Patents

Literature

34results about How to "Easy to react" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

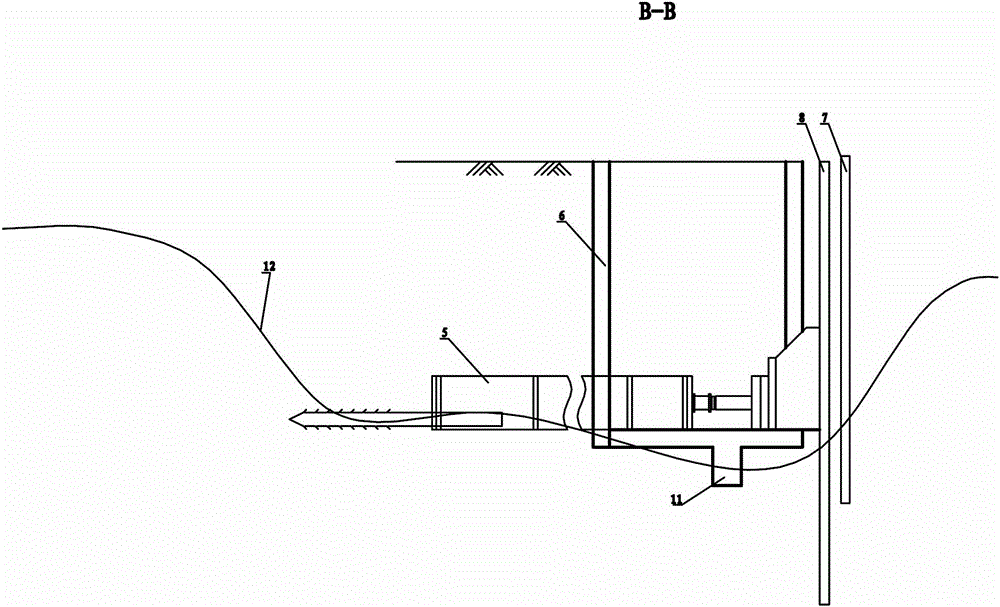

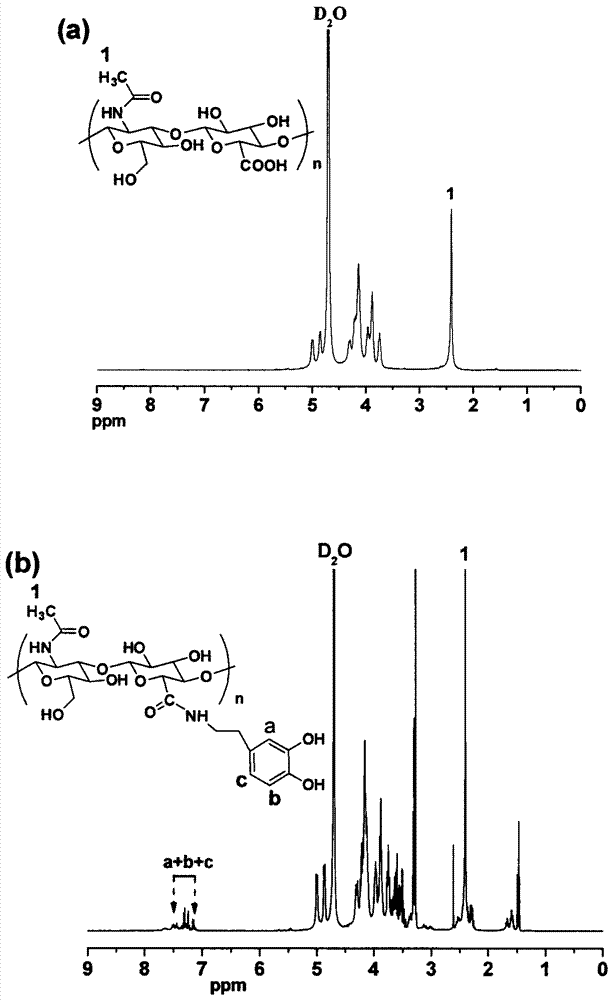

Method for preparing dopamine-modified hyaluronic acid micelle

ActiveCN102702539AUnique moisturizing typeGood biocompatibilityBiocompatibility TestingBiological materials

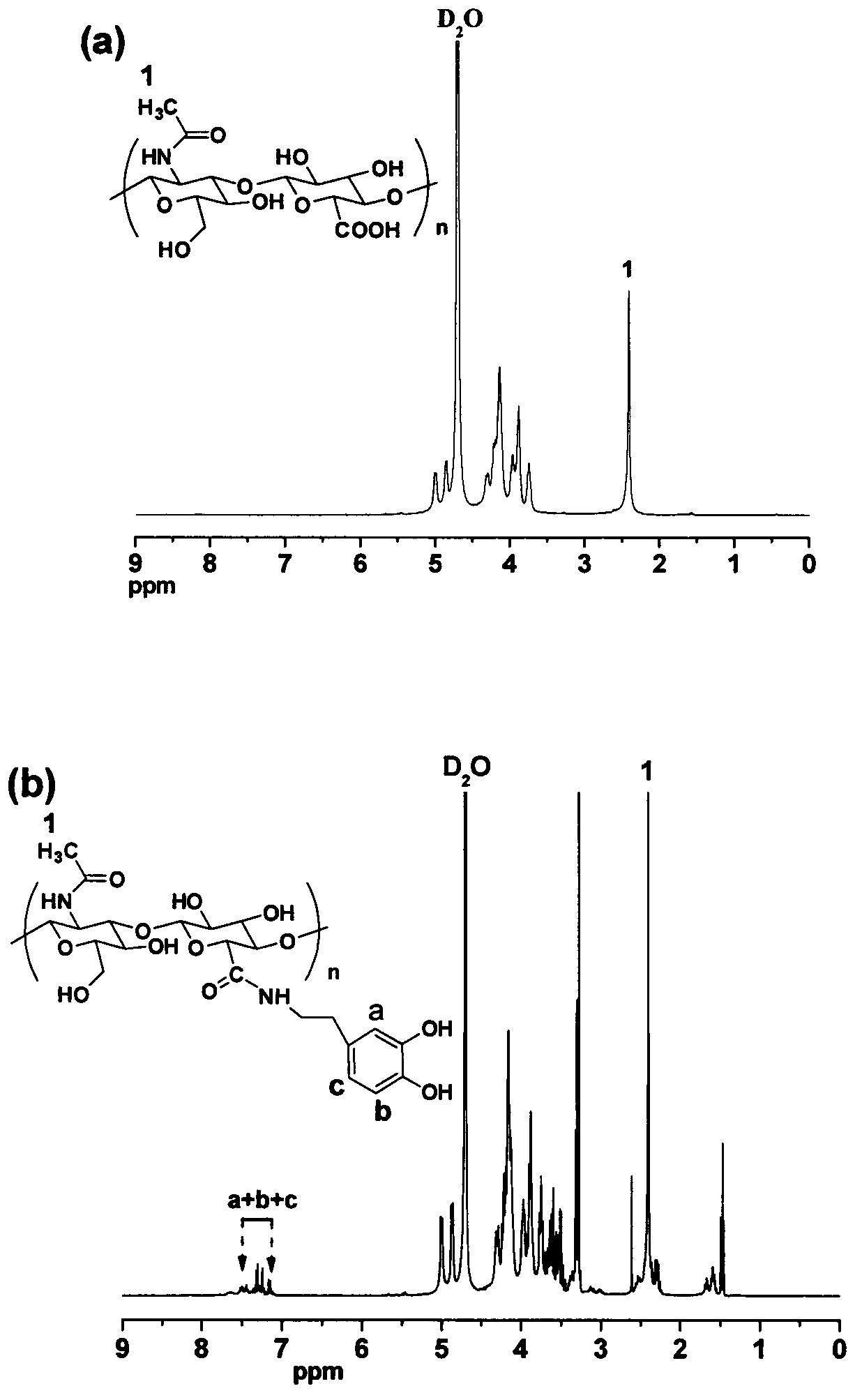

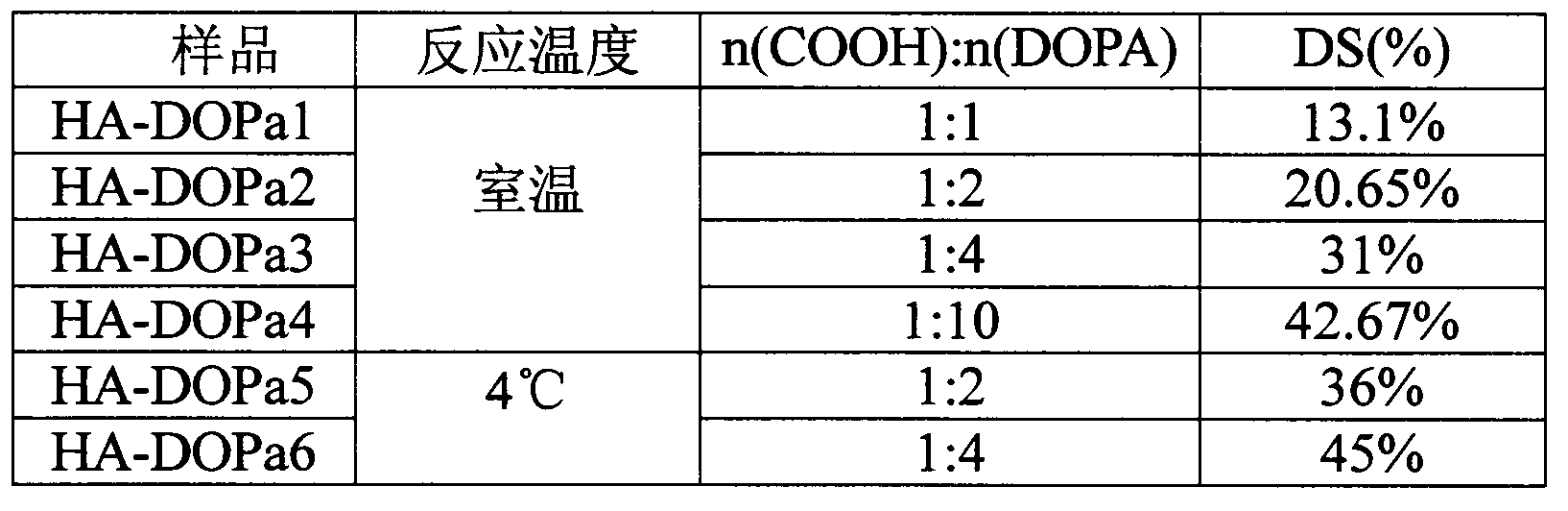

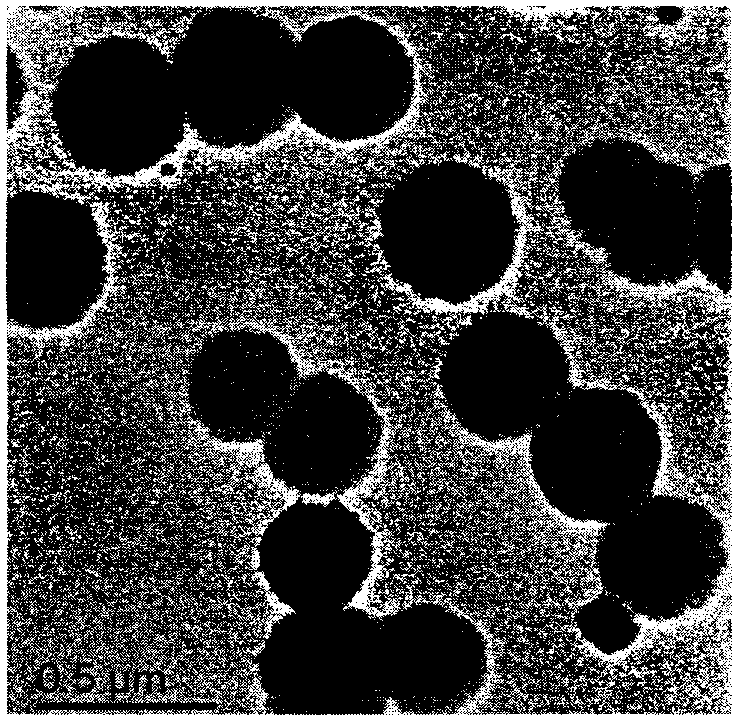

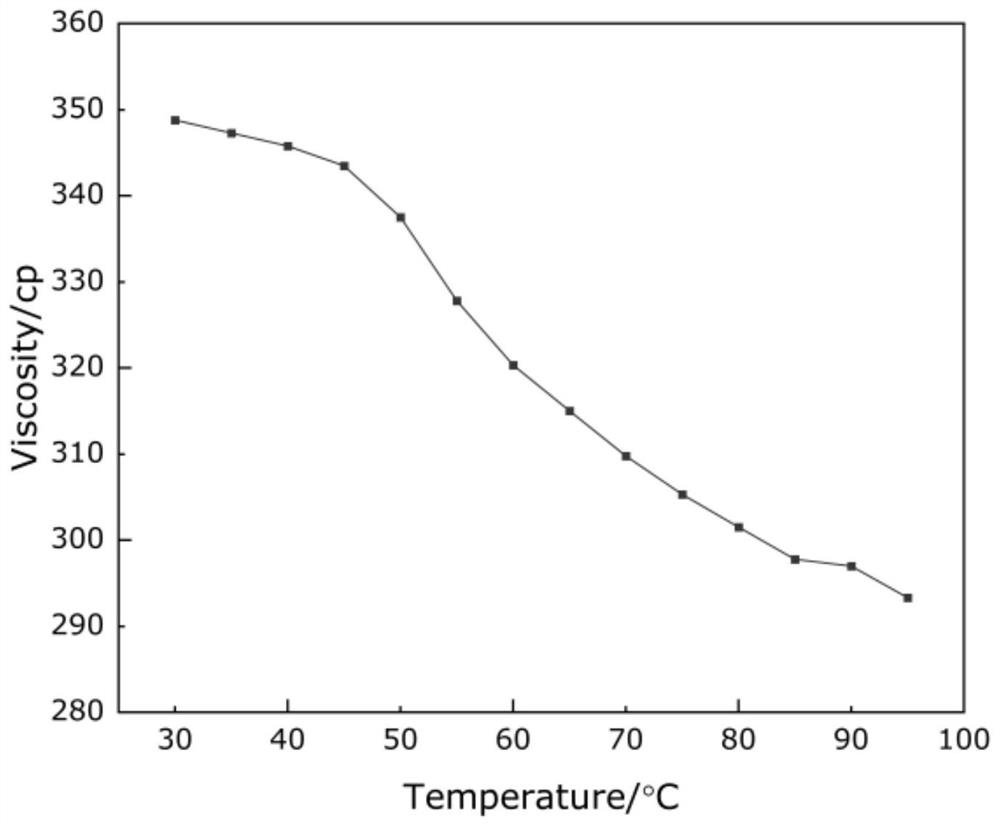

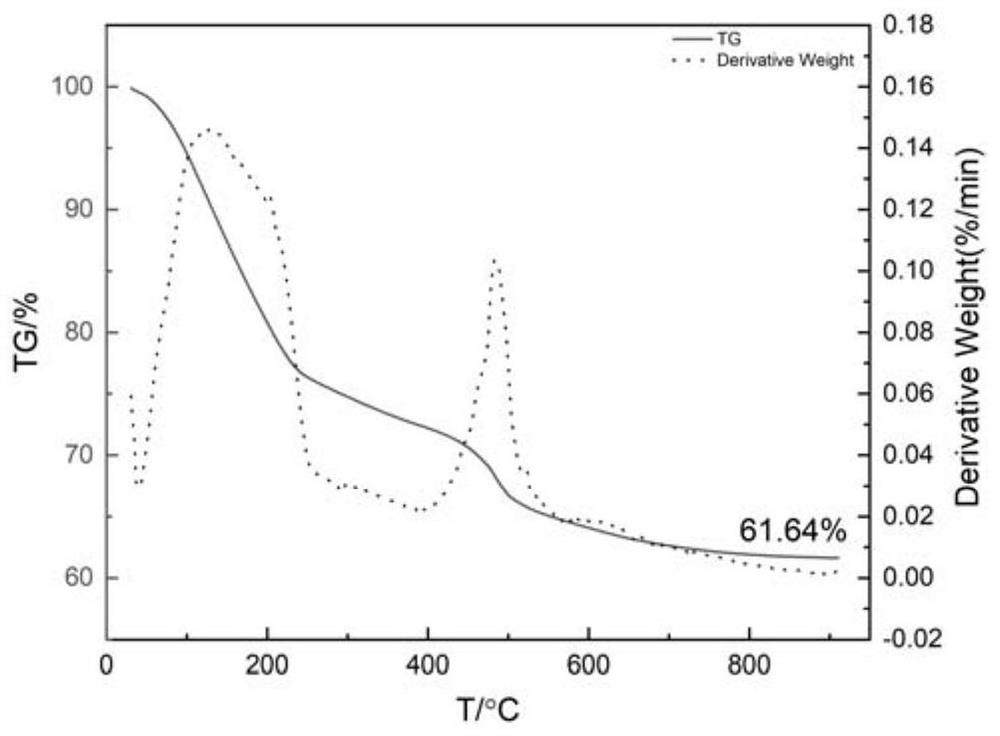

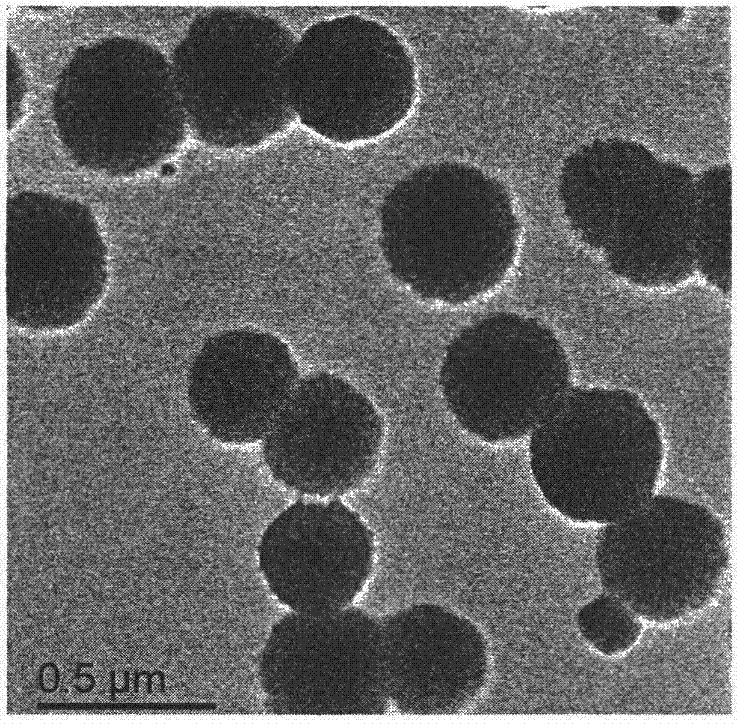

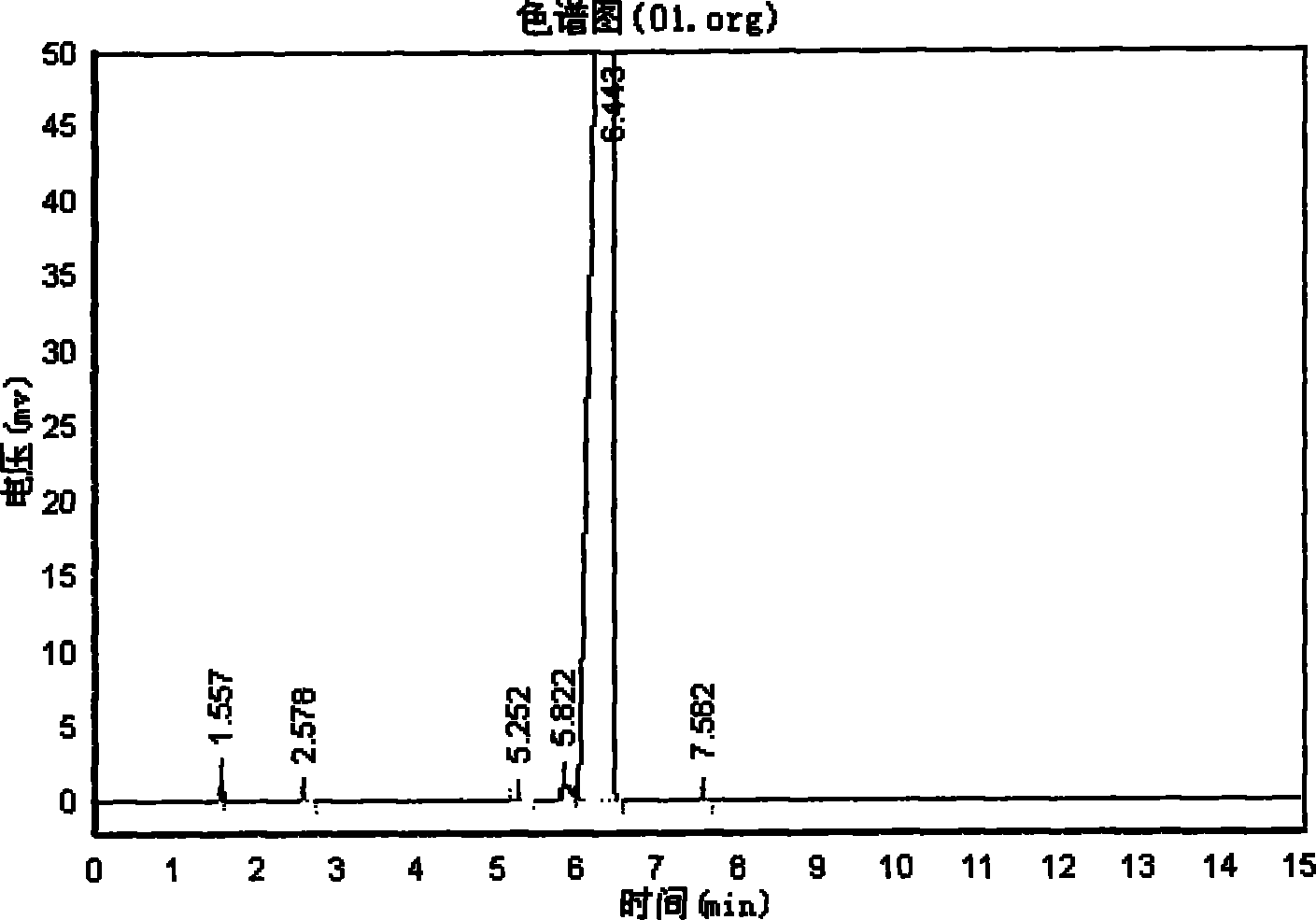

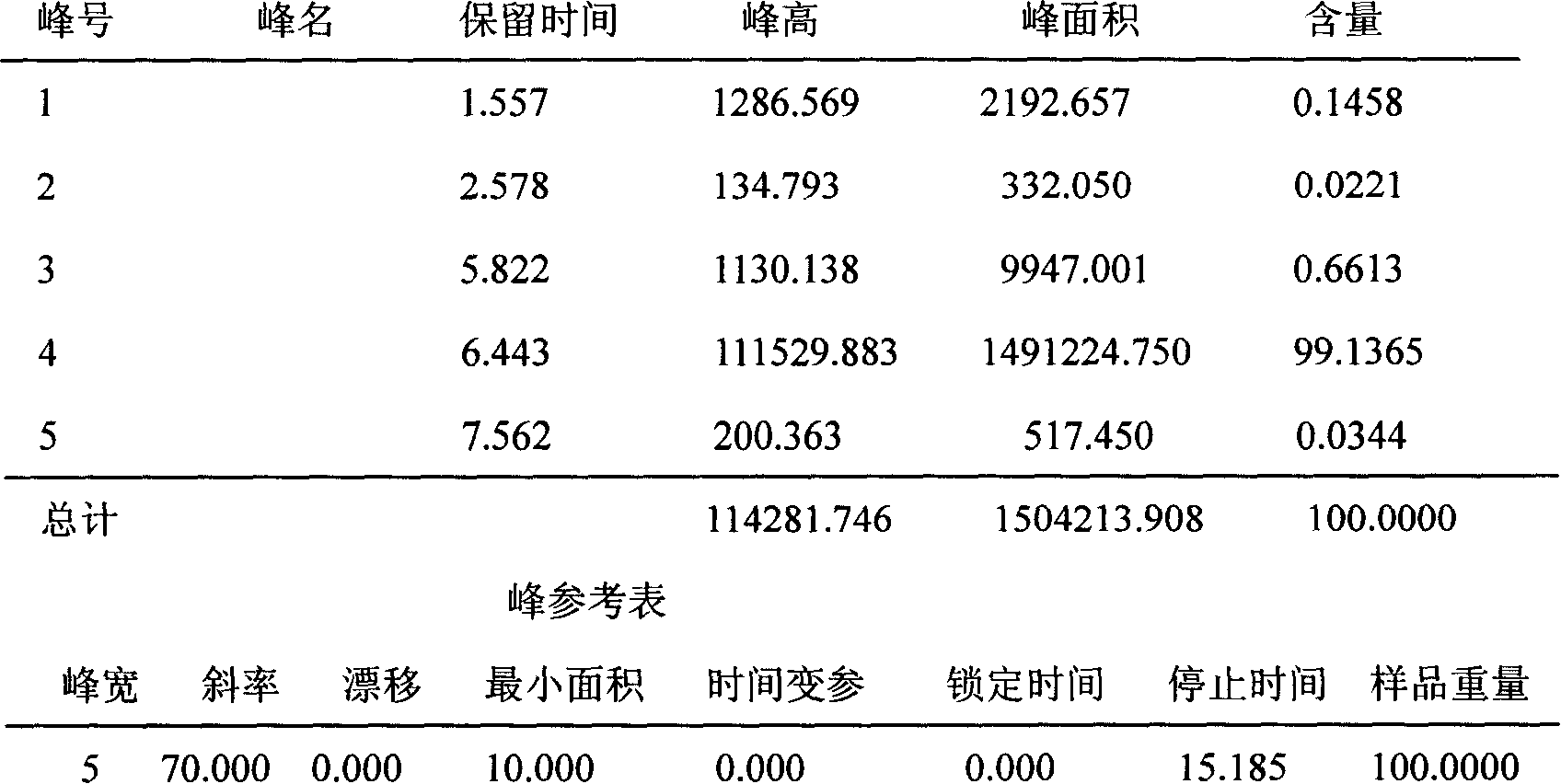

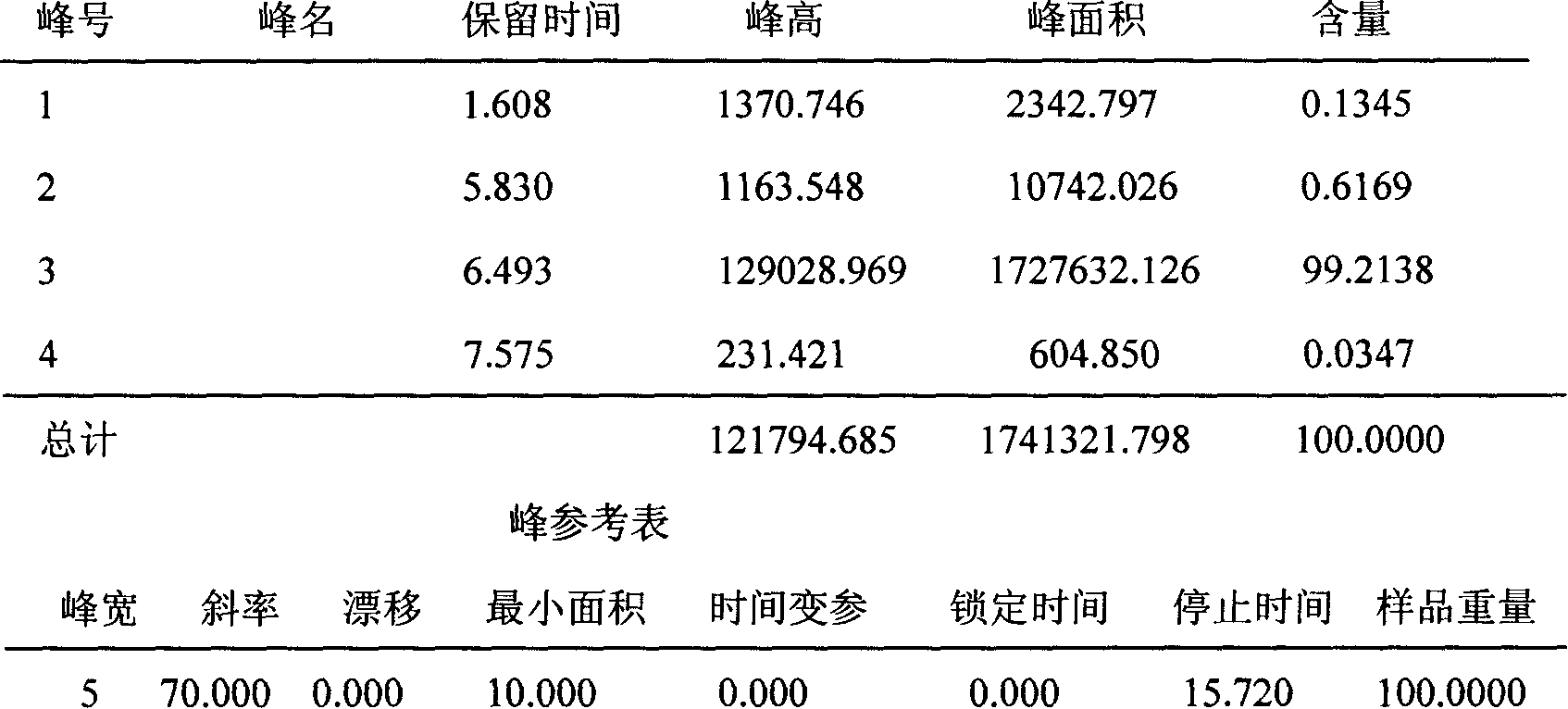

The invention provides a method for preparing dopamine-modified hyaluronic acid micelle and belongs to the technical fields of polymer material and natural polymer. The method comprises the steps of introducing dopamine element on a hyaluronic acid main chain by amidation so as to provide certain amphipathy to the hyaluronic acid, so that micelle with the grain size of 100-700nm is formed in water solution by self-assembling. The hyaluronic acid micelle is excellent in biocompatibility, hydrophilicity and viscoelasticity, and can be applied to the fields such as biological materials and hydrophilic colloid. The adhesiveness of the dopamine provides excellent interface property, and the micelle can be applied to the fields such as emulsion, food, cosmetic and the like as emulsifier.

Owner:林玉洪

Composite titanium dioxide nano-sheet photocatalyst, preparation method and applications thereof

ActiveCN104841470AReduce experiment costEasy to preparePhysical/chemical process catalystsHydrogen productionSynthesis methodsTitanium nitride

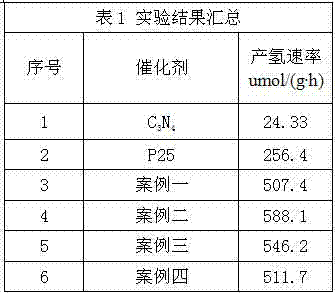

The present invention relates to a composite titanium dioxide nano-sheet photocatalyst, a preparation method and applications thereof, wherein the composite titanium dioxide nano-sheet photocatalyst comprises, by weight, 0.01-0.02% of carbon quantum dots, 39.44-70.73% of carbon nitride, and 29.25-60.55% of titanium dioxide. According to the present invention, titanium tetraisopropanolate and melamine are respectively adopted as the titanium source and the nitrogen source, and the precursor synthesis method is used to compound the titanium dioxide, the carbon nitride and the carbon quantum dots, wherein the carbon quantum dot mass content is extremely low while the high photocatalytic activity is provided, and the product can be used in organic wastewater treatment and hydrogen production through water photodecomposition.

Owner:ZHEJIANG UNIV OF TECH

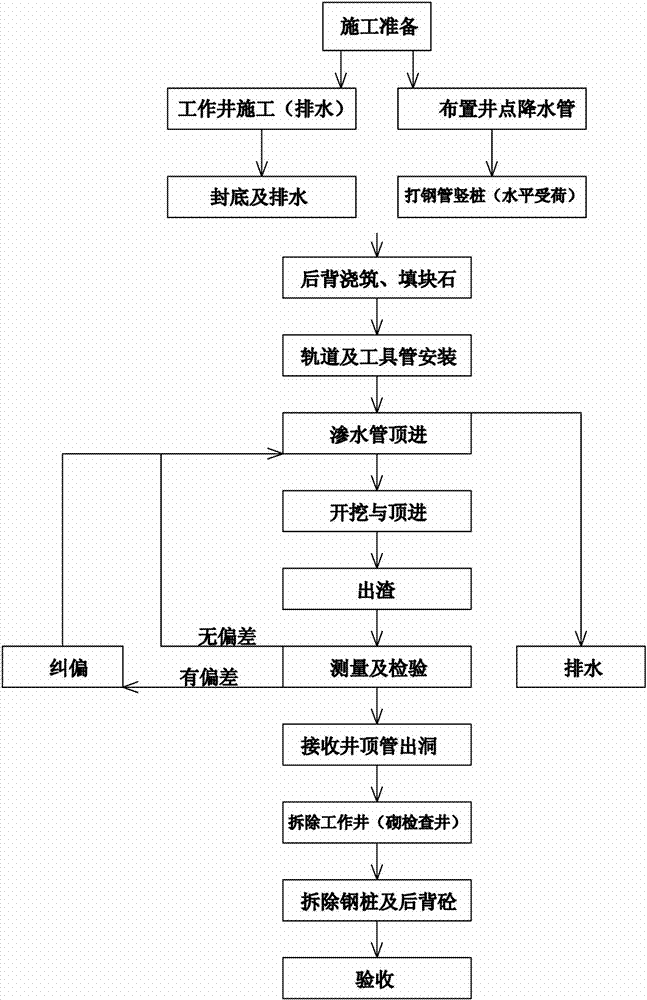

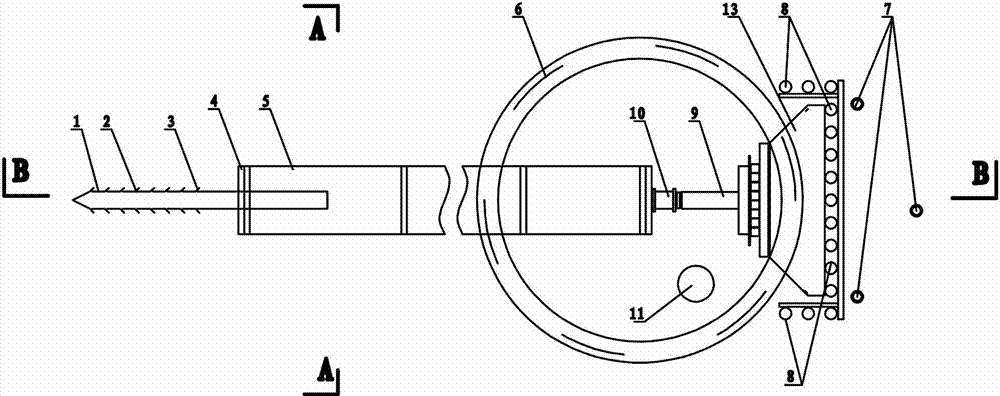

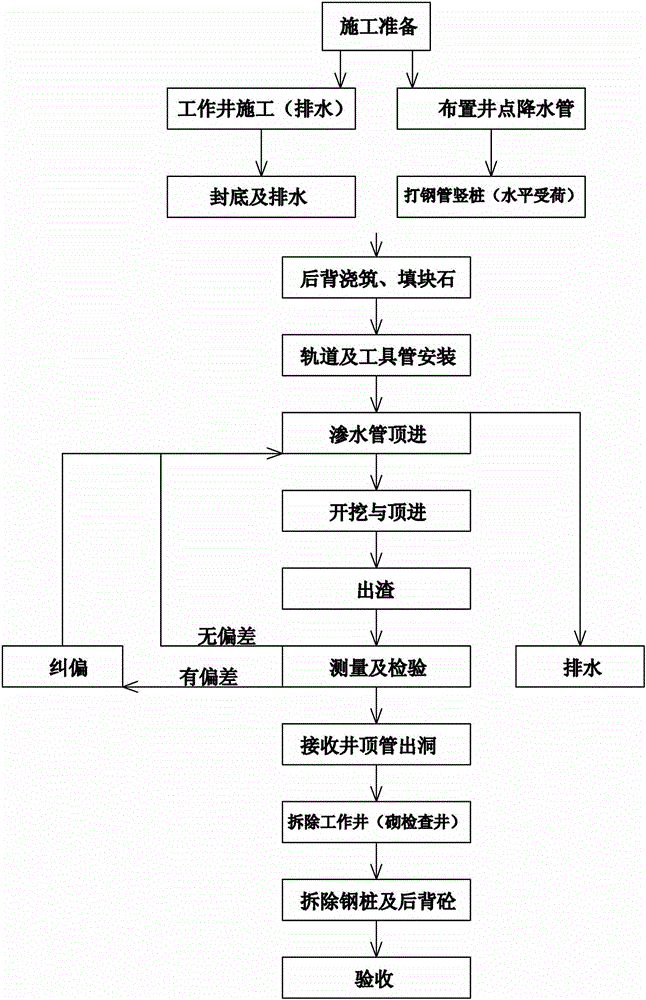

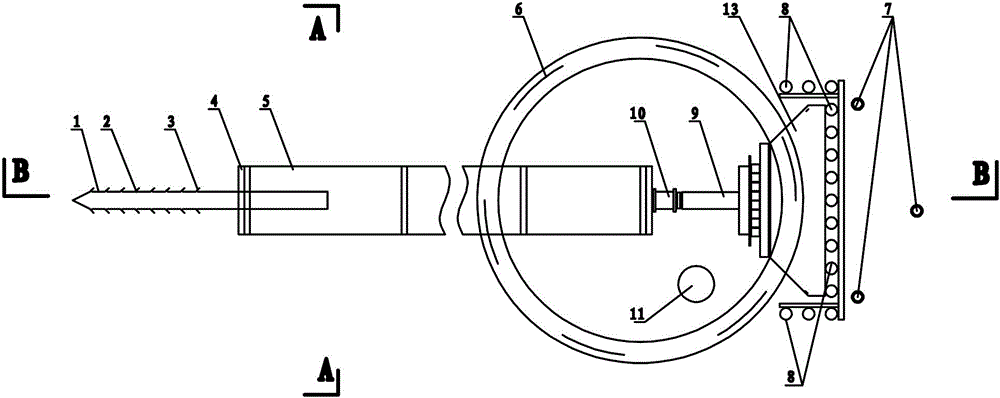

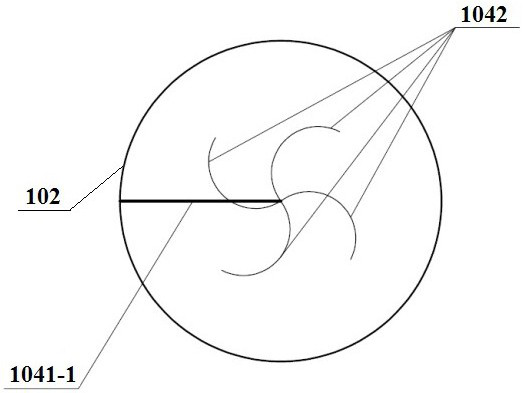

Hand digging type pipe jacking construction device and method for sediment and sludge areas

The invention provides a hand digging type pipe jacking construction device and method for sediment and sludge areas. The hand digging type pipe jacking construction device comprises a tool pipe, wherein jacks are arranged between the tool pipe and a concrete back. A water seepage pipe is arranged at the front end of the tool pipe. Part of the water seepage pipe penetrates through a pipe cap, and the other part of the water seepage pipe is located in the tool pipe. The rear end of the water seepage pipe is open, and a plurality of water seepage holes are formed in the pipe wall of the water seepage pipe. According to the hand digging type pipe jacking construction device and method for sediment and sludge areas, the water seepage pipe is arranged at the front end of the tool pipe, the underground water level is lowered through the water collection action of the water seepage pipe, and therefore strength of a work soil body is improved, and conditions are created for hand digging type work. Well-point dewatering pipes are arranged, and therefore deep well point dewatering is achieved, the water content of the portion, provided with the concrete back, of the soil body is lowered, and strength of the position of the soil body is improved. Load-bearing piles are arranged, and therefore the force borne by the concrete back is further increased, and end reaction can be conveniently borne by the jacks.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

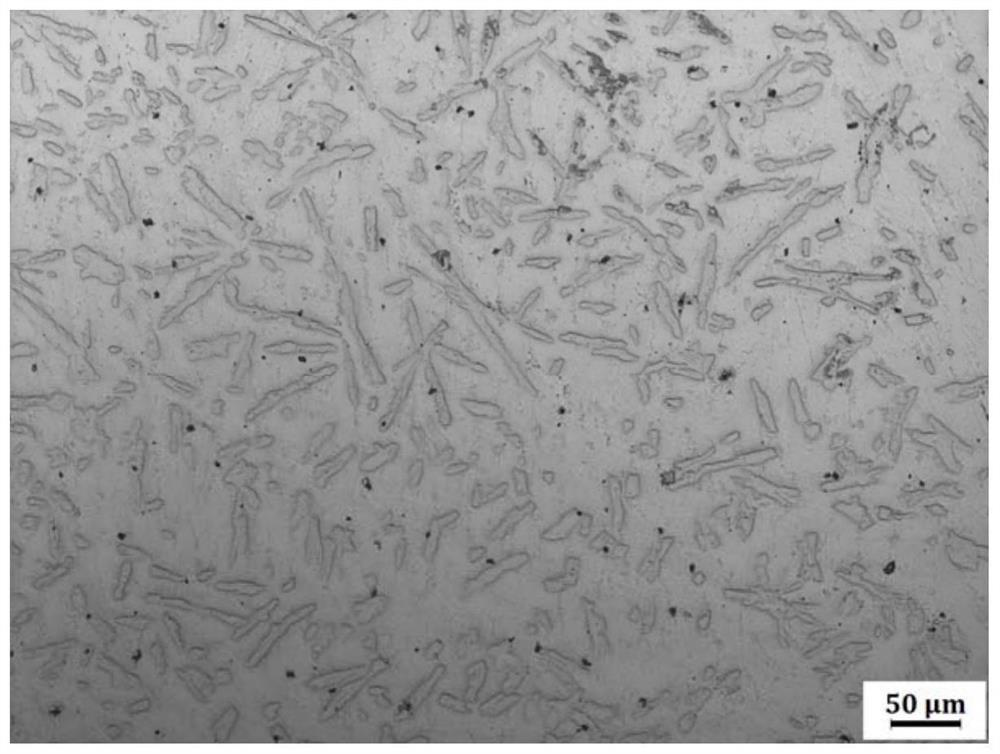

Method for producing high purity MnOOH

InactiveCN101428860AEasy to reactMild reaction conditionsManganese oxides/hydroxidesRoom temperatureReaction temperature

The invention belongs to the field of hydrometallurgy, and particularly relates to a method for preparing high-purity MnOOH, which is characterized in that MnOOH is prepared in the presence of MnO2 and Mn3O4 as reaction precursors. The method comprises the following steps: mixing MnO2 and Mn3O4 by the molar ratio of (0.8-1.2) to 1; adding water by the liquid-to-solid ratio of (0.5-10) to 1; subjecting MnO2 and Mn3O4 to the reaction, wherein, the reaction formula is as follows: MnO2 + Mn3O4 + 2H2O = 4MnOOH, and the reaction temperature is in the range from the room temperature to 100 DEG C; stirring; and reacting for 0.5 to 60 hours to obtain MnOOH. The invention has the advantages that the reaction easily occurs, the reaction condition is mild, the raw material is easily accessible, no impurity is involved, and the purity of the product is high.

Owner:UNIV OF SCI & TECH BEIJING

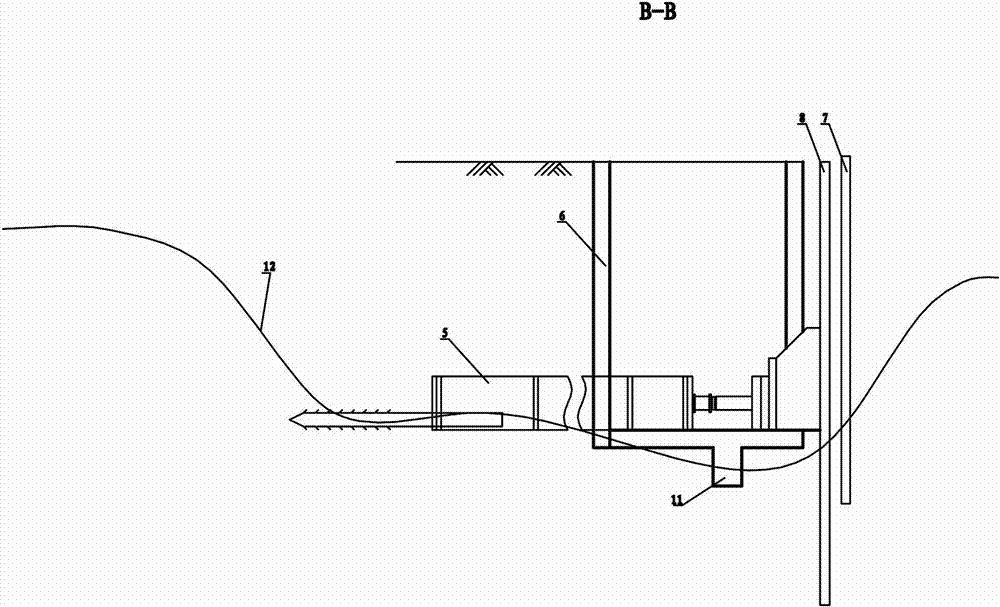

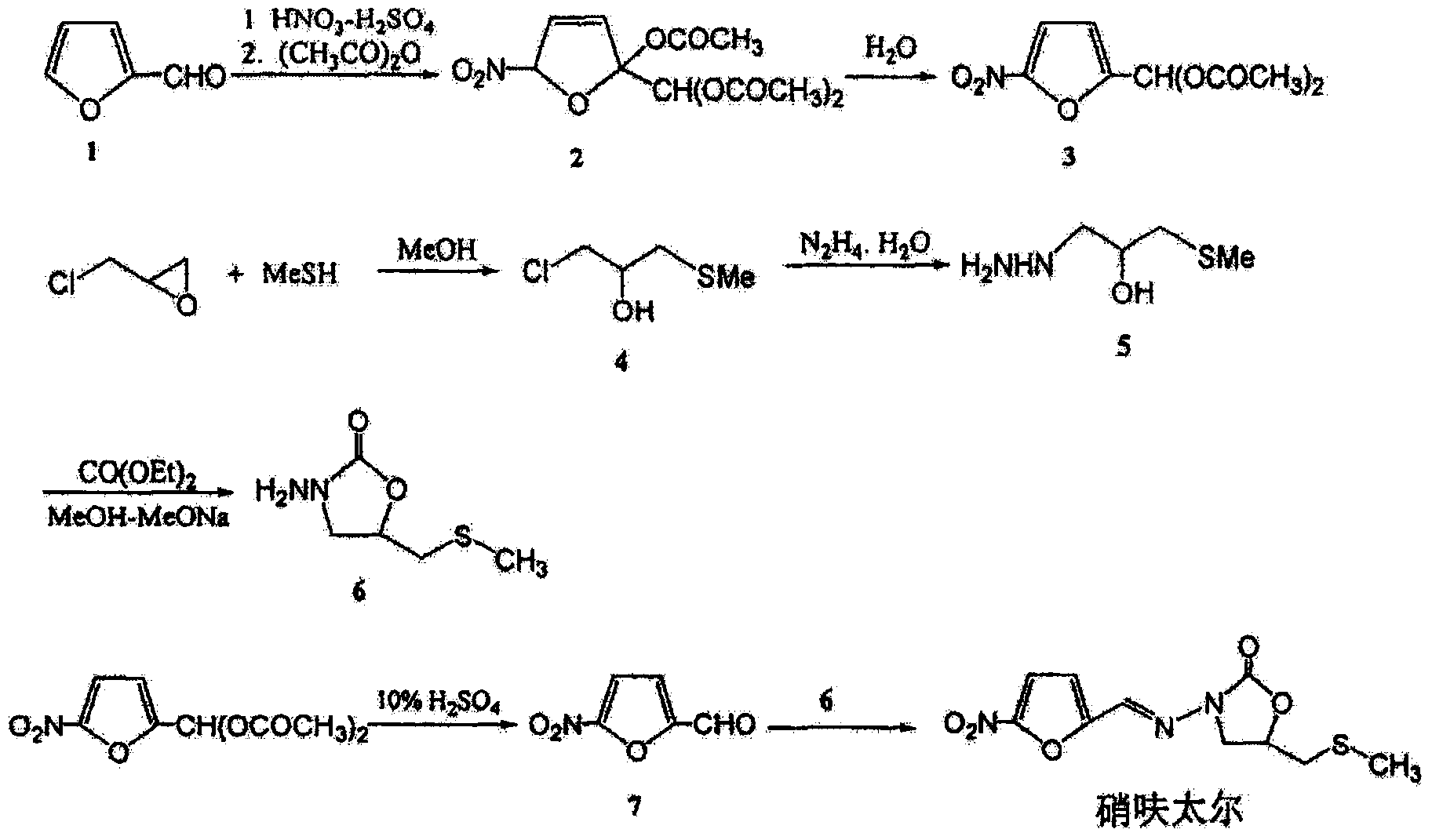

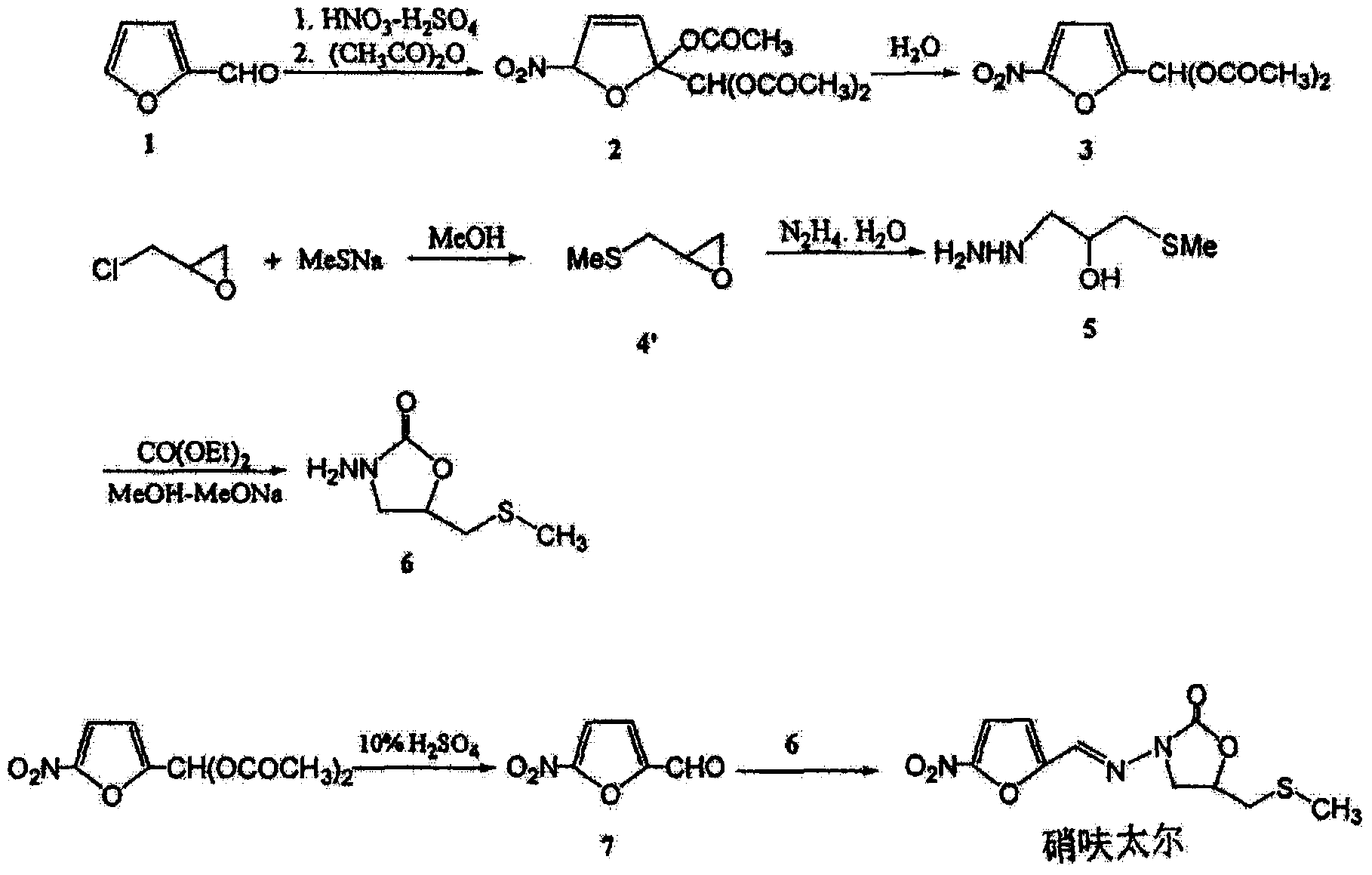

Synthetic method of nifuratel

The invention discloses a synthetic method of nifuratel. The synthetic method comprises the steps of carrying out a substitution reaction between epoxy chloropropane and sodium methyl mercaptide in the presence of a phase transfer catalyst to obtain epoxy propyl dimethyl sulfide, and then performing hydrazinolysis, cyclization and condensation on the obtained epoxy propyl dimethyl sulfide to obtain the nifuratel. The synthetic method is high in nifuratel yield, high in purity and low in impurity content; besides the method has the advantages that a ring-closure reaction is carried out under the alkaline condition of sodium methoxide, the use of metal sodium is avoided, production safety is ensured, and simultaneously, the reaction is easy to arouse, easy to control in process, the used raw materials are easy to get, basically no waste liquid is generated in the reaction of each step, and therefore, industrial pollution is greatly reduced; and as a result, the synthetic method of nifuratel is applicable to industrial production.

Owner:BEIJING CHENGYI INVESTMENT CO LTD

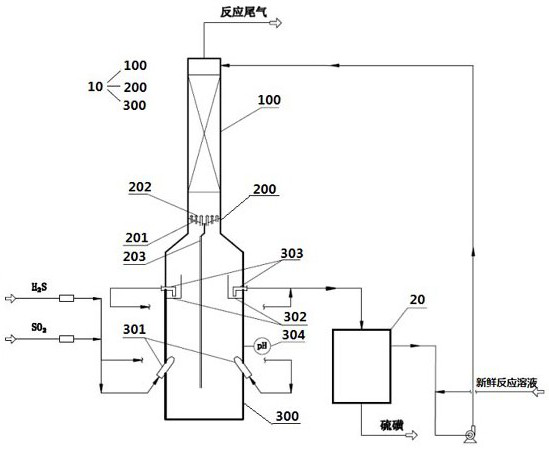

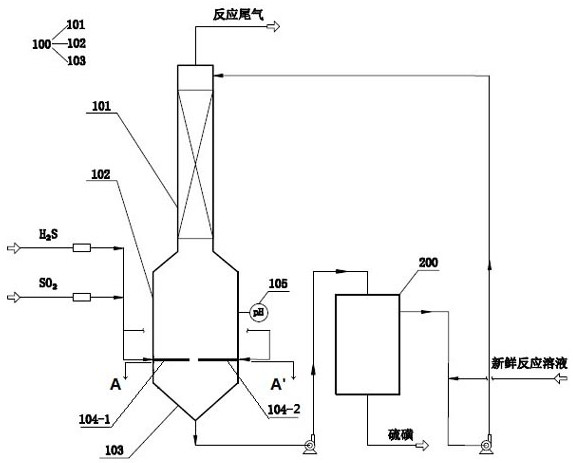

Process for desulfurization by reacting hydrogen sulfide with sulfur dioxide

ActiveCN109529567AIncrease acidityRapid responseGas treatmentDispersed particle separationAtmospheric pressureSafe operation

Disclosed is a process for desulfurization by reacting hydrogen sulfide with sulfur dioxide. The process includes the following steps: gas containing hydrogen sulfide and gas containing sulfur dioxideare introduced into a reactor, wherein the reactor is filled with a reaction solution, the reaction solution comprises water and at least one organic alkaline compound mutually soluble with water, and the organic alkaline compounds make the pH value of the solution greater than or equal to 7.2; and the hydrogen sulfide reacts with the sulfur dioxide to produce sulfur, the sulfur is removed in thereaction process, the reaction solution is replenished online, and liquid and solid in the reactor are separated after the reaction is completed to obtain the sulfur. The process of the invention utilizes the addition of the organic alkaline compounds in the reaction solution to greatly shorten the reaction time of H2S and SO2 in liquid phase, the reaction response time is less than 15 seconds, and the reaction can be carried out at normal temperature and atmospheric pressure for desulfurization. The high-purity sulfur can be obtained by simply liquid-solid separation without refinement. Theprocess of the invention has the advantages of mild reaction conditions required, simple and easy processing equipment, low investment and safe operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

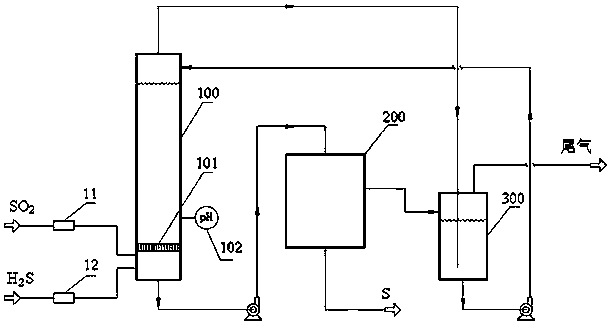

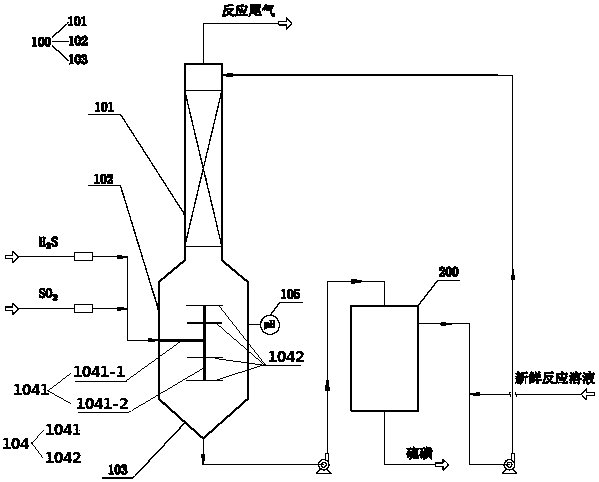

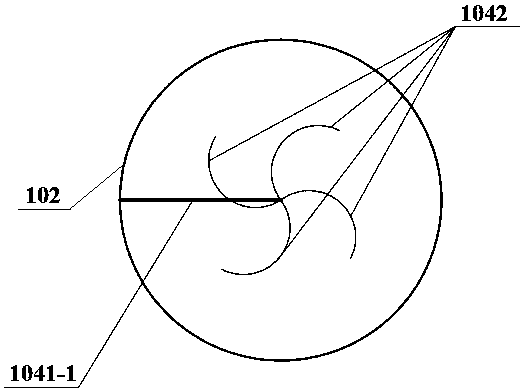

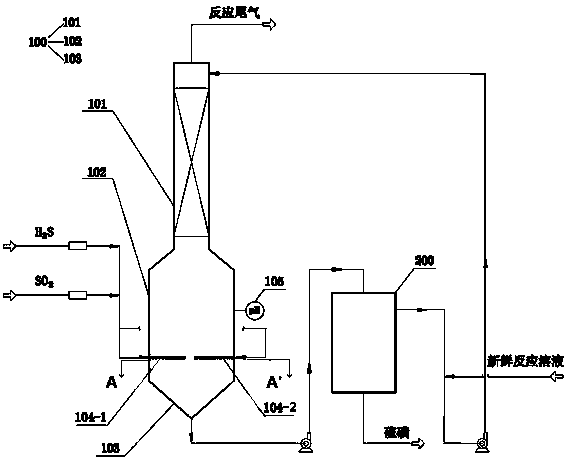

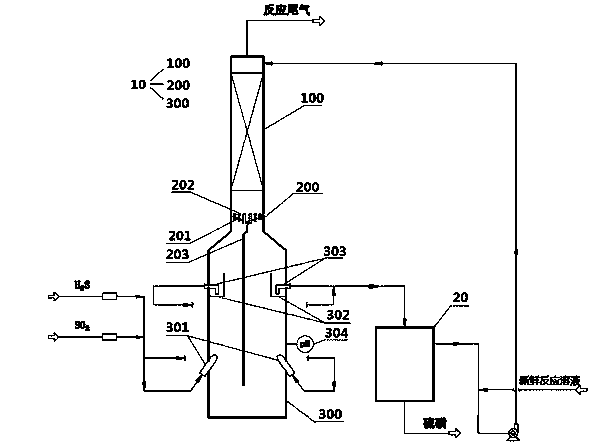

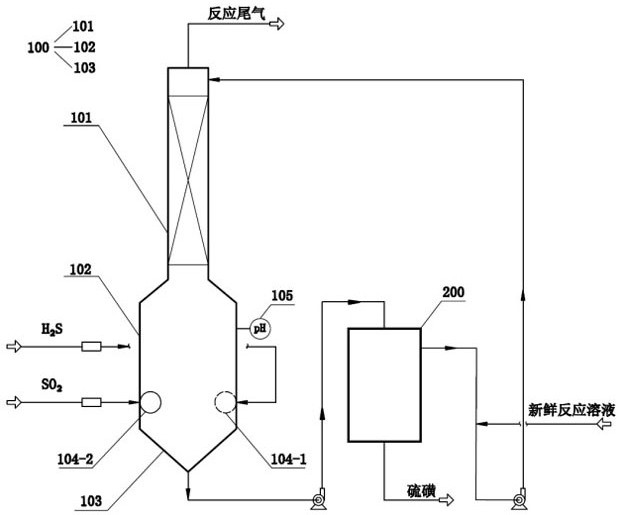

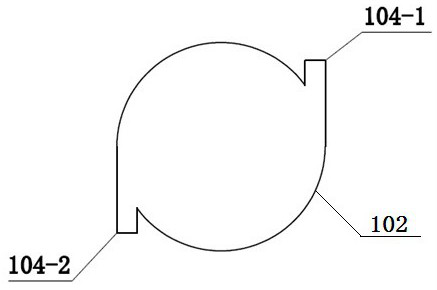

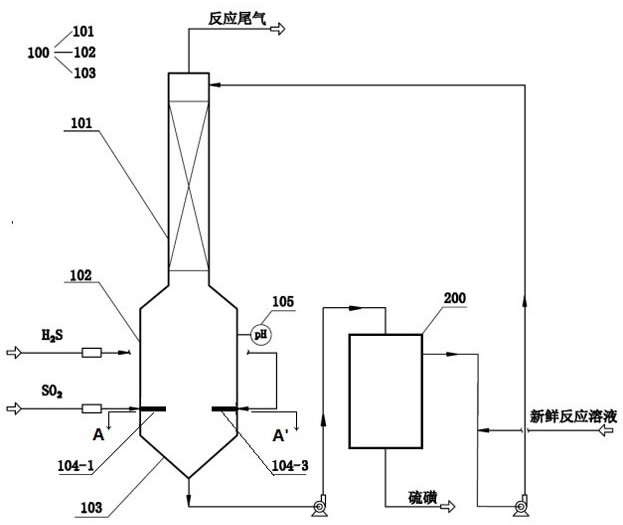

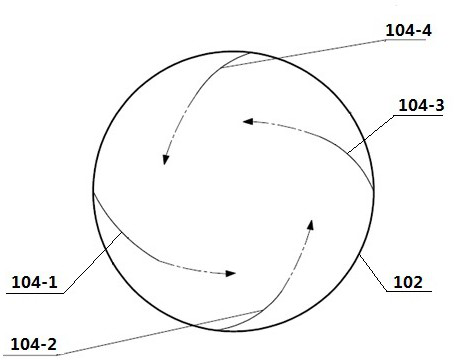

Process device and process method of liquid phase reaction desulfurization of hydrogen sulfide and sulfur dioxide

ActiveCN109529578AEvenly dispersedIncrease dissolution rateDispersed particle separationSulfur preparation/purificationReaction rateDissolution

Disclosed are a process device and a process method of liquid phase reaction desulfurization of hydrogen sulfide and sulfur dioxide. The process device includes a reactor and a separator. The reactorincludes a tail gas absorption zone, a reaction zone and a sedimentation zone. The sedimentation zone is connected to the separator. The other end of the separator is connected to the top of the tailgas absorption zone of the reactor. The reaction zone is provided with gas pipes which consist of gas main pipes and gas branch pipes. The pipelines in the gas pipes communicate with each other. The two ends of the main pipe II are closed. The device is used for a desulfurization reaction of the hydrogen sulfide and sulfur dioxide, and a reaction solution includes water and at least one organic alkaline compound soluble in water so as to make the pH value of the solution greater than or equal to 7.2. The device and method of the invention can make reaction gas entering the reactor form a jet with a certain radian to push liquid to self-stir, which facilitates the uniform dispersion of the gas in the reaction solution and greatly increases the dissolution rate and reaction rate of the gas in the reaction solution. The respond time of the reaction of the hydrogen sulfide and sulfur dioxide is less than 15 s. The reaction conditions are mild, obtained sulfur does not need to be refined and is high in purity, the equipment is simple and easy in processing, the investment is low, and the operation is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of titanium oxide film electrode based on titanium mesh

InactiveCN109675539AHigh catalytic activityEasy to reactCatalyst activation/preparationOxideTitanium oxide

Owner:WUYI UNIV

Preparation method of 1,4-naphthoquinone

InactiveCN109400456AIncrease surface tensionLower surface energyQuinone preparation by oxidationQuinone separation/purificationLiquid wasteElectrolysis

The invention discloses a preparation method of 1,4-naphthoquinone. The preparation method comprises the following steps: taking ceric sulfate as an oxidizing agent, and dissolving the ceric sulfate into a sulfuric acid solution, thus forming a water phase; dissolving naphthalene into an organic solvent, thus forming an oil phase; mixing the water phase with the oil phase, adding an emulsifying agent, and carrying out oxidation reaction under the conditions of carrying out heat preservation and stirring; after completing the reaction, integrally cooling the water phase and the oil phase untilafter-filtration is carried out on all cerous sulfate, thus obtaining solid 1,4-naphthoquinone; separating the water phase from the oil phase, recycling the oil phase, and recycling the water phase after carrying out electrolytic regeneration on the water phase. According to the preparation method disclosed by the invention, the reaction speed is increased, and byproducts are reduced; an extraction phase of an old technology is omitted, and meanwhile, the recovery rate of naphthoquinone is increased; meanwhile, the water phase and the oil phase are both completely recycled and reused, zero emission of liquid waste is realized, the environment is not polluted, and a production method of the 1,4-naphthoquinone is economical and environment-friendly.

Owner:四川锐华科技有限公司

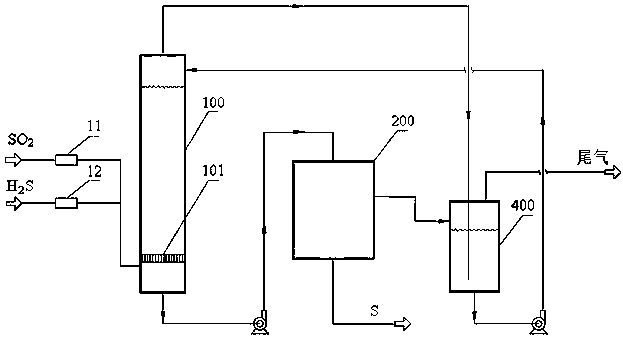

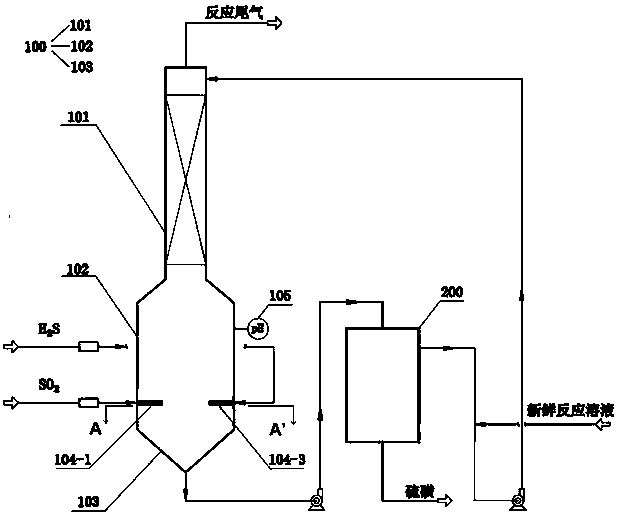

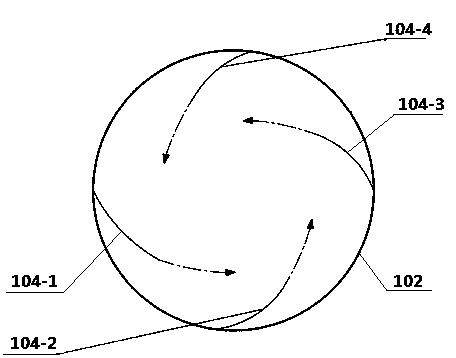

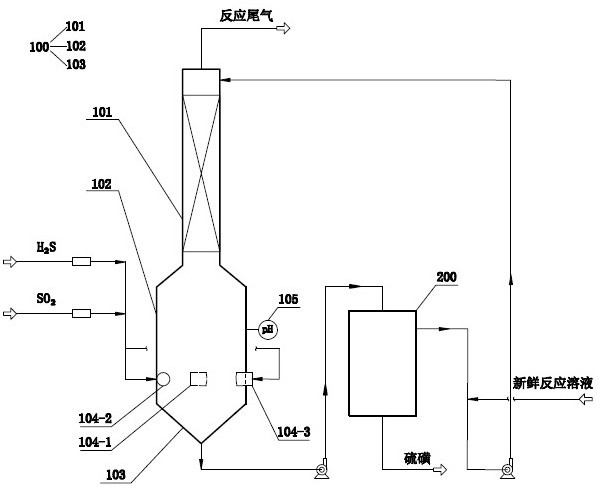

Process device and process method of liquid phase desulfurization of hydrogen sulfide and sulfur dioxide

ActiveCN109529573AIncrease dissolution rateIncrease reaction rateDispersed particle separationOperational safetyFlue-gas desulfurization

Disclosed are a process device and a process method of liquid phase desulfurization of hydrogen sulfide and sulfur dioxide. The process device includes a reactor and a separator. The reactor includesa tail gas absorption zone, a reaction zone and a sedimentation zone. A shell of the reaction zone is provided with at least two gas inlet tubes which are arranged on the same horizontal plane. The gas inlet tubes extend to the inside of the reaction zone and are arc-shaped tubes or straight tubes with the ends being curved into an arc shape. The sedimentation zone is connected to the separator. The other end of the separator is connected to the top of the tail gas absorption zone of the reactor. The device is used for a desulfurization reaction of the hydrogen sulfide and sulfur dioxide, anda reaction solution includes water and at least one organic alkaline compound soluble in water so as to make the pH value of the solution greater than or equal to 7.2. The device and method of the invention can increase the dissolution rate and reaction rate of gas in the reaction solution. The respond time of the reaction of the hydrogen sulfide and sulfur dioxide is less than 15 s. The reactionconditions are mild, obtained sulfur does not need to be refined and is high in purity, the equipment is simple and easy in processing, the investment is low, and the operation is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

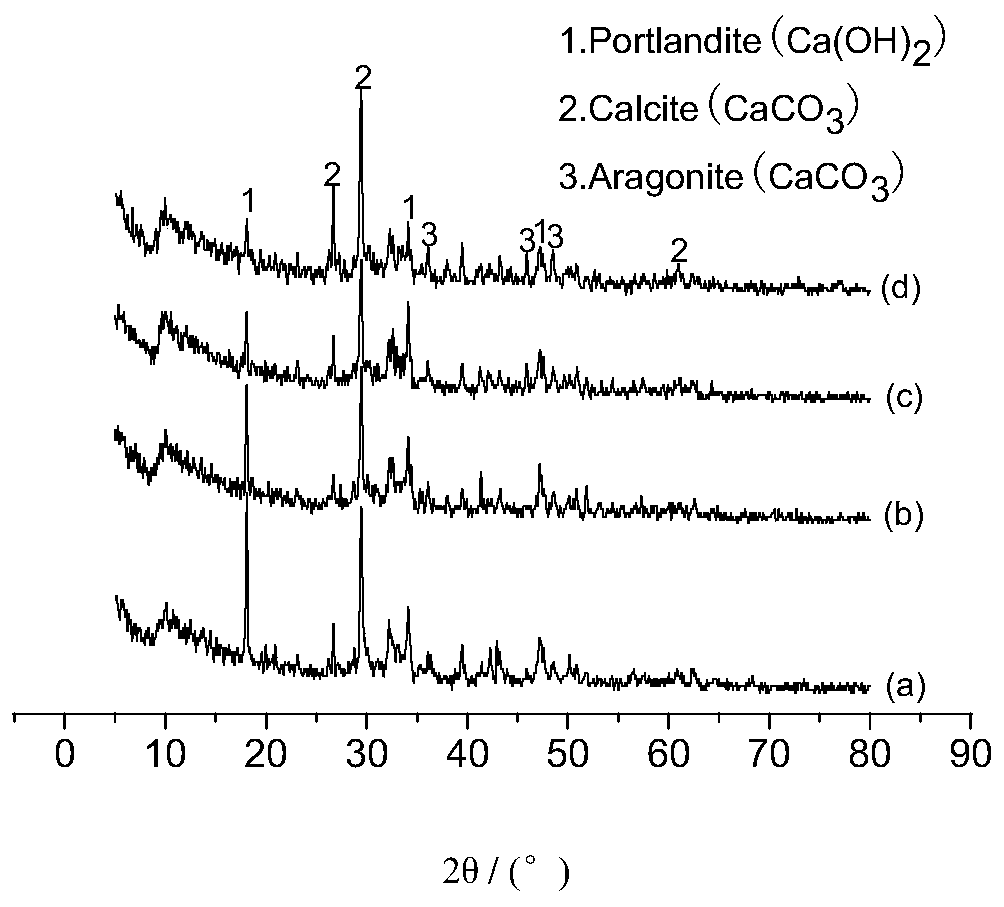

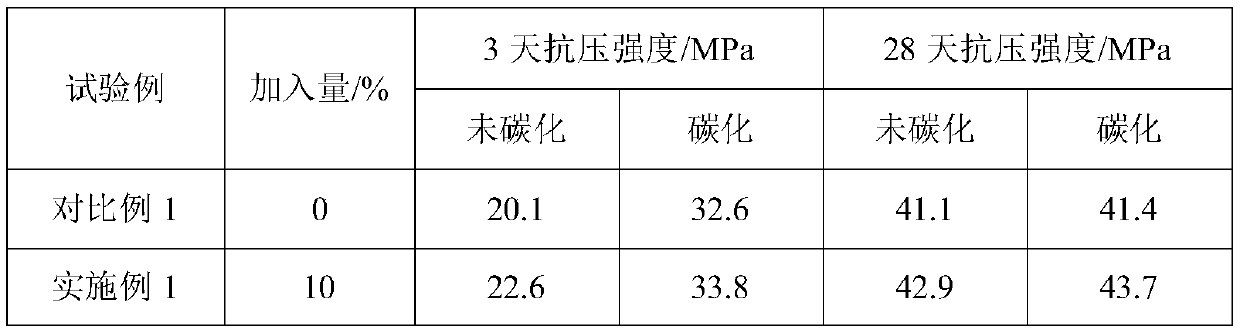

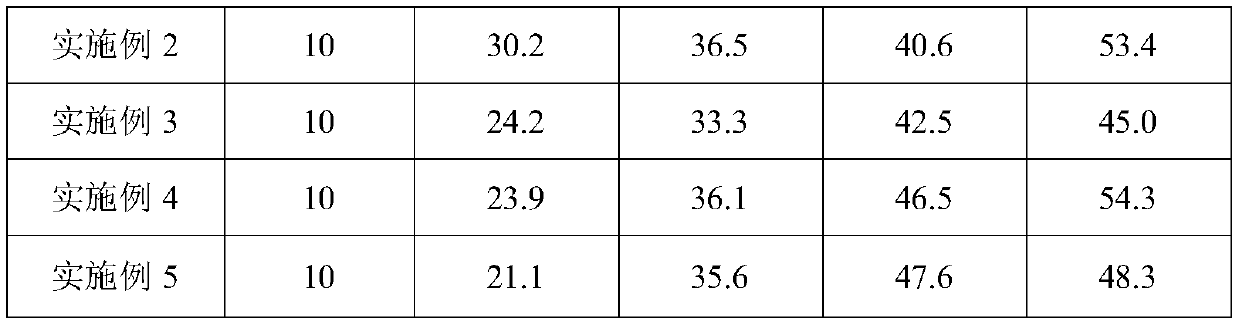

Accelerator for preparing low-carbon cementitious materials with carbonized steel slag cement and its application method

The invention discloses an accelerator for preparation of a low-carbon cementitious material from carbonized steel slag and cement and belongs to the field of energy saving and emission reduction and ecological building materials. One, two or three of a mineral accelerator fly ash, CaCO3 seed crystals, basic accelerators Mg(OH)2 and Na2CO3 and an acid accelerator C2H2O4 are added to a steel slag and cement composite cementitious material, and the accelerator has a better acceleration effect. After the accelerator is added, activity of easily carbonized components in the steel slag and cement composite cementitious material is improved, the components are subjected to a reaction more easily with H2CO3 formed by dissolving CO2 in water vapor, and stable carbonate is formed. The acceleration effect of Mg(OH)2 and C2H2O4 is better, the strength of the carbonized steel slag and cement composite cementitious material is improved greatly, CO2 is consumed to a larger degree, and the low-carbon cementitious material with good performance is prepared.

Owner:YANCHENG INST OF TECH

Polyaluminocarbosilane with high aluminum content and low oxygen content, preparation method and SiAlC ceramic

ActiveCN114015057AThe process is simple and easy to controlReduce manufacturing costFiberAluminoxane

The invention discloses a preparation method of polyaluminocarbosilane with high aluminum content and low oxygen content. Liquid hyperbranched liquid polycarbosilane and methylaluminoxane are adopted as raw materials, polyaluminocarbosilane is prepared under closed inert conditions, and the content of aluminum element in the polyaluminocarbosilane can be adjusted by adjusting the ratio of the raw materials. The invention also discloses the polyaluminocarbosilane prepared based on the method, the mass percentage content of aluminum element can be 0-20%, and the mass percentage content of oxygen element is less than 2%. The invention further discloses SiAlC ceramic obtained after high-temperature cracking of the polyaluminocarbosilane, Si, Al and C elements in the SiAlC ceramic are adjustable in composition, and the SiAlC ceramic has excellent high temperature resistance and oxidation resistance, can be used for preparing an ultrahigh-temperature-resistant C / SiAlC ceramic-based composite material through a PIP method, and can also be used for preparing an ultrahigh-temperature oxidation-resistant coating and fiber.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

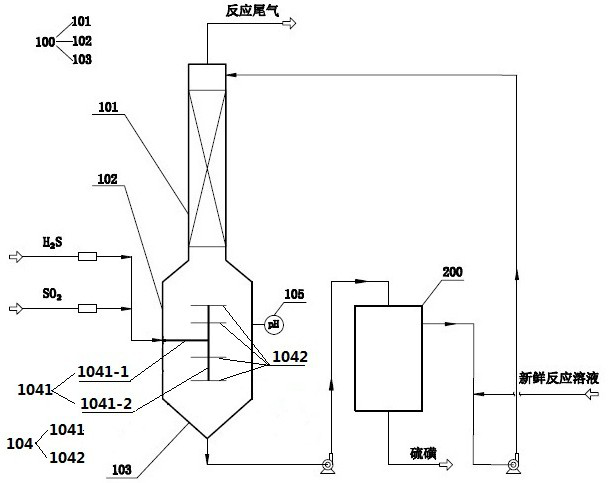

Process device and process method of liquid phase reaction desulfurization of sulfur dioxide and hydrogen sulfide

ActiveCN109529580AIncrease dissolution rateIncrease reaction rateGas treatmentDispersed particle separationReaction rateDissolution

Disclosed are a process device and a process method of liquid phase reaction desulfurization of sulfur dioxide and hydrogen sulfide. The process device includes a reactor and a separator. The reactorincludes a tail gas absorption zone, a liquid holding tank zone and a reaction zone. The liquid holding tank zone includes a separating plate, multiple gas lifting cylinders and a liquid down pipe andcommunicates with the tail gas absorption zone and the reaction zone. The lower part of the reaction zone is provided with at least two nozzles which are symmetrically distributed. The nozzles are obliquely fixed to the device wall of the reaction zone, and nozzle heads extends obliquely upward to the inside of the reaction zone. A liquid collection tank is arranged on the upper part of the reaction zone. A liquid phase extraction pipe is arranged at the bottom of the liquid collection tank and communicates the liquid collection tank and the separator. The other end of the separator is connected to the top of the tail gas absorption zone. Reaction gas is injected into the reactor through the nozzles to be violently mixing with a reaction solution in the reactor by using the process deviceof the invention, which greatly increases the dissolution rate and reaction rate of the gas in the reaction solution. The gas ejected from two symmetrical nozzles reacts in the reaction solution to generate sulfur, and the continuously injected gas pushes the reaction solution entrained with the sulfur to flow obliquely upward into the liquid collection tank. The solution in the reactor is alwaysin a flowing state so as to prevent the sulfur from depositing and scaling on the device wall and the bottom of the reactor to ensure safe, stable and long-term operation of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

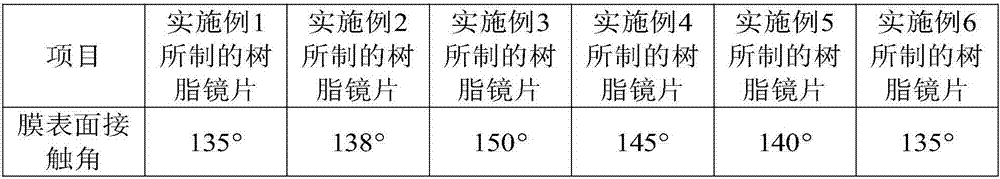

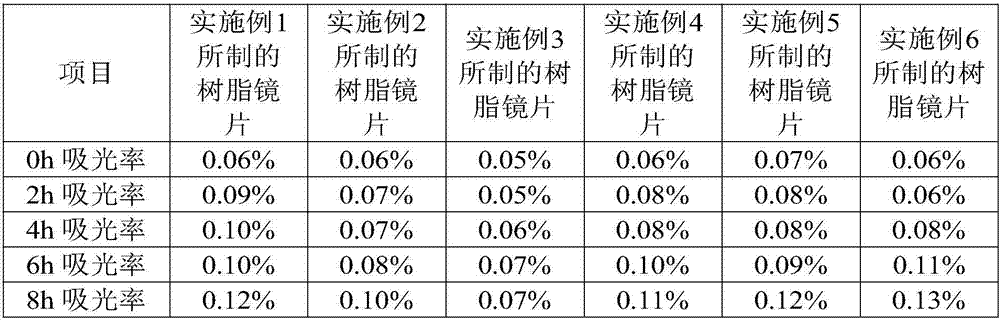

A kind of self-cleaning optical resin lens and preparation method thereof

ActiveCN105785484BSmall granularityEfficient preparation methodOptical partsOptical elementsMicrowaveRadio frequency sputtering

The invention discloses a self-cleaning optical resin lens and a preparation method therefor. The preparation method comprises the steps: putting nano-powder and nonionic surfactant into alkaline solution, moving a system into a polytetrafluoroethylene reaction still, and carrying out microwave hydrothermal reaction; slowly putting a resin substrate I into a nano solution, enabling the nano solution to be stationary for dipping, enabling the surface of the resin substrate I to grow a dense hydrophobic membrane, taking out the resin substrate I for drying, and obtaining a resin substrate II; carrying out the thermal curing processing of the resin substrate II, and obtaining a resin substrate III; carrying out the medium voltage radio-frequency sputtering of the resin substrate III, coating the surface of the resin substrate with an SiO2 film, and obtaining a resin substrate IV; carrying out the thermal curing processing of the resin substrate IV, and obtaining the self-cleaning optical resin lens. The self-cleaning optical resin lens is simple in technological method, is easy to operate, and can be produced in a large scale. The prepared self-cleaning optical resin lens has a super-hydrophobic surface, and achieves a good sterilizing effect.

Owner:JIANGSU MAAT OPTICAL CO LTD

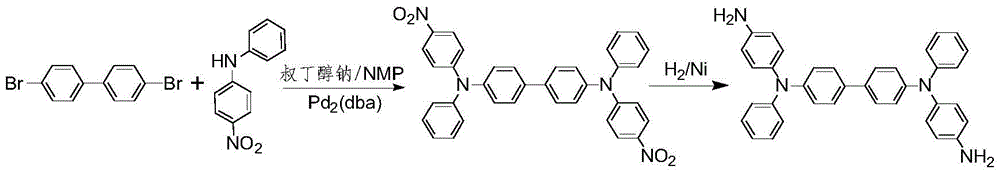

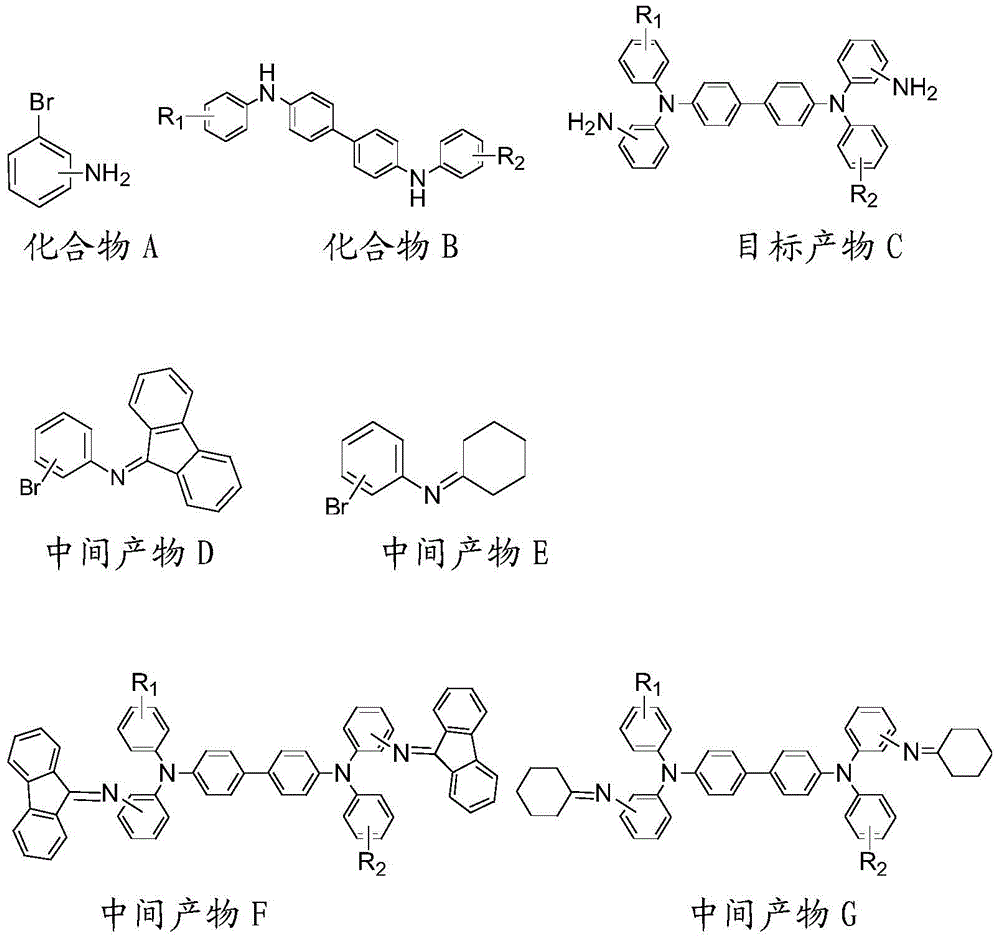

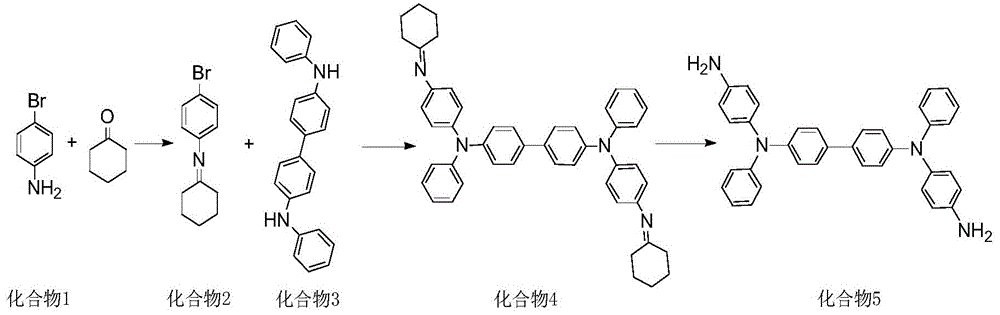

A kind of preparation method of oled intermediate material triphenylamine derivatives

ActiveCN105348109BMild reaction conditionsReduce the coupling reaction temperatureOrganic compound preparationAmino compound preparationCyclohexanoneN dimethylformamide

The invention relates to a preparation method of an OLED intermediate material terphenylamine derivative. The method includes: taking compound A and 9-fluorenone or cyclohexanone as the raw materials, dissolving the raw materials in a benzene solvent, under the catalysis of p-toluenesulfonic acid, carrying out protective reaction to generate an intermediate product D or an intermediate product E; taking a compound B and the intermediate product D or intermediate product E, dissolving them in an N, N-dimethylformamide solvent, under the catalysis of a palladium catalyst, carrying out Ullmann coupling reaction to generate an intermediate product F or intermediate product G; taking the intermediate product F or intermediate product G, adding it into an acid solution, under acidic conditions, subjecting the intermediate product F or intermediate product G to deprotection reaction so as to generate a target product C. The target product C prepared by the method provided by the invention is mainly used as an OLED organic electroluminescent material intermediate. The preparation method provided by the invention is carried out under normal pressure, and has the advantages of cheap and easily available raw materials, mild reaction conditions, simple operation, high yield and high product purity, thus being suitable for industrial mass production.

Owner:烟台九目化学股份有限公司

Process device and process method for liquid phase reaction desulfurization of sulfur dioxide and hydrogen sulfide

ActiveCN109529580BIncrease dissolution rateIncrease reaction rateGas treatmentDispersed particle separationFluid phaseReaction rate

The process device and process method of sulfur dioxide and hydrogen sulfide liquid phase reaction desulfurization, including reactor and separator, the reactor is followed by tail gas absorption area, liquid holding tank area and reaction area from top to bottom; liquid holding tank area includes partition, A number of lifters and downcomers are connected to the tail gas absorption area and the reaction area; at least two nozzles are arranged in the lower part of the reaction area, which are symmetrically distributed, and the nozzles are obliquely fixed on the wall of the reaction area, and the nozzles extend obliquely upward to the inside of the reaction area; The upper part of the reaction zone is provided with a liquid collection tank; the bottom of the liquid collection tank is provided with a liquid phase extraction pipe, which communicates with the liquid collection tank and the separator, and the other end of the separator is connected to the top of the tail gas absorption area. Using the process device of the present invention, the reaction gas is sprayed into the reactor through the nozzle and violently mixed with the reaction solution in the reactor, which greatly increases the dissolution rate and reaction rate of the gas in the reaction solution; the two symmetrical nozzles spray The gas reacts in the reaction solution to generate sulfur, and the gas that continues to be injected pushes the reaction solution entrained with sulfur to flow obliquely upward into the liquid collection tank. The solution in the reactor is always in a flowing state, preventing sulfur from depositing and scaling on the wall of the reactor and the bottom of the reactor, and ensuring the safe, stable and long-term operation of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

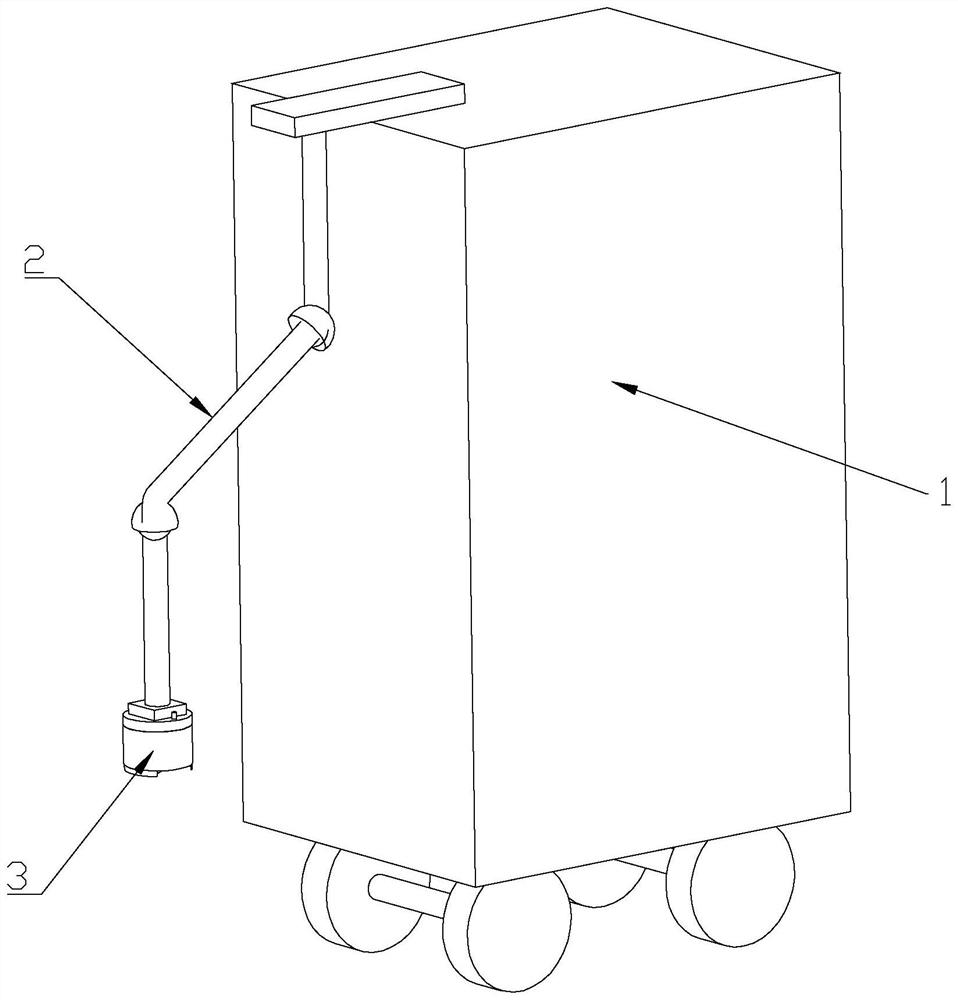

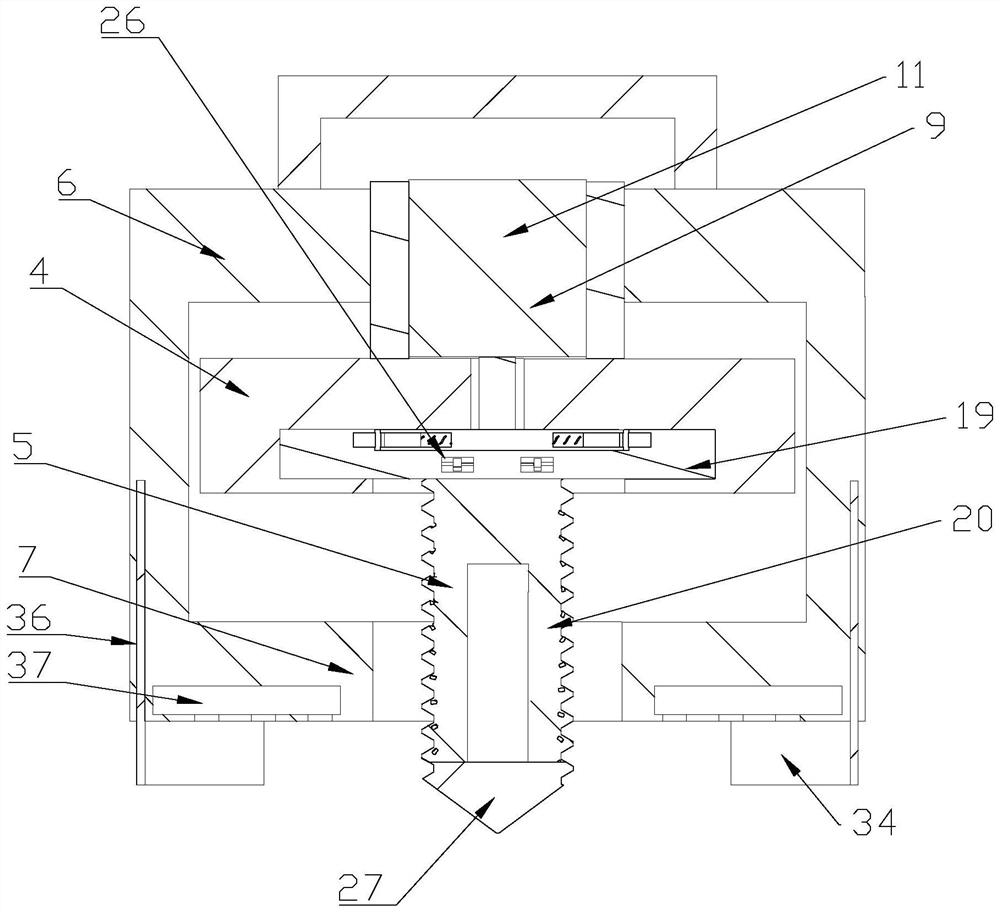

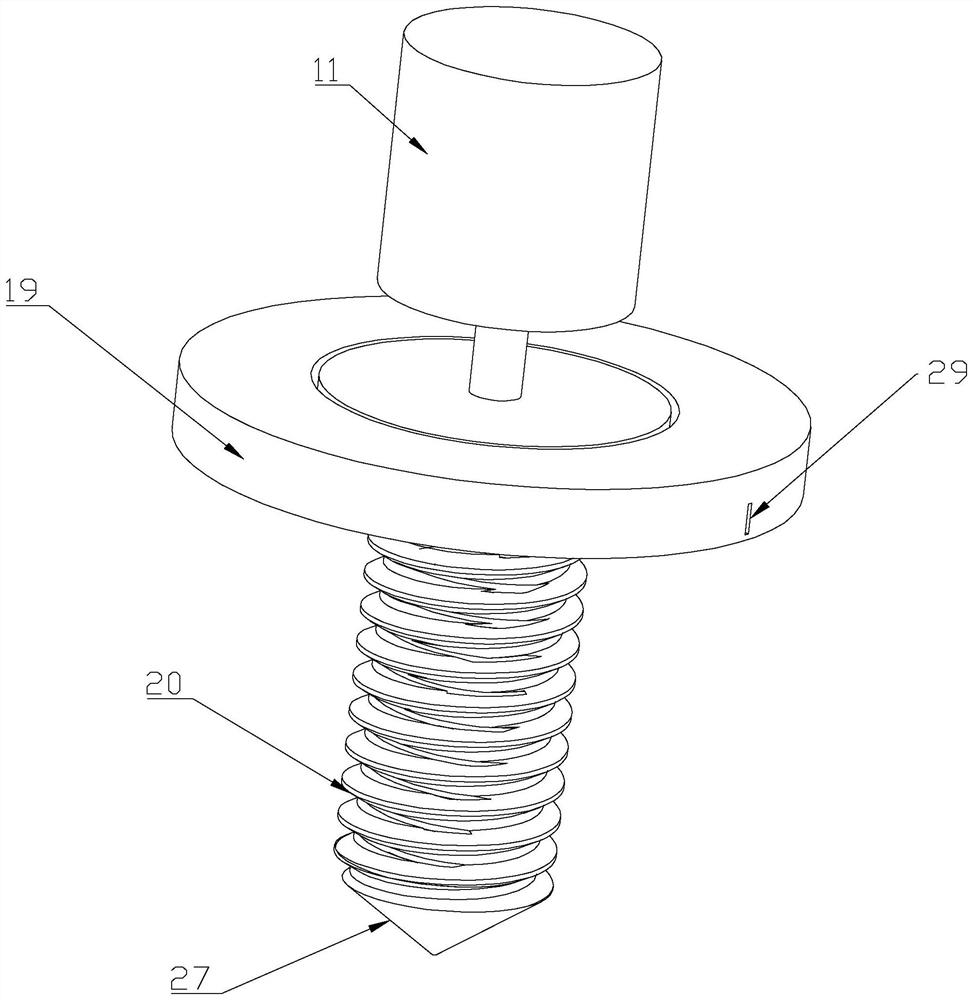

Craniotomy robot and system thereof

InactiveCN114305579AAvoid harmPrevent back movementSurgeryCranium bonePhysical medicine and rehabilitation

The craniotomy surgical robot comprises a frame body with moving rollers, the frame body is connected with a craniotomy component through a mechanical arm, the craniotomy component comprises a mounting base, a drill bit and a sleeve, a displacement assembly is arranged in the sleeve and connected with the mounting base, and the mounting base is connected with the drill bit. The displacement assembly drives the mounting base to move in the direction away from the drill bit, an emergency stop mechanism is arranged in the drill bit, an emergency stop assembly matched with the emergency stop mechanism is arranged on the mounting base, the drill bit can be suddenly stopped through the arrangement of the emergency stop mechanism, and the pump body control unit is connected with the pump body control unit. And meanwhile, the mounting seat has a certain displacement function through the arrangement of the displacement assembly, so that the mounting seat can be displaced after the skull is drilled through, and a doctor can conveniently respond to the force.

Owner:WENZHOU CENT HOSPITAL

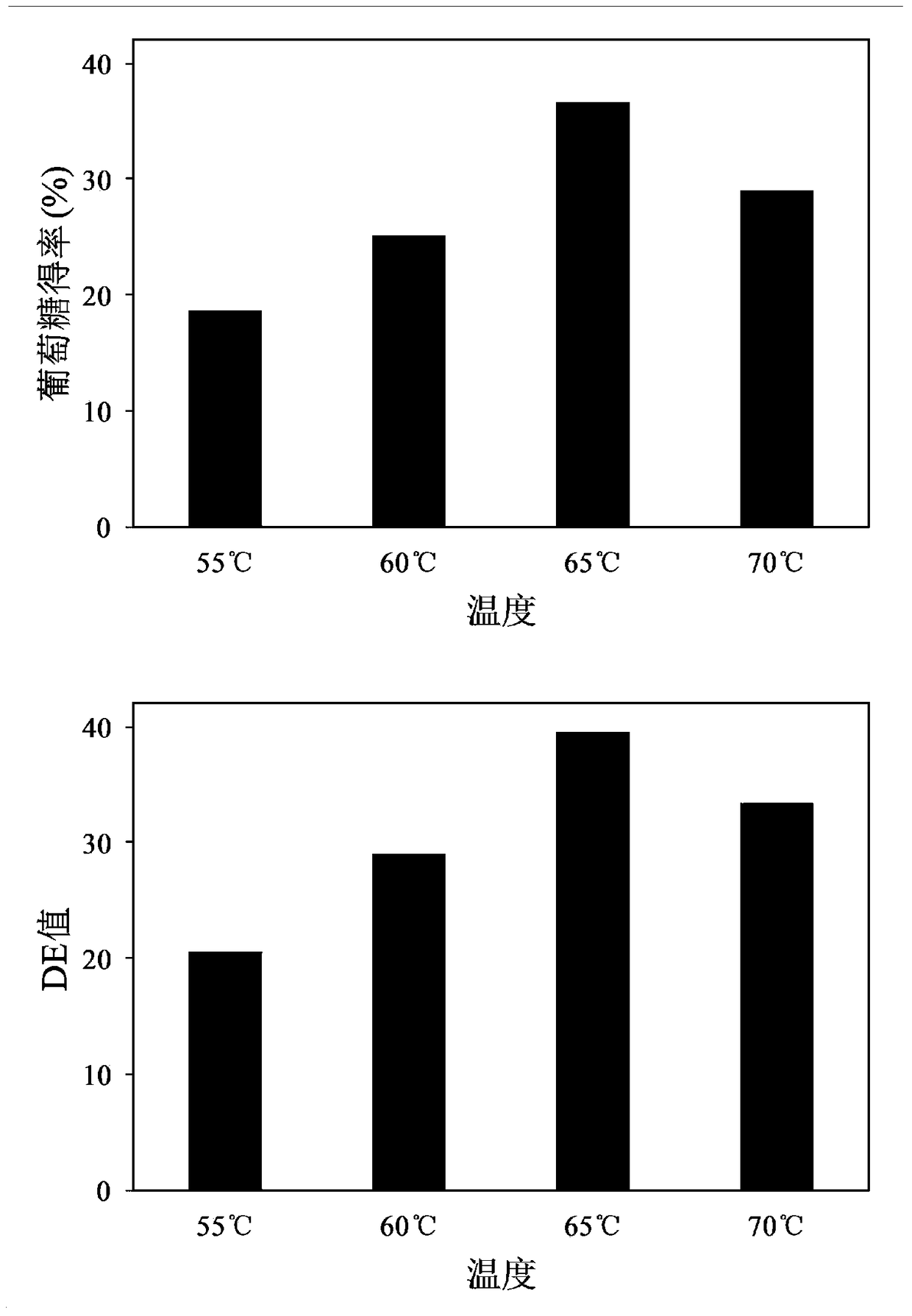

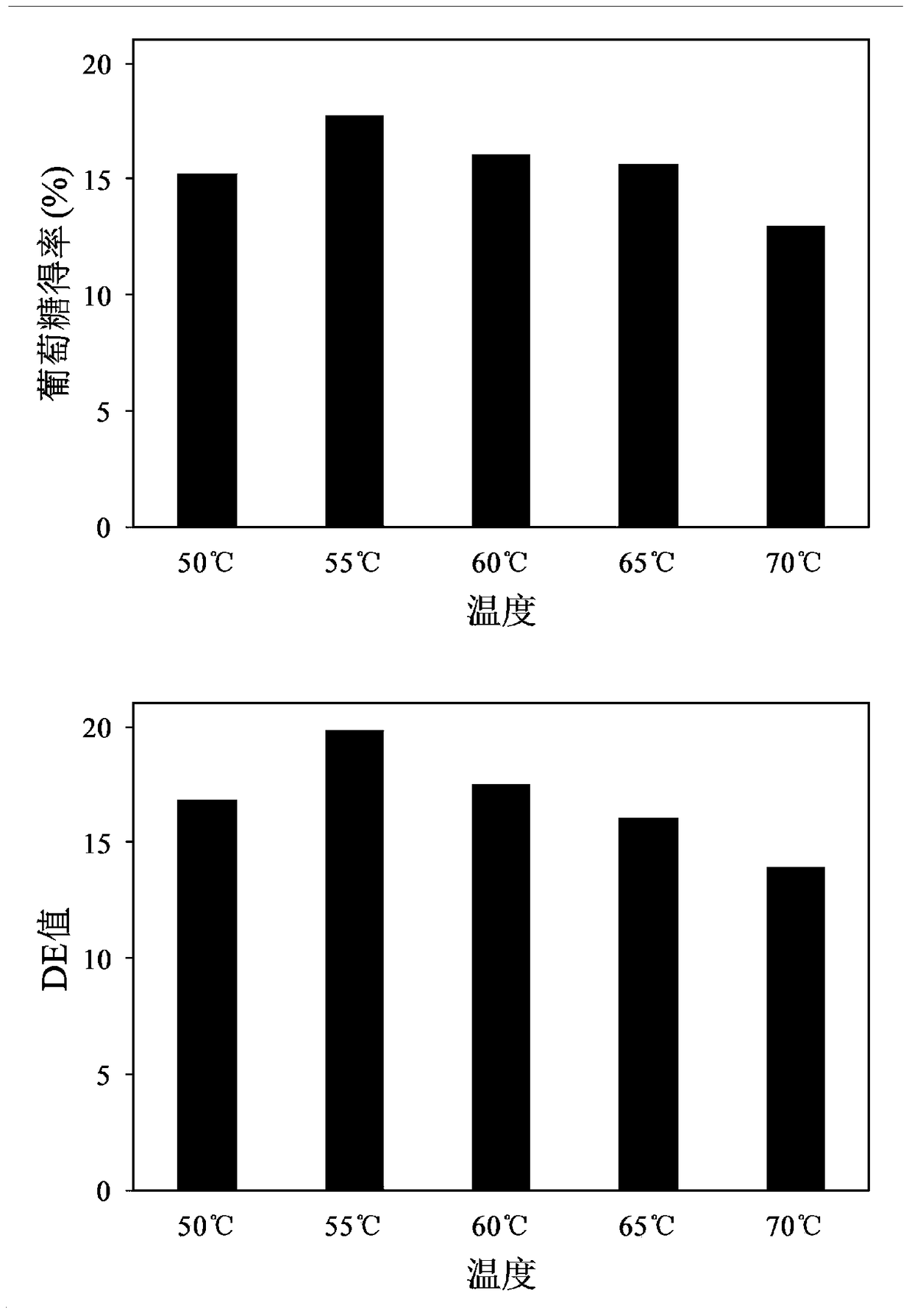

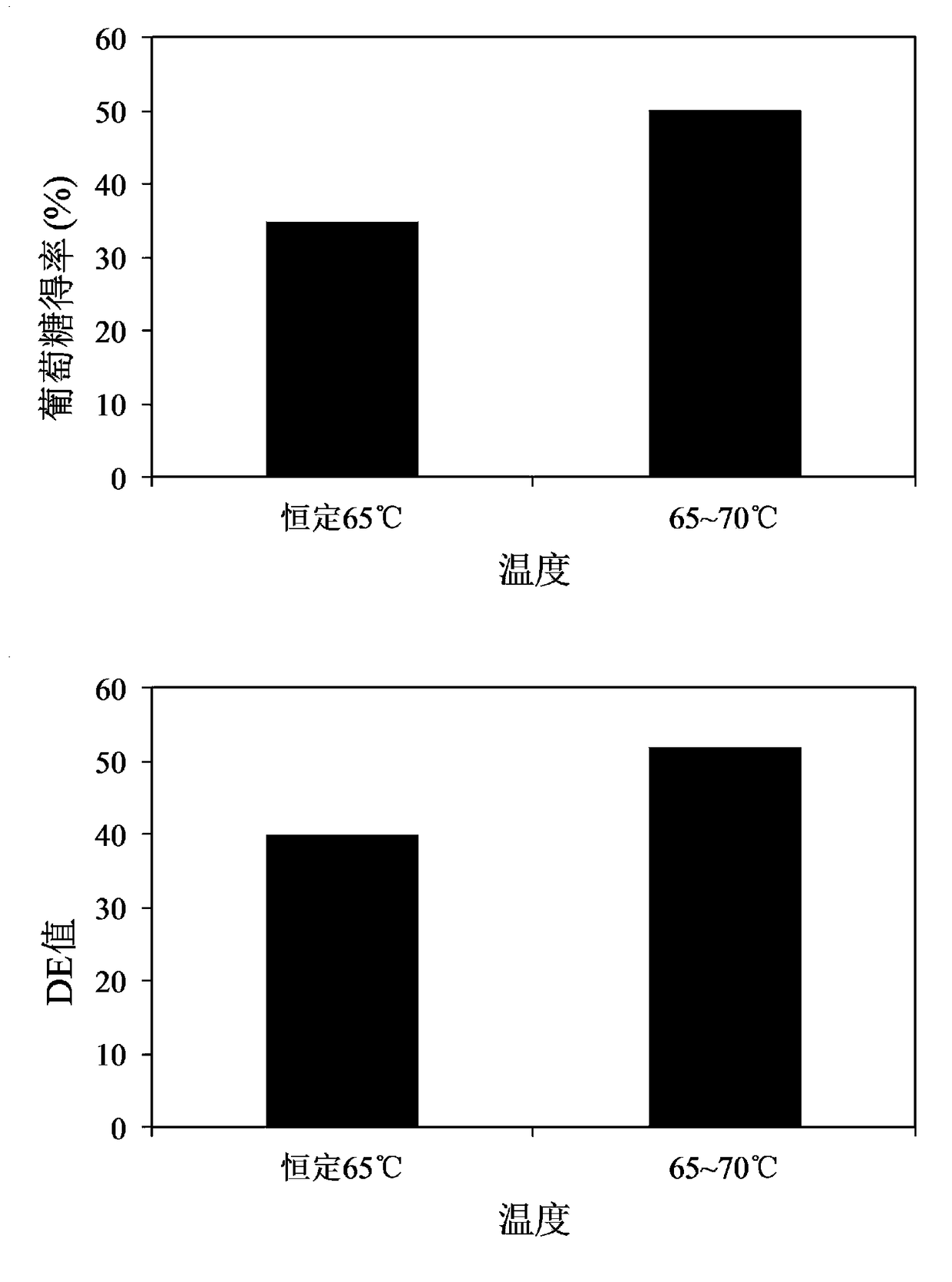

A method for improving the enzymatic hydrolysis efficiency of raw starch

The invention discloses a method for improving the enzymolysis efficiency of raw starch, and belongs to the technical field of sugar preparation with starch. According to the method, high-concentration starch is used a substrate and added with raw amylase, the enzymolysis efficiency is improved by adopting a two-stage temperature control method, and the production cost of glucose or other starch sugar is finally reduced.

Owner:JIANGNAN UNIV

A method for reactive desulfurization of hydrogen sulfide and sulfur dioxide

ActiveCN109534297BIncrease acidityRapid responseDispersed particle separationSulfur preparation/purificationSolubilitySulfur product

A method for desulfurization by reaction of hydrogen sulfide and sulfur dioxide. Hydrogen sulfide and sulfur dioxide are reacted in a solution, the solution includes water and at least one organic basic compound soluble in water, and the initial pH value of the solution is ≥7.2. The mass fraction of the organic basic compound in the solution is 0.1% to 30%; in the above method, the selected organic basic compound is a compound with a solubility in water ≥ 0.1g / 100g water, preferably a solubility ≥ 1g / 100g water. The above reaction can be carried out at normal temperature and pressure, and the addition of organic basic compounds makes H 2 S and SO 2 The reaction time is greatly shortened, indicating that the dissolution rates of the two in water tend to be similar, so that the reaction is more likely to occur, and the sulfur product obtained by the reaction is high in purity, only liquid-solid separation is required without refining. The required reaction conditions of the method of the invention are mild, the equipment is simple and easy to process, the investment is low, and the operation is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

Construction device and method of hand-digging pipe jacking in mud, sand and silt areas

The invention provides a hand digging type pipe jacking construction device and method for sediment and sludge areas. The hand digging type pipe jacking construction device comprises a tool pipe, wherein jacks are arranged between the tool pipe and a concrete back. A water seepage pipe is arranged at the front end of the tool pipe. Part of the water seepage pipe penetrates through a pipe cap, and the other part of the water seepage pipe is located in the tool pipe. The rear end of the water seepage pipe is open, and a plurality of water seepage holes are formed in the pipe wall of the water seepage pipe. According to the hand digging type pipe jacking construction device and method for sediment and sludge areas, the water seepage pipe is arranged at the front end of the tool pipe, the underground water level is lowered through the water collection action of the water seepage pipe, and therefore strength of a work soil body is improved, and conditions are created for hand digging type work. Well-point dewatering pipes are arranged, and therefore deep well point dewatering is achieved, the water content of the portion, provided with the concrete back, of the soil body is lowered, and strength of the position of the soil body is improved. Load-bearing piles are arranged, and therefore the force borne by the concrete back is further increased, and end reaction can be conveniently borne by the jacks.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

A preparation method of dopamine-modified hyaluronic acid micelles

ActiveCN102702539BUnique moisturizing typeGood biocompatibilityBiocompatibility TestingBiological materials

The invention provides a method for preparing dopamine-modified hyaluronic acid micelles, which belongs to the technical field of polymer materials and natural macromolecules. The invention introduces a dopamine unit into the main chain of the hyaluronic acid through amidation reaction, endows the hyaluronic acid with a certain amphiphilicity, and self-assembles in an aqueous solution to form micelles with particle diameters in the range of 100-700nm. This hyaluronic acid micelle has excellent biocompatibility, hydrophilicity and viscoelasticity, and can be used in the fields of biomaterials, hydrophilic colloids, etc., and the adhesion of dopamine endows it with good interfacial properties, which is used for emulsification Agents can be used in emulsion, food and cosmetics and other fields.

Owner:林玉洪

Method for preparing methyl mercaptan through reaction of methyl chloride and hydrogen sulfide

The invention discloses a method for preparing methyl mercaptan through a reaction of methyl chloride and hydrogen sulfide. The method comprises the following steps: inflating quantitative methyl chloride and hydrogen sulfide gas into a reactor in which a catalyst is added, and performing a chemical reaction at a certain temperature and under a certain pressure, cooling after the completion of thereaction, and separating to obtain the methyl mercaptan. By the method, the gas-gas reaction is adopted, the operation is simple, a target product has high selectivity and high purity, no waste wateris produced in the process, the pollution is low and a byproduct is mainly hydrogen chloride which can be sold as a product, so that the method has a relatively great economic significance.

Owner:山东祥维斯生物科技股份有限公司

Serialization production method for direct synthesizing alkoxy silane by chlorine-free process

InactiveCN101041668BHigh catalytic activityImprove conversion rateSilicon organic compoundsHydrogenAlcohol

The invention discloses a continual manufacturing method of tetraalkoxy silicane, which comprises the following steps: blending alkaline catalyst and solvent in the autoclave with weight rate at 1:5-5:1; heating to 130-210 deg.c to activate 2-5h; adding alcohol and 20-80% silicon powder with molar rate at 3:1-1:3 under 150-220 deg.c; transmitting composition into separating tower; draining hydrogen from top of tower; separating tetraalkoxy silicane and low-boiling point component in the separating tower; returning alcohol to autoclave.

Owner:句容市兴春化工有限公司 +1

A process device and process method for reactive desulfurization of hydrogen sulfide and sulfur dioxide

ActiveCN109529579BRealize the effect of self-stirringIncrease dissolution rateDispersed particle separationSulfur preparation/purificationOrganic baseReaction rate

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for producing sulfuric acid from gypsum

The invention discloses a method for producing sulfuric acid by using gypsum. The method comprises the following steps of: (1) putting gypsum powder into a roasting device, heating the temperature to a range between 700 and 850 DEG C, and continually introducing methane gas into the roasting device to react with the gypsum, wherein the molar ratio of the methane gas to the gypsum is 1: (4-4.2); and (2) sequentially introducing the mixed gas of generated sulfur dioxide, carbon dioxide and water vapor into a dust remover and a drying pipeline, then introducing the mixed gas to a condensation pipe of less than 10 DEG C below zero, introducing the rest mixed gas into a sodium hydroxide solution of which the concentration is more than or equal to 50 weight percent, newly introducing the mixed gas into the roasting device, introducing the sulfur dioxide liquefied through the condensation pipe into an oxidation chamber containing a vanadium pentoxide catalyst to convert the sulfur dioxide into sulfur trioxide at the temperature between 500 and 900 DEG C, finally introducing the generated sulfur trioxide into concentrated sulfuric acid of which the concentration is more than or equal to 75 percent, and thus obtaining the sulfuric acid. The roasting temperature in the method is lower than that in other methods for preparing the sulfuric acid by using calcium sulfate, and the method is low in energy consumption and can reduce the production cost.

Owner:刘立文

Process device and process method for liquid phase reaction desulfurization of hydrogen sulfide and sulfur dioxide

ActiveCN109529578BEvenly dispersedIncrease dissolution rateDispersed particle separationSulfur preparation/purificationFluid phaseReaction rate

A process device and process method for hydrogen sulfide and sulfur dioxide liquid-phase reaction desulfurization, including a reactor and a separator. The other end of the reactor is connected to the top of the tail gas absorption area of the reactor; the reaction area is provided with a gas pipe, which is composed of a main gas pipe and a gas branch pipe, and the pipes in the gas pipe are connected to each other, and the two ends of the main pipe II are closed. The hydrogen sulfide and sulfur dioxide desulfurization reaction is carried out by using the above-mentioned device, and the reaction solution includes water and at least one organic basic compound that can dissolve in water, so that the pH value of the solution is ≥ 7.2. The device and method of the present invention can make the reaction gas entering the reactor form a spray with a certain arc, promote the self-stirring of the liquid, facilitate the uniform dispersion of the gas in the reaction solution, and greatly increase the concentration of the gas in the reaction solution. Dissolution rate and reaction rate; the reaction time of hydrogen sulfide and sulfur dioxide is less than 15s, the reaction conditions are mild, the obtained sulfur does not need to be refined, the purity is high, the equipment is simple and easy to process, the investment is low, and the operation is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

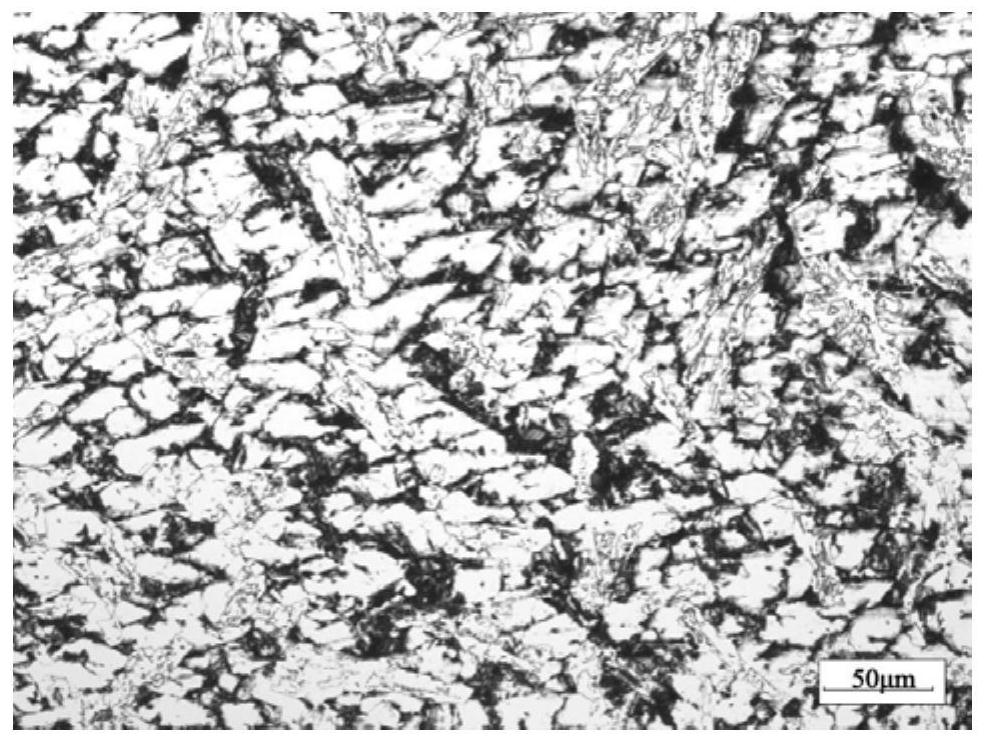

A kind of ternary boride and its preparation method and application

ActiveCN112008294BImprove wear resistanceImprove toughnessArc welding apparatusPlasma welding apparatusMo elementSlag (welding)

The invention belongs to the technical field of welding material preparation, and in particular relates to a ternary boride and its preparation method and application. The raw materials of the ternary boride include, by mass fraction, 2-8% boron, 20-50% iron, 31-55% molybdenum, 1-15.5% chromium, 0.2-3% silicon element, 1‑5% nickel and 0.5‑2.5% manganese. Using boron, iron, molybdenum, chromium, silicon, nickel and manganese in a specific ratio as raw materials can ensure that the ternary boride surfacing layer generated in the surfacing process has good wear resistance, toughness and hardness; the present invention The provided raw materials can be used as welding materials in surfacing welding, and ternary borides are synthesized in situ by welding metallurgy. The ternary borides have good bonding strength with the metal matrix and are not easy to fall off. Adding silicon element in the ternary boride can remove the oxygen in the boride and form welding slag to be discharged.

Owner:山东旭拓新材料科技有限公司

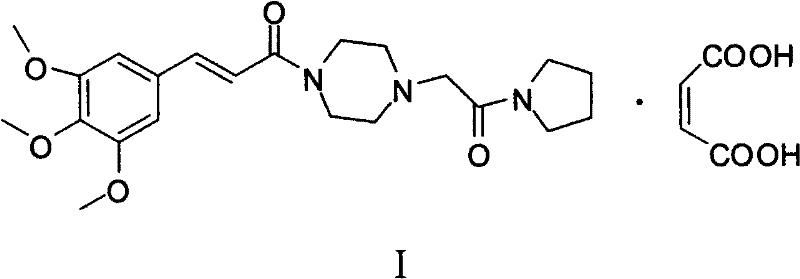

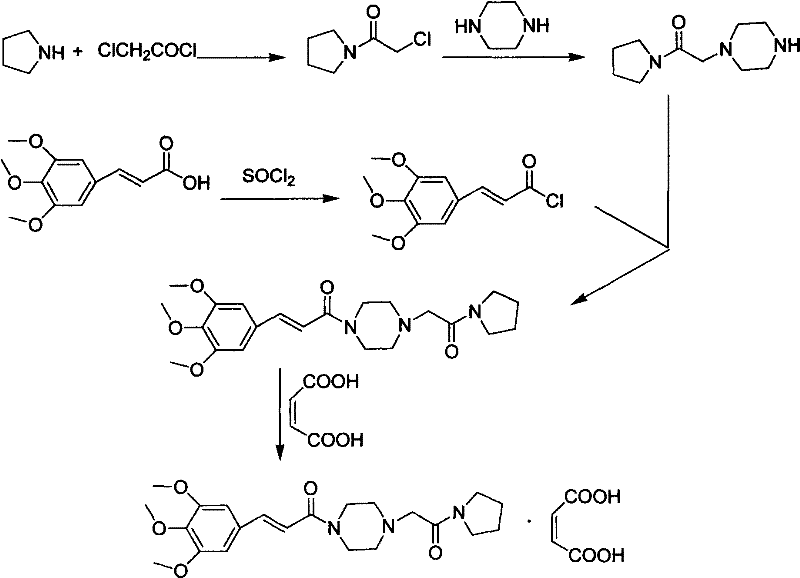

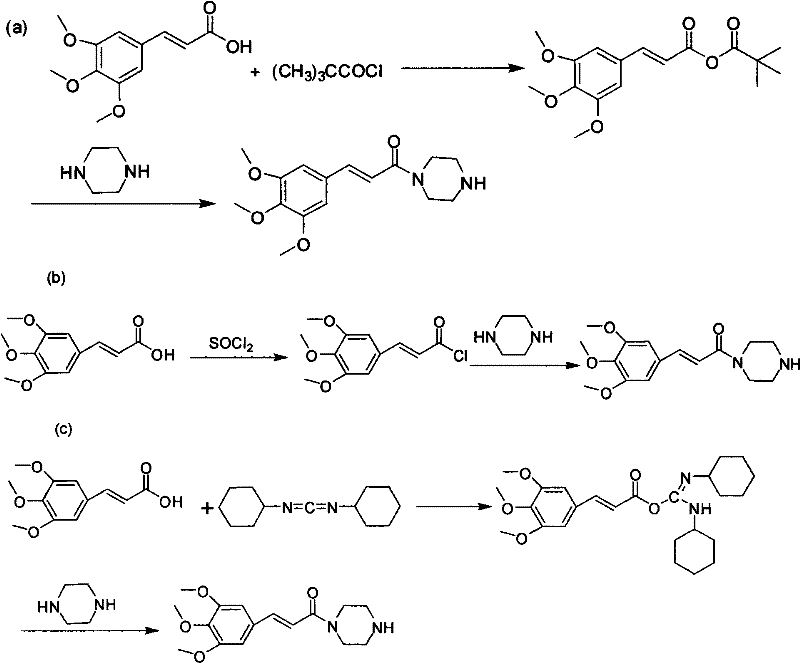

Method for preparing cinepazide maleate

InactiveCN101591310BEasy to removeSimple ingredientsOrganic chemistryCardiovascular disorderCarboxylic acid halidesPyrrole

The invention provides a method for preparing cinepazide maleate. The method comprises the following steps: preparing mixed acid anhydride or acyl halide by taking 3,4,5-trimethoxycinnamic acid as a raw material; then, reacting the mixed acid anhydride or the acyl halide with absolute piperazidine to prepare 1-(3,4,5-trimethoxyphenyl)piperazidine, or dehydrating the 3,4,5-trimethoxycinnamic acid and the absolute piperazidine to generate 1-(3,4,5-trimethoxyphenyl)piperazidine under the action of dicyclohexylcarbodiimide; reacting chloracetyl chloride with nafoxidine to prepare N-(2-chloracetyl)nafoxidine; reacting the N-(2-chloracetyl)nafoxidine with 1-(3,4,5-trimethoxyphenyl)piperazidine to prepare cinepazide free alkali; and salifying the cinepazide free alkali and maleic acid to preparethe cinepazide maleate. The method has the advantages of accessible raw materials, mild reaction condition, simple and easy operation, short synthesis route, high yield, industrial production availability and the like.

Owner:北京兴德通医药科技股份有限公司

Process device and process method for liquid phase desulfurization of hydrogen sulfide and sulfur dioxide

ActiveCN109529573BIncrease dissolution rateIncrease reaction rateDispersed particle separationFluid phaseOrganic base

A process device and process method for liquid phase desulfurization of hydrogen sulfide and sulfur dioxide, including a reactor and a separator. Inlet pipe, which is arranged on the same level, and the gas inlet pipe extends to the inside of the reaction zone, which is an arc-shaped pipe, or a straight pipe whose end is bent into an arc-shaped; the settling area is connected to the separator, and the separator The other end is connected to the top of the tail gas absorption zone of the reactor. The hydrogen sulfide and sulfur dioxide desulfurization reaction is carried out by using the above-mentioned device, and the reaction solution includes water and at least one organic basic compound that can dissolve in water, so that the pH value of the solution is ≥ 7.2. The device and method of the present invention can increase the dissolution rate and reaction rate of gas in the reaction solution, the response time of hydrogen sulfide and sulfur dioxide reaction is below 15s, the reaction conditions are mild, the obtained sulfur does not need to be refined, the purity is high, and the equipment is simple and easy to process , low investment, safe operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

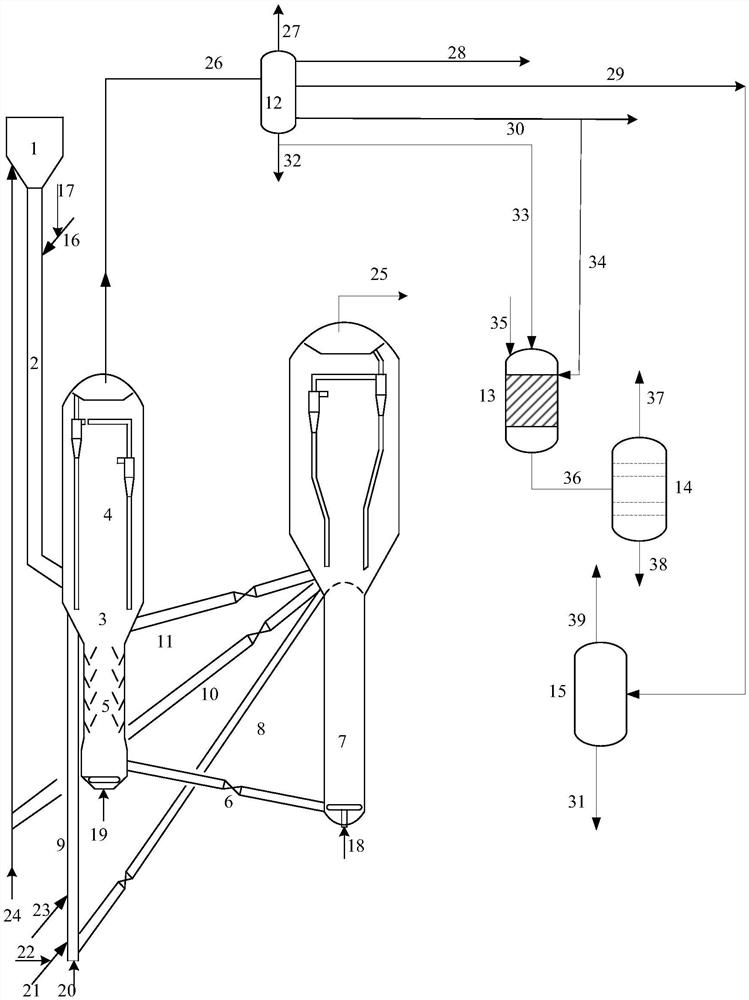

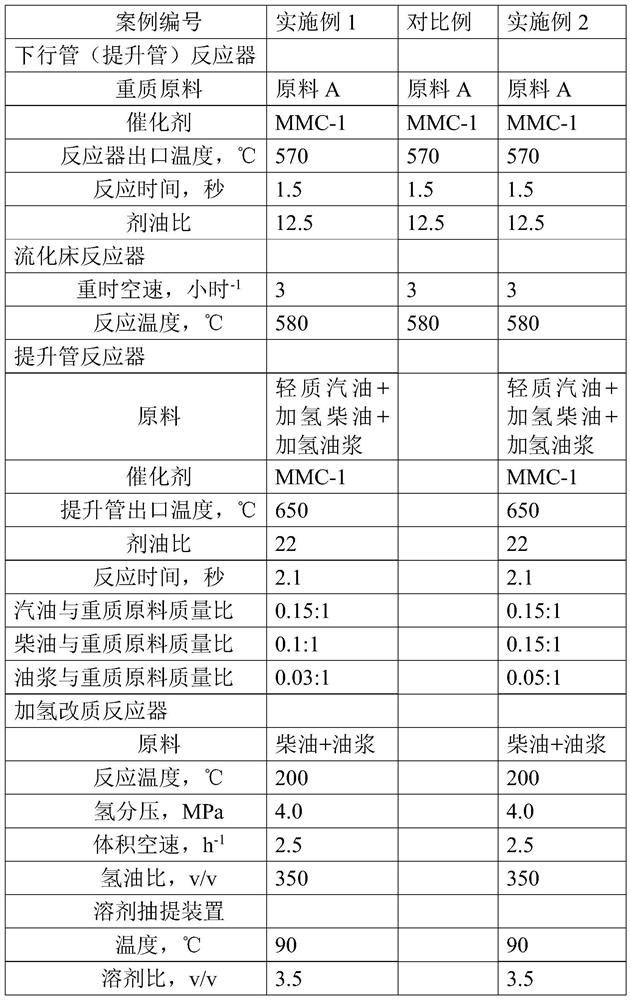

Catalytic cracking method and system

ActiveCN113897216AImprove conversion ratePromotes re-lysisCatalytic crackingHydrocarbon oils treatment productsProcess engineeringAromatic hydrocarbon

The invention relates to a catalytic cracking method and a system. The catalytic cracking method comprises a combined process of catalytic cracking, hydro-upgrading and aromatic hydrocarbon extraction. According to the process, benzene, methylbenzene and xylene can be co-produced while low-carbon olefin is produced to the maximum extent, and product distribution is optimized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com