Method and device for producing sodium thiomethoxide from by-product obtained through synthesis of dimethyl sulfide

A technology of dimethyl sulfide and sodium methyl mercaptide, which is applied to the preparation of mercaptans, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as difficult handling, potential safety hazards, and large environmental impacts, and achieve material utilization. High, product quality improvement, high economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

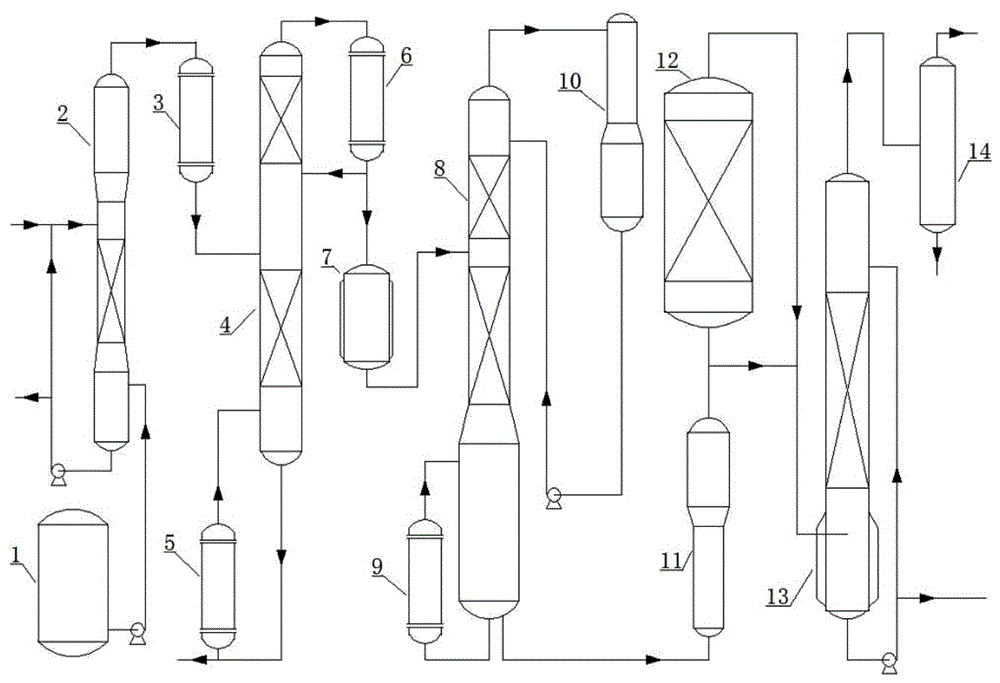

[0030] A device for producing sodium methyl mercaptide by using the by-product of dimethyl sulfide synthesis. The raw material storage tank 1 is connected to the pump and then connected to the bottom of the water extraction tower 2 through the feed pipe, and the top of the water extraction tower 2 is connected to the top of the preheater 3. Connection, the bottom of the preheater 3 is connected with the middle part of the sulfide rectification tower 4, the top of the sulfide rectification tower 4 is connected with the condenser 6 of the rectification tower, and the bottom of the condenser 6 of the rectification tower is connected with the top of the buffer tank 7 through a feeding pipe , the bottom of the buffer tank 7 is connected to the upper part of the stripper 8 through the feed pipe, the bottom of the stripper 8 is connected to the bottom of the vaporizer 11 through the feed pipe, the top of the vaporizer 11 is connected to the bottom of the fine desulfurization reactor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com