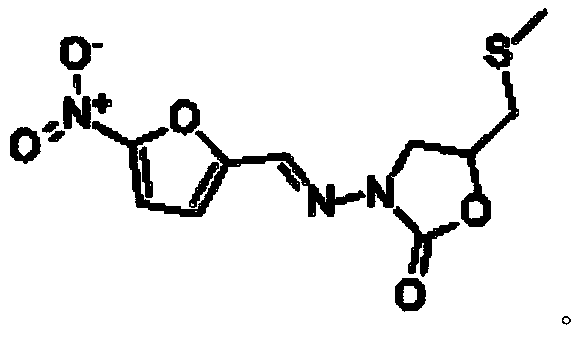

Synthetic method of nifuratel

A synthesis method and nifuratel technology are applied in the field of pharmaceutical synthesis and can solve the problems of low purity, many product impurities, low reaction rate and yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

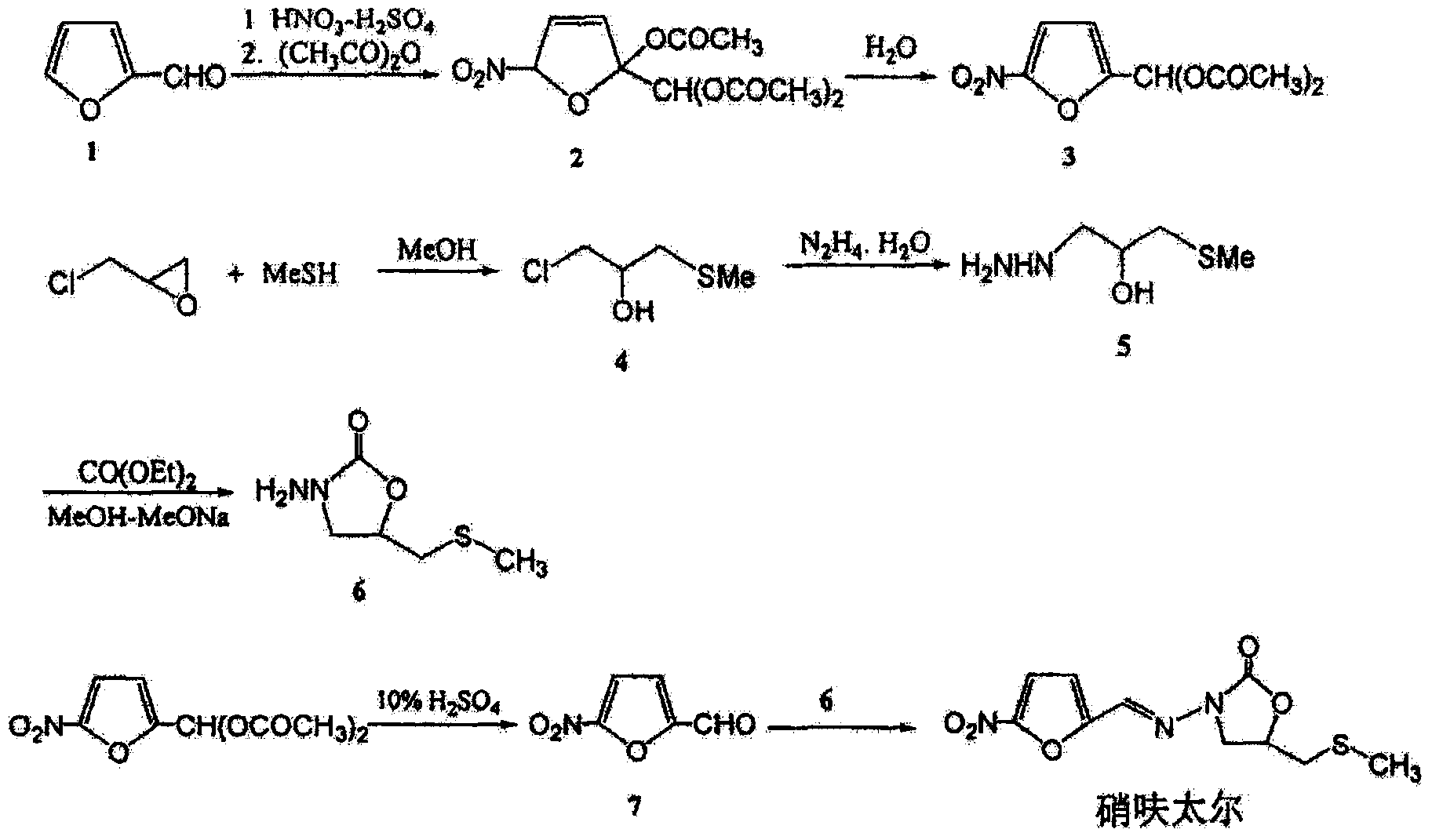

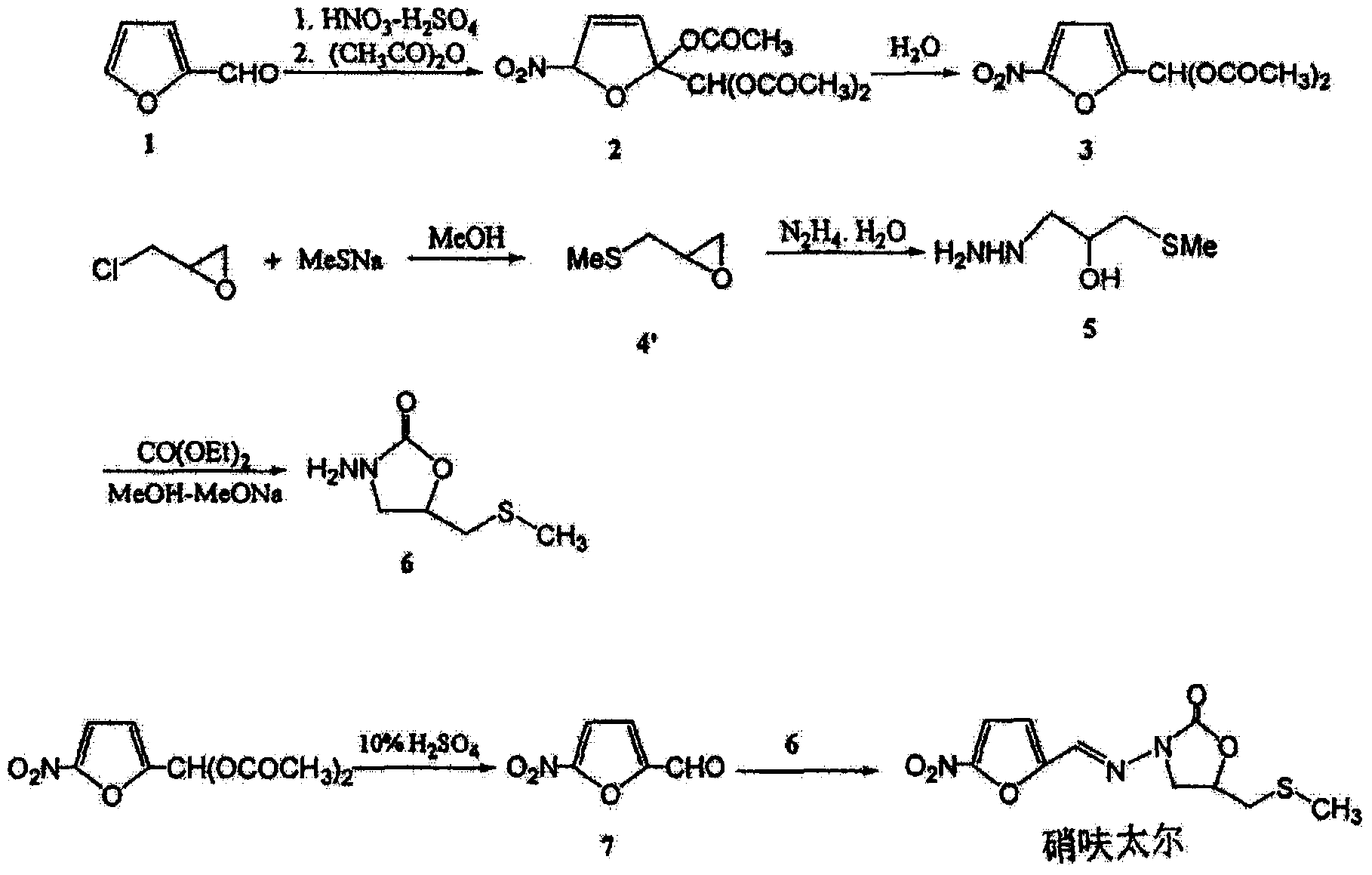

Method used

Image

Examples

Embodiment 1

[0043] Carry out the preparation of nifuratel according to the following process:

[0044] (1) Put 1mol epichlorohydrin, 280ml dichloromethane, and 0.05mol tetrabutylammonium bromide into the reaction flask, and slowly add 20% aqueous solution of sodium methylmercaptide (sodium methylmercaptan 6.5mol) dropwise under stirring , the dropping time is 2 hours, and the temperature is controlled at 15-25°C during the dropping process; after the dropping is completed, the temperature is kept at 18°C for 3 hours. Epoxypropyl methyl sulfide, yield is 78%;

[0045] (2) Put hydrazine hydrate into another reaction bottle according to the molar ratio of epoxypropyl methyl sulfide and hydrazine hydrate as 1:1.05, stir and raise the temperature to 95°C, slowly drop the epoxy obtained in step (1) Propyl methyl sulfide, dropwise time is 1h; then react at 95-98°C for 3h, after the reaction is completed, lower to room temperature; first concentrate the reaction solution to viscous, then disti...

Embodiment 2

[0050] Carry out the preparation of nifuratel according to the following process:

[0051] (1) Put 1mol of epichlorohydrin, 280ml of dichloromethane, and 0.055mol of tetrabutylammonium bromide into the reaction flask, and slowly add 20% aqueous solution of sodium methyl mercaptide (7 mol of sodium methyl mercaptide) dropwise under stirring. The dropping time is 2 hours, and the temperature is controlled at 15-25°C during the dropping process; after the dropping, keep the temperature at 20°C for 3 hours, after the reaction, distill the reaction solution under reduced pressure, and collect the fractions of bp2050-55°C to obtain purified ring Oxypropyl methyl sulfide, yield is 80%;

[0052] (2) According to the molar ratio of glycidyl methyl sulfide and hydrazine hydrate as 1:1.1, put hydrazine hydrate into another reaction bottle, stir and raise the temperature to 95°C, slowly drop the epoxy obtained in step (1) Propyl methyl sulfide, dropwise time is 1h; then react at 95-98°C ...

Embodiment 3

[0057] Carry out the preparation of nifuratel according to the following process:

[0058] (1) Put 1mol of epichlorohydrin, 280ml of dichloromethane, and 0.06mol of tetrabutylammonium bromide into the reaction flask, and slowly add 20% aqueous solution of sodium methyl mercaptide (8 mol of sodium methyl mercaptide) dropwise under stirring. The dropping time is 2 hours, and the temperature is controlled at 15-25°C during the dropping process; after the dropping, keep the temperature at 20°C for 3 hours, after the reaction, distill the reaction solution under reduced pressure, and collect the fractions of bp2050-55°C to obtain purified ring Oxypropyl methyl sulfide, yield is 82%;

[0059] (2) According to the molar ratio of glycidyl methyl sulfide and hydrazine hydrate as 1:1.2, put hydrazine hydrate into another reaction bottle, stir and raise the temperature to 95°C, slowly drop the epoxy obtained in step (1) Propyl methyl sulfide, dropwise time is 1h; then react at 95-98°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com