Method for reducing sulfur content in gasoline

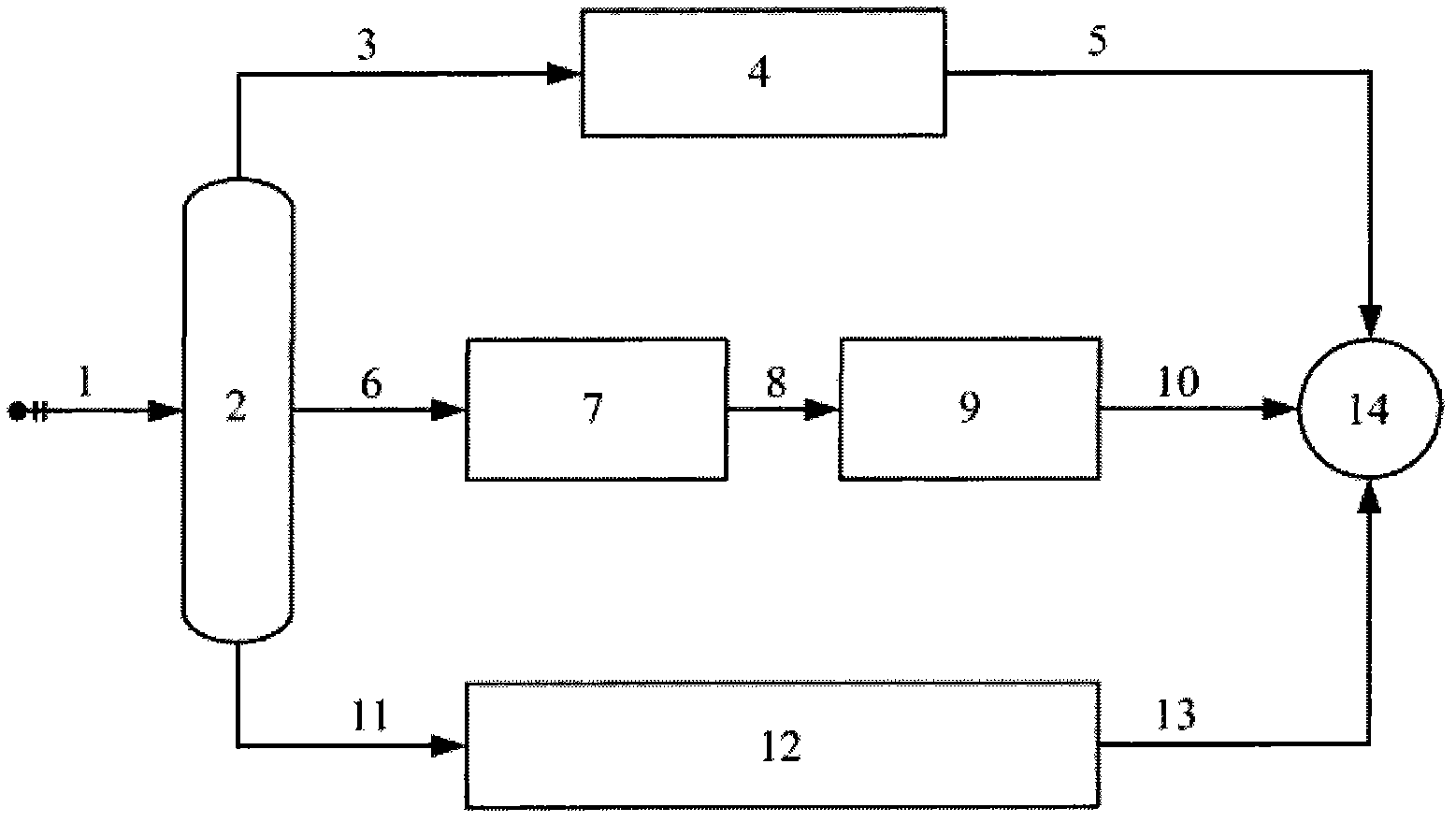

A technology for sulfur content and gasoline, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of large loss of octane number and low yield, and achieve small loss of octane number, reduced olefin content, The effect of reducing octane loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

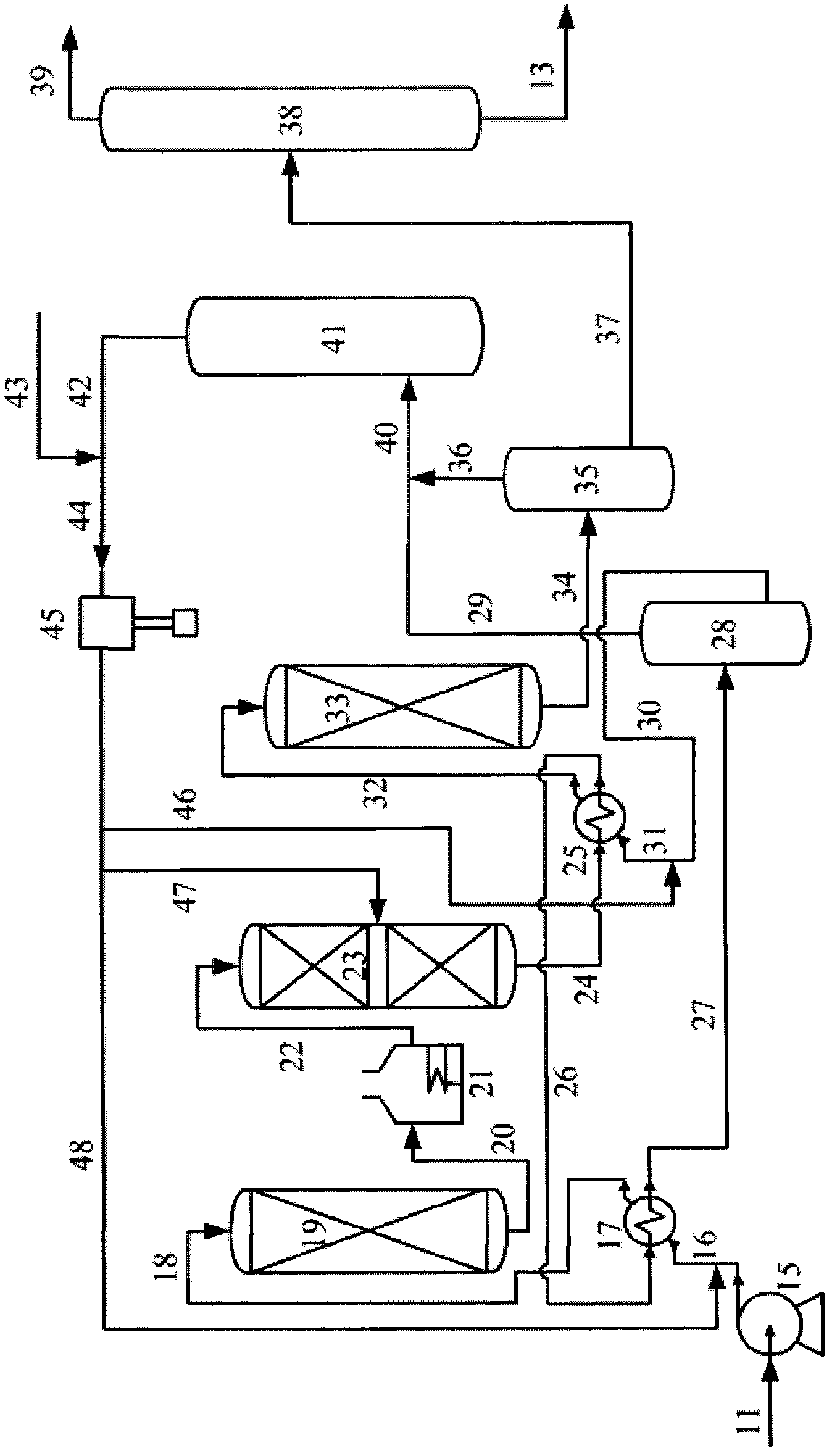

[0065] In this example, the same raw material oil A as that in Comparative Example 1 was used, and the raw material oil A was cut into three fractions at 60°C and 120°C as cut points, and the obtained light gasoline fraction, intermediate gasoline fraction and heavy gasoline fraction accounted for 30.0% of the raw material respectively. % by weight, 30.0% by weight and 40.0% by weight. The distillate of light gasoline is refined by alkali washing to remove mercaptan sulfur. The middle gasoline fraction is mixed with hydrogen and enters the fixed bed reactor for hydrofining reaction, and then sent to catalytic reforming treatment. The heavy gasoline fraction is mixed with hydrogen and then enters three hydrotreating reactors for selective hydrodediene, selective hydrodesulfurization and selective hydrodemercaptan reactions. The products of the above-mentioned three-stage gasoline fractions are blended to obtain full fraction gasoline products.

[0066] The hydrogenation react...

Embodiment 2

[0068] A catalytically cracked gasoline is used as feedstock B, and its feedstock properties are shown in Table 1. The feed oil B was cut into three fractions at 65°C and 140°C as cut points, and the obtained light gasoline fraction, middle gasoline fraction and heavy gasoline fraction accounted for 33.0 wt%, 33.0 wt% and 34.0 wt% of the raw material respectively. The distillate of light gasoline is refined by alkali washing to remove mercaptan sulfur. The middle gasoline fraction is mixed with hydrogen and enters the fixed bed reactor for hydrofining reaction, and then sent to catalytic reforming treatment. The heavy gasoline fraction is mixed with hydrogen and then enters three hydrotreating reactors for selective hydrodediene, selective hydrodesulfurization and selective hydrodemercaptan reactions. The products of the above-mentioned three-stage gasoline fractions are blended to obtain full fraction gasoline products.

[0069] The hydrogenation reaction conditions of the ...

Embodiment 3

[0071] A catalytically cracked gasoline is used as feedstock C, and its feedstock properties are shown in Table 1. The raw material oil C was cut into three fractions at 80°C and 160°C as cut points, and the obtained light gasoline fraction, middle gasoline fraction and heavy gasoline fraction accounted for 40.0 wt%, 40.0 wt% and 20.0 wt% of the raw material respectively. The distillate of light gasoline is refined by alkali washing to remove mercaptan sulfur. The middle gasoline fraction is mixed with hydrogen and enters the fixed bed reactor for hydrofining reaction, and then sent to catalytic reforming treatment. The heavy gasoline fraction is mixed with hydrogen and then enters three hydrotreating reactors for selective hydrodediene, selective hydrodesulfurization and selective hydrodemercaptan reactions. The products of the above-mentioned three-stage gasoline fractions are blended to obtain full fraction gasoline products.

[0072] The hydrogenation reaction conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com