Performance testing device of carbon dioxide refrigeration compressor for refrigeration systems

A refrigeration compressor, carbon dioxide technology, applied in pump testing, mechanical equipment, machines/engines, etc., can solve the problems of high working pressure of equipment and high system pressure, and achieve the goal of improving safety, reducing costs, and improving active safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

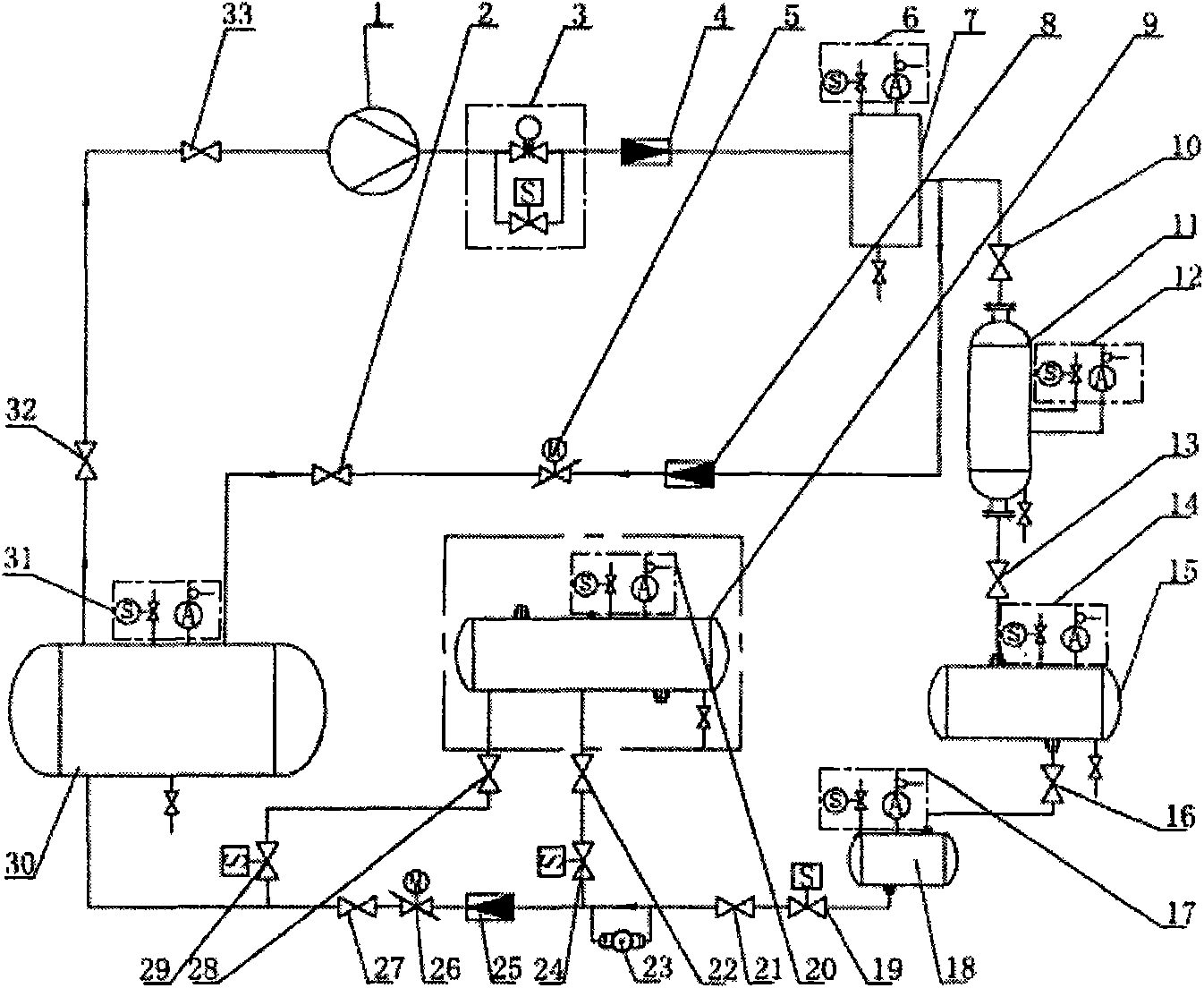

[0026] see figure 1 , the carbon dioxide refrigeration compressor performance test device for the refrigeration system includes an oil separator 7, a condenser 11, a liquid receiver 15, a subcooler 18 and a gas cooler 30 connected in series; an exhaust gas flowmeter is installed at the inlet end of the oil separator 7 4. A shut-off valve A10 is installed on the pipeline between the outlet of the oil separator 7 and the inlet of the condenser 11; a shut-off valve B13 is installed on the pipeline between the outlet of the condenser 11 and the inlet of the liquid storage 15; the outlet of the liquid storage 15 and the A shut-off valve C16 is provided on the pipeline between the inlet of the subcooler 18, and a solenoid valve 19, a shut-off valve D21, a mass flow meter 25, and a liquid pipe are sequentially installed on the pipeline between the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com