Transcritical thermally activated cooling, heating and refrigerating system

a thermal activated cooling, heating and refrigerating system technology, applied in the direction of machines/engines, lighting and heating apparatus, machine operation modes, etc., can solve the problem of super-critical high-pressure portion of the vapor expansion circui

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]While the present disclosure has been particularly shown and described with reference to the preferred mode as illustrated in the drawing, it will be understood by one skilled in the art that various changes in detail may be effected therein without departing from the spirit and scope of the disclosure as defined by the claims.

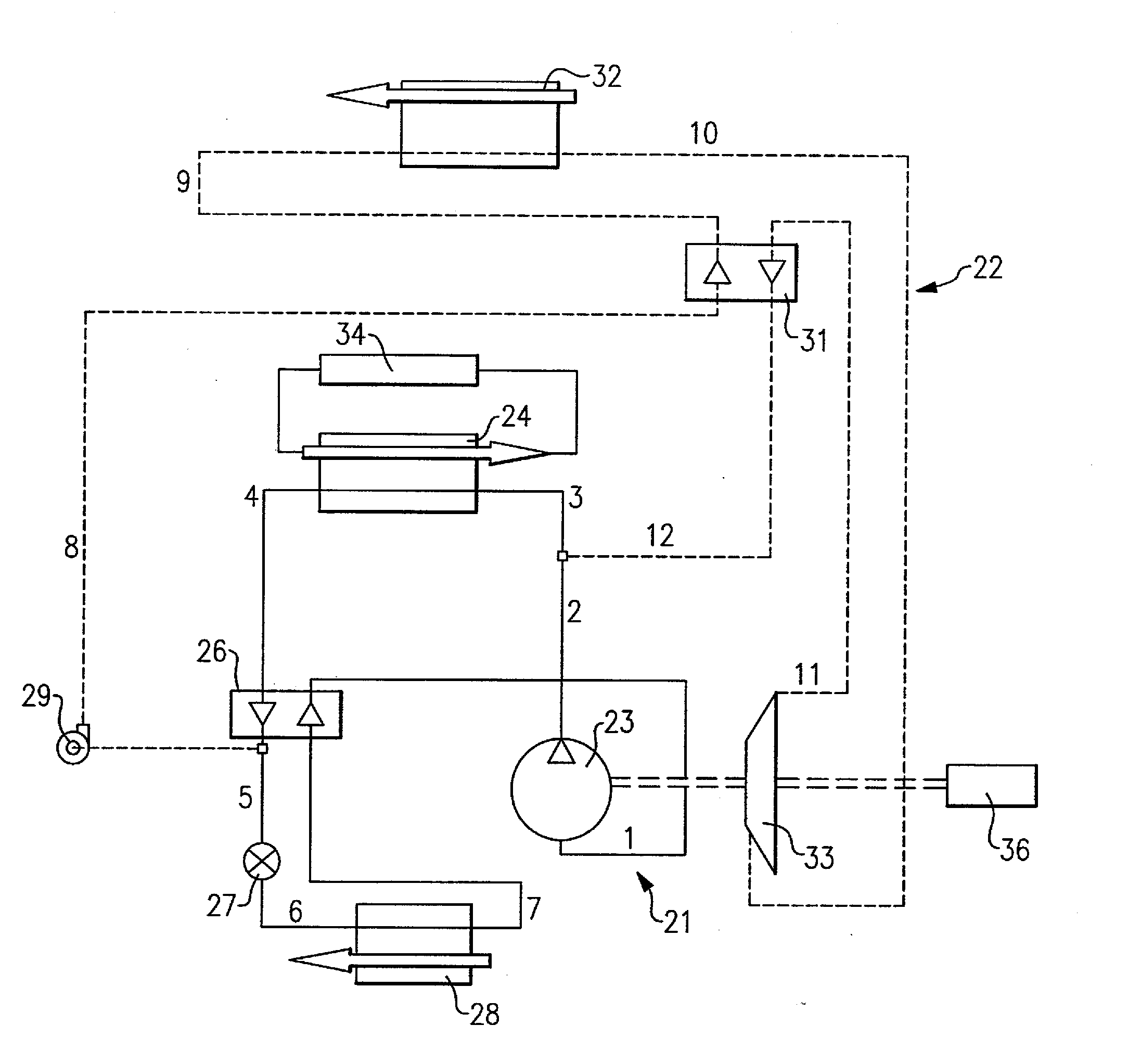

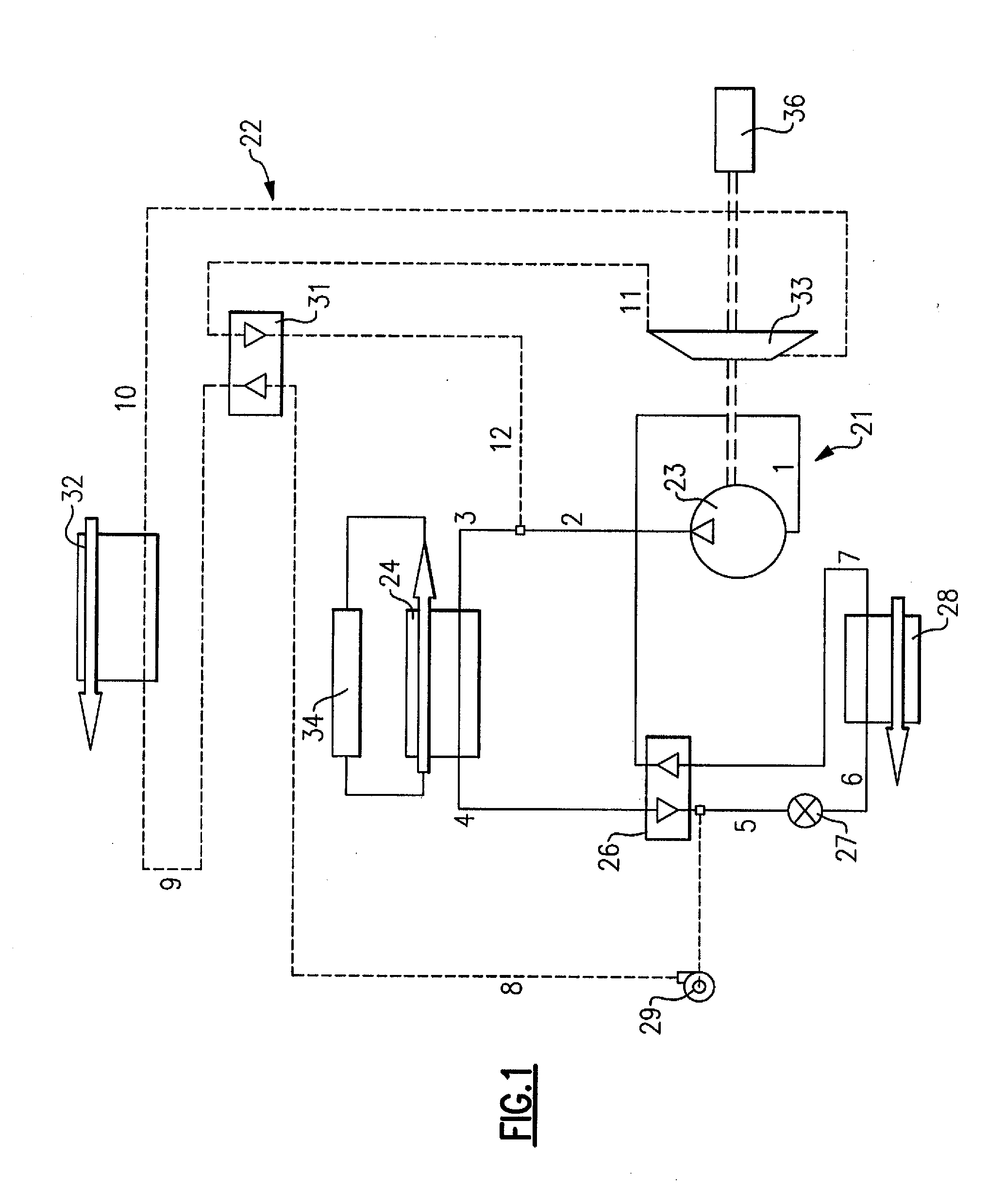

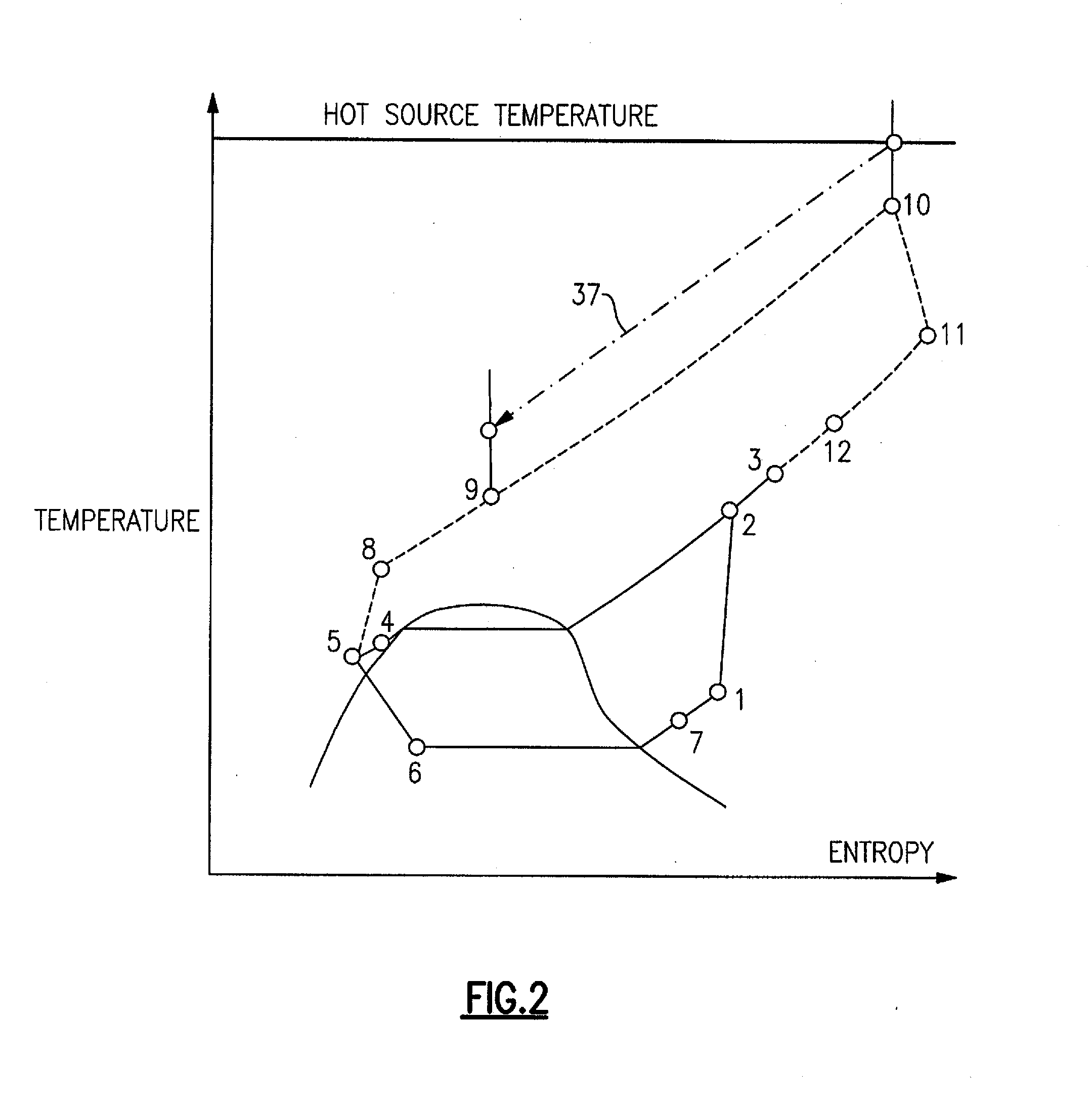

[0029]In accordance with FIG. 1 a thermally activated refrigerant system incorporates a vapor compression circuit 21 shown as solid lines and a vapor expansion circuit 22 shown as dashed lines. The vapor compression circuit 21 includes a compressor 23, a condenser 24, a liquid-to-suction heat exchanger 26, an expansion device 27, and an evaporator 28. The vapor expansion circuit 22 consists of a pump 29, a topping heat exchanger 31, a heater 32, an expander 33, and the condenser 24. A refrigerant vapor stream at the outlet from the compressor and a vapor refrigerant stream at the outlet from the expander are connected at the condenser inlet to provide a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com