Hydrotreating of fischer-tropsch derived feeds prior to oligomerization using an ionic liquid catalyst

a technology of ionic liquid catalyst and derived feed, which is applied in the direction of organic chemistry, chemistry apparatus and processes, and thermodynamic non-catalytic cracking, etc., can solve the problems of interfering with the ability of ionic, material hydrotreated, etc., to improve the cold flow properties of products, improve the uv and oxygen stability, and improve the color of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

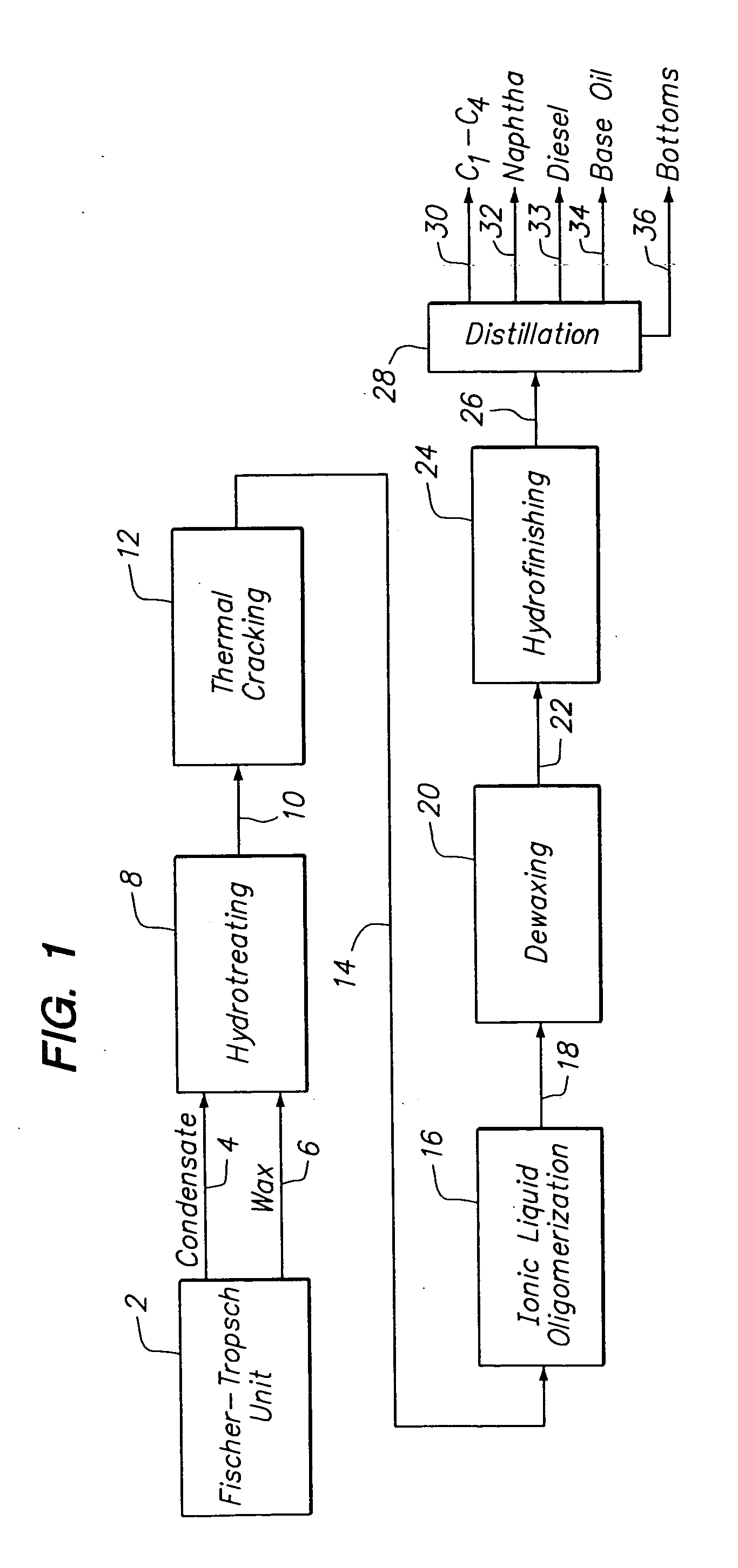

[0018] The present invention will be more clearly understood by referring to FIG. 1 which illustrates a simplified processing scheme showing the elements of the invention. Two separate Fischer-Tropsch feed streams are shown leaving the Fischer-Tropsch unit 2. They include a Fischer-Tropsch condensate feed 4 and a Fischer-Tropsch wax feed 6 shown as being carried to the hydrotreating unit 8 where the oxygenates and any nitrogen compounds in the feed streams are removed. In the hydrotreating unit, most of the unsaturated bonds in the hydrocarbon molecules are also saturated. The hydrotreated Fischer-Tropsch derived feed comprising a mixture of both the condensate and wax fractions is collected in line 10 and carried to the thermal cracking unit 12 where the paraffin molecules are cracked to form olefins. The olefin-enriched Fischer-Tropsch feed from the thermal cracker is carried by line 14 to the oligomerization unit 16 where the feed is contacted with an ionic liquid catalyst in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com