Patents

Literature

167results about "Treatment with polymerisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for Co-Producing Jet Fuel and LPG from Renewable Sources

ActiveUS20080244962A1Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

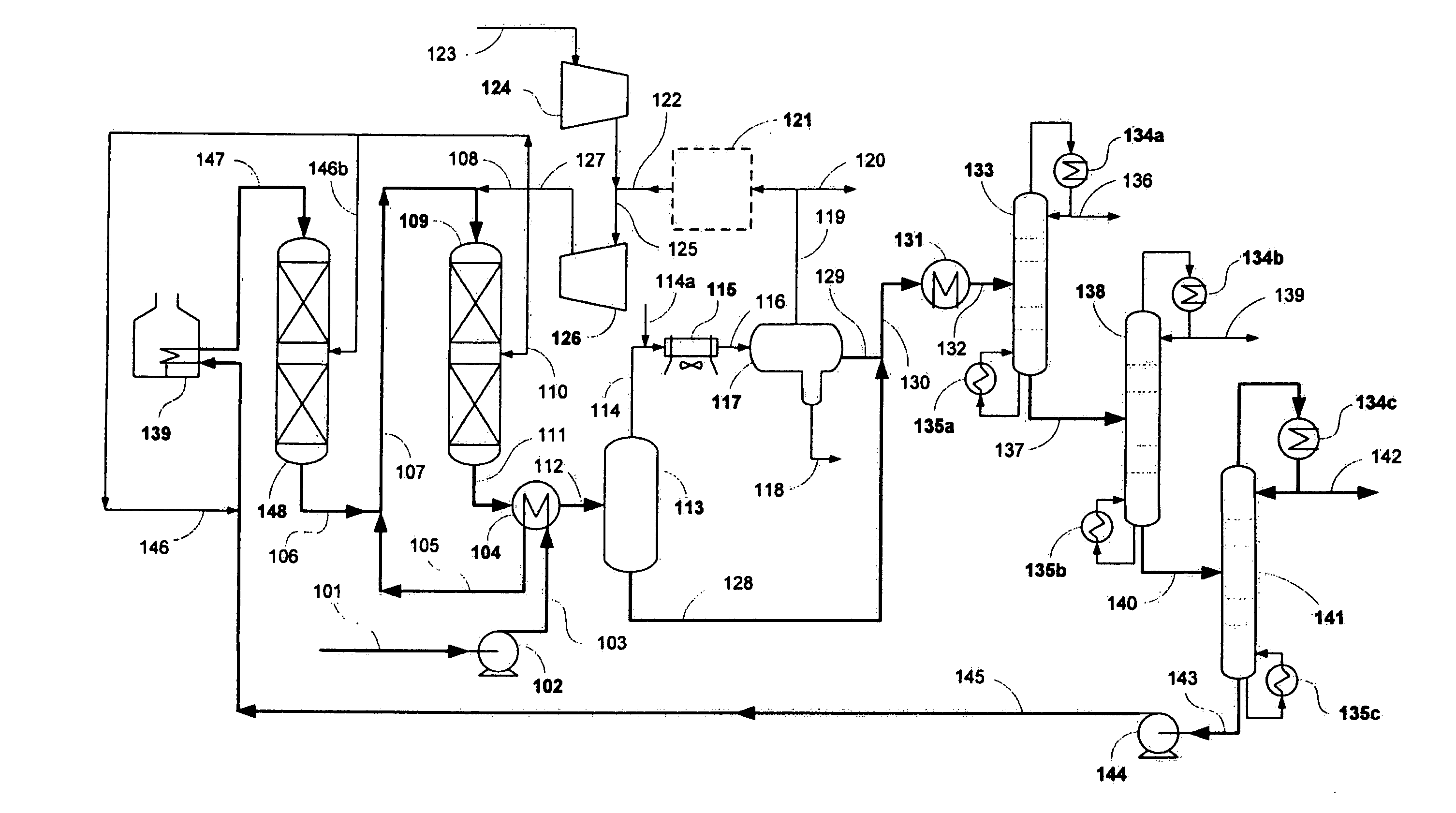

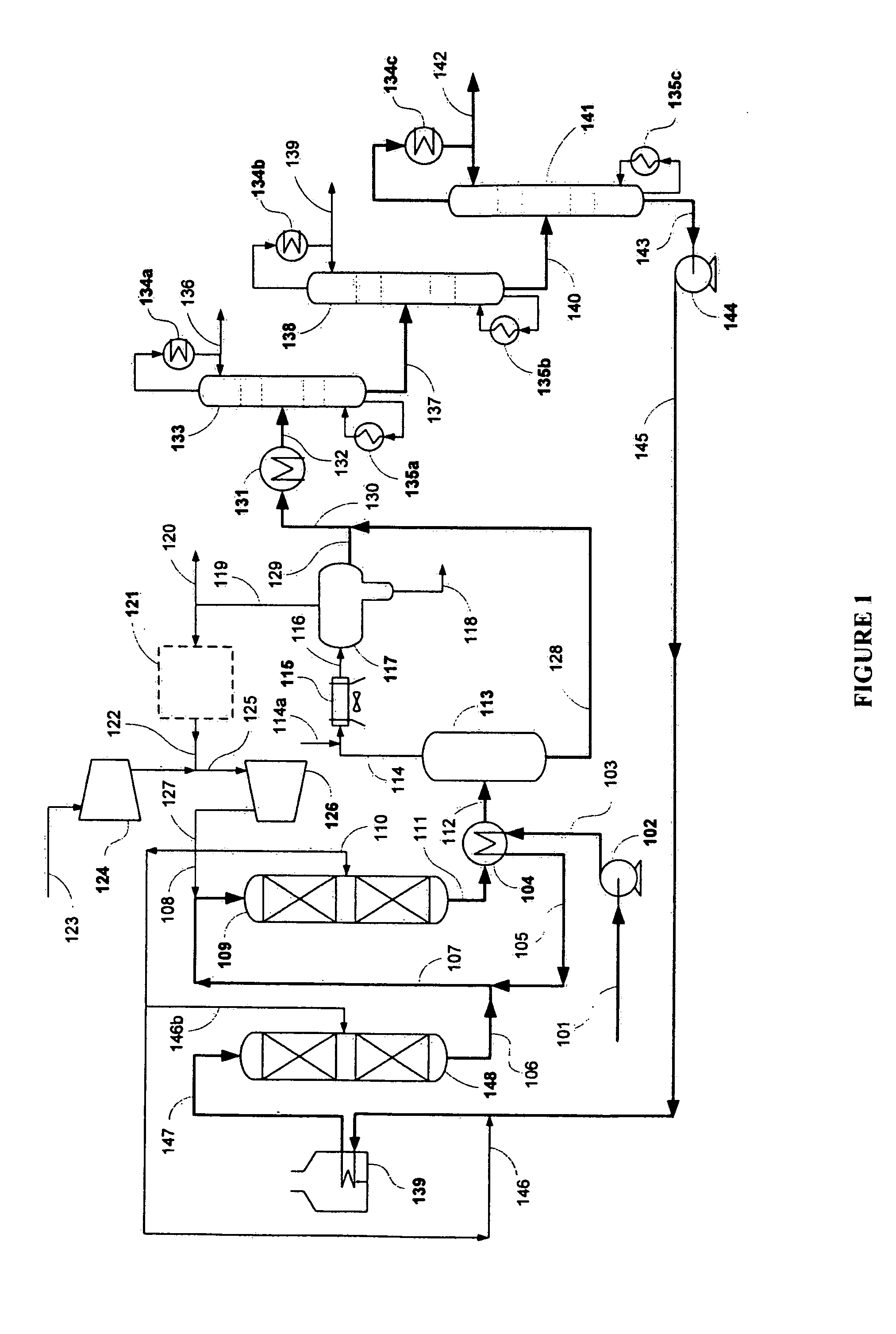

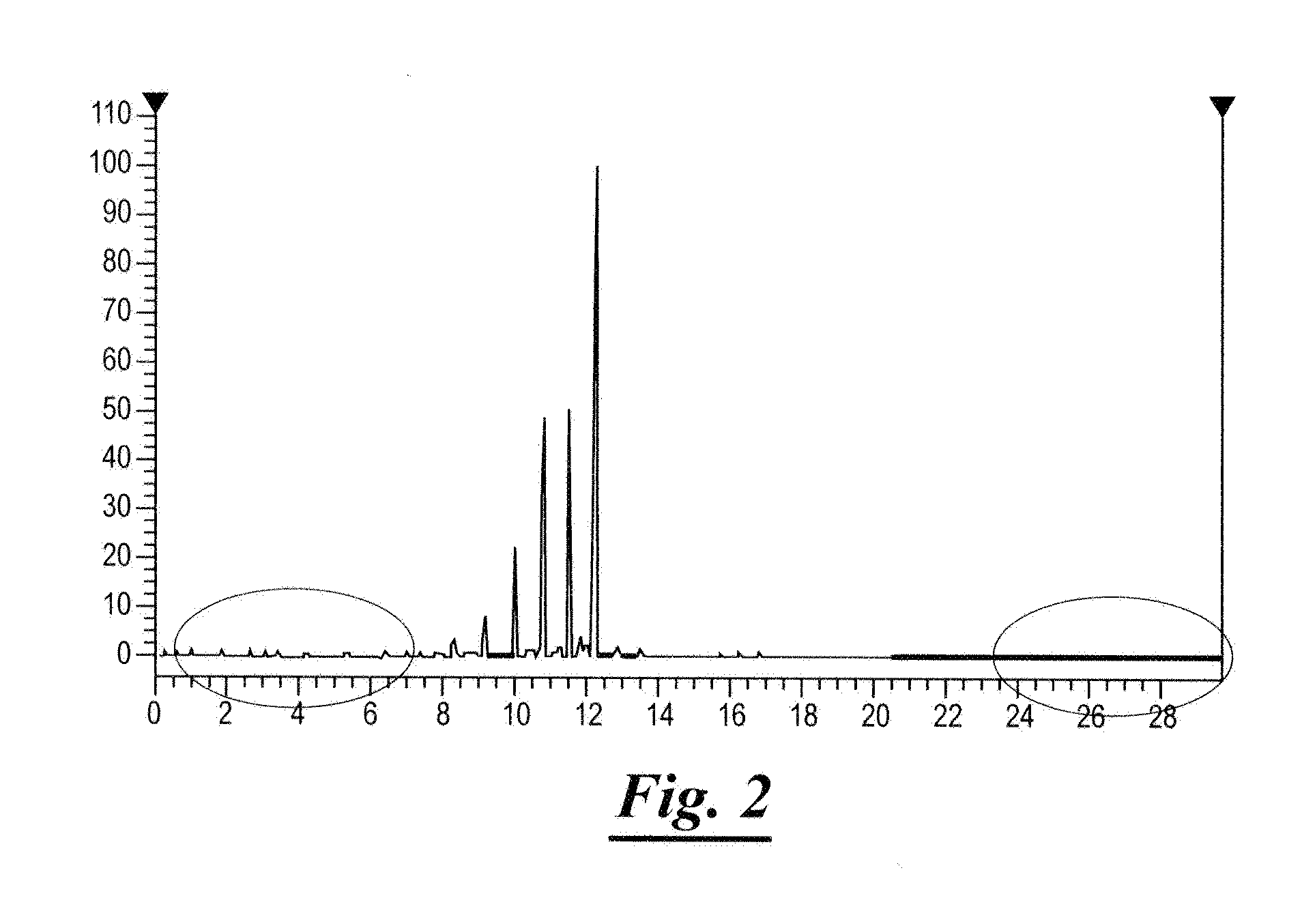

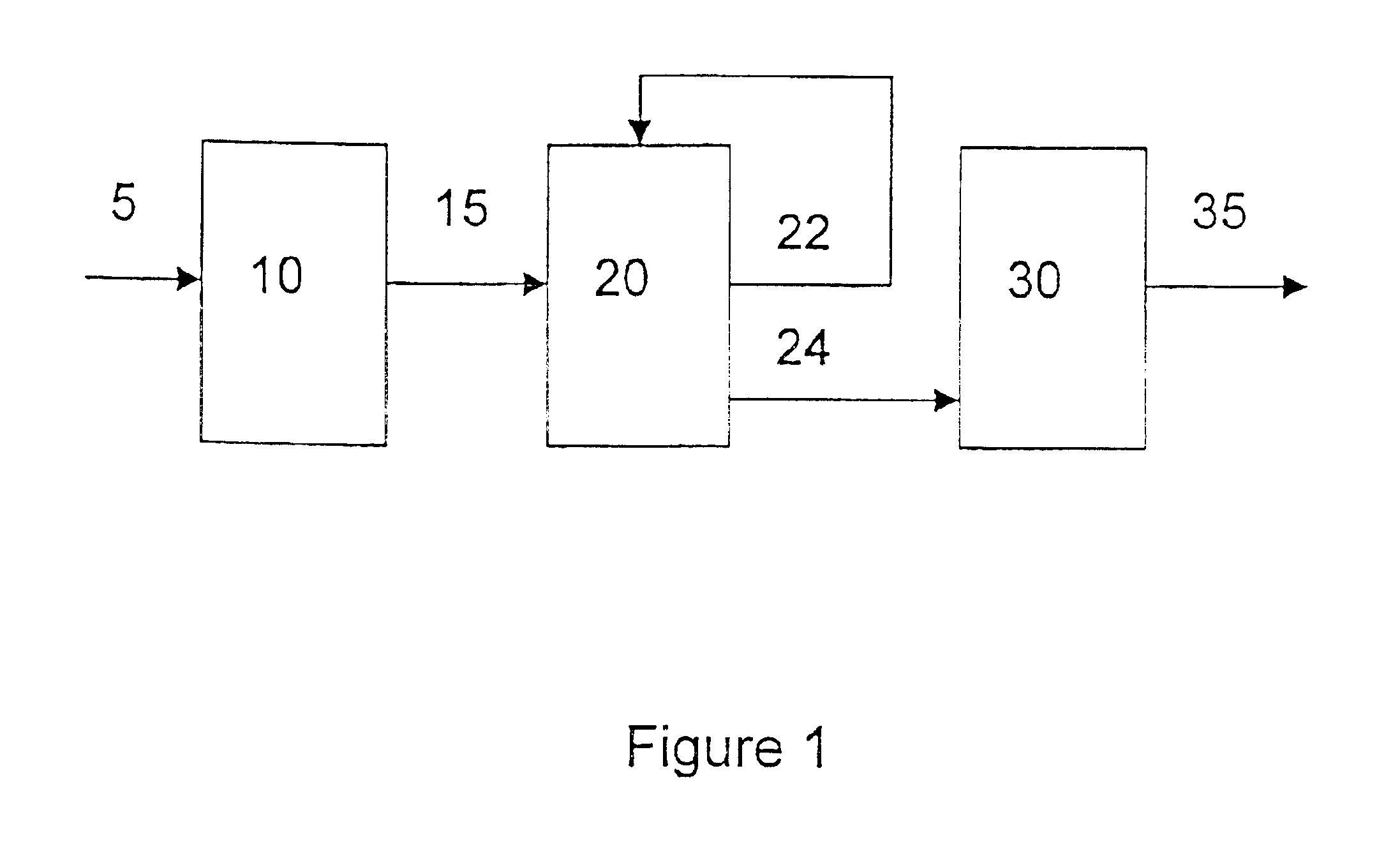

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

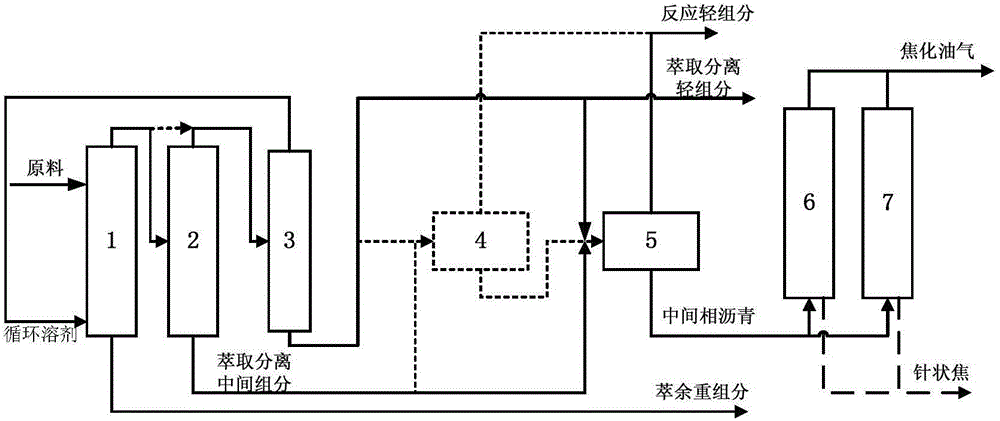

Improvement method of needle coke used refined aromatic hydrocarbon oil

InactiveCN104560082AIncrease contentSimple processCoke ovensTreatment with polymerisationVapor–liquid separatorRoom temperature

The invention relates to an improvement method of needle coke used refined aromatic hydrocarbon oil. The improvement method of the needle coke used refined aromatic hydrocarbon oil comprises the following steps: taking oil rich in aromatic hydrocarbon, heating the oil to 400-490 DEG C by a heating furnace, introducing the oil into a polymerization tower, taking the material at the bottom of the polymerization tower and introducing the material into a flash tower, taking the flashed material at the bottom of the flash tower, cooling the material to the room temperature, introducing the material into a gas-liquid separator, controlling the vacuum degree in the gas-liquid separator to be 5-10kpa, taking the material at the bottom of the gas-liquid separator, and enabling the material to flow into a refined aromatic hydrocarbon oil buffering tank to prepare the raw material which is refined aromatic hydrocarbon oil for producing needle coke. The improvement method of the needle coke used refined aromatic hydrocarbon oil is simple in process; the oil rich in aromatic hydrocarbon with low content of aromatic hydrocarbon in domestic oil refining plant is processed, the content of the aromatic hydrocarbon is increased; the prepared refined aromatic hydrocarbon oil is applicable to production of the needle coke.

Owner:SHANDONG YIDA NEW MATERIAL

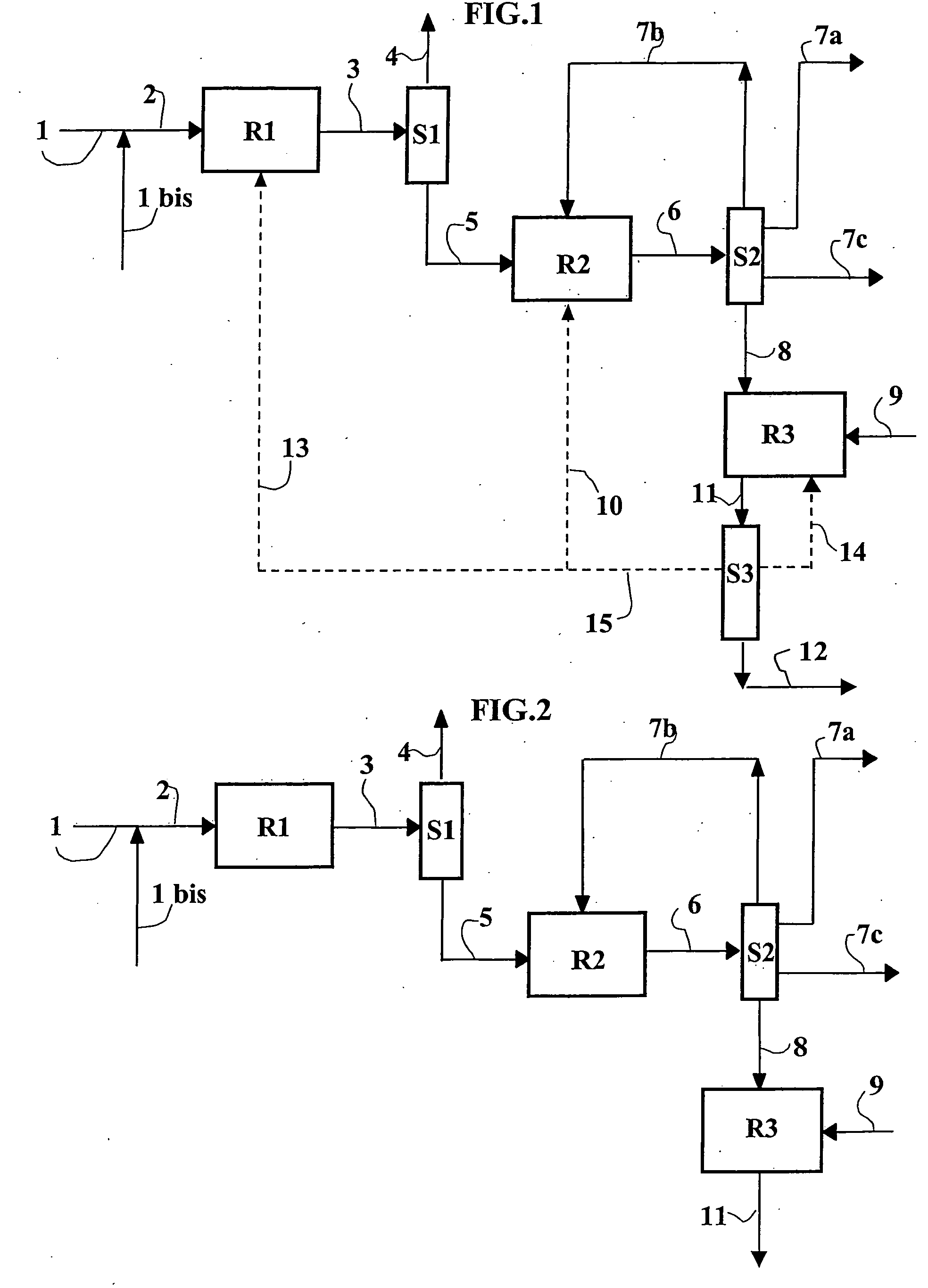

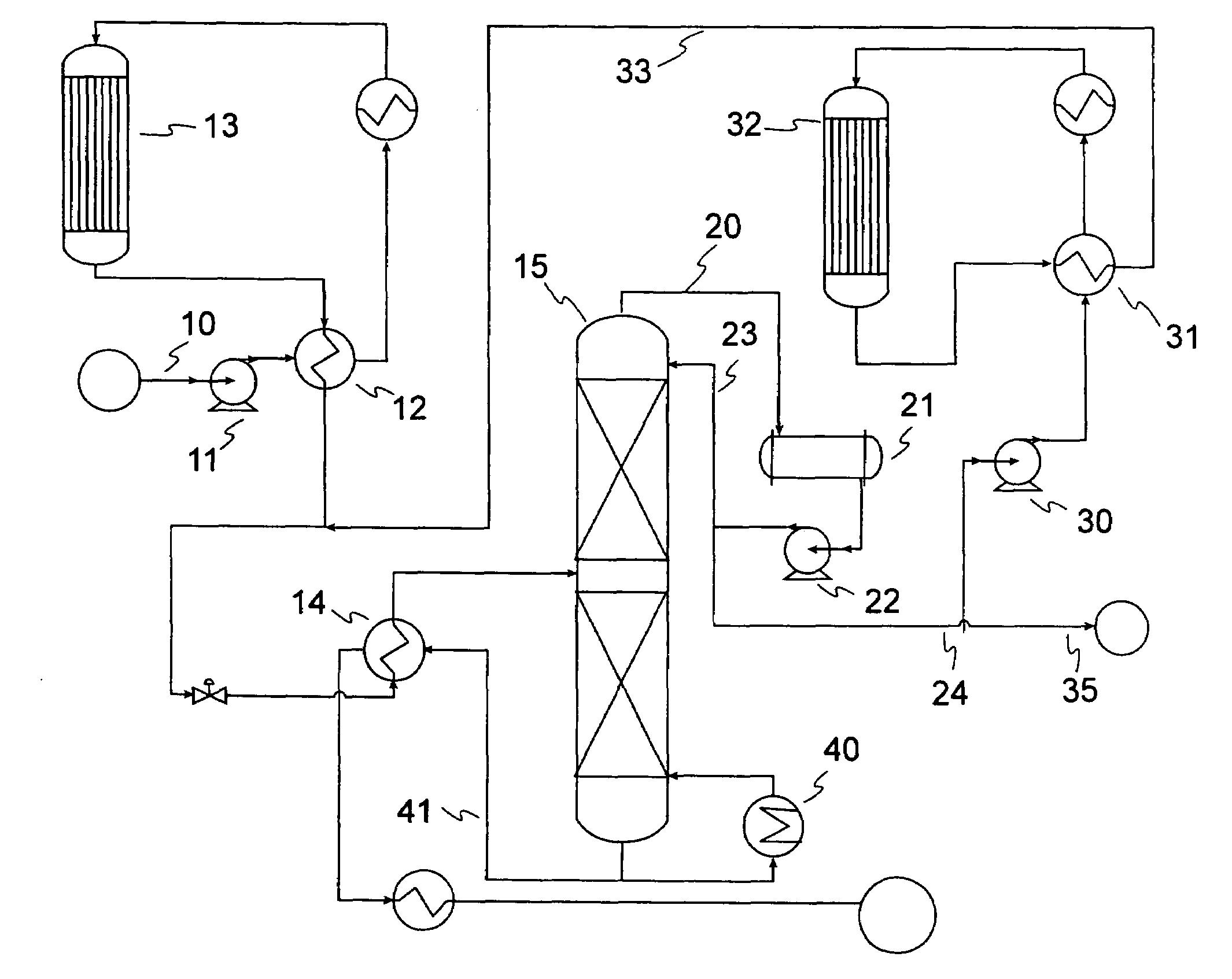

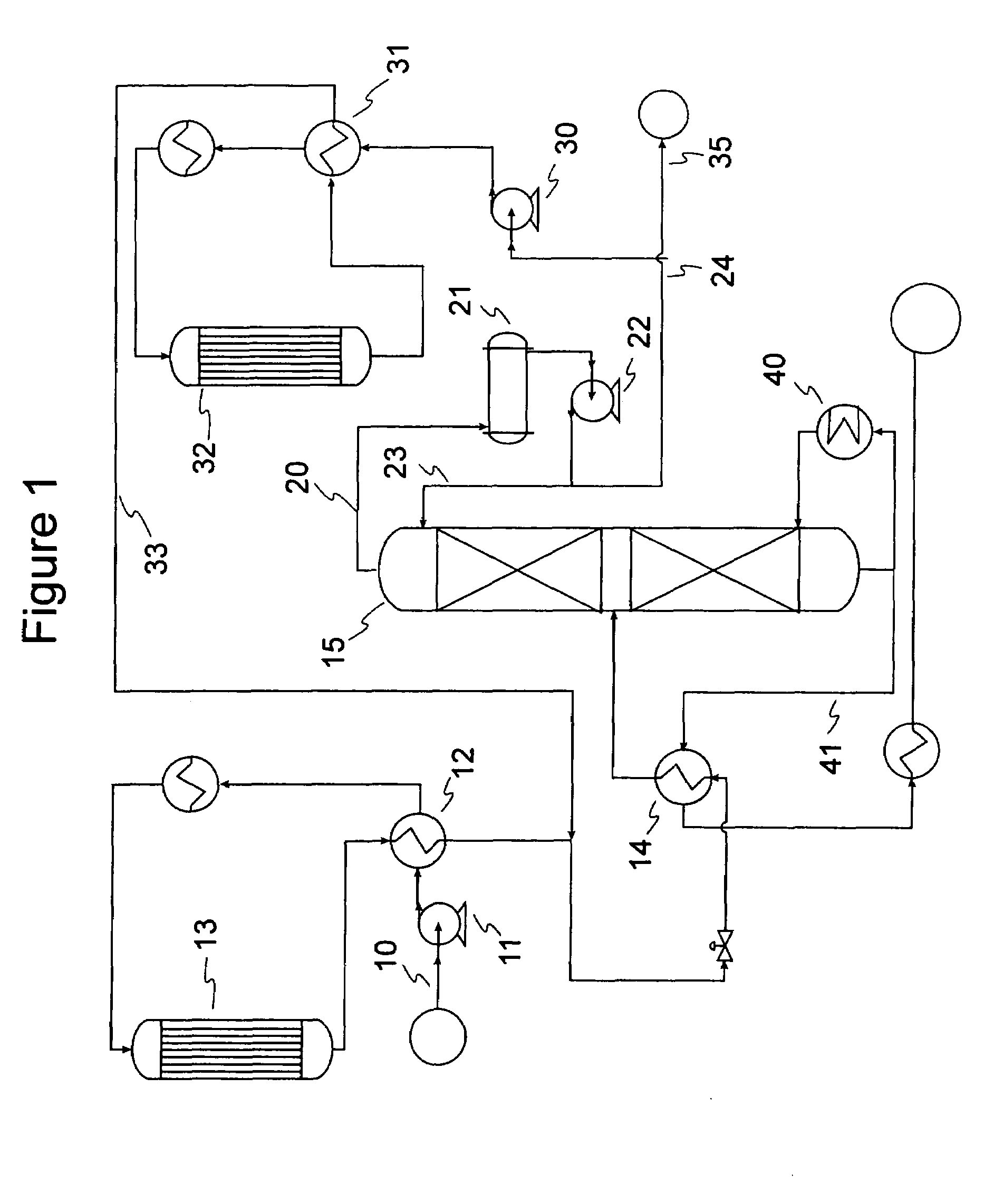

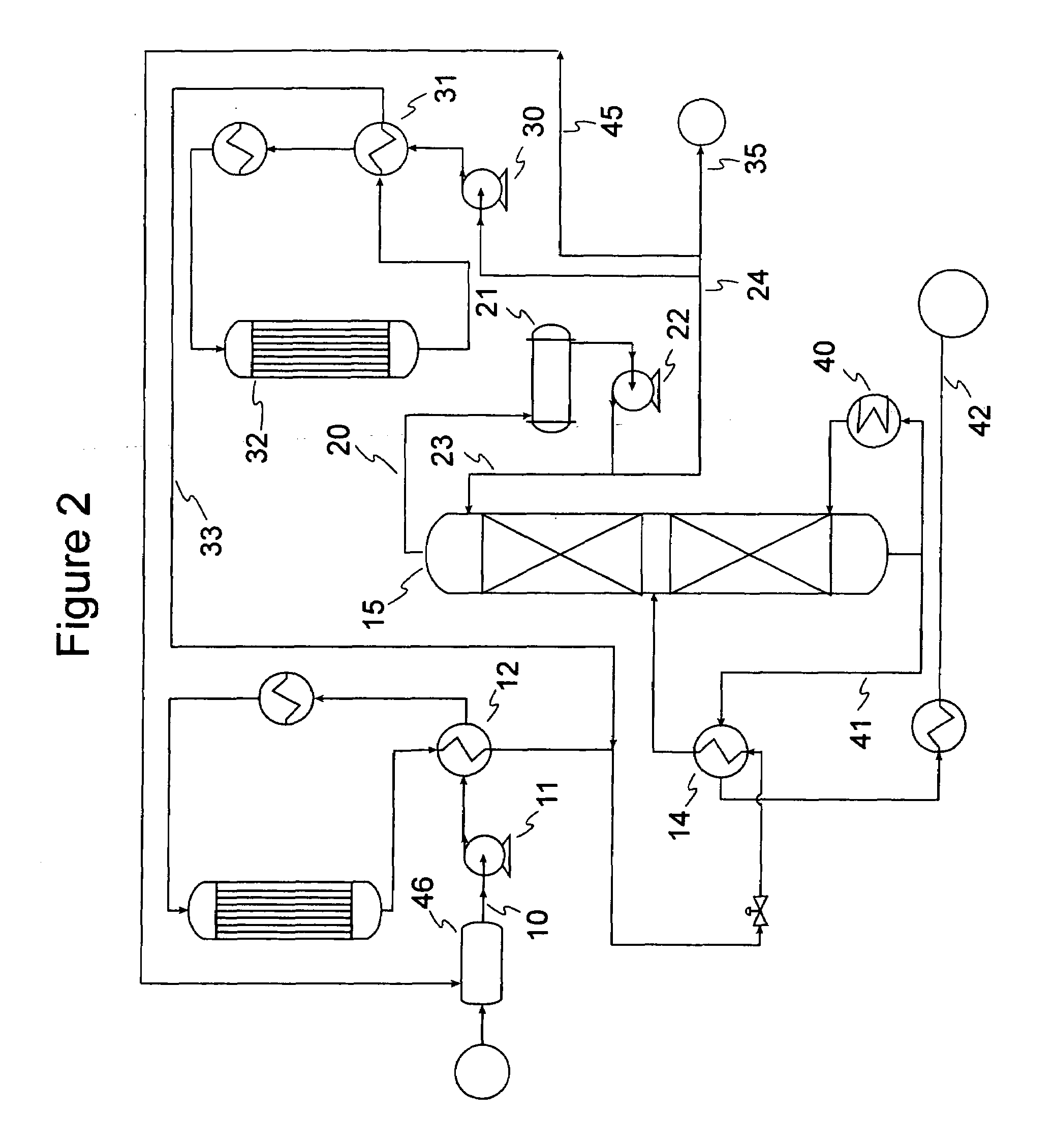

Method for jointly producing propylene and petrol from a relatively heavy charge

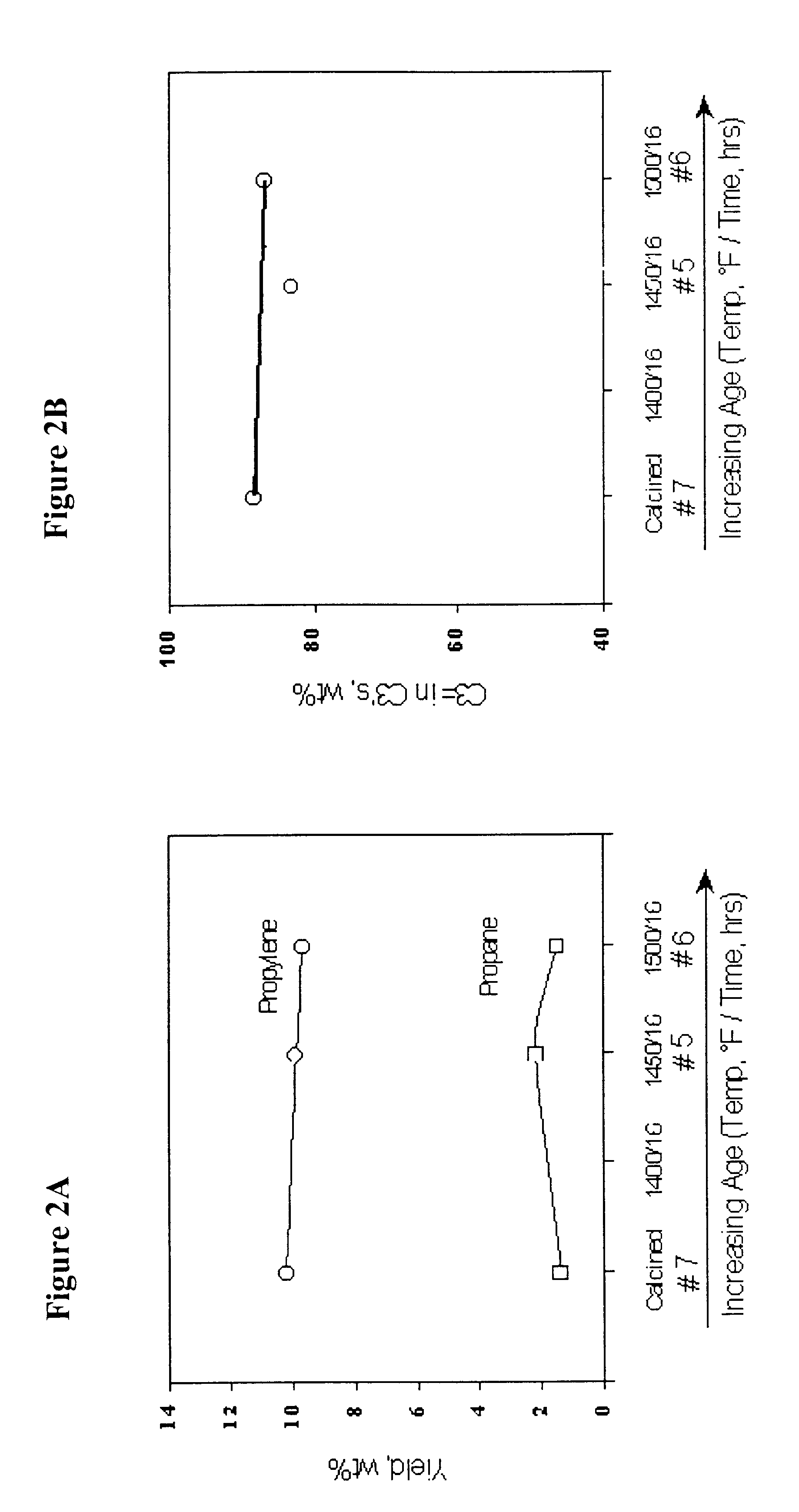

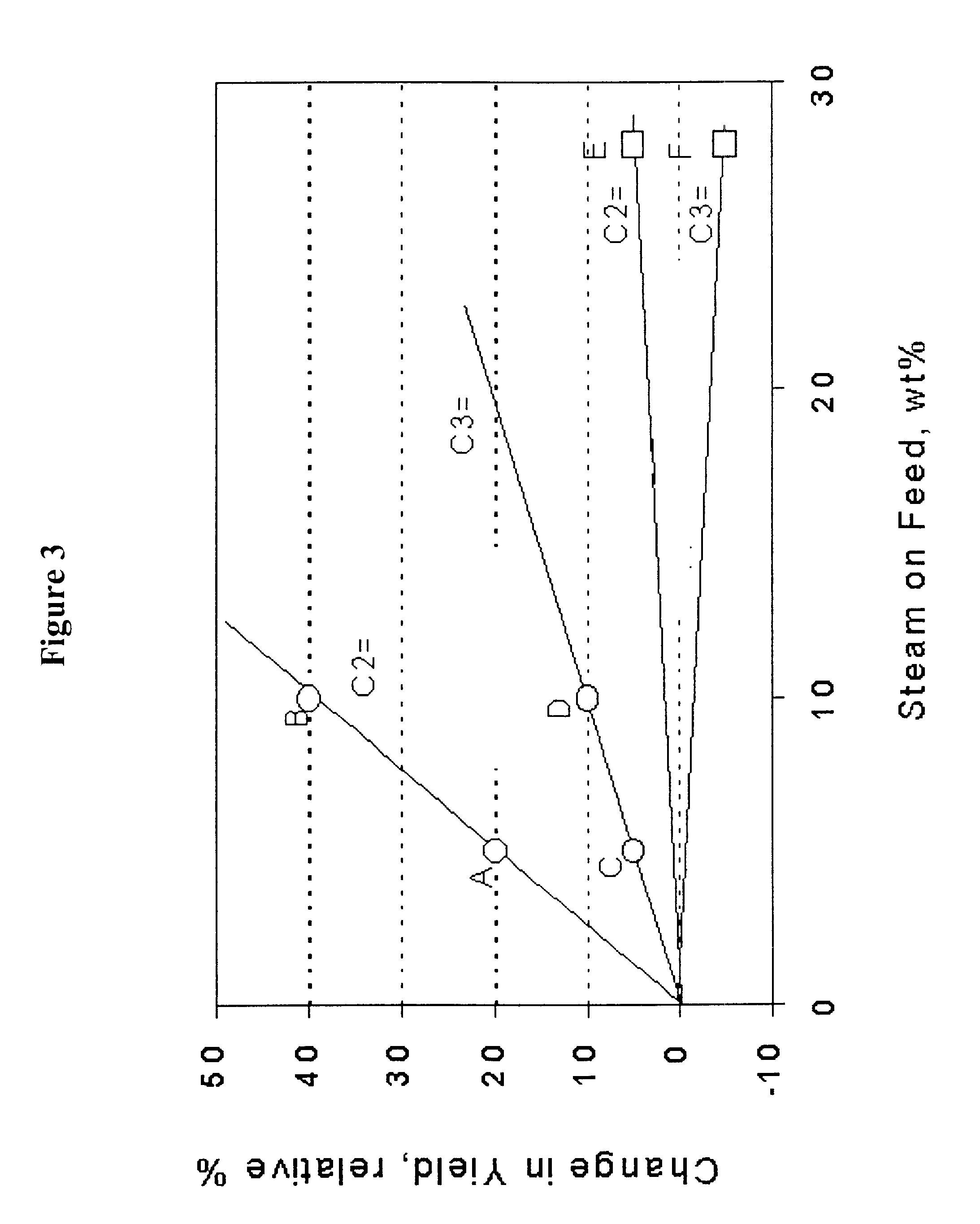

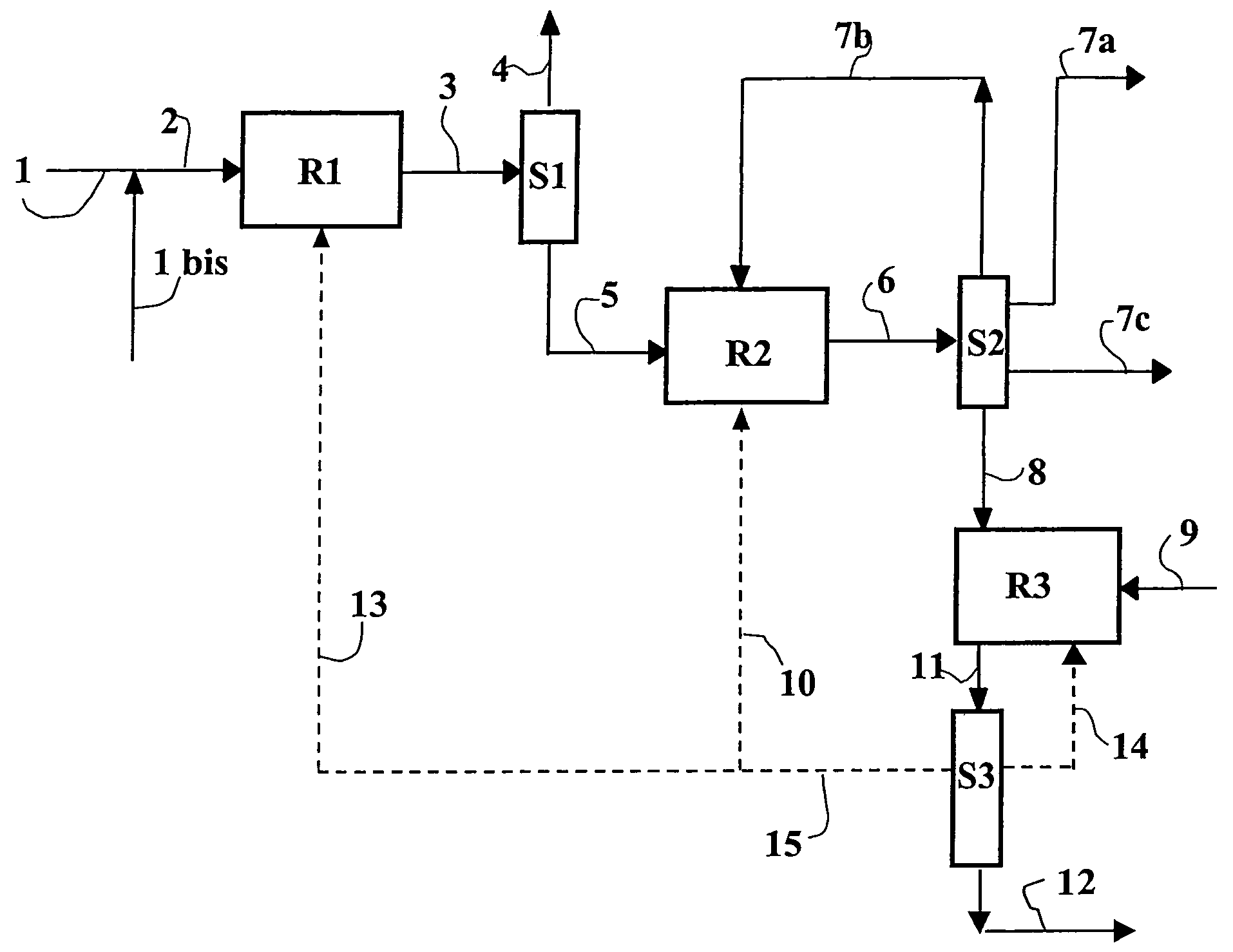

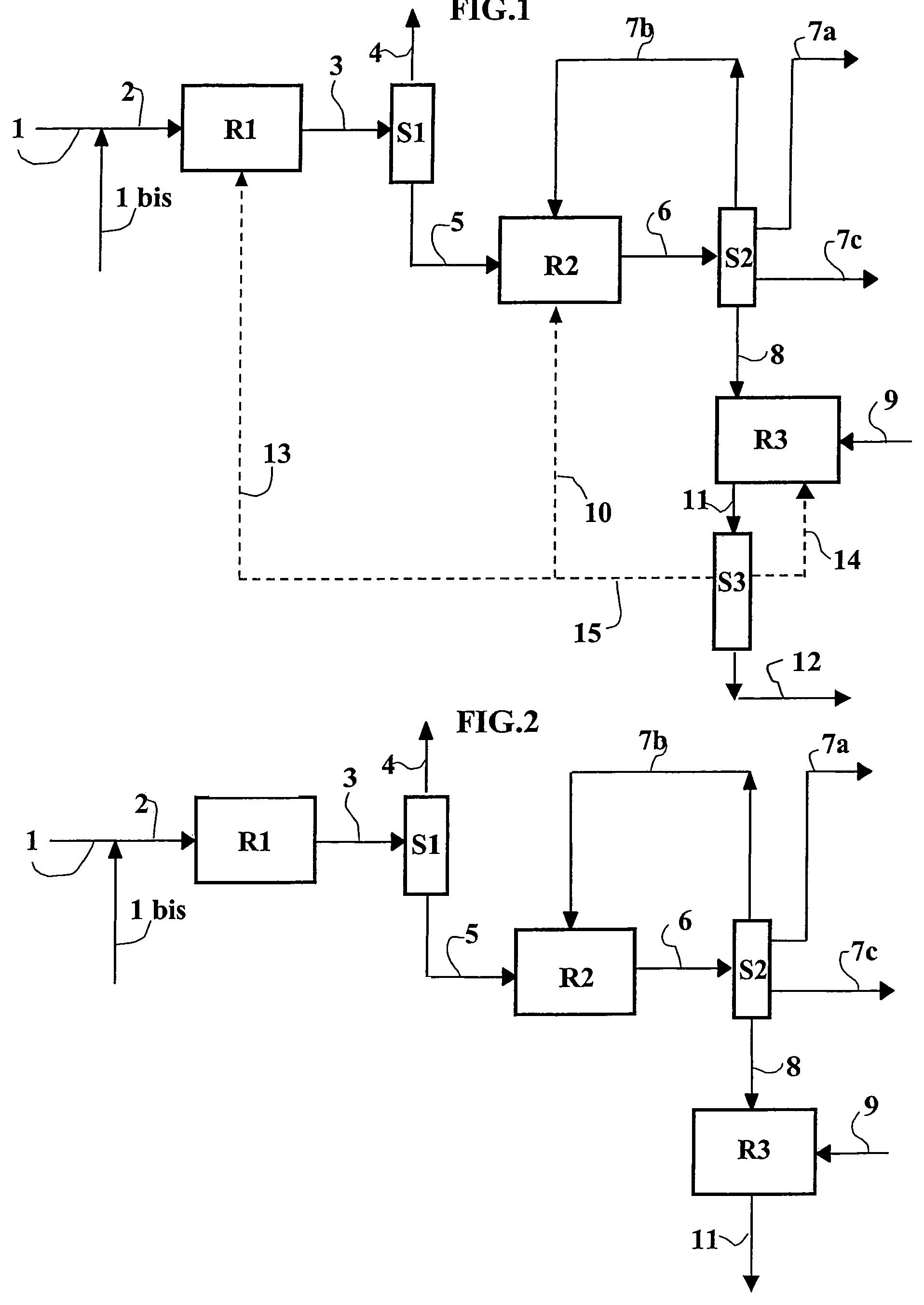

ActiveUS20050121361A1Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerBoiling point

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein, the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst, the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

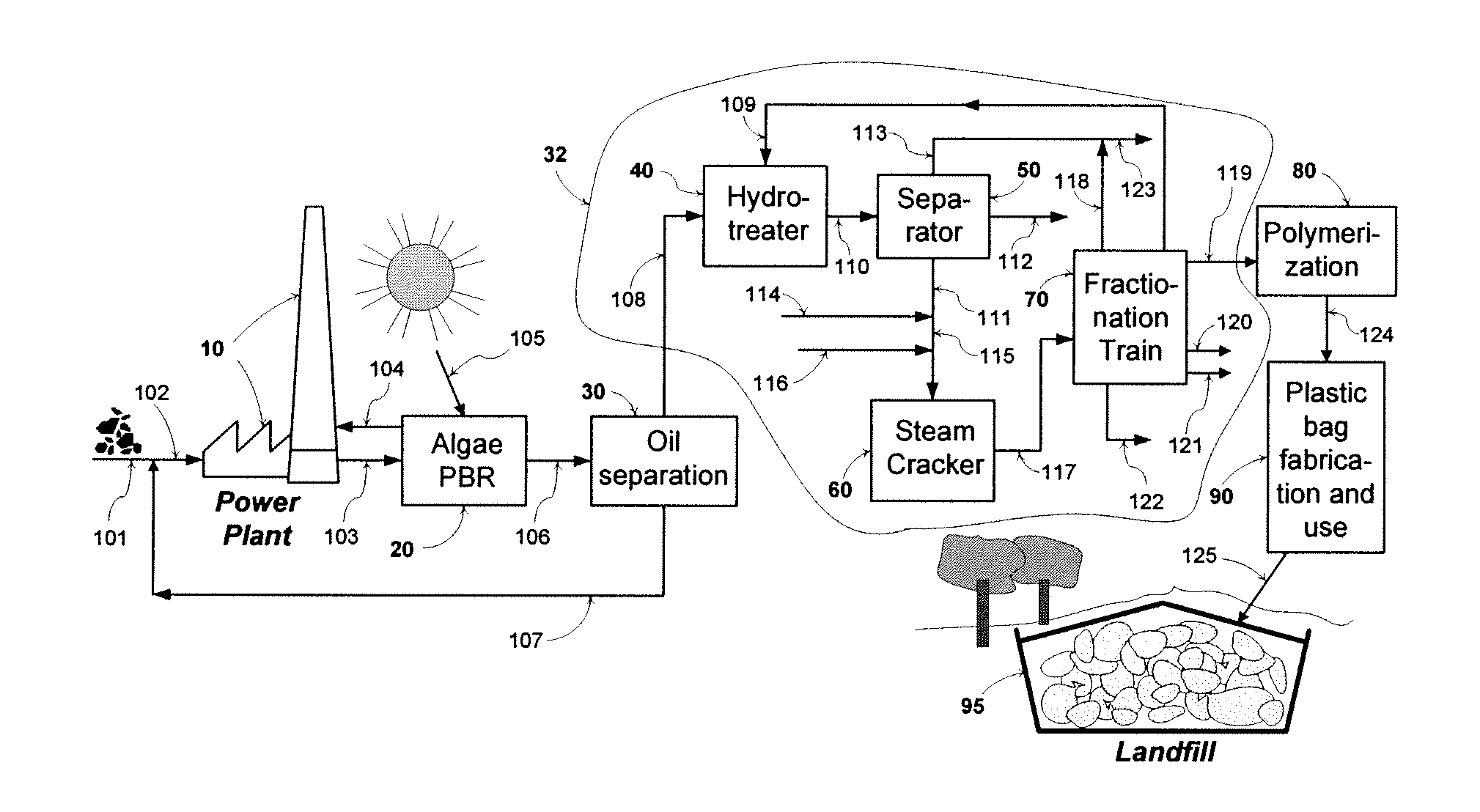

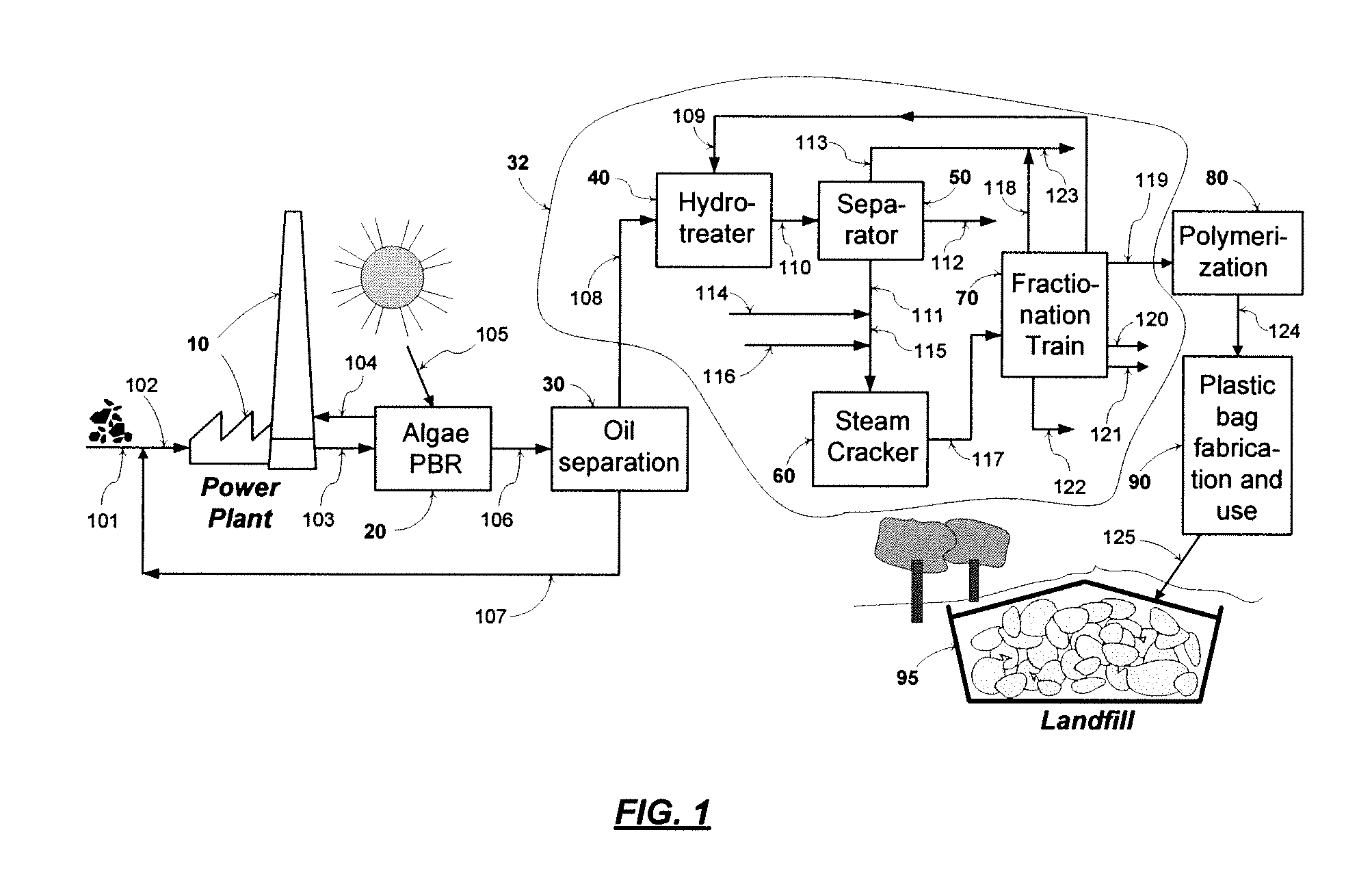

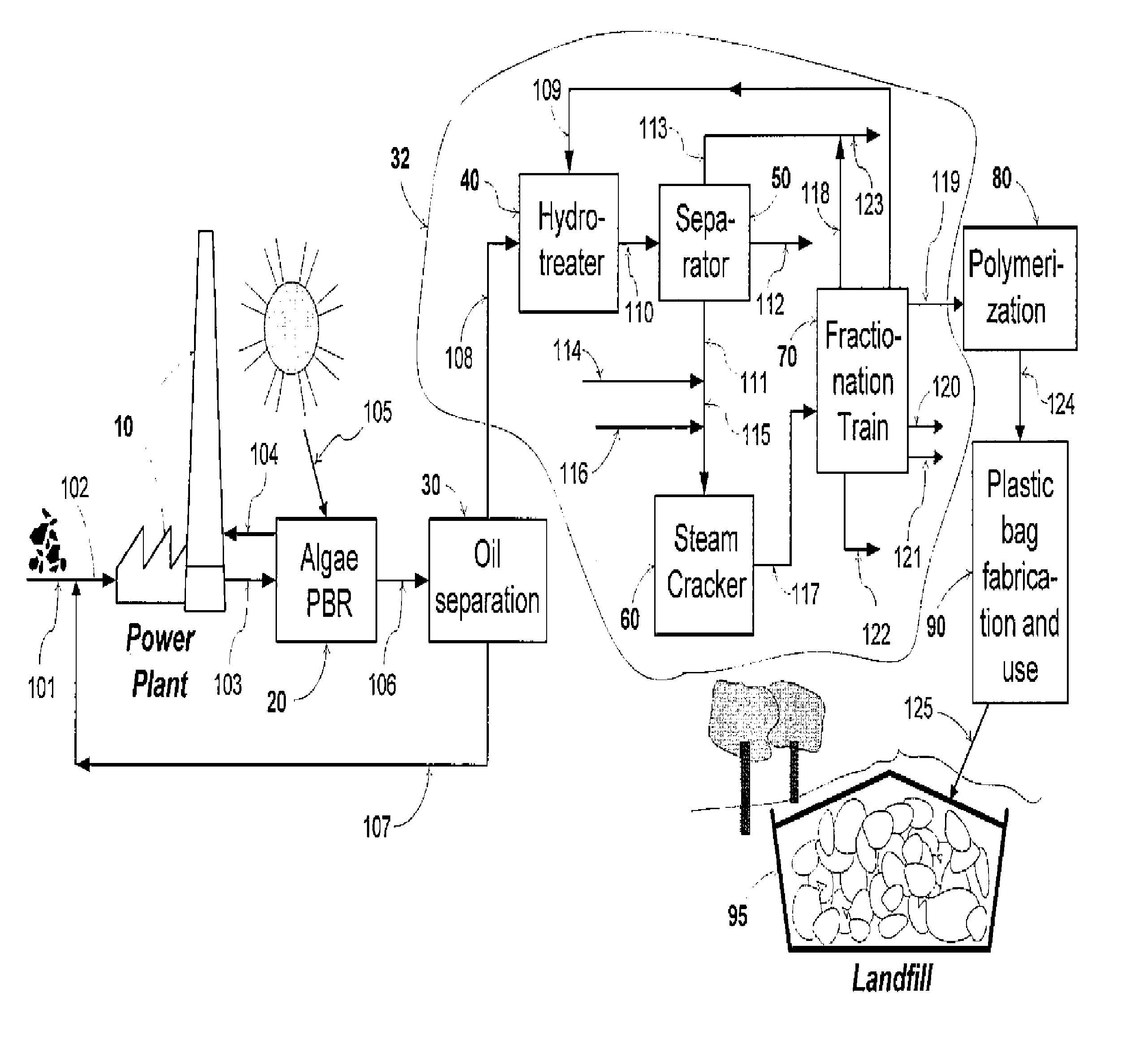

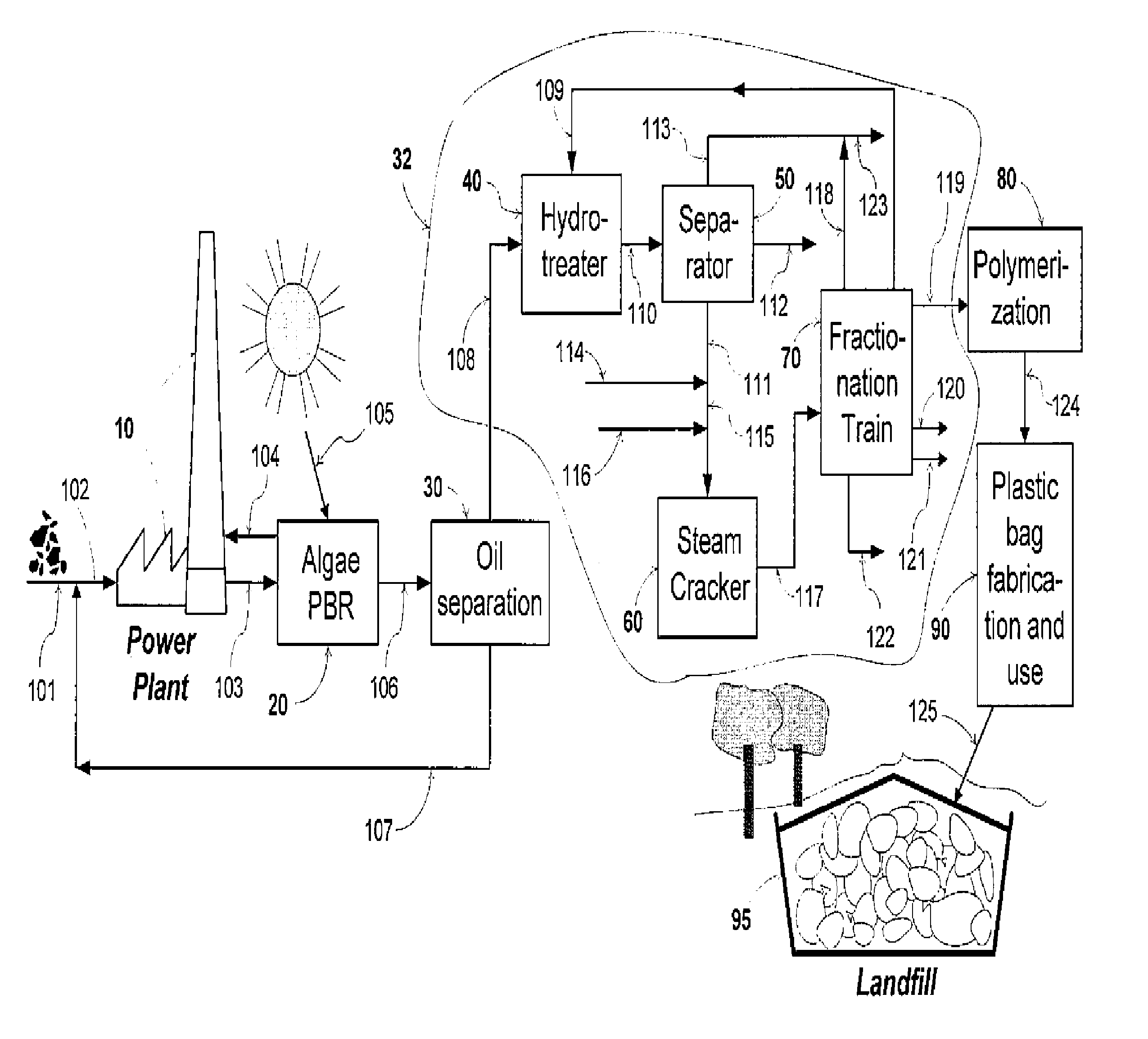

Profitable method for carbon capture and storage

The present invention generally relates to a method for sequestering carbon dioxide. Biomass is converted into paraffinic hydrocarbons. The paraffinic hydrocarbons are steam cracked into olefins. The olefins are polymerized into non-biodegradable polyolefins.

Owner:REG SYNTHETIC FUELS LLC

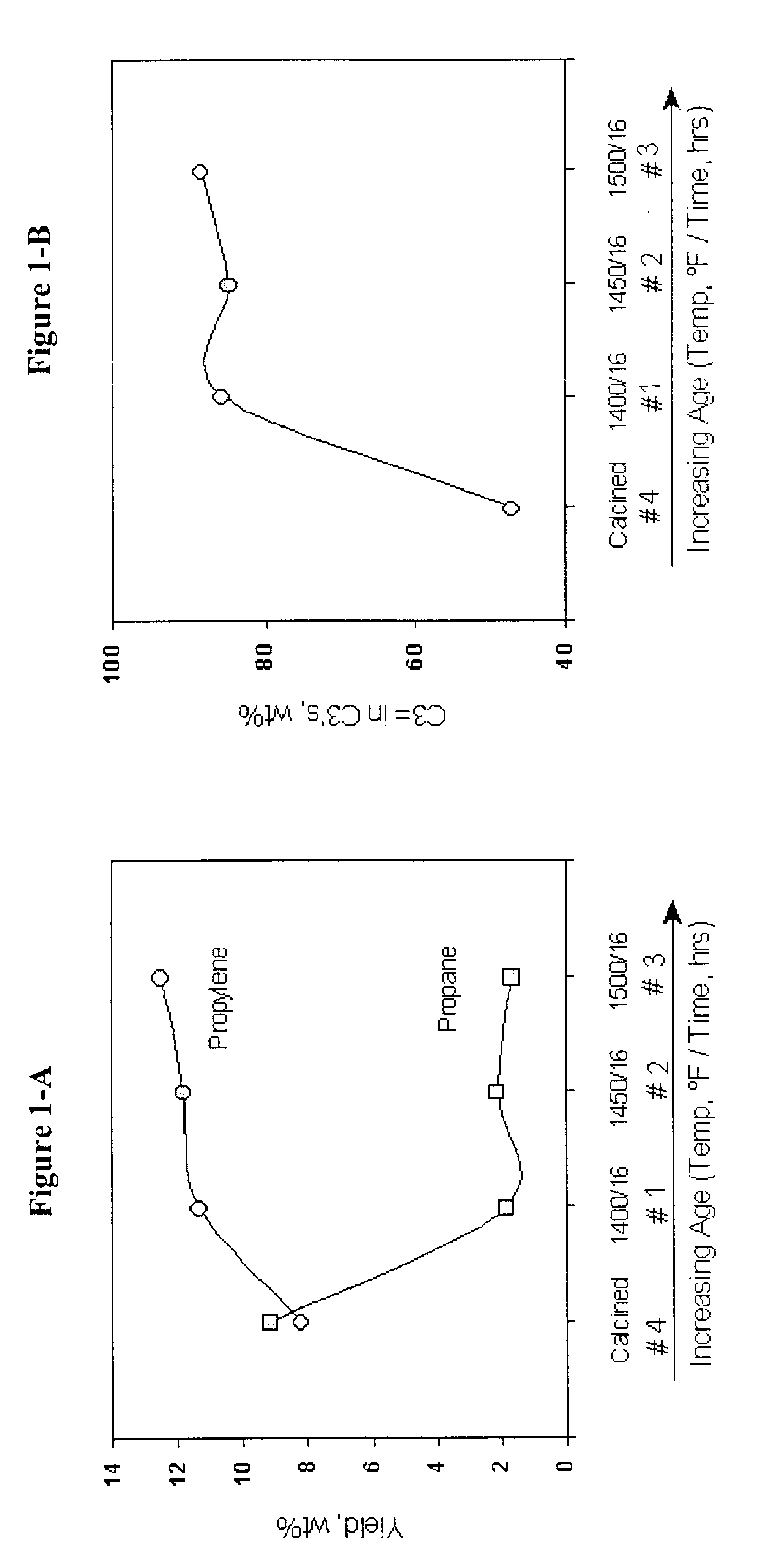

Process for selectively producing light olefins

InactiveUS6455750B1Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaSteam activation

The invention is related to a catalyst and a process for selectively producing light (i.e., C2-C4) olefins from a catalytically cracked or thermally cracked naphtha stream. The naphtha stream is contacted with a catalyst containing from about 10 to 50 wt. % of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions. The catalysts do not require steam activation.

Owner:EXXONMOBIL CHEM PAT INC

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS7374662B2Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerFluidized bed

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein,the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst,the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS20060049080A1Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationProcess engineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

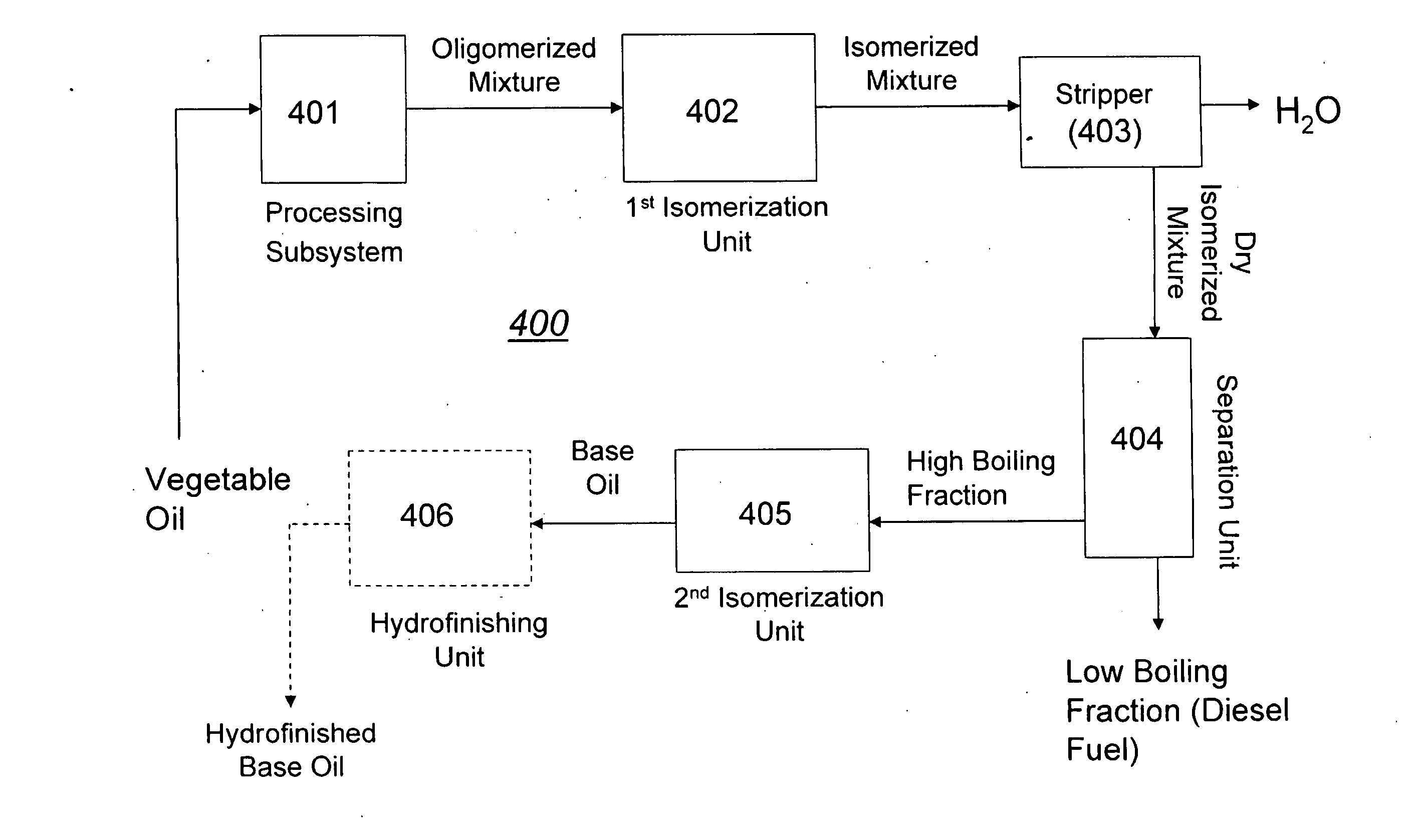

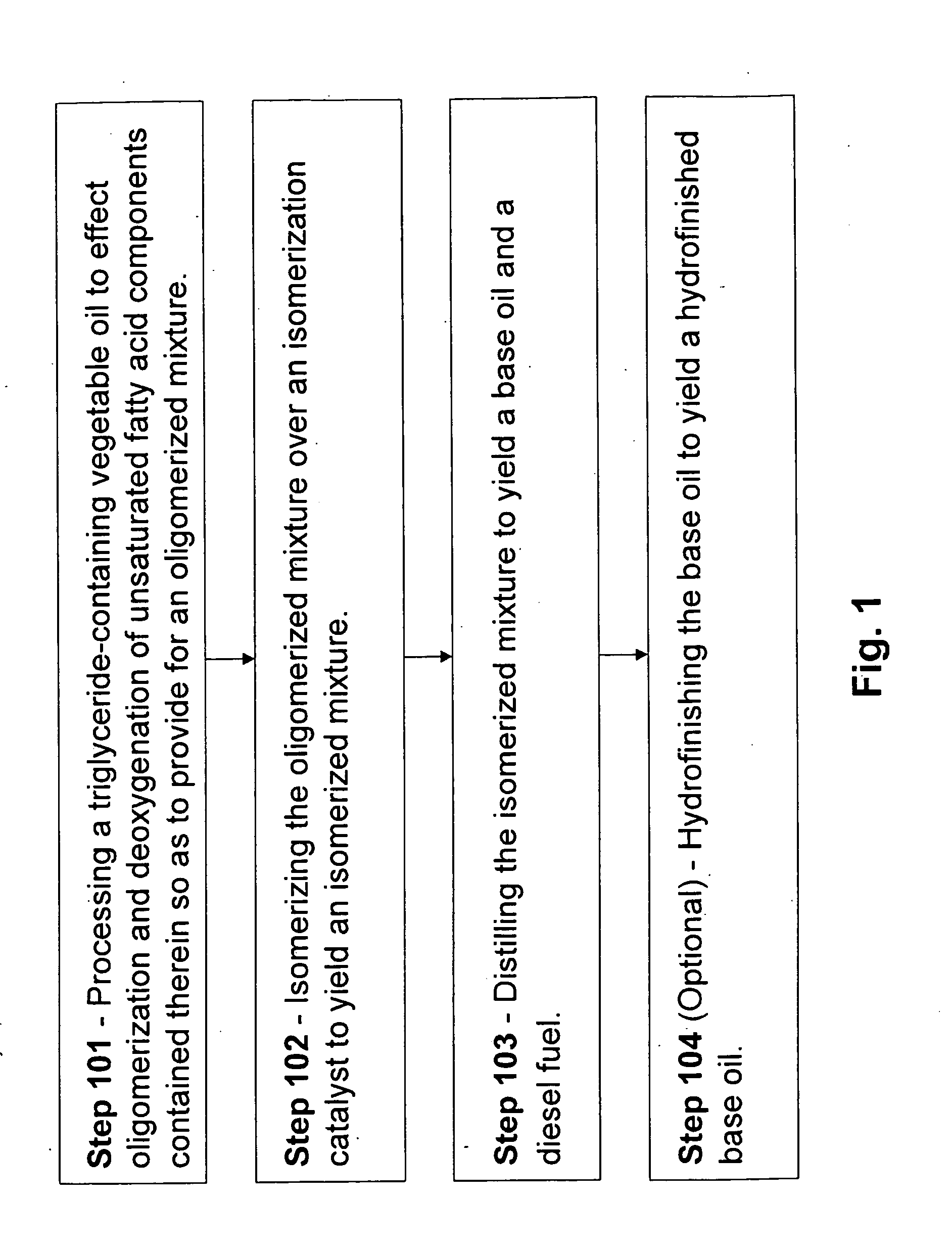

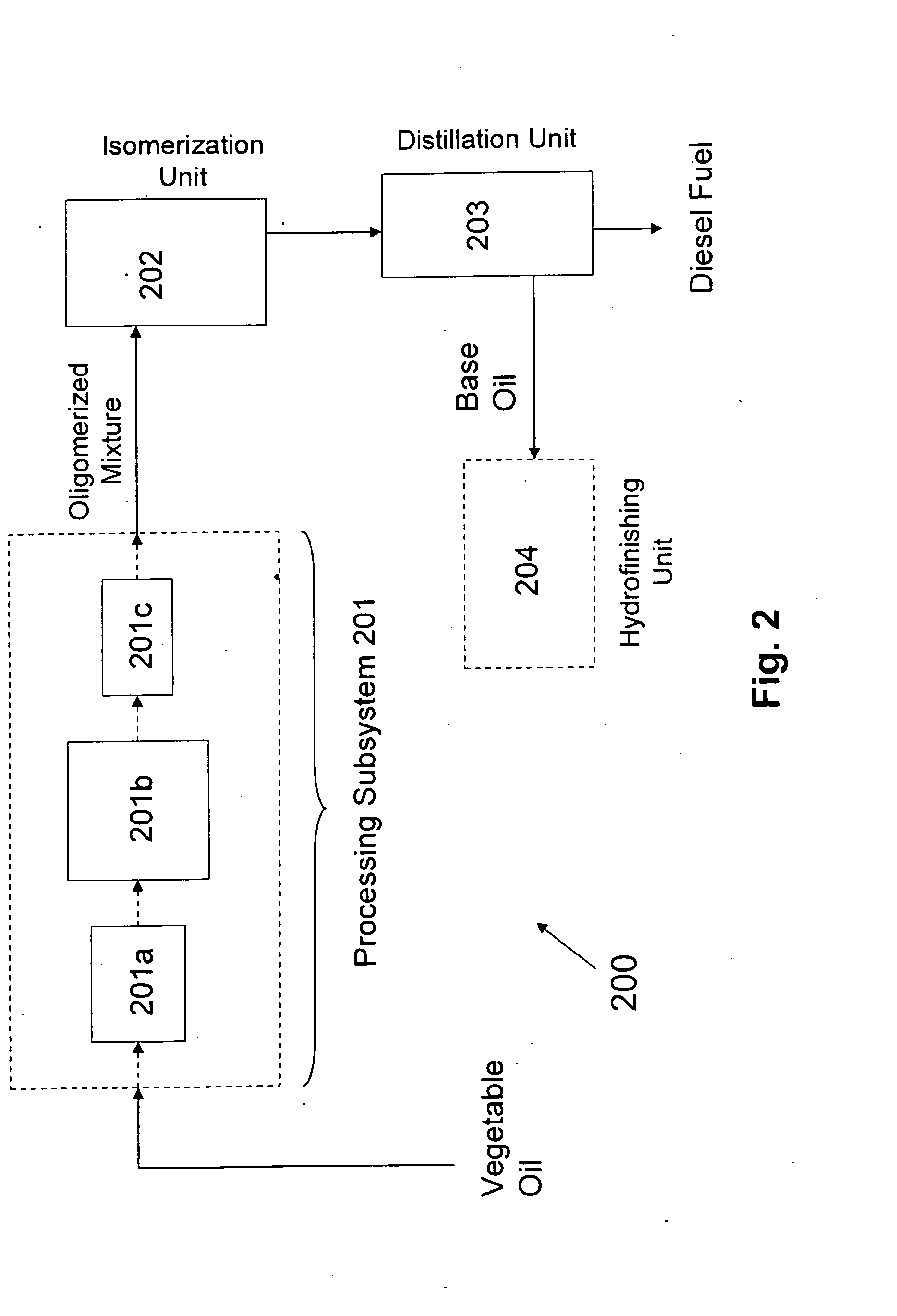

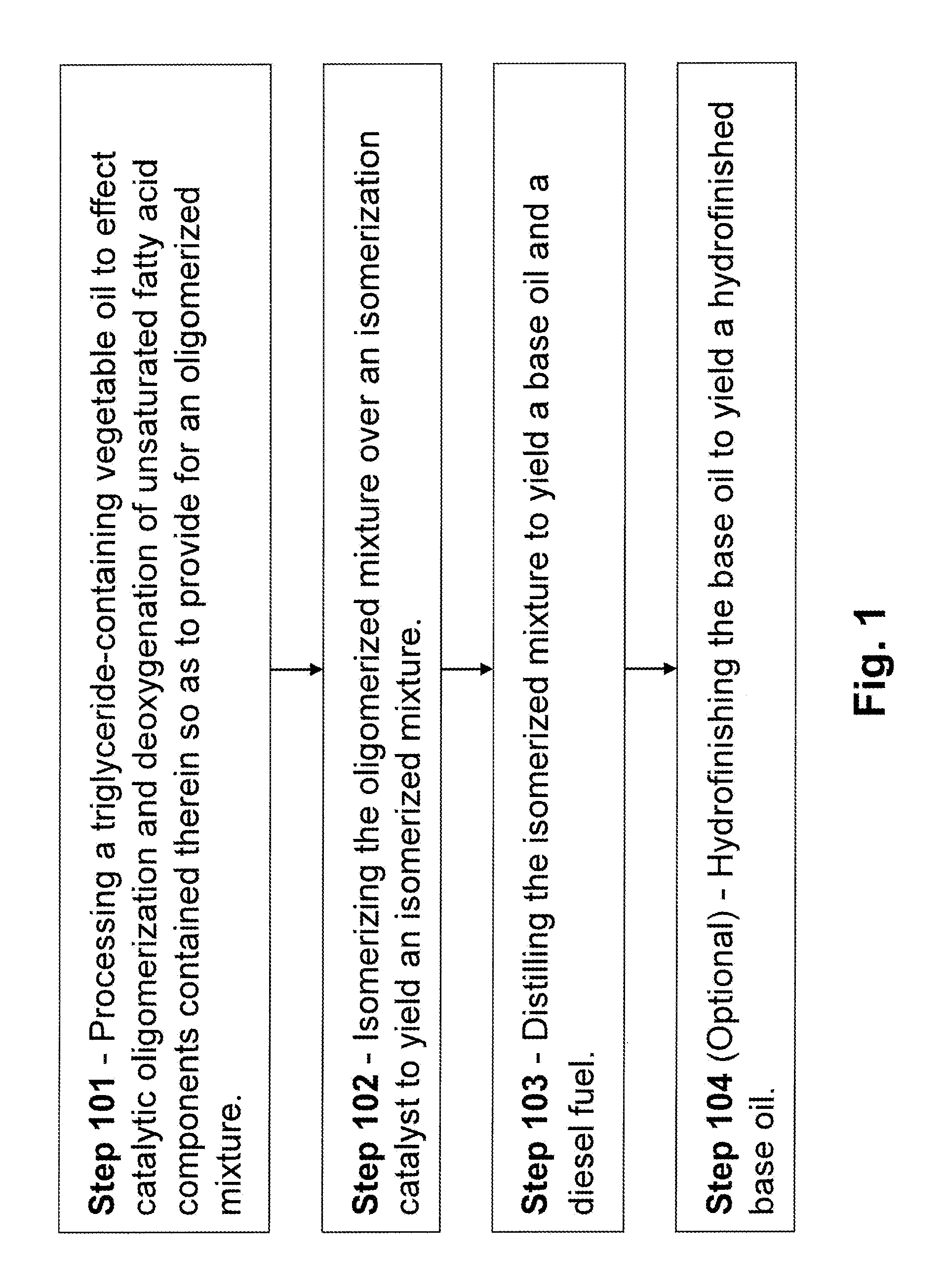

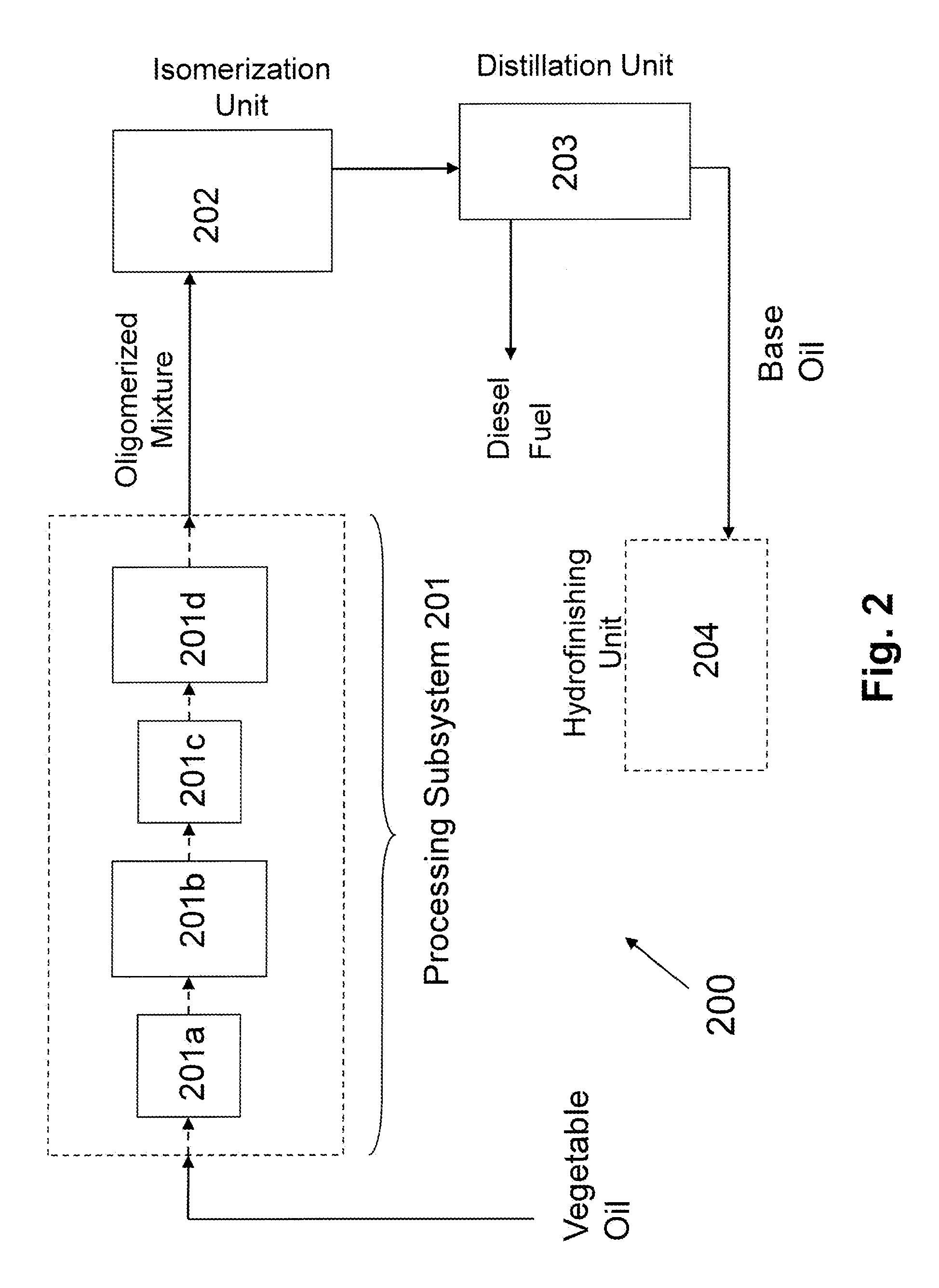

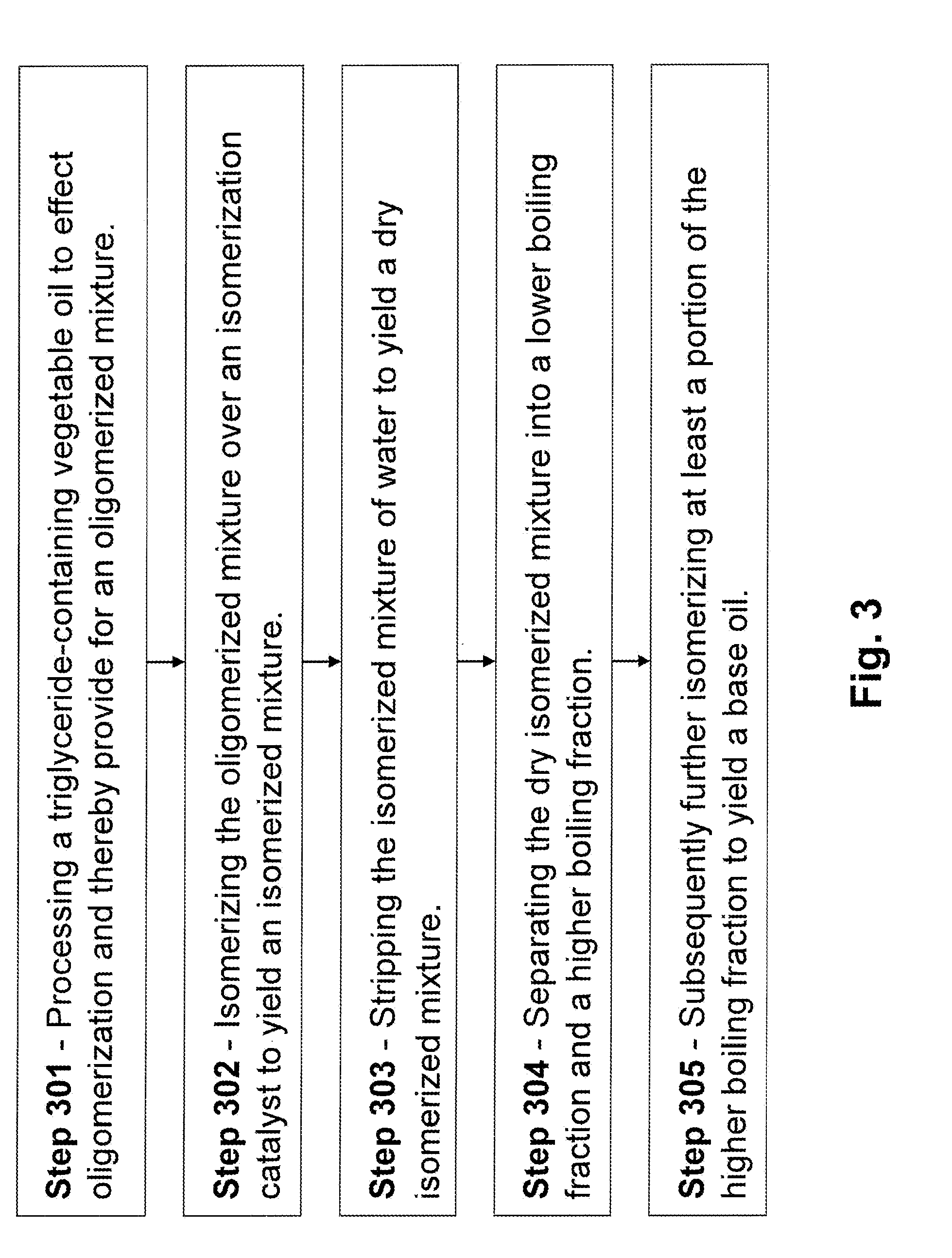

Conversion of Vegetable Oils to Base Oils and Transportation Fuels

ActiveUS20100018108A1Increase the number ofImprove economyLiquid hydrocarbon mixtures productionBiofuelsIsomerizationVegetable oil

The present invention is directed to methods (processes) and systems for processing triglyceride-containing, biologically-derived oils to provide for base oils and transportation fuels, wherein partial oligomerization of fatty acids contained therein provide for an oligomerized mixture from which the base oils and transportation fuels can be extracted. Such methods and systems can involve an initial hydrotreating step or a direct isomerization of the oligomerized mixture.

Owner:CHEVROU USA INC

Process for making a lube base stock from a lower molecular weight feedstock in a catalytic distillation unit

InactiveUS6841711B2Sufficient reaction rateImprove oil yieldHydrocarbon by hydrogenationLiquid hydrocarbon mixtures productionCatalytic distillationHydrocarbon

A process for making a lube base stock wherein an olefinic feedstock is contacted with an oligomerization catalyst in a catalytic distillation unit to produce a product having a higher number average molecular weight than the olefinic feedstock. That product is separated zone in the catalytic distillation unit into a light byproduct fraction and a heavy product fraction that includes hydrocarbons in a lube base stock range.

Owner:CHEVROU USA INC

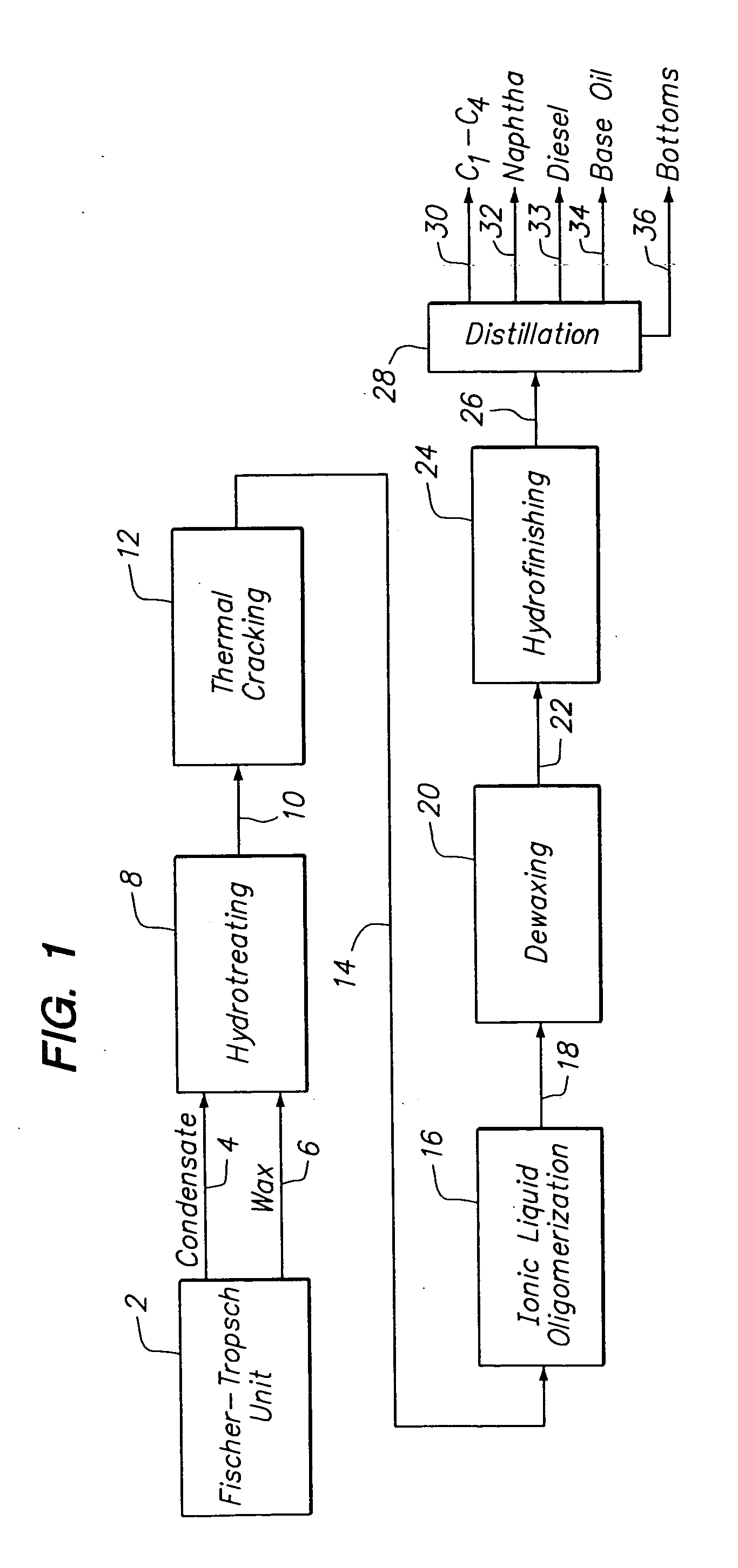

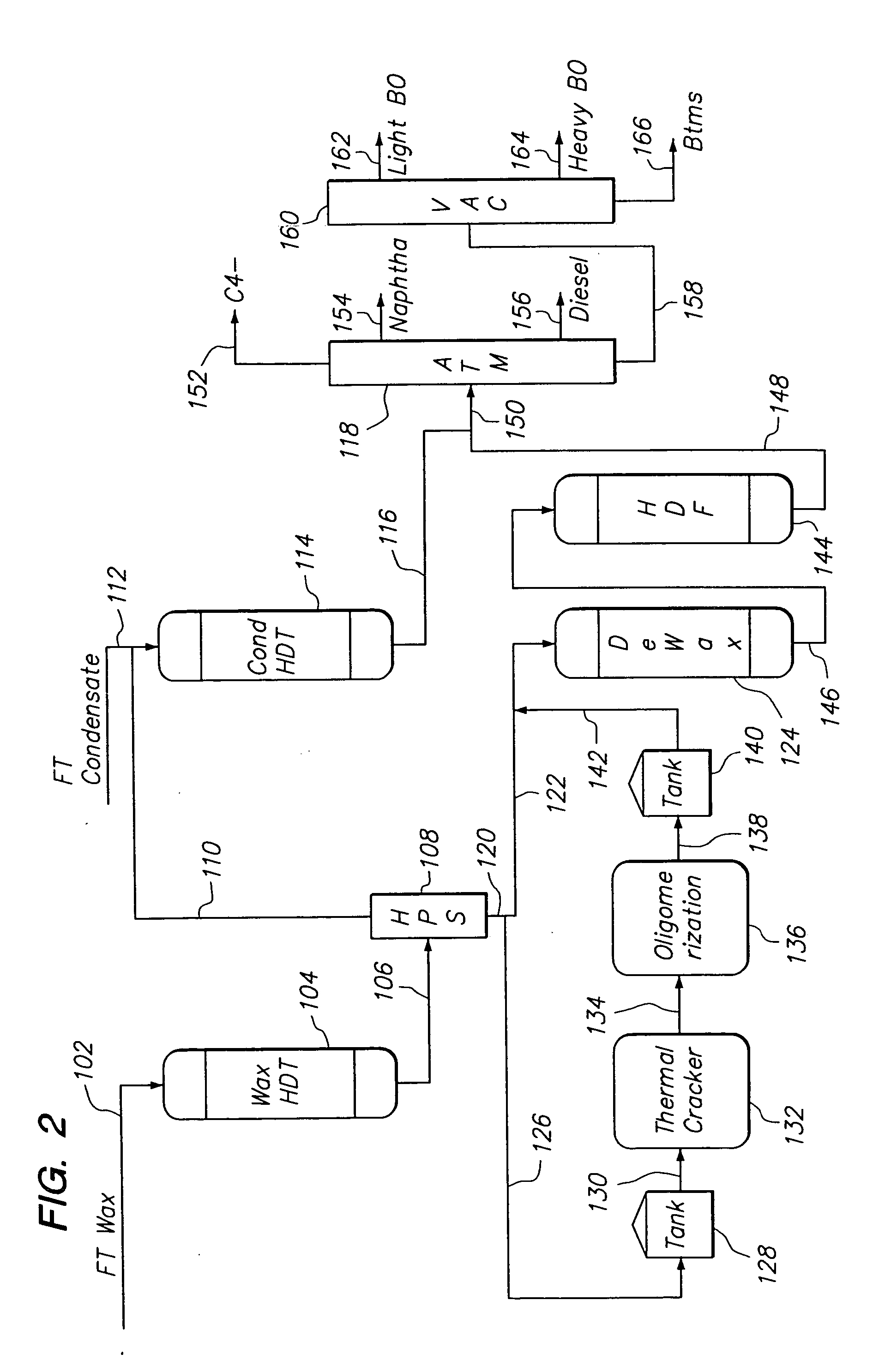

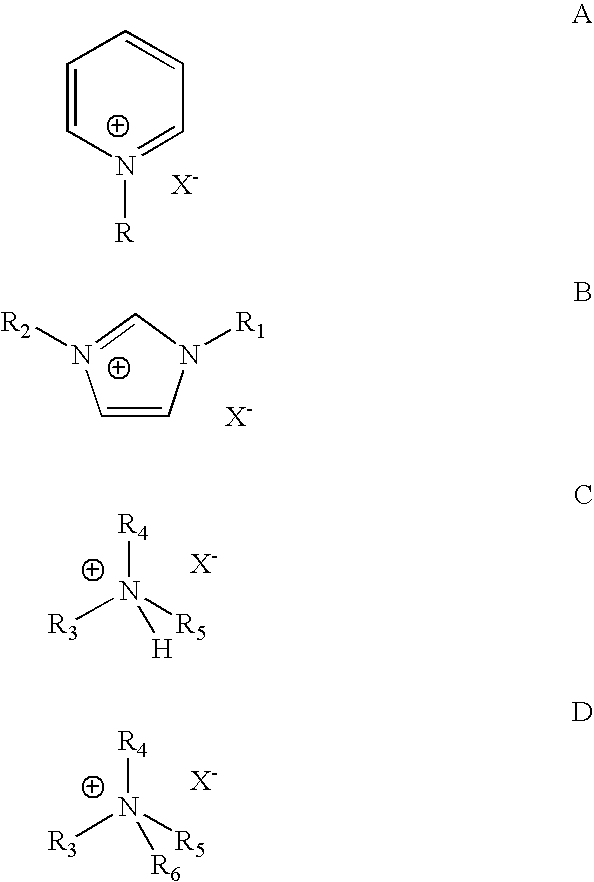

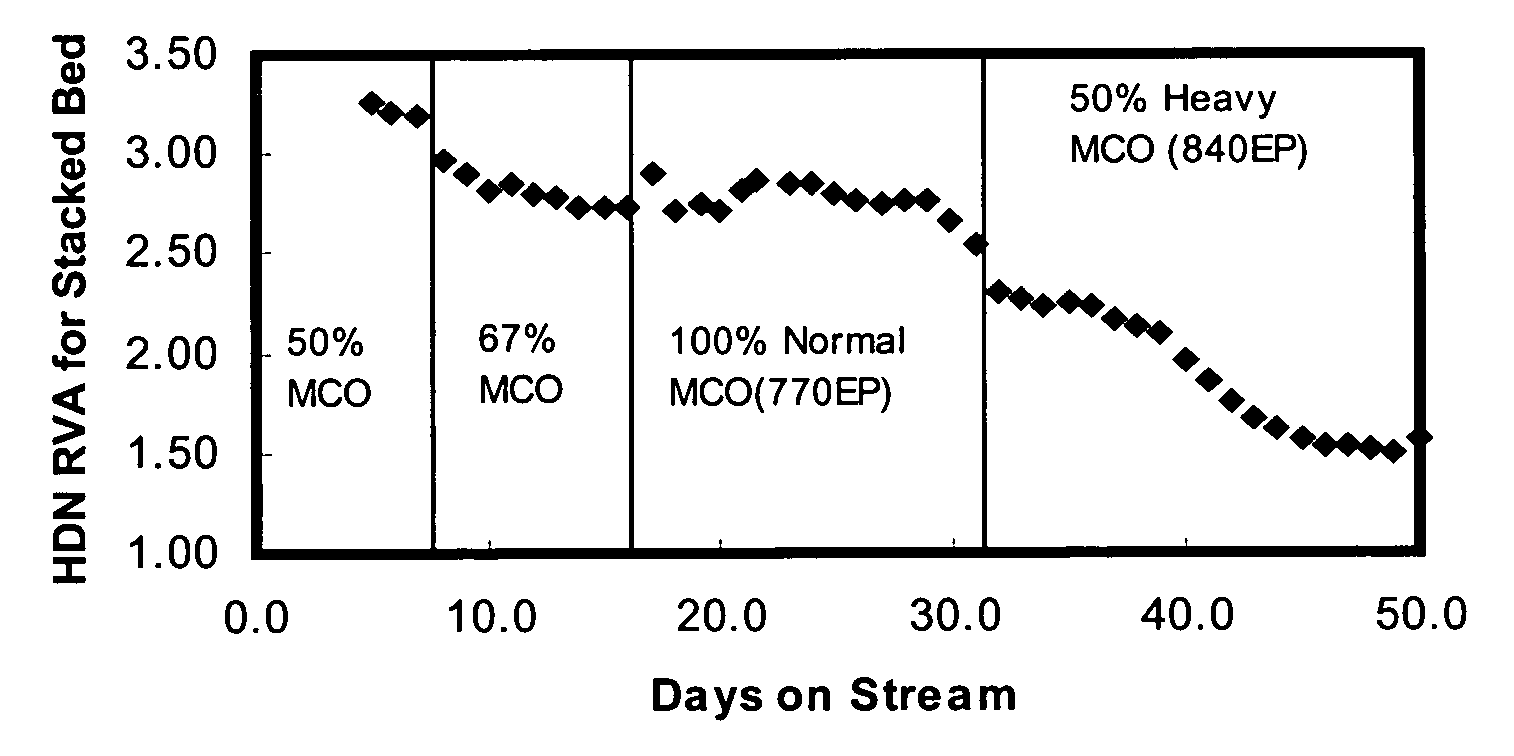

Hydrotreating of fischer-tropsch derived feeds prior to oligomerization using an ionic liquid catalyst

InactiveUS20050245778A1Improve cold flowImproves oxygen stabilityThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAlkaneOxygenate

Owner:CHEVROU USA INC

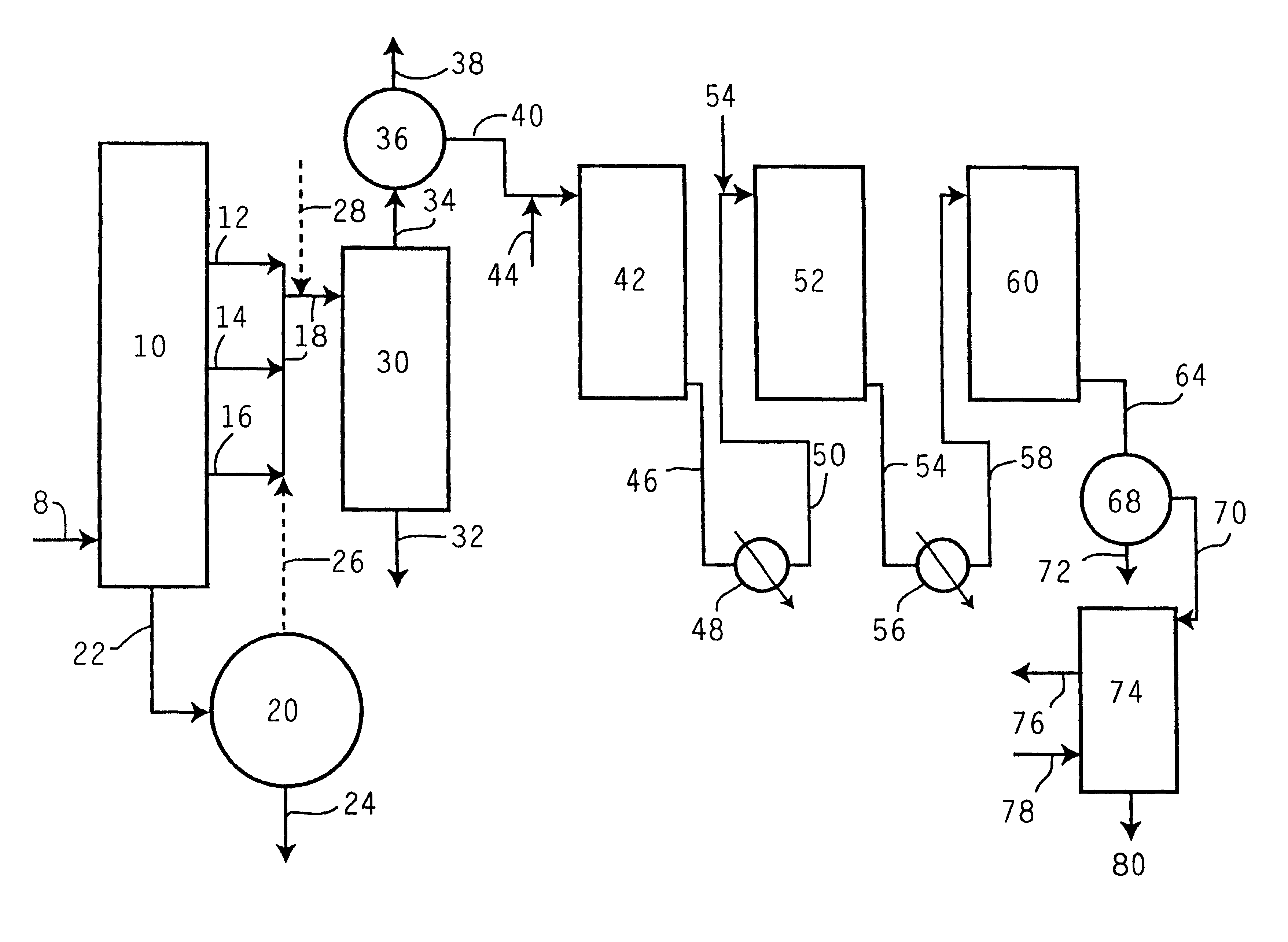

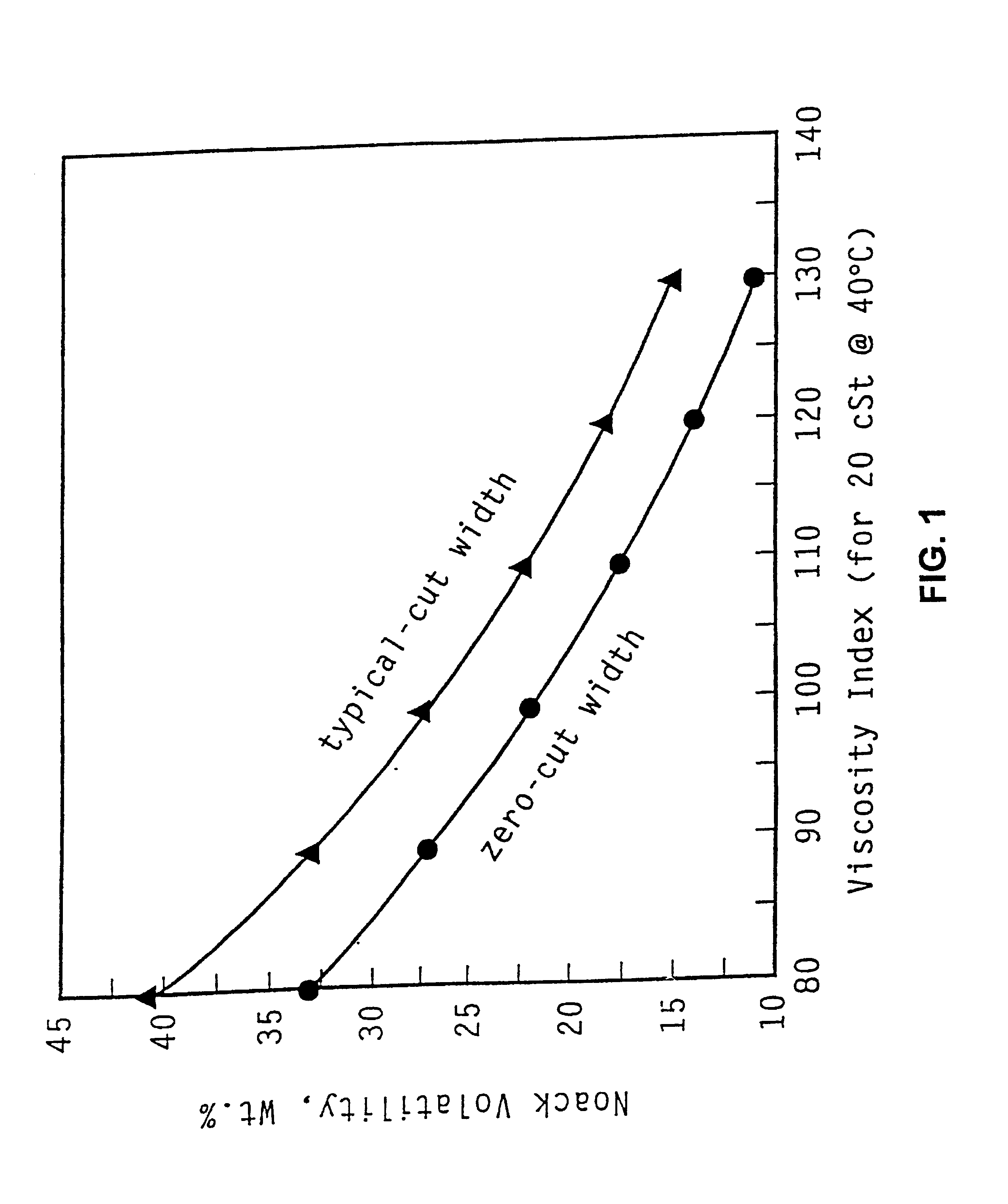

Hydroconversion process for making lubricating oil basestockes

InactiveUS6974535B2Excellent low volatility propertyImprove economyTreatment with plural serial cracking stages onlyCatalytic naphtha reformingBase oilRaffinate

A process for producing a lubricating oil basestock having at least 90 wt. % saturates and a VI of at least 105 by selectively hydroconverting a raffinate from a solvent extraction zone in a two step hydroconversion zone followed by a hydrofinishing zone, and a lubricating oil basestock produced by said process.

Owner:EXXON RES & ENG CO

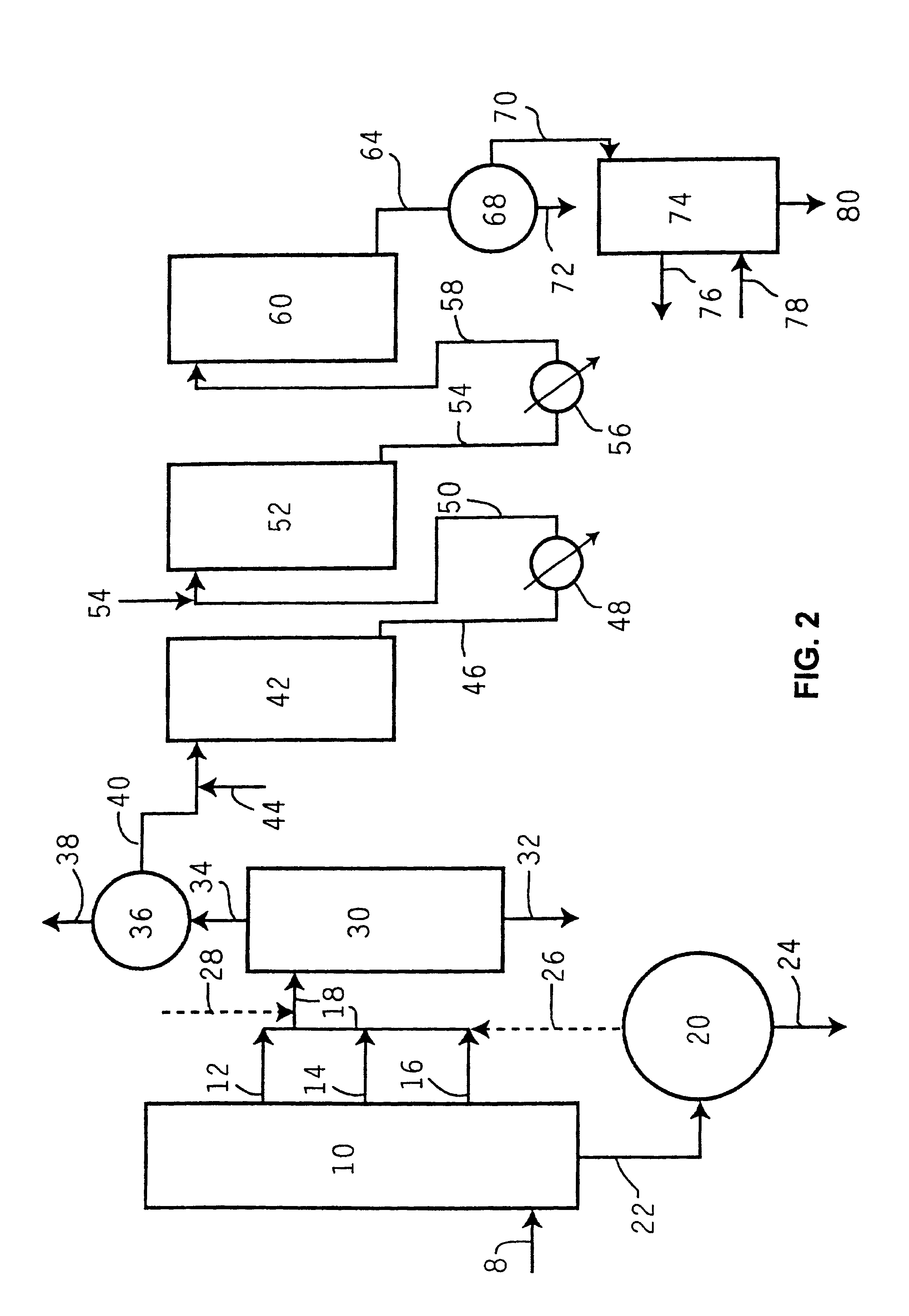

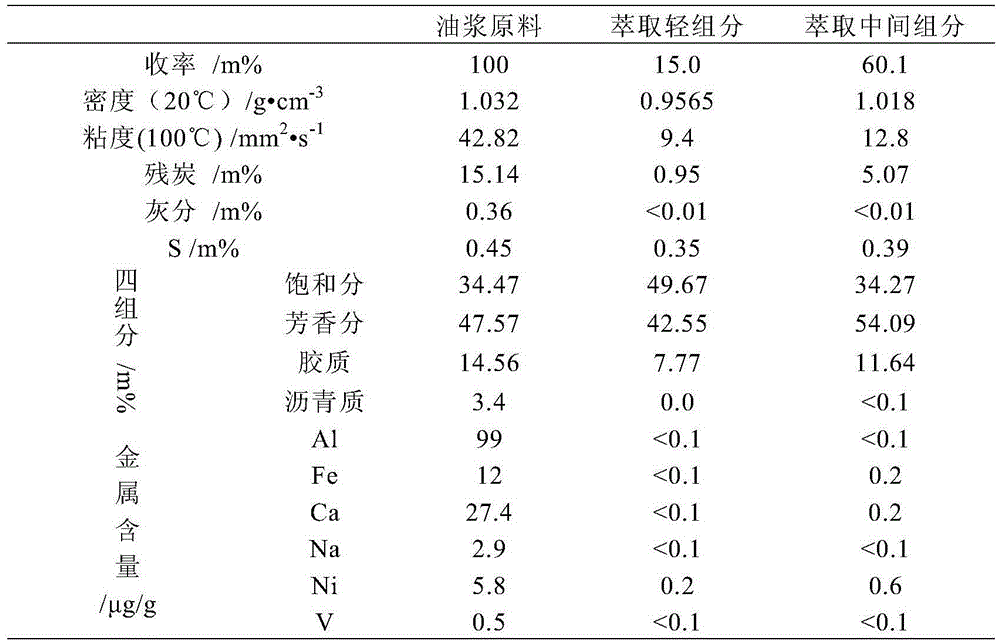

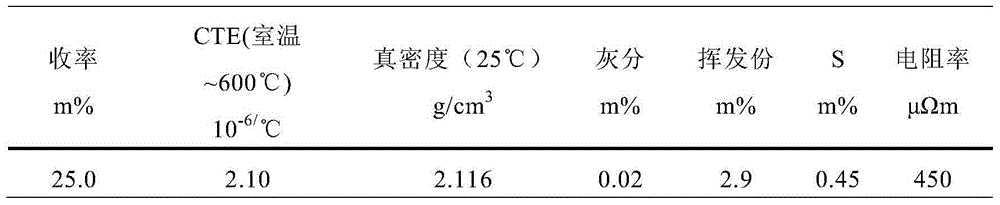

Combined method for separating fluid catalytic cracking slurry oil and preparing oil-series needle coke

ActiveCN106147835AImprove qualityEasy to industrializeTreatment with hydrotreatment processesTreatment with polymerisationHydrodesulfurizationCombined method

The invention provides a combined method for separating fluid catalytic cracking slurry oil and preparing oil-series needle coke. C3-C5 light dydrocarbon cut fraction is adopted as extraction solvent for conducting sub-critical or super-critical extraction on fluid catalytic cracking slurry oil, solvent is recovered from an obtained extraction oil phase in a super-critical mode to prepare extraction components, the extraction components serve as raw materials for preparing middle phase asphalt, and the middle phase asphalt is prepared through retrogressive reaction and then subjected to delayed coking reaction to prepare high-quality oil-series needle coke. When the sulfur content of fluid catalytic cracking slurry oil is high, extraction light components can be subjected to hydrodesulfurization treatment first, hydrogenated oil is subjected to fractionation to collect hydrogenation tail oil, the hydrogenation tail oil serves as a raw material for preparing middle phase asphalt, and then the needle coke is prepared. By means of the method, by controlling the preparation of middle phase asphalt and the coking procedure of the needle coke to be independent of each other, industrial implementation is easier, and fluid catalytic cracking slurry oil can be sufficiently used and the high-quality needle coke material can be prepared.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

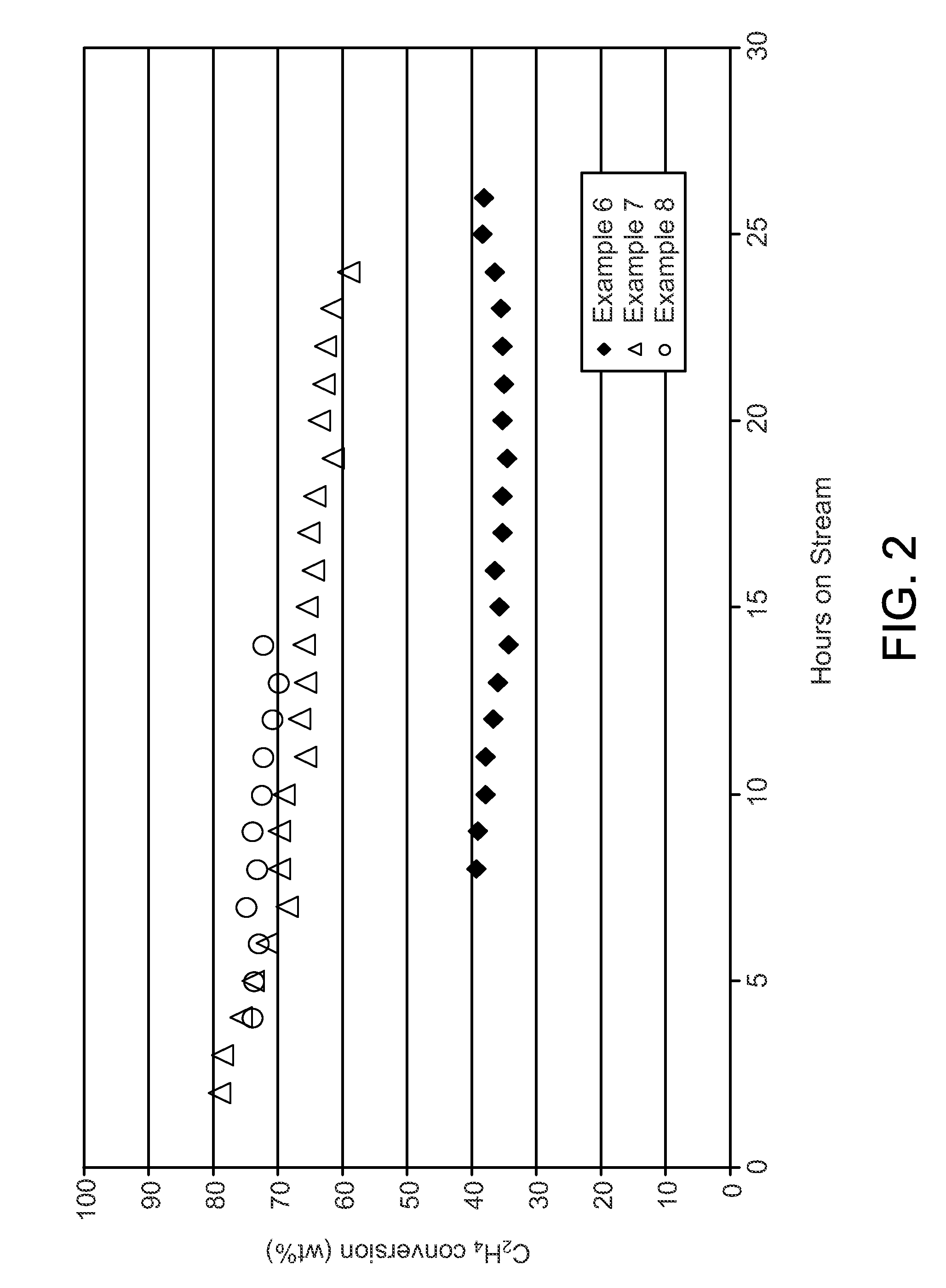

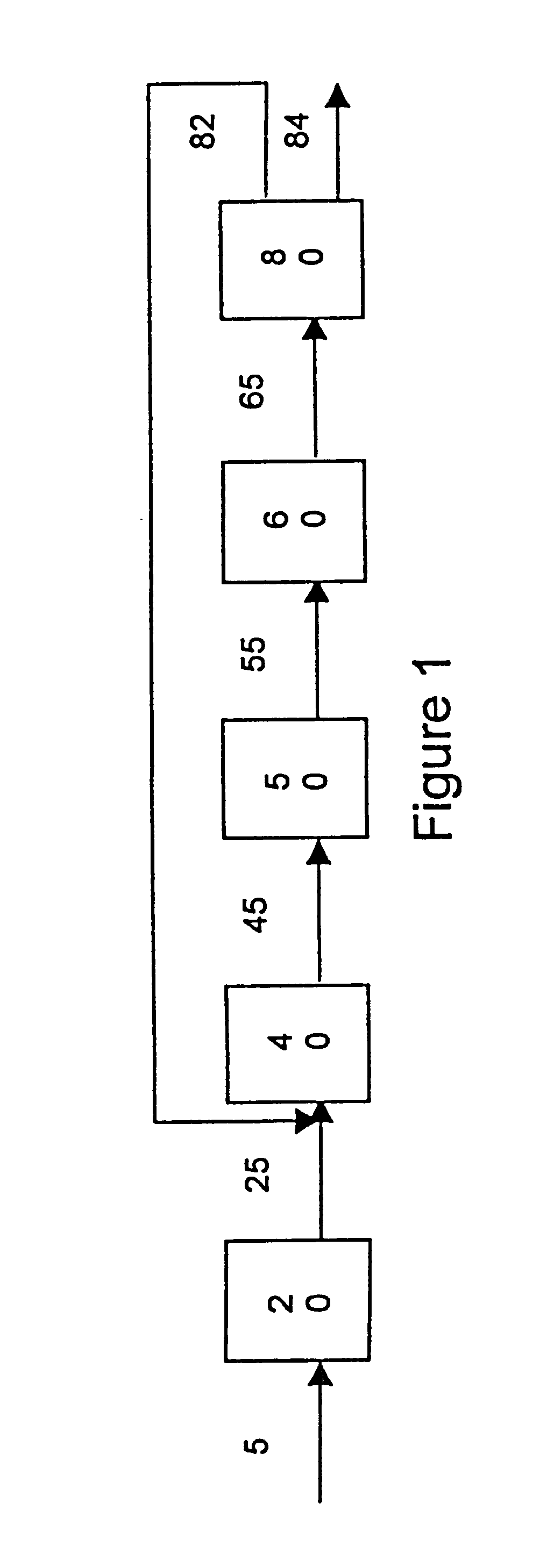

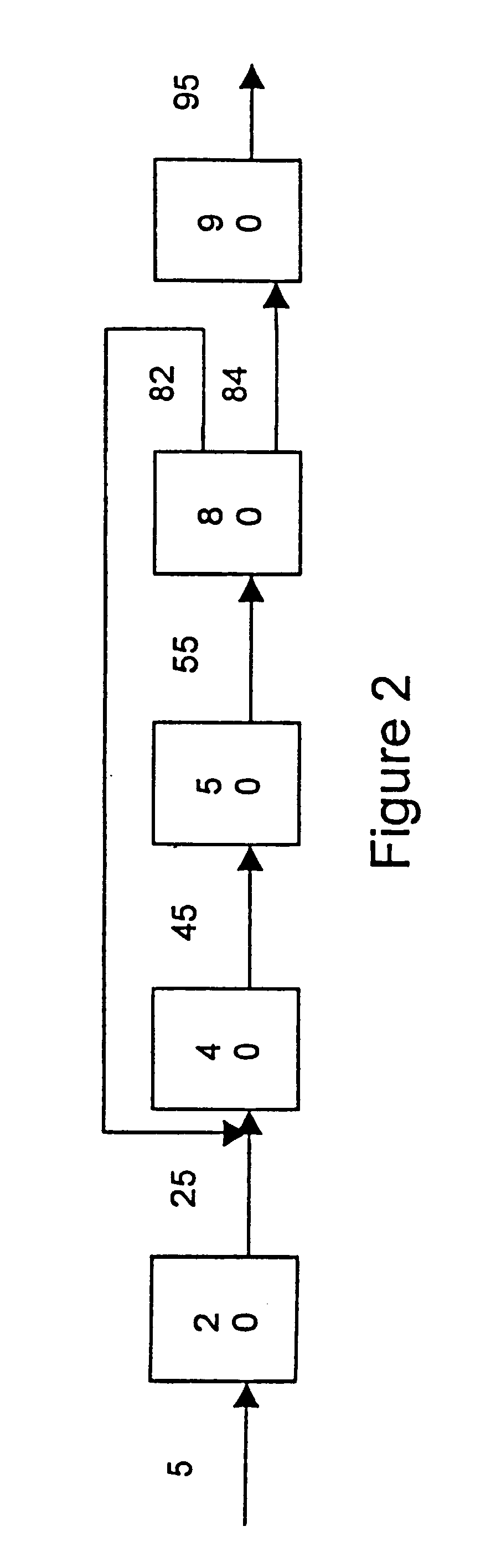

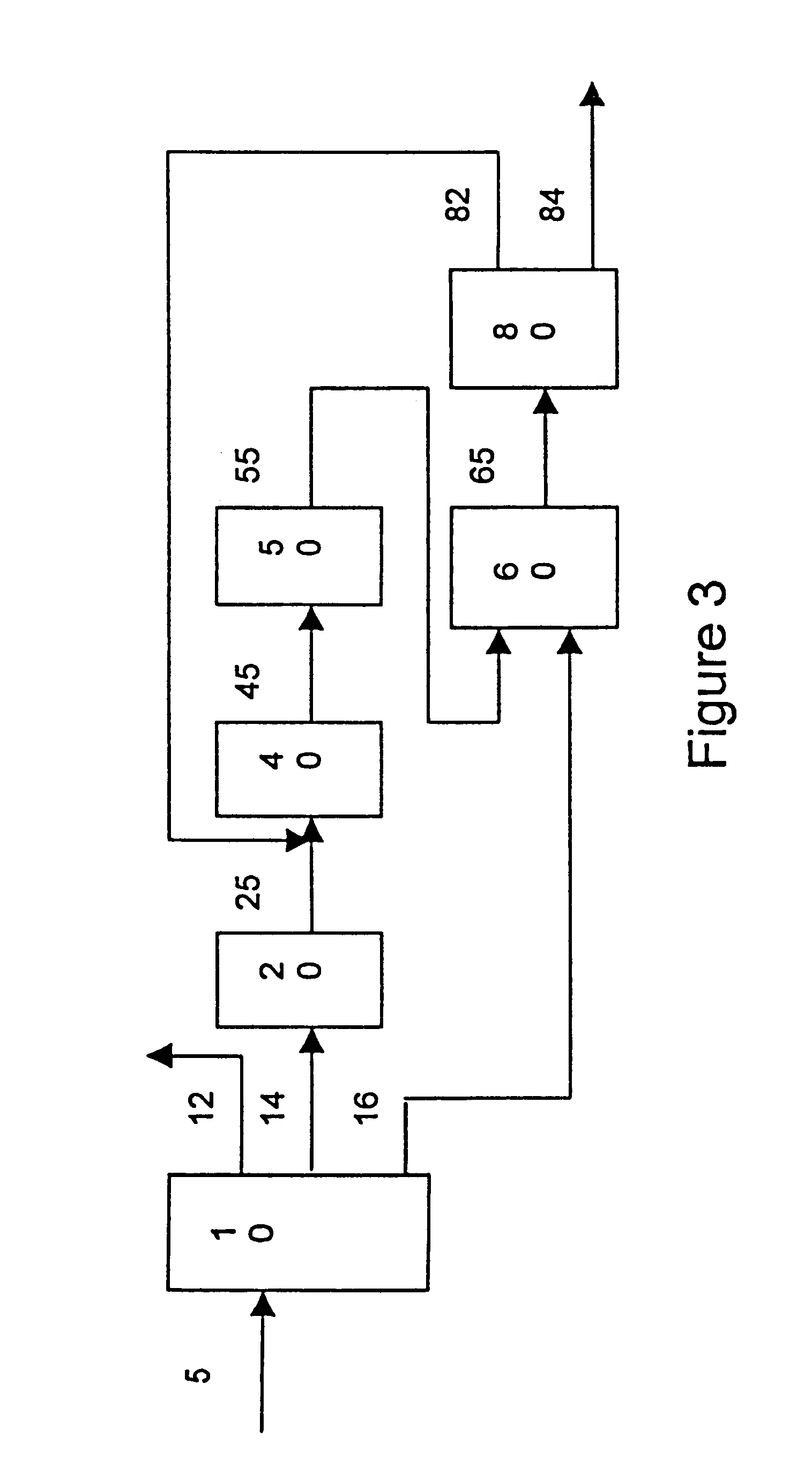

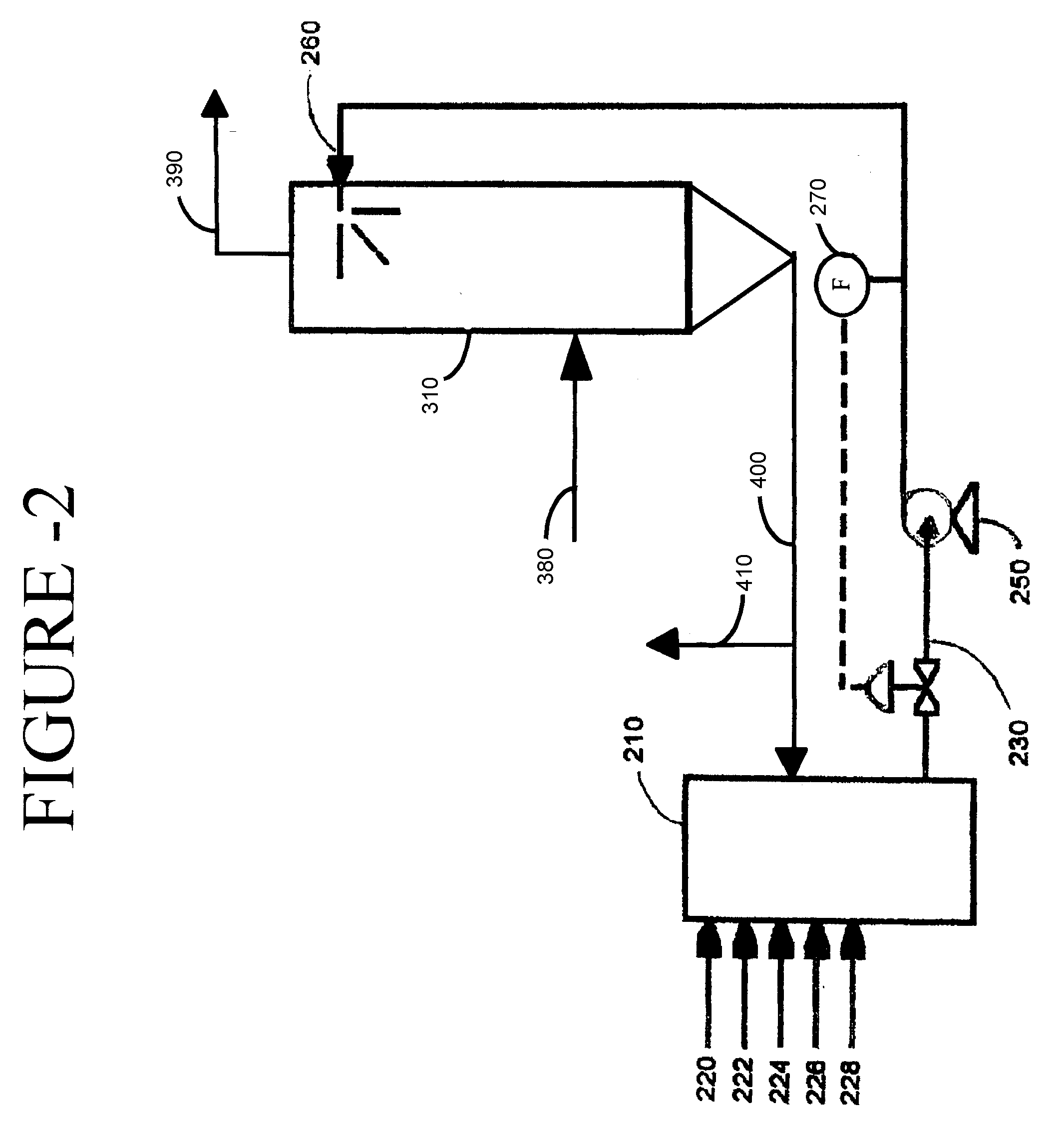

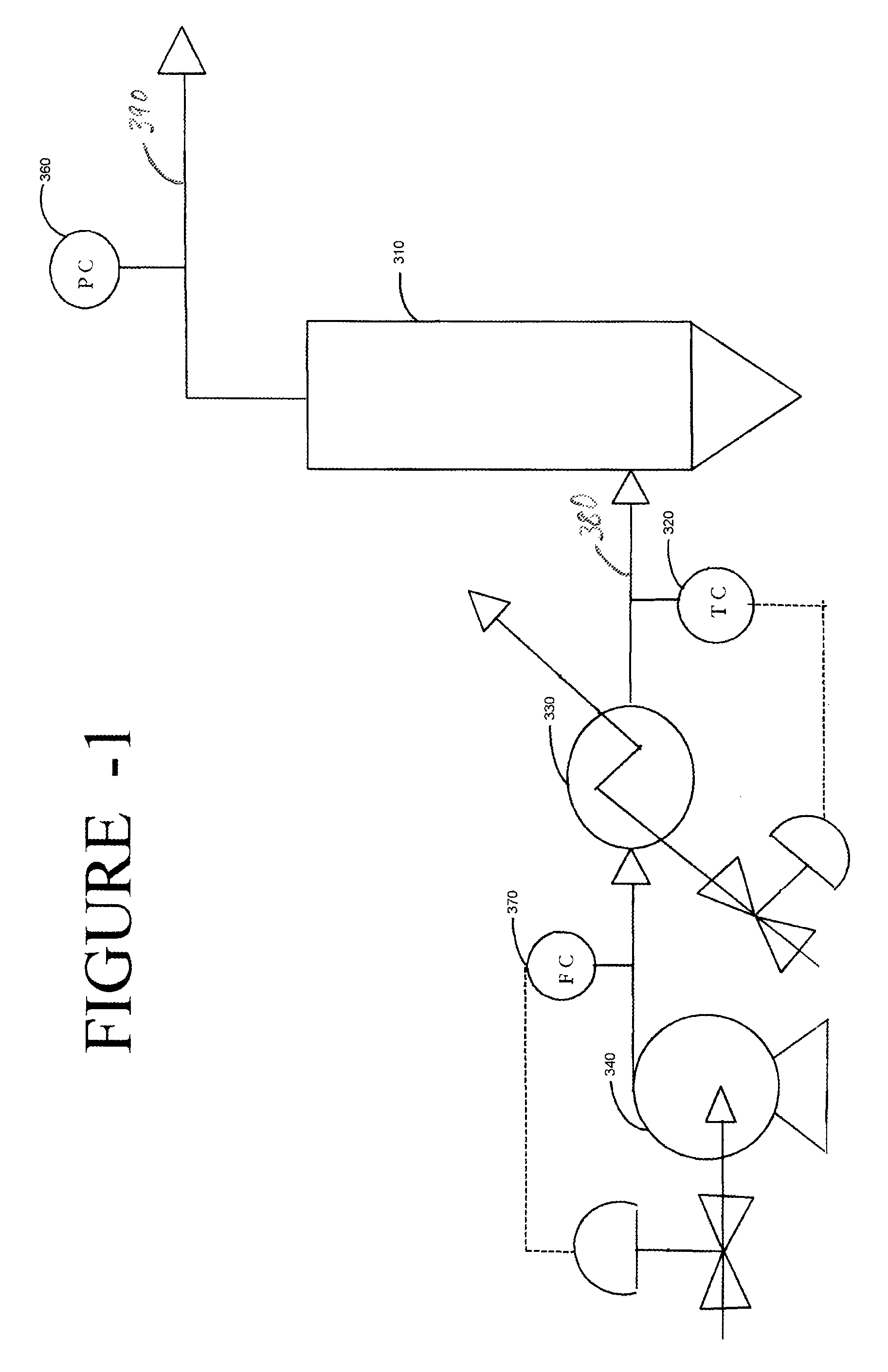

Process for oligomerizing dilute ethylene

ActiveUS8748682B2Easy to separateMolecular sieve catalystsHydrocarbons from unsaturated hydrocarbon additionHydrogenCarbon oxide

The process and apparatus converts ethylene in a dilute ethylene stream that may be derived from an FCC product to heavier hydrocarbons. The catalyst may be an amorphous silica-alumina base with a Group VIII and / or VIB metal. The catalyst is resistant to feed impurities such as hydrogen sulfide, carbon oxides, hydrogen and ammonia. At least 40 wt-% of the ethylene in the dilute ethylene stream can be converted to heavier hydrocarbons.

Owner:UOP LLC

Process for selectively producing propylene in fluid catalytic cracking process

InactiveCN1380898ATreatment with plural serial cracking stages onlyCatalytic crackingPtru catalystNaphtha

The invention discloses a method for selectively producing olefins from catalytic cracking or thermal cracking naphtha streams and producing polypropylene from the olefins. The naphtha stream is contacted with a catalyst containing 10-50 wt% crystalline zeolites having an average pore size of less than 0.7 nm under reaction conditions comprising a temperature of 500-650°C and a hydrocarbon partial pressure of 10-40 psia. The catalyst may be pre-coked with a carbonaceous feedstock. Additionally, carbonaceous feedstock for coking the catalyst may be added with the naphtha feedstock.

Owner:EXXONMOBIL CHEM PAT INC

Naphtha cracking and hydroprocessing process for low emissions, high octane fuels

InactiveUS6315890B1Treatment with plural serial cracking stages onlyCatalytic crackingNaphthaLow emission

The invention is related to a two step process wherein the first step comprises cracking an olefinic naphtha resulting in a cracked product having a diminished total concentration of olefinic species. The second step comprises hydroprocessing at least a portion of the cracked product, especially a naphtha fraction, to provide a hydroprocessed cracked product having a reduced concentration of contaminant species but without a substantial octane reduction.

Owner:EXXONMOBIL CHEM PAT INC

Process for making a lube base stock from a lower molecular weight feedstock

InactiveUS6706936B2Treatment with plural serial cracking stages onlyCoke ovensPtru catalystProcess engineering

Owner:CHEVROU USA INC

Conversion of vegetable oils to base oils and transportation fuels

ActiveUS20110107656A1Increase the number ofImprove economyRefining to change hydrocarbon structural skeletonBiofuelsVegetable oilIsomerization

The present invention is directed to methods (processes) and systems for processing triglyceride-containing, biologically-derived oils to provide for base oils and transportation fuels, wherein partial oligomerization of fatty acids contained therein provide for an oligomerized mixture from which the base oils and transportation fuels can be extracted. Such methods and systems can involve an initial hydrotreating step or a direct isomerization of the oligomerized mixture.

Owner:CHEVROU USA INC

Preparation method of medium-viscosity poly alpha-olefin base oil

ActiveCN103666552AEasy to separateReduce pollutionTreatment with polymerisationOligomerDistilled water

The invention relates to a preparation method of medium-viscosity poly alpha-olefin base oil. The preparation method comprises the following steps: under conditions with a temperature of 20 DEG C-120 DEG C, reaction pressure of 0.1 MPa-1.4 MPa and a volume ratio of alpha-olefin / a solvent of (1:0)-(1:3), catalyzing 1-decene or 1-decene and alpha-olefin of C8-C12 for oligomerization for 2 hours-12 hours by using an alkaline-modified AlCl3 / Al2O3 immobilized catalyst; and filtering the catalyst after stopping reaction, washing by distilled water, distilling under the normal pressure to remove the solvent, distilling under reduced pressure to remove un-reacted alpha-olefin to obtain alpha-olefin oligomer base oil, wherein the yield of the poly alpha-olefin is greater than 60 omega%, the movement viscosity of the oligomer at 100 DEG C is 10.0mm<2> / s-25.0mm<2> / s, and the chlorine content of the oligomer is less than 2.0 omega%.

Owner:PETROCHINA CO LTD +1

Profitable method for carbon capture and storage

The present invention generally relates to a method for sequestering carbon dioxide. Biomass is converted into paraffinic hydrocarbons. The paraffinic hydrocarbons are steam cracked into olefins. The olefins are polymerized into non-biodegradable polyolefins.

Owner:REG SYNTHETIC FUELS LLC

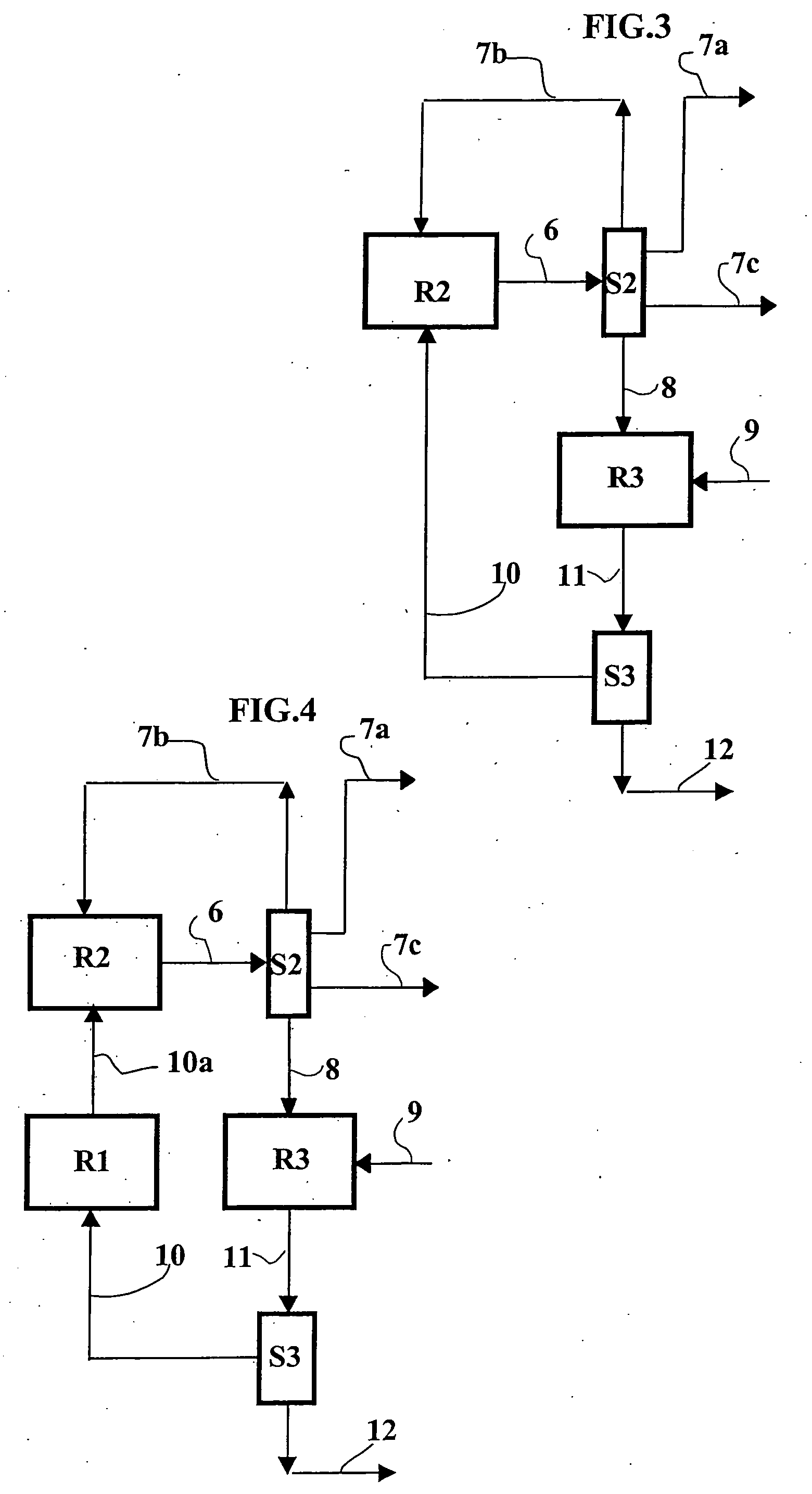

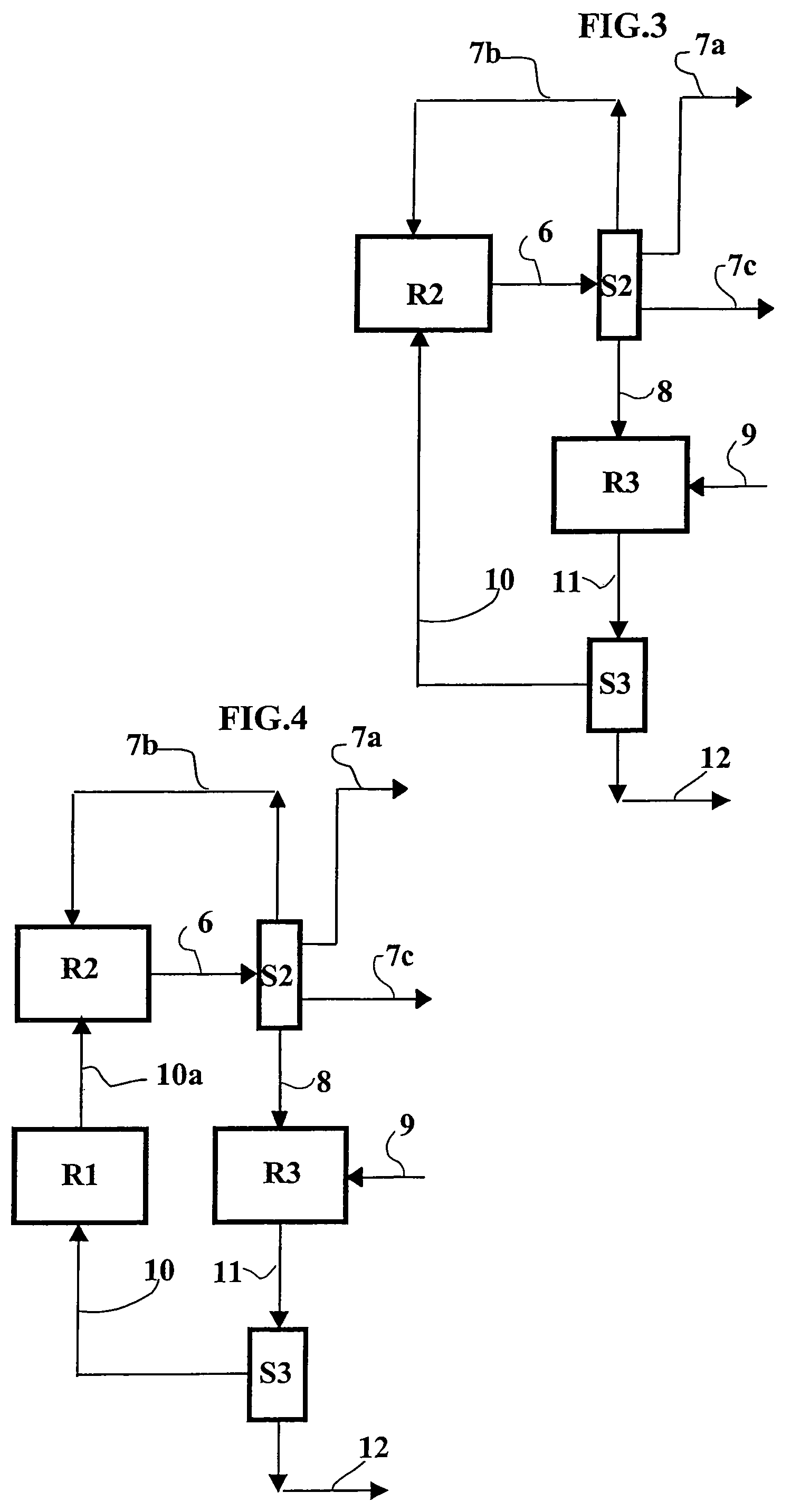

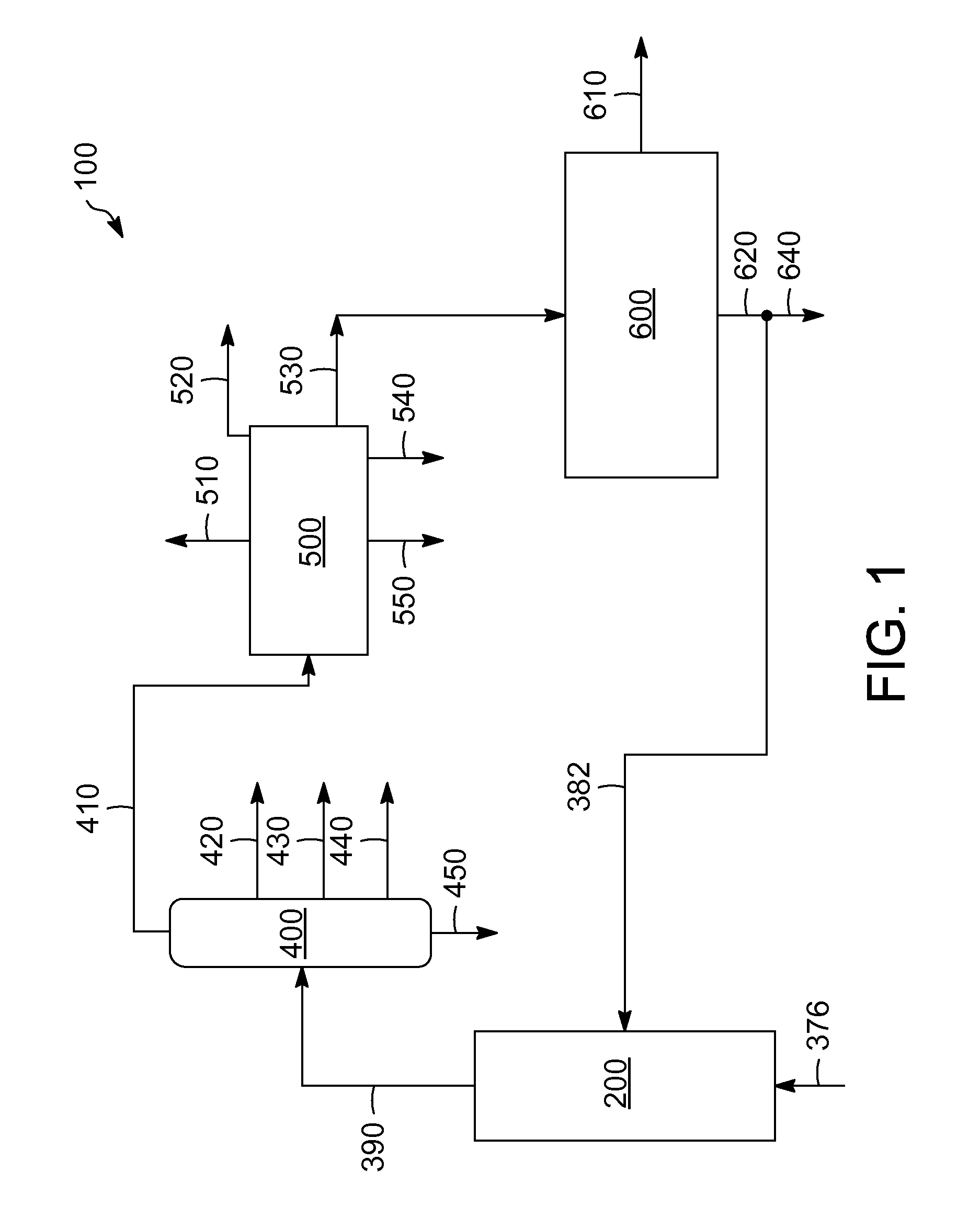

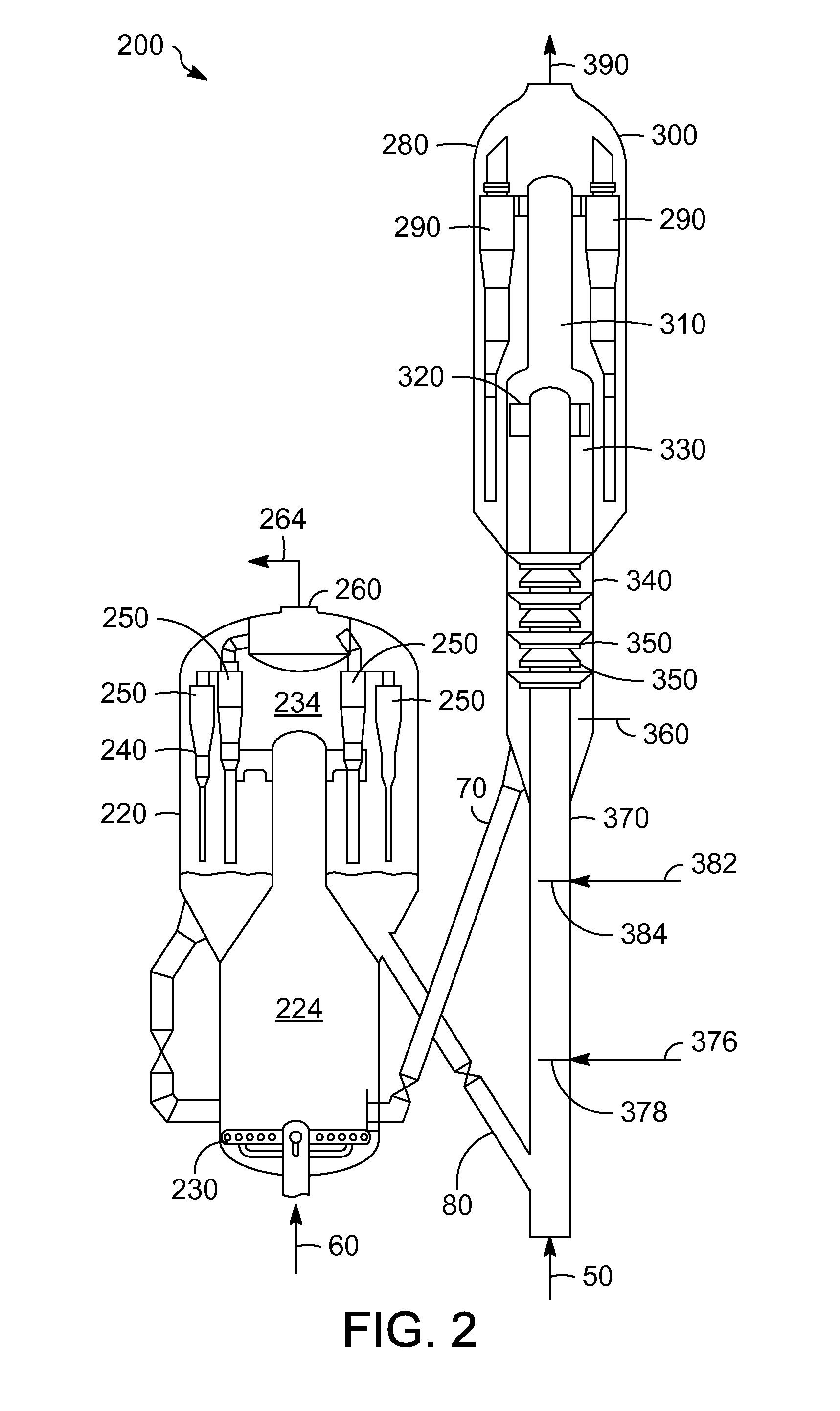

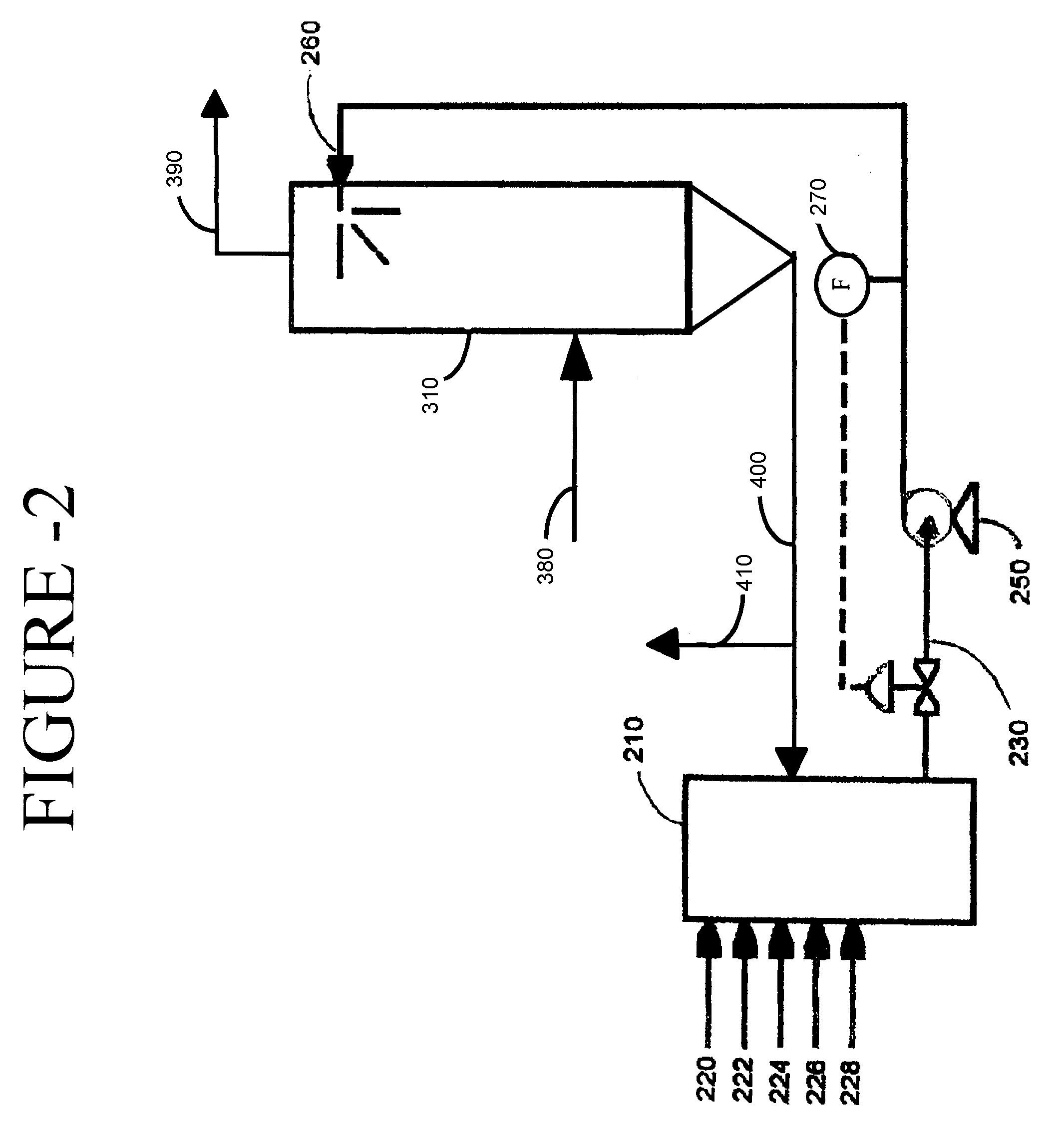

Addition of a Reactor Process to a Coking Process

InactiveUS20090145810A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyProcess engineeringEngineering

Owner:ETTER ROGER G

Reduction of organic halide contamination in hydrocarbon products

ActiveUS8105481B2Reducing organic halide concentrationCatalystsHydrocarbon preparation catalystsMolecular sieveHalogen

A method for reducing halide concentration in a hydrocarbon product having an organic halide content from 50 to 4000 ppm which is made by a hydrocarbon conversion process using an ionic liquid catalyst comprising a halogen-containing acidic ionic liquid comprising contacting at least a portion of the hydrocarbon product with at least one molecular sieve having pore size from 4 to 16 Angstrom under organic halide absorption conditions to reduce the halogen concentration in the hydrocarbon product to less than 40 ppm is disclosed.

Owner:CHEVROU USA INC

Reduction of organic halide contamination in hydrocarbon products

ActiveUS20090163759A1Reducing organic halide concentrationCatalystsHydrocarbon preparation catalystsMolecular sieveHalogen

A method for reducing halide concentration in a hydrocarbon product having an organic halide content from 50 to 4000 ppm which is made by a hydrocarbon conversion process using an ionic liquid catalyst comprising a halogen-containing acidic ionic liquid comprising contacting at least a portion of the hydrocarbon product with at least one molecular sieve having pore size from 4 to 16 Angstrom under organic halide absorption conditions to reduce the halogen concentration in the hydrocarbon product to less than 40 ppm is disclosed.

Owner:CHEVROU USA INC

Process for making lube oil basestocks

ActiveUS7597795B2Treatment with plural serial cracking stages onlyCatalyst activation/preparationBase oilRaffinate

Owner:EXXON RES & ENG CO

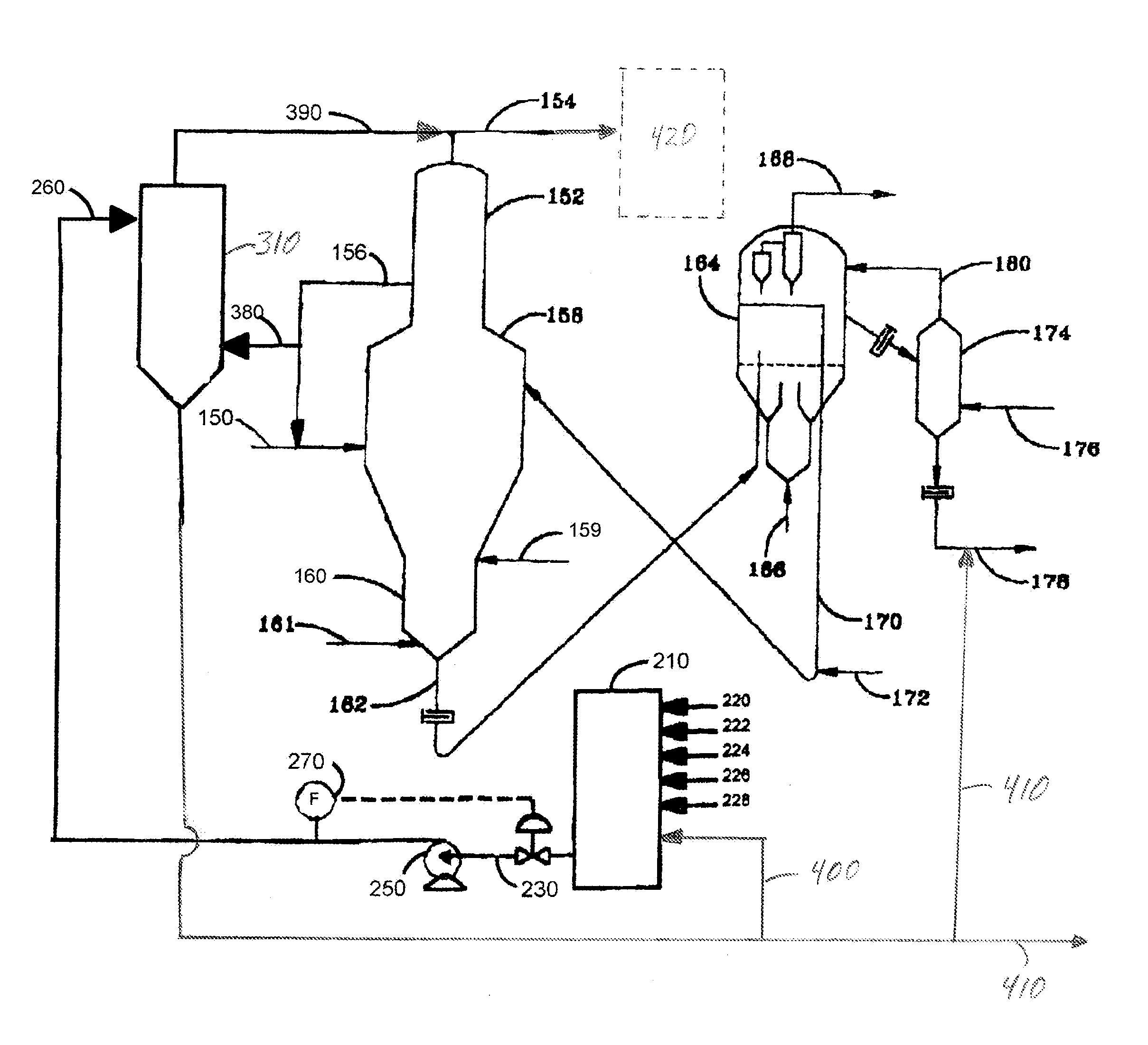

Process for fluid catalytic cracking oligomerate

ActiveUS20140135557A1Easy to crackReadily cracked down to propylene moleculeCatalytic crackingLiquid hydrocarbon mixtures productionOligomerMaterials science

Distillate cracks to propylene more readily than VGO. Additionally, less branched hydrocarbons crack to propylene more readily than more branched hydrocarbons. Oligomerization to diesel range oligomers followed by catalytic cracking with less branched oligomers can provide more propylene.

Owner:UOP LLC

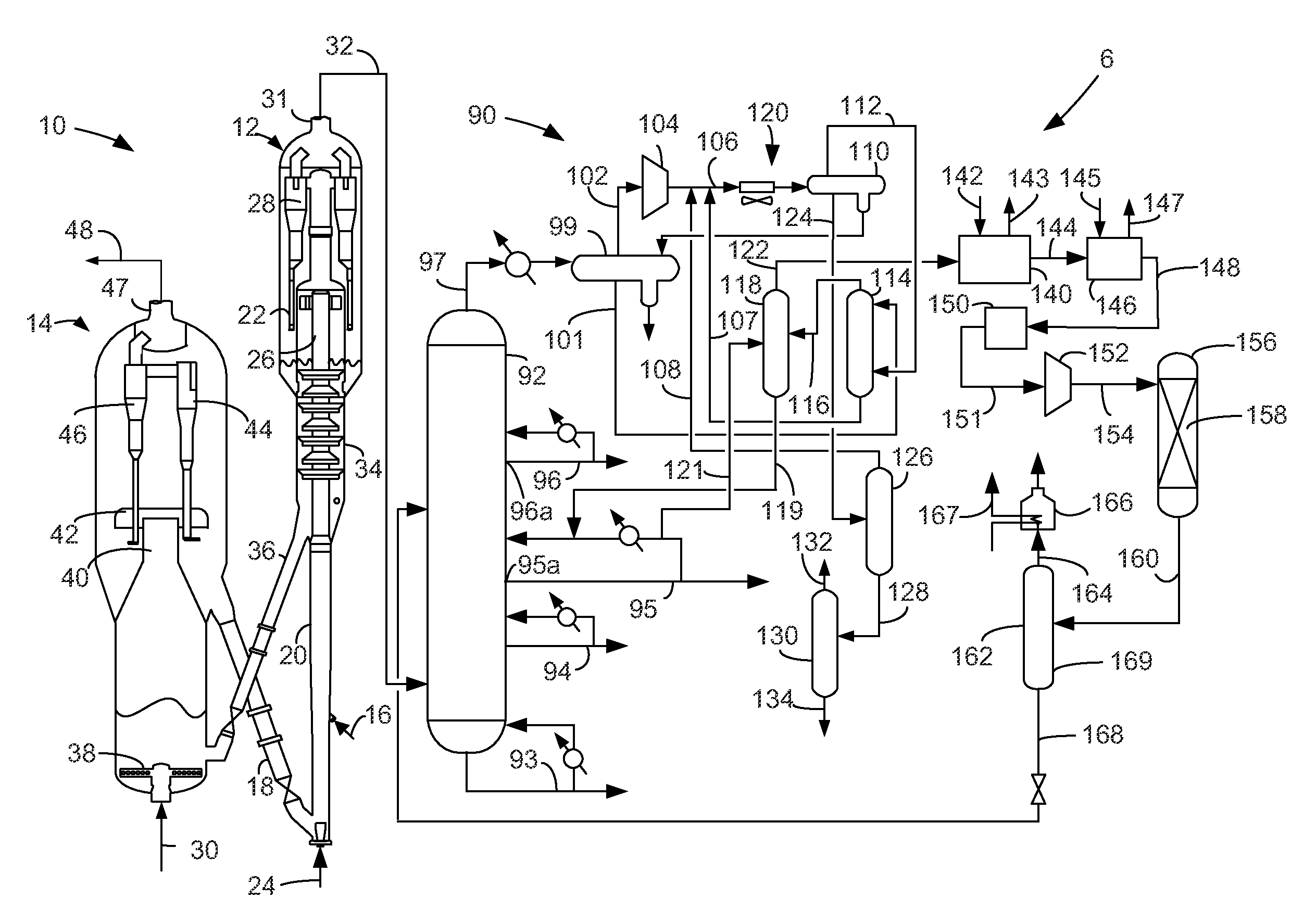

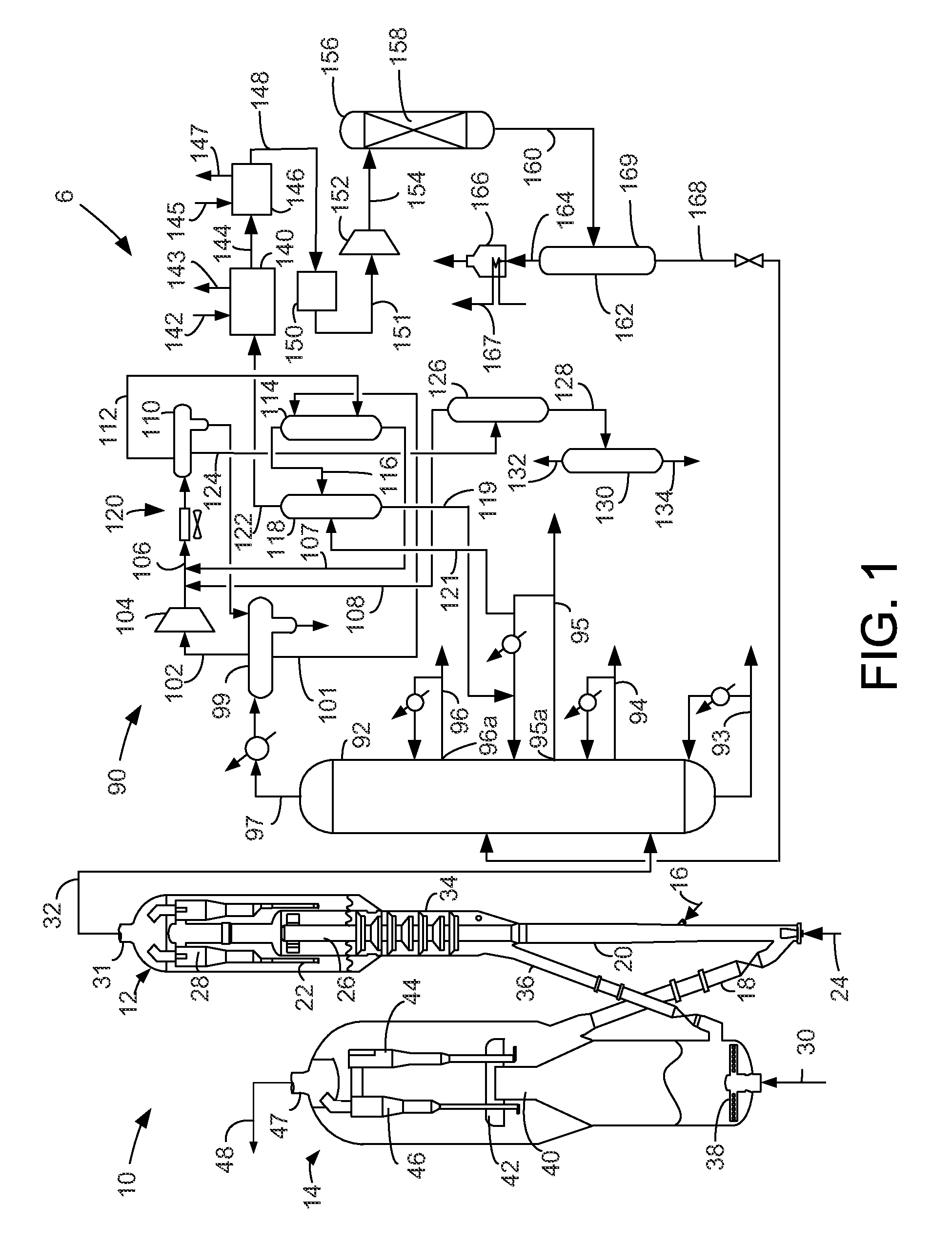

Fluid catalytic cracking process

InactiveUS20140135545A1Reduce dwell timeResidence timeCatalytic crackingMolecular sieve catalystHydrocarbonChemistry

One exemplary embodiment can be a process for fluid catalytic cracking. The process can include providing a first feed including one or more heavy hydrocarbons to a riser of a riser-reactor, and obtaining a second feed from an oligomerization zone. Usually, the second feed includes one or more light alkene oligomeric hydrocarbons and is provided downstream from the first feed for producing propene.

Owner:UOP LLC

Addition of a reactor process to a coking process

InactiveUS8206574B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyEngineeringProcess engineering

Owner:ETTER ROGER G

Process for the oligomerization of olefins in fischer-tropsch derived condensate feed

InactiveUS20060149107A1Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionOxygenateOxygen compound

A process for oligomerizing the olefins present in a Fischer-Tropsch derived condensate containing a mixture of olefins and oxygenates and boiling in the range of diesel which comprises (a) removing substantially all of the oxygenates present in the Fischer-Tropsch condensate; (b) contacting the Fischer-Tropsch derived condensate having less than 100 ppmw elemental oxygen with an ionic liquid catalyst in an oligomerization zone under oligomerization reaction conditions; and (c) recovering from the oligomerization zone a Fischer-Tropsch derived product having molecules characterized by a higher average molecular weight and increased branching as compared to the Fischer-Tropsch derived condensate.

Owner:CHEVROU USA INC

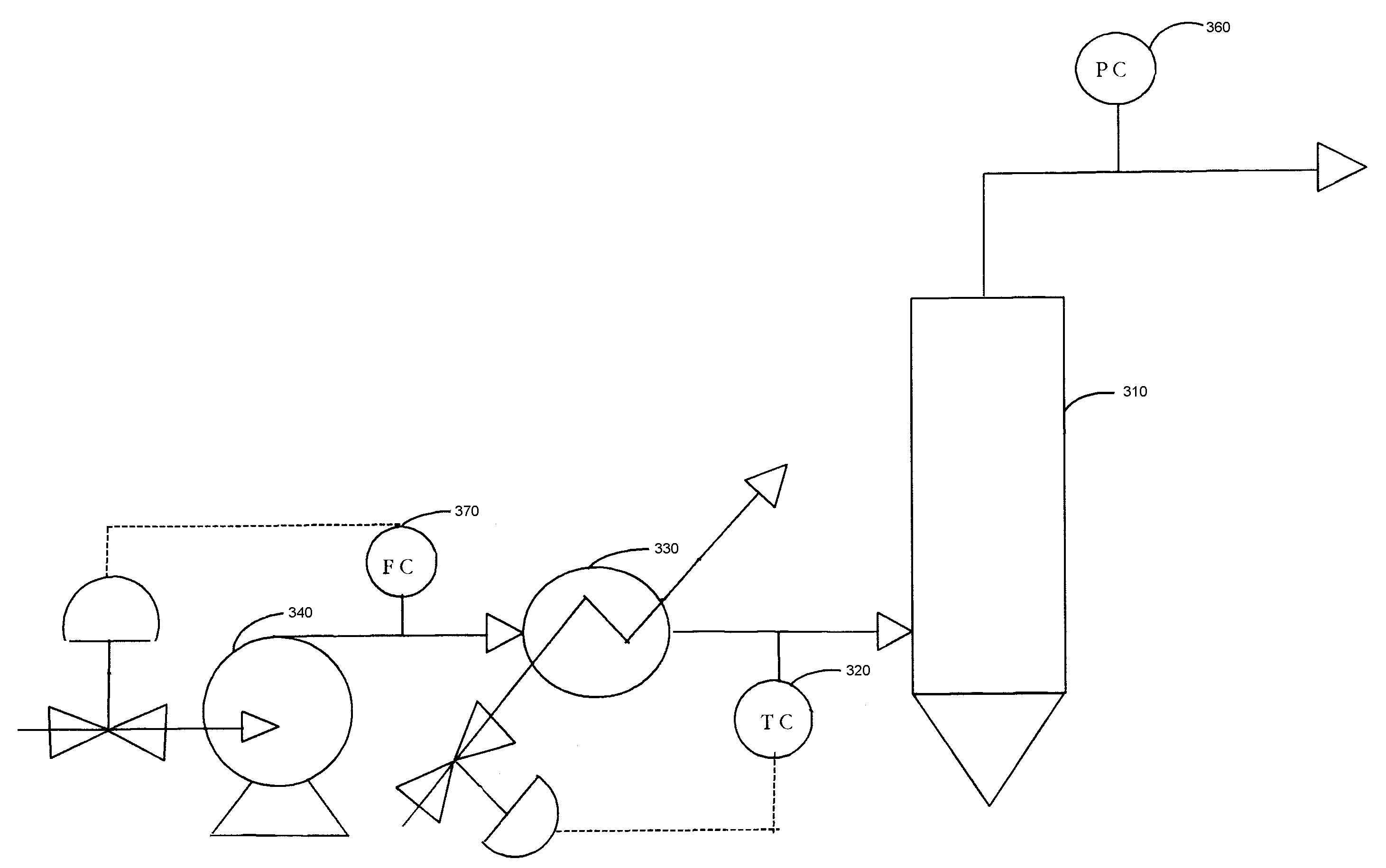

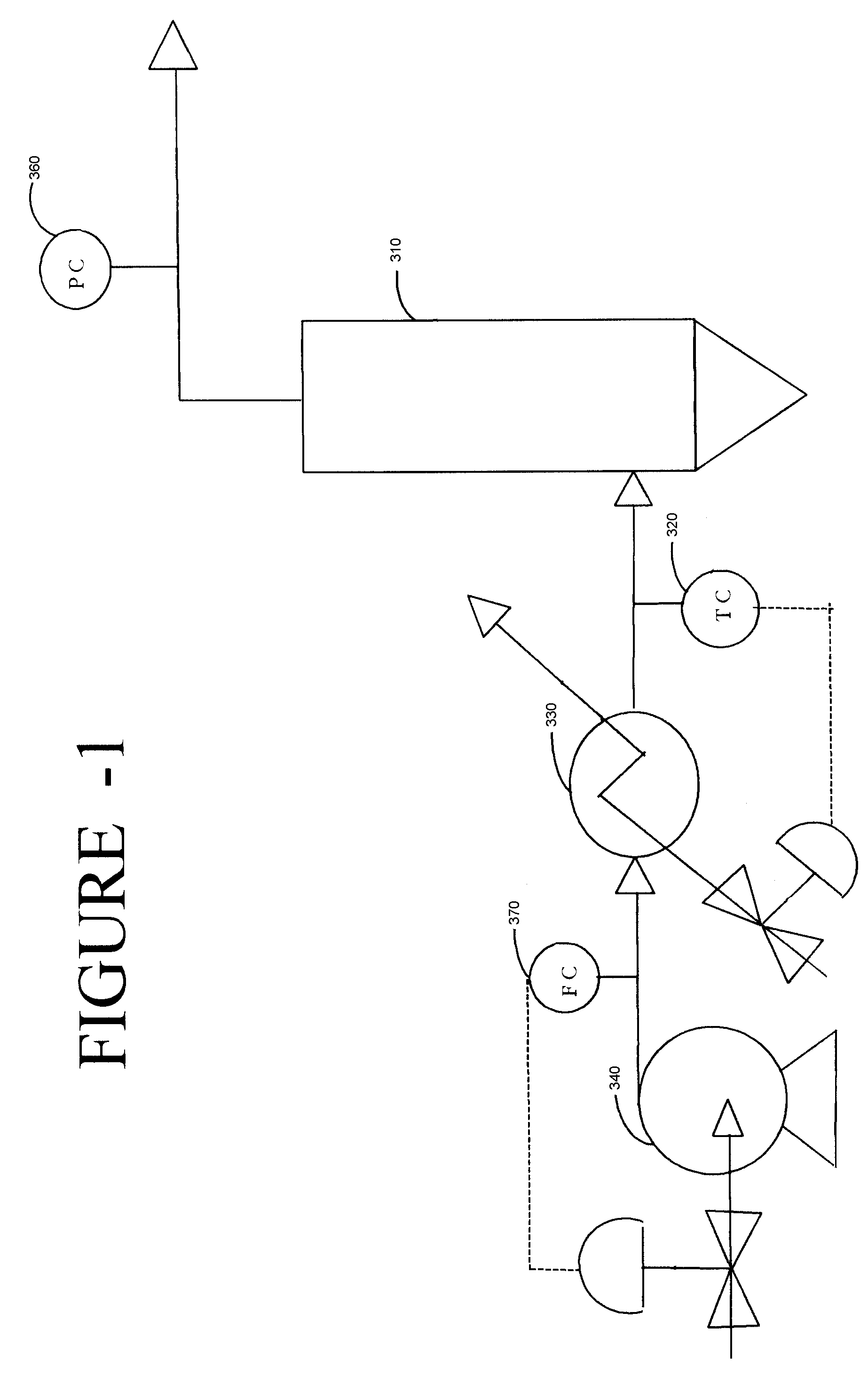

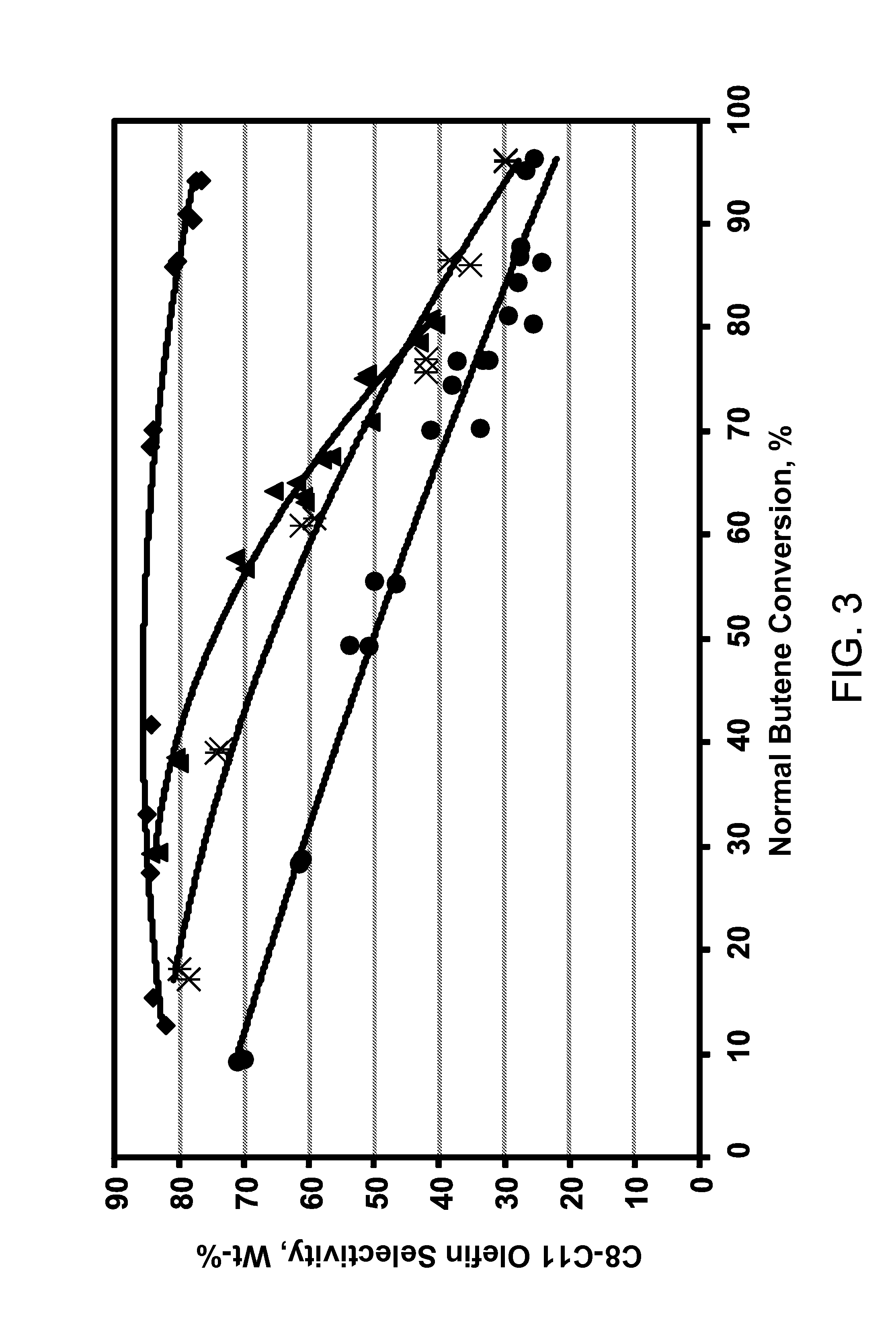

Gasoline production by olefin polymerization

InactiveUS20070185359A1Reduce over-polymerizationEasy to convertMolecular sieve catalystsLiquid hydrocarbon mixtures productionButeneFractionation

A process unit for the zeolite-catalyzed conversion of light refinery olefins from an FCC unit such as ethylene, propylene, and butylene to gasoline boiling range motor fuels comprises at least two sequential, serially connected reactors connected in parallel to a fractionation section with at one or two fractionators for separating the reactor effluents into product fraction with an optional recycle stream or streams. The configurations according to this scheme allow the adjustment of reactor temperature and / or pressure and / or space velocity to be based on the reactivities of the olefin compounds present in the LPG streams so that the gasoline produced in each reactor will be separated immediately, to reduce over-polymerization of the gasoline in the low severity reactor and to ensure that gasoline formed in the low severity reactor will not be sent to the higher severity reactor e.g. with a higher reactor temperature, where excessive polymerization to undesirable higher molecular with products may take place.

Owner:EXXON RES & ENG CO

Apparatus for fluid catalytic cracking oligomerate

ActiveUS20140134058A1Easy to crackReadily cracked down to propylene moleculeCatalytic crackingFluidised-bed furnacesOligomerMaterials science

Distillate cracks to propylene more readily than VGO. Additionally, less branched hydrocarbons crack to propylene more readily than more branched hydrocarbons. Oligomerization to diesel range oligomers followed by catalytic cracking with less branched oligomers can provide more propylene.

Owner:UOP LLC

Method for preparing road asphalt through catalytic slurry oil

ActiveCN104559241AReduce interactionHigh yieldTreatment with polymerisationBuilding insulationsLiquid productSlurry

The invention discloses a method for preparing road asphalt through catalytic slurry oil. The method comprises the following steps: (1) catalytic cracking slurry oil is distilled under reduced pressure, and topped slurry oil is obtained; (2) a crosslinking agent and an activation crosslinking agent are added to the topped slurry oil, stirred and mixed to have a crosslinking condensation reaction and then modified slurry oil is obtained; (3) modified slurry oil and basic asphalt are blended, and a road asphalt product is obtained. The catalytic slurry oil is topped, has the crosslinking condensation reaction and then is blended with the basic asphalt, the road asphalt product with good temperature sensing performance and anti-aging performance is obtained, and meanwhile, the yield of liquid products of a secondary machining device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com