Patents

Literature

31results about How to "Create value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

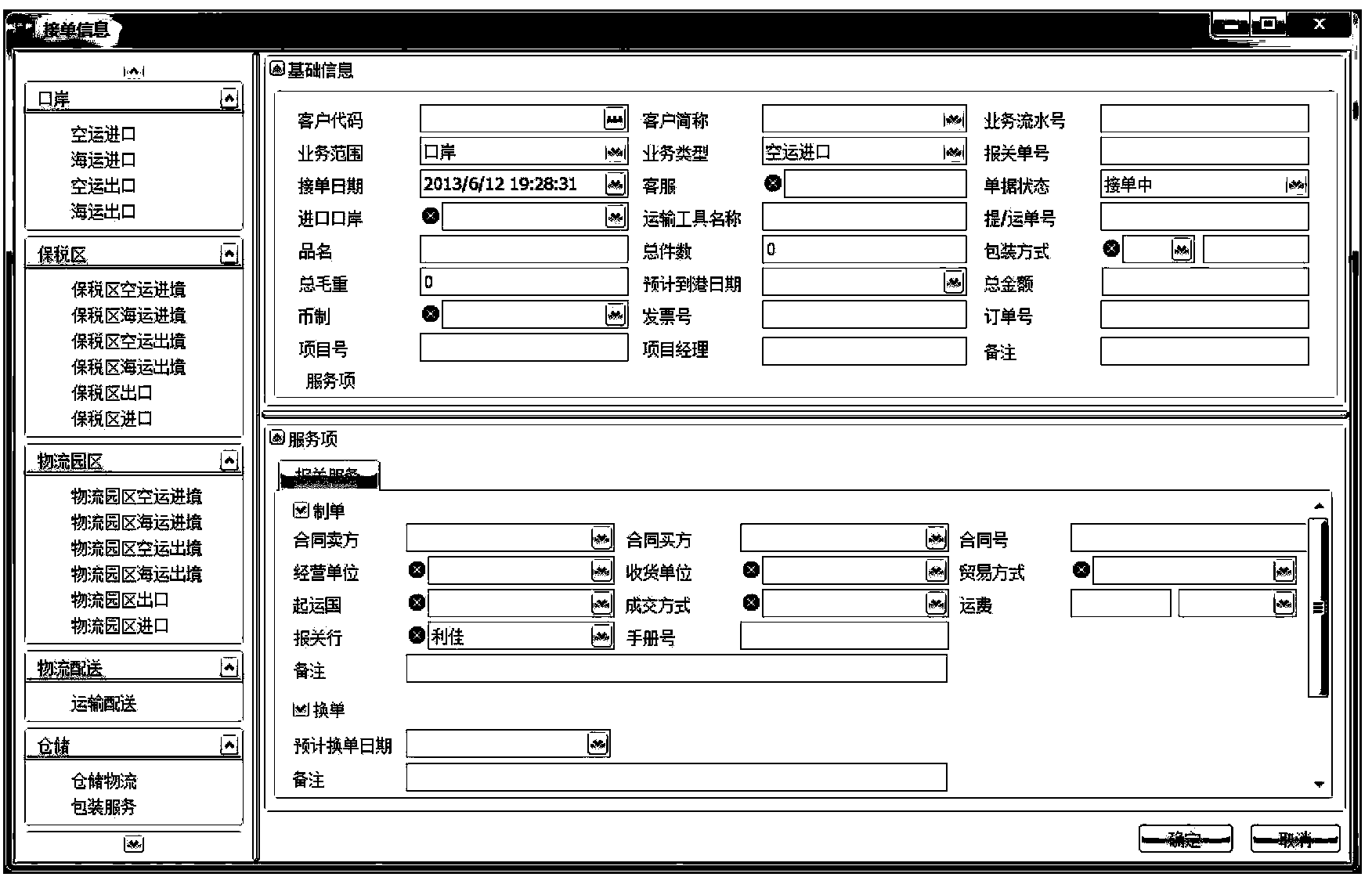

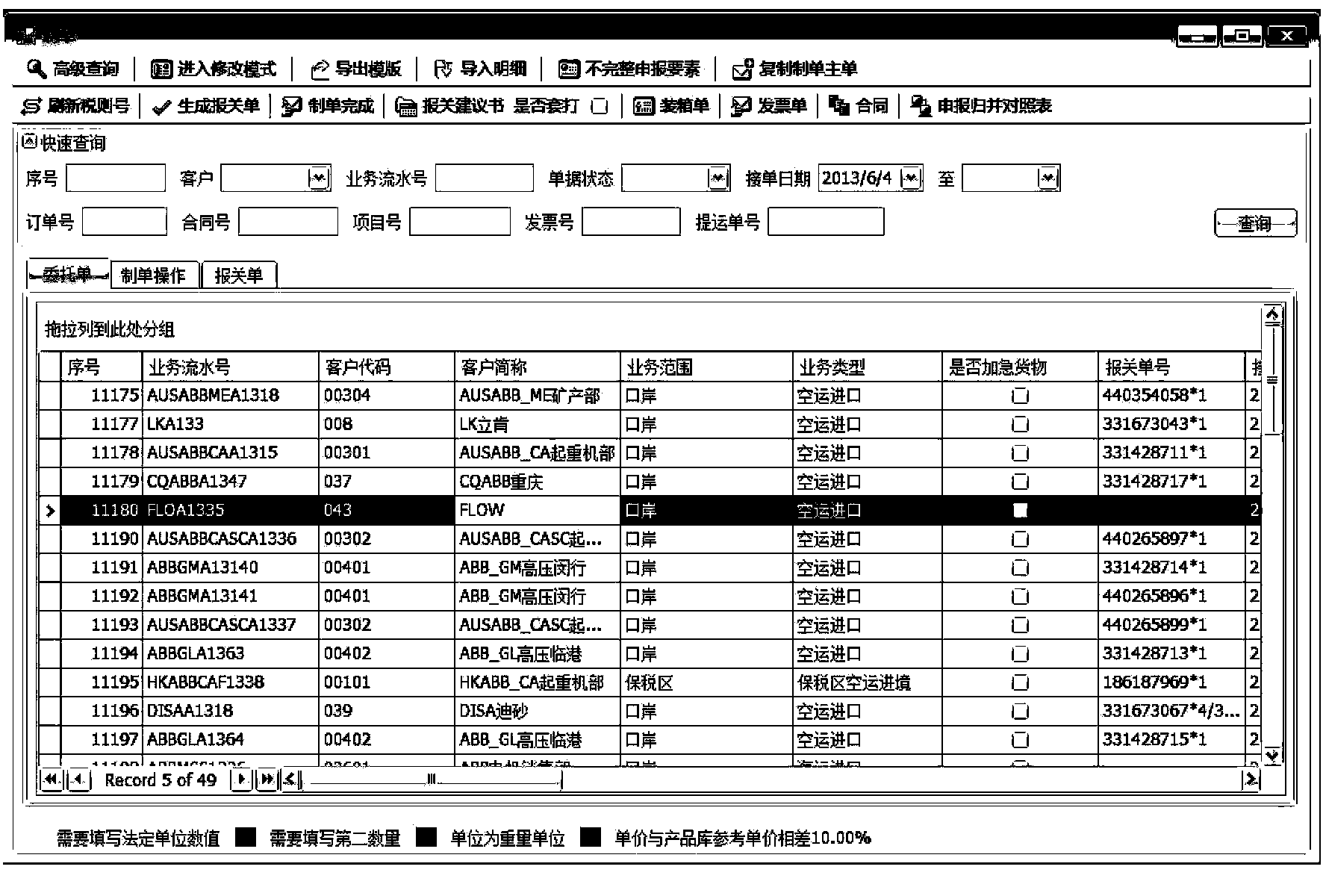

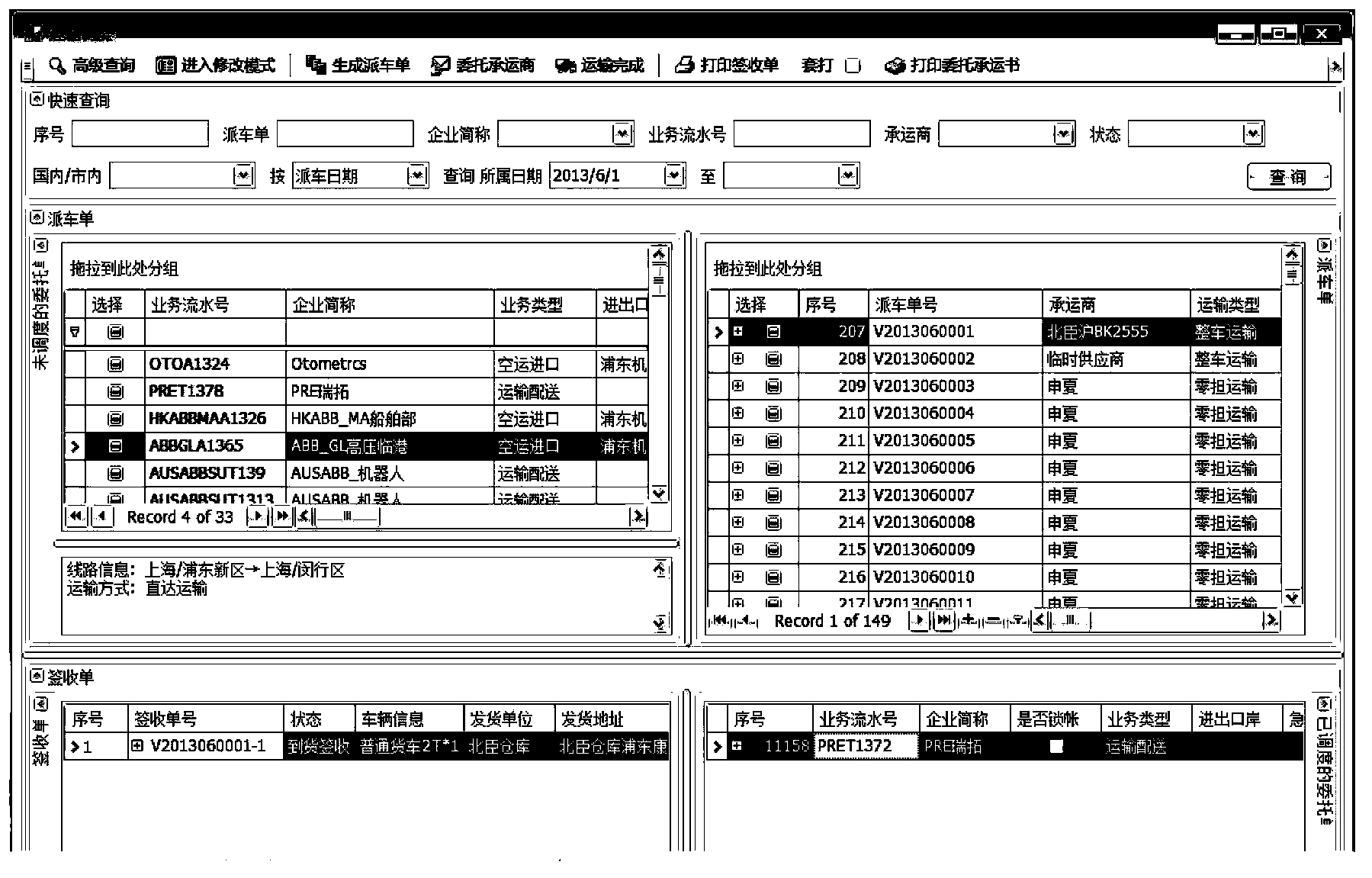

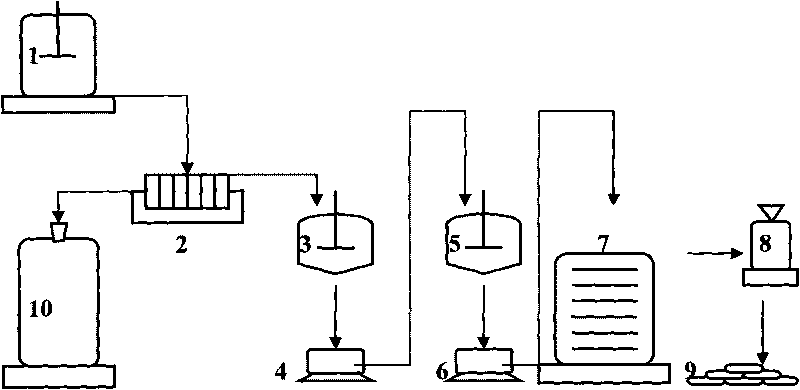

Supply chain management system of one-stop integrated logistic service

InactiveCN103366263ASimple and efficient process managementReal-time alert responseLogisticsInformatizationLogistics management

The invention provides a supply chain management system of one-stop integrated logistic service. The supply chain management system comprises a customer management module, a customs declaration and inspection module, a logistic distribution module, a storage module, a process module and a balance account module, wherein the customer management module is used for carrying out customer management operation to customer service staff; the customs declaration and inspection module is used for carrying out customs clearance operation on enterprise import and export practices; the logistic distribution module is used for carrying out the operation of dispatch, order supervision, order acknowledgement and the like for transportation business; the storage module is used for carrying out warehouse in / out and inventory management of cargos; the process module is used for carrying out real-time management and control, reminding and early warning on the processes of all businesses; and the balance account module is used for carrying out charge balance account for all the businesses. The supply chain management system is not only a set of informatization management software of a third logistic enterprise, but also a set of supply chain solution scheme providing the one-stop integrated logistic service for a cargo owner enterprise; the supervisory control and management are realized for the whole supply chain links; the execution performance of the whole supply chain is improved; the cost is reduced; and the supply chain value is created.

Owner:SHANGHAI BEICHEN IND

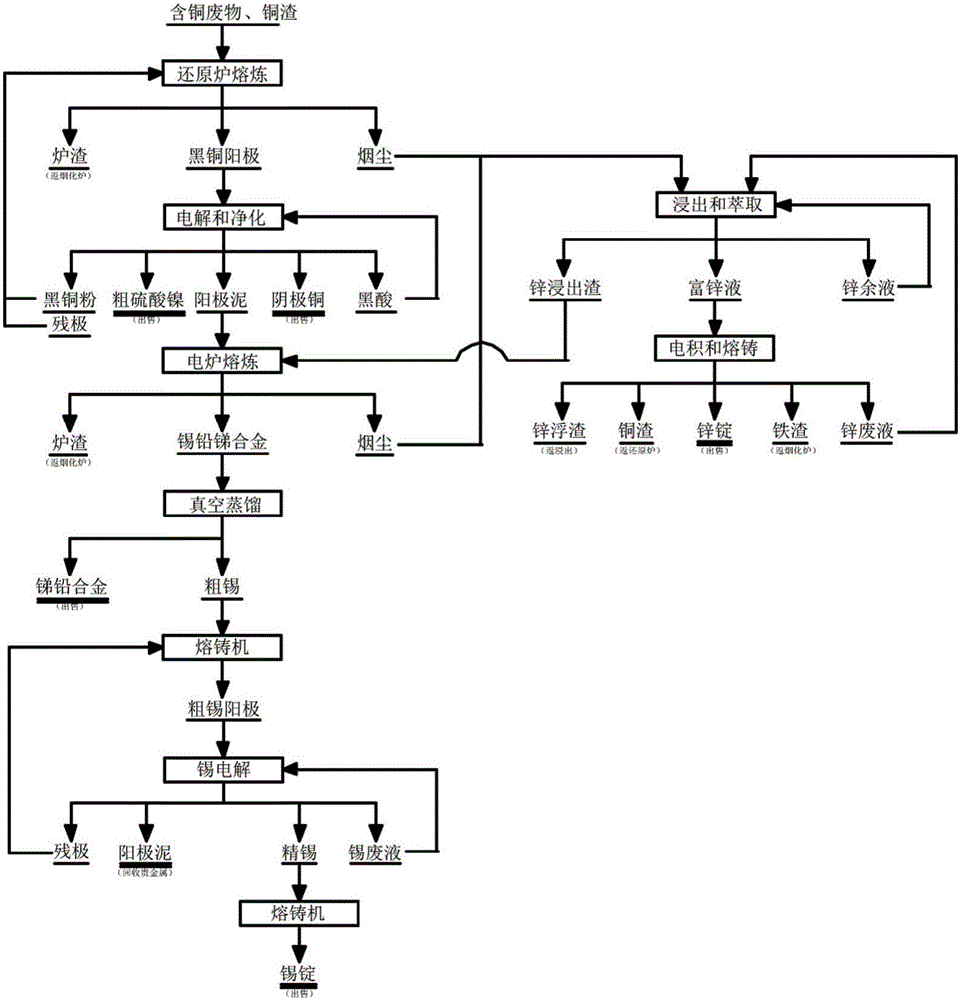

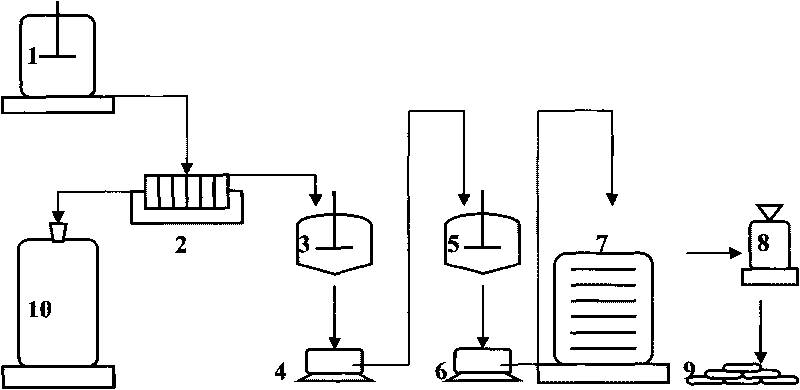

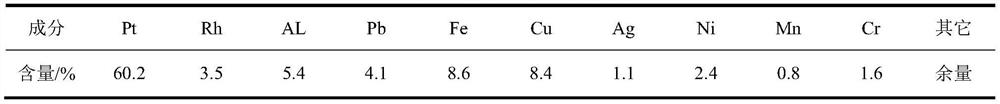

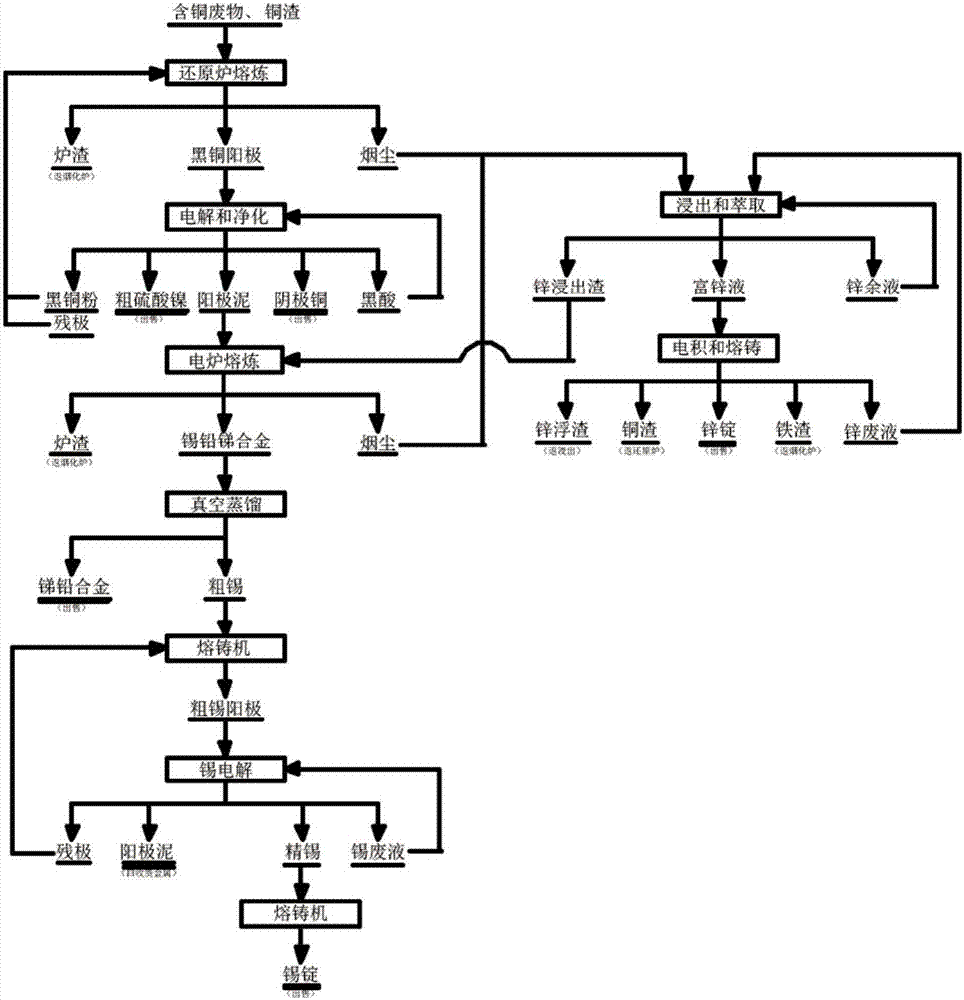

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

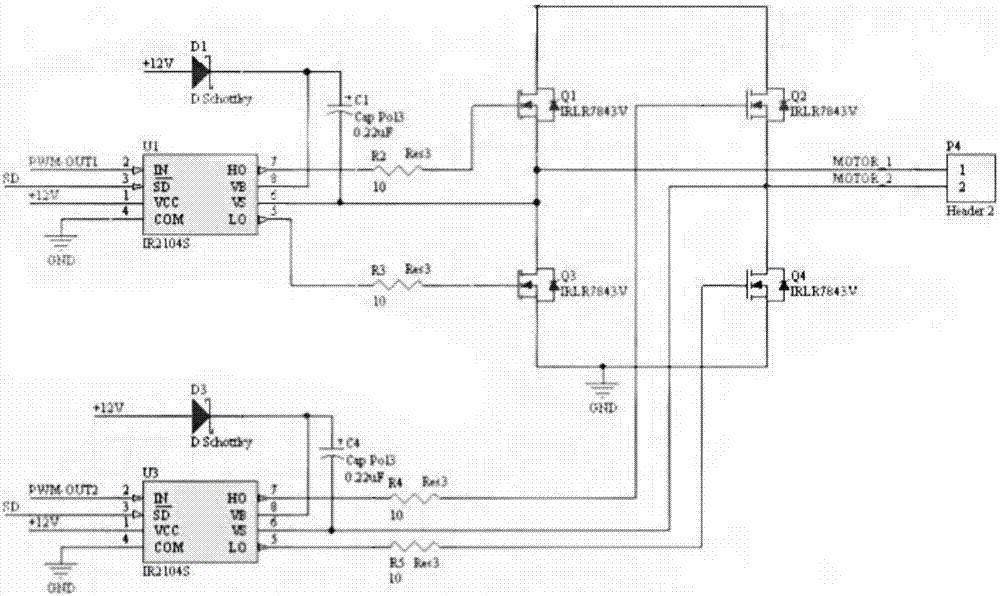

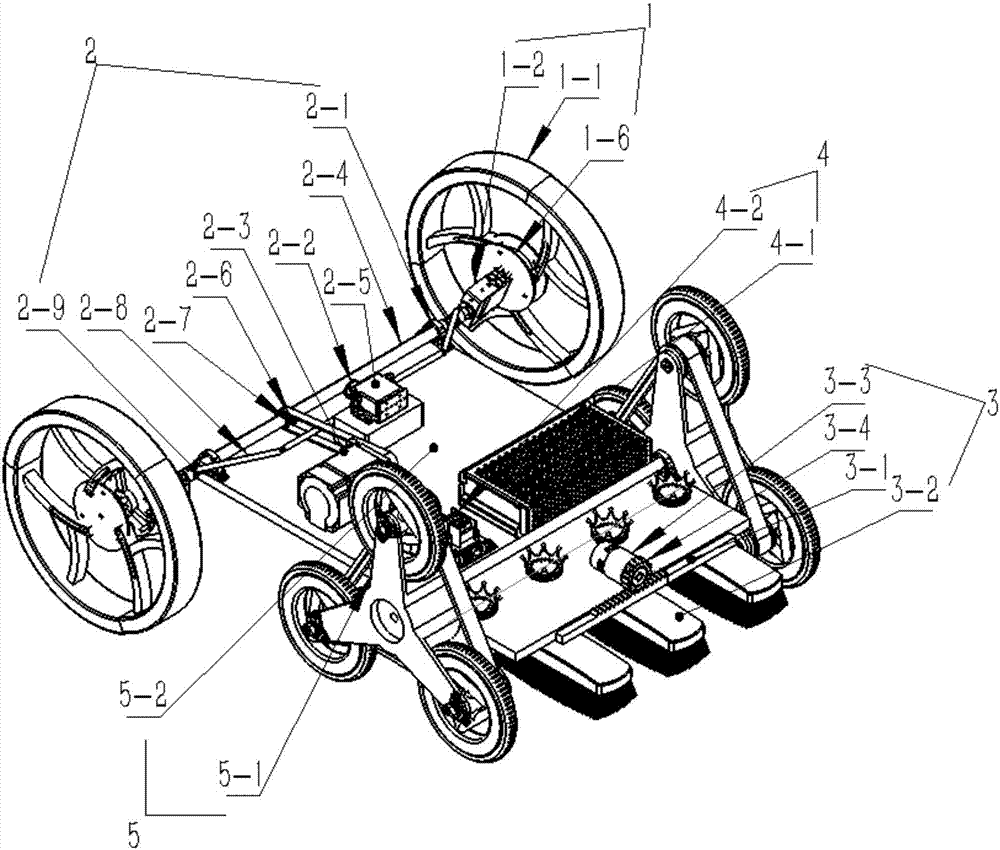

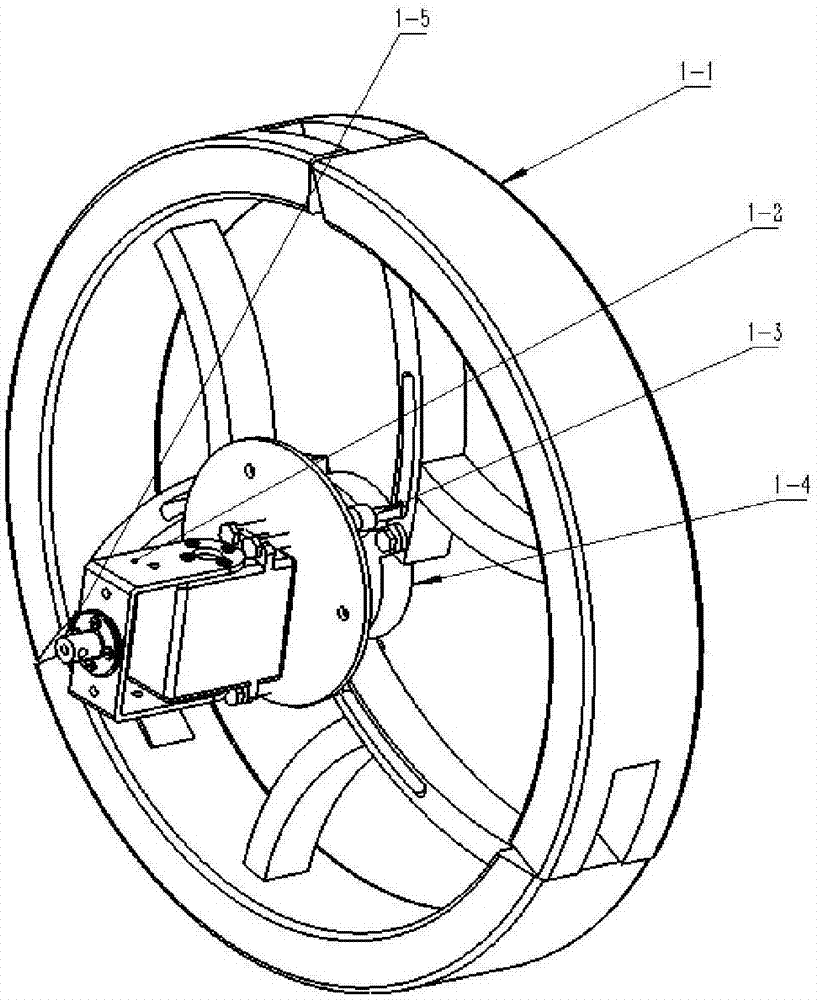

Intelligent tracking, building-climbing and carrying cleaning device

InactiveCN107963140AFlexible controlSimple structureCarpet cleanersFloor cleanersIntelligent lightingEngineering

The invention provides an intelligent tracking, building-climbing and carrying cleaning device and belongs to the technical field of service robots. The intelligent tracking, building-climbing and carrying cleaning device is invented for solving the problems that time and labor are wasted and efficiency is low due to the fact that manual work is still required for carrying weights upstairs and downstairs at certain occasions. The intelligent tracking, building-climbing and carrying cleaning device is mainly used for loaded carrying to the upstairs and the downstairs and stairway cleaning. Transformation and steering of wheels are realized by controlling three steering engines through STM32, whether the device reaches a wall and needs to turn or not is detected through ultrasonic ranging, whether the device reaches a stairway or not is judged according to the distance difference, so that automatic transformation is carried out, and intelligence of walking on a flat ground and going upstairs and downstairs is realized. Transformation wheels are folded as a whole when located on the flat ground and are divided into three parts to facilitate stairway-climbing advancing when going upstairs and downstairs, centrosymmetric pin claws are driven by the steering engines to control folding and separating of the transformation wheels, and meanwhile, a cleaning unit is mounted at the tail to clean a stairway.

Owner:DALIAN UNIV OF TECH

Android platform-based big dipper and GPS dual-mode on-line positioning method

InactiveCN105005058ASolve the problem of difficult transmissionIncrease demandSatellite radio beaconingDual modeThe Internet

The invention relates to an Android platform-based big dipper and GPS dual-mode on-line positioning method, which comprises a mobile positioning terminal capable of receiving the information sent by a satellite, a remote cloud server, a mobile webpage client, and an Android handset client. The mobile positioning terminal is connected with the remote cloud server through the internet. The remote cloud server is respectively connected with the mobile webpage client and the Android handset client through the internet. A mobile platform of the Freescale i.MX 6q series is operated based on the android system, so that the real-time location information of a Big Dipper / GPS dual-mode module can be received in real time. Therefore, problems in the prior art that in some remote areas, corresponding services cannot be supplied to people or enterprise and public institutions in need due to the bare coverage of communication base stations and the large transmission difficulty of information can be solved.

Owner:LIUZHOU BAISIDE INFORMATION TECH CO LTD

Method for extracting gasoline and diesel fuel and recovering clay from petrifaction waste clay

InactiveCN101700492AEfficient extractionEliminate pollutionOther chemical processesContaminated soil reclamationFiltrationGasoline

The invention discloses a method for extracting gasoline and diesel fuel and recovering clay from petrifaction waste clay; the main technical proposal is that: solvent oil extraction, pressure filtration, saponification, activation, centrifugal dehydration, drying, crushing measures are carried out to the petrifaction waste bleaching earth to obtain the gasoline and diesel fuel and regenerative activated clay. The invention provides a method for extracting gasoline and diesel fuel and recovering clay from petrifaction waste clay, which effectively extracts gasoline and diesel fuel and recovers the activated clay; the pollution is eliminated and the value is created, therefore, the method has double benefits.

Owner:王嘉兴

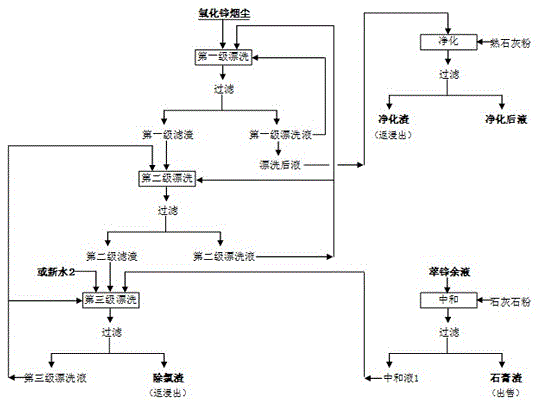

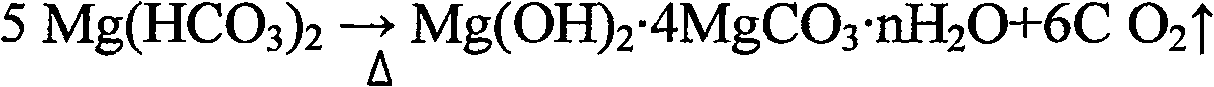

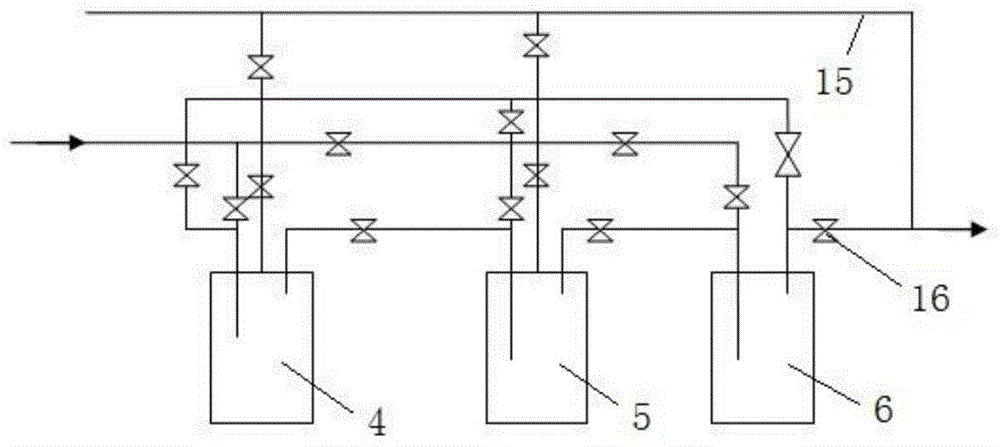

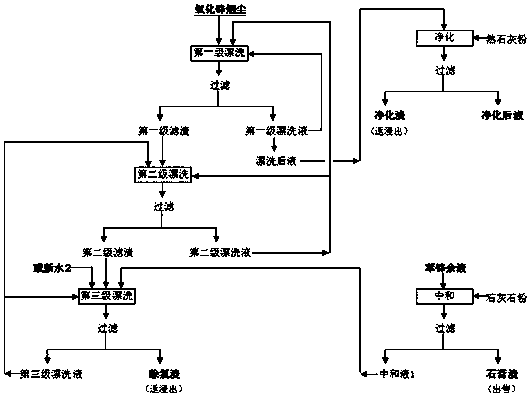

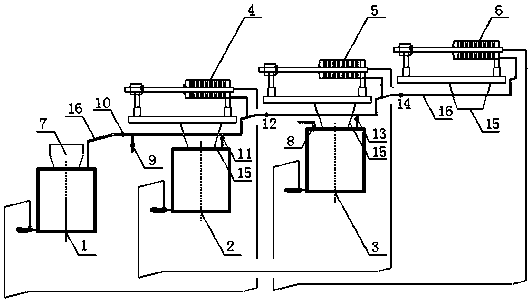

Multi-level countercurrent continuous rinsing and chlorine removing technology and device for zinc oxide smoke

ActiveCN105483362ARealize reverse flowEnsure balanceProcess efficiency improvementHydrometallurgyMetal salts

The invention discloses a multi-level countercurrent continuous rinsing and chlorine removing technology and device for zinc oxide smoke. Raw materials are chlorine containing zinc oxide smoke. The technology comprises the steps that neutralizing, rinsing and purifying are carried out; free acid in zinc extraction residual liquid of an extraction-electrodeposition method is neutralized through limestone flour; zinc oxide smoke rich in chlorine is rinsed through neutralized liquid; and zinc ions are deposited through slaked lime powder via rinsed liquid, zinc oxide residues subjected to chlorine removing are rinsed, and the chlorine residues are removed. According to the technology and device, reverse circulation of solid materials and liquid materials is achieved, a water-soluble compound in the solid materials can be deeply removed, and the problem of removing of a water-soluble chlorine fluorine compound in the zinc oxide smoke raw materials during zinc hydrometallurgy is solved. Meanwhile, the technology and device are suitable for rinsing and recycling of soluble valuable metal salt in various hydrometallurgy residues, and material balance, size balance and concentration balance in a multi-level countercurrent rinsing device system can be guaranteed; and it can also be guaranteed that chemical components of generated rinsed residues and the rinsed liquid are stable, and linkage with a next procedure is facilitated.

Owner:江西自立环保科技有限公司

Domestic garbage incineration, regeneration and utilization process

ActiveCN105945028ASave on landfill costsAvoid secondary pollutionSolid waste disposalTunnel kilnBrick

The invention discloses a domestic garbage incineration, regeneration and utilization process including the steps of: 1) crushing and fermenting the garbage and processing a leachate, wherein qualified reclaimed water is used for producing green bodies, sludge is dried and incinerated, and biogas is used for supporting combustion; 2) incinerating the garbage, wherein the coke residue and fly ash after incineration are collected for later use and generated heat energy is used for power generation; 3) employing high-temperature flue gas from a residual heat boiler for drying the green bodies; and 4) mixing the coke residue and fly ash with shale earth, coal gangue and polluted soil from the original domestic garbage landfill, grinding and fining the mixture, producing green bodies and sintering the green bodies in a tunnel kiln at 850-1100 DEG C for 25-28 h. In the coke residue and fly ash, heavy metals are immobilized in bricks and dioxin can be completely decomposed due to continuous high temperature. The process can completely decompose the dioxin and immobilize the heavy metals in bricks and meanwhile generates stable salt minerals, which can be harmlessly recycled, so that the process can avoid cost of landfill, turns wastes into resources, creates values and avoids secondary pollution.

Owner:于继林

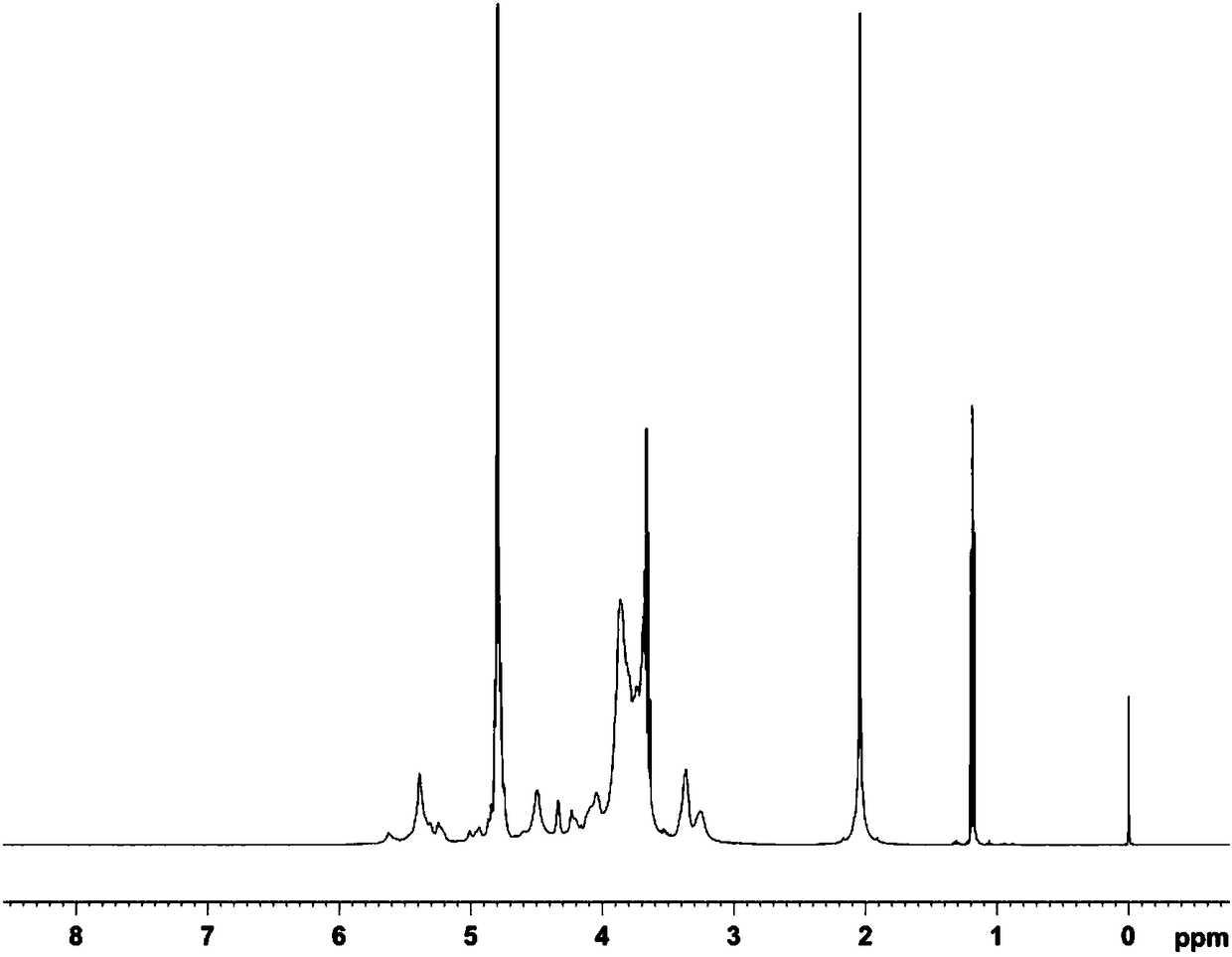

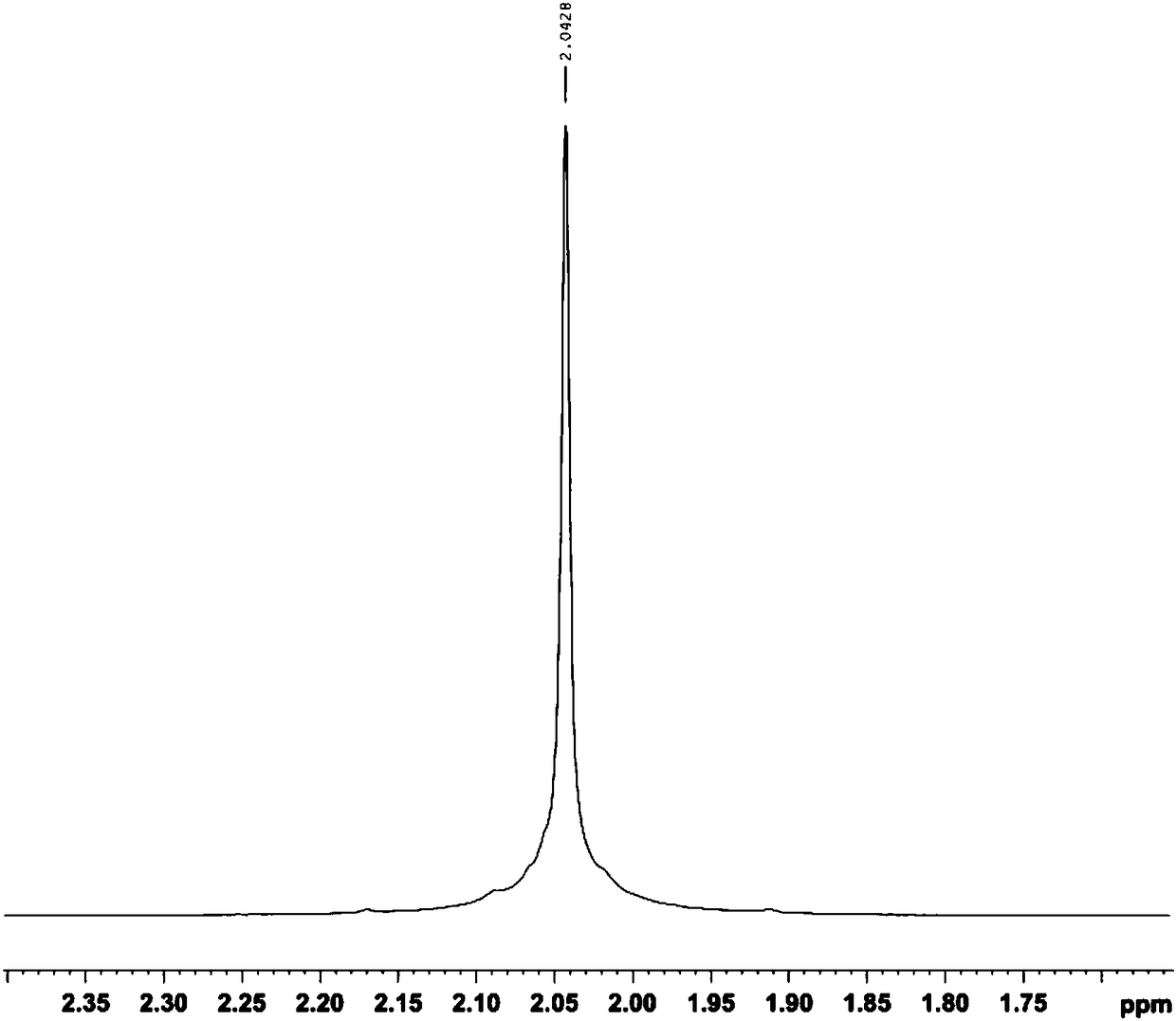

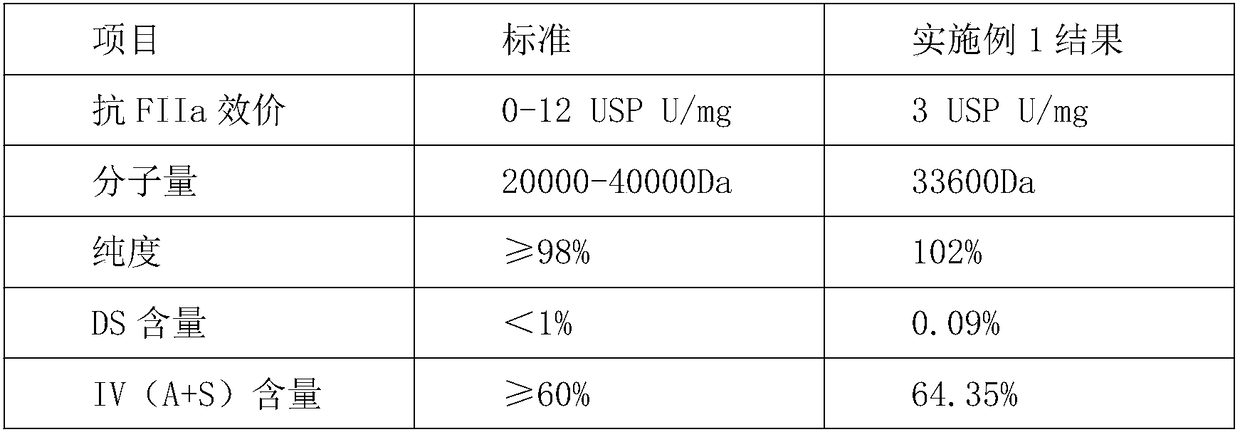

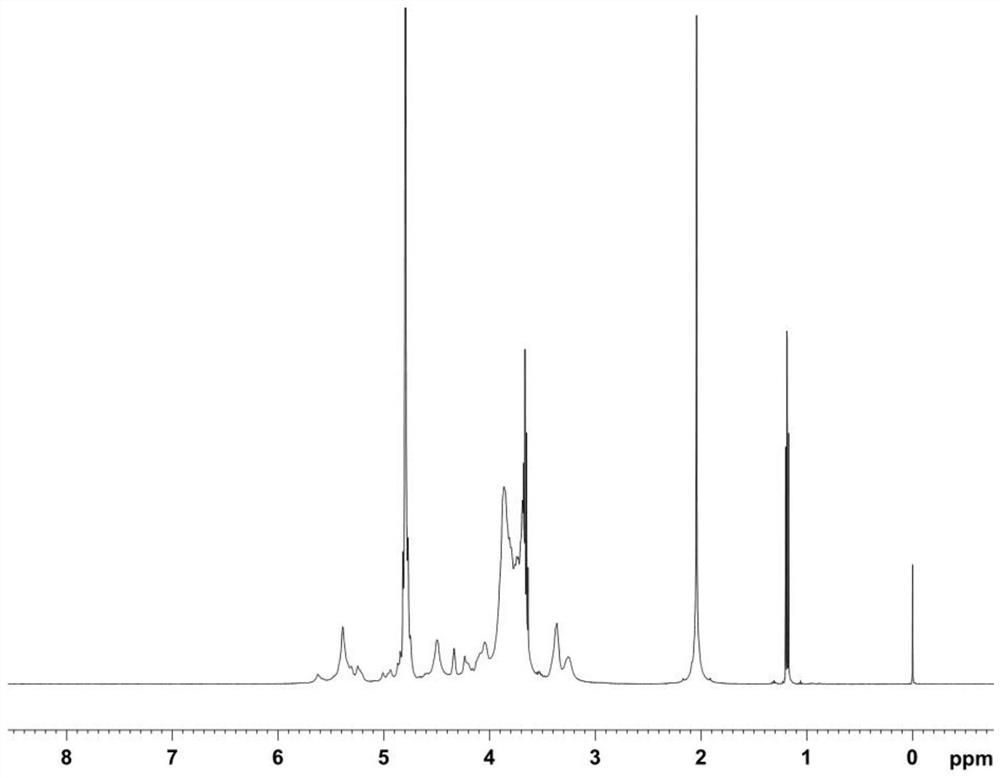

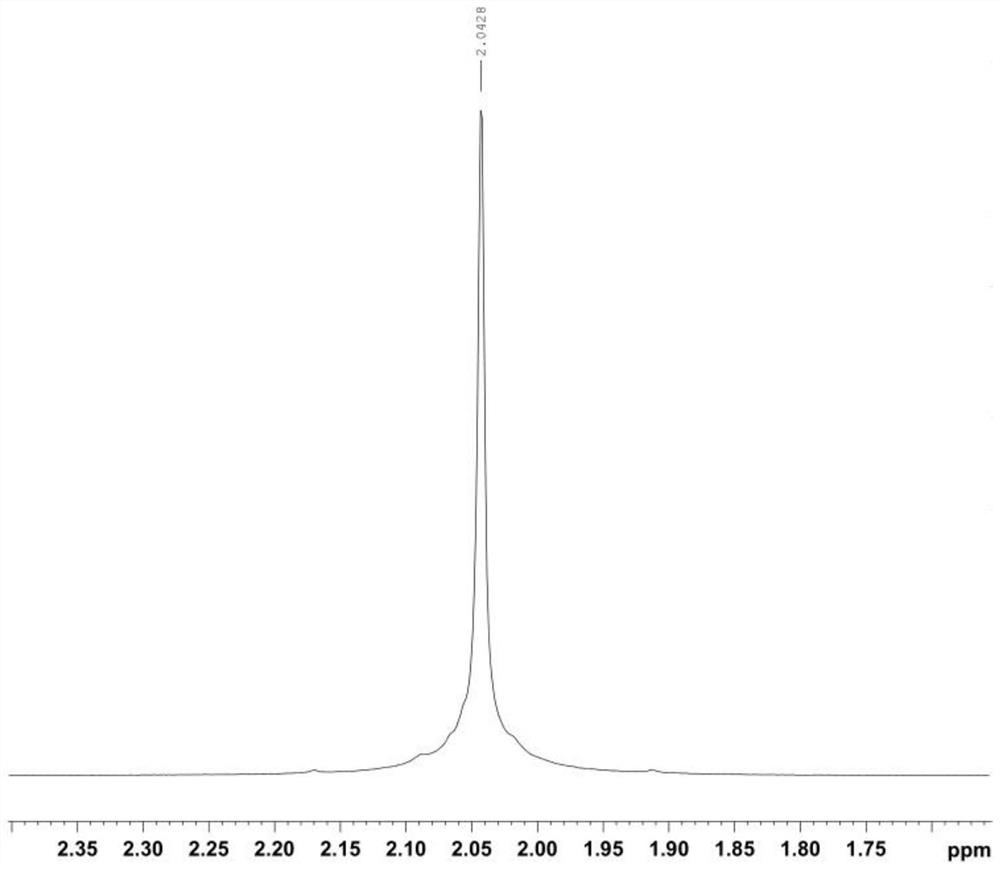

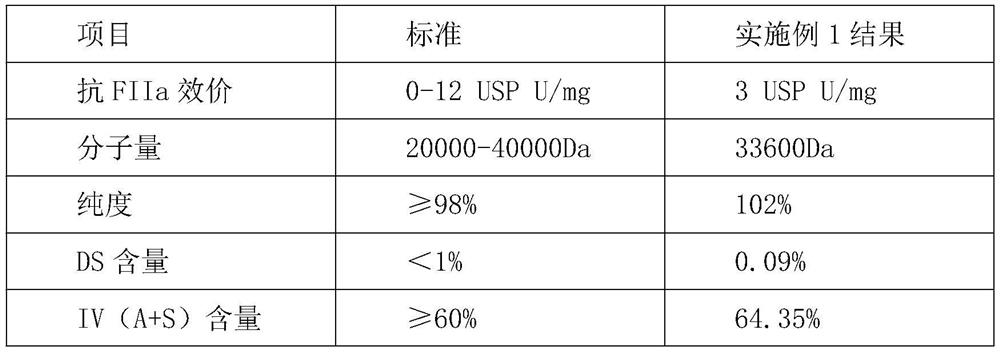

Sulodexide production method

ActiveCN104398533ASolve financial and material resourcesSave a lot of costOrganic active ingredientsBlood disorderDermatan sulfateHeparin

The invention discloses a sulodexide production method and belongs to the technical field of bio-pharmaceuticals. The sulodexide production method comprises the following steps: using a heparin byproduct as a raw material, and performing oxidization to obtain an intermediate crude product heparin solution; adding acetate into the intermediate crude product heparin solution, and separating by ultra-filtration to obtain a rapid movement heparin crude product and a dermatan sulfate crude product; then respectively refining a rapid movement heparin crude product and a dermatan sulfate crude product; performing refinement on the rapid movement heparin crude product and the dermatan sulfate crude product; finally mixing and dissolving precipitates obtained by refining, filtering, collecting a filtrate, and carrying out freeze-drying processing to obtain a sulodexide raw material. The method has the advantages that product purity and stability are improved; as the byproduct produced during the production of heparin is used as the raw material, the production cost is reduced, required production equipment is simple, and production conditions are easy to control.

Owner:SHANDONG CHENZHONG BIOPHARM +1

Method for extracting high-purity heparan sulfate from heparan production wastes

The method discloses a method for extracting high-purity heparan sulfate from heparan production wastes, and aims at providing a method used for extracting purified heparan sulfate taking the heparanproduction wastes as raw material. The method has the advantages of low cost, convenient operation and easy industrial scaling. The method is characterized by comprising the steps that 1), the heparanproduction wastes are prepared into a solution; 2), acid is added to adjust the pH to 1.9-2.3, ethanol is added, and stirring, centrifugation and standing are conducted; 3), supernatant liquid is collected, aqueous alkali is added to adjust pH to 6-8, and water is added; 4), absorbent is added to the solution is step 3), and stirring is conducted until all mucopolysaccharide in the solution is absorbed by the absorbent; 5), the absorbent is collected and washed with clean water, a sodium chloride solution is added to conduct elution, elution liquid is collected after the elution is completed,and precipitant is added for precipitation; 6), precipitations are collected and dried; the method belongs to the field of mucopolysaccharide pharmaceuticals.

Owner:深圳市格利科生物科技有限公司

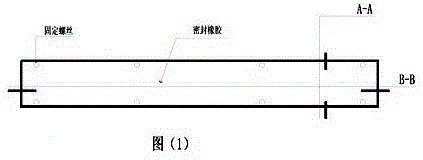

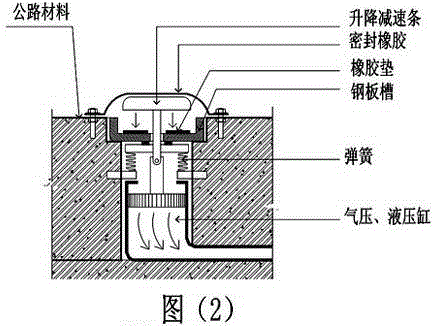

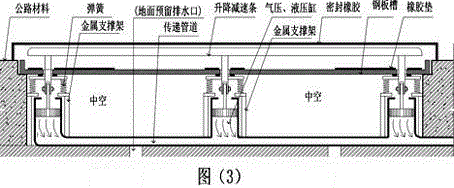

Method for driving power generators to generate power under descending actions of lifting deceleration strips rolled by wheels

The invention discloses a method for driving power generators to generate power under the descending actions of lifting deceleration strips rolled by wheels. The method has the advantages that kinetic energy generated when the 'lifting deceleration strips' rolled by the wheels is transmitted to certain positions by pneumatic and hydraulic transmitters, the power generators can be conveniently mounted at the certain positions, a plurality of gears can be driven to rotate after the speeds are increased, or various bidirectional rotation and unidirectional rotation output gears on shafts of the power generators can be respectively driven by hydraulic motors to rotate, so that each power generator can rotate towards a direction to generate electric energy; 13-25V varying alternating currents outputted by the power generators only can be used for charging 12V storage batteries to be stored after being rectified by rectifiers due to unstable vehicle flow, and the electric energy generated by the miniature power generators driven by the 'lifting deceleration strips' rolled by the wheels can be converted into chemical energy; the chemical energy in the storage batteries can be converted into alternating-current 220V mains supply by inverter power supplies with protection circuits, and the alternating-current 220V mains supply can be transmitted to diversified electric devices to be stably utilized by the various electric devices.

Owner:康国强

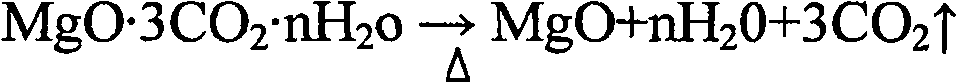

Method for producing basic magnesium carbonate with boric sludge

InactiveCN100558637CShorten the production cycleQuality improvementMagnesium carbonatesMagnesium hydroxideActivated sludgeFiltration

The method for producing basic magnesium carbonate from boron mud of the present invention belongs to the technical field of inorganic compound and sludge treatment. Including the process steps of activating boron mud, carbonization and finished products; said carbonization is to mix the calcined boron mud, water and the wood vinegar liquid catalyst with disconnected water molecules at normal temperature and feed CO2 to stir the reaction, The reaction is terminated at pH=7; the finished product is to filter the slurry produced in the carbonization step, take the mother liquor and heat it for heat preservation, and filter and dry to obtain the finished basic magnesium carbonate. All the industrial water in the invention is circulating water, so a large amount of water can be saved; the energy can be greatly saved and the production cycle can be shortened, and micronutrients necessary for ecological agriculture can be produced after neutralization of magnesium mud. In this way, the resource utilization of boron mud can not only create value, turn waste into wealth, but also protect the environment.

Owner:吉林省新世纪农业科技有限公司

Method for producing high-quality potassium chloride

ActiveCN102145902BRealize valuable useAchieving a circular economyAlkali metal chloridesMultiple-effect evaporationEnvironmental resistanceEvaporation

The invention provides a method for producing high-quality potassium chloride. The method is characterized by comprising the following steps of: preheating leach liquor containing potassium dust to the temperature of between 110 and 130 DEG C; performing first-effect evaporation, second-effect evaporation and third-effect evaporation sequentially to obtain a high-quality potassium chloride product; performing fourth-effect evaporation on evaporated liquor obtained after the third-effect evaporation to obtain an industrial potassium chloride product; returning evaporated liquor obtained after the fourth-effect evaporation and mixed condensed water to an extraction process; and extracting potassium-containing dust for recycling. The method has a simple process flow and is low in energy consumption; and by the method, wastewater discharging is avoided, environment friendliness is facilitated, resources are saved, a new application way is provided for the utilization of potassium-containing industrial wastes, and the aims of energy conservation, emission reduction and circular economy are fulfilled.

Owner:唐山汇鑫嘉德节能减排科技股份有限公司

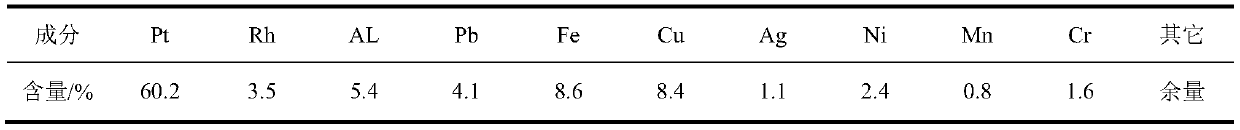

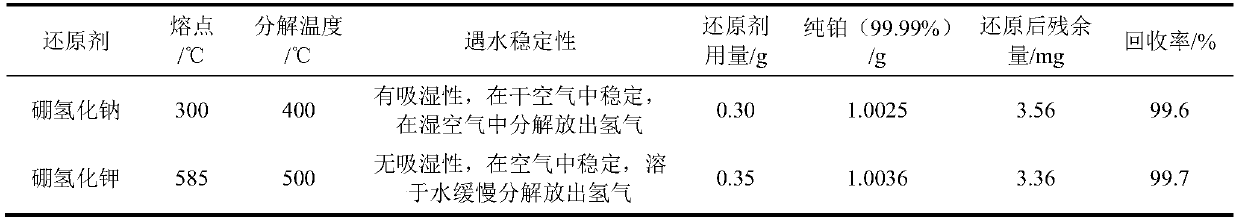

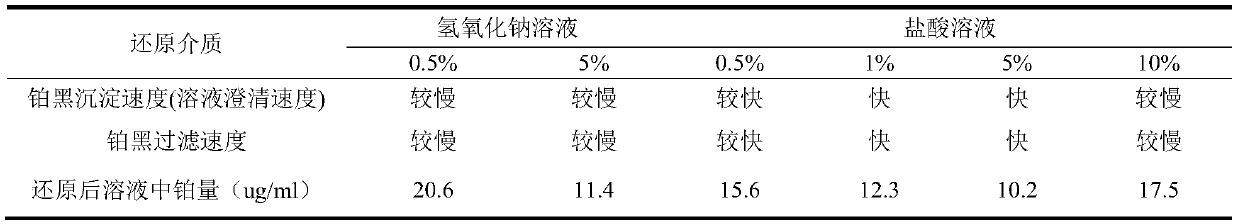

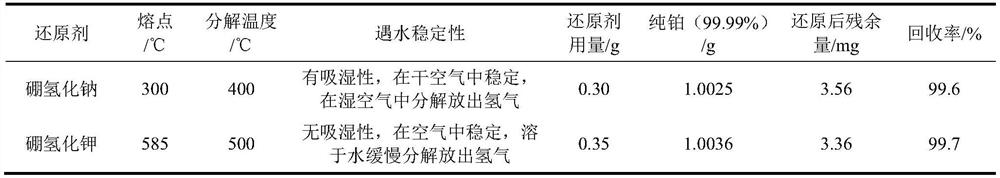

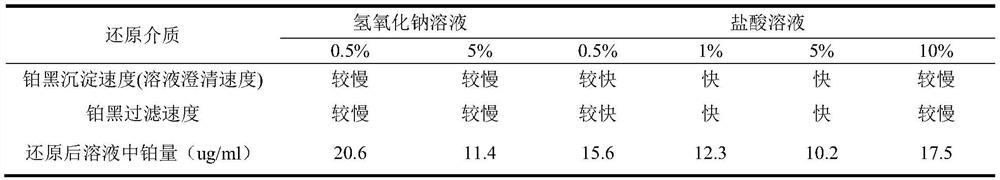

Method for recovering platinum from laboratory waste noble metal material through potassium borohydride-ammonium chloride reduction

ActiveCN111455184AAvoid wastingAvoid lostProcess efficiency improvementPotassium borohydrideNitric oxide

The invention discloses a method for recovering platinum from a laboratory waste noble metal material through potassium borohydride-ammonium chloride reduction. The method for recovering the platinumthrough a potassium borohydride reduction-ammonium chloride precipitation method by taking a laboratory platinum-containing waste consumable as a raw material is researched and established. Nitric acid is adopted to separate impurity elements, the platinum is dissolved in aqua regia, nitric oxide is repeatedly expelled with hydrochloric acid, and the platinum is fully converted into chloroplatinicacid. The method comprises the following steps of reducing the chloroplatinic acid into platinum black by using potassium borohydride in a 40 DEG C and 5% (V / V) hydrochloric acid medium, then dissolving the platinum black by using the aqua regia, completely converting the platinum black into chloroplatinic acid, forming yellow ammonium chloroplatinate precipitate by using the chloroplatinic acidand excessive ammonium chloride, and performing aging and overnighting; and performing drying by using a segmented slow heating firing method, and decomposing the ammonium chloroplatinate to obtain pure loose platinum powder or dense metal platinum. The method is low in cost and easy and convenient to operate, and residual platinum ions in the two precipitation solutions are smaller than 20 ug / mL,the purity of the recovered platinum is not less than 99.5%, and the recovery rate is greater than 99%.

Owner:河南省岩石矿物测试中心

Production method of sulodexide

ActiveCN104398533BLow costCreate valueOrganic active ingredientsBlood disorderFiltrationFreeze-drying

The invention discloses a sulodexide production method and belongs to the technical field of bio-pharmaceuticals. The sulodexide production method comprises the following steps: using a heparin byproduct as a raw material, and performing oxidization to obtain an intermediate crude product heparin solution; adding acetate into the intermediate crude product heparin solution, and separating by ultra-filtration to obtain a rapid movement heparin crude product and a dermatan sulfate crude product; then respectively refining a rapid movement heparin crude product and a dermatan sulfate crude product; performing refinement on the rapid movement heparin crude product and the dermatan sulfate crude product; finally mixing and dissolving precipitates obtained by refining, filtering, collecting a filtrate, and carrying out freeze-drying processing to obtain a sulodexide raw material. The method has the advantages that product purity and stability are improved; as the byproduct produced during the production of heparin is used as the raw material, the production cost is reduced, required production equipment is simple, and production conditions are easy to control.

Owner:SHANDONG CHENZHONG BIOPHARM +1

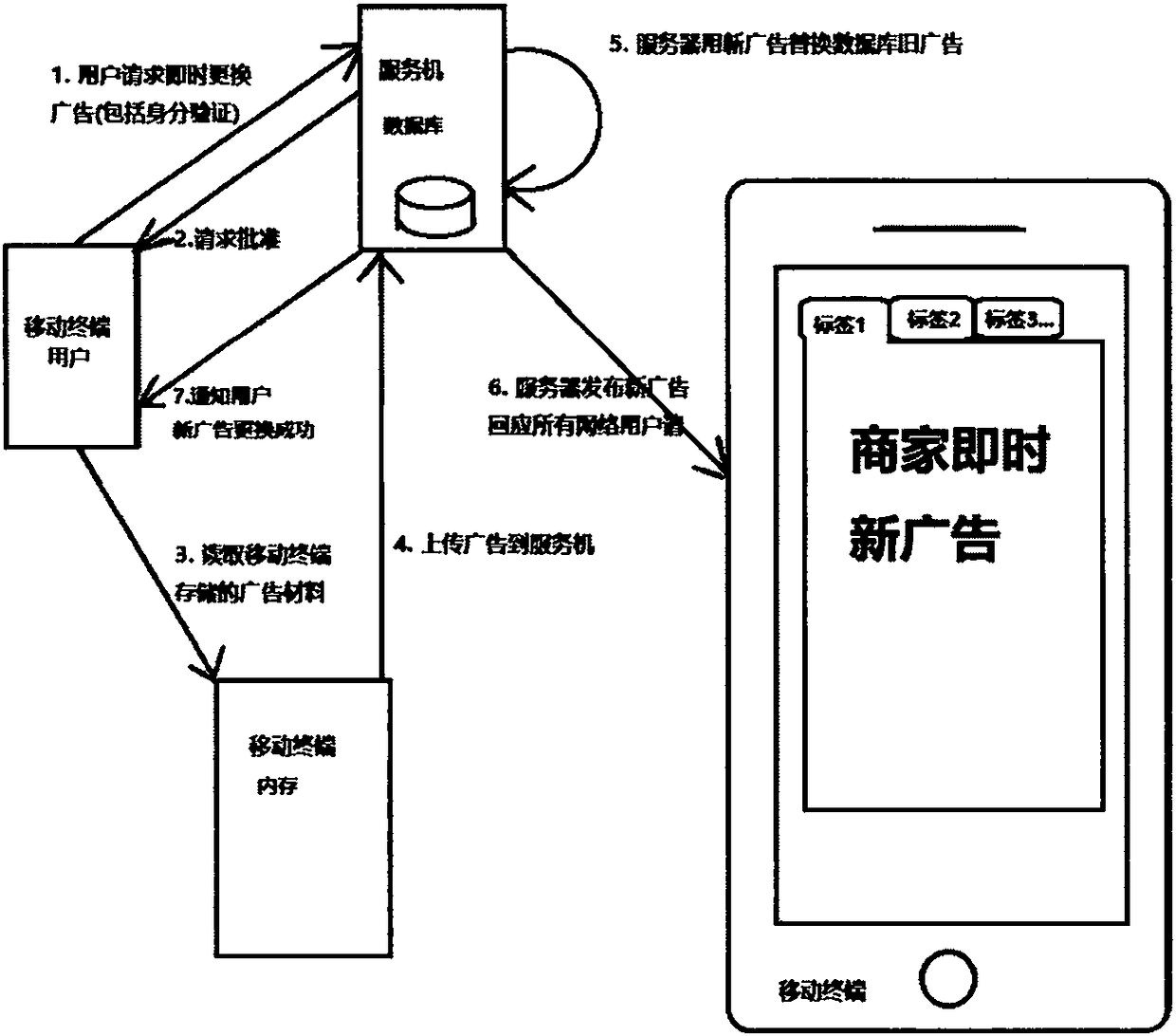

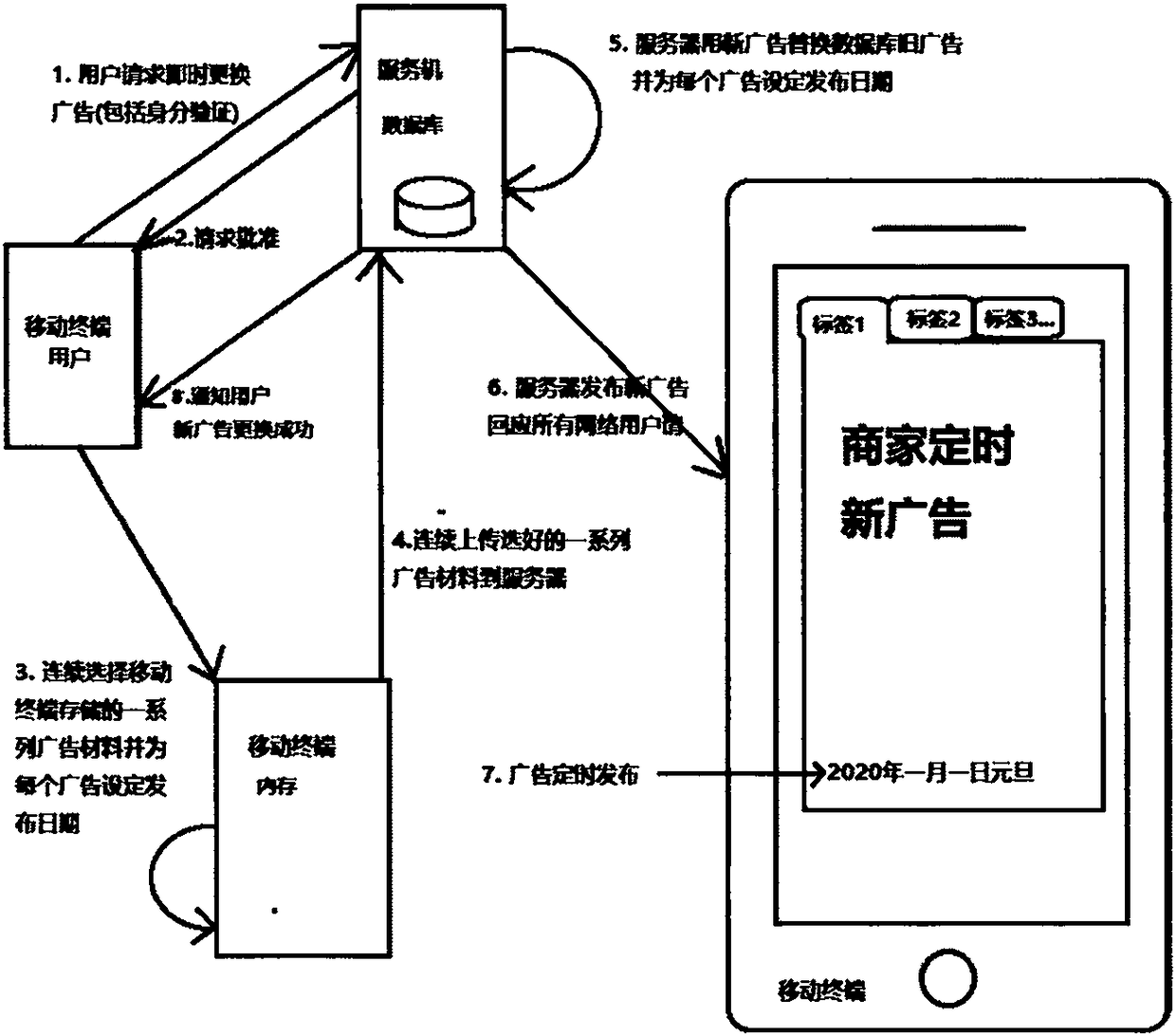

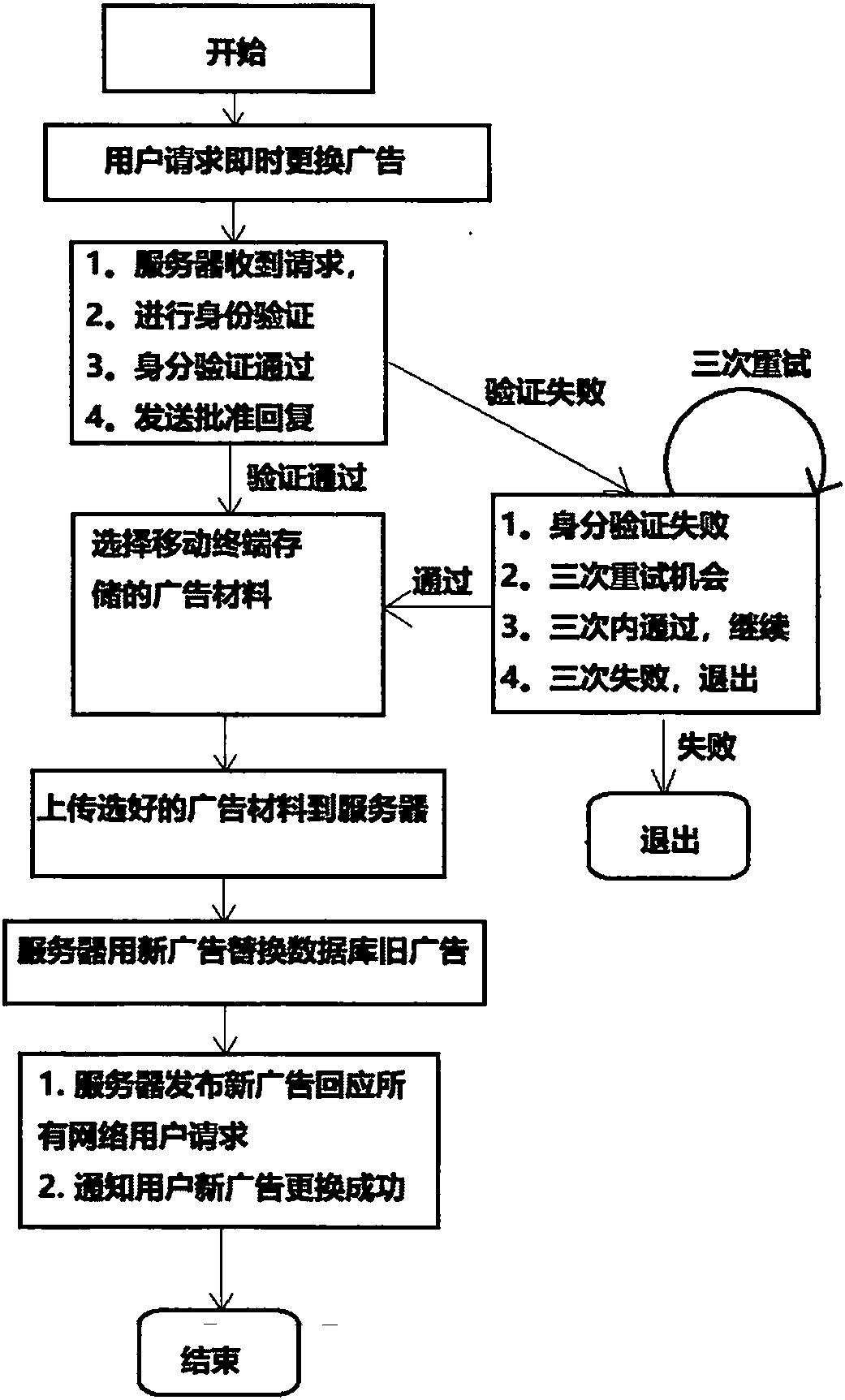

Method for dynamic replacement of label advertisements on network map business icon interface

InactiveCN107993093A9Good business effectEasy to browseGeographical information databasesMarketingWeb Map ServiceNetwork service

Owner:王勇 +2

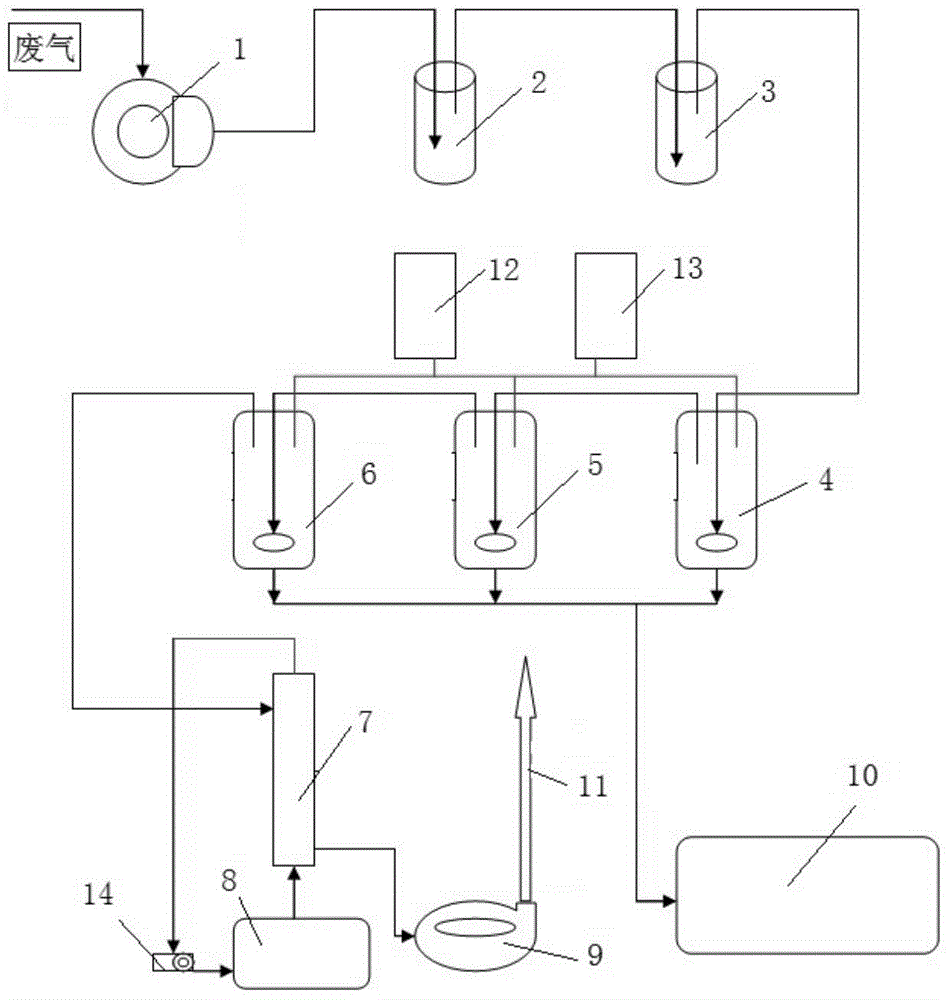

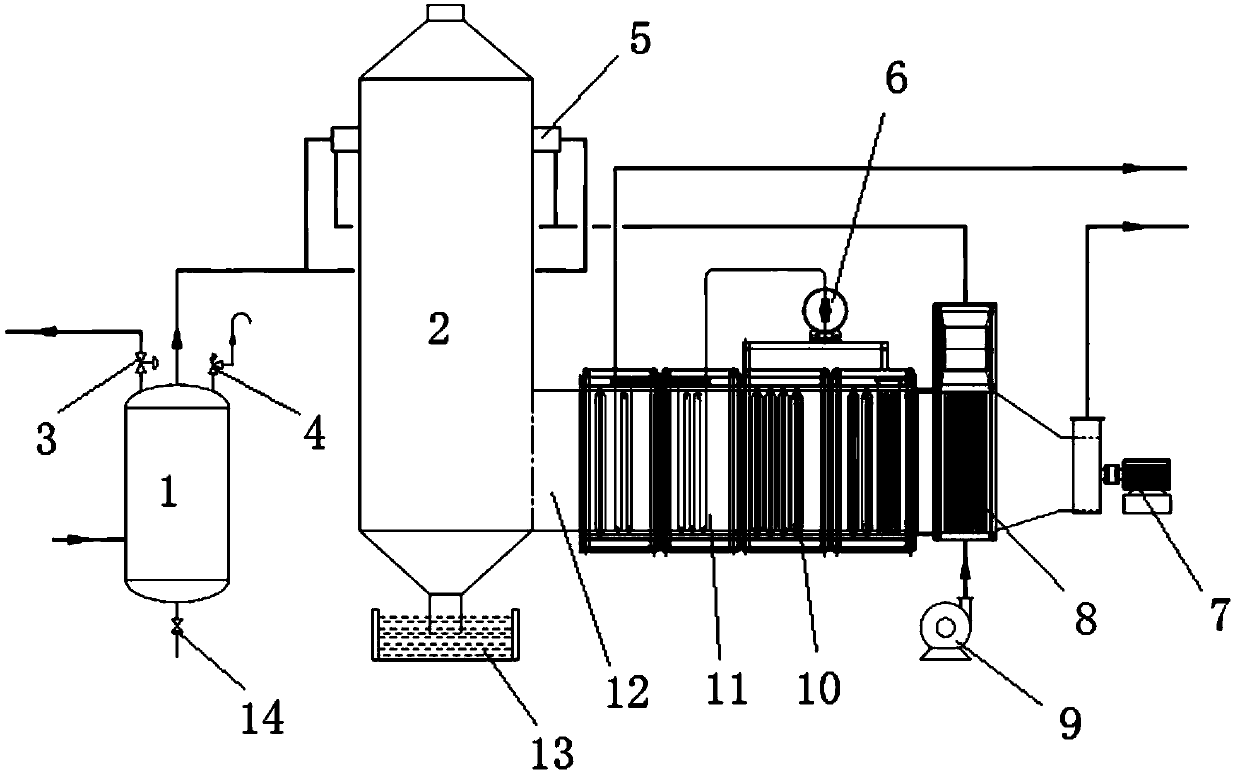

Waste gas treatment and methyl mercaptan recycling process in cimetidine and ranitidine production

InactiveCN104258704BAvoid emissionsCreate valueOrganic chemistryOrganic compound preparationBoiling pointEnvironmental engineering

The invention discloses a waste gas treatment and methyl mercaptan recycling process in cimetidine and ranitidine production. The waste gas treatment and methyl mercaptan recycling process comprises the following steps: (1) introducing waste gas in the production process of cimetidine and ranitidine into a washing tank, controlling pressure to 0.2-0.3MPa, removing volatile substances which are low in boiling point and easily soluble in water in the waste gas; (2) introducing the waste gas subjected to washing treatment into an alkaline washing tank, controlling pressure to 0.2-0.3MPa, removing volatile substances which are insoluble in water and soluble in alkaline by alkaline liquor in the alkaline washing tank; (3) introducing the waste gas subjected to the alkaline washing into a three-stage absorbing device, removing methyl mercaptan in the waste gas to generate sodium thiomethoxide; and (4) introducing the waste gas subjected to the three stages of absorption into a hydrogen peroxide falling film absorbing tower for performing oxidation treatment, and then discharging. According to the waste gas treatment and methyl mercaptan recycling process, useful chemical raw materials in the waste gas are recycled on the basis of solving the problem of waste gas emission, and thus the waste gas is prevented from being discharged, the economic benefit is increased, a new value is created, and the recycling economy is realized. The waste gas treatment and methyl mercaptan recycling process is good in application prospect.

Owner:SHANDONG WEIZHEN TEST & ANALYSIS

Domestic waste incineration recycling process

ActiveCN105945028BSave on landfill costsAvoid secondary pollutionSolid waste disposalThermal energyTunnel kiln

The invention discloses a technology for incineration and recycling of domestic garbage. Process steps: (1) Garbage crushing and fermentation, leachate treatment, standard reclaimed water to make billets, sludge drying and incineration, biogas combustion; (2) Garbage incineration, the coke residue and fly ash after incineration are collected for use, and the generated thermal energy is used for power generation (3) The high-temperature flue gas from the waste heat boiler is used for green body drying; (4) Coke slag and fly ash are mixed with shale soil, coal gangue, and polluted soil from the original domestic waste landfill, ground and refined, and made into green bodies. Sent into the tunnel kiln for firing at 850-1100°C for 25-28 hours. The fly ash and coke residue in the bricks contain heavy metals and dioxins. The continuous high temperature can completely decompose the dioxins and solidify the heavy metal elements in the bricks. , forming stable salt minerals. Advantages: Dioxins are completely decomposed, heavy metal elements are solidified in bricks, and stable salt minerals are generated for harmless reuse, saving landfill costs, turning waste into treasure, creating value, and avoiding secondary pollution.

Owner:于继林

Potassium borohydride-ammonium chloride reduction recovery method for platinum in laboratory waste precious metal materials

ActiveCN111455184BAvoid wastingAvoid lostProcess efficiency improvementPotassium borohydrideAmmonium chloroplatinate

The invention discloses a potassium borohydride-ammonium chloride reduction recovery method for platinum in laboratory waste precious metal materials. Using laboratory platinum-containing waste consumables as raw materials, a potassium borohydride reduction-ammonium chloride precipitation method is established to recover platinum. Methods. Nitric acid is used to separate impurity elements, aqua regia dissolves platinum, and hydrochloric acid is used repeatedly to drive away nitrogen oxides, so that platinum is fully converted into chloroplatinic acid. At 40°C, 5% ( V / V ) in hydrochloric acid medium with potassium borohydride to reduce chloroplatinic acid to platinum black, then dissolve platinum black with aqua regia and completely convert it into chloroplatinic acid, and form yellow ammonium chloroplatinate precipitate with excess ammonium chloride, aging overnight. Select the step-by-step slow heating method to dry and decompose ammonium chloroplatinate, so as to obtain pure loose platinum powder or dense metallic platinum. The method is low in cost and easy to operate, and the residual platinum ions in the two precipitation solutions are all less than 20 ug / mL. The purity of recovered platinum is not less than 99.5%, and the recovery rate is greater than 99%.

Owner:河南省岩石矿物测试中心

A multi-metal full-path full-valence separation method

ActiveCN105695744BInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementElectrolysisFull Rate

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

A system and method for recycling low-pressure exhaust gas of chemical industry

ActiveCN107477603BPlay the role of collection bufferIncrease concentrationCombustion technology mitigationIncinerator apparatusExhaust valveCombustor

Owner:YANKUANG GRP CO LTD

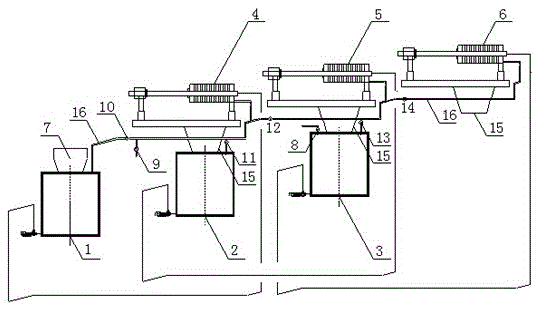

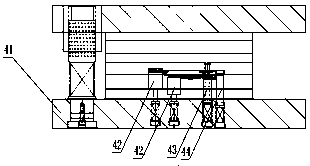

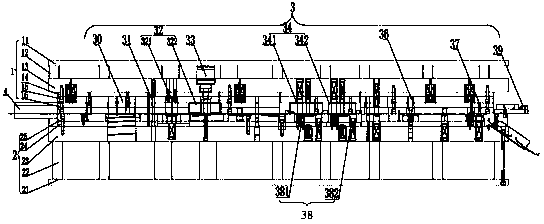

Continuous stamping die for end cover bottom plate of automobile heater motor

ActiveCN106493224BReduce waste of resourcesSave resourcesShaping toolsMetal-working feeding devicesMechanical engineeringSizing

The invention relates to a stamping die, in particular to a continuous stamping die for a bottom plate of an automobile heating motor end cover. The continuous stamping die comprises an upper die part, a lower die part and an air cylinder forming part, wherein the air cylinder forming part comprises a tearing terrace die, a forming terrace die, a spring, a flanging-sizing terrace die, a piercing die, a plunging die and a blanking die, which are sequentially arranged on the upper die part, as well as a flanging-sizing cavity die which is arranged on the lower die part. Compared with the prior art, the continuous stamping die has the advantages that the die structure and the process are improved, so that a plurality of pairs of conventional single dies are integrated onto one pair of dies, and therefore, production efficiency and product quality are greatly improved; and dual floating blocks are adopted to guide and feed, so that too heavy products carried unilaterally are fed smoothly inside the die.

Owner:镇江先锋汽车零部件有限公司

Michelia alba silkworm pupa facial mask and preparation method thereof

InactiveCN108324663AImprove qualityCreate valueCosmetic preparationsToilet preparationsHydrolysateMichelia

The invention provides a michelia alba silkworm pupa facial mask. The michelia alba silkworm pupa facial mask is prepared from silkworm pupa protein powder, duck feather hydrolysate, michelia alba drypowder, hyaluronic acid, valeriana officinalis powder and xylitol. silkworm pupa and michelia alba dregs are processed respectively, and silkworm pupa protein powder and michelia alba dry powder areobtained, and the obtained michelia alba silkworm pupa facial mask has the original fragrance of michelia alba, and has the effects of refining pores, tightening skin, moisturizing and retaining moisture and removing freckles and scars.

Owner:杨巧

A method for extracting high-purity heparan sulfate from heparin production waste

The method discloses a method for extracting high-purity heparan sulfate from heparan production wastes, and aims at providing a method used for extracting purified heparan sulfate taking the heparanproduction wastes as raw material. The method has the advantages of low cost, convenient operation and easy industrial scaling. The method is characterized by comprising the steps that 1), the heparanproduction wastes are prepared into a solution; 2), acid is added to adjust the pH to 1.9-2.3, ethanol is added, and stirring, centrifugation and standing are conducted; 3), supernatant liquid is collected, aqueous alkali is added to adjust pH to 6-8, and water is added; 4), absorbent is added to the solution is step 3), and stirring is conducted until all mucopolysaccharide in the solution is absorbed by the absorbent; 5), the absorbent is collected and washed with clean water, a sodium chloride solution is added to conduct elution, elution liquid is collected after the elution is completed,and precipitant is added for precipitation; 6), precipitations are collected and dried; the method belongs to the field of mucopolysaccharide pharmaceuticals.

Owner:深圳市格利科生物科技有限公司

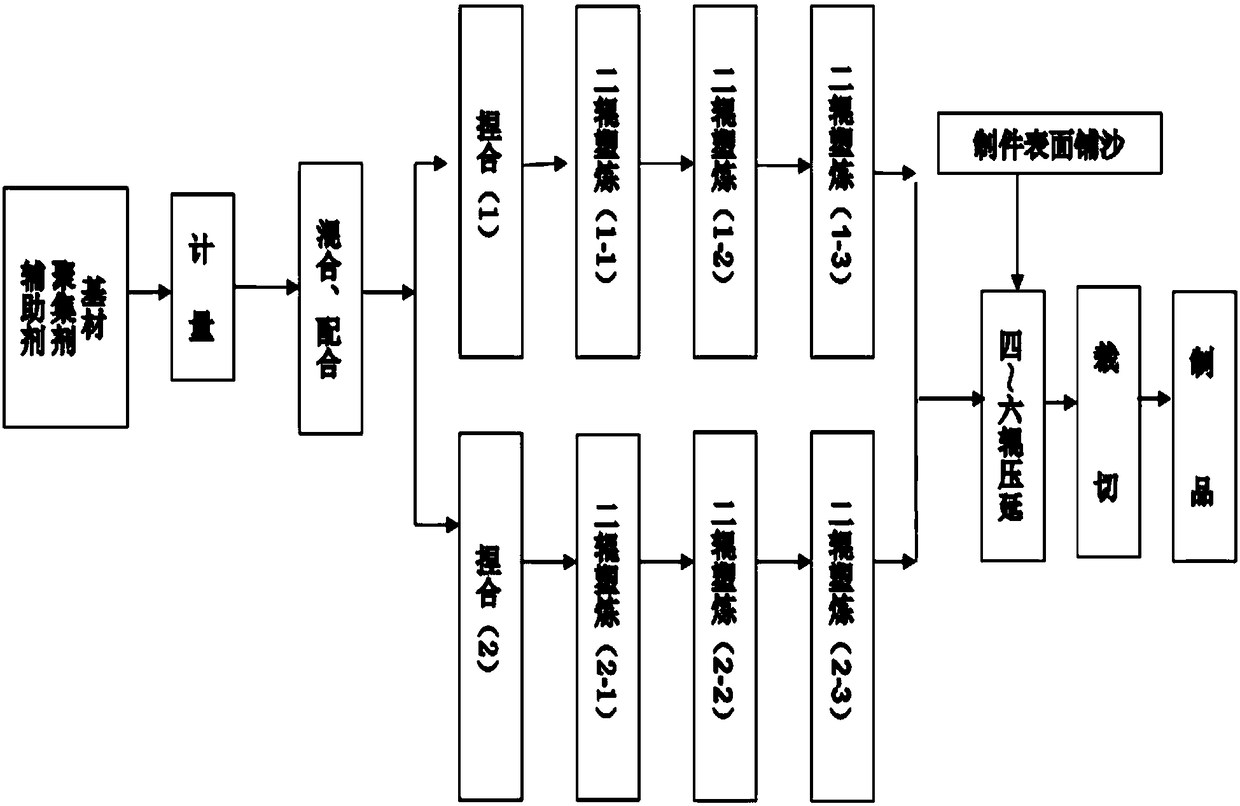

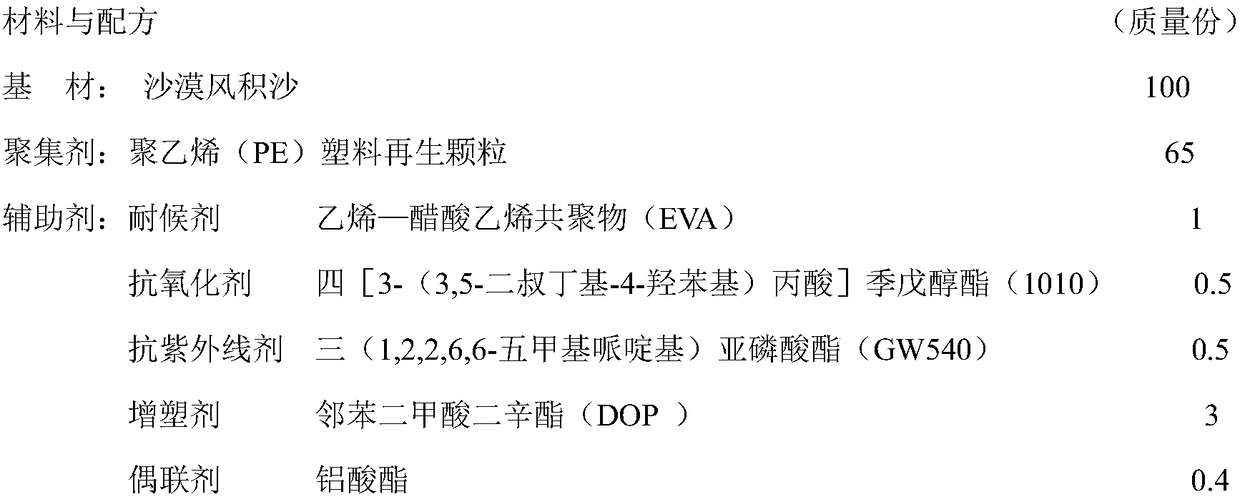

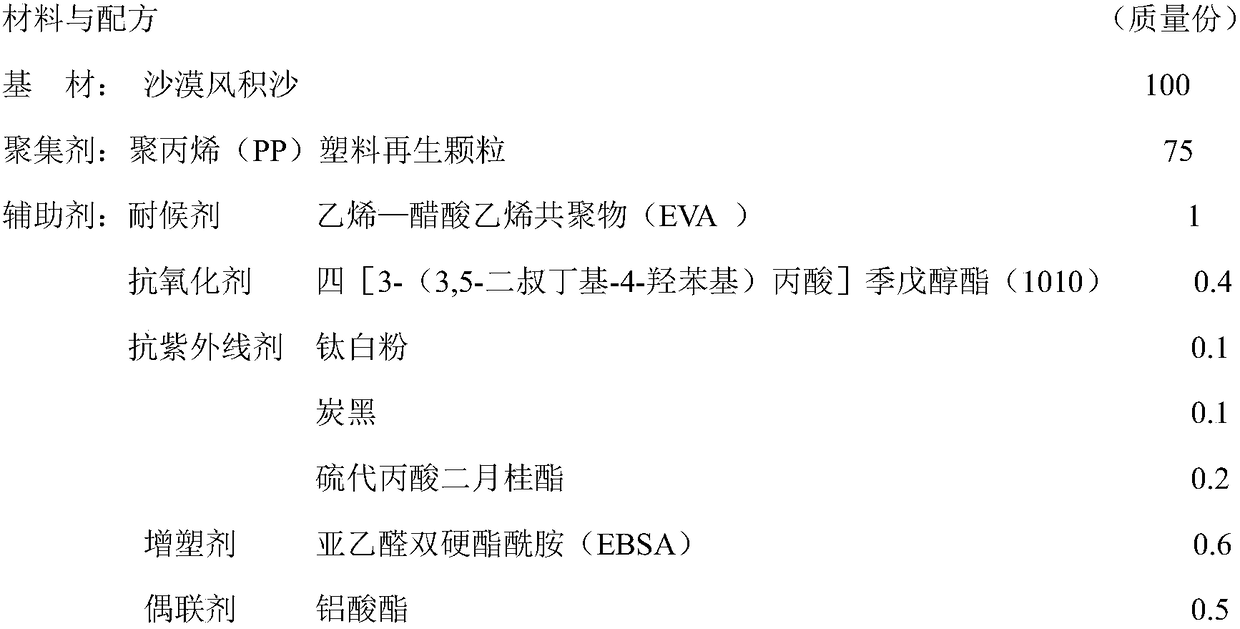

Aeolian sand aggregation and sand control cover product and preparation method thereof

PendingCN108277018ALarge reservesReduce governance costsProductsOther chemical processesVegetationErosion

The invention relates to an aeolian sand aggregation and sand control cover product and a preparation method thereof, wherein desert aeolian sand is used as a base material, and the desert aeolian sand, an aggregating agent and an auxiliary agent are subjected to mixing pressing to prepare the aeolian sand aggregation and sand control cover product. According to the present invention, the aeoliansand aggregation and sand control cover product is prepared by matching and mixing the aeolian sand, the aggregating agent recycled plastic and the auxiliary agent according to a certain ratio, wherein the aeolian sand aggregation and sand control cover product can provide the significant effects in sand surface covering, wind erosion inhibiting, shifting sand control and evaporation preventing; the production does not consume water, and the used raw materials are useless, abandoned and recycled materials in the economic society, and have characteristics of wide and abundant source, worthlessness and low price; the industrial manufacturing is convenient, fast and low-energy-consuming; the aeolian sand aggregation and sand control cover product is easily subjected to mechanized laying; during the use, environmental pollution is not generated, the promoting of the desert vegetation restoration and other comprehensive advantages can be easily achieved, the sand control difficulty and thesand control cost can be reduced, and the hazard caused by sandstorm can be reversed as soon as possible; and the desert resource environment can be completely utilized, and the large-scale, good-effect, high-speed and sustainable sand control with the minimum investment can be achieved.

Owner:银川市瑞沙沙业研究所

Efficient oil and gas mixture recycling process

InactiveCN109772119AReduce pollutionCreate valueDispersed particle separationFuel feedersRecovery methodCombustor

The invention discloses an efficient oil and gas mixture recycling process. The recycling process is carried out according to the following steps: (1) first, a soot mixture generated in an electricalcarbon carbonization process is introduced into a condenser for condensation separation, and heavy oil in the soot mixture falls into a collection tank to be used as a chemical raw material after coagulation; (2) then, the sootmixture from which most of the heavy oil is removed is introduced into a burner to be mixed with natural gas, then the mixture is burned in a furnace, and the heat obtainedduring combustion is introduced into other equipment for use; and (3) the soot mixture produced during combustion in step (2) is introduced below the liquid surface of an alkaline aqueous solution through a pipeline for purification, and the purified gas is discharged into the atmosphere. The recycling process turns waste into treasure, and recycles used soot to produce chemical raw materials andheat while reducing environmental pollution, thereby creating value, saving energy and protecting the environment.

Owner:原东

Jasmine flower and silkworm chrysalis facial mask and preparation method thereof

InactiveCN108524410AImprove qualityCreate valueCosmetic preparationsToilet preparationsHyaluronic acidGaultheria

A jasmine flower and silkworm chrysalis facial mask comprises silkworm chrysalis protein powder, dry powder of jasmine flower, hyaluronic acid, Gaultheria cumingiana powder and xylitol. Broken silkworm chrysalis and jasmine flower are processed into silkworm chrysalis protein powder and dry powder of jasmine flower. The jasmine flower and silkworm chrysalis facial mask has fragrance of natural jasmine flower and can contract pores, compact skin, hold moisture and remove freckle and mark.

Owner:杨巧

Method for recycling lampblack mixture produced in electrical carbon carbonization process

InactiveCN109692559AReduce pollutionCreate valueGas treatmentDispersed particle separationRecovery methodCombustor

The invention discloses a method for recycling a lampblack mixture produced in the electrical carbon carbonization process, and the method comprises the following steps: (1) firstly introducing the lampblack mixture produced in the electrical carbon carbonization process into a condenser to carry out condensation and separation; and allowing a heavy oil component in the lampblack mixture to fall into a collecting tank to serve as a chemical material after being condensed; (2) introducing the smoke mixture in which a large part of the heavy oil component is removed into a burner to mix with natural gas to burn in a hearth; and introducing heat obtained from the burning into other equipment to use; and (3) introducing the smoke mixture generated from the burning in the step 2 below the liquid level of an alkaline aqueous solution through a pipeline to carry out purification treatment, and discharging a purified gas into atmosphere. By adopting the method disclosed by the invention, wastecan be changed into a precious resource; the waste lampblack is recycled, a chemical material and heat are produced while the environmental pollution is reduced; the value is created; an energy source is saved; and the environment is protected.

Owner:贾琳

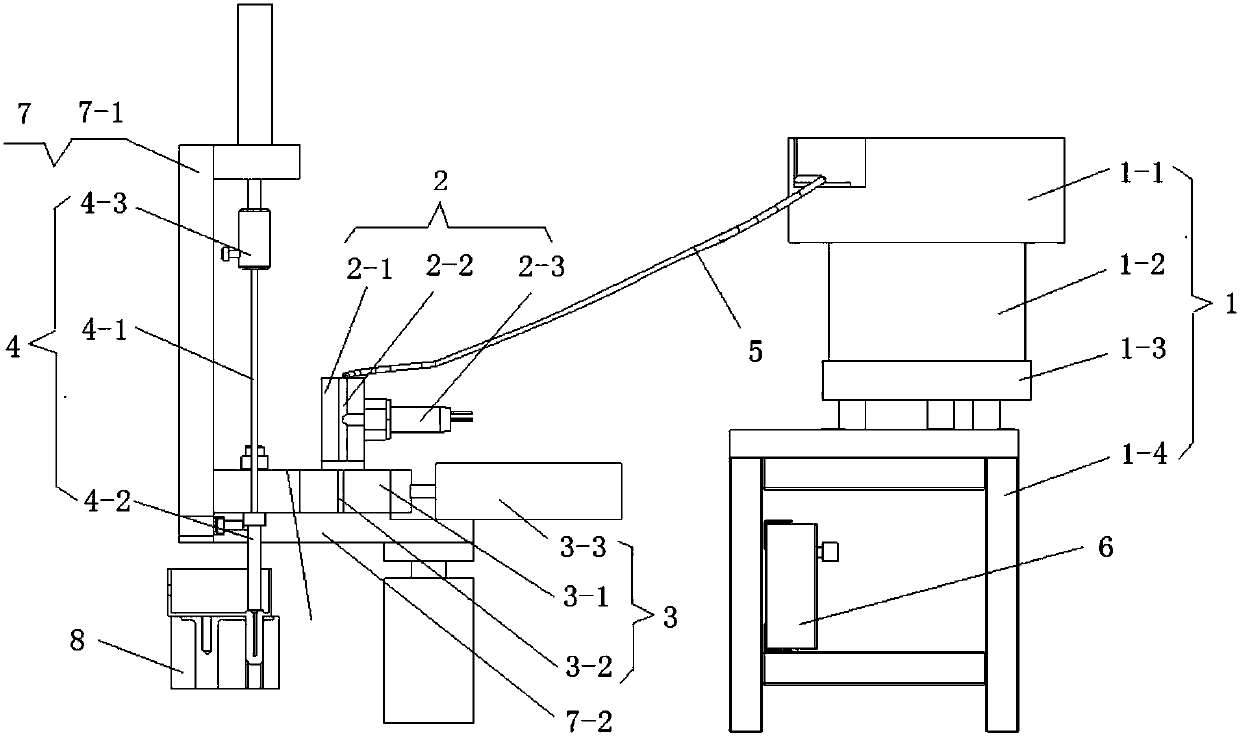

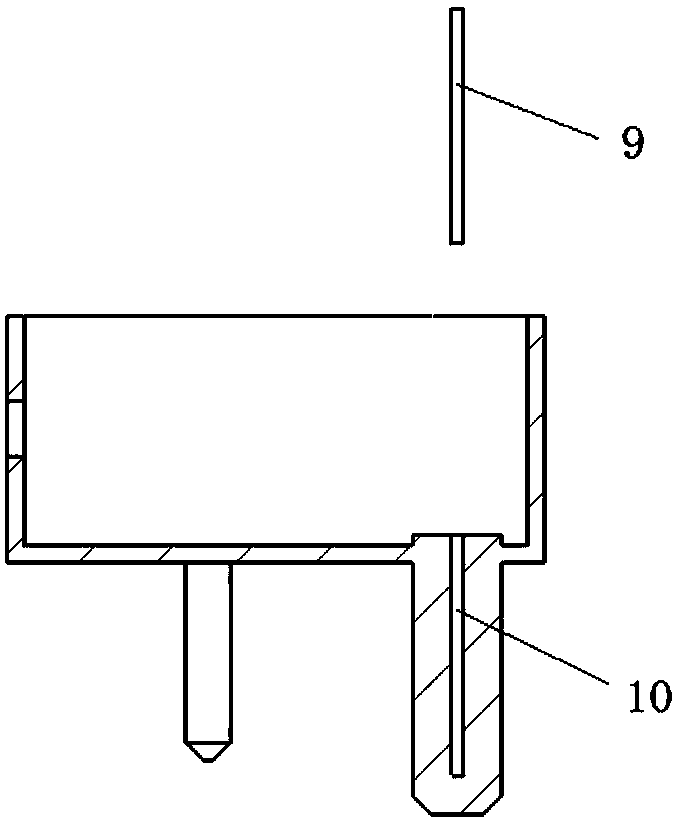

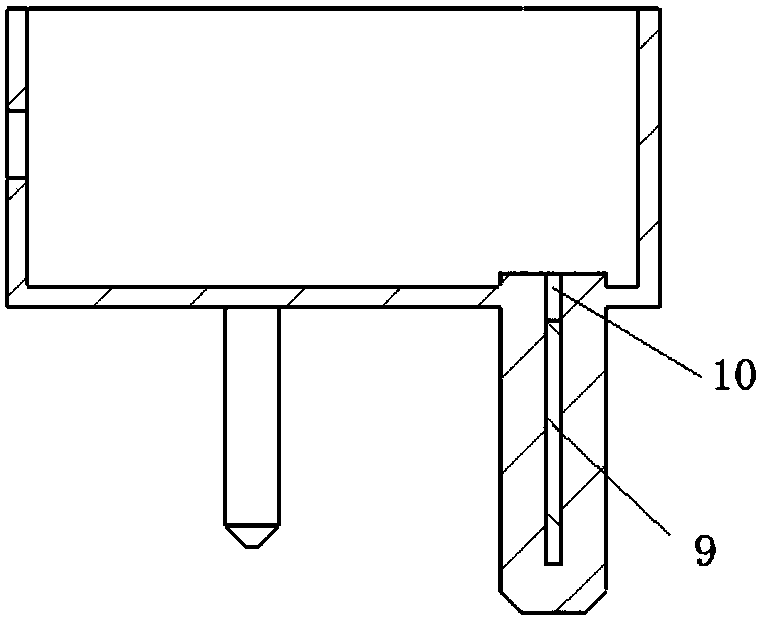

An automatic needle pressing machine for assembling the grounding pole core needle of a triangular plug

The invention discloses an automatic needle pressing machine used for triangle plug grounding electrode core needle assembling. The machine comprises a needle sending mechanism, a needle falling mechanism, a needle pushing mechanism, a needle pressing mechanism, a needle sending guide rail and a central controller. The needle sending mechanism and the needle falling mechanism are connected through the needle sending guide rail. The needle pushing mechanism moves back and forth on a working position of the needle falling mechanism and a working position of the needle pressing mechanism. The central controller is connected to the needle sending mechanism, the needle falling mechanism, the needle pushing mechanism and the needle pressing mechanism in a signal connection mode. In the invention, a ''fission manufacturing + pressure assembling'' design scheme is adopted; a harbor-type triangle plug is formed through injection molding separately; a core needle assembling hole is reserved on a grounding electrode; and a core needle separately adopts a wire rod and is formed through direct clipping. During assembling, the triangle plug is fixed; through applying certain pressure to the core needle, a grounding electrode assembling hole is aligned and is vertically pressed into the assembling hole; an assembling technology is simple and assembling is reliable; manual secondary tail cutting, glue sealing and other operations are not needed and a next step of automation operation can be directly entered into.

Owner:FOSHAN POLYTECHNIC

A process and device for multi-stage countercurrent continuous rinsing and dechlorination of zinc oxide fumes

ActiveCN105483362BRealize reverse flowEnsure balanceProcess efficiency improvementHydrometallurgySoot

Owner:江西自立环保科技有限公司

Method for separating and purifying heparin sodium and heparan sulfate from heparin byproducts

ActiveCN102911290BHigh purityEfficient removalOrganic active ingredientsBlood disorderMaterial resourcesIon-exchange resin

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com