Patents

Literature

202results about How to "High aromatic content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

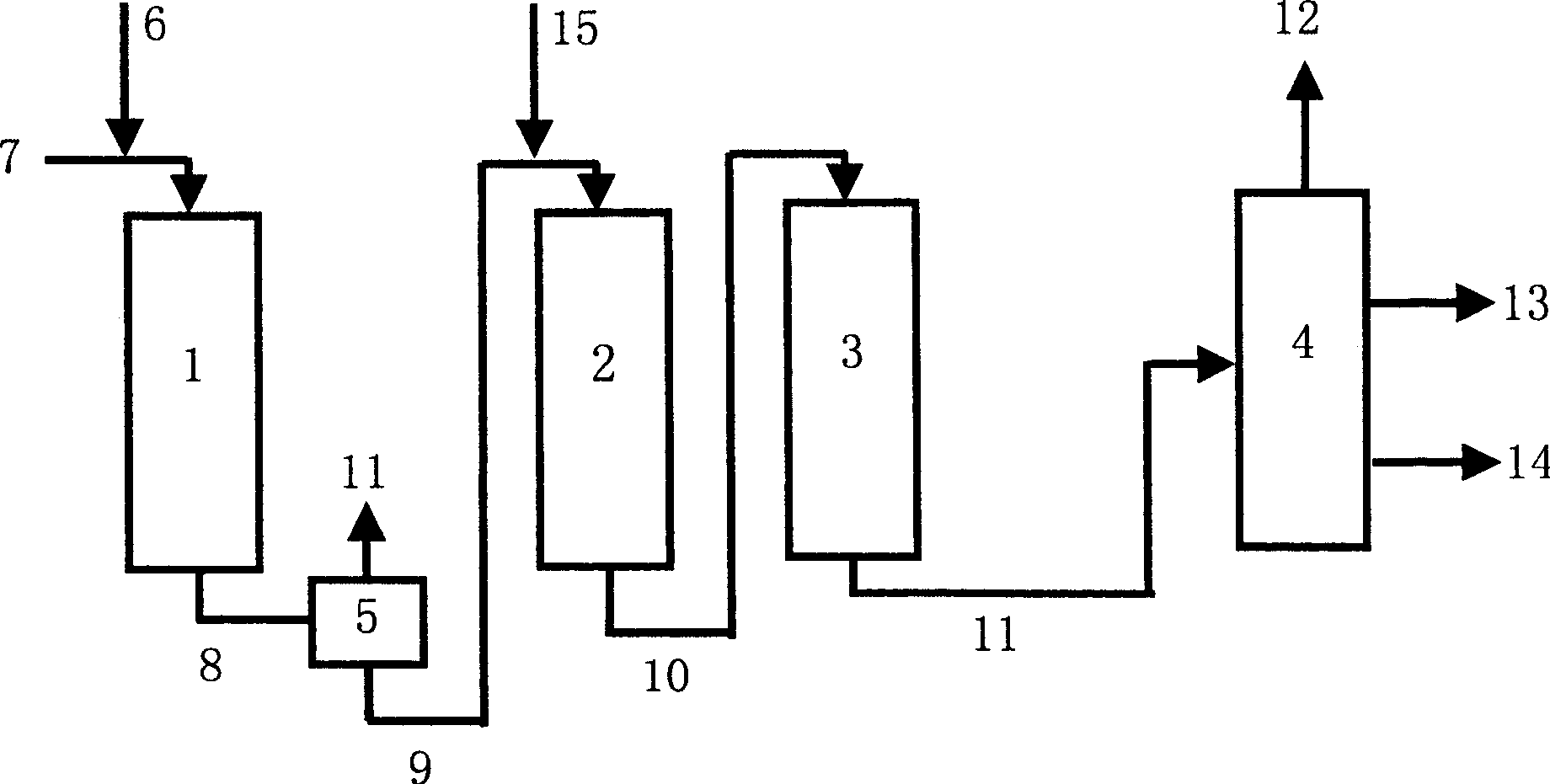

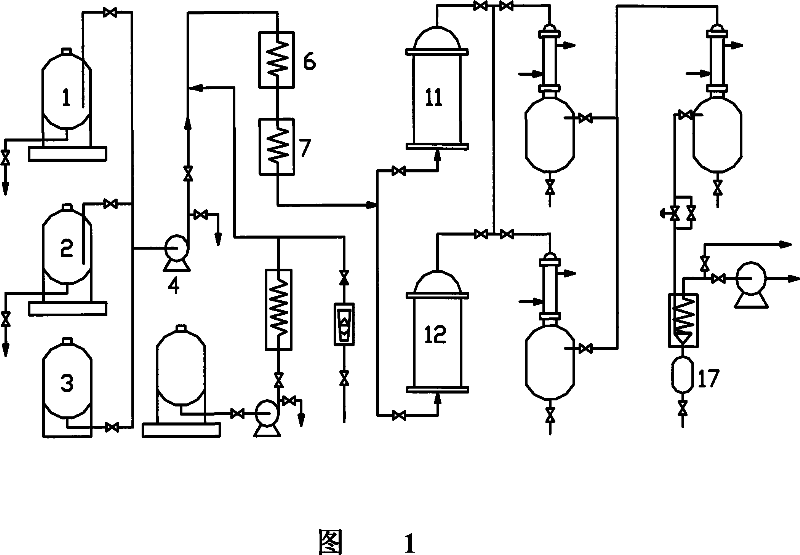

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Method for preparing mesophase asphalt by coal liquefaction residue

ActiveCN101580729AHigh C/H atomic ratioLow ashWorking-up pitch/asphalt/bitumen by chemical meansSolventChemistry

The invention relates to a method for preparing mesophase asphalt by coal liquefaction residue. In the method, the coal liquefaction residue is ground, screened and dried, and is extracted at certain temperature for certain time by using organic solvent as extracting solvent; the extracted mixed liquor is filtered, purified and evaporated; the extracting solvent in the extract liquor is evaporatedto obtain refined coal liquefaction oil asphalt, thus obtaining the mesophase asphalt by charring for 4-10 hours in a high-pressure autoclave under the conditions of 410-460 DEG C, 3-4MPa of constantpressure and stirring. The method has simple process and convenient and safe operation, the mesophase asphalt with high quality is prepared and can be used as raw materials of high power and ultra high power graphite electrode, carbon fiber and the like.

Owner:CHINA COAL RES INST +1

Method for preparing lubricating oil base oil

This invention is a preparation method of basic oil of lubricating oil. This method includes: a) in the hydro-treatment reacting area, the hydro-pressure is more than 11-30 MPa, under 320-430deg.C contact a hydrocarbon oil filler with hydro-treating catalyst; b) in a dewaxing area, the hydro-pressure is more than 11-30 MPa, under 320-430deg.C contact hydro-treated oil with a dewaxing catalyst; c) in a hydro-refining area, the hydro-pressure is more than 11-30 MPa, under 170-320deg.C contact the dewaxing oil with a hydro-catalyst containing SiO2 / alumina, platinum and Pd metal to prepare the basic oil of the lubricating oil.

Owner:CHINA PETROLEUM & CHEM CORP

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS20060049080A1Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationProcess engineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Method for preparing lubricating oil base oil

This invention is a preparation method of basic oil of lubricating oil. This method includes: a) in the hydro-treatment reacting area, the hydro-pressure is more than 11-30 MPa, under 320-430deg.C contact a hydrocarbon oil filler with hydro-treating catalyst; b) in a dewaxing area, the hydro-pressure is more than 11-30 MPa, under 320-430deg.C contact hydro-treated oil with a dewaxing catalyst; c) in a hydro-refining area, the hydro-pressure is more than 11-30 MPa, under 170-320deg.C contact the dewaxing oil with a hydro-catalyst containing SiO2 / alumina, platinum and Pd metal to prepare the basic oil of the lubricating oil.

Owner:CHINA PETROLEUM & CHEM CORP

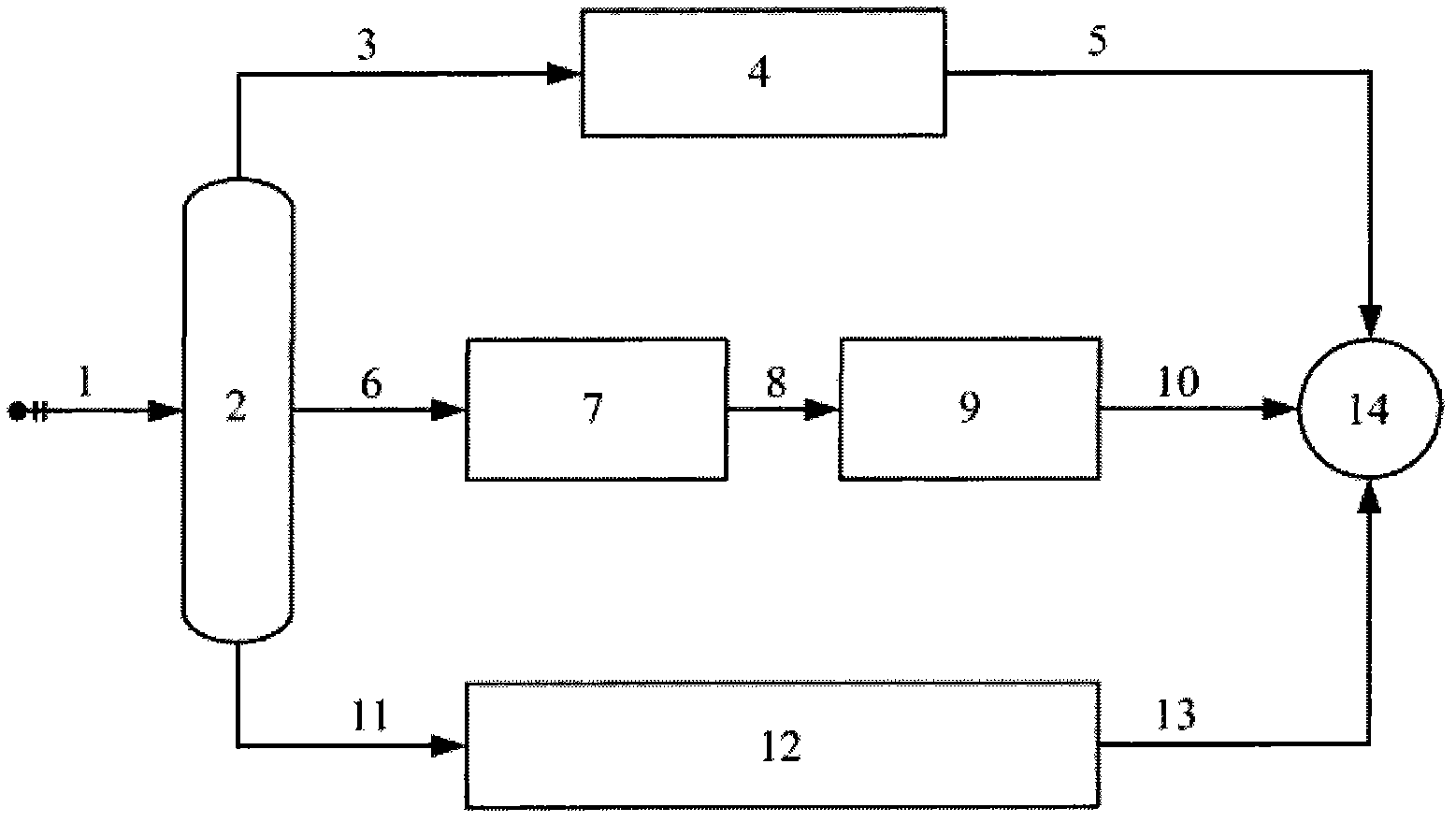

Utilization method of catalytic cracking diesel

ActiveCN101760239AHigh aromatic contentBoost octaneTreatment with hydrotreatment processesBoiling pointAromatic hydrocarbon

The invention relates to a utilization method of catalytic cracking diesel, wherein the method comprises the following steps: (1) separating the catalytic cracking diesel into a component with the boiling point being less than 230 DEG C and a component with the boiling point being more than 230 DEG C; (2) hydrogenering for the component with the boiling point being more than 230 DEG C obtained inthe step (1) under the condition that poly-aromatic hydrocarbon is inverted into monocyclic aromatic hydrocarbon; (3) separating the component with the boiling point being less than 230 DEG C obtained in the step (1) and hydrogenation product obtained in the step (2) to obtain diesel rich in the monocyclic aromatic hydrocarbon, and catalytically cracking the diesel rich in the monocyclic aromatichydrocarbon. In the method, firstly, the catalytic cracking diesel is separated into the component with the boiling point being less than 230 DEG C and the component with the boiling point being morethan 230 DEG C, and then the poly-aromatic hydrocarbon in the component with the boiling point being more than 230 DEG C can be hydro-fined into the monocyclic aromatic hydrocarbon, therefore, the hydrogenation selectivity can be improved, and the FCC gasoline with high content of aromatic hydrocarbon and high octane number can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

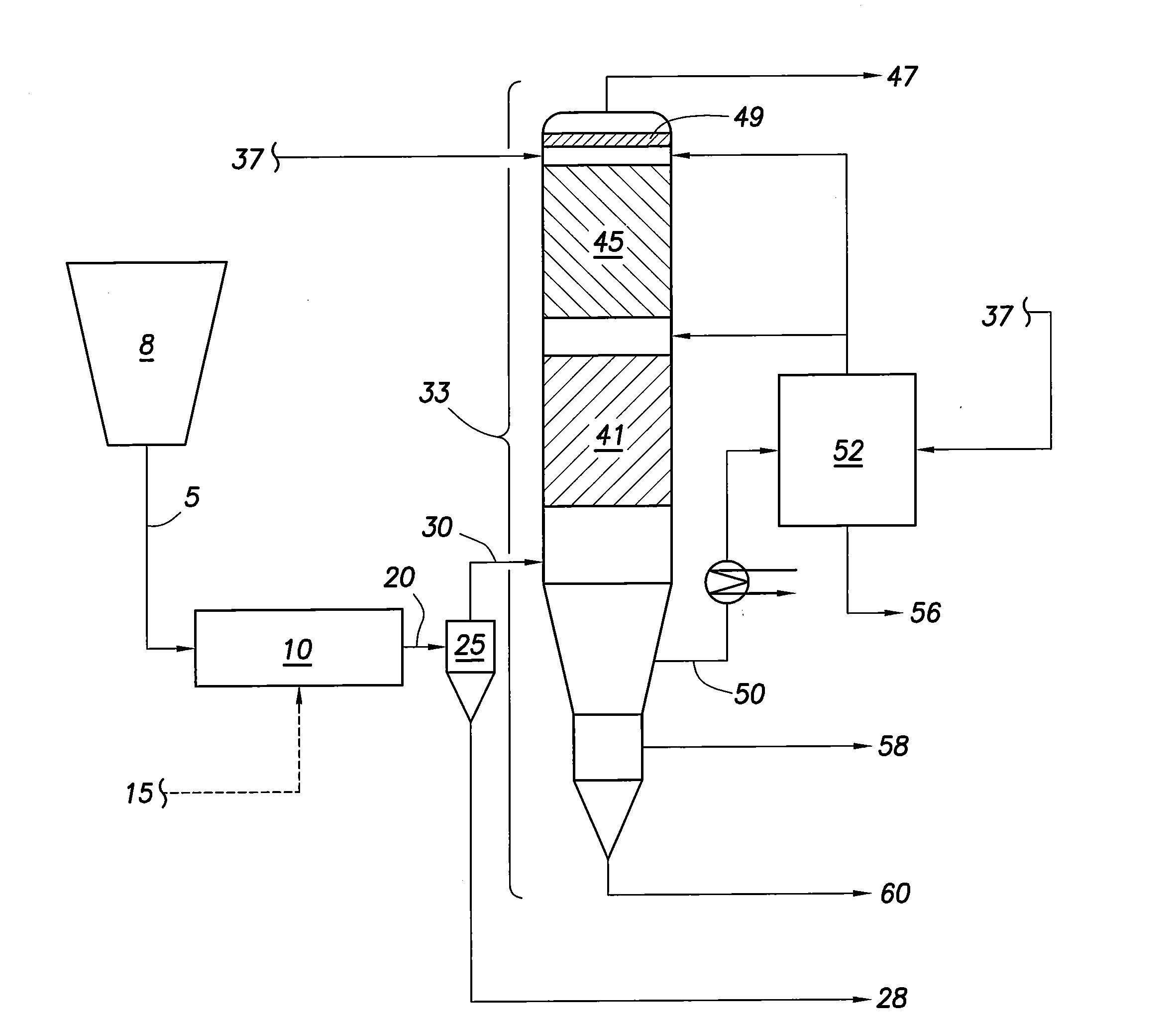

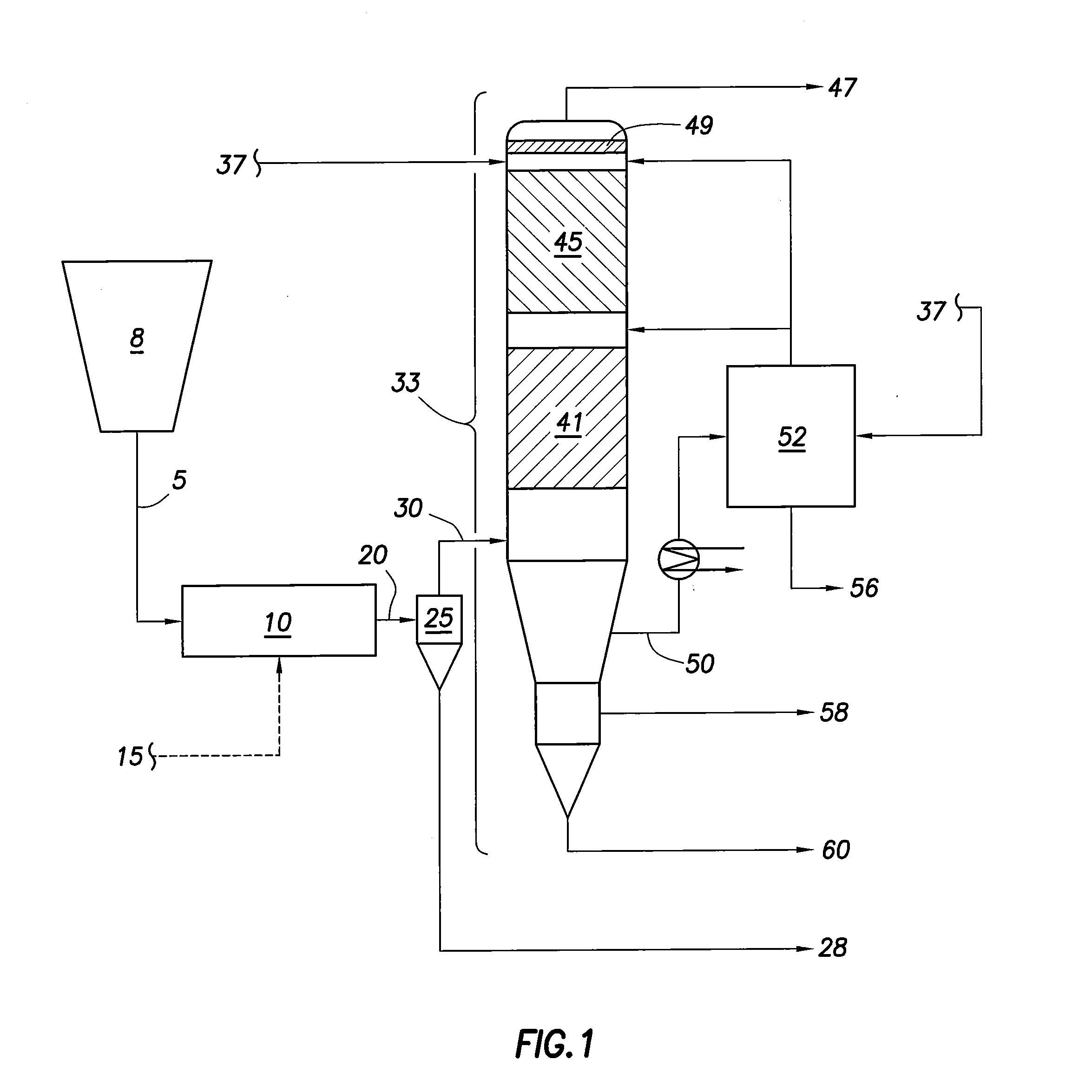

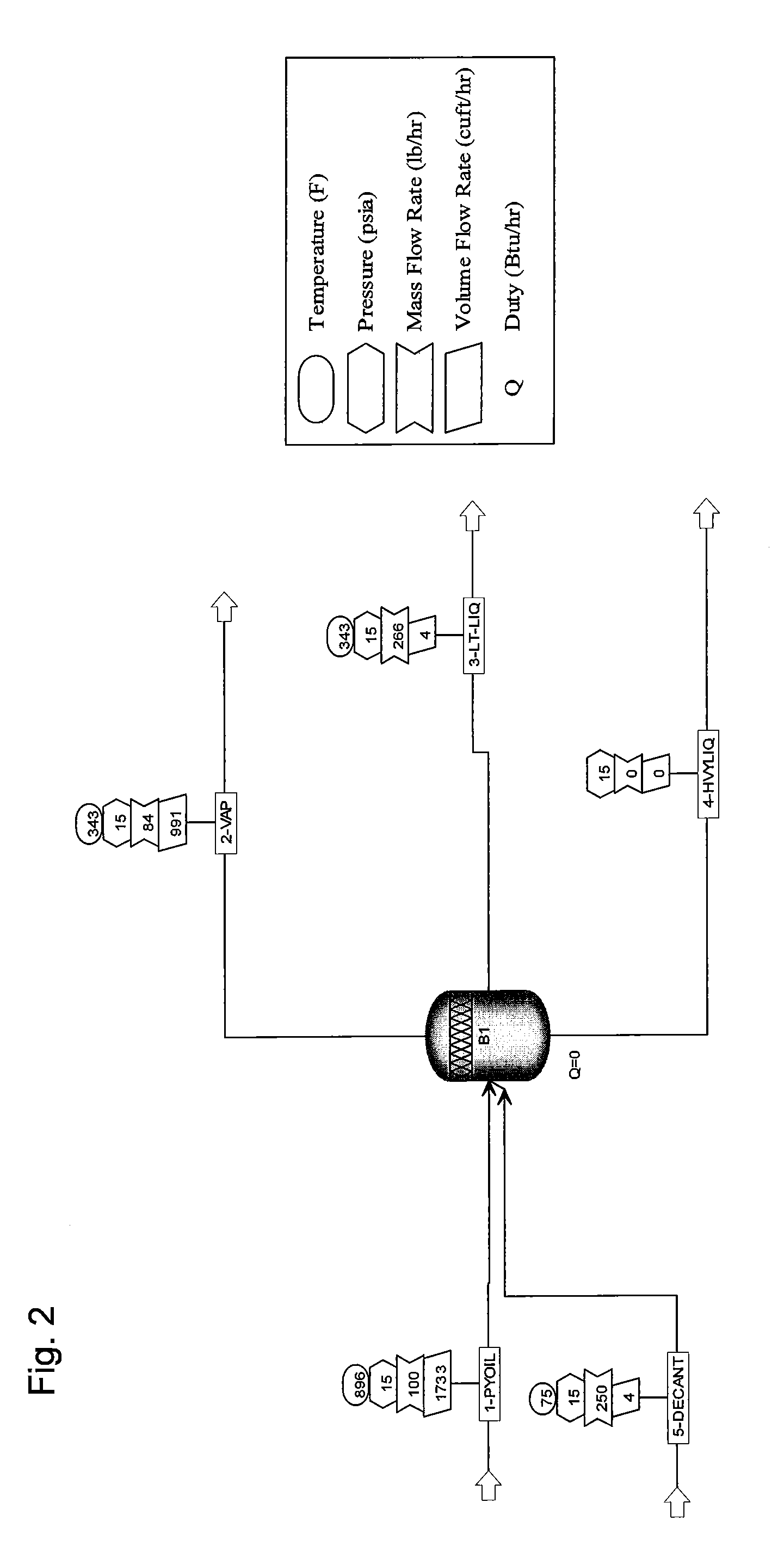

Absorption and quench method for biomass pyrolysis product

ActiveUS20120167452A1High aromatic contentFaster quenching rateGas treatmentOrganic chemistryBoiling pointBiomass

A biomass pyrolysis product is quenched by direct cooling with a cold quench fluid and initial product separation is performed based on boiling point and solubility in the quench fluid. A properly chosen quench fluid may act as a selective solvent, thus providing dilution of unstable precursors of pyrolytic lignin or other heavy by-products, and / or separation of certain undesirable pyrolysis oil components such as water and light acids.

Owner:PHILLIPS 66 CO

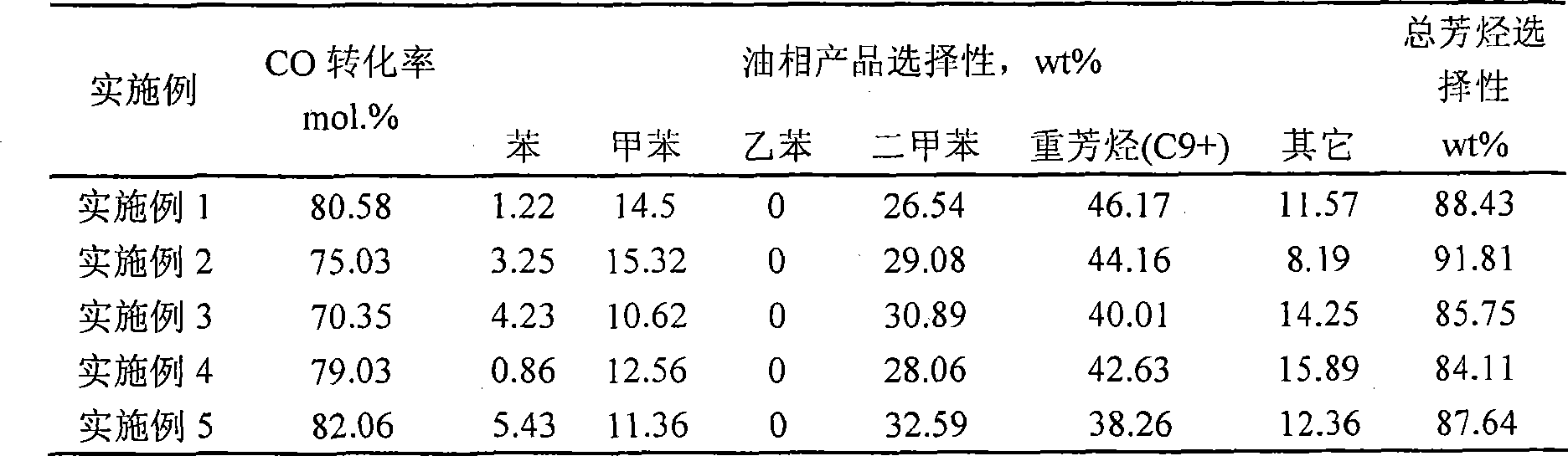

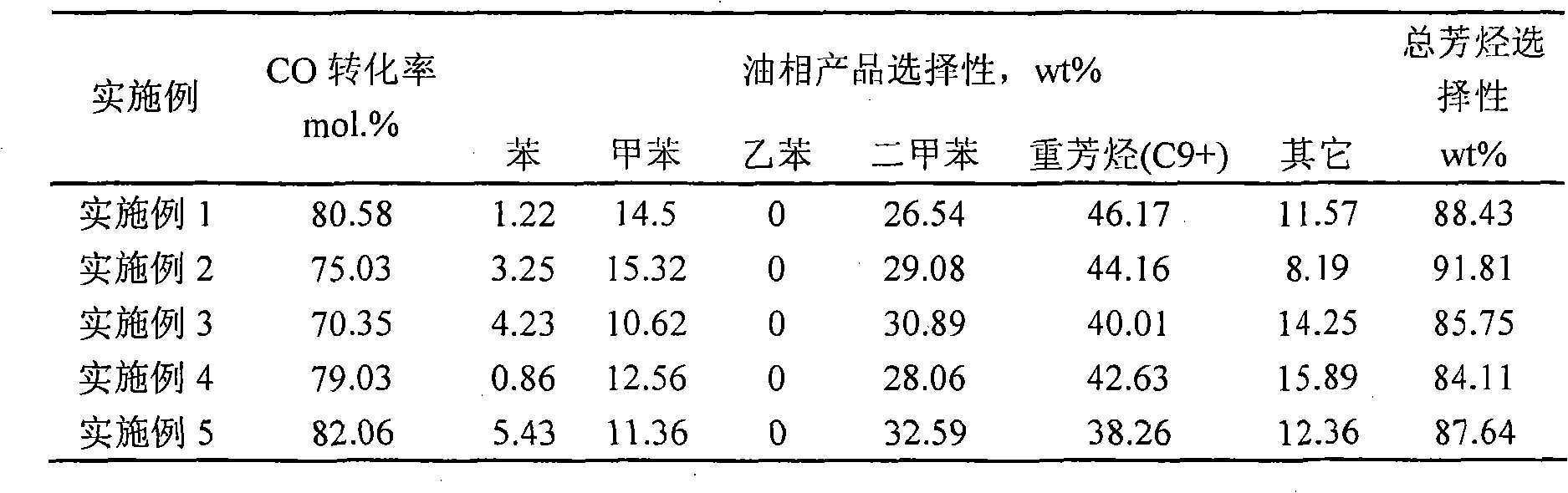

Catalyst for direct synthesis of arene by synthesis gas and production method and use thereof

InactiveCN101422743ASuitable for aciditySimple processHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a catalyst for directly synthesizing aromatic hydrocarbon by synthesis gas, which has the composition with following weight ratio: HNKF-5:aluminophosphate molecular sieve:Ga2O3:ZnO:BaO equal to 1:1-3:0.01-0.3:0.01-0.3:0.01-0.3. The invention has the advantages of simple technical process, medium catalyst acidity of aromatic hydrocarbon synthesis, better aromatization performance, and high aromatic hydrocarbon content.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of hydrocracking catalyst

ActiveCN103100400AIncrease the apertureIncrease contentMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises: first selecting a solution containing a hydrogenation active metal and an organic reagent to dip mixed powder of a molecular sieve and alumina, conducting drying, then subjecting the obtained material and a peptizing agent or a binder together to rolling, molding, drying and roasting, thus obtaining the catalyst. Only through one time high temperature roasting can the catalyst product be obtained. The preparation method is simple, and the preparation cost is obviously reduced. In addition, the hydrogenation activity center and the cracking activity center of the catalyst coordinate, so that the catalyst has very high catalytic activity. Also with a large specific surface area and pore volume, the hydrocracking catalyst is more suitable for a catalytic process of treating high dry point inferior vacuum distillate oil by hydrocracking for high production of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Method for producing high-octane gasoline

ActiveCN101429452AReduce gasoline olefin contentHigh aromatic contentCatalytic naphtha reformingRare-earth elementSimulated moving bed

The invention provides a method for producing high octane gasoline by aromatization reaction of a mixed raw material of catalytic gasoline and C4, and catalyst on an aromatization reactor after the mixed raw material contacts the catalyst. The method is as follows: the catalytic gasoline is mixed with the C4 olefin, and the mixed raw material enters into a fixed bed aromatization reactor or a simulated moving bed aromatization reactor which is filled with the molecular sieve catalyst, contacts the aromatizing catalyst, and undergoes olefin aromatization reaction, wherein the reaction conditions are as follows: the reaction temperature is between 250 and 340 DEG C; the pressure is between 0.5 and 3.0 MPa; the weight space velocity is between 0.5 and 10h<-1>; the mass ratio of the C4 olefin to the catalytic gasoline is between 90 to 10 and 2 to 98; and active ingredients of a molecular sieve carrier of the catalyst are one or more than one among rare earth element, No. 4B element and No. 8 element, and the weight of the active ingredients is 0.01 to 10 percent of that of the carrier. The method can obviously reduce the olefin content of the raw gasoline, effectively improve the octane number, and achieve the aim of production of the clean high-octane gasoline.

Owner:PETROCHINA CO LTD

Hydrocracking process for maximally producing middle distillate

InactiveCN1493667ALow aromatic contentIncrease profitHydrocarbon oil crackingTreatment with hydrotreatment processesChemistryPetroleum

A hydrocracking process for increasing the output of intermediate fractional oil to maximum features that the hydrorefined heavy petroleum hydrocarbon is contacted first with the beta-zeolite hydrocracking catalyst for cracking the most of raw material and then with the Y-zeolite hydrocracking catalyst for cracking the rest of raw material. Its advantages are high selectivity and low content of olefin in intermediate fractional oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

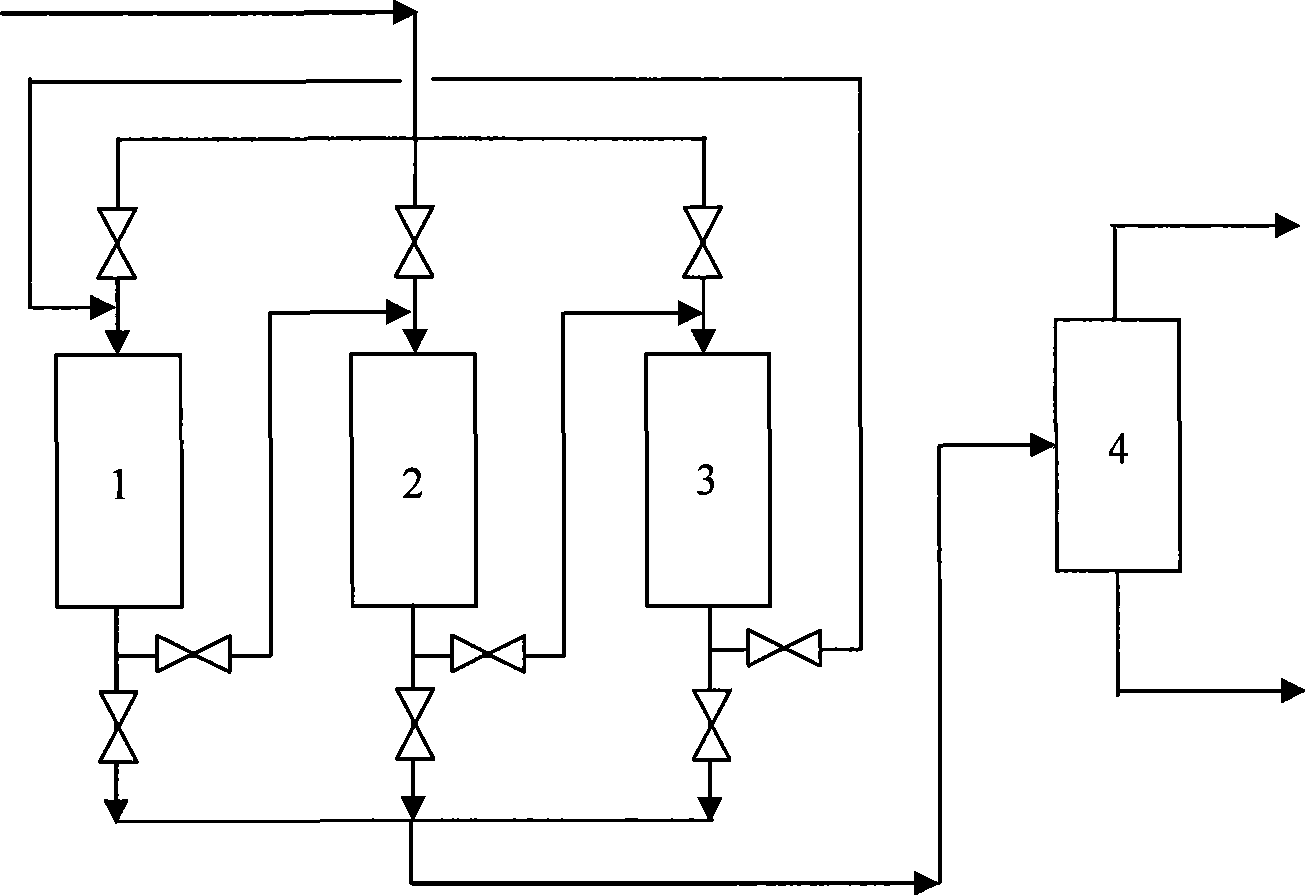

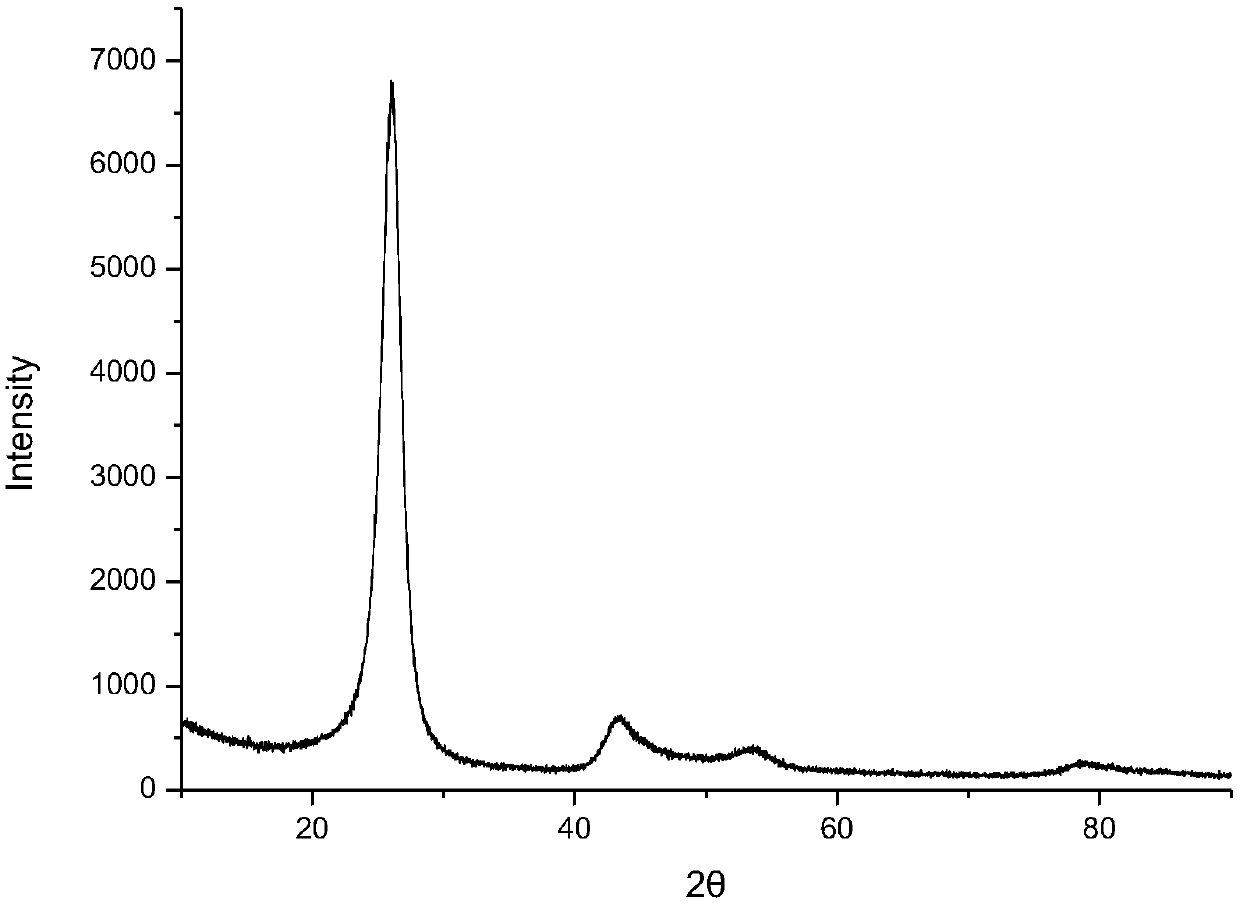

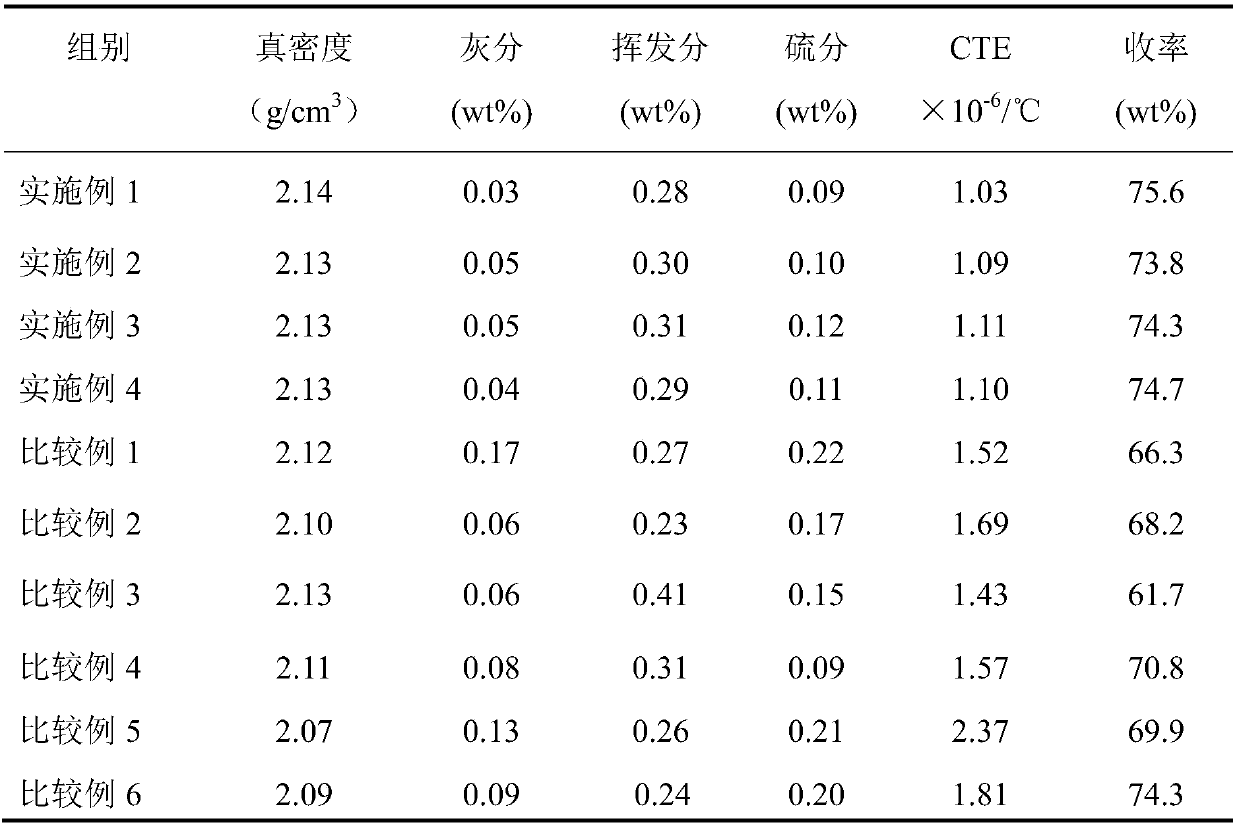

Technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as raw material

ActiveCN107694552AGood qualityHigh yieldWorking-up pitch/asphalt/bitumen by selective extractionPhysical/chemical process catalystsPre treatmentWide area

The invention relates to a technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as a raw material. The technology mainly comprises the following steps: carrying out decompression and distillation, and extraction and removal on middle-temperature and low-temperature coal tar; combining hydrogenation treatment, thermal polymerization andcalcining technologies under the action of a non-metal homogeneous mild-hydrogenation catalyst to prepare the coal-series needle coke with good performance and relatively high yield. The non-metal homogeneous mild-hydrogenation catalyst is mainly prepared from the following raw materials in percentage by mass: 55 weight percent to 79 weight percent of semi-coke, 20 weight percent to 40 weight percent of coke and 1 weight percent to 5 weight percent of graphene. According to the technology provided by the invention, after the raw material is subjected to combined pre-treatment, a refined asphalt raw material is reasonable in constitution and has a few of impurities; the catalyst has excellent modification performance and does not need to be separated subsequently; the graphene component also can be used for promoting a middle phase in a thermal polymerization process to form a wide-area and ordered fibrous structure and a high-performance needle coke product is easy to form.

Owner:NORTHWEST UNIV +1

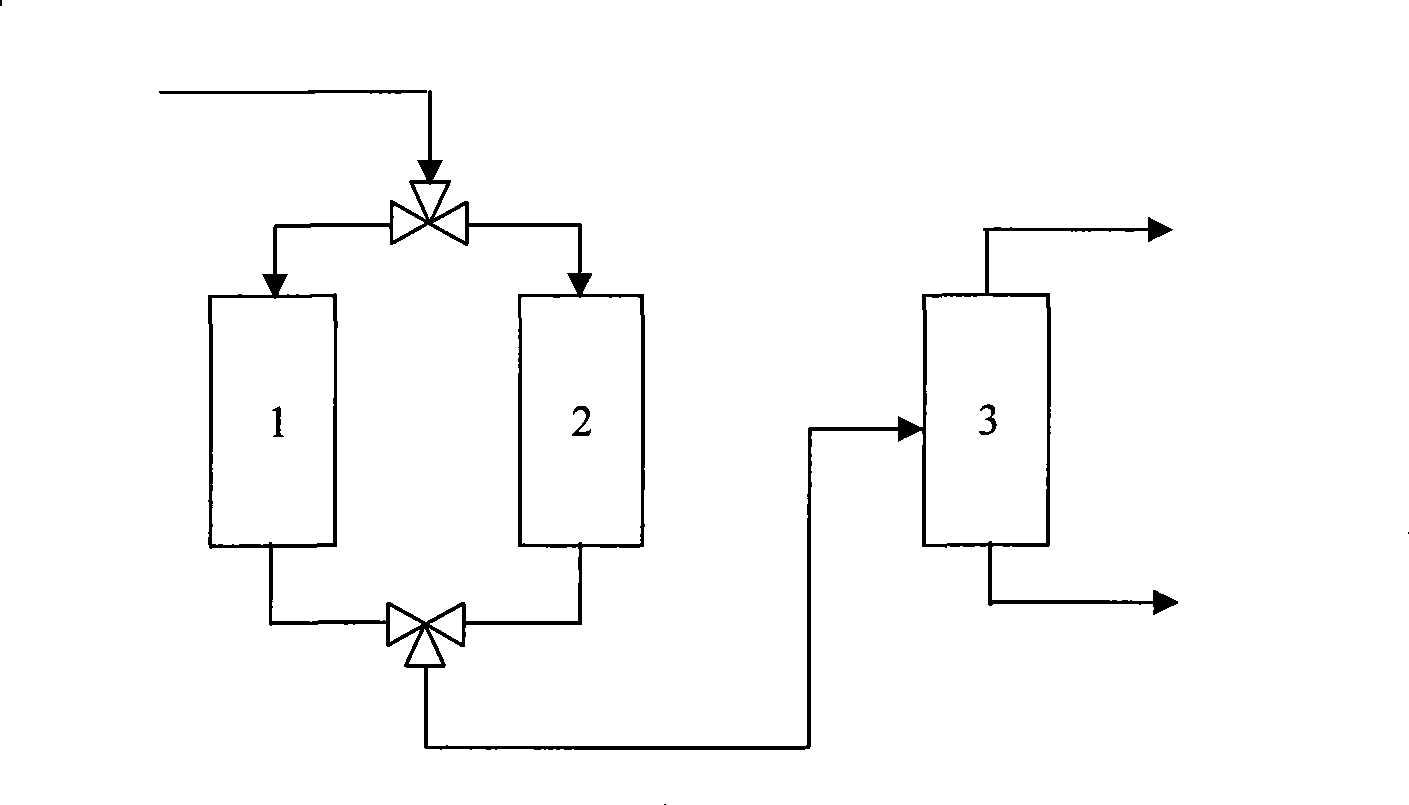

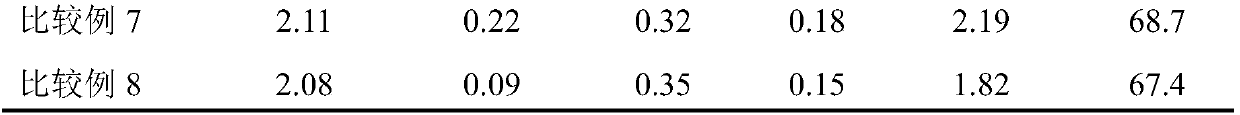

Pretreatment method for producing needle coke raw material

ActiveCN103789028AImprove thermal stabilityExcellent graphitization performanceTreatment with hydrotreatment processesPretreatment methodSlurry

The invention discloses a pretreatment method for producing needle coke raw material from catalytic slurry oil. The method includes the following steps: filtering the catalytic oil slurry and subjecting the catalytic oil slurry to a mild hydrogenation treatment; introducing 20-50 wt% of the oil produced by hydrogenation into a vacuum distillation device with the operation conditions of pressure of 5-100 mmHg and temperature of 300-450 DEG C; and mixing the hydrogenation light distillates and the rest oil produced by hydrogenation and using the mixture as the raw material for production of needle coke. The method is applicable to production of needle coke raw material from the catalytic slurry oil rich in aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

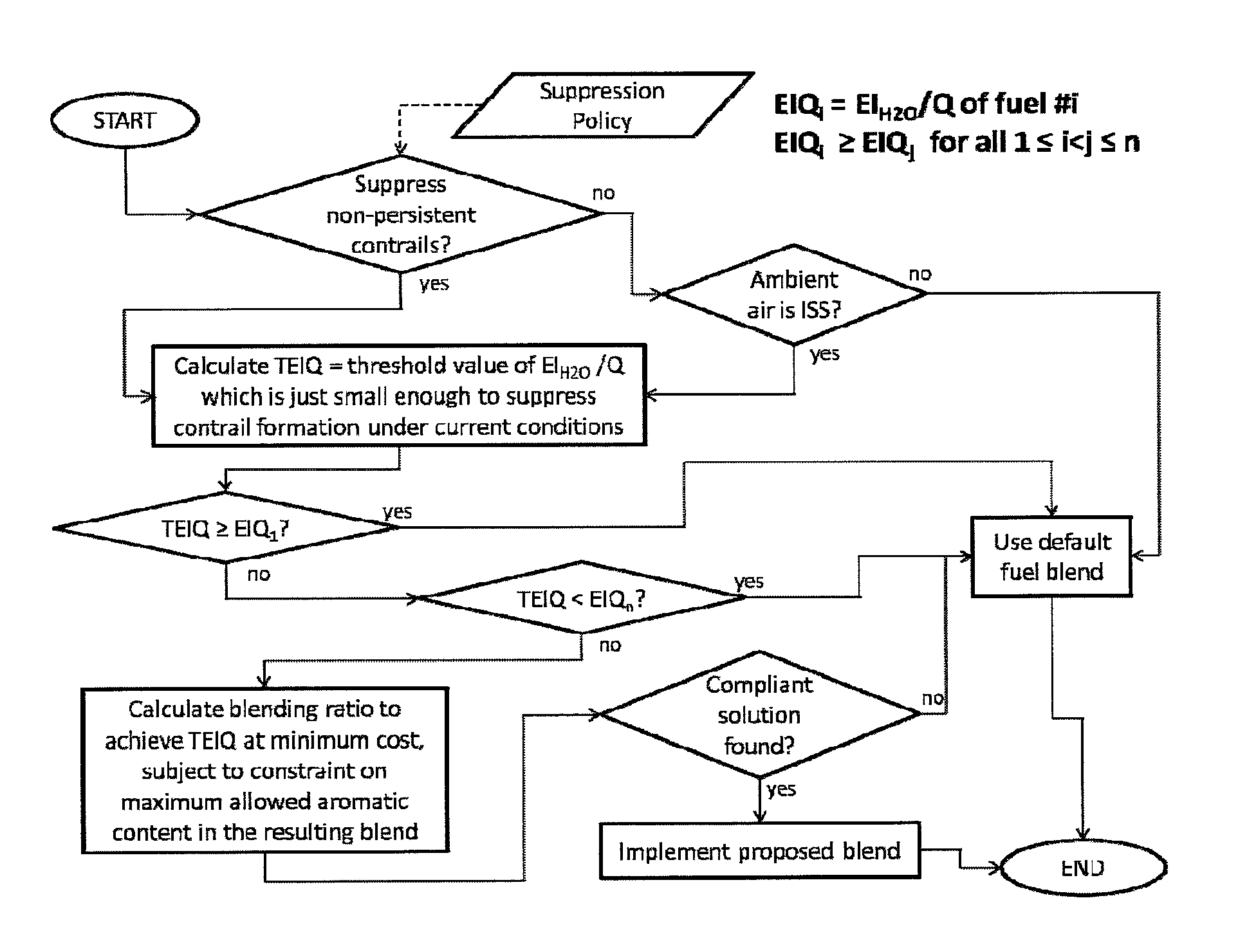

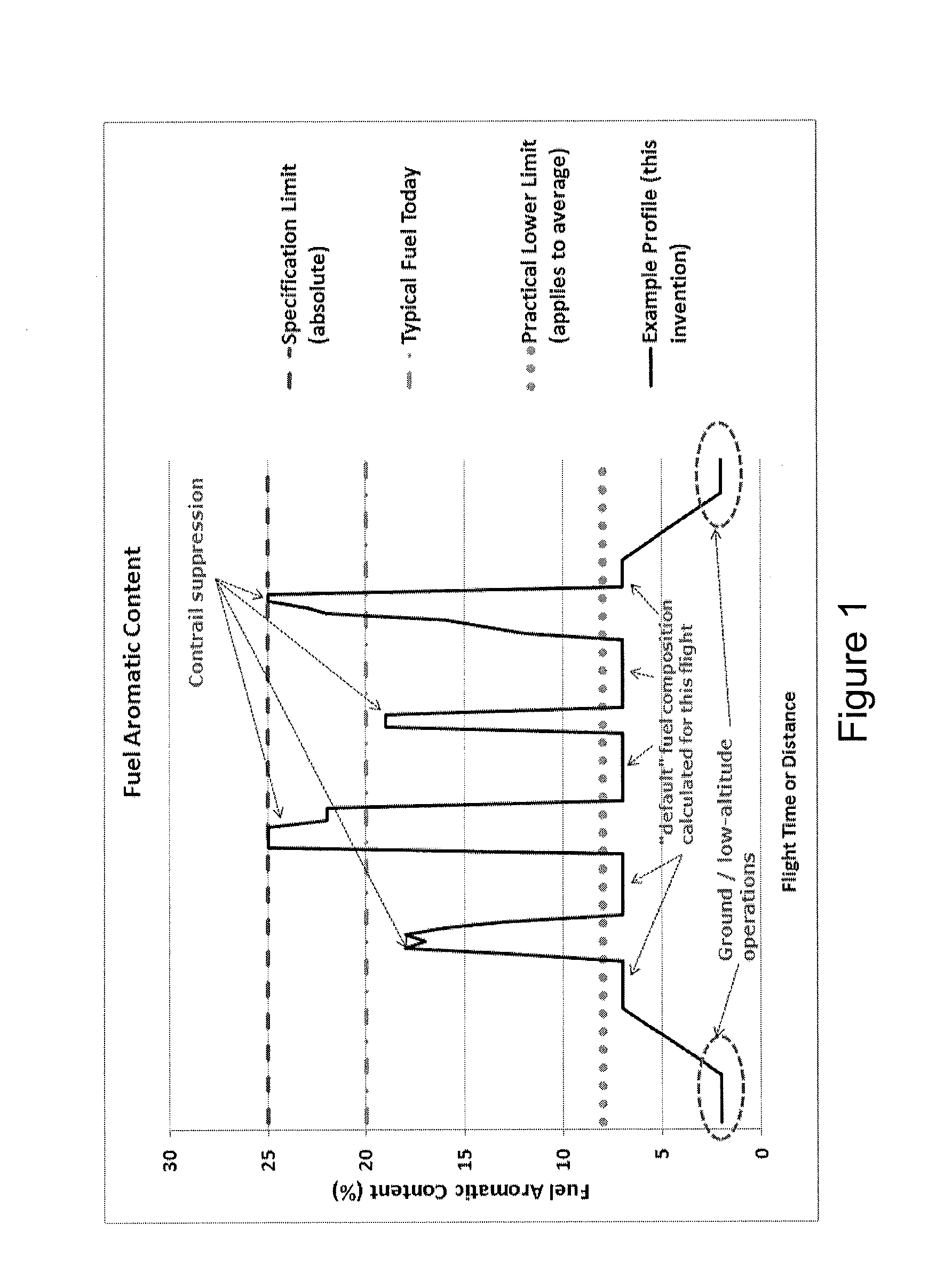

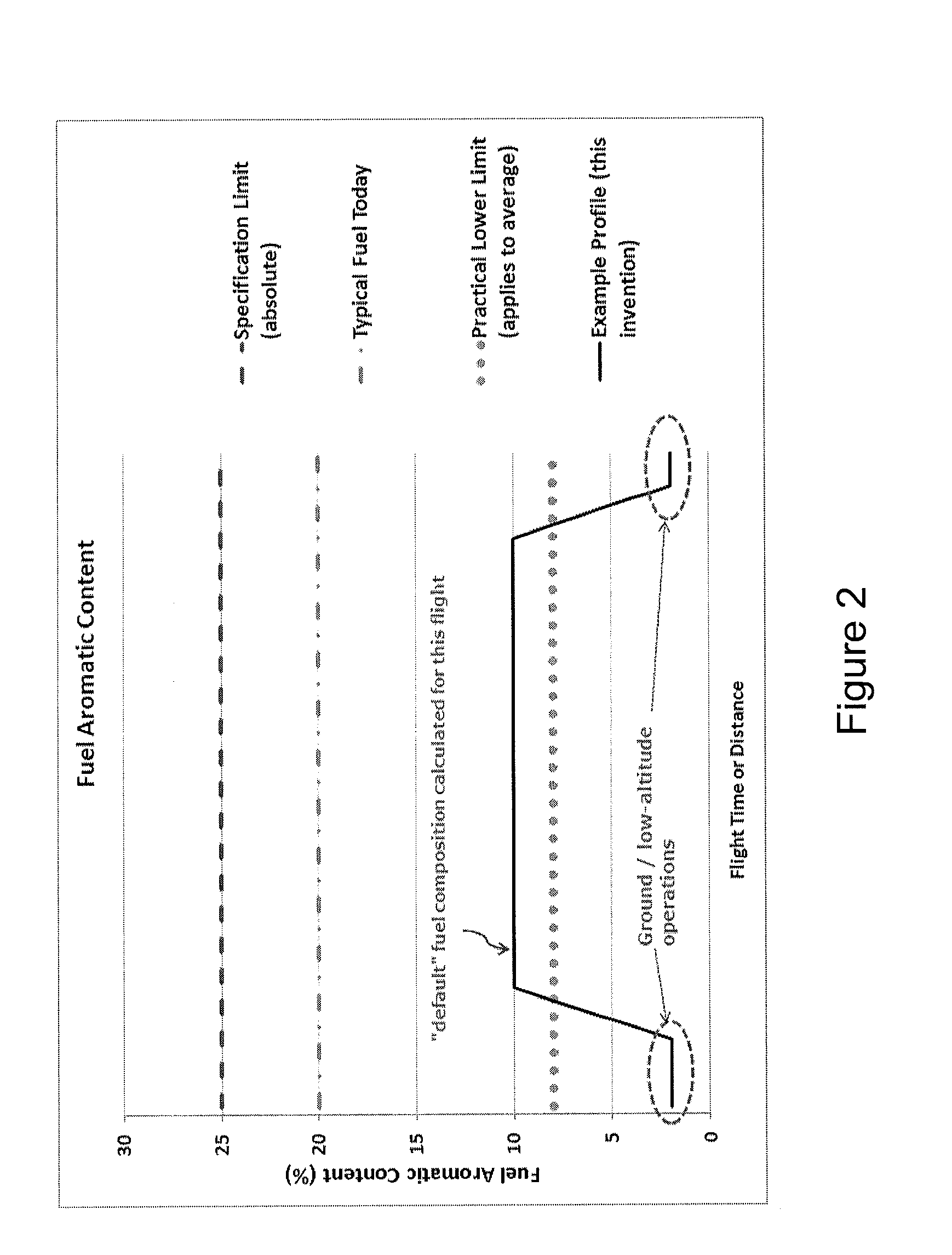

Aircraft engine fuel system

ActiveUS20150100220A1Optimising engine efficiencyNo additional benefitAnalogue computers for vehiclesEfficient propulsion technologiesCombustionEngineering

This invention concerns a method of delivering fuel to an aircraft engine 60, which involves providing a plurality of distinct fuel sources 20, 22, a first fuel source 20 comprising a first fuel having a first aromatic content and a second fuel source 22 comprising a second fuel having a second aromatic content. One or more ambient atmospheric condition is determined for at least a portion of a flight path of the aircraft, said condition being indicative of a likelihood of contrail 135 formation by the engine 60. A desirous fuel composition for combustion by the engine is determined based upon the one or more ambient atmospheric condition and a ratio of the first and second fuels from said respective fuel sources is selected according to said desirous fuel composition. The selected ratio of the first and second fuels is delivered to the aircraft engine 60.

Owner:ROLLS ROYCE PLC

Catalyst for deep desulfuration and octane number increase for gasoline and preparation and application methods thereof

ActiveCN102343276ATo achieve the purpose of deep desulfurizationHigh aromatic contentMolecular sieve catalystsHydrocarbon oils treatmentAlkaneReaction temperature

The invention discloses a catalyst for deep desulfuration and octane number increase for gasoline and preparation and application methods thereof. The functional catalyst comprises NiM / ZnO-ZSM-5. The preparation method comprises the steps of: firstly, synthesizing nanometer zinc oxide with high specific surface by using a low-temperature solid-phase method, then respectively steeping nickel and auxiliary metal, in the form of ions, onto the surface of the zinc oxide by using a steeping method, drying, roasting, and reducing in hydrogen to obtain a nanometer composite of the nickel, the auxiliary metal and the zinc oxide, wherein the nickel and the auxiliary metal are bonded in an alloy manner and uniformly disperse on crystalline phases of the zinc oxide. The catalyst has the reaction conditions that the reaction temperature is 350-450 DEG C, the pressure is 0.5-1.6MPa, the hydrogen-oil volume ratio is 100-300 and the air speed is 2<-10>h<-1>. By using the catalyst disclosed by the invention to treat straight-run gasoline, the deep desulfuration and the aromatization of alkane and olefin are performed at the same time, so that the octane number of a product gasoline is obviously increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

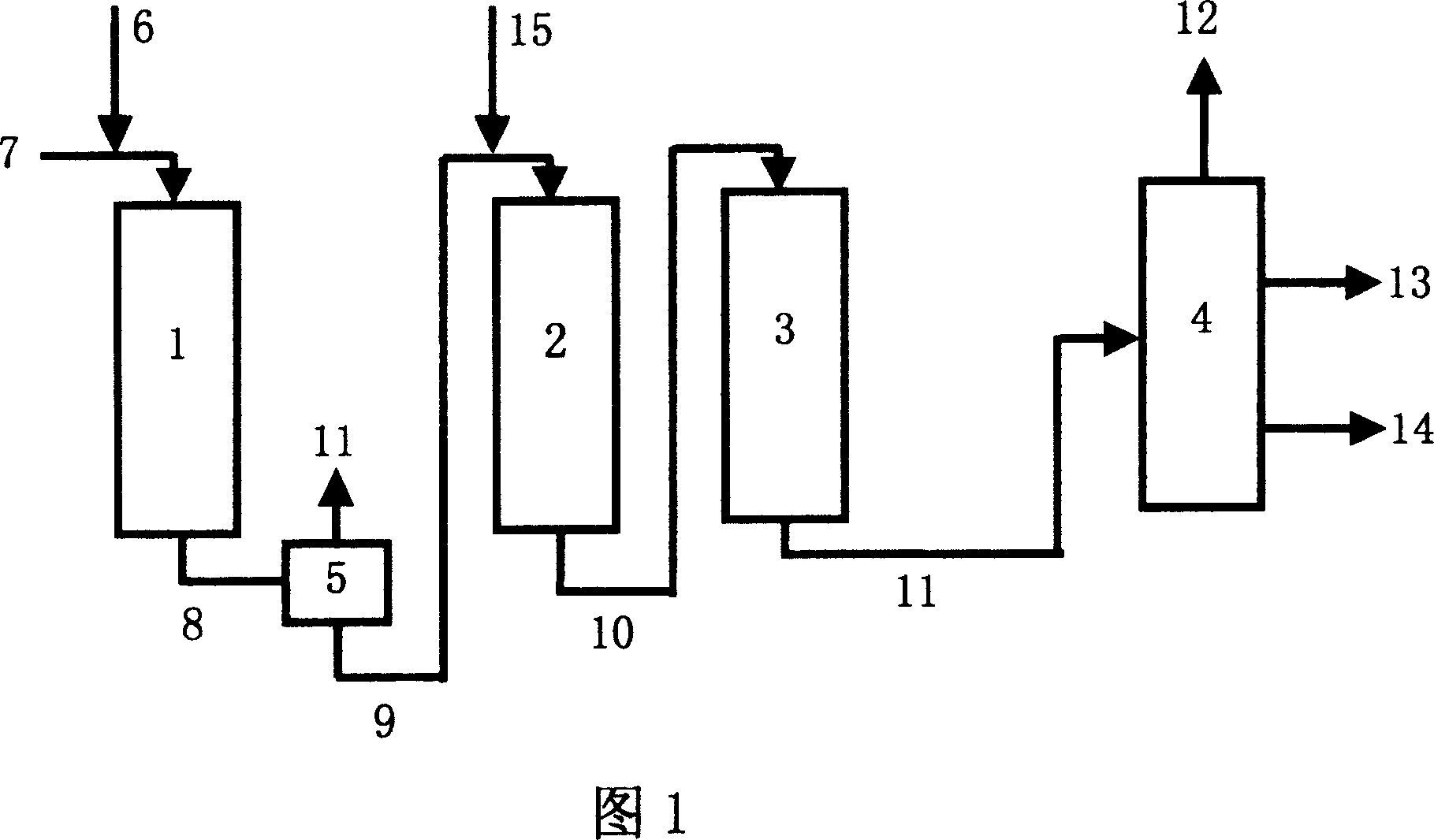

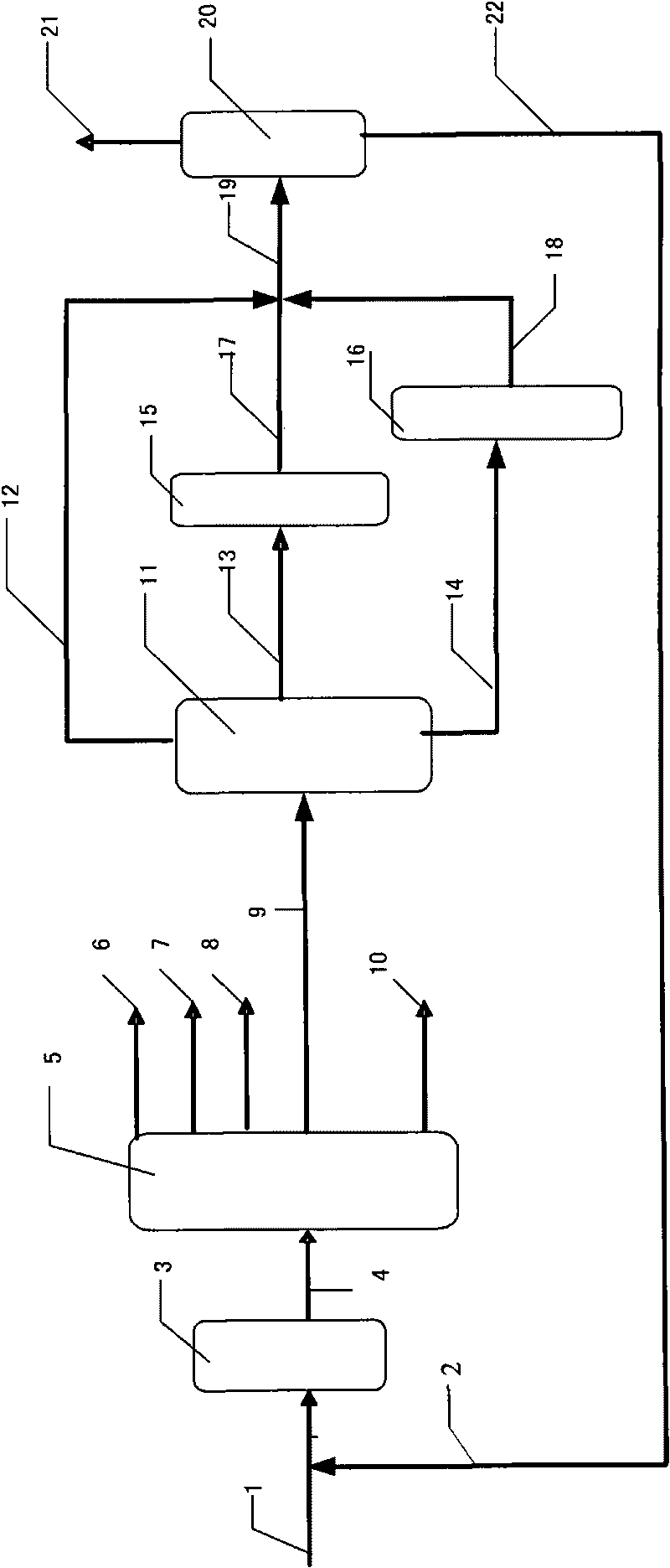

Hydrotreatment and catalytic cracking combined method for residuum

InactiveCN102732314AHigh aromatic contentHigh content of impurities such as sulfurTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of a catalytically cracked diesel fraction undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked recycle oil and catalytically cracked slurry are separated out; a part or all of the catalytically cracked diesel fraction is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction; and the catalytically cracked recycle oil is fed back to the catalytic cracking device and then undergoes a catalytic cracking reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

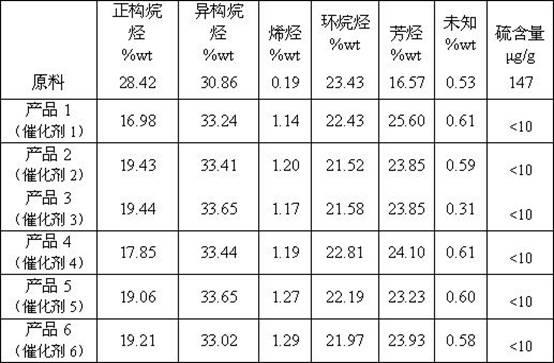

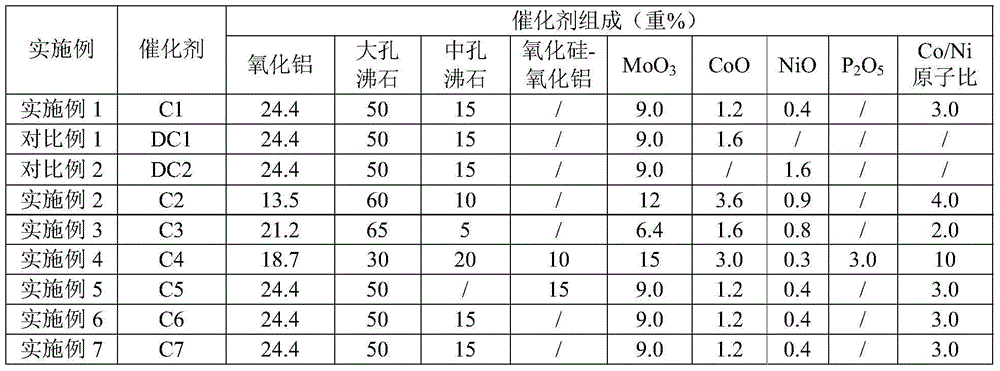

Hydrocracking catalyst and preparation method thereof, and hydrocracking reaction method

ActiveCN105413741AOvercome the defect of easy carbon deposition and deactivationEasy to deposit carbonMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveCobalt atom

The present invention provides a hydrocracking catalyst and a preparation method thereof, and a hydrocracking reaction method. The hydrocracking catalyst comprises a carrier and active components loaded on the carrier, wherein the active components comprise three components such as molybdenum, cobalt and nickel, the molybdenum content is 3-20 wt%, the cobalt content is 0.5-5 wt% and the nickel content is 0.1-1.5 wt% by adopting the total weight of the hydrocracking catalyst as the reference (calculated as the oxide), a molar ratio of cobalt atoms to nickel atoms in the active components is 1-10:1, the carrier contains a solid acid component and an inorganic heat-resistant oxide, and the solid acid component comprises at least two components selected from amorphous silicon-aluminum, a macroporous zeolite molecular sieve and a mesoporous zeolite molecular sieve. The hydrocracking catalyst of the present invention does not easily produce carbon deposition, can obtain the hydrocracking product having the high aromatic hydrocarbon content, and has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

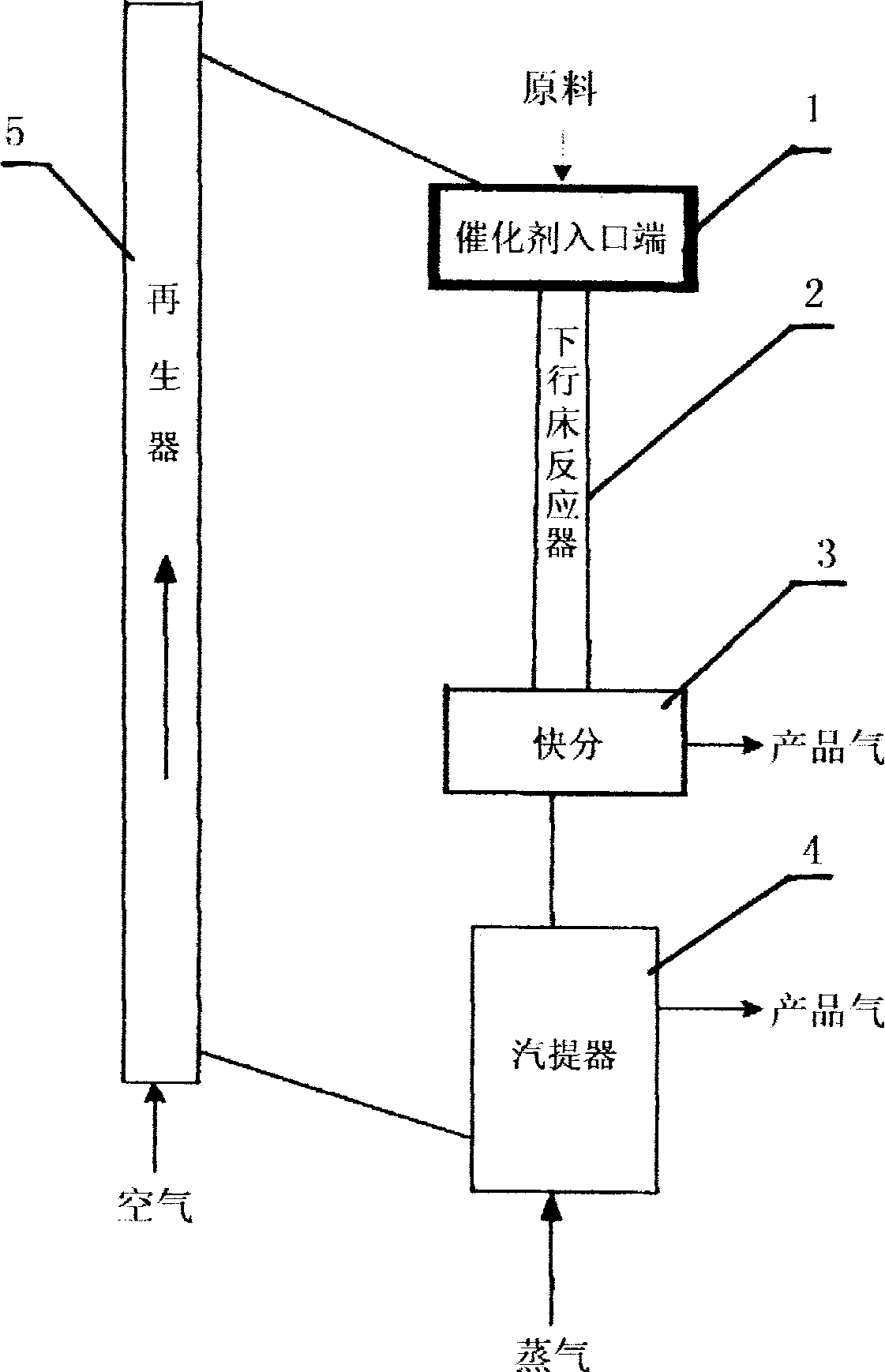

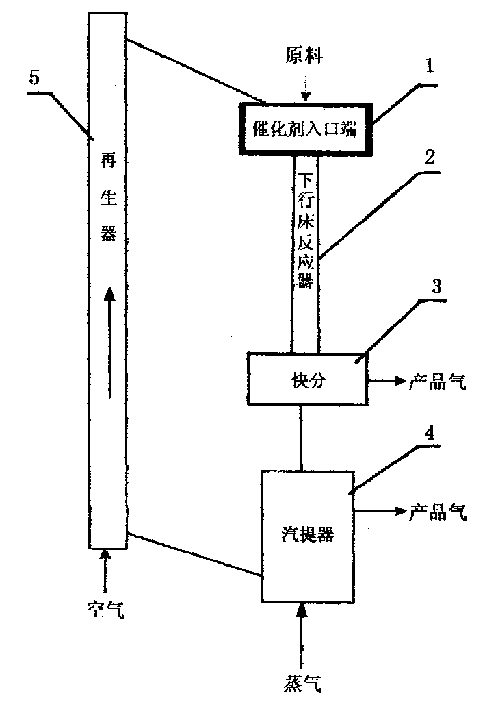

Process for catalytic thermocracking of bydrocarbon by descending-bed reactor

A process for catalytic cracking of hydrocarbons by descending-bed reactor features that the crude oil takes part in catalytic thermocracking reaction under the action of high temp and catalyst to obtain the gas prdouct whose main component is light olefine (ethylene, propylene and butylene) and the liquid product rich in arylhydrocarbon. Its advantages are high output rate of light hydrocarbons, thorough suppression to by-products (methane and coke), and easy control.

Owner:TSINGHUA UNIV

Wax-resin surface polishes

InactiveUS6258882B1Easy to useLow of applicationNon-fibrous pulp additionPaper coatingAcrylic resinAliphatic hydrocarbon

Polish formulations are provided which comprise:a) an aliphatic hydrocarbon solvent comprising 0-10% aromatic hydrocarbons;b) an acrylic resin; andc) a wax product that is thermoplastic, transparent, a solid at room temperature and has a melting / softening point of about 60° to about 90° C.; wherein wt:wt ratio of said acrylic resin and wax is about 1:3 to about 1:8 and the wt:wt ratio of said resin and wax to said solvent is about 1:1 to about 1:9. The formulations function as surface polishes that can be used on any hard surface including wood, metal, stone, and other non-porous surfaces.

Owner:SMITHSONIAN INSTION THE

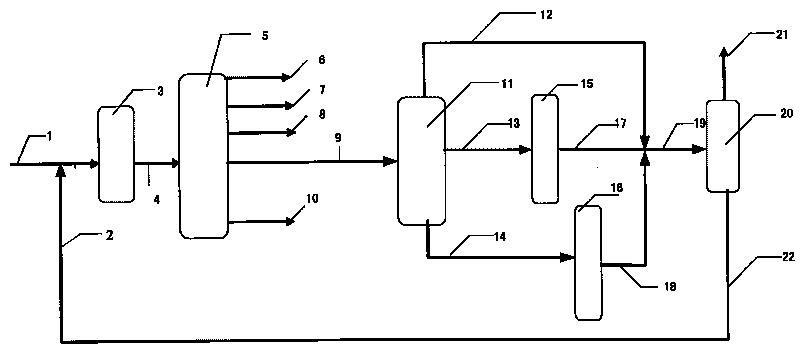

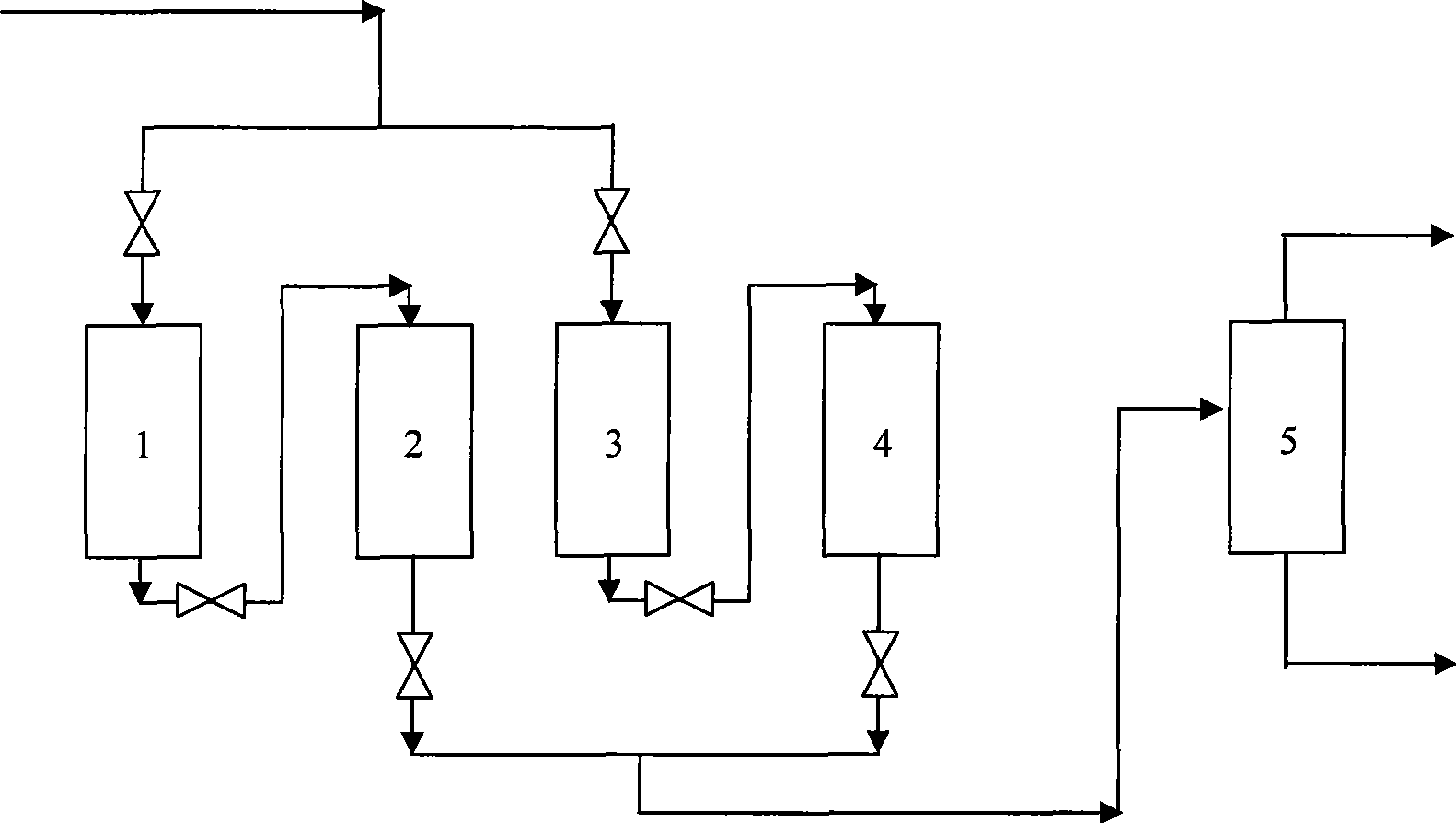

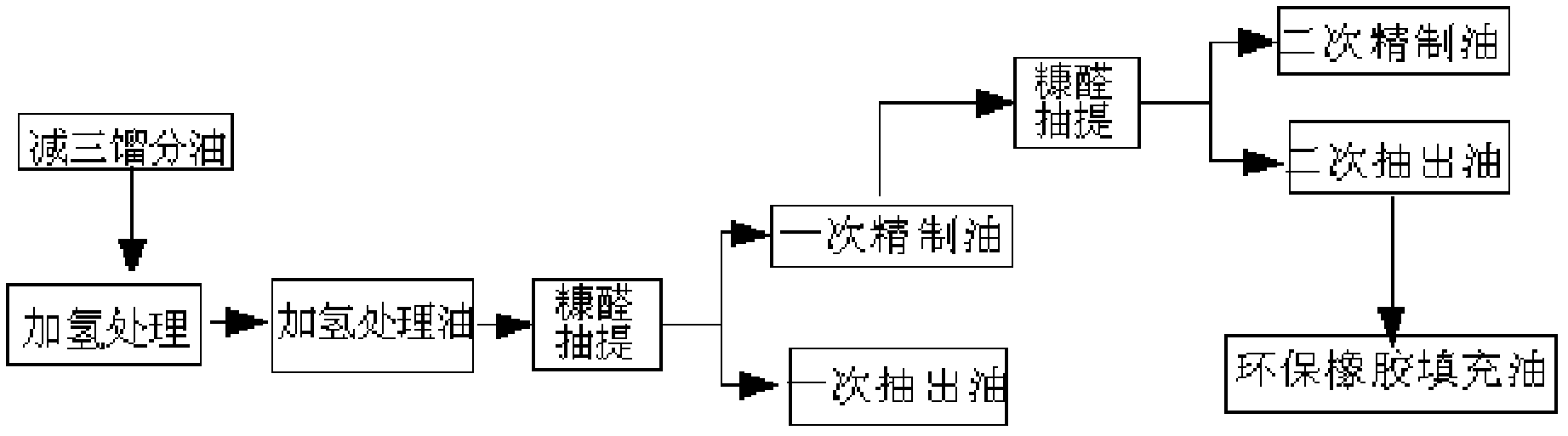

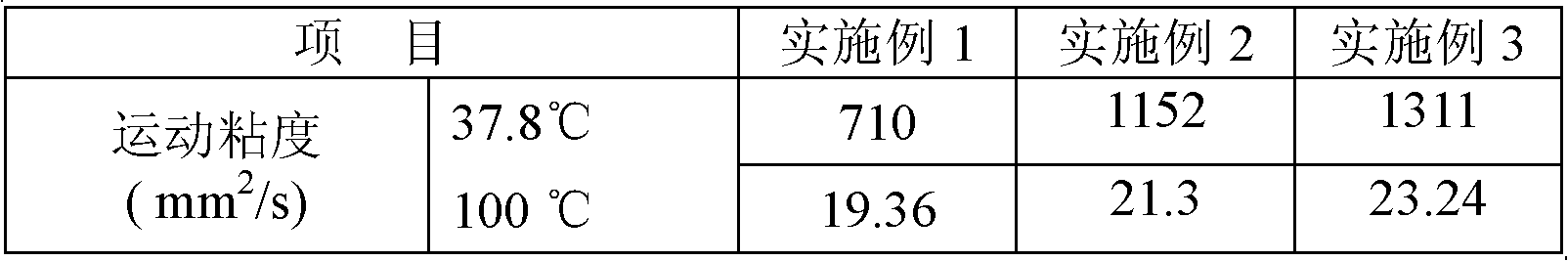

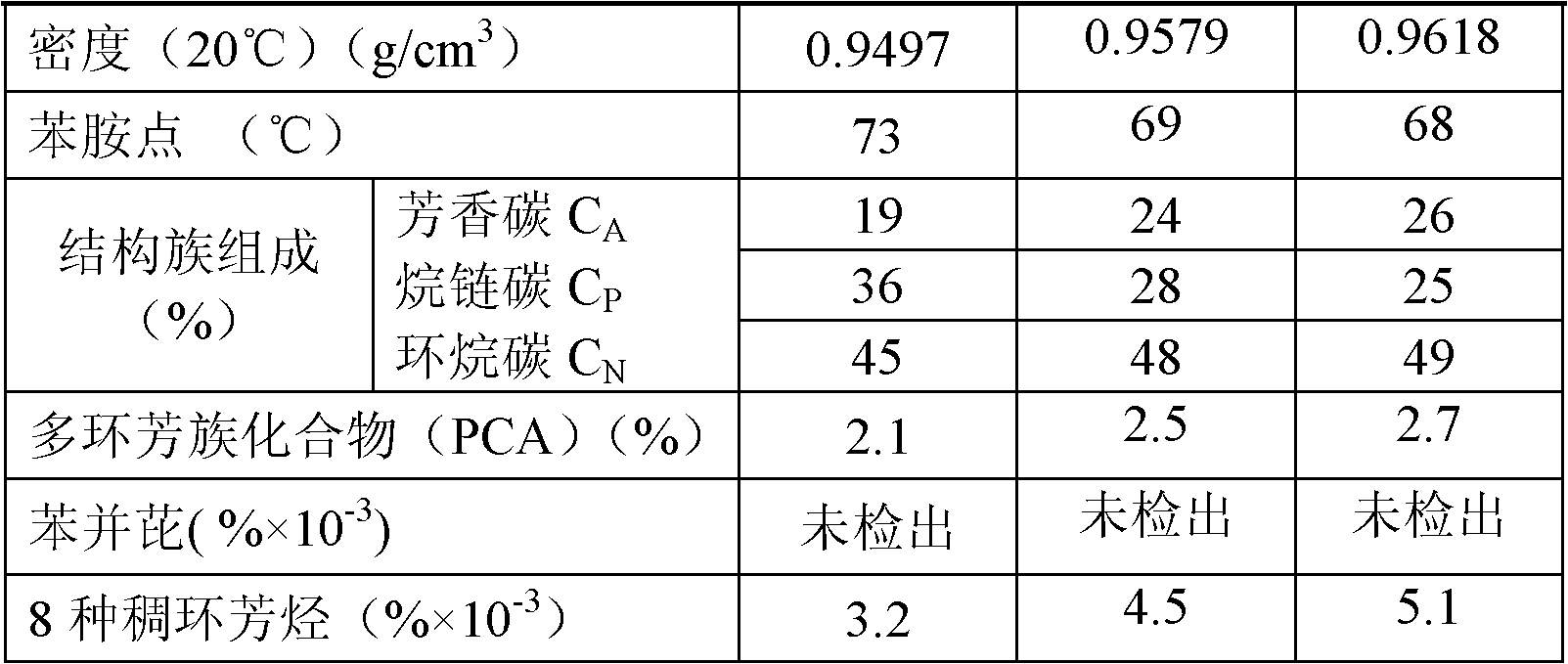

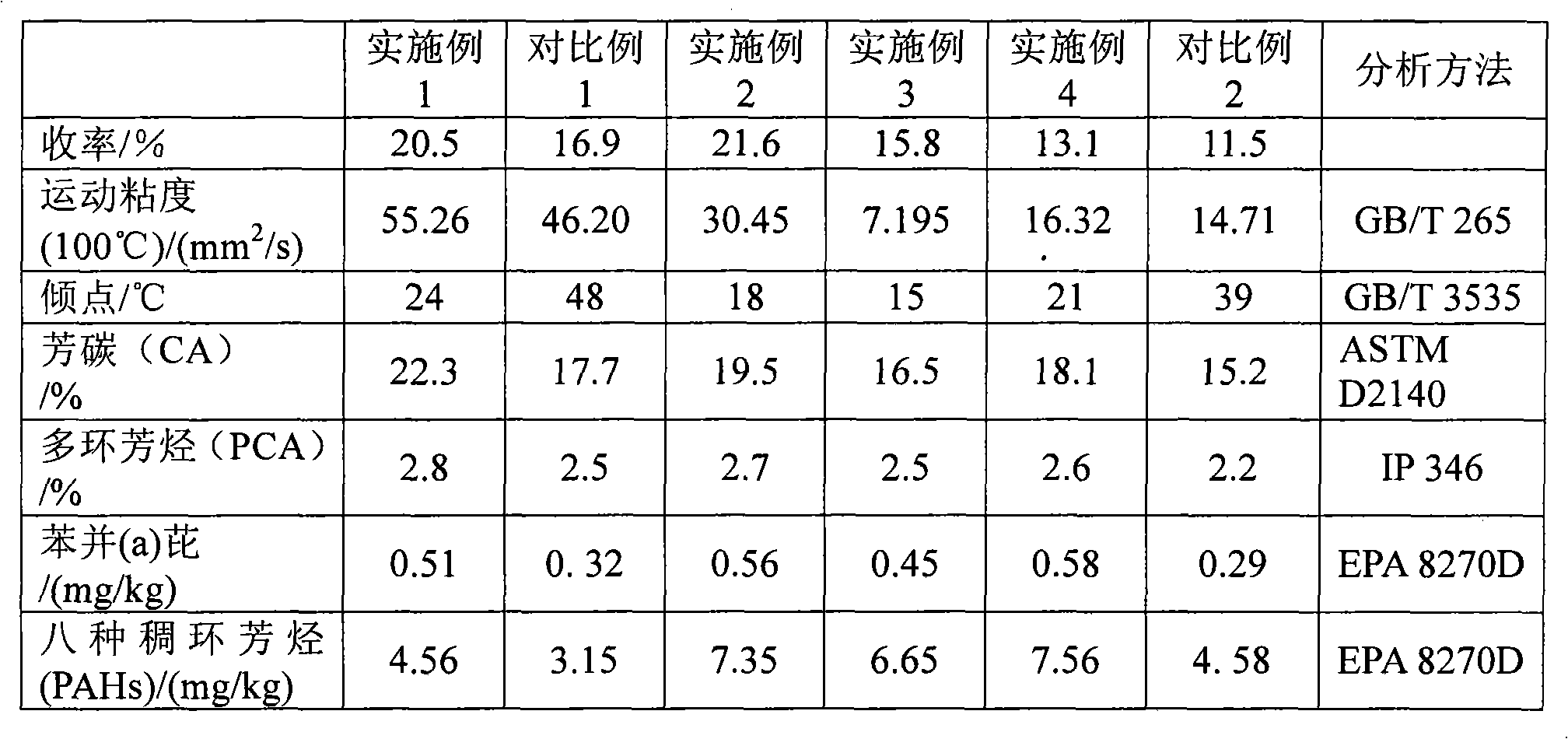

Environmental-friendly rubber filling oil and preparation method thereof

InactiveCN102604674AHigh aromatic contentImprove wet skid resistanceTreatment with hydrotreatment processesTowerAromatic hydrocarbon

The invention discloses environmental-friendly rubber filling oil and a preparation method thereof. The method comprises the following steps of: (1) hydrotreating a vacuum cut 3 distillate to obtain hydrotreating oil; (2) extracting the hydrotreating oil in an extraction tower for the first time to obtain raffinate at the tower top of the extraction tower, and recycling a solvent to obtain primary refined oil; preparing extract at the tower bottom of the extraction tower, and recycling the solvent to obtain primary extract oil; (3) extracting the primary refined oil into the extraction tower for the second time to obtain the raffinate at the tower top of the extraction tower, and recycling the solvent to obtain secondary refined oil; preparing extract at the tower bottom of the extraction tower, and recycling the solvent to obtain secondary extract oil, that is to say, environmental-friendly rubber filling oil. The environmental-friendly rubber filling oil, provided by the invention, has the advantages of high aromatic hydrocarbon content, good compatibility with the rubber and excellent processing performance, the mass percentage composition of the aromatic hydrocarbon reaches 19-26%, the environmental-friendly rubber filling oil can be used in a tire manufacturing process, and excellent performances such as good wet traction and the like can be given.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS7033484B2Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationEngineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Catalyst for direct synthesis of arene by synthesis gas and production method and use thereof

InactiveCN101422743BSuitable for aciditySimple processHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveAromatization

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

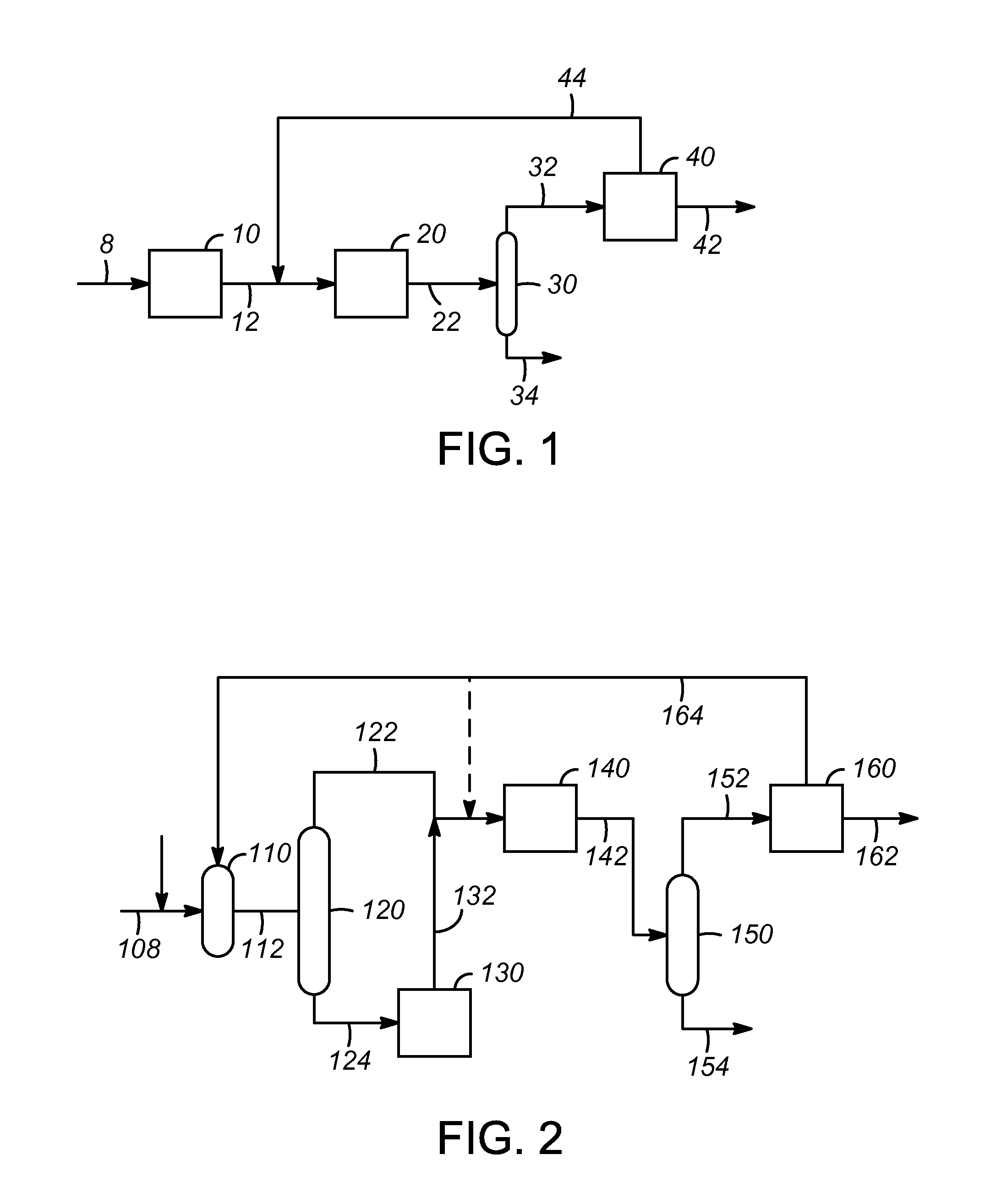

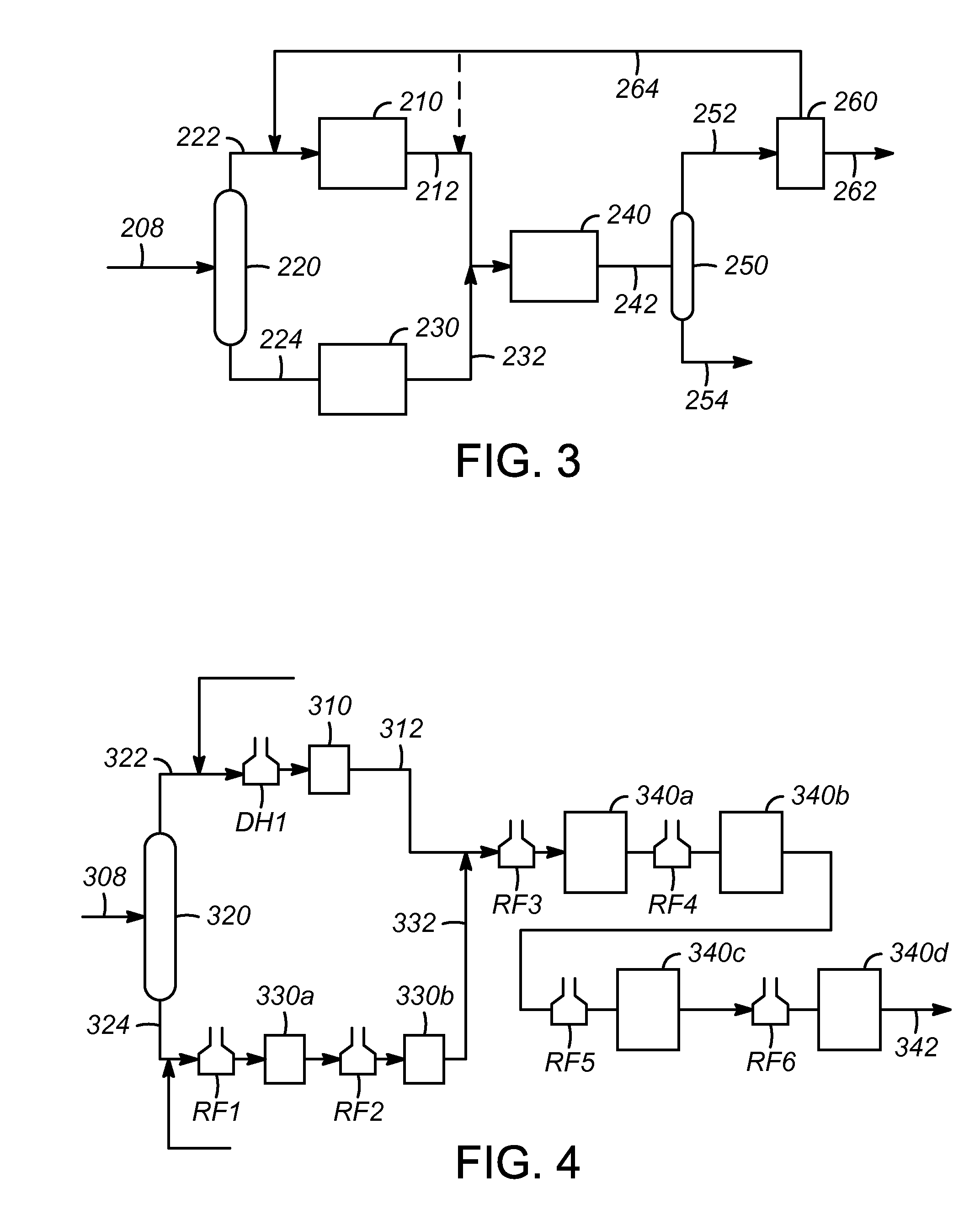

Initial hydrotreating of naphthenes with subsequent high temperature reforming

InactiveUS20130158320A1Reduce energy loadHigh aromatic contentHydrocarbon by dehydrogenationHydrocarbonsCycloparaffinsHydrocarbon

A process for the production of aromatics through the reforming of a hydrocarbon stream is presented. The process utilizes the differences in properties of components within the hydrocarbon stream to increase the energy efficiency. The differences in the reactions of different hydrocarbon components in the conversion to aromatics allows for different treatments of the different components to reduce the energy used in reforming process.

Owner:UOP LLC

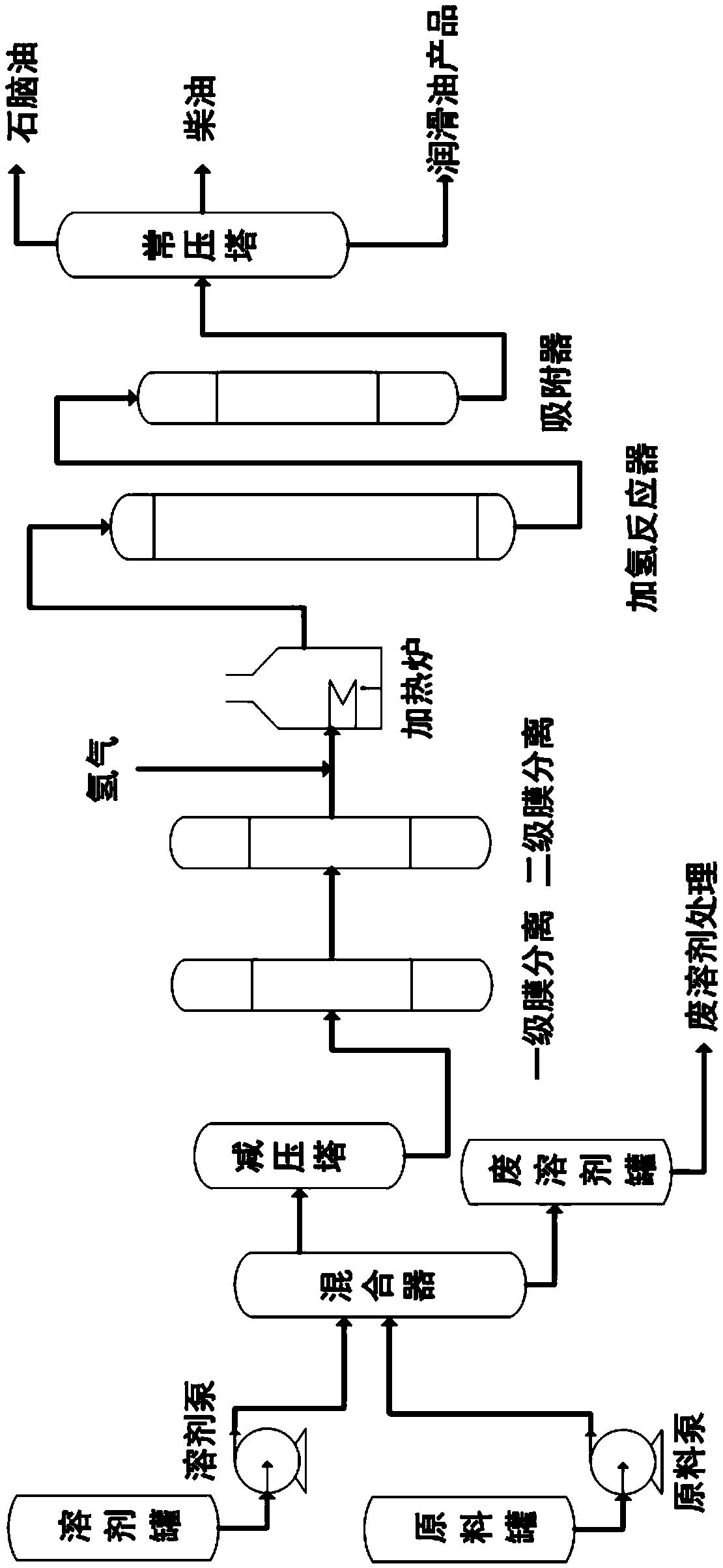

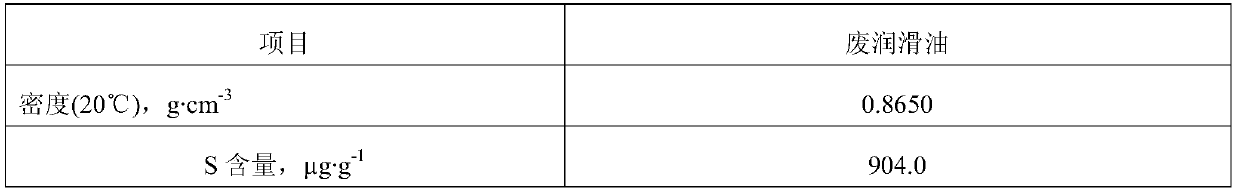

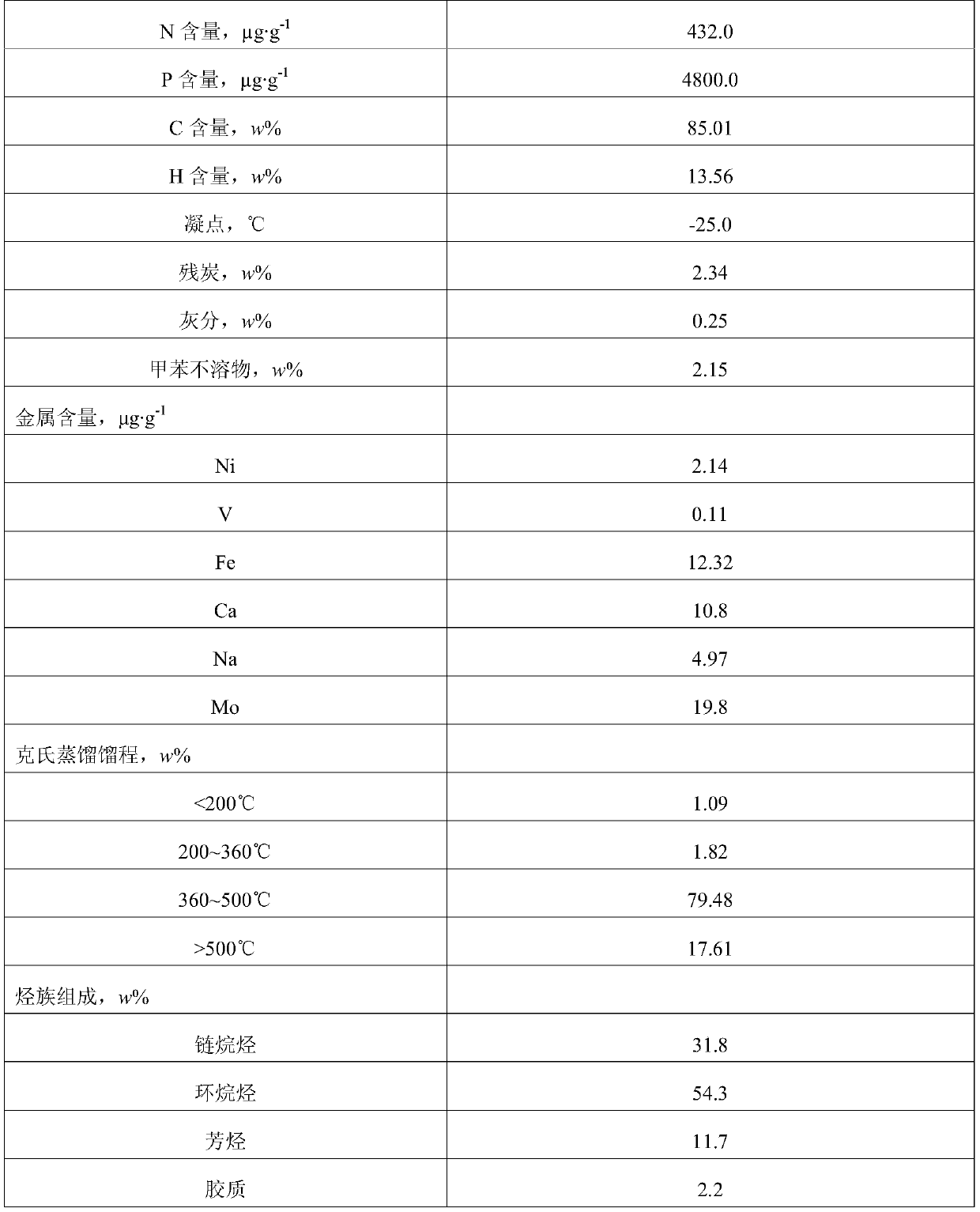

Method for carrying out regeneration treatment on useless lubricating oil

InactiveCN105505550AIncrease profitModerate ConditionsTreatment with hydrotreatment processesLubricant compositionSolventChemistry

The invention discloses a method for carrying out regeneration treatment on useless lubricating oil, and belongs to the technical field of an oil product quality improving technological process in a petroleum processing technology. The method comprises a solvent treatment step, a membrane separation step, a hydrogenation modification step, an adsorption, supplementation and purification step and a normal-pressure fractionation step. According to the method disclosed by the invention, most of metal and polar additives can be removed by adopting a solvent treatment method and a membrane separation method, aromatic hydrocarbon, heteroatoms, undissolved matters and most of residual carbon and residual metal can be removed through the hydrogenation modification step of a stationary bed, and residual polar additives can be further removed through the adsorption, supplementation and purification step, so that the light stability and the thermal stability of a product are increased, high-quality lubricating oil base oil can be produced, and byproducts of high-quality naphtha and high-quality diesel can be produced.

Owner:台州天天环保科技有限公司 +1

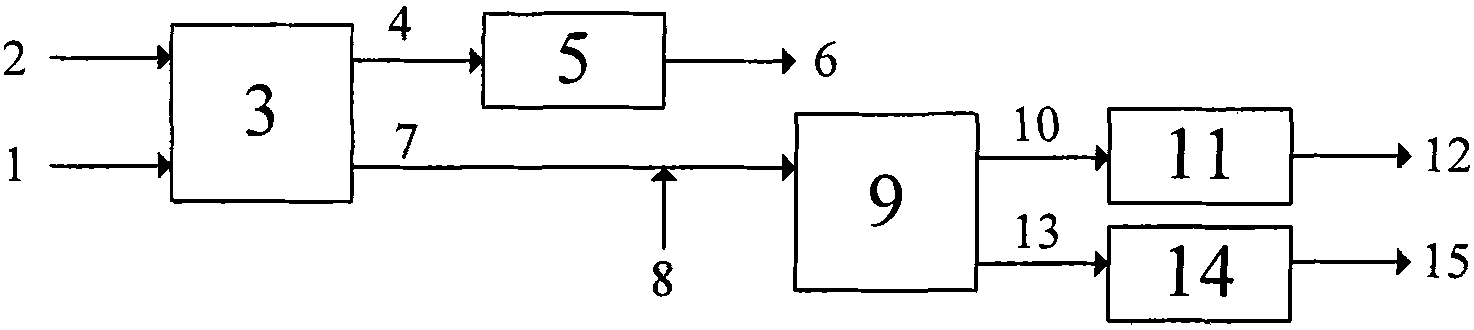

Method for preparing aromatic rubber oil

ActiveCN102311776ALow pour pointHigh aromatic contentTreatment with plural serial refining stagesSolvent refiningMass content

The invention discloses a method for preparing aromatic rubber oil, which comprises: fully contacting raw material oil and an extract solvent to obtain first extract ad first raffinate, wherein the raw material oil is solvent refining extract oil, the extract solvent mainly comprises a primary solvent and a first counter solvent, and the primary solvent content in the extract solvent is higher than the content of first counter solvent in the extract solvent; fully contacting the first extract with a second counter solvent to obtain second raffinate and second extract; and recovering second raffinate from the second raffinate to obtain the aromatic rubber oil. The total content of eight polycyclic aromatic hydrocarbons (PAHs) in the aromatic rubber oil prepared by the method provided by the invention is low and meets the requirement of 2005 / 69 / EC instruction of the European Union, the mass content of polycyclic aromatic hydrocarbon (PCA) is less than 3 percent, and because of the low saturated hydrocarbon content, the pour point of the aromatic rubber oil is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

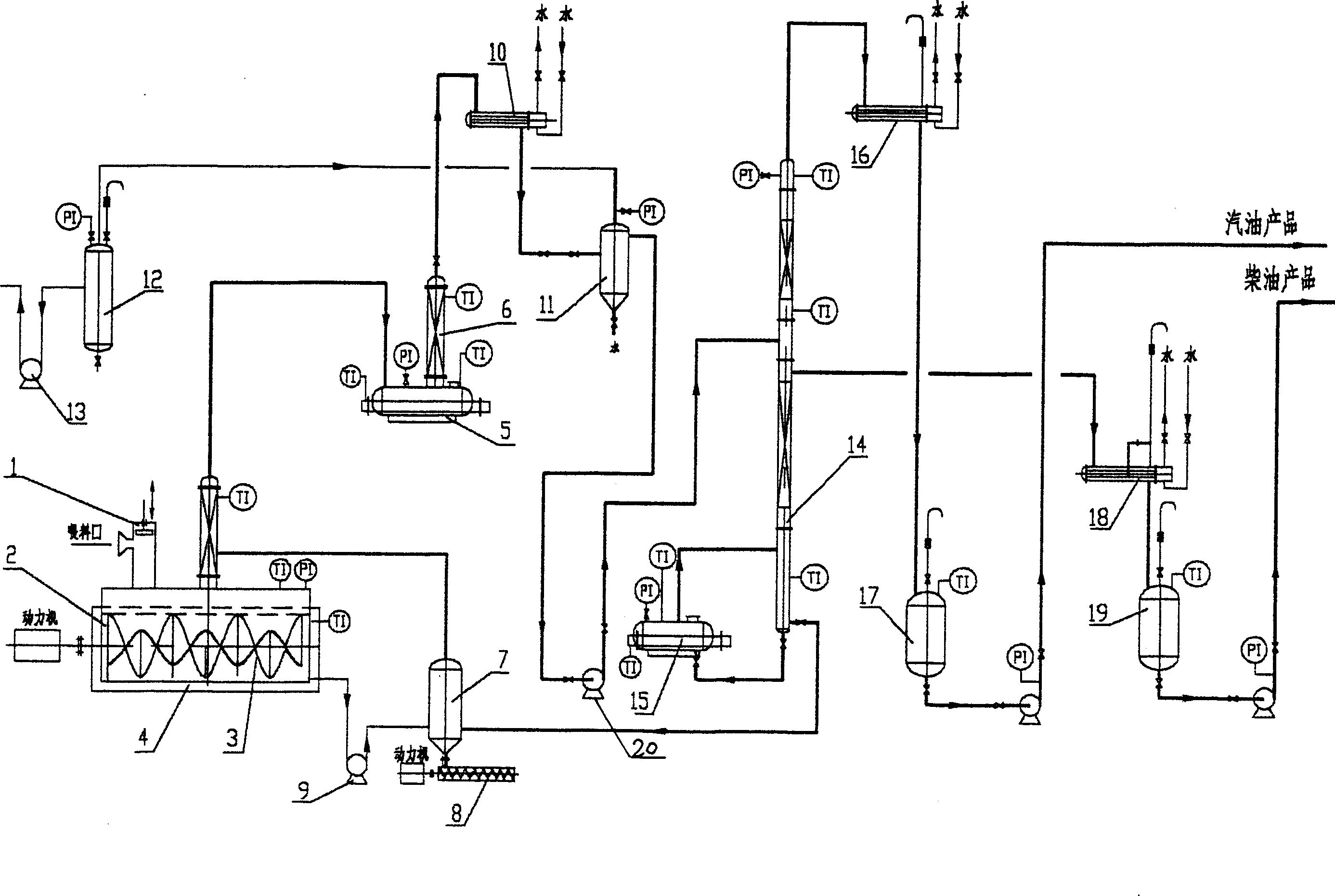

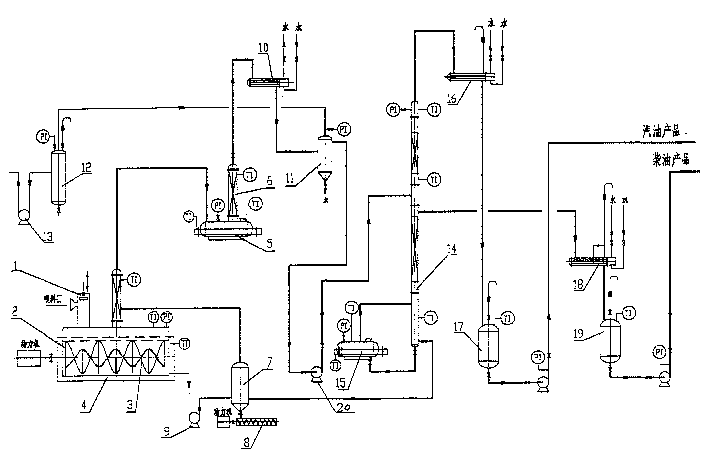

Industrial method of reusing waste plastics to produce gasoline and diesel oil

The present invention is industrial method of reusing waste plastics to produce gasoline and diesel oil. Waste plastics including polyethylene, polypropylene and polystyrene in certain proportion are mixed and heated to liquefy and crack inside one reactor with double-screw stirrer inside it and molten salt inside sandwiched layer as heat conducting medium; the produced material is viscosity reducing cracked and the cracked gas is condensated into liquid fed to rectifying tower; molten plastic liquid is pumped from the reactor into one solid-liquid separator with separating molten salt liquid to separate residue and dirt; clean molten plastic is returned to the reactor while the separated residue and dirt is exhausted via screw extruder in the bottom of the separator; and decompression distillation is performed to produce oil. The present invention can produce oil with high quality in low cost and high conversion rate while tackling white pollution.

Owner:北京斯泰普文投资顾问有限公司

Molecular Sieve With Mfi Structure Containing Phosphorus and Metal Components, Preparation Process and Use Thereof

ActiveUS20070275852A1Increase productionHigh selectivityAluminium compoundsCatalytic crackingMolecular sieveActive component

A MFI-structured molecular sieve containing phosphorus and metal components has a formula expressed in anhydrous form and on the basis of oxide weight, as follows: (0˜0.3) Na2O (0.5˜5.5) Al2O3 (1.3˜10) P2O5 (0.7˜15) MlxOy (0.01˜5) M2mOn (70˜97) SiO2, wherein M1 is one of transition metals selected from the group consisting of Fe, Co and Ni, and M2 is any one of metals selected from the group consisting of Zn, Mn, Ga and Sn. Preparation processes and uses of the instant molecular sieve are also provided. The molecular sieve has an excellent performance for increasing the yield of lower olefins and increasing the aromatics content in gasoline, and can be used as a shape-selective active component for the catalytic cracking catalyst of petroleum hydrocarbons or its additives.

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

Method for reducing sulfur content in gasoline

ActiveCN103074106AHigh olefin contentReduce olefin contentTreatment with hydrotreatment processesCatalytic reformingHydrodesulfurization

The invention provides a method for reducing sulfur content in gasoline. According to the invention, full-fraction gasoline is fractionated to obtain a light gasoline fraction, an intermediate gasoline fraction and a heavy gasoline fraction, wherein the light gasoline fraction is subjected to alkali washing and refining so as to remove mercaptan sulfur therein, the intermediate gasoline fraction enters into a first hydrogenation unit for catalytic reforming so as to obtain a reformed intermediate gasoline fraction with an increased octane number, the heavy gasoline fraction enters into a second hydrogenation unit and contacts with a selective hydrodesulfurization catalyst for selective hydrodesulfurization, and the refined light gasoline fraction, the reformed intermediate gasoline fraction and the hydrogenated heavy gasoline fraction are mixed to obtain a full-fraction gasoline fraction with ultra low content of sulfur. The obtained full-fraction gasoline product has total sulfur content of less than 10 mu g / g, and compared with a full-fraction gasoline raw material, loss of the octane number ROC of the full-fraction gasoline product is less than 1.0 unit.

Owner:CHINA PETROLEUM & CHEM CORP +1

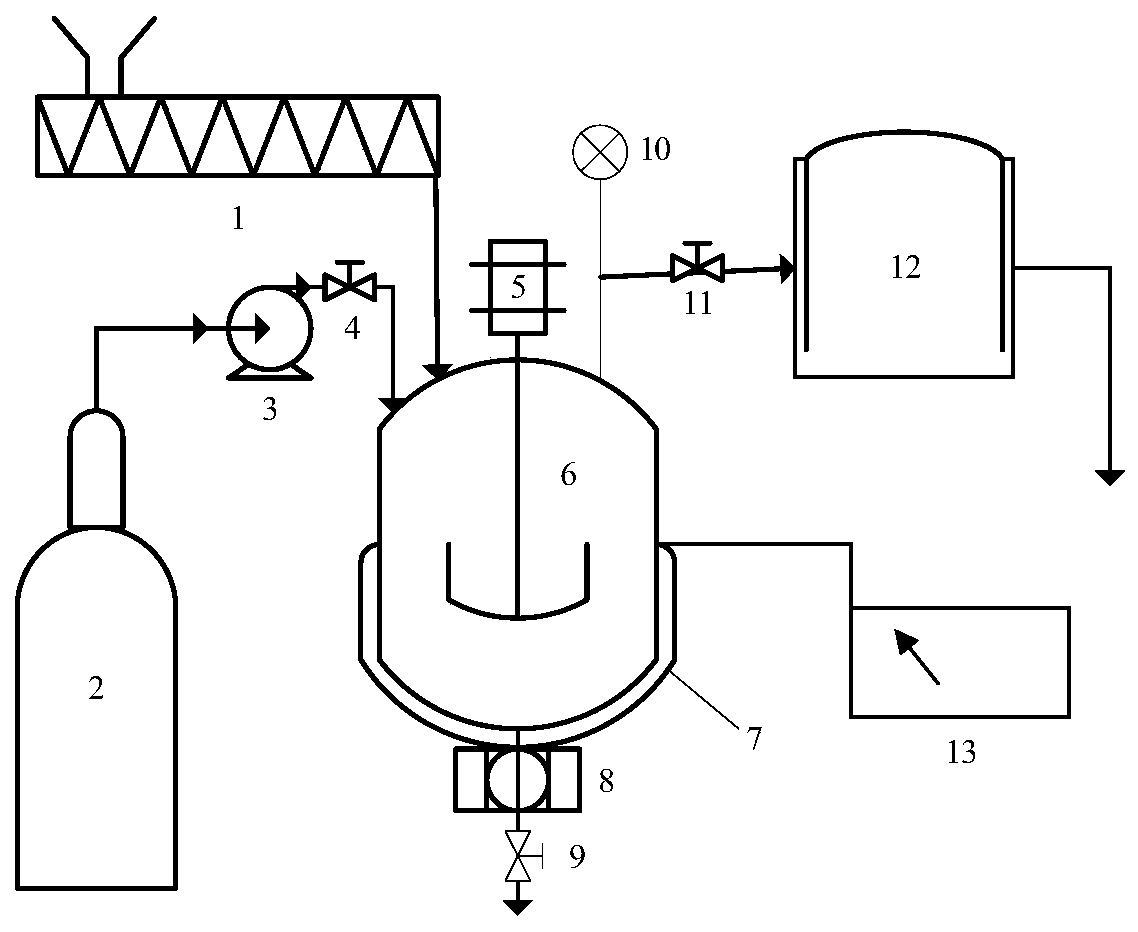

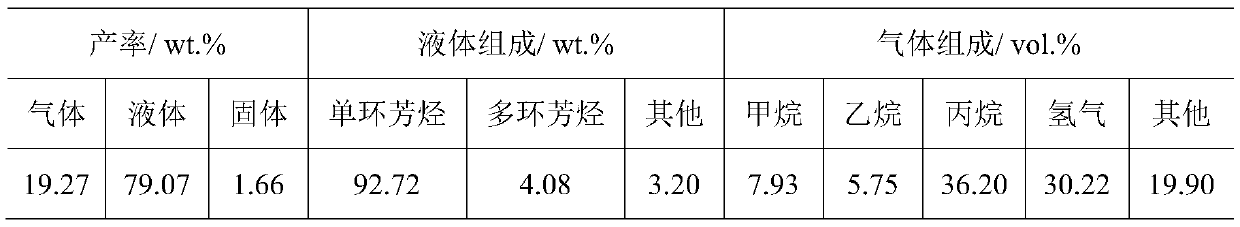

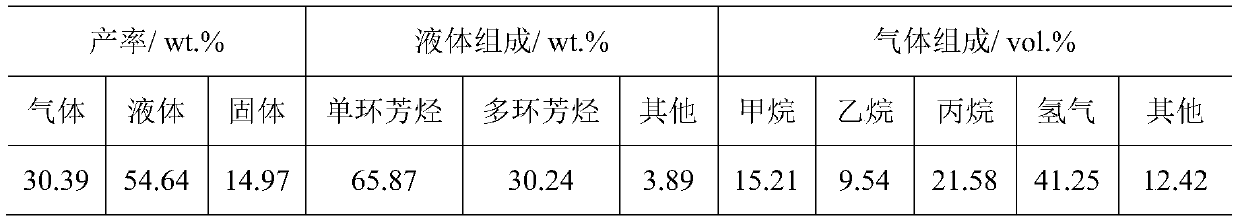

Method for preparing aromatic hydrocarbon and hydrogen-rich fuel gas through catalytic thermal conversion of polyolefin waste plastics

The invention discloses a method for preparing aromatic hydrocarbon and hydrogen-rich fuel gas through catalytic thermal conversion of polyolefin waste plastics. The method comprises: feeding pretreated polyolefin waste plastics into a reaction container, and using a metal-loaded zeolite molecular sieve as a catalyst, wherein a mass ratio of the polyolefin waste plastics to the catalyst is 5-30:1;introducing nitrogen into the reaction container; after the initial nitrogen pressure in the reaction container reaches 1-30 bar, maintaining the reaction system closed, heating the reaction container to 320-500 DEG C, stopping the heating, and collecting a gas product and a solid-liquid product in the reaction container after the reaction container is cooled to a normal temperature, wherein thegas product is collected through a gas collecting tank, the solid-liquid product passes through a filter to collect the catalyst and the residue of the reaction raw material, and the obtained liquid product is further treated. According to the invention, the aromatic hydrocarbon compound is directionally prepared through catalytic thermal conversion by using the polyolefin waste plastics as the raw material, and is used as a chemical raw material for production processing, so that the method is an effective waste plastic resource utilization method.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com