High power fuel compositions

a fuel composition and high-power technology, applied in the petroleum industry, liquid carbonaceous fuels, fuel additives, etc., can solve the problems of increasing smoke emissions, limiting the amount of blended fuel, and the density of the fuel, so as to increase the power performance, increase the viscosity, and increase the power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

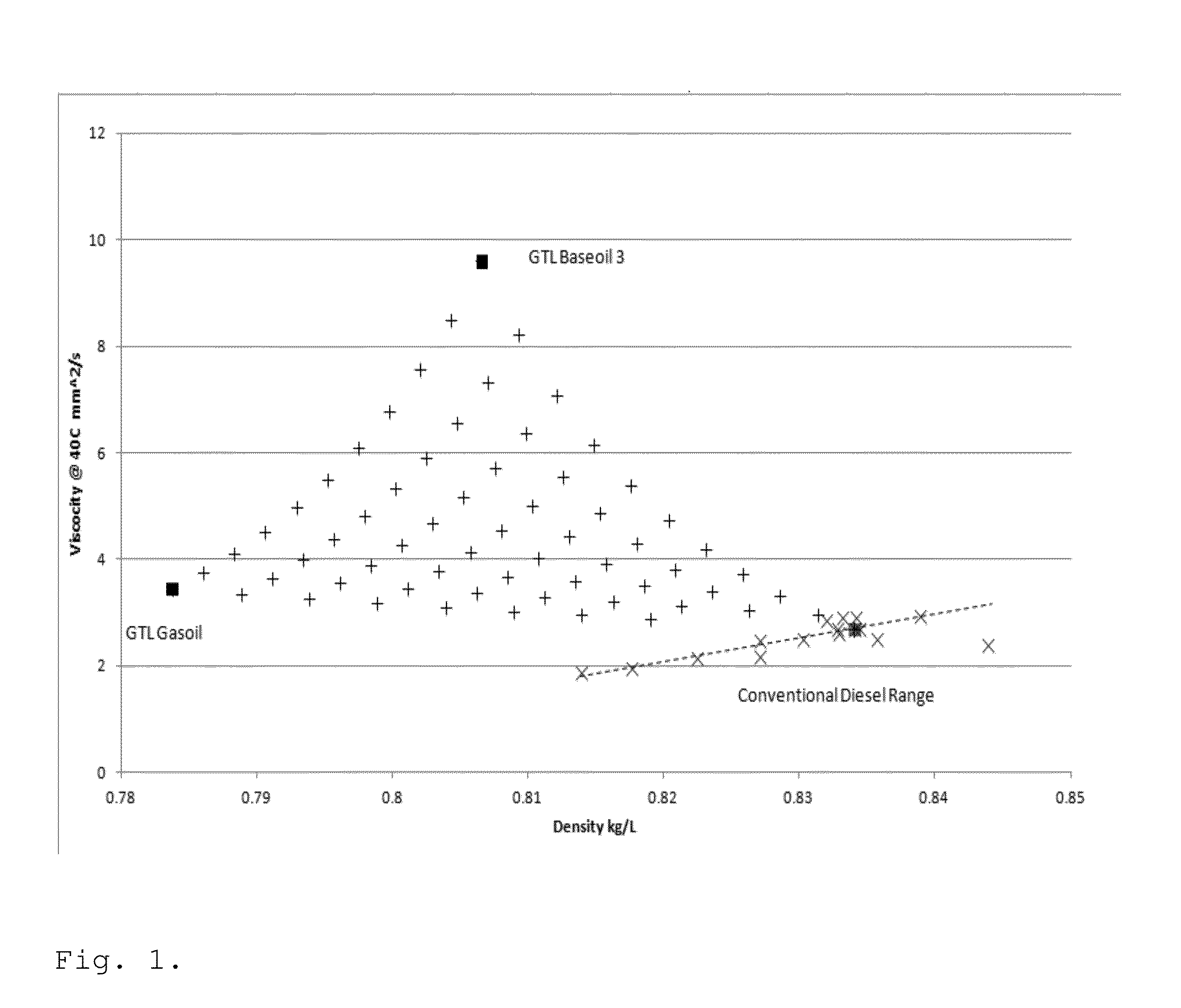

[0039]A Shell internal fuel blend modelling program ‘blendpro 2000’ was used to model the density and viscosity of a range of potential blends of the three components. The properties of the components used in this modelling are listed in Table 1. The complete possible blend range from 0-100% of each component was modelled at 10% increments, as represented in Table 2 and FIG. 1.

TABLE 1Components used for ‘blendpro’ modellingGTLGTLNameULSDGasoilBO3Density (Kg / l)0.8340.7840.807IBP166.0227.7334.0T10%205.0247.1353.0T20%225.0259.4354.5T30%244.0271.2356.0T40%259.0282.7357.0T50%272.0293.2358.5T60%284.0303.4360.5T70%295.0313.3362.5T80%309.0323.1364.5T90%325.0336.0367.5T95%339.0346.1370.0FBP355.0351.3374.0Cetane Number53.589.872.0Viscosity (cSt) at 40 deg2.683.439.58Sulphur (ppm w)48.03.01.0Total Aromatics24.30.50.1Cloud Point(C.)−8.0−9.0−28.0Flash Point(C.)64.5104.0190.0ULSD = Ultra Low Sulphur Diesel (50 mg S / kg)

TABLE 2Modelled Density and Viscosity of the possible blendsGTLGTLDensityViscos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com