Catalytic cracking method and system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

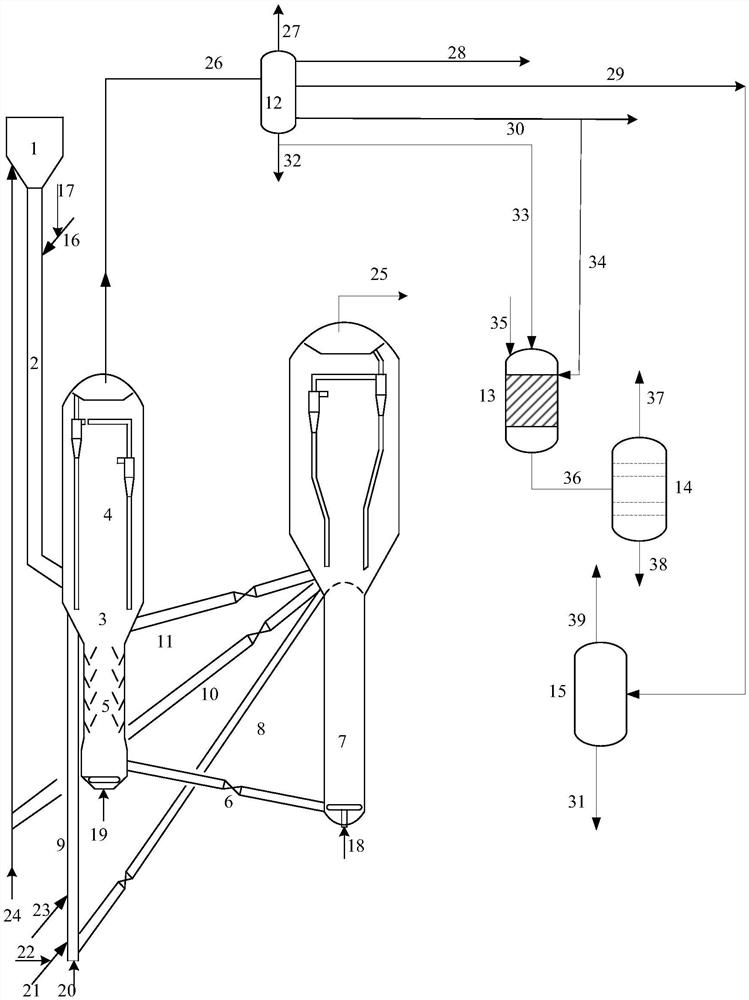

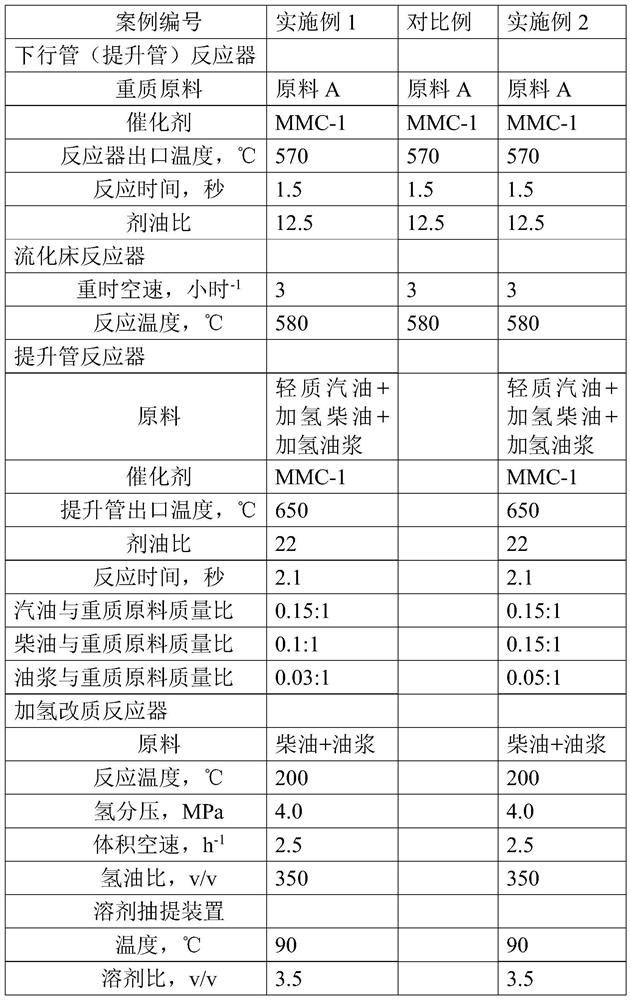

[0117] The test was carried out in a medium-sized catalytic cracking unit. The device includes a set of composite reaction system: downcomer reactor, riser reactor plus fluidized bed combination reactor, hydrogenation reforming reactor and solvent extraction device, the bottom outlet of the downcomer reactor is connected to the fluidized bed reactor bottom. The catalyst used is MMC-2 catalyst, the raw materials shown in Table 1 are cracked, the product and catalyst obtained from the reaction are separated in the settling section, the product enters the separation device for separation, and the catalyst enters the fluidized bed reactor; the top of the riser is fluidized in series Bed reactor, the catalyst that adopts is MMC-2 catalyst, to the light gasoline (distillation range is 30-85 ℃, olefin content is 52%, weight accounts for 15% of heavy feedstock) rich in olefins from the product separation unit, Hydrogenated diesel oil (distillation range 204-350°C, weight accounted fo...

Embodiment 2

[0121] Referring to Example 1, the difference is that the weight of hydro-upgraded diesel oil increases from 10% to 18% of the heavy feedstock, and the weight of hydro-upgraded oil slurry increases from 3% to 5% of the heavy feedstock. Its reaction operating conditions and reaction results are shown in Table 3 and Table 4.

[0122] It can be seen from Table 3 and Table 4 that, compared with the comparative example in which there is no downcomer reactor, hydrogenation upgrading reactor, and solvent extraction device, embodiment 1 increases the downcomer reactor and increases the hydrogenation upgrading reaction Device and solvent extraction unit, the reduction of diesel yield indicates that more diesel is converted into low-carbon olefins, and the increase of cetane number of diesel oil indicates that the quality of diesel oil is improved; at the same time, the yield of low-carbon olefins increases significantly, and benzene, toluene and C8 are recovered Aromatics and other pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com