A process and device for multi-stage countercurrent continuous rinsing and dechlorination of zinc oxide fumes

A zinc oxide, smoke and dust technology, applied in the field of hydrometallurgy, to achieve the effect of short process flow, elimination of hazards, and improvement of use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

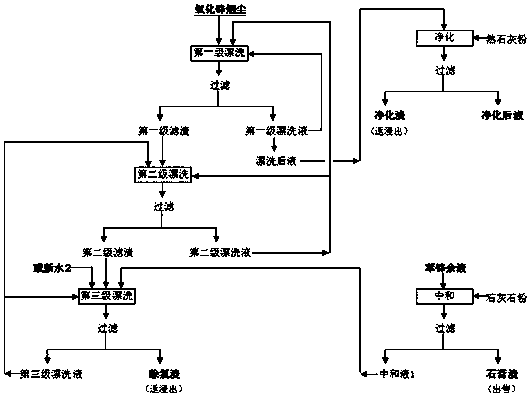

Method used

Image

Examples

Embodiment 1

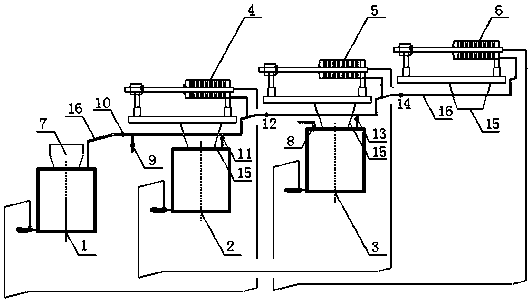

[0041] 1. Multi-stage countercurrent continuous rinsing and dechlorination device for zinc oxide smoke and dust:

[0042] It includes three rinsing tanks arranged side by side, three filter presses and connecting pipes arranged in dislocation above them; the bottom and one side of the three rinsing tanks are respectively equipped with a slurry outlet, and the top is respectively equipped with a material inlet and a filtrate inlet. Each filter press is equipped with a slurry inlet, a filtrate outlet, and a slag outlet; the three rinsing tanks are the first-stage agitated rinsing tank 1, the second-stage agitated rinsing tank 2, and the third-stage agitated rinsing tank 3. The filter is the first-stage filter press 4, the second-stage filter press 5 and the third-stage filter press 6; filtrate control valves are installed at the filtrate inlets of the three rinsing tanks and the filtrate outlets of the three filter presses. valve. The filtrate control valves include a second fi...

Embodiment 2

[0072] Embodiment 2: The three-stage countercurrent continuous rinsing dechlorination device of zinc oxide smoke dust and the dechlorination process are the same as in Example 1, according tofigure 1 The process shown is carried out.

[0073] The chemical composition of a typical ZnO fume is shown in Table 1. The rinse solution is fresh water.

[0074] 1. Rinse

[0075] According to the zinc oxide dust shown in Table 1, three-stage countercurrent process equipment was used to continuously rinse the water-soluble chloride. Rinse pool 30m 3 , filter press 80m 2 , 3 units each, and the rinse solution is new water.

[0076] 10m of rinsing solution of this level is returned to the first level rinsing pool 3 , and then return to the second stage rinse solution 10m 3 . Add 5t of zinc oxide dust in Table 1, mechanically stir at room temperature, 60 rpm; filter and separate the pulp with a filter press, and discharge 7.5m from the filtrate 3 The rinsing liquid is stored as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com