Multistage countercurrent rinsing device and method of zinc oxide smoke rich in chlorine and fluorine

A technology of countercurrent rinsing and zinc oxide, which is applied in the field of rinsing devices for removing chlorine and fluorine in zinc oxide fumes and multi-stage countercurrent rinsing devices for zinc oxide fumes rich in chlorine and fluorine, which can solve the problems of high equipment investment and operating costs, zinc oxide fumes Poor adaptability, high energy consumption and other problems, to achieve the effect of small footprint, balanced volume and stable chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

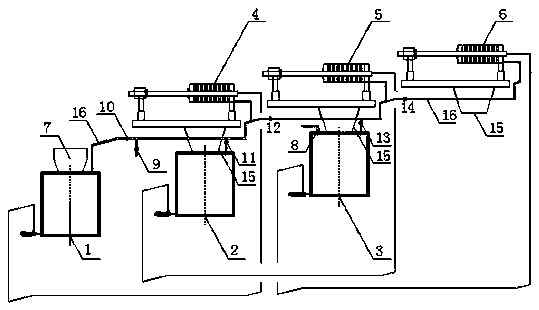

[0021] Example: see figure 1 .

[0022] One, three-stage countercurrent rinsing device,

[0023] It includes three rinsing tanks arranged side by side, three filter presses and connecting pipes arranged in dislocation above them; the bottom and one side of the three rinsing tanks are respectively equipped with a slurry outlet, and the top is respectively equipped with a material inlet and a filtrate inlet. Each filter press is equipped with a slurry inlet, a filtrate outlet, and a slag outlet; the three rinsing tanks are the first-stage agitated rinsing tank 1, the second-stage agitated rinsing tank 2, and the third-stage agitated rinsing tank 3. The filter is the first-stage filter press 4, the second-stage filter press 5 and the third-stage filter press 6; filtrate control valves are installed at the filtrate inlets of the three rinsing tanks and the filtrate outlets of the three filter presses. valve. The filtrate control valves include a second filtrate control valve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com