Patents

Literature

73 results about "Sodium methanethiolate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium methanethiolate or sodium thiomethoxide (CH₃SNa, MeSNa) is the sodium conjugate base of methanethiol. This compound is commercially available as a white solid. It is a powerful nucleophile that can be used to prepare methylthioethers. Its hydrolysis in moist air produces methanethiol, which has a low odor threshold and a noxious fecal smell.

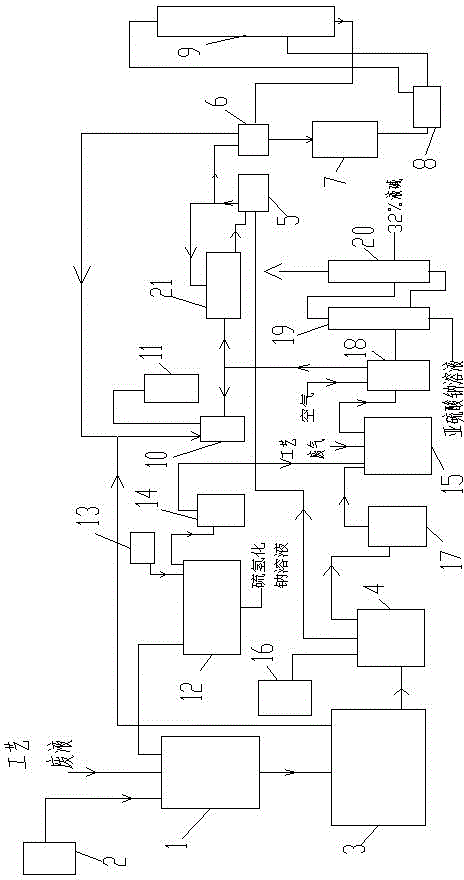

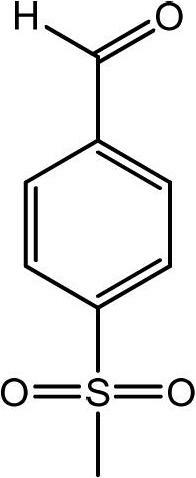

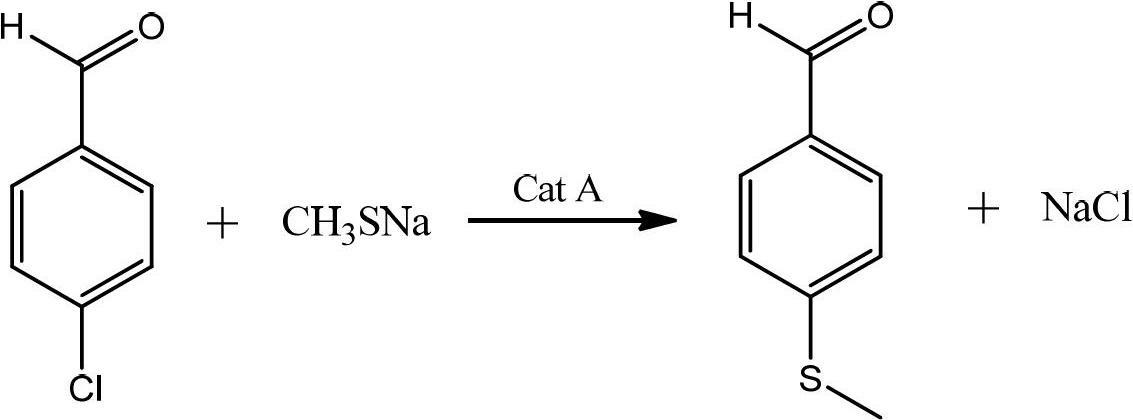

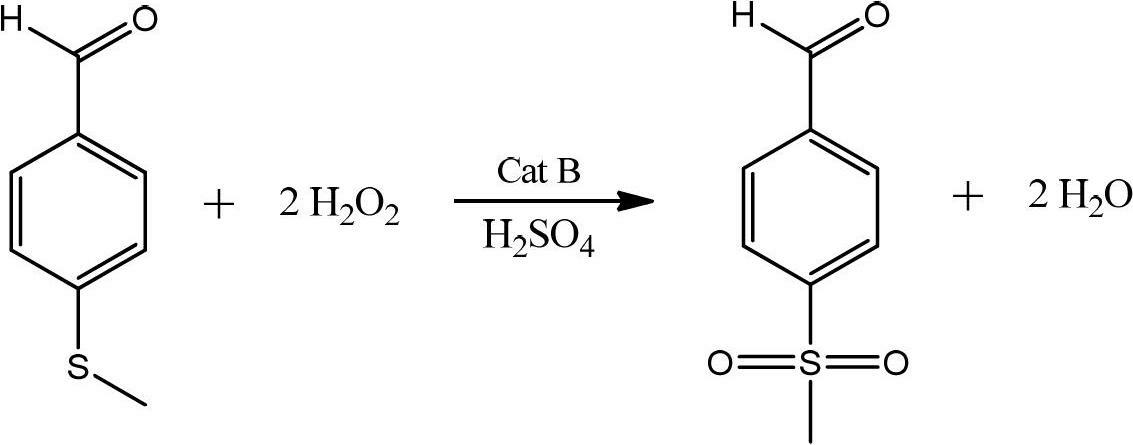

Preparation method of p-methylsulfonyl benzaldehyde

ActiveCN102675167AShort reaction pathShorten the production cycleOrganic chemistryOrganic compound preparationP-chlorobenzaldehydeBenzaldehyde

The invention discloses a preparation method of p-methylsulfonyl benzaldehyde, which takes p-chlorobenzaldehyde as starting material, and comprises the steps of: enabling the starting material to have reaction with sodium methyl mercaptide water solution under the action of phase transfer catalyst to obtain p-methylthio benzaldehyde; and oxidizing the p-methylthio benzaldehyde by hydrogen peroxide under the action of sulfuric acid and oxidation catalyst to obtain the p-methylsulfonyl benzaldehyde. The preparation method is easy in obtaining of raw material of the p-methylsulfonyl benzaldehyde, simple and convenient in operation, low in cost, high in yield and suitable for industrial production.

Owner:SHANDONG HANXING PHARM TECH CO LTD +1

Synthetic method for sulforaphane

ActiveCN102249968AAvoid hydrazinolysisSimple and fast operationOrganic chemistryBulk chemical productionSulforaphaneSodium methanethiolate

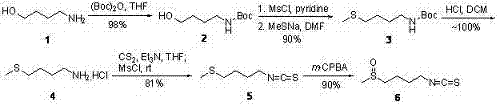

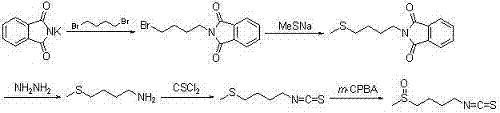

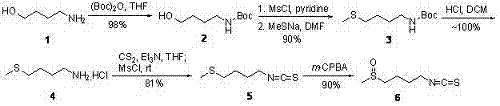

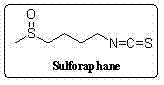

The invention provides a synthetic method for sulforaphane and belongs to the field of drug synthesis. The method comprises the following steps that: after amino in 4-amino-1-butanol is protected by Boc groups, hydroxy in 4-amino-1-butanol is changed into methanesulfonyl ester by methanesulfonyl chloride, and then the resultant reacts with sodium methyl mercaptide to produce 4-methylthio butyl-1-tert-butoxycarbonylamide; Boc protective groups are removed under acidic condition to obtain 4-methylthio-1-butylamine; 4-methylthio-1-butylamine reacts with carbon disulfide for one hour in the presence of triethylamine and p-toluenesulfonyl chloride is added for treatment for half an hour to produce 4-methylthio butyl-1-isothiocyanate; and at last 4-methylthio butyl-1-isothiocyanate is oxidized by m-CPBA to produce sulforaphane. According to the invention, complex hydrazinolysis of phthalimide in aftertreatment is avoided and toxic thiophosgene is not needed in the preparation of isothiocyanate; overall yield of sulforaphane is 64%, substantially higher than the overall yield of 8% reported in literature; the whole preparation process is simple and time-saving and is suitable for large scale production.

Owner:江苏宁录科技股份有限公司

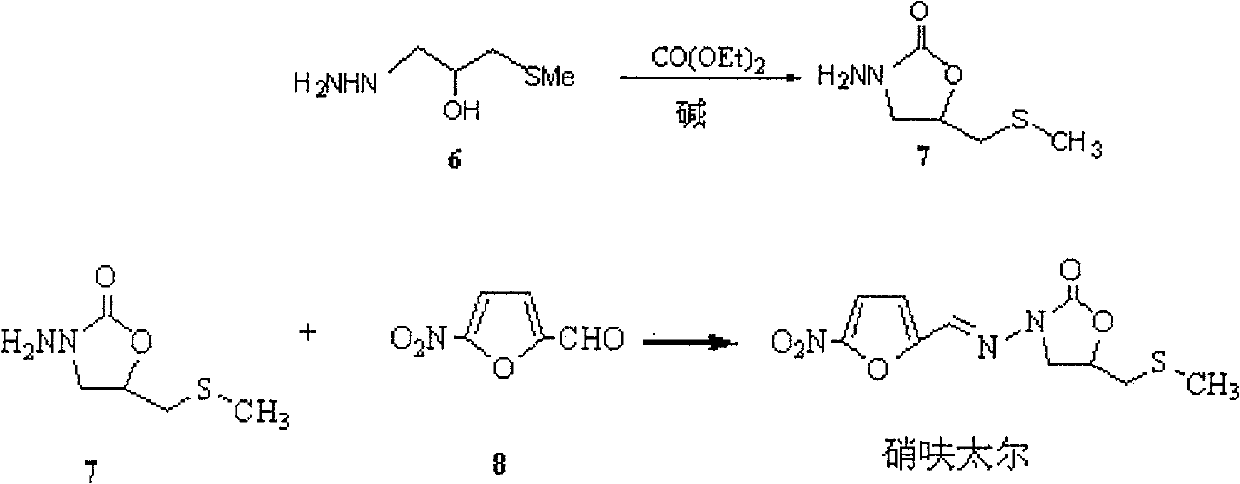

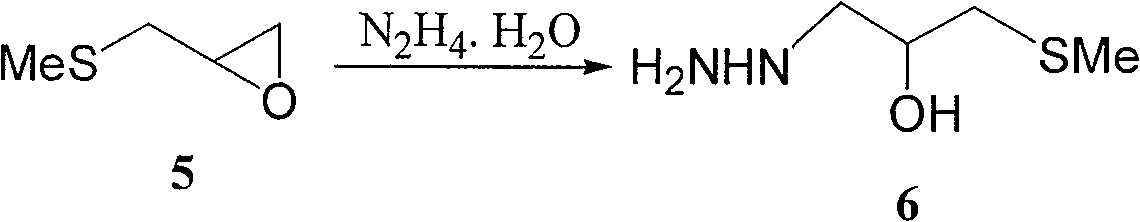

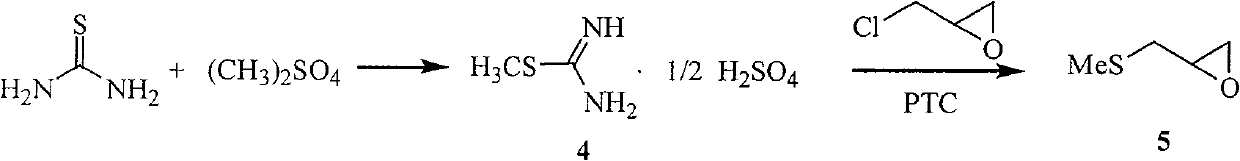

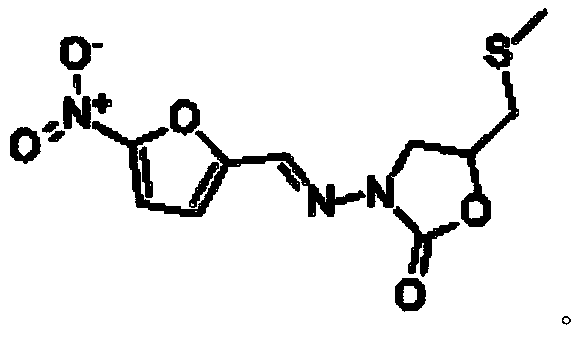

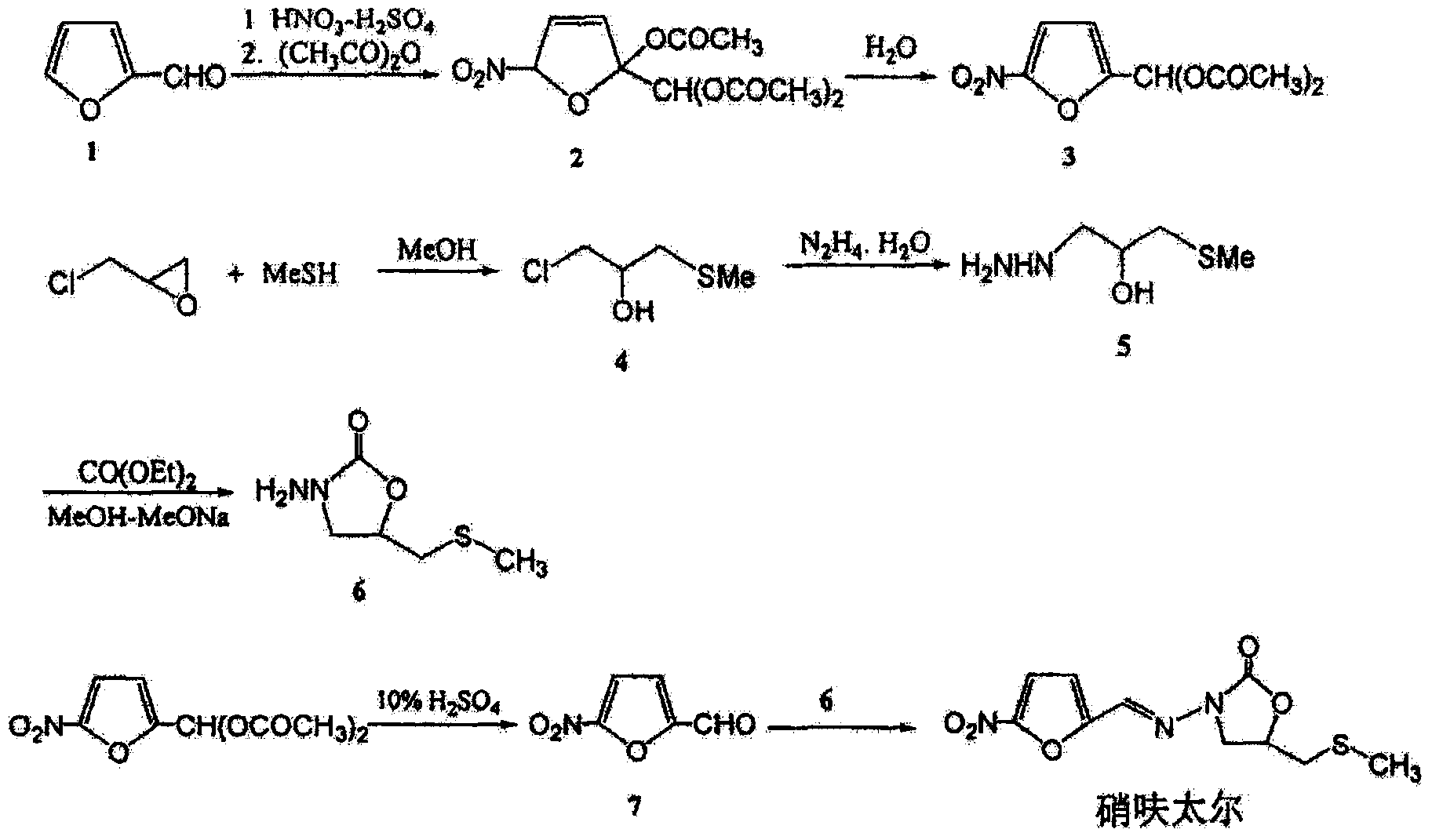

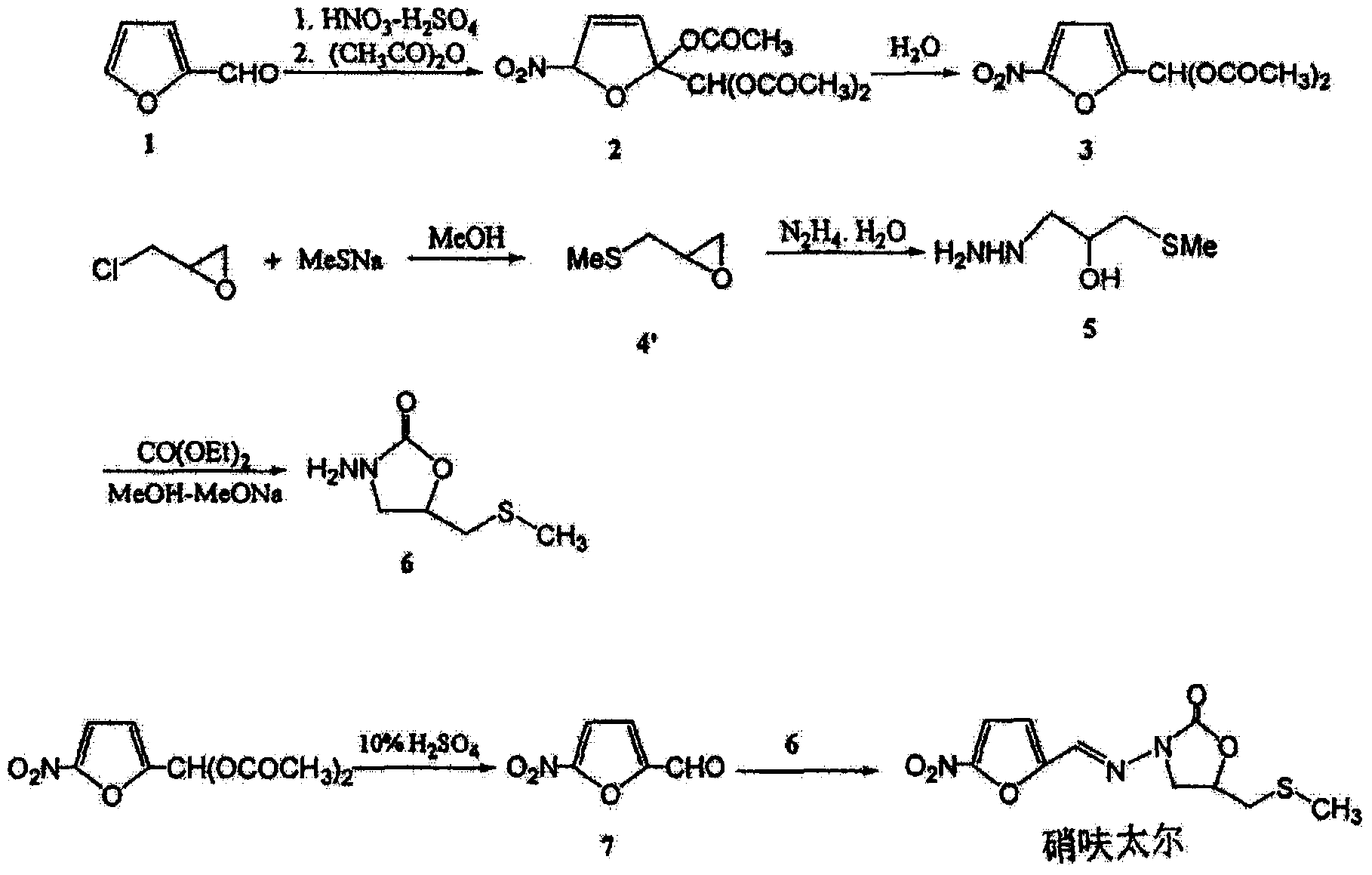

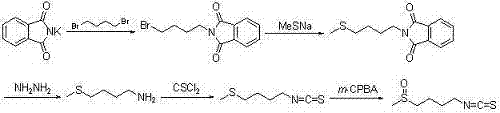

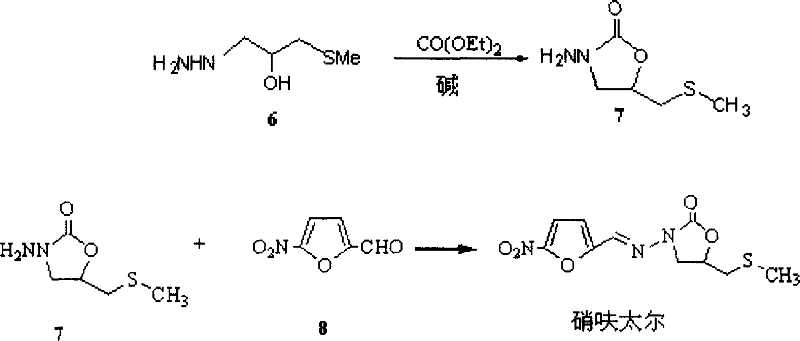

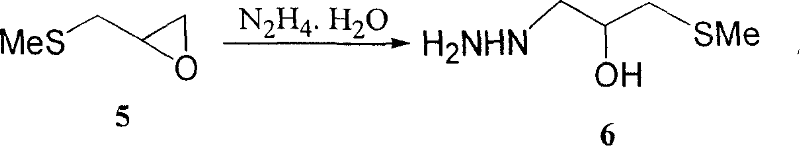

Production method of nifuratel

The invention relates to a medicine producing field, specifically, to an improved producing method of antibacterial medicine nifuratel. The method makes use of thiourea as initial material to produce nifuratel. The improvement is that it is no longer to use methyl mercaptan or methomyl in the known method while producing the intermediate 2-(methylthiomethyl)hydropropane. Furthermore, the invention is no longer to use metal natrium in the known method when the 3-methylthio-2-hydroxy-propylhydrazine and diethyl carbonate are heated to produce N-amido-5-methylthiomethyl-2-oxazolidone in the existance of alkali. All of the improvements largely improve the preparation of the nifuratel, especially for the production condition in a large scale, reduce the environment pollution and benefit to ensure the production safety.

Owner:SUNSTONE TANGSHAN PHARM CO LTD

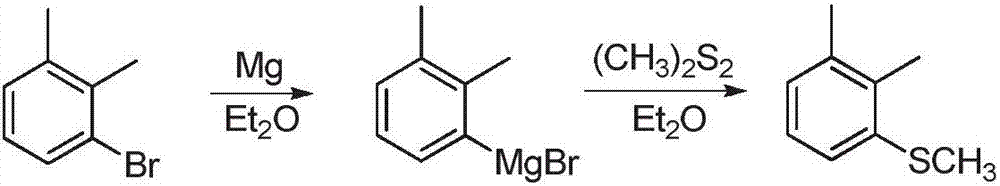

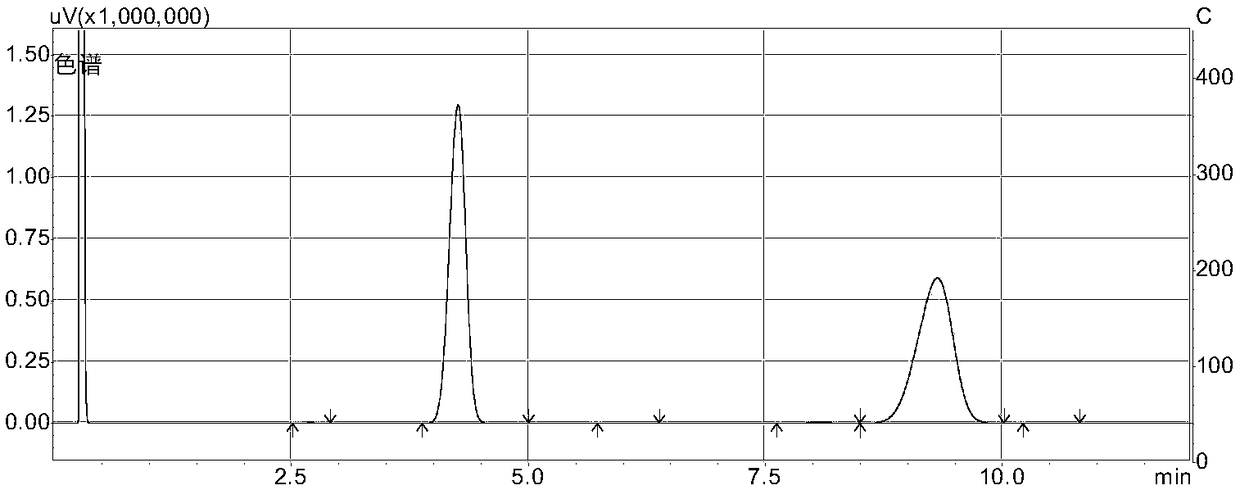

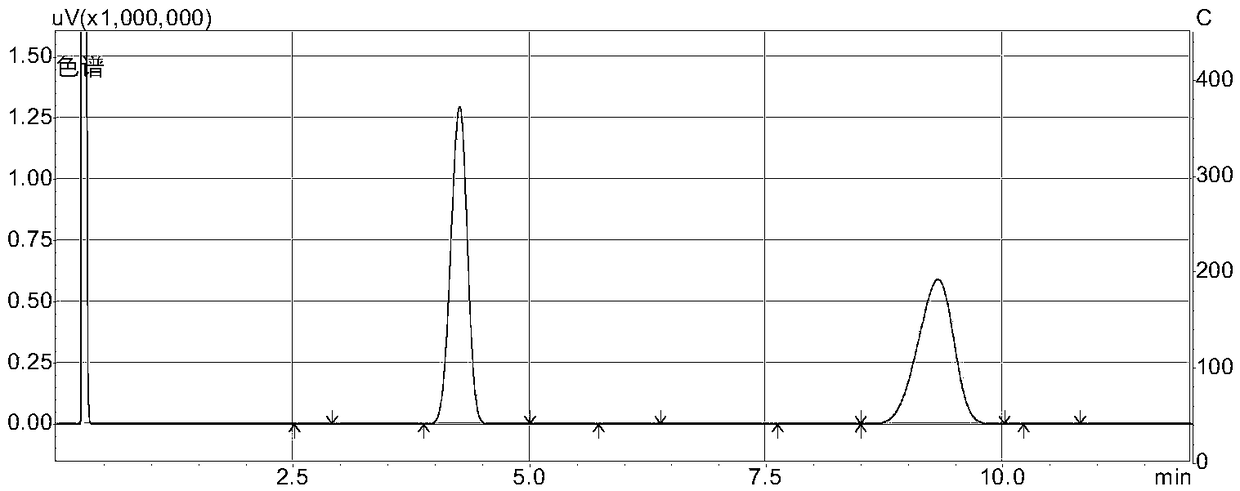

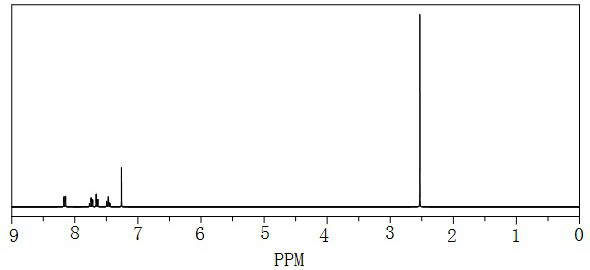

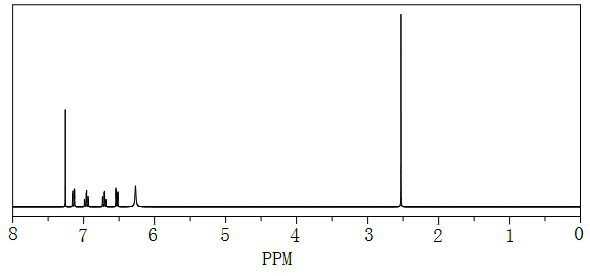

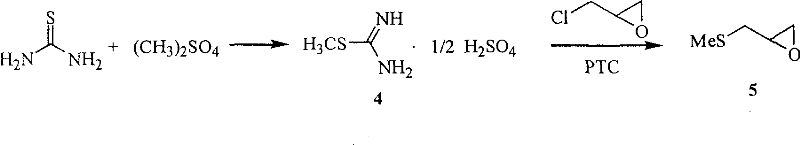

Method for synthesizing 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon

ActiveCN101659644AReduce manufacturing costEasy to operateOrganic chemistrySolution systemPhotoinitiator

The invention relates to a method for synthesizing a high-efficiency photoinitiator 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon. In the method, 2-methyl-1-[4-(chloro)phenyl]-2-(4-morpholinyl)-1-propanon serving as a raw material is reacted with sodium methyl mercaptide in an organic water two phase solution system taking quaternary ammonium salt as a catalyst to generate the target product.

Owner:INSIGHT HIGH TECH (BEIJING) CO LTD

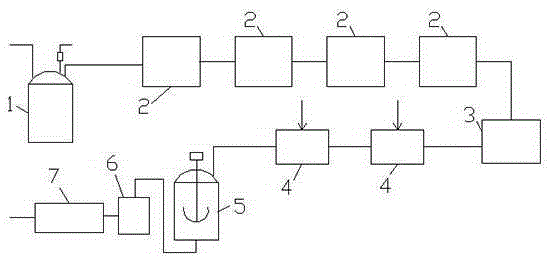

Method for co-producing sodium methyl mercaptide and dimethyl sulfide

ActiveCN102976987AShort reaction timeMild reaction conditionsThiol preparationSulfide preparationSodium hydrosulfideSodium methanethiolate

The invention relates to a method for co-producing sodium methyl mercaptide and dimethyl sulfide, which essentially comprises the following steps of: under a negative pressure condition, filling methane chloride gas into a sodium hydrosulfide solution; implementing a four-stage cascade reaction, absorbing by a sodium hydroxide solution to obtain a sodium methyl mercaptide solution; and making the reaction liquid obtained from the four-stage cascade reaction standing and layering to obtain the dimethyl sulfide. The method for co-producing the sodium methyl mercaptide and the dimethyl sulfide is low in toxicity of the adopted raw materials, short in reaction duration, moderate in required reaction condition, simple in operation, high in product yield and simple in post-treatment; and the method can be massively adopted in the industrial production, and has a great economic value.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

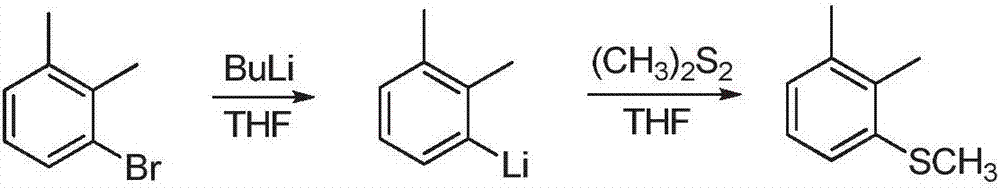

Preparation method of 1,2-Dimethyl-3-methylsulfanyl-benzene

The invention discloses a preparation method of 1,2-Dimethyl-3-methylsulfanyl-benzene. The preparation method comprises the following steps: under the protection of inert atmosphere, using 3-nitro-o-xylene as a raw material to be heated and reacted with sodium thiomethoxide in an organic solvent under action of nickel salt and a cocatalyst; and performing post-treatment on a reaction solution to obtain 1,2-Dimethyl-3-methylsulfanyl-benzene. The preparation method has advantages of high yield, low cost, simple operation, green and environmental protection and the like.

Owner:HUNAN CHEM RES INST

Production method of nifuratel

ActiveCN100516063CEasy to getHigh yieldAntibacterial agentsOrganic chemistryThioureaHydrazine compound

The invention relates to the field of medicine production, in particular, the invention discloses an improved production method of antibiotic nifuratel. The method uses thiourea as a starting material for the preparation of nifuratel, which is improved in that the intermediate 2-(methylthiomethyl)-oxirane is no longer used in the known method. Methyl mercaptan or sodium methyl mercaptide; In addition, 3-methylthio-2-hydroxyl-propylhydrazine and diethyl carbonate are heated to react in the presence of a base for ring closure to generate N-amino-5-methylthio In the technology of methyl-2-oxazolidinone, the production method of the present invention no longer uses metal sodium commonly used in known methods. All these improvements have greatly improved the preparation of nifuratel, especially the production conditions for large-scale industrial production, reduced environmental pollution, and are conducive to ensuring safe production.

Owner:SUNSTONE TANGSHAN PHARM CO LTD

Synthetic method of nifuratel

The invention discloses a synthetic method of nifuratel. The synthetic method comprises the steps of carrying out a substitution reaction between epoxy chloropropane and sodium methyl mercaptide in the presence of a phase transfer catalyst to obtain epoxy propyl dimethyl sulfide, and then performing hydrazinolysis, cyclization and condensation on the obtained epoxy propyl dimethyl sulfide to obtain the nifuratel. The synthetic method is high in nifuratel yield, high in purity and low in impurity content; besides the method has the advantages that a ring-closure reaction is carried out under the alkaline condition of sodium methoxide, the use of metal sodium is avoided, production safety is ensured, and simultaneously, the reaction is easy to arouse, easy to control in process, the used raw materials are easy to get, basically no waste liquid is generated in the reaction of each step, and therefore, industrial pollution is greatly reduced; and as a result, the synthetic method of nifuratel is applicable to industrial production.

Owner:BEIJING CHENGYI INVESTMENT CO LTD

Production method of 1,2- benzisothiazole-3-ketone

InactiveCN101353330AAvoid pollutionAvoid Governance FeesOrganic chemistryAir quality improvementChlorobenzeneKetone

A preparation method of 1, 2-benzisothiazole-3-ketone (BIT) is a BIT synthetic route realized by adopting a 2-chlorobenzonitrile method which selects water to replace chlorobenzene as a sulfurization and chlorination solvent. By adopting the method, the pollution of the chlorobenzene to atmosphere and water body is thoroughly eliminated and the total production cost of BIT is greatly reduced. The method comprises the following steps: chlorobenzonitrile is added with water accounting for 0-50% of the mass of the chlorobenzonitrile, and is added with a catalyst, then is added with sodium methyl mercaptide solution dropwise for a sulfuration reaction after heating, and the reactant is cooled for standing, a lower layer water phase is given out, water is added to rinse an upper layer organic phase, then the organic phase obtained in the sulfurization process is added with water accounting for 30%-200% of the volume of the organic phase; and chlorine is introduced into for reacting for 2-5h while stirring, then filtration is carried out to obtain a filter cake after the organic phase completely disappears and a white-pink suspended solid is produced, the filter cake is washed by clear water and is dried at low temperature to obtain the BIT product.

Owner:NANJING UNIV

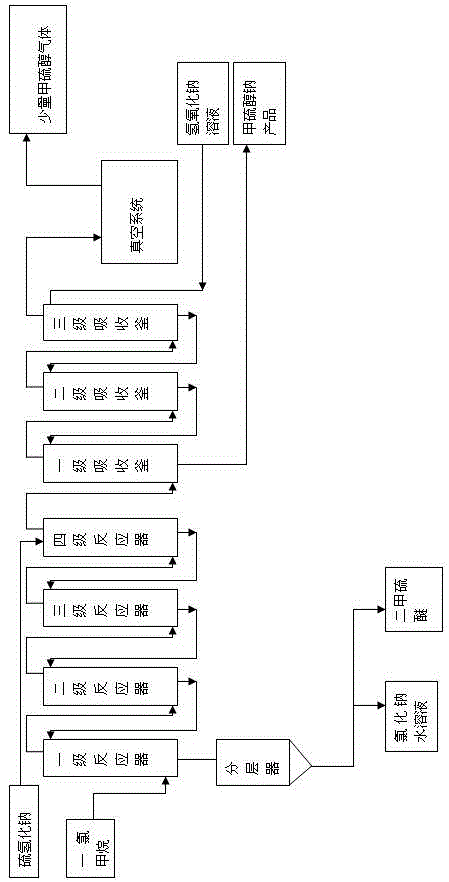

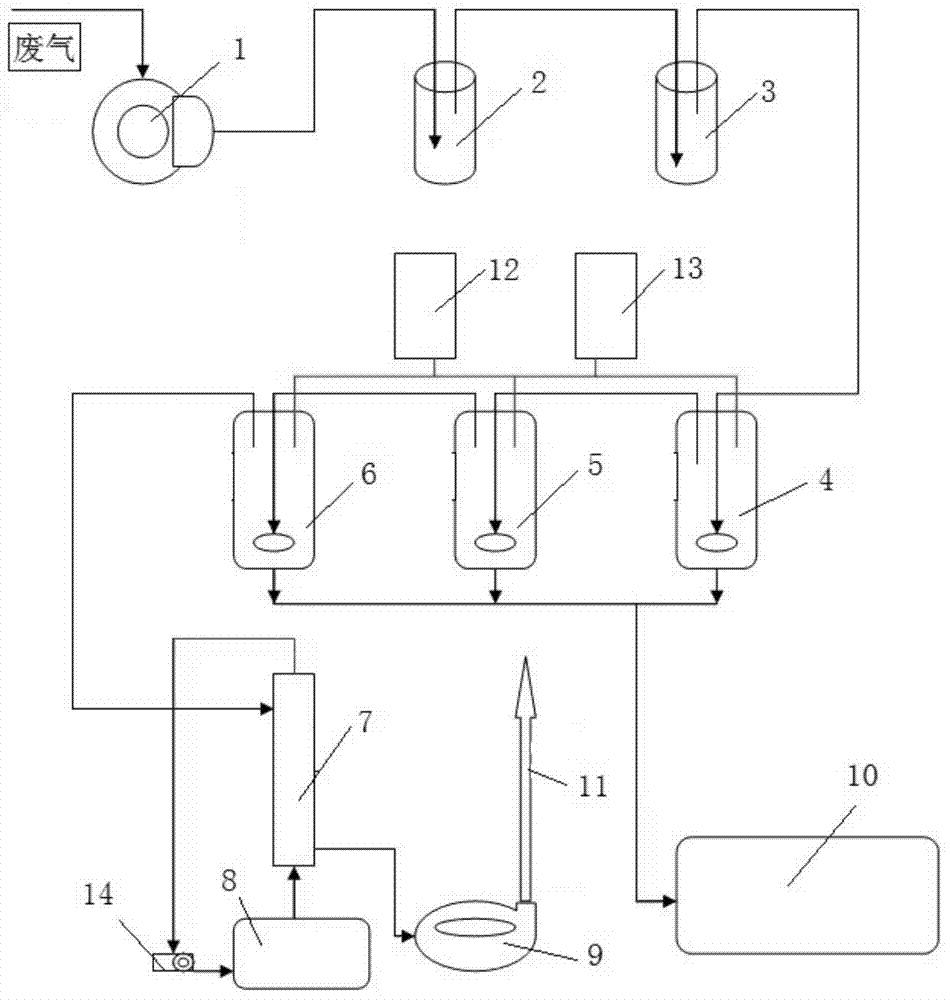

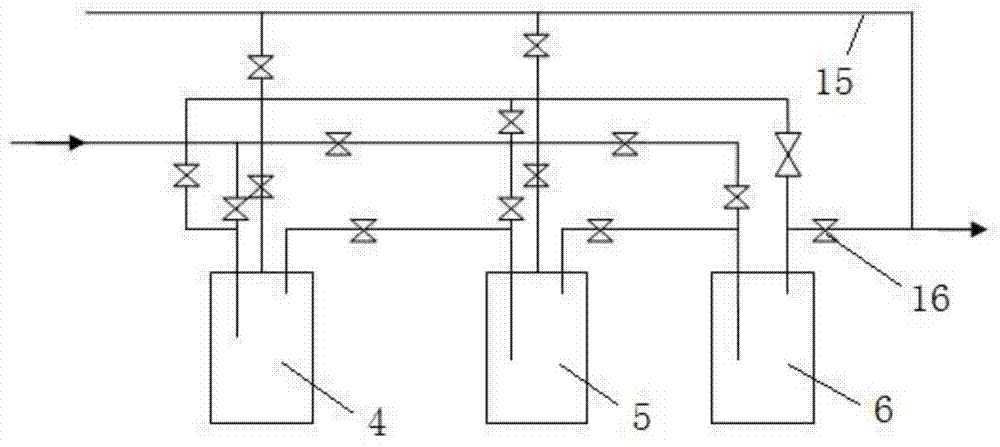

Waste gas treatment and methyl mercaptan recycling process in cimetidine and ranitidine production

InactiveCN104258704AAvoid emissionsCreate valueOrganic chemistryOrganic compound preparationExhaust gas emissionsWaste treatment

The invention discloses a waste gas treatment and methyl mercaptan recycling process in cimetidine and ranitidine production. The waste gas treatment and methyl mercaptan recycling process comprises the following steps: (1) introducing waste gas in the production process of cimetidine and ranitidine into a washing tank, controlling pressure to 0.2-0.3MPa, removing volatile substances which are low in boiling point and easily soluble in water in the waste gas; (2) introducing the waste gas subjected to washing treatment into an alkaline washing tank, controlling pressure to 0.2-0.3MPa, removing volatile substances which are insoluble in water and soluble in alkaline by alkaline liquor in the alkaline washing tank; (3) introducing the waste gas subjected to the alkaline washing into a three-stage absorbing device, removing methyl mercaptan in the waste gas to generate sodium thiomethoxide; and (4) introducing the waste gas subjected to the three stages of absorption into a hydrogen peroxide falling film absorbing tower for performing oxidation treatment, and then discharging. According to the waste gas treatment and methyl mercaptan recycling process, useful chemical raw materials in the waste gas are recycled on the basis of solving the problem of waste gas emission, and thus the waste gas is prevented from being discharged, the economic benefit is increased, a new value is created, and the recycling economy is realized. The waste gas treatment and methyl mercaptan recycling process is good in application prospect.

Owner:SHANDONG WEIZHEN TEST & ANALYSIS

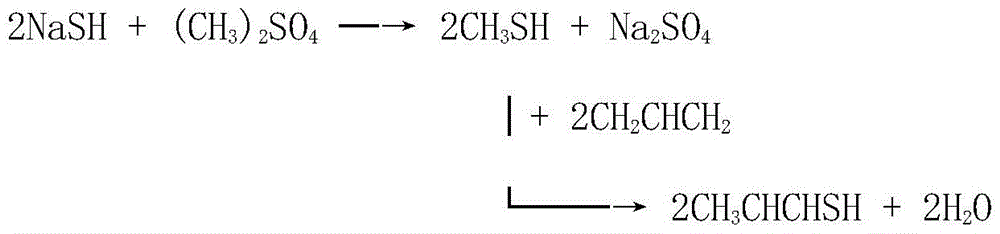

Production technology of high-purity sodium methyl mercaptide

InactiveCN105330577AAdapt to the requirements of the marketHigh purityThiol preparationSodium hydrosulfideSodium methanethiolate

A production technology of high-purity sodium methyl mercaptide includes the steps that a reaction product of the raw materials of sodium hydrosulfide and dimethyl sulfate is subjected to washing and alkali liquor absorption for concentration adjustment and then subjected to cooling crystallization and drying, and then the high-purity sodium methyl mercaptide product is obtained. By means of the technology, the high-purity sodium methyl mercaptide liquid or solid product can be obtained, the transportation cost of the sodium methyl mercaptide product is greatly lowered, meanwhile, the equipment investment and operating cost of manufacturers using sodium methyl mercaptide are also lowered, and requirements of sodium methyl mercaptide using markets are met.

Owner:白国强

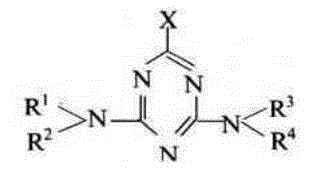

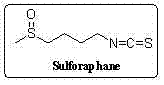

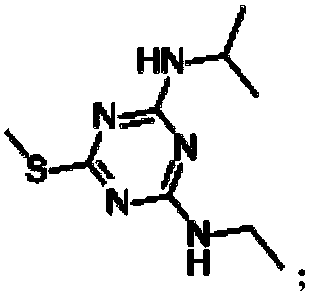

Synthesis method of s-triazine clean-series weedicide

ActiveCN104628666ASolve process problemsSolve complexityOrganic chemistryHerbicides and algicidesPtru catalystEconomic benefits

The invention discloses a synthesis method of an s-triazine clean-series weedicide. An s-triazine Jin-series weedicide and sodium methyl mercaptide used as raw materials are synthesized under closed conditions to obtain the s-triazine clean-series weedicide technical toxicant. The method solves the problems of uncontrollable smell, complex wastewater treatment and the like in the existing technique, enhances the reaction efficiency and yield, lowers the power and raw material consumption, lowers the production cost, and has the advantages of accessible reaction raw materials, closed reaction process, controllable smell, no use of catalyst, environment friendliness, high controllability, high efficiency and the like; and the obtained product has high quality and high yield, has wide application range, and can bring in considerable economic benefits and social benefits after implementing industrialization.

Owner:SHANDONG WEIFANG RAINBOW CHEM

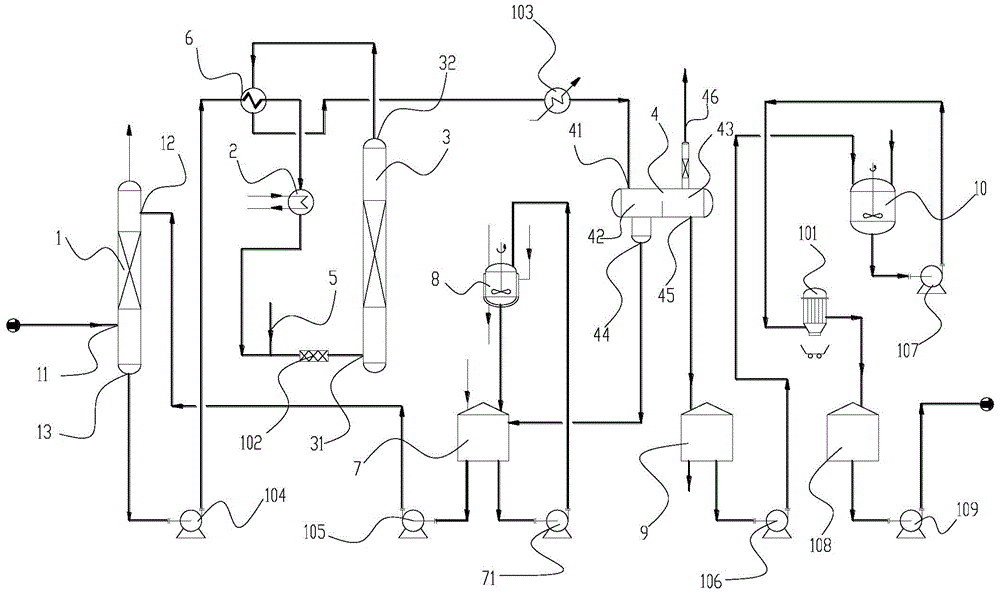

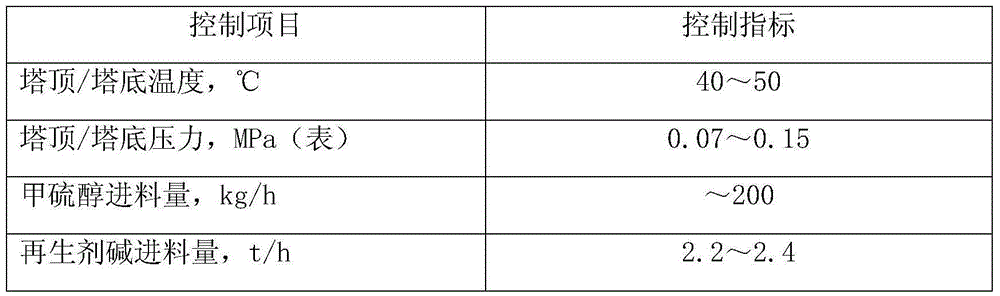

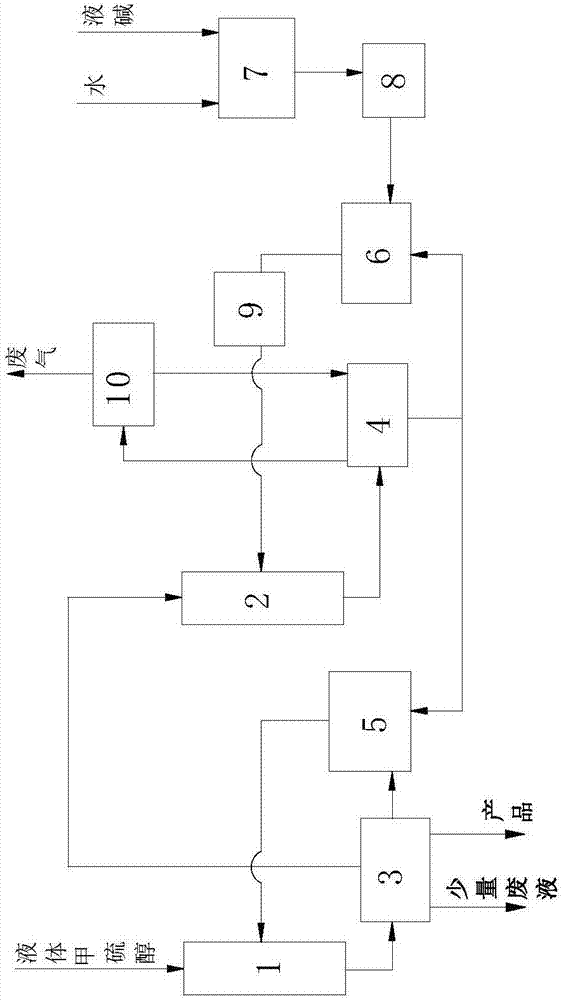

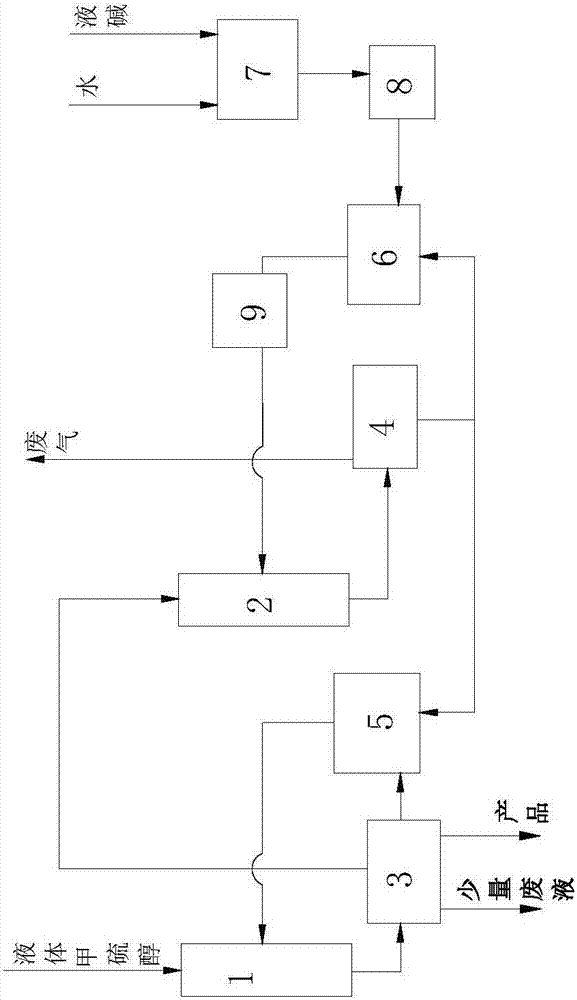

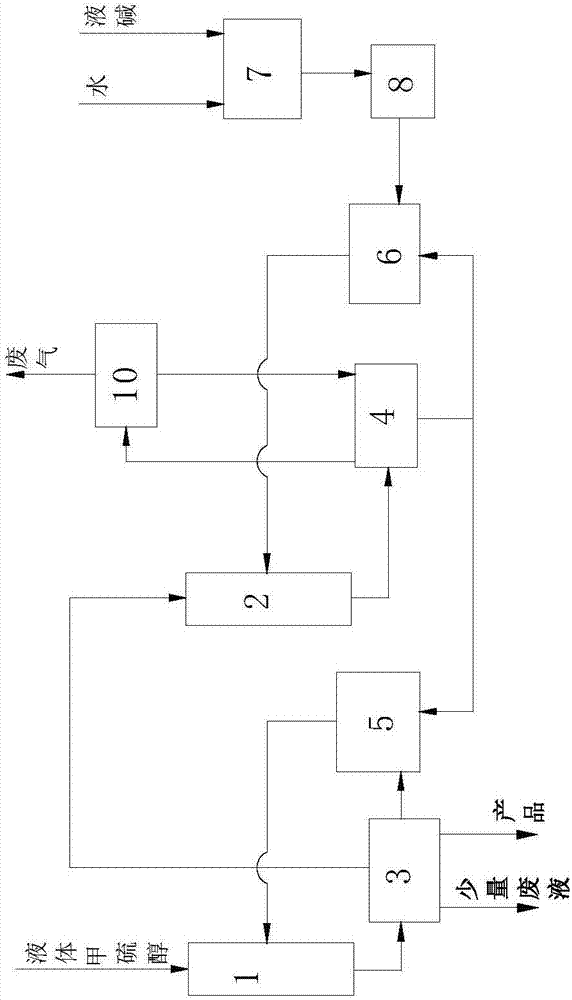

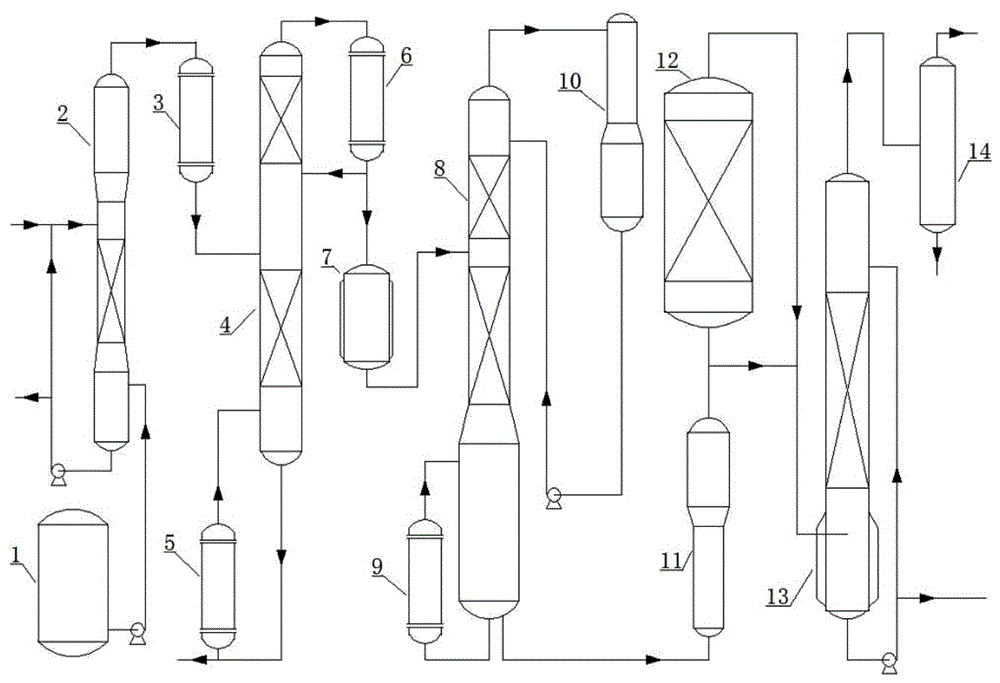

Sodium methyl mercaptide production process and device

PendingCN108250114ALow impurity contentAvoid long distance transportThiol preparationGas phaseSodium methanethiolate

The invention discloses a process and a device for producing a sodium methyl mercaptide solution. The process comprises the following steps: enabling refined methyl mercaptan to enter a primary heat exchanger tube pass through a methyl mercaptan storage tank, and enabling a sodium hydroxide-sodium methyl mercaptide mixed solution collected from the bottom of a secondary absorption tower to enter aprimary heat exchanger shell layer, after heat exchanging, enabling the gasified methyl mercaptan to enter a primary absorption tower; enabling the sodium hydroxide-sodium methyl mercaptide mixed solution to enter the adsorption tower from the upper part of the primary adsorption tower, wherein a sodium methyl mercaptide finished product is collected from the bottom of the primary absorption tower; enabling the methyl mercaptan from the top of the primary absorption tower to enter the tower from a feeding port in the lower part of the secondary absorption tower; enabling liquid caustic soda from a liquid caustic soda storage tank to enter the absorption tower from the upper part of the secondary absorption tower, enabling a gas phase and a liquid phase to reversely contact and mix in thetower to obtain the sodium hydroxide-sodium methyl mercaptide mixed solution. The sodium methyl mercaptide produced through the process and the device can utilize the reaction heat as a methyl mercaptanvaporization heat source, thereby freely adjusting the concentration of the sodium methyl mercaptide; and meanwhile, the logistics and transportation cost of a manufacturer who takes the sodium methyl mercaptide as the production raw material is saved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Synthetic method for sulforaphane

ActiveCN102249968BAvoid hydrazinolysisSimple and fast operationOrganic chemistryBulk chemical productionSulforaphaneSodium methanethiolate

The synthesis method of sulforaphane of the present invention belongs to the field of medicine synthesis. After the amino group in 4-amino-1-butanol is protected by the Boc group, its hydroxyl group is converted into a methylsulfonyl ester by methylsulfonyl chloride, and then reacted with sodium methylthiolate to generate 4-methylthiobutyl-1 - tert-butoxyamide. Under acidic conditions, the Boc protecting group is removed to obtain 4-methylthio-1-butylamine. The latter reacted with carbon disulfide for 1 hour in the presence of triethylamine, and then added p-toluenesulfonyl chloride for half an hour to generate 4-methylthiobutyl-1-thioisocyanate. Finally m-CPBA is oxidized to produce sulforaphane. The present invention avoids the complex phthalimide hydrazinolysis reaction in post-treatment, and does not need to use toxic thiophosgene to prepare thioisocyanate; the total yield is 64%, significantly higher than the total yield of 8% reported in the literature The whole preparation process is easy to operate, saves time, and is suitable for large-scale production.

Owner:江苏宁录科技股份有限公司

Method for removing iron ions from sodium thiomethoxide solution

ActiveCN103351316AReduce iron contentRaw materials are easy to getOrganic chemistryOrganic compound preparationIon contentSodium methanethiolate

The invention discloses a method for removing iron ions from a sodium thiomethoxide solution. The method for removing iron ions from the sodium thiomethoxide solution comprises the following steps: adding appropriate complexing agent iron ions into an alkaline solution, heating to a certain temperature, stirring at constant temperature for an appropriate period of time, standing, settling for a certain period of time and filtrating. The iron ion content in the alkaline solution treated by the method is obviously reduced, namely the solution is changed from red to be colorless and transparent, does not become red any longer after exposure to air and has an basically unchanged content. The method for removing iron ions from the sodium thiomethoxide solution is easy to operate, readily available in raw materials, and is applicable to industrial treatment.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

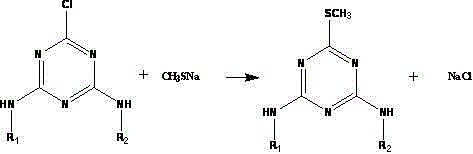

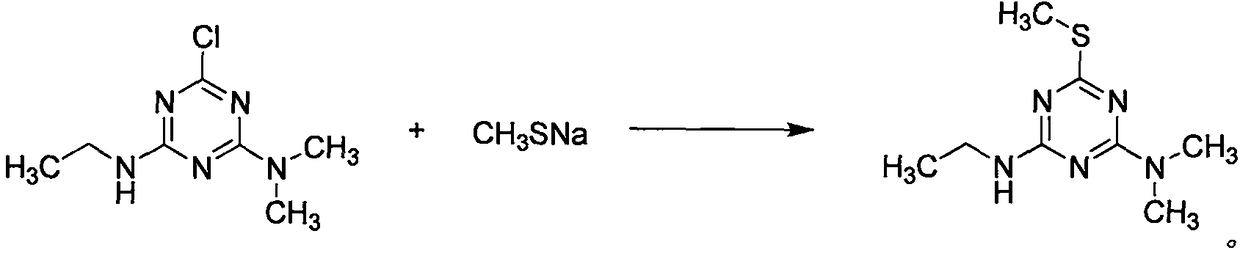

Catalyst-free ametryn production method

PendingCN108341787ALow costReduce pressure on environmental protectionOrganic chemistryChemical reactionSynthesis methods

The invention discloses a catalyst-free ametryn production method. The production method comprises that in a pressurized reaction kettle, atrazine and sodium methyl mercaptide undergo a reaction in anorganic solvent according to a mole ratio of atrazine to sodium methyl mercaptide of 1: 1.01-1: 1.2 at 80-145 DEG C under pressure of 0.1-1MPa for 1-2h and the chemical reaction formula is shown in the description. The method utilizes a heating and sealed pressurization reaction process. Compared with the traditional ametryn synthesis method, the production method reduces a raw material cost, reduces the environmental pressure of treatment on a large amount of wastewater and has better economic and social benefits.

Owner:ZHEJIANG ZHONGSHAN CHEM IND GRP

Production method and apparatus of dimethyl disulfide

ActiveCN105085338ALow costReduce consumptionOrganic compound preparationHydropoly/poly sulfide preparationAbsorption columnSodium methanethiolate

The invention relates to the technical field of preparation of dimethyl disulfide and provides a production method of dimethyl disulfide. The production method includes the steps of A, using sodium hydroxide solution containing catalyst to absorb a methyl mercaptan mixture so as to obtain mixed solution containing sodium thiomethoxide; B, mixing oxygen or oxygen-rich air with the alkaline solution obtained in the step A, allowing reaction to generate dimethyl disulfide, dimethyl sulfide and sodium hydroxide; and C, separating the oxygen or oxygen-rich air surplus in the reaction to generate dimethyl sulfide so as to obtain dimethyl disulfide liquid. The production method has low cost, high yield and low pollution. A production apparatus of dimethyl disulfide is further provided; the production apparatus comprises an absorption column, a heater, an oxidization column, a flash separator tank and a recovery system connected in order through a pipeline, wherein the heater is used for heating the alkaline solution to a set temperature, the oxidization column is used for generating dimethyl disulfide, the flash separator tank is used for separating materials, and the recovery system is used for recovering the alkaline solution. The production apparatus is automatically controllable, thus labor is saved, reutilization of the alkaline solution is achieved and production cost is lowered.

Owner:CHENGDU DEMEI ENG TECH

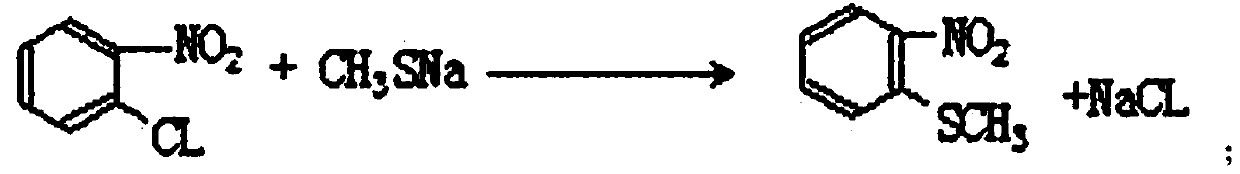

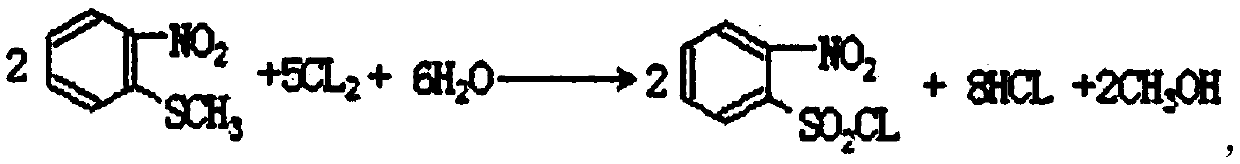

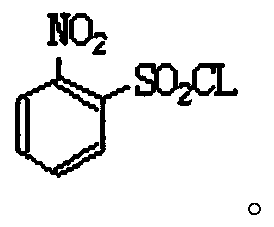

Industrial production method of o-nitrobenzenesulfonyl chloride

InactiveCN110105251ALow toxicityAddressing Purity IssuesOrganic compound preparationSulfonic acid preparationO-nitrochlorobenzeneNitrobenzene

The invention discloses an industrial production method of o-nitrobenzenesulfonyl chloride. The method comprises the following steps that o-nitrochlorobenzene and sodium methyl mercaptide are subjected to an etherification reaction, filtering is conducted, an obtained filter cake is subjected to recrystallization, and through centrifugation separation and drying, a dry product of o-nitrobenzene dimethyl sulfide is obtained; the dry product of o-nitrobenzene dimethyl sulfide is subjected to a chlorination reaction in batches to obtain a wet crude product, an appropriate amount of hydrochloric acid is added in a chlorination reaction system, the chlorination reaction is carried out in a hydrophilic organic acid solvent, and the mole ratio of the o-nitrobenzene dimethyl sulfide to water during the chlorination reaction is 1:(5-15); a finished product of o-nitrobenzenesulfonyl chloride is obtained through refining and drying. Through HPLC detection, the content of the o-nitrobenzenesulfonyl chloride synthesized by means of the method is 98-98.5%; the yield is 0.72-0.75, the acquisition rate is 0.97 or above, the turbidity (ppm) is 1.5-2, and the melting point is 66-67 DEG C. By adopting the hydrophilic organic acid solvent, the problems about large-scale production discharging, yield and quality are solved, and meanwhile the purposes of mixed application and post-treatment separation of large-scale production water-soluble solvents are achieved.

Owner:苏州市泽宸贸易有限公司

A kind of production method of methyl mercaptide

ActiveCN105646302BRealize multiple cross cyclesEliminate cloggingThiol preparationMass contentSodium methanethiolate

The invention relates to a production method of methyl mercaptan salt. The method comprises the steps that a strong alkali solution is subjected to second-level preheating and conducts an absorption reaction with methyl mercaptan gas to prepare the methyl mercaptan salt, and the percentage mass content of the methyl mercaptan salt in a reaction product is controlled to be 18%-24%. By means of the method, crystallization of sodium methyl mercaptide generated through the reaction can be avoided, and the risk of plugging a pipeline is thoroughly eliminated.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

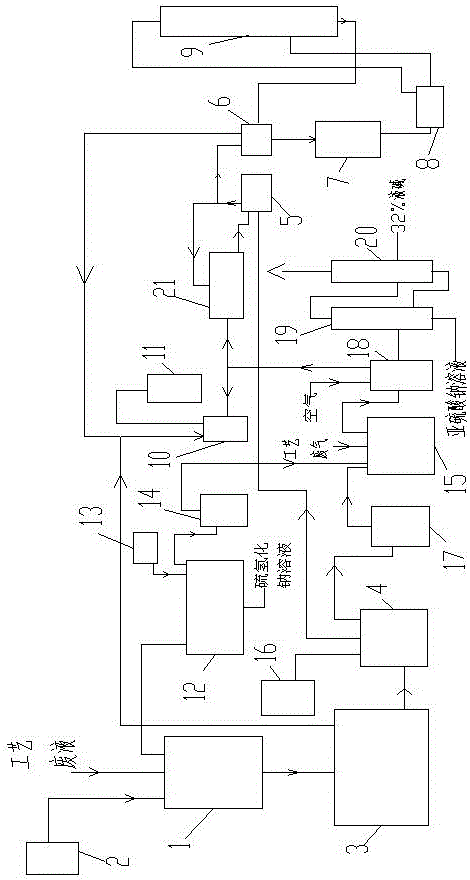

Environmental protection treatment device for sodium methyl mercaptide production and its environmental protection treatment process

ActiveCN104944660BAchieve deodorizationAchieve disinfectionDispersed particle separationEnergy inputAir preheaterEnvironmental resistance

The invention discloses a sodium methyl mercaptide production environment-protecting processing device and technology. The device comprises a technology waste liquid processing mechanism and a technology waste gas processing mechanism which mainly comprises a burner, an air preheater, a front absorption tower and a back absorption tower. The technology waste liquid processing mechanism mainly comprises an acid pickling device, a sulfuric acid middle tank, a waste liquid filtering tank, a sodium sulfate solution circulating tank, a crystallization liquid circulating pool, a crystallization tower, a flash dryer, an anhydrous sodium sulphate storage tank, a washer group, an alkali liquid middle tank and a humidifying evaporator. Sodium methyl mercaptide production waste liquid and waste gas are creatively combined organically for processing, technology waste gas high in combustion value is used for incineration and absorbing, sodium sulfite by-products are obtained, a large amount of high-temperature gas is obtained, the high-temperature gas is used for obtaining anhydrous sodium sulphate by-products with higher value, the purposes of sodium methyl mercaptide production deodorization disinfecting and environment improving can be achieved, sodium bisulfide, sodium sulfite and anhydrous sodium sulphate can be obtained by recycling, and the production cost of sodium methyl mercaptide is lowered.

Owner:陵县鲁鑫工贸有限公司

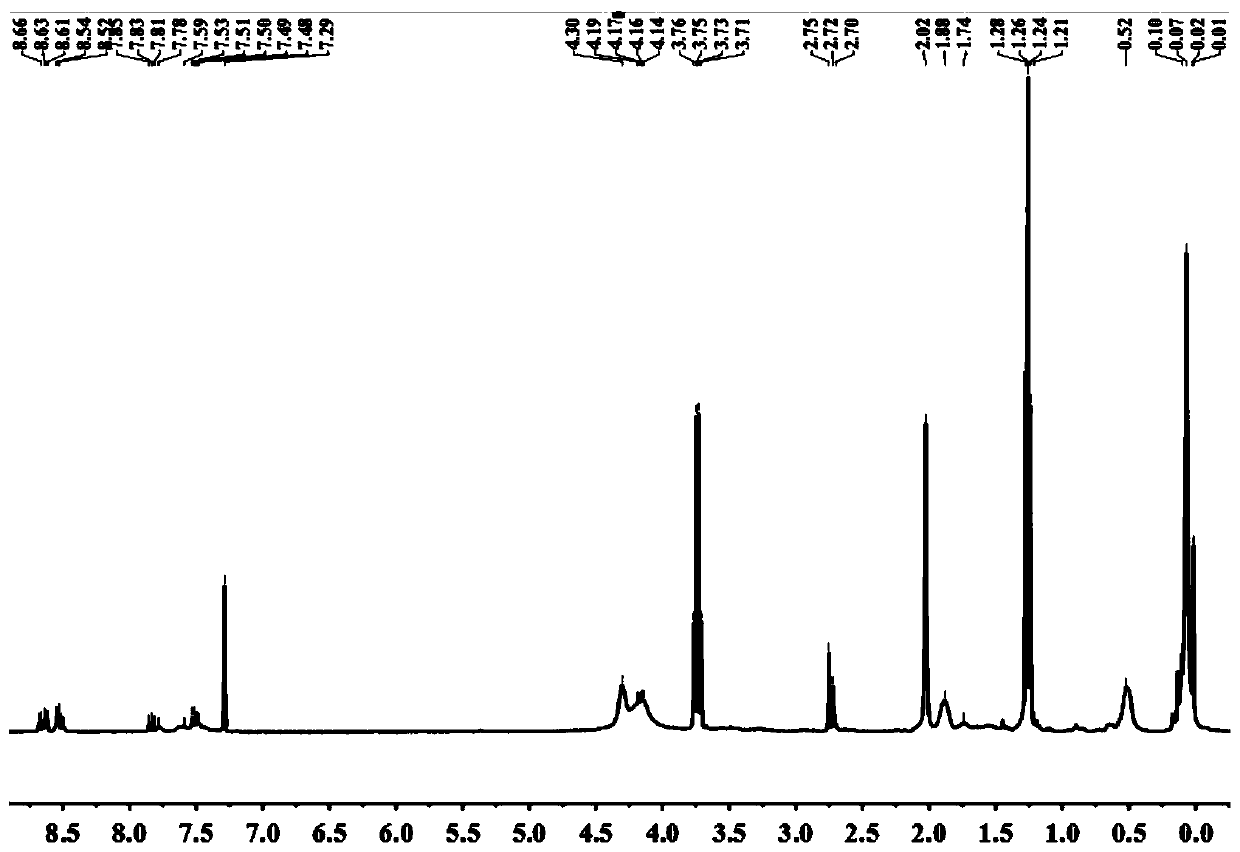

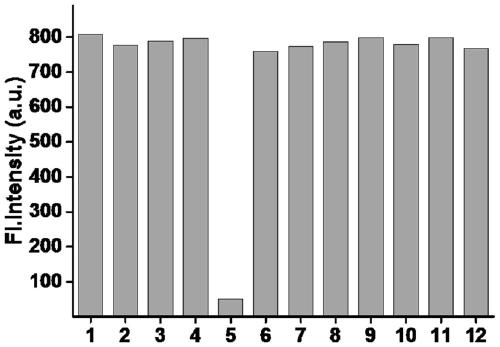

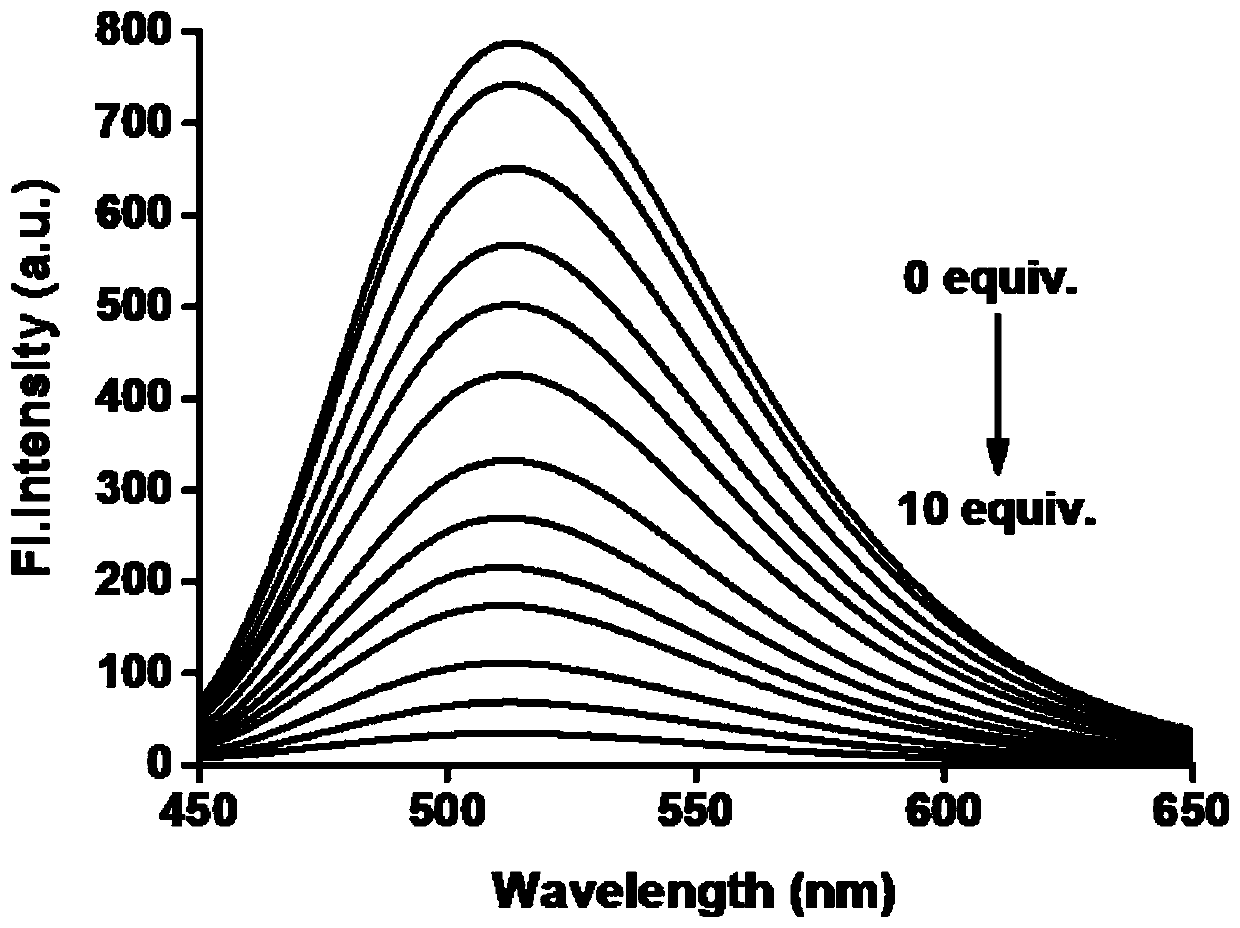

Fluorescent probe for detecting thiocyanate radicals as well as preparation method and application thereof

InactiveCN109929106AQuick responseImprove anti-interference abilityFluorescence/phosphorescenceLuminescent compositionsSynthesis methodsFluorescence

The invention provides an organic silicon fluorescent probe for detecting thiocyanate radicals. The structural formula of the organic silicon fluorescent probe is shown in the specification. The invention also provides a synthesis method of the probe. The probe is synthesized from 4-bromo-1,8-naphthalene anhydride, sodium methyl mercaptide, an aminopropyl double-terminator, glyoxal, formaldehyde and other raw materials. The method is easily available in raw materials and simple. The probe can specifically identify thiocyanate radicals. The probe emits fluorescence of thiomethyl naphthalimide;after thiocyanate radicals are added, thiomethyl on the site 4 in the probe is replaced by the thiocyanate radicals to cause fluorescence quenching. The probe is high in response speed and strong in anti-interference capability, and can be applied to detection of thiocyanate radicals in solutions, cells or organisms.

Owner:UNIV OF JINAN

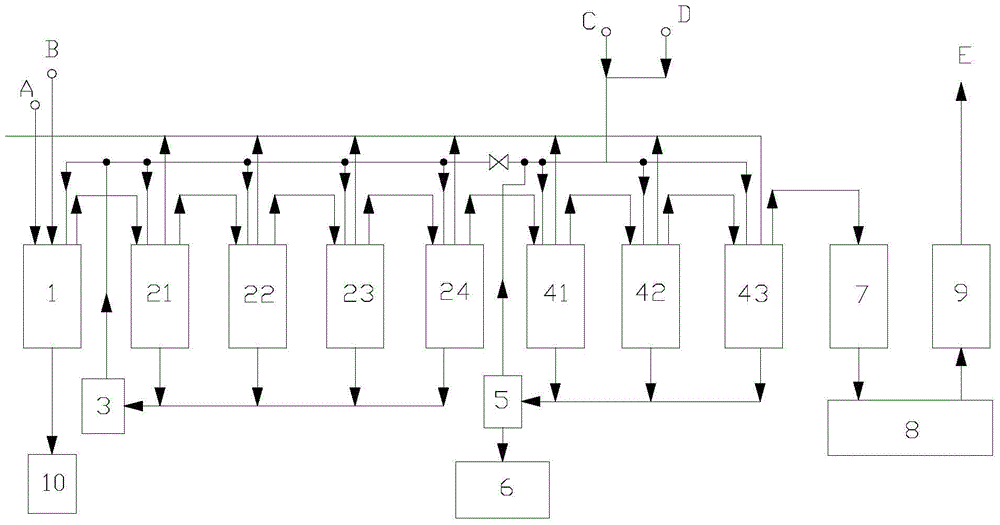

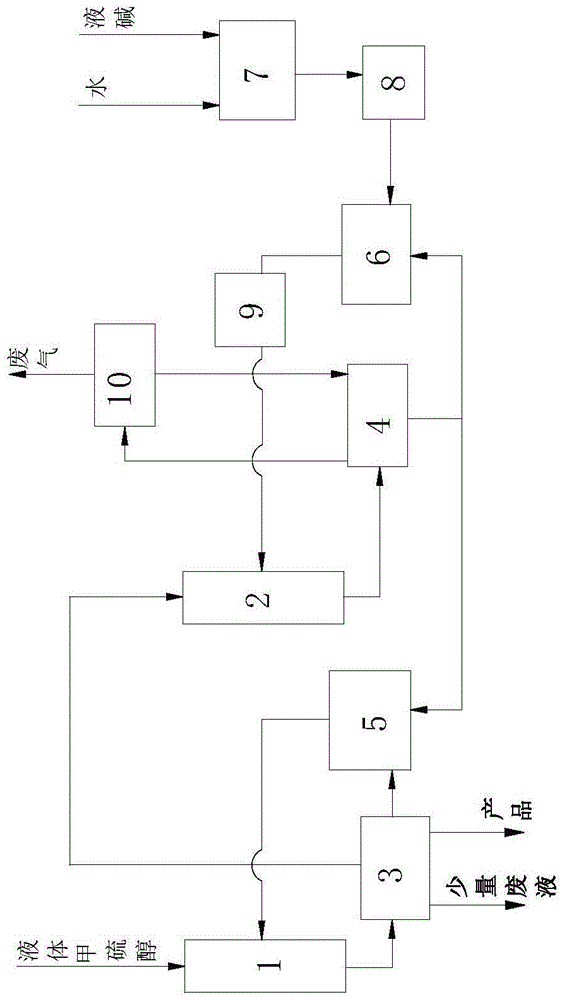

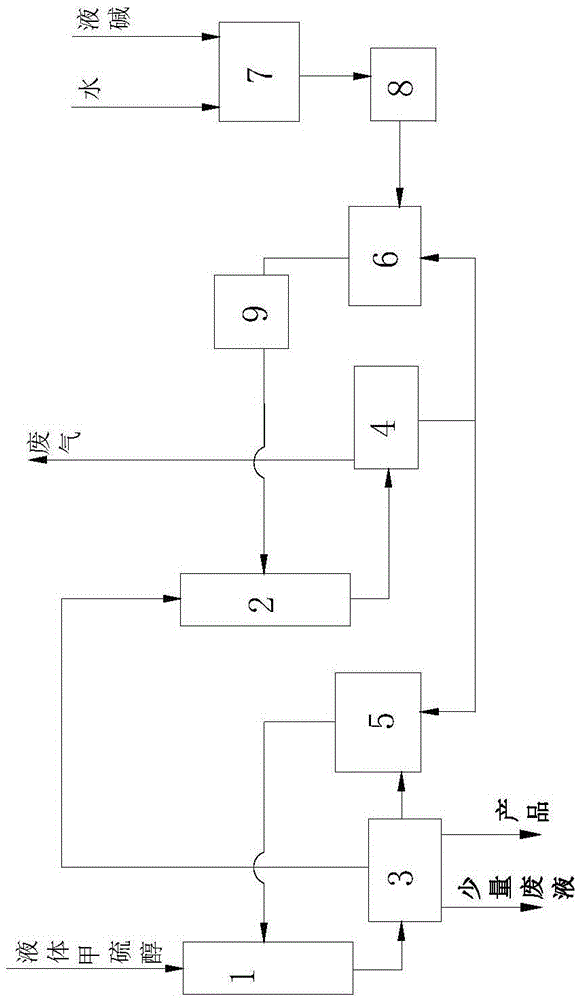

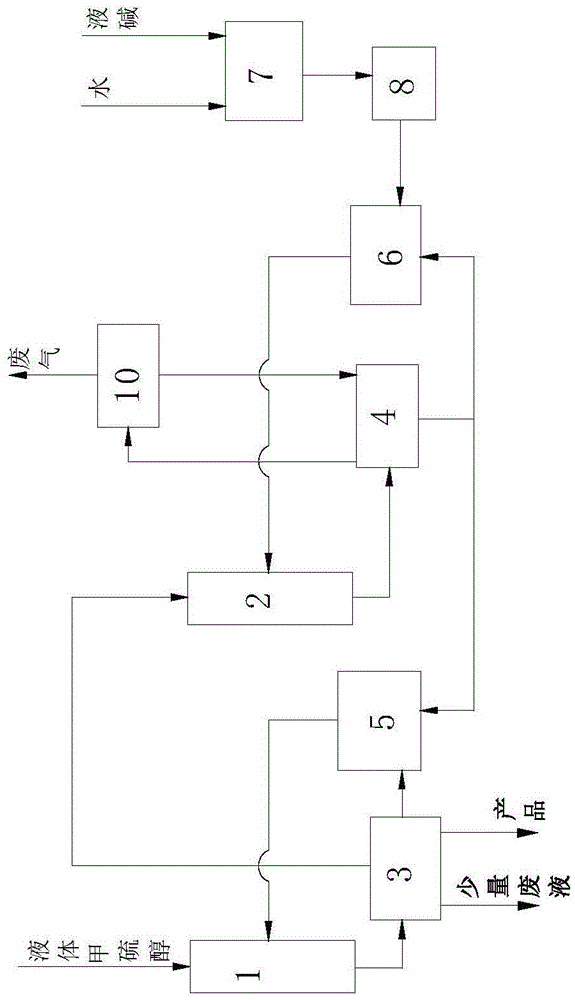

Preparation device and preparation method of 3-methylmercapto propionaldehyde

InactiveCN105732450AStable concentrationSmooth responseThiol preparationSulfide preparationSodium hydrosulfideAcrolein

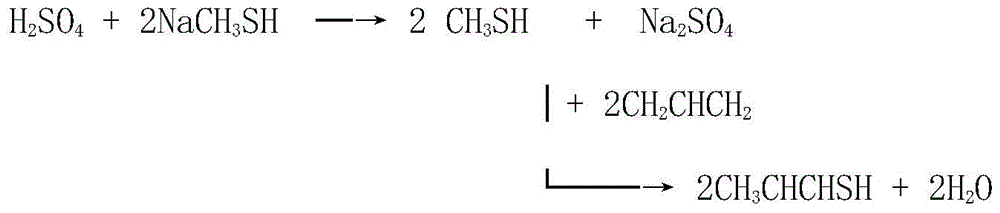

The invention relates to a preparation device and a preparation method of 3-methylmercapto propionaldehyde. The preparation device is provided with a reaction kettle, washing tanks, a washing circulating pump, absorbing kettles, an absorbing circulating pump, a separating device and a vacuum pump, wherein a methanthiol outlet of the reaction kettle is connected with methanthiol inlets of the washing tanks, an acrolein solution inlet of the reaction is externally connected with an acrolein solution source, and discharging holes of the washing tanks are connected with the reaction kettle and the washing tanks; and methanthiol outlets of the washing tanks are connected with methanthiol inlets of the absorbing kettles, acrolein inlets of the absorbing kettles are connected with the acrolein source, discharging holes of the absorbing kettles are communicated with a feeding hole of the absorbing circulating pump, a discharging hole of the absorbing circulating pump is communicated with feeding holes of the absorbing kettles, and 3-methylmercapto propionaldehyde is conveyed to a finished product through discharging holes of the absorbing kettles. A first preparation method comprises the steps of adding dimethyl sulfate into a sodium hydrosulfide water solution to obtain methanthiol, washing with cooling water, and reacting methanthiol with acraldehyde liquid, so as to obtain 3-methylmercapto propionaldehyde. A second preparation method comprises the steps of adding sulfuric acid into a sodium methyl mercaptide solution to obtain methanthiol gas, washing, cooling, and reacting methanthiol gas with acrolein, so as to obtain 3-methylmercapto propionaldehyde.

Owner:曾庆云

Production method of methyl mercaptan salt

ActiveCN105646302ARealize multiple cross cyclesEliminate cloggingThiol preparationMass contentSodium methanethiolate

The invention relates to a production method of methyl mercaptan salt. The method comprises the steps that a strong alkali solution is subjected to second-level preheating and conducts an absorption reaction with methyl mercaptan gas to prepare the methyl mercaptan salt, and the percentage mass content of the methyl mercaptan salt in a reaction product is controlled to be 18%-24%. By means of the method, crystallization of sodium methyl mercaptide generated through the reaction can be avoided, and the risk of plugging a pipeline is thoroughly eliminated.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

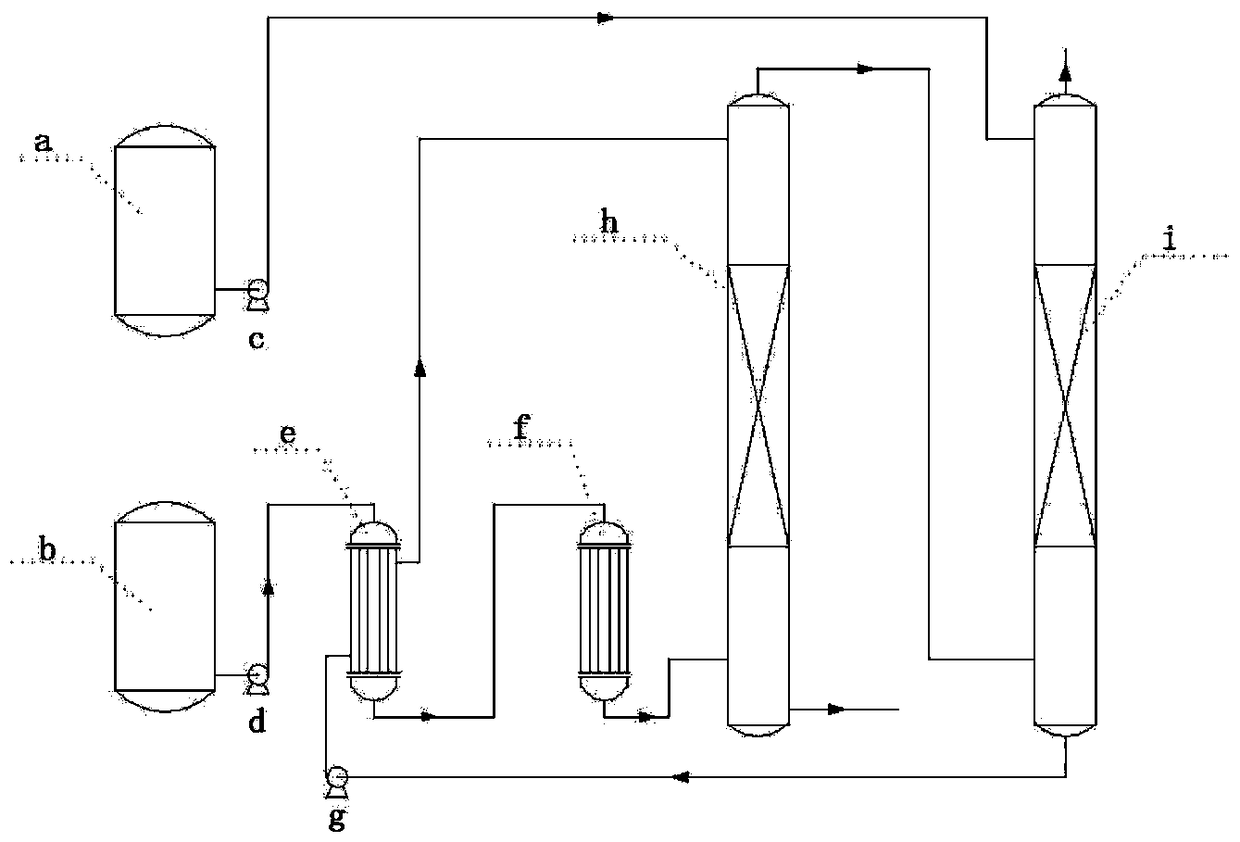

Method and device for producing sodium thiomethoxide from by-product obtained through synthesis of dimethyl sulfide

ActiveCN105693573ALow in sodium sulfideImprove product qualityThiol preparationOrganic compound preparationAbsorption columnDistillation

The invention discloses a method and a device for producing sodium thiomethoxide from a by-product obtained through synthesis of dimethyl sulfide. Specifically, the by-product in a synthesis process of dimethyl sulfide is taken as a raw material, feed gas is pumped into a water extraction column, soft water is fed into the water extraction column from the upper part of the water extraction column, and methanol in the feed gas is extracted with the soft water; the material with methanol removed is subjected to distillation, and removed thioether returns to a dimethyl sulfide workshop for use; crude methyl mercaptan after thioether is removed is fed into a stripper, and most hydrogen sulfide in the raw material is removed through stripping; trace hydrogen sulfide is removed with an iron oxide desulfurizer, and refined methyl mercaptan gas is obtained; refined methyl mercaptan gas is fed into an absorption column and absorbed by liquid caustic soda, and a sodium thiomethoxide solution is obtained. The invention further provides the device corresponding to the method. The method can effectively produce a sodium thiomethoxide product from the by-product methyl mercaptan obtained through synthesis of dimethyl sulfide, waste is changed into wealth, and higher economic and environmental protection values are realized.

Owner:新疆兴发化工有限公司

Preparation method of ametryn

The invention provides a method for preparing ametryn through a green salt-free technology. The method comprises the following step: under the action of a catalyst, enabling atrazine and methanethiolto react in isopropyl alcohol to prepare the ametryn. According to the method provided by the invention, the production and utilization of sodium thiomethoxide with an offensive odor are avoided; meanwhile, a catalyst with the offensive odor, i.e., trimethylamine hydrochloride, is not used, and the environment-friendly catalyst is used, so that the odor can be avoided radically and the quality ofa product and the environment of a production site are extremely improved; meanwhile, industrial salt is not generated; the method is environmentally friendly and the environment protection cost is greatly reduced.

Owner:NINGXIA G R FINE CHEM CO LTD

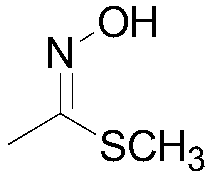

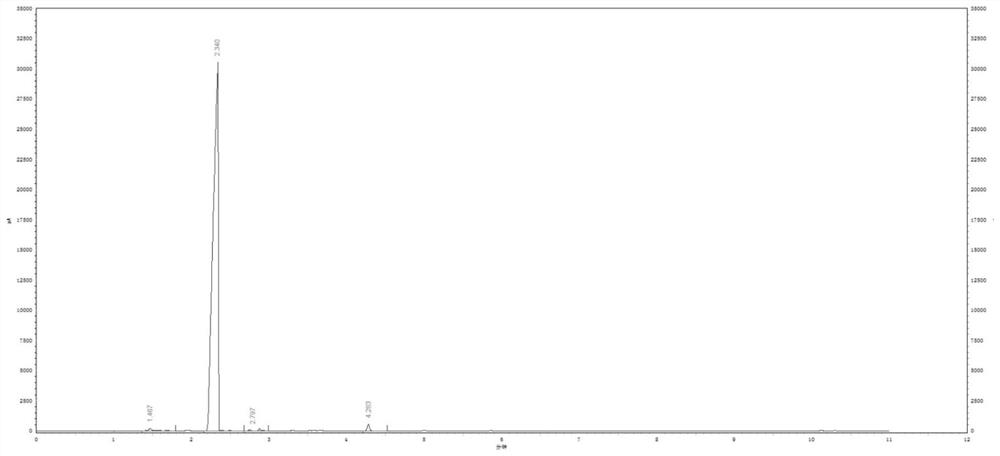

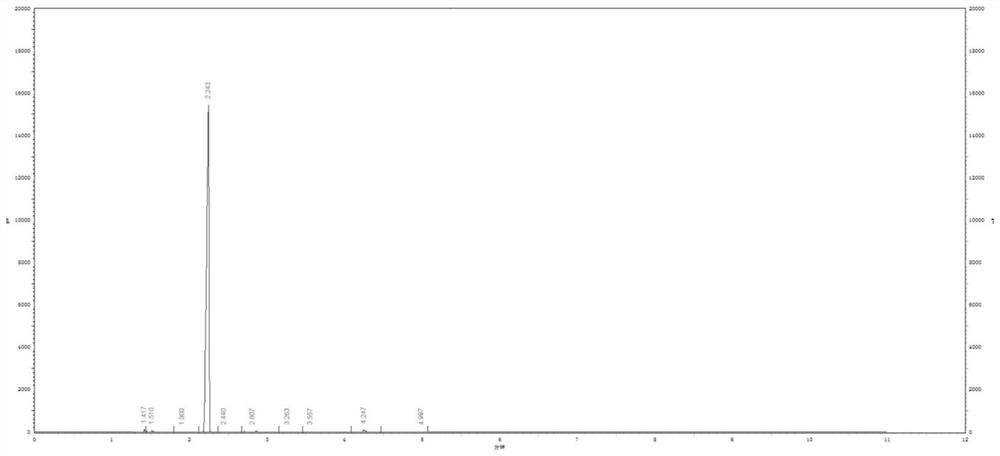

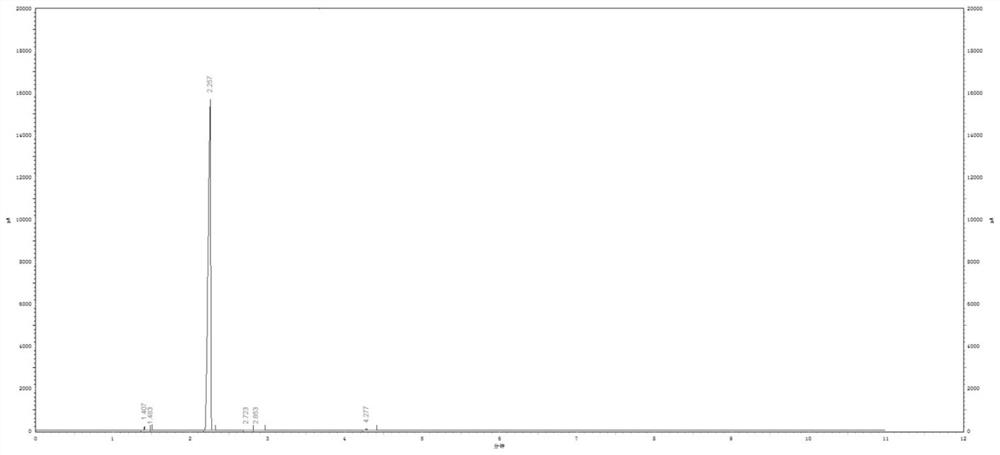

Preparation method of methomyl oxime

The invention discloses a preparation method for methomyl oxime. The preparation method comprises the following steps: (1) respectively dissolving acetaldehyde oxime and chlorine gas in an organic solvent to obtain an organic solution of acetaldehyde oxime and an organic solution of chlorine gas, and dissolving sodium methyl mercaptide and sodium hydroxide in an organic solvent to obtain a mixed organic solution; (2) with the organic solution of acetaldehyde oxime and the organic solution of chlorine gas as raw materials, carrying out continuous feeding for a chlorination reaction; and (3) immediately subjecting a chlorinated mixed solution obtained by a chlorination reaction to a methylthio substitution reaction with the mixed organic solution, removing the solvent from a crude methomyl oxime product obtained by the reaction, and adding a small amount of water to wash the crude methomyl oxime product so as to obtain high-quality methomyl oxime. The method is controllable in reaction heat, small in by-product influence, short in time, capable of avoiding decomposition of chloroacetaldoxime, low in the amount of generated wastewater and free of wasterwater odor, and the obtained finished methomyl oxime is high in yield and quality.

Owner:HUNAN HAILI CHEM IND

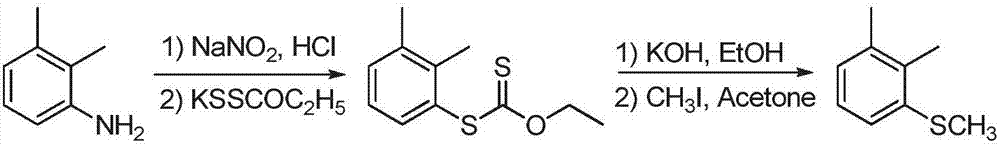

Continuous synthesis method of 2, 3-dimethylphenylsulfide

PendingCN114315666AReduce dosageEasy to operateOrganic compound preparationSulfide preparationDimethylaniline N-oxideSulfide

The invention relates to a continuous synthesis method of 2, 3-dimethyl phenyl dimethyl sulfide, and belongs to the technical field of fine chemical engineering. According to the method, a micro-channel reactor is used as reaction equipment, a channel A is a hydrochloric acid solution of 2, 3-dimethylaniline, a channel B is a sodium nitrite solution, and a channel C is a sodium methyl mercaptide solution; the method comprises the following steps: reacting substances in a channel A and a channel B in a first reaction zone, and then reacting an obtained reaction solution with substances in a channel C in a second reaction zone to obtain a reaction solution containing 2, 3-dimethylphenylmethyl sulfide. According to the method, the continuous production of synthesizing the 2, 3-dimethylphenylsulfide by taking the 2, 3-dimethylaniline as the raw material is realized, the operation process is simplified, the production cost is reduced, and the safety of subsequent production is improved.

Owner:山东亿盛实业股份有限公司

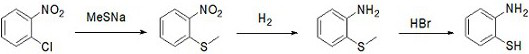

A kind of preparation method of o-aminothiophenol

ActiveCN112062699BHigh yieldHigh purityThiol preparationSulfide preparationPtru catalystNitrobenzene

The invention provides a preparation method of o-aminothiophenol. The preparation method comprises the following steps: putting o-chloronitrobenzene into sodium methyl mercaptide, and performing heating under the action of a catalyst to carry out a methyl vulcanization reaction so as to prepare o-nitrophenyl dimethyl sulfide; putting o-nitrophenyl thioether into a solvent, and carrying out hydrogenation reduction to prepare o-aminobenzene thioether; and demethylating the o-aminothiophenol under the action of hydrobromic acid to obtain the o-aminothiophenol. The preparation method of o-aminothiophenol has the advantages of high yield and high product purity.

Owner:SUZHOU KAIYUAN MINSHENG SCI & TECH CORP

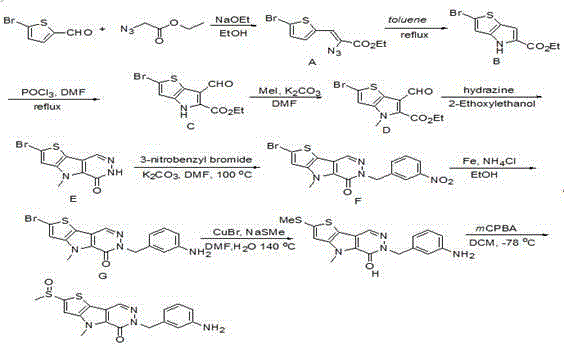

Novel pyruvate kinase M2 activator and its synthetic method

InactiveCN104370936AAvoid purification processLower synthesis costOrganic active ingredientsOrganic chemistryBenzoic acidStructural formula

The invention relates to a synthetic method of a novel pyruvate kinase M2 activator. The structural formula of the pyruvate kinase M2 activator is shown in the specification. The method comprises the following steps: 1, condensing 5-bromo-2-formylthiophene and ethyl triazoacetate to generate a compound A; 2, refluxing the compound A in toluene to carry out loop closing in order to generate a compound B; 3, reacting the compound B with DMF and POCl3 to introduce an aldehyde group in order to generate a compound C; 4, introducing a methyl group to the compound C by using iodomethane in order to generate a compound D; 5, carrying out ring formation on the compound D under the action of hydrazine hydrate to generate a compound E; 6, condensing the compound E and 3-nitrobenzyl bromide to generate a compound F; 7, carrying out a reaction on the compound F under the action of reduced iron powder to generate a compound G; 8, reacting the compound G with sodium methyl mercaptide to generate a compound H; and 9, oxidizing the compound H by m-chloroperbenzoic acid to generate the product I.

Owner:SUZHOU VIVOTIDE BIOTECH

Sodium methyl mercaptide production environment-protecting processing device and technology

ActiveCN104944660AAchieve deodorizationAchieve disinfectionDispersed particle separationEnergy inputAir preheaterLiquid waste

The invention discloses a sodium methyl mercaptide production environment-protecting processing device and technology. The device comprises a technology waste liquid processing mechanism and a technology waste gas processing mechanism which mainly comprises a burner, an air preheater, a front absorption tower and a back absorption tower. The technology waste liquid processing mechanism mainly comprises an acid pickling device, a sulfuric acid middle tank, a waste liquid filtering tank, a sodium sulfate solution circulating tank, a crystallization liquid circulating pool, a crystallization tower, a flash dryer, an anhydrous sodium sulphate storage tank, a washer group, an alkali liquid middle tank and a humidifying evaporator. Sodium methyl mercaptide production waste liquid and waste gas are creatively combined organically for processing, technology waste gas high in combustion value is used for incineration and absorbing, sodium sulfite by-products are obtained, a large amount of high-temperature gas is obtained, the high-temperature gas is used for obtaining anhydrous sodium sulphate by-products with higher value, the purposes of sodium methyl mercaptide production deodorization disinfecting and environment improving can be achieved, sodium bisulfide, sodium sulfite and anhydrous sodium sulphate can be obtained by recycling, and the production cost of sodium methyl mercaptide is lowered.

Owner:陵县鲁鑫工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon Method for synthesizing 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon](https://images-eureka.patsnap.com/patent_img/404513ee-a36e-4edc-bc71-3f9c73e78624/A20081011887200031.PNG)

![Method for synthesizing 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon Method for synthesizing 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon](https://images-eureka.patsnap.com/patent_img/404513ee-a36e-4edc-bc71-3f9c73e78624/A20081011887200041.PNG)

![Method for synthesizing 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon Method for synthesizing 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanon](https://images-eureka.patsnap.com/patent_img/404513ee-a36e-4edc-bc71-3f9c73e78624/A20081011887200042.PNG)