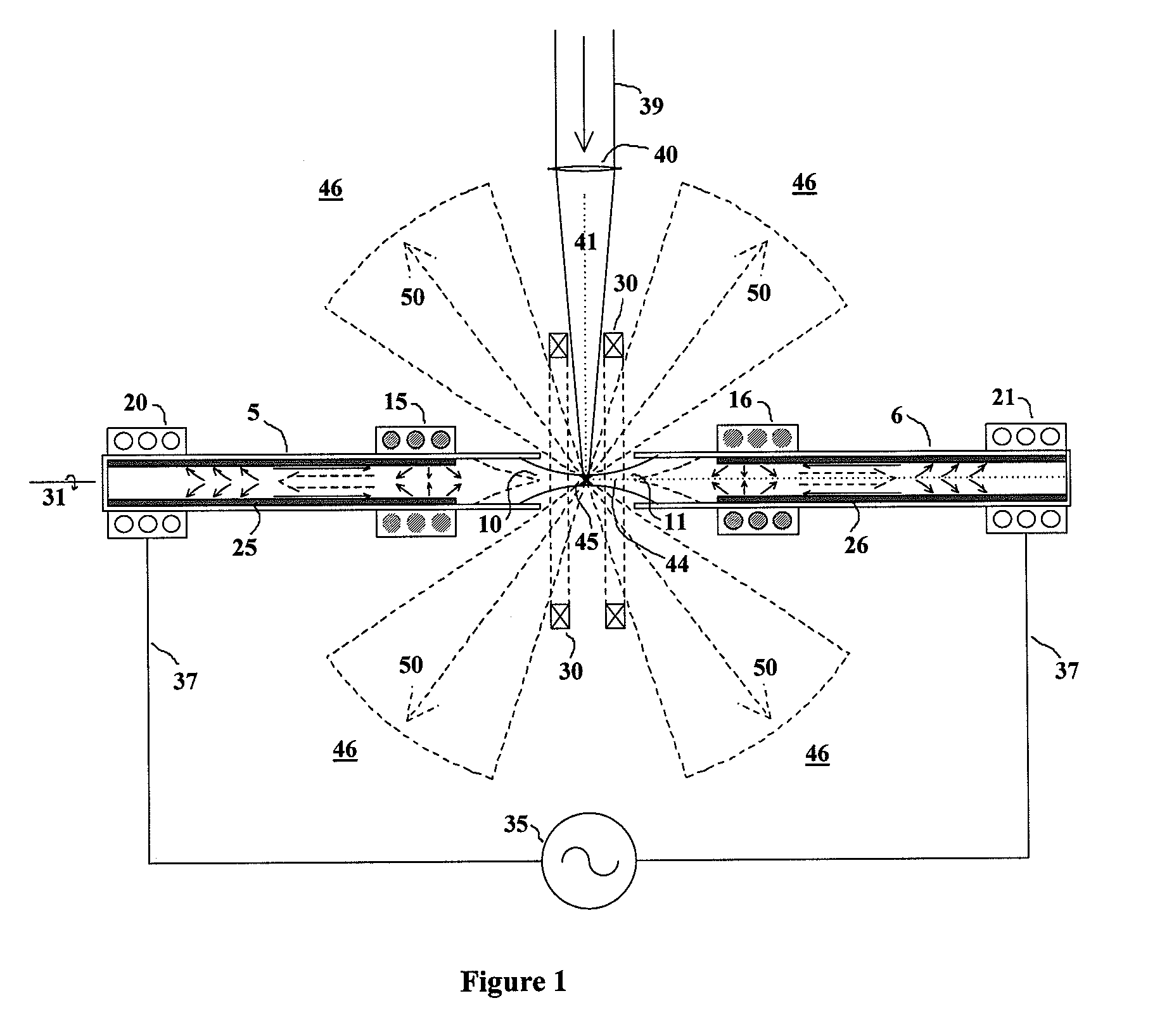

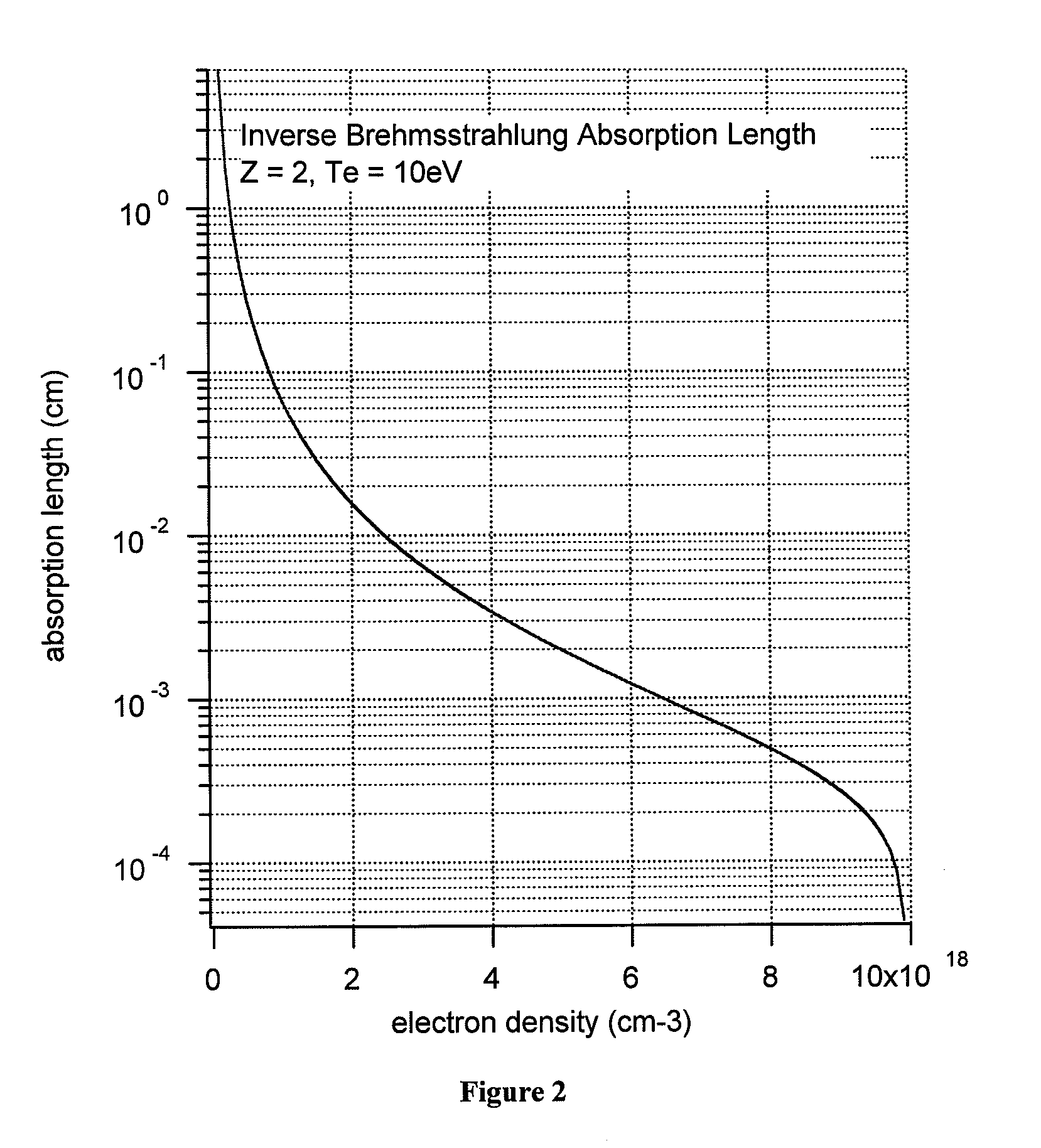

Laser Heated Discharge Plasma EUV Source With Plasma Assisted Lithium Reflux

InactiveUS20090224182A1Ultraviolet radiation is enhancedAvoid dischargeRadiation pyrometryX-ray tube with very high currentRefluxLength wave

A self-magnetically confined lithium plasma that has an applied axial magnetic field is irradiated at sub-critical density by a perpendicularly oriented carbon dioxide laser to generate extreme ultraviolet photons at the wavelength of 13.5 nm with high efficiency, high power and small source size. Lithium reflux is facilitated by ionization, electric field induced drift toward, and capture on surfaces intersected perpendicularly by the applied axial magnetic field.

Owner:PUREX

Laser heated discharge plasma EUV source

InactiveUS20090212241A1Keep energy smallHigh energyRadiation pyrometryPhotometryLength waveExtreme ultraviolet

A self-magnetically confined lithium plasma which also may have an applied axial magnetic field is irradiated at sub-critical density by a carbon dioxide laser to generate extreme ultraviolet photons at the wavelength of 13.5 nm with high efficiency, high power and small source size.

Owner:PUREX

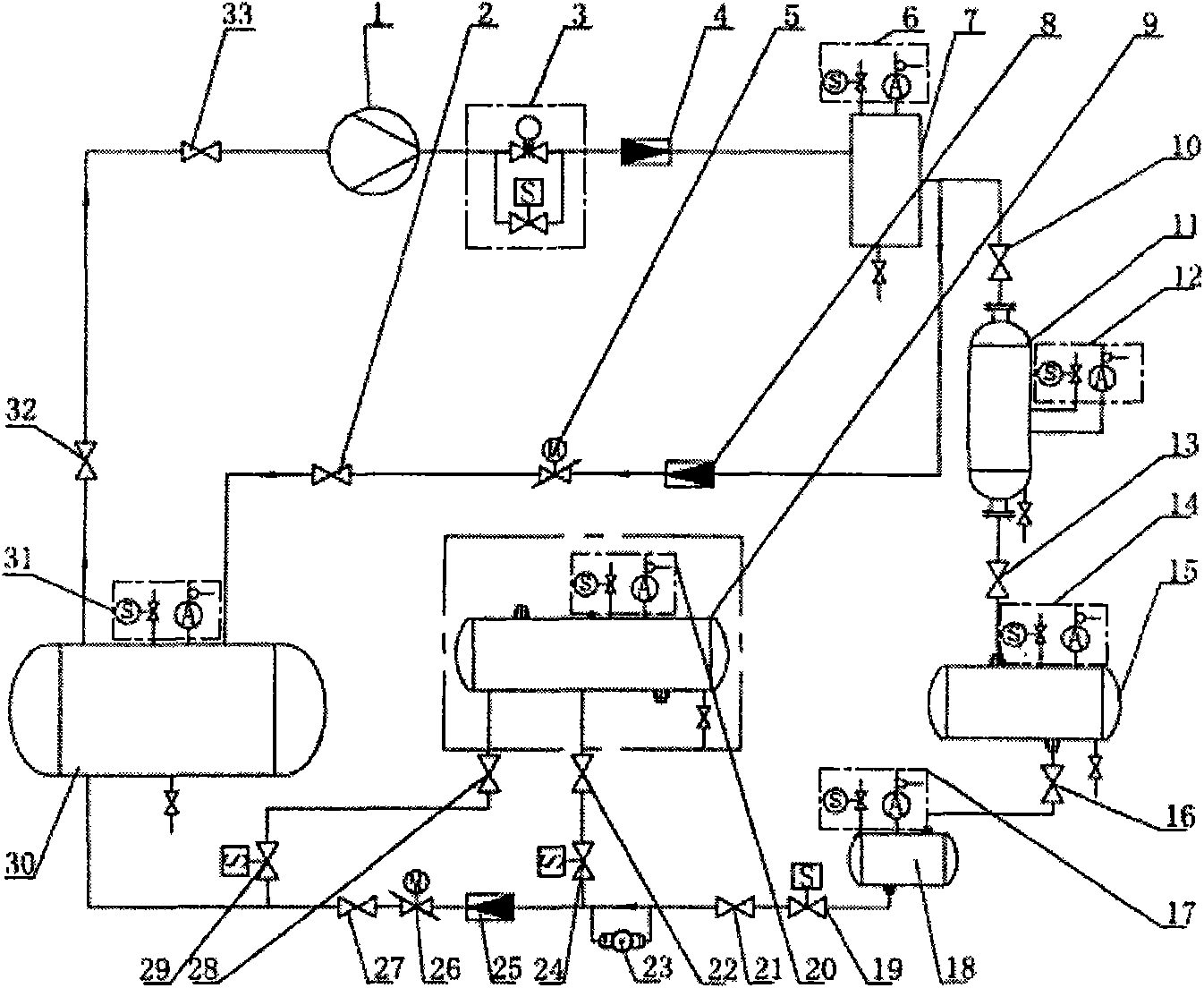

Performance testing device of carbon dioxide refrigeration compressor for refrigeration systems

ActiveCN101649831ALow costImprove active safetyPump testingPositive-displacement liquid enginesEngineeringGas cooler

The invention relates to a performance testing device of a carbon dioxide refrigeration compressor for trans-critical and sub-critical refrigeration systems. The prior art is improved in the way thata component for pressure regulation and pressure reduction is connected between a compressor exhaust opening and an exhaust flowmeter in parallel; a safety valve component A is arranged on an oil separator; a safety valve component B is arranged on a condenser; a safety valve component C is arranged on a liquid reservoir; a subcooler is connected between a shutoff valve C of an outlet of the liquid reservoir and an electromagnetic valve in series; a safety valve component D is arranged on the subcooler; a refrigerant filling and recovering storage tank is connected between an inlet of a mass flowmeter and an outlet of a shutoff valve E in parallel; a recovering shutoff valve and a recovering electromagnetic valve are arranged at the position of an inlet of the refrigerant filling and recovering storage tank, a filling shutoff valve and a filling electromagnetic valve are arranged at the position of an outlet of the refrigerant filling and recovering storage tank, and a safety valve component E is arranged on the refrigerant filling and recovering storage tank; and a safety valve component F is arranged on a gas cooler. In the invention, most of parts can adopt products of the conventional pressure resisting grade, thereby solving the problem of higher pressure of the whole system, reducing the cost and improving the safety of the system.

Owner:HEFEI GENERAL ENVIRONMENT CONTROL TECH

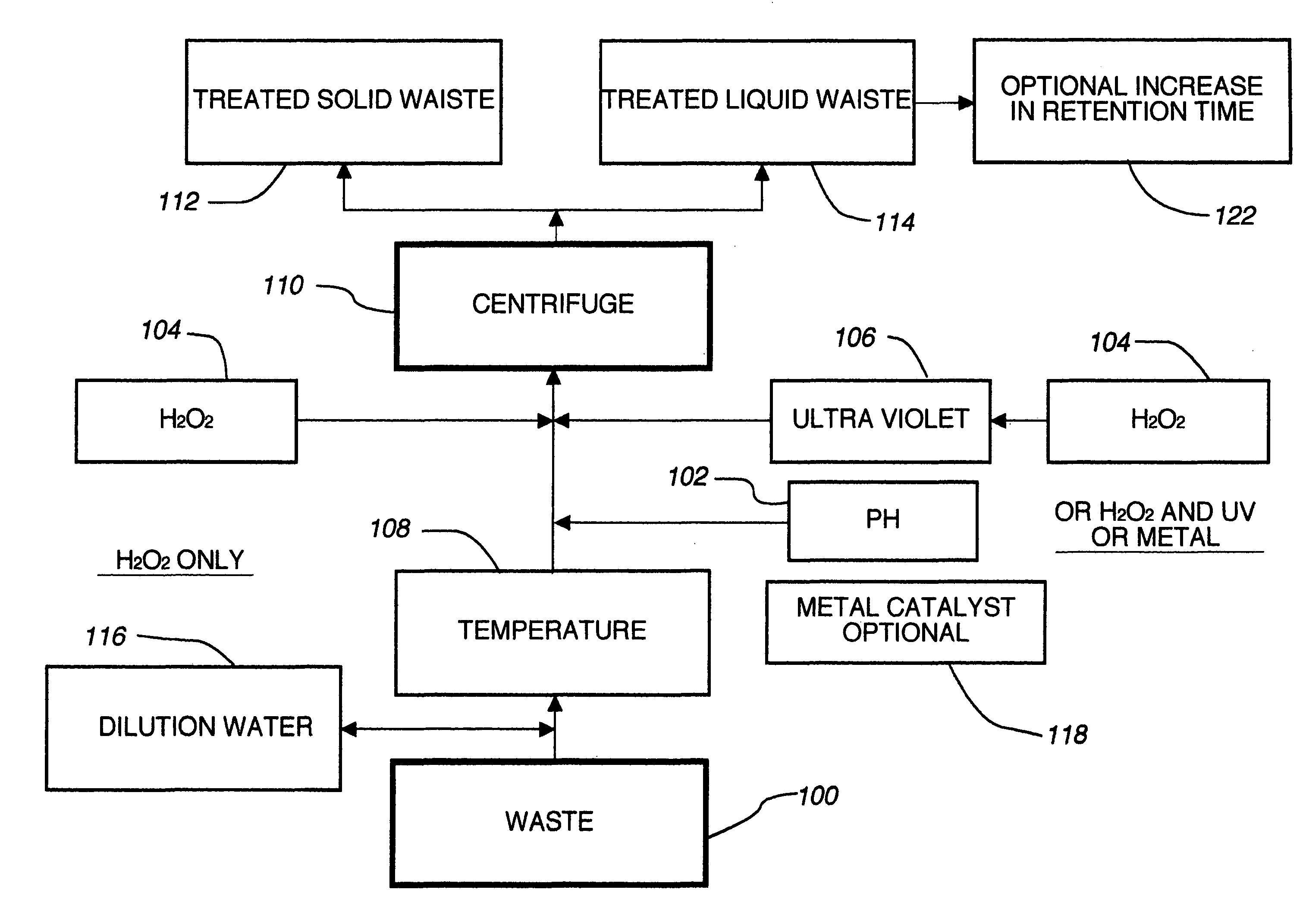

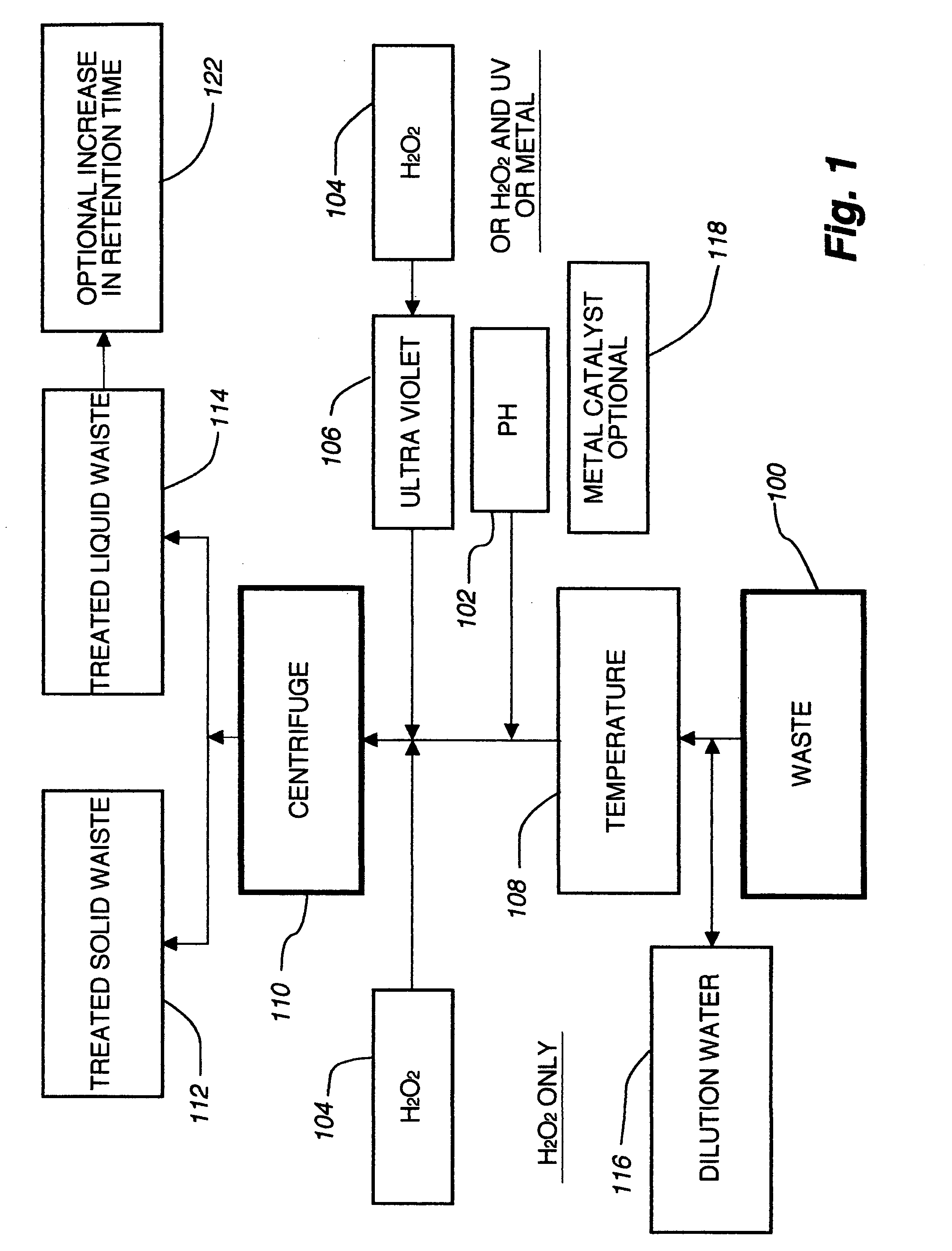

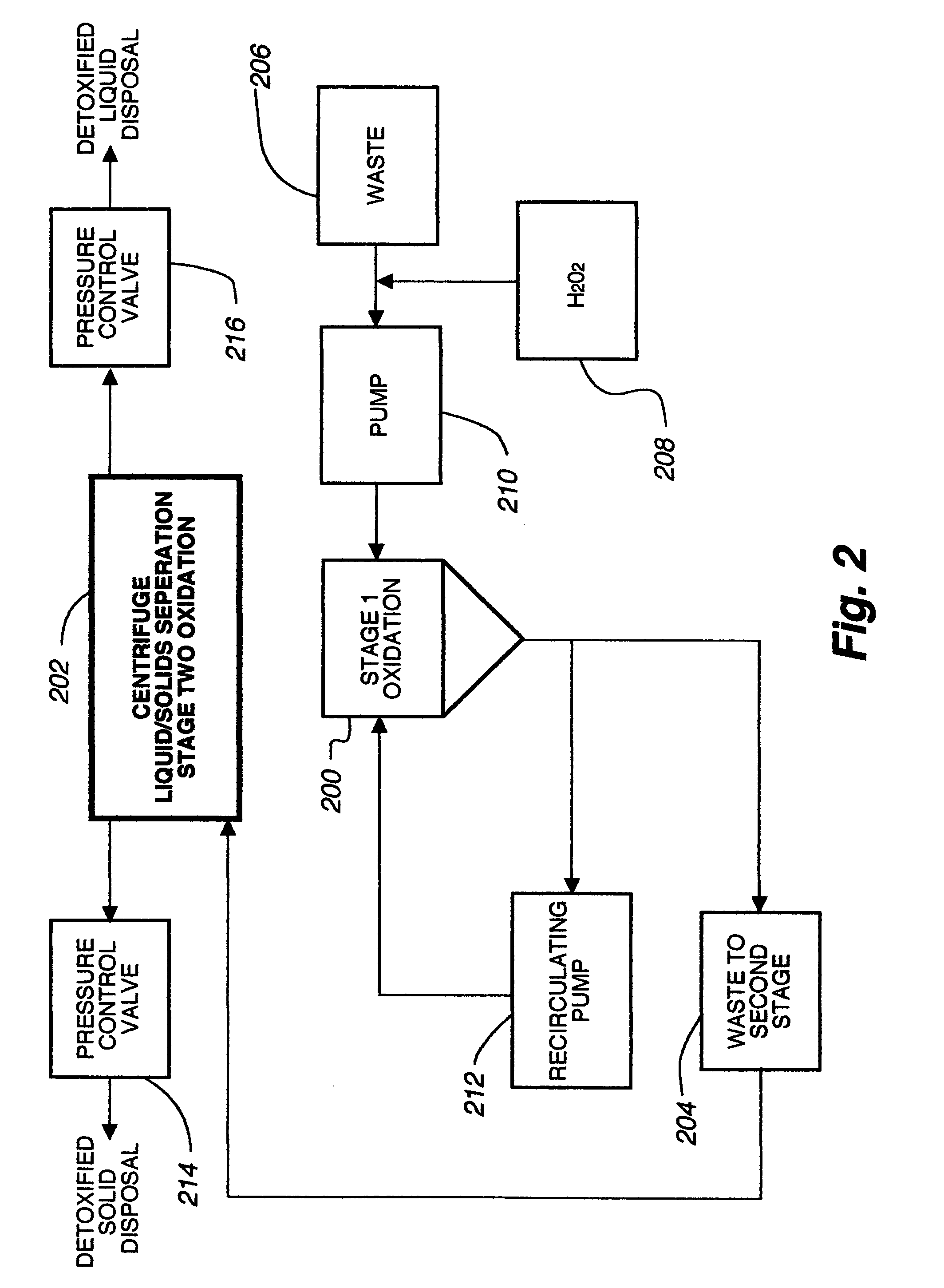

Sub-critical oxidative processes

InactiveUS20050178733A1ReactionImprove responseWater/sewage treatment by centrifugal separationWater treatment parameter controlTime rangeCritical condition

The invention relates to sub-critical processes and systems for accomplishing the same. In one aspect, the process is a sub-critical oxidation process for the destruction of organic and inorganic contaminates within a waste fluid or gas. The sub-critical processes are preferably carried out in a reactor and / or continuous flow centrifuge operating at sub-critical temperature and pressure. The processes and systems provide for destruction of high levels of organic and inorganic contaminates within a contaminate source, which represents a vast improvement over other conventional approaches. The processes and systems also accomplish this superior destruction of contaminates in a much faster time frame, i.e., minutes as compared to hours. Finally, the processes and systems described herein provide a safe and highly economical sub-critical approach as compared to the super-critical conditions, i.e., exceeding high temperatures and pressures, used in most conventional approaches.

Owner:CONGER HARRY C +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com