Combined method for separating fluid catalytic cracking slurry oil and preparing oil-series needle coke

A technology of catalytic cracking oil slurry and oil-based needle coke, which is applied in the fields of petroleum industry, hydrocarbon oil treatment, polymerization reaction treatment, etc. It can solve the problems of difficult to improve extract extraction rate, coking of heating furnace and distillation tower, and coking process Control difficulties and other problems to achieve the effect that is conducive to the realization of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

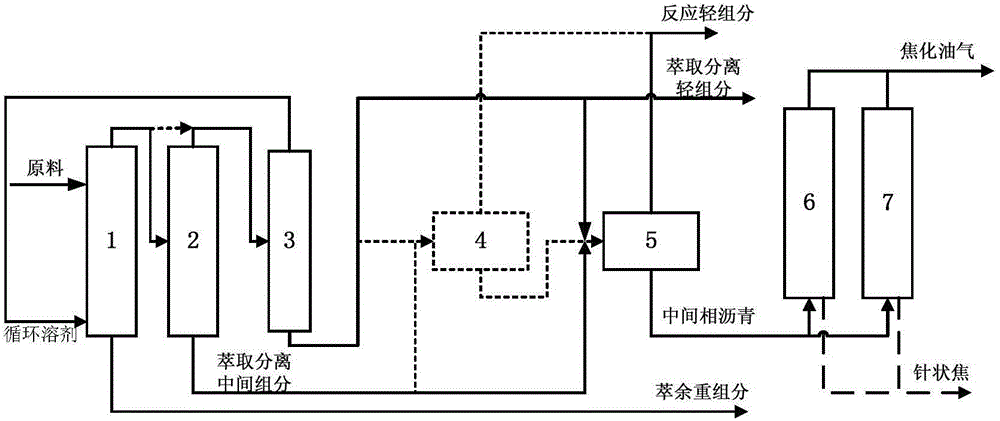

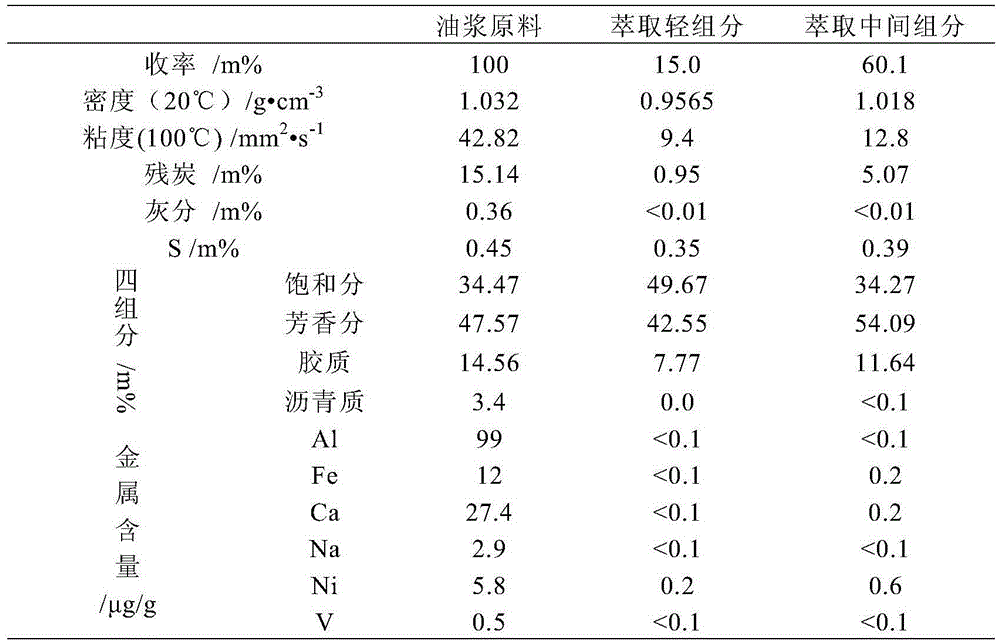

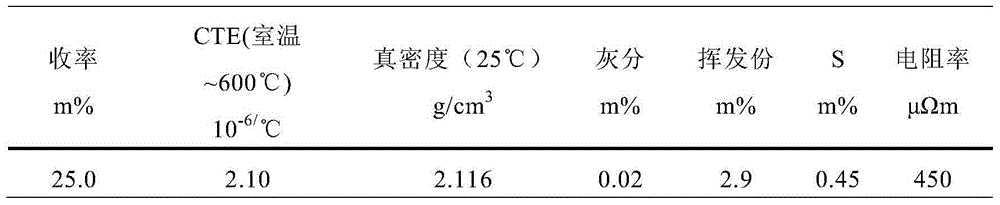

[0055] A catalytic cracking oil slurry is used as raw material, and the properties of the oil slurry are shown in Table 1 below, according to figure 1 The flow shown is implemented.

[0056] The light hydrocarbon solvent is composed of isobutane and n-butane respectively accounting for 75m%, 25m%, and its pseudocritical temperature is 139.4°C. The catalytic oil slurry enters from the top of extraction tower 1 (this embodiment is a sieve tray tower), and the inlet temperature is 120°C. ℃, the solvent is fed from the bottom of the extraction tower, the temperature of the tower is 80°C, the mass ratio of agent to oil is 2.5:1, and the pressure inside the tower is 4.5MPa. It is sent from the top of the tower and enters the separation tower 2. The temperature at the top of tower 1 is 86.2°C, and the raffinate phase is discharged from the bottom of the tower and recovered as the heavy component of the raffinate.

[0057] Table 1 Example 1 Oil slurry raw material properties and extr...

Embodiment 2

[0065] A catalytic cracking oil slurry is used as raw material, and its properties are shown in Table 3. The light hydrocarbon solvent composition is propane, isobutane, and n-butane, accounting for 25m%, 50m%, and 25m%, respectively, and its pseudocritical temperature is 127.0°C. The extraction and separation operation flow All the same as in Example 1, the difference is: the extraction tower 1 is a packed tower, the catalytic cracking oil slurry enters the top of the tower 1 at a temperature of 100°C, the solvent enters the bottom of the tower 1 at a temperature of 70°C, and the mass ratio of solvent to oil is 3.5:1. The pressure is 5.0MPa, and the tower top temperature of the extraction tower is 75.6°C; the separation tower 2 is a packed tower, the inlet temperature of the extraction oil phase is 135°C, and the pressure in the tower 2 is 4.8MPa; the light oil phase enters the supercritical solvent recovery tower 3, The pressure inside the control tower 3 is 4.7MPa, the tempe...

Embodiment 3

[0074] A catalytic cracking oil slurry is used as the raw material. The properties of the oil slurry are shown in Table 5 below. The light hydrocarbon solvent composition is n-butane and n-pentane accounting for 85m% and 15m% respectively, and its pseudo-critical temperature is 149.5°C. The extraction and separation operation process is the same as in Example 1, the difference is that the extraction tower 1 is a packed tower, the temperature of the top of the catalytic oil slurry entering the tower 1 is 150°C, the temperature of the bottom of the solvent entering the tower 1 is 120°C, and the mass ratio of solvent to oil is 4.5:1 , the pressure in tower 1 is 6.0MPa, and the temperature at the top of the tower during the extraction process is 124.5°C; the separation tower 2 is a sieve plate tower, the inlet temperature of the extracted oil phase is 175°C, and the pressure in tower 2 is 5.8MPa; the light oil phase enters the supercritical solvent recovery tower 3. The pressure in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com