Patents

Literature

148results about How to "Solve the removal problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

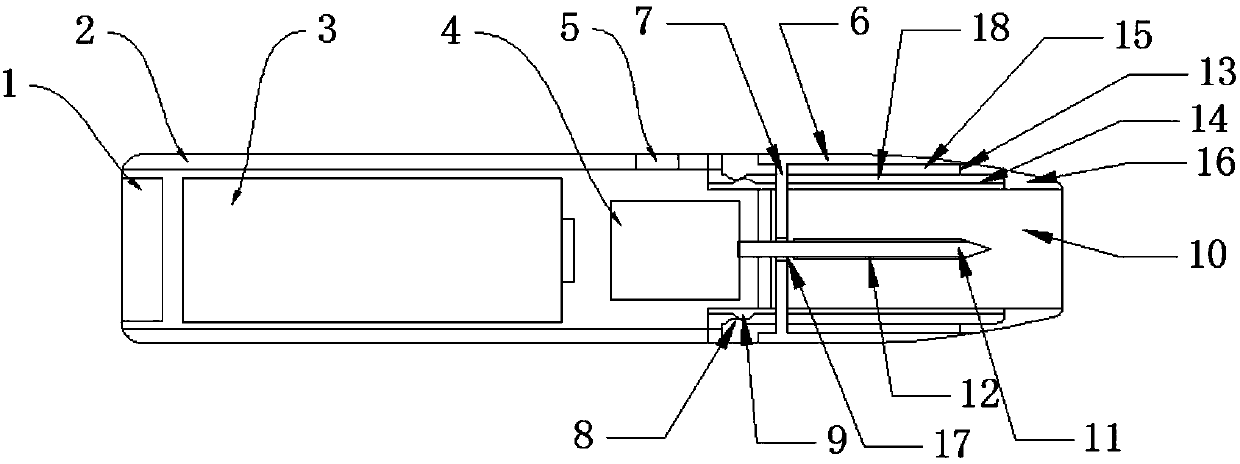

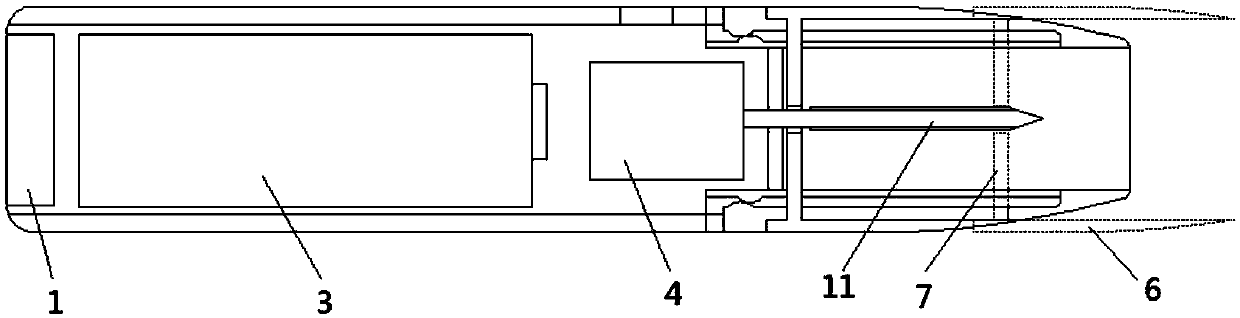

Electric heating device which facilitates taking out of cigarettes

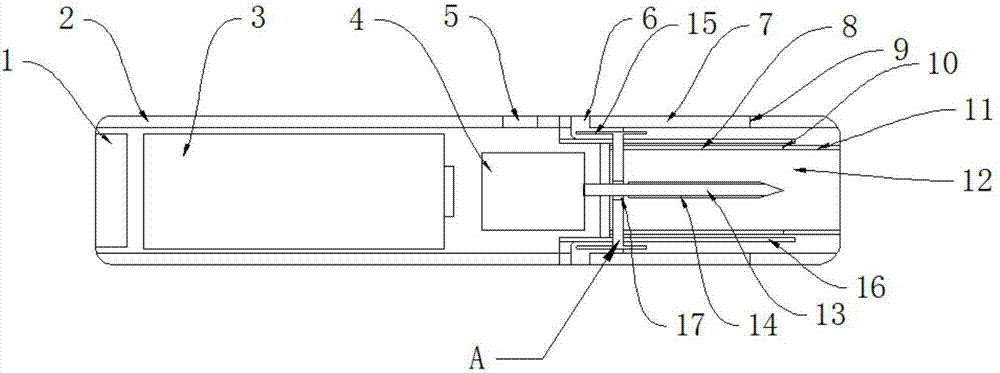

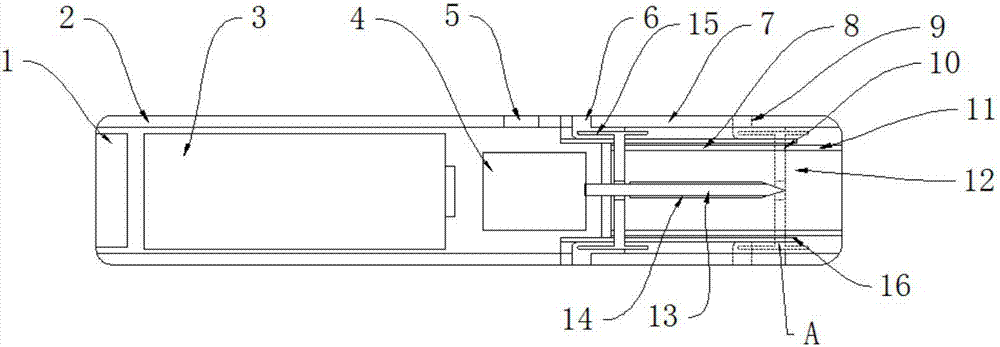

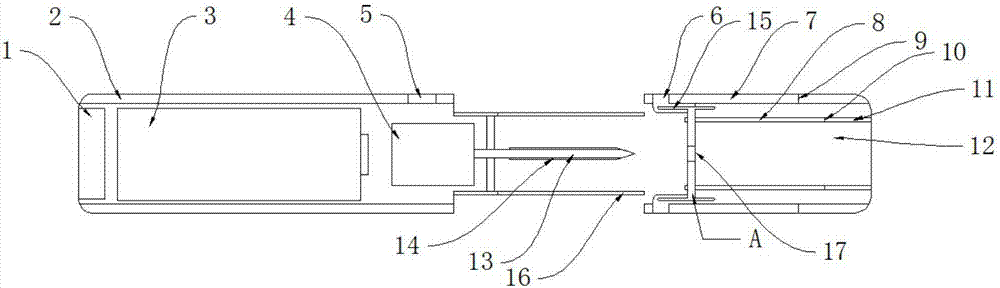

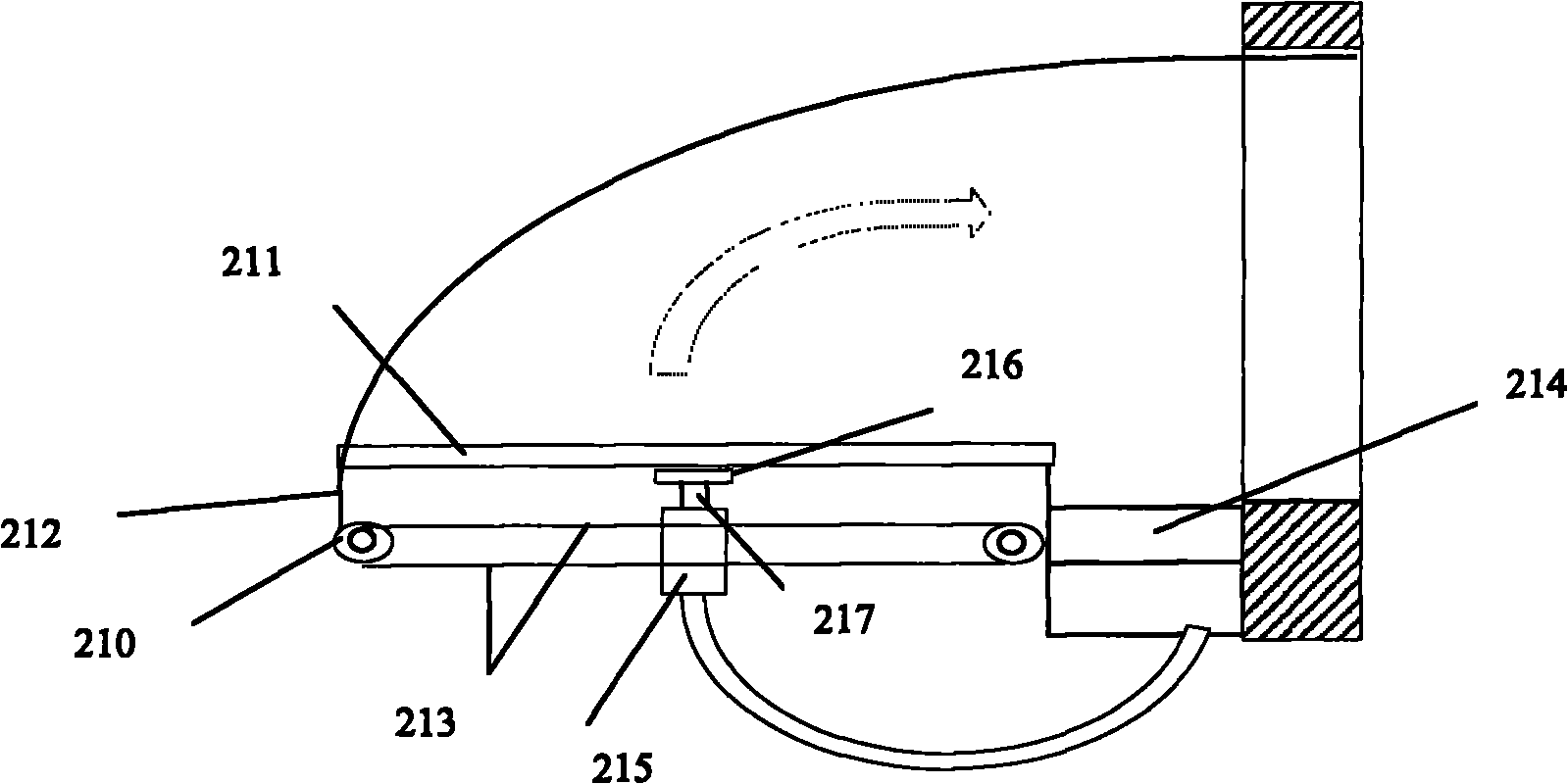

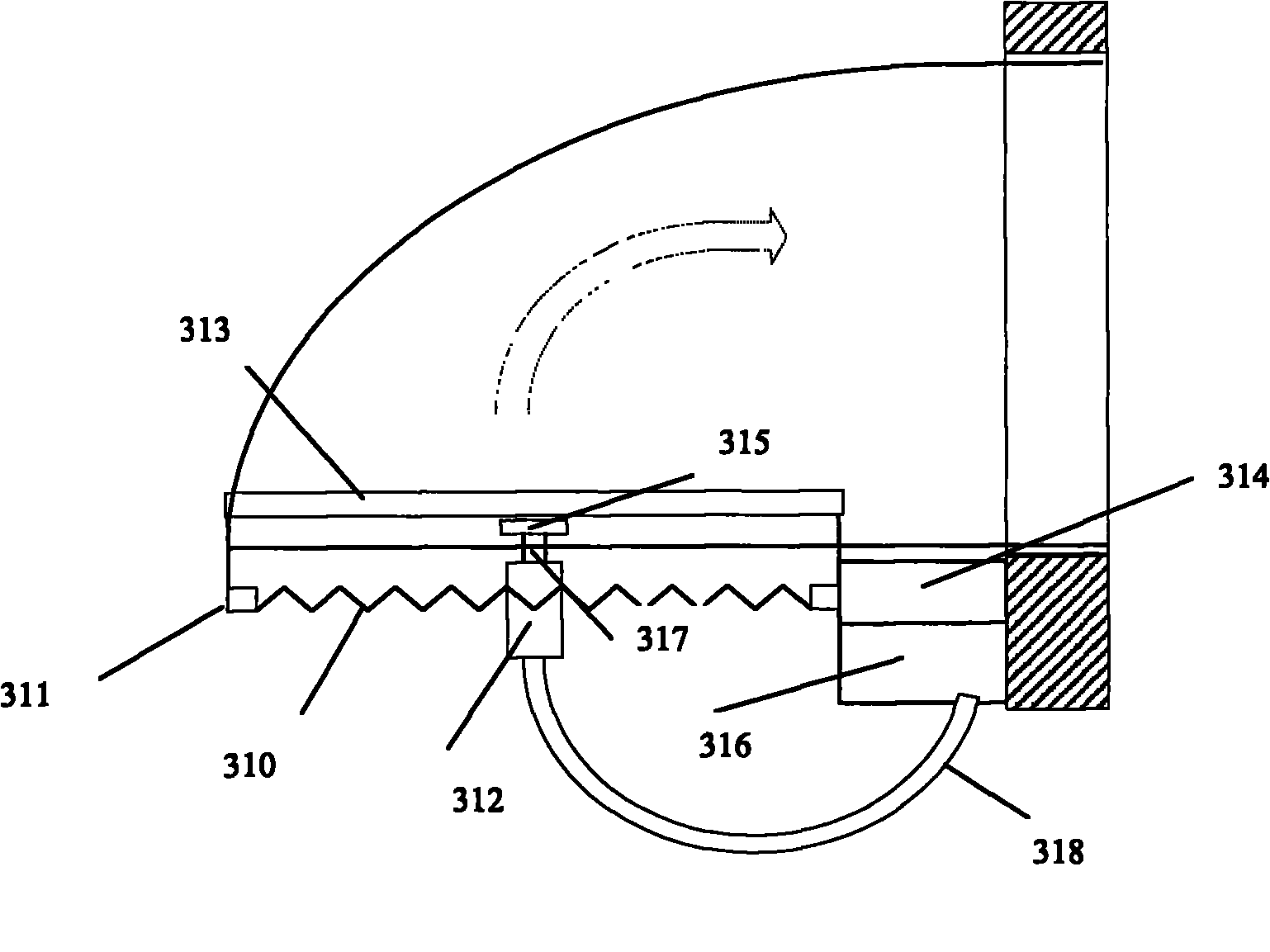

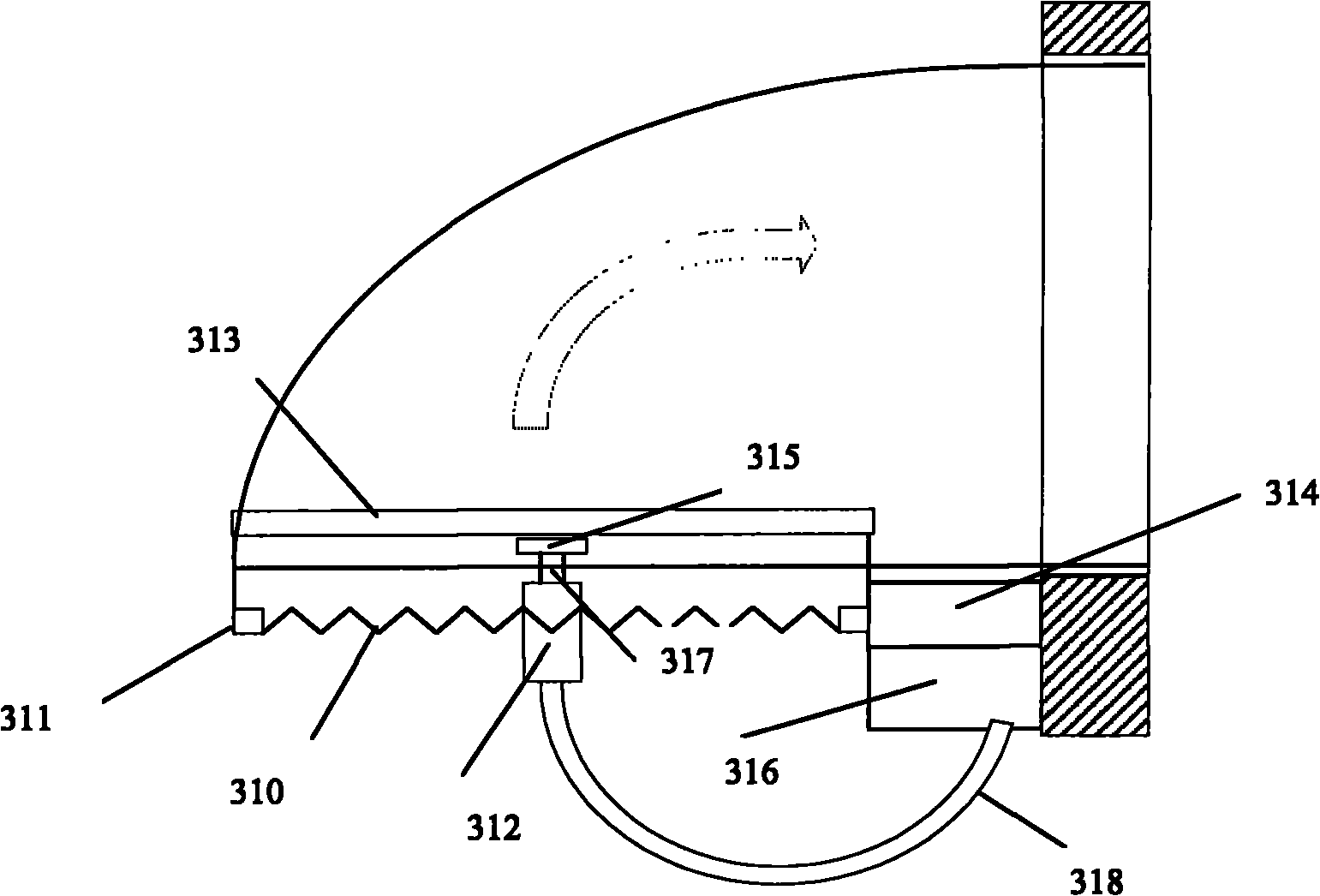

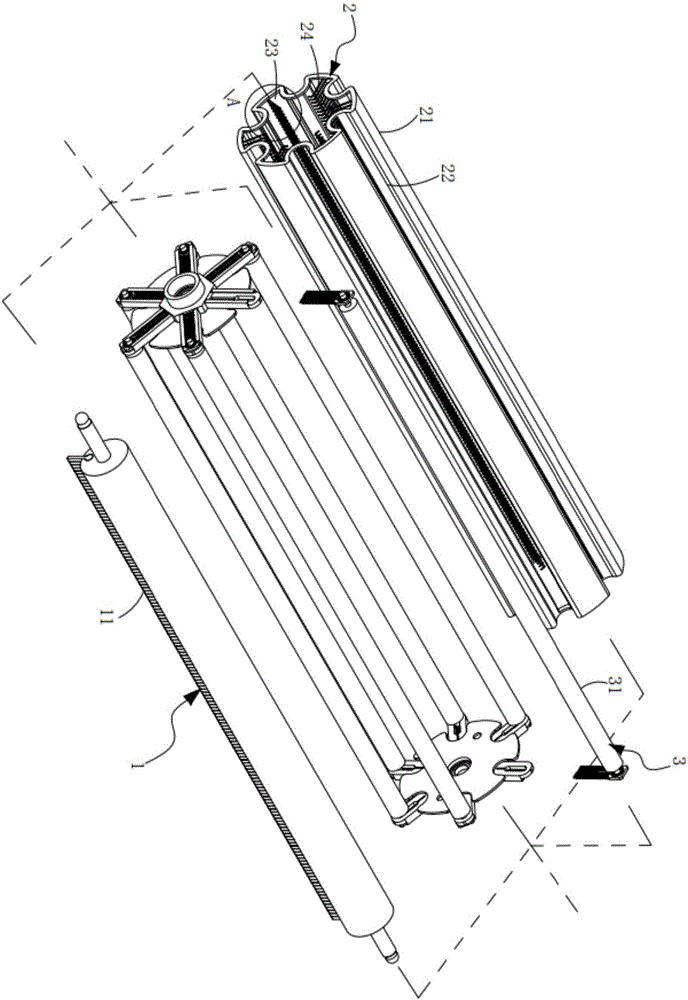

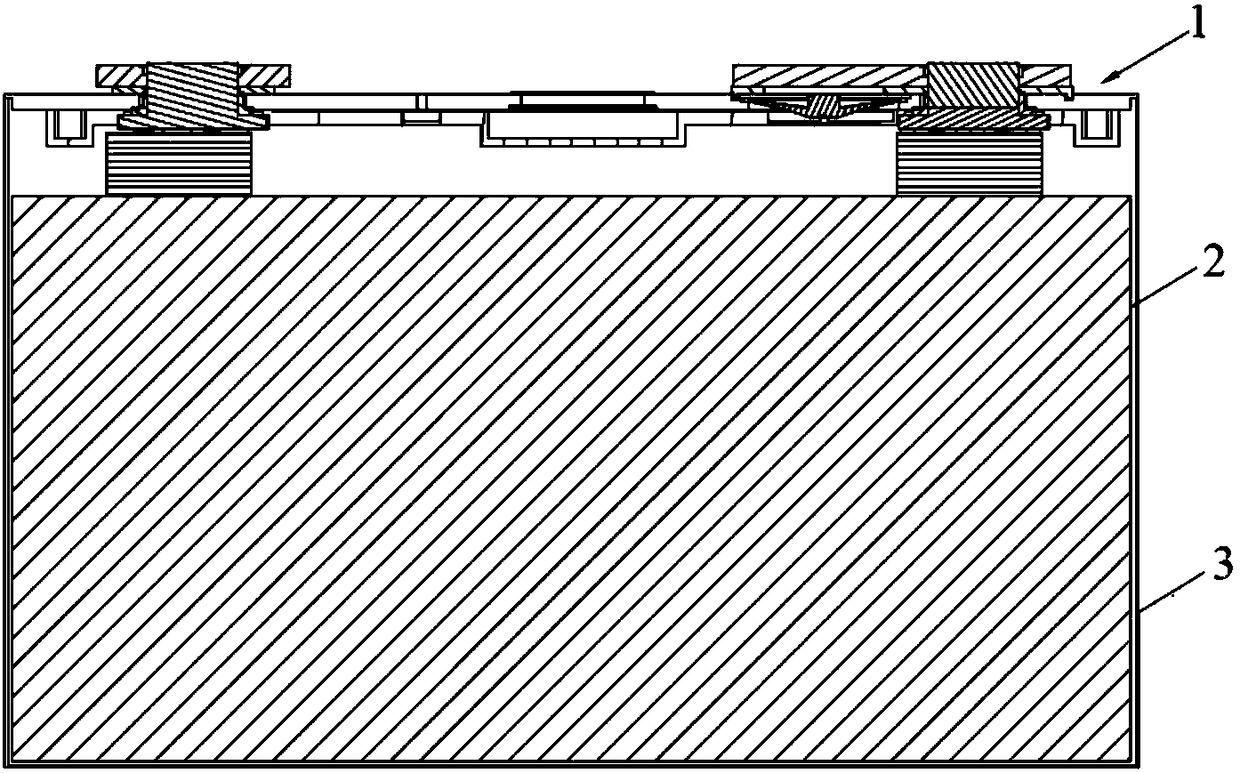

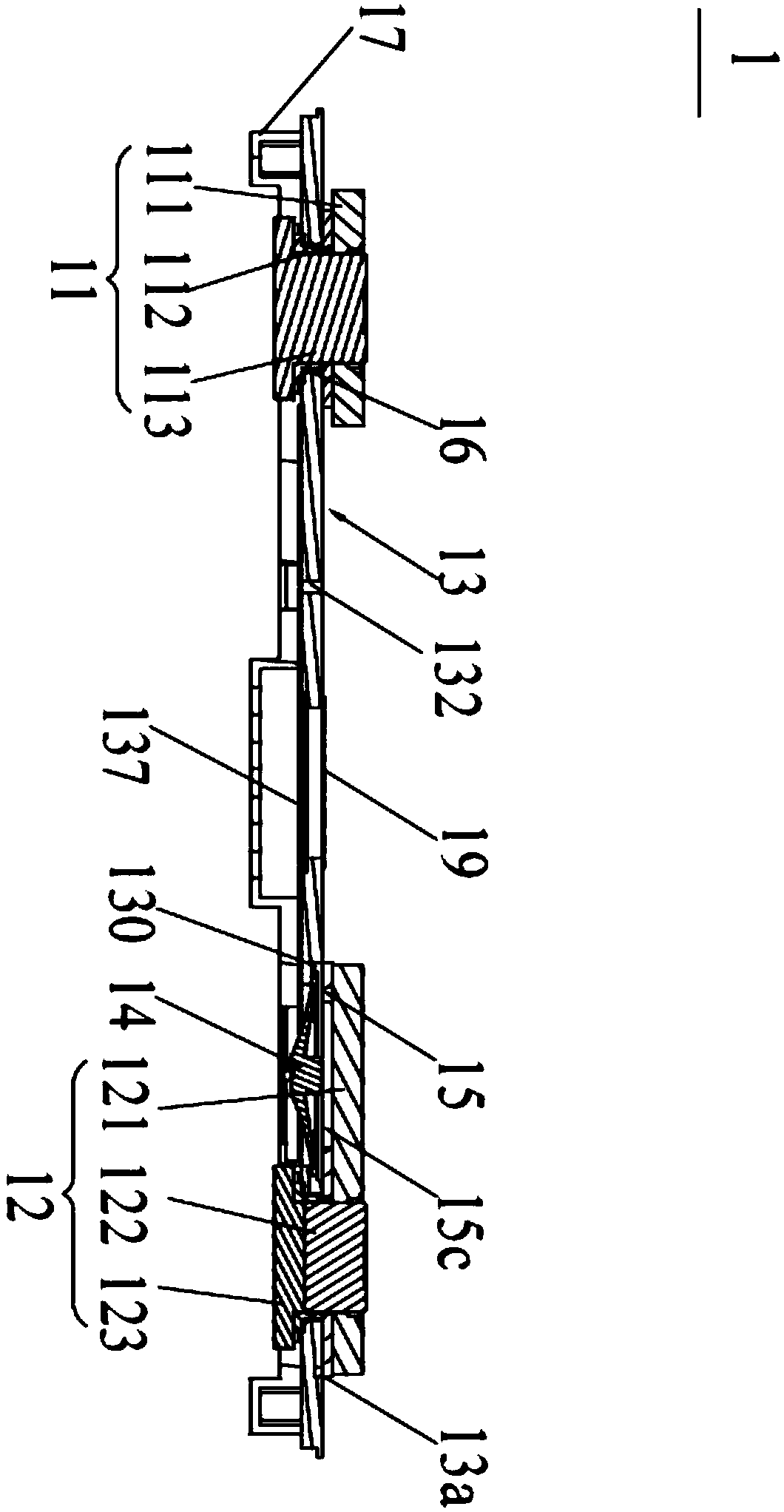

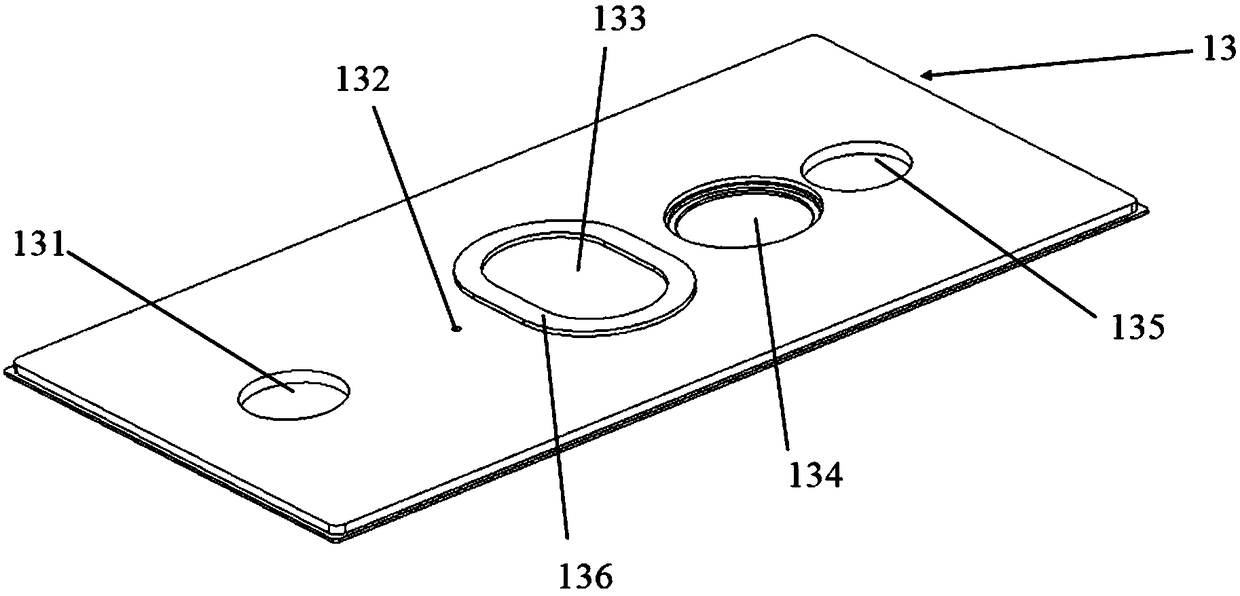

The invention provides an electric heating device which facilitates taking out of cigarettes. The electric heating device comprises a heating assembly and a cigarette taking-out assembly, wherein the heating assembly comprises a heating cavity and a heating element which is located in the heating cavity, the heating cavity is used for accommodating fuming products, the cigarette taking-out assembly comprises a sliding part and a push-and-pull part which is in linkage with the sliding part, and the sliding part can be driven by the push-and-pull part to move in the direction away from the heating element and in the axial direction of the heating cavity, so that the fuming products in the heating cavity can be moved out of the heating cavity. According to the electric heating device which facilitates taking out of the cigarettes, the sliding part is driven to move through the push-and-pull part, and the fuming products are driven to move out of the heating cavity through the movement of the sliding part. Compared with the prior art, the problem in taking out the tobacco after low-temperature tobacco products are inserted and consumed is solved, which makes it easy for residual tobacco in the heating cavity to be cleared.

Owner:HUBEI CHINA TOBACCO IND

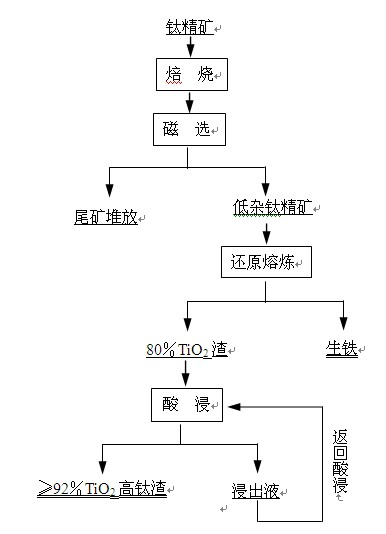

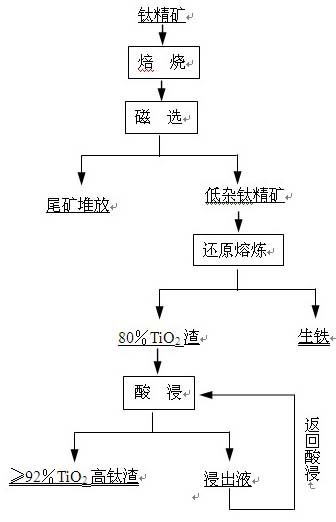

Method for preparing titanium-enriched material from high-impurity-content ilmenite concentrate

The invention discloses a method for preparing a titanium-enriched material from high-impurity-content ilmenite concentrate, which relates to the technical field of a preparation method of a titanium-enriched material. The technical route is as follows: raw ore, magnetic separation, iron concentrate, tailings, floatation, ilmenite concentrate, roasting, magnetic separation, reduction smelting, titanium slag, purification and titanium-enriched material. The invention integrates the advantages of an electric-furnace smelting method and an acid leaching method, and overcomes the defects of the two methods; and thus, the method provided by the invention can be used for treating high-impurity-content rock-type ilmenite concentrate, and can also be used for producing a high-quality titanium slag product.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

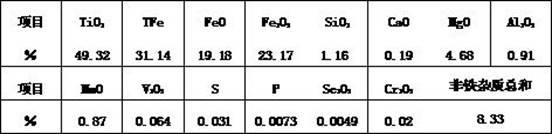

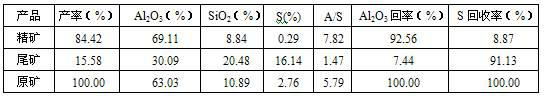

Method for dressing, desilicication and desulfuration of sulfur-containing bauxite

The invention discloses a method for the dressing, desilicication and desulfuration of sulfur-containing bauxite, which relates to a method for the dressing, desilicication and desulfuration of low-quality sulfur-containing bauxite and is characterized in that: a dressing process to mill the sulfur-containing bauxite, regulate the pH to 3 to 6 by using sulfuric acid, add an inhibitor, an activator, a silicate mineral collector and a sulfur-containing gangue collector in turn, stir, perform size mixing and perform flotation; and after flotation, the silicate minerals and sulfur-containing gangue in a major part of the sulfur-containing bauxite are enriched in foam as tailings, and the ore pulp obtained after flotation is used as concentrate. When the method disclosed by the invention is used, the synchronous dressing, desulfuration and desilicication of the sulfur-containing bauxite can be realized quickly. The method has the characteristics of short flow and simple process.

Owner:河南华慧有色工程设计有限公司 +1

Polishing liquid for grinding and polishing lithium niobate optical wafer

InactiveCN1858131AEasy to break awayIncrease viscosityOptical surface grinding machinesAqueous dispersionsLithiumLiquid viscosity

The present invention discloses polishing liquid for grinding and polishing optical lithium niobate wafer. The polishing liquid consists of silica sol 30-90 vol%, organic amine alkali 1-10 vol%, inorganic alkali 1-5 vol%, activator 0.5-5 vol%, chelating agent FA / O 0.5-5 vol%, and deionized water for the rest. Under CMP and high pH condition, lithium is formed into stable complex and water soluble niobate to raise polishing efficiency and surface quality. The present invention has organic alkali and lithium niobate surface matter to form soluble amine salt easy to separate from the reaction surface, and this avoids the increase in the abrasive granularity and polishing liquid viscosity to ensure no scoring, high flatness and no adsorbate.

Owner:HEBEI UNIV OF TECH

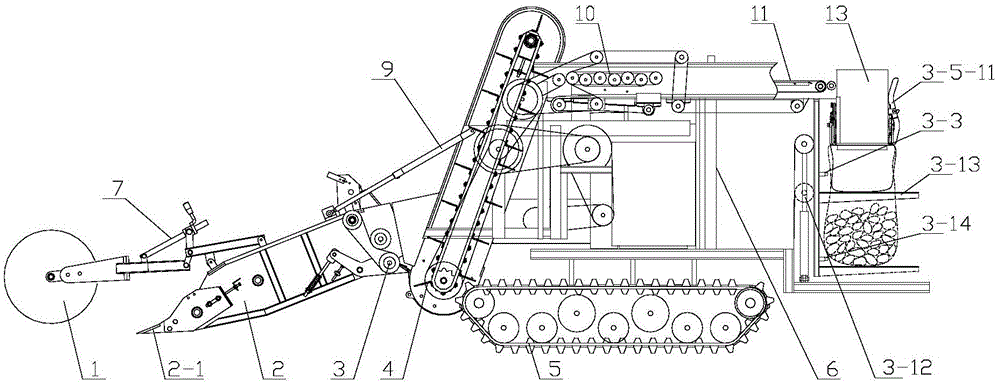

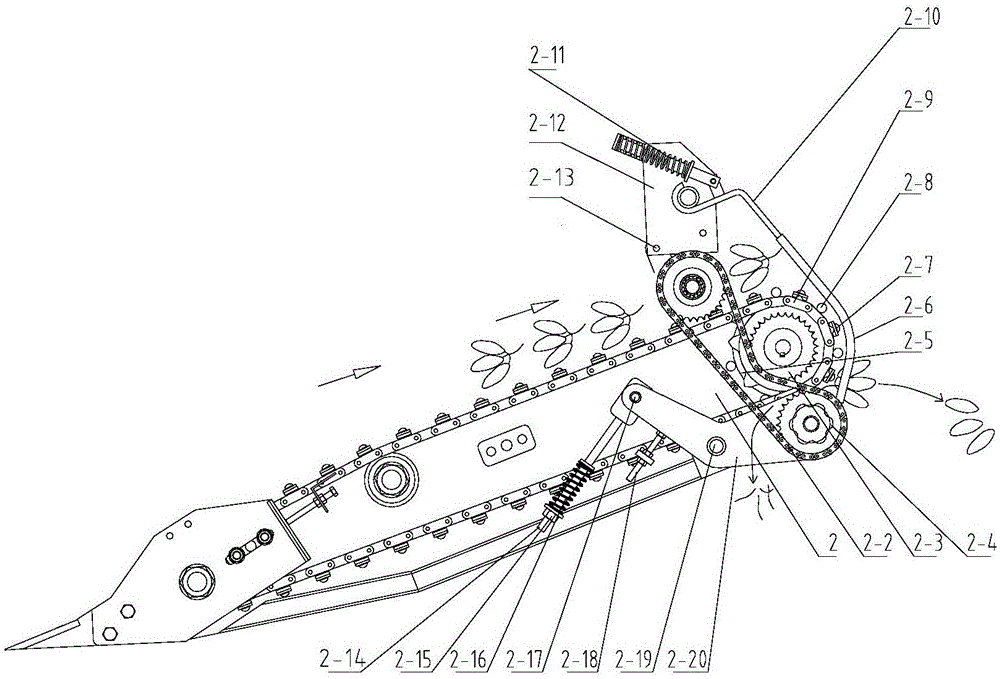

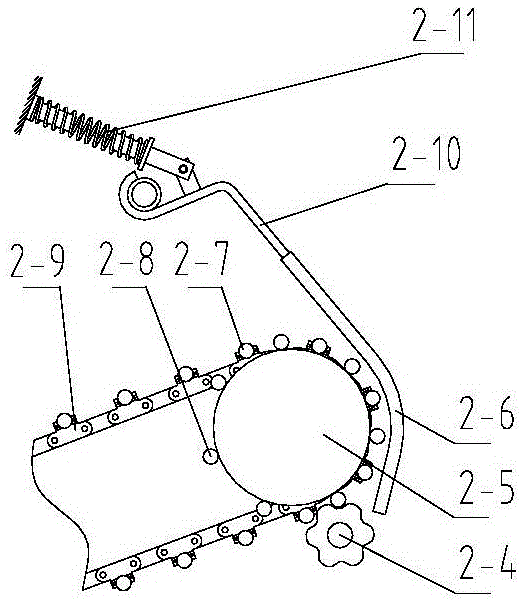

Multifunctional self-propelled potato combined harvester

ActiveCN105009775ALess chance of breaking freeIncrease frictional pullDiggersAgricultural engineeringStructural engineering

The invention discloses a multifunctional self-propelled potato combined harvester, and belongs to the technical field of agricultural harvesting machines. The lower part of the front side of the main frame of the combined harvester is provided with an excavating and conveying device, and the output end of the excavating and conveying device is connected with the lower part of a lift conveyer disposed at the front side of the main frame. The upper end of the lift conveyer is connected with the input end of a cleaning mechanism on the top surface of the main frame. The rear end of a sorting platform at the output end of the cleaning mechanism is connected with a blanking warehouse of a bagging mechanism. A conveying bar strip lift conveying chain is disposed around the excavating and conveying device, and the higher end of the conveying bar strip lift conveying chain is provided with a bar stripe jacking roller driven by a power device. An elastic bar strip mechanism is disposed above the bar stripe jacking roller, and extends out to form an elastic curved bar strip pressing the output end of the conveying bar strip lift conveying chain. A groove-type seedling-removing roller which is engaged with the bar stripe jacking roller through axial extension grooves distributed in the peripheral direction is disposed below the bar stripe jacking roller. The combined harvester is very low in probability that seedling stems escape from the combined harvester, enables the seedling stems to be just pulled off from potatoes, and remarkably improves the removal rate of seedling stems.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

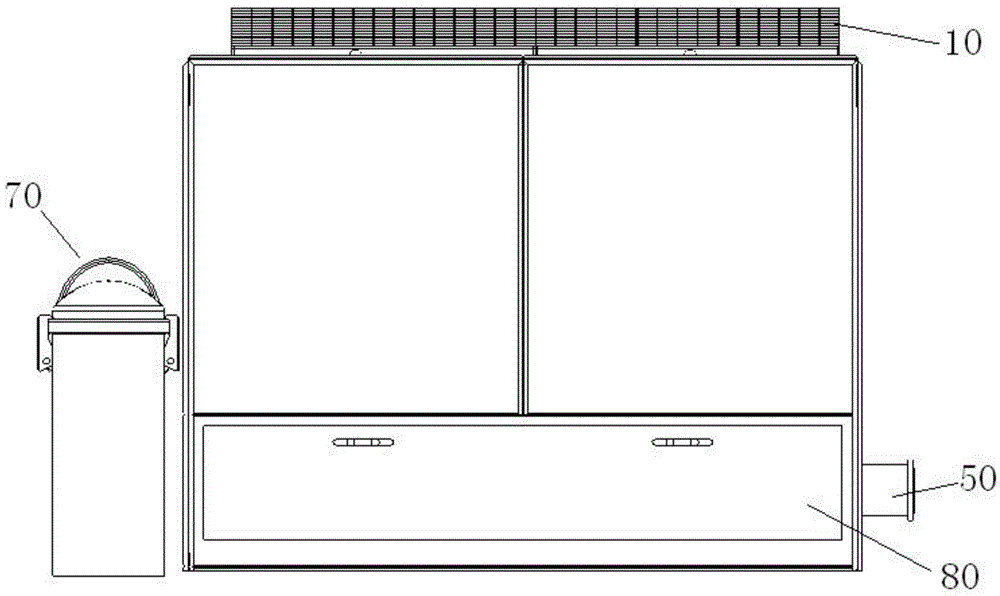

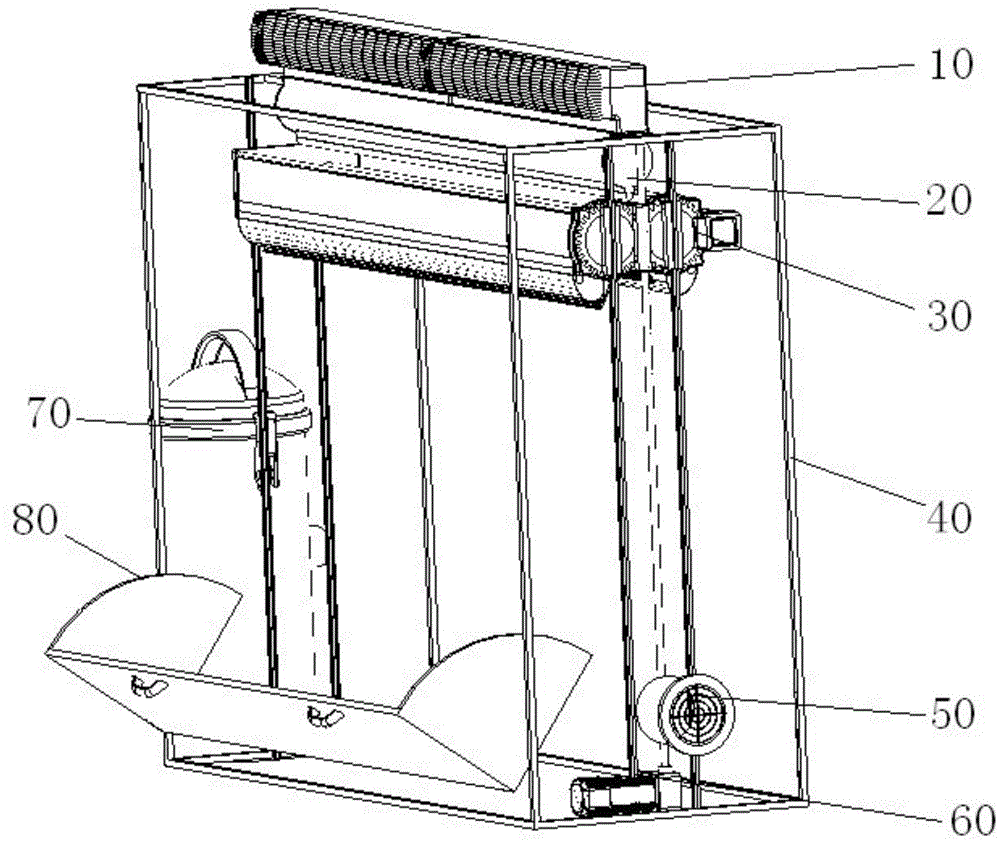

Dust removal device, equipment and system

InactiveCN101766939AImprove ventilationReduce maintenance difficultyDispersed particle filtrationLighting and heating apparatusSuction forceEngineering

The embodiment of the invention discloses a dust removal device which comprises a dust removal head, a sliding unit, a traction unit and an air exhaust unit. The traction unit is fixed at the plane of one side of a filter screen to be subject of dust removal by adopting at least one supporting point and is used for providing the traction force of the movement of the sliding unit and providing the sliding travel of the sliding unit, wherein dust removal is to be carried out one the side of the filter screen; the sliding unit is connected with the traction unit and slides in the sliding travel provided by the traction unit under the traction force of the traction unit; and the dust removal head is connected on the sliding unit and used for removing dust on the filter screen under the suction force of the air exhaust unit when the sliding unit slides. The invention solves the problem of removal of a great deal of dust brought from a ventilation air inlet of a machine room or a factory building, keeps a filter from being blocked by the dust for a long time, solves the problem of maintenance of a dust removal system, enhances the dust removal effect and reduces the maintenance difficulty of the dust removal system.

Owner:HUAWEI TECH CO LTD

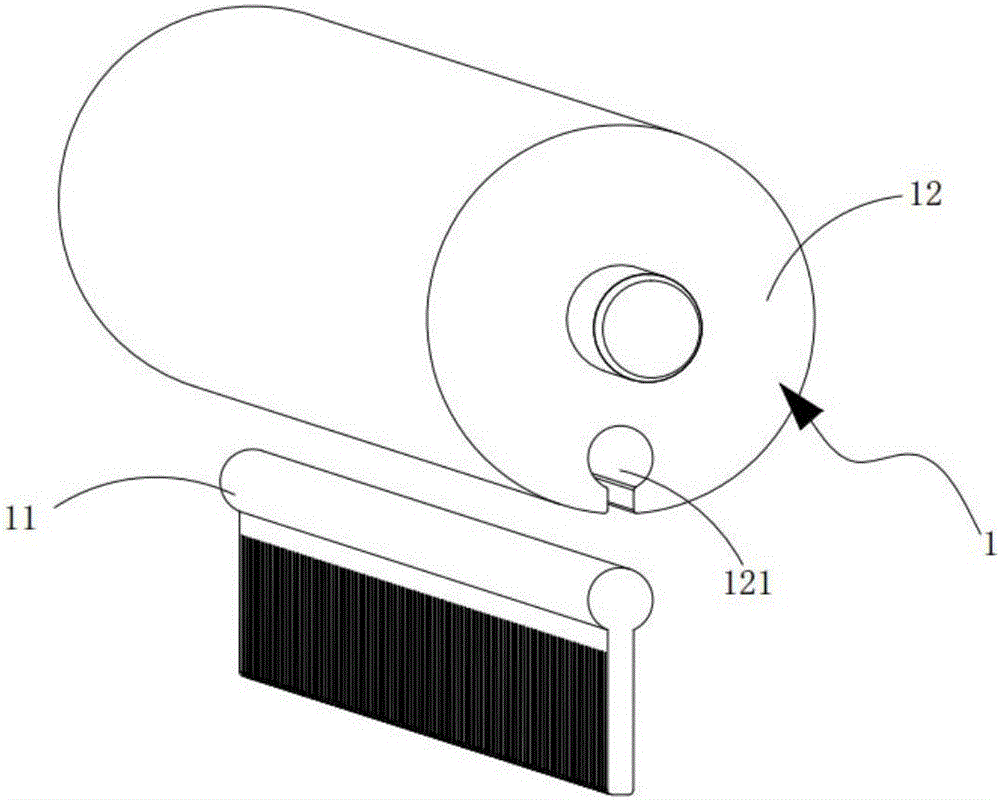

Dedusting composite cloth roller with self-cleaning function

InactiveCN106801327ASolve the removal problemAvoid secondary attachmentMechanical cleaningPressure cleaningEngineeringImpurity

The present invention relates to a dedusting composite cloth roller with a self-cleaning function. A brush roll mechanism and a fine cloth roller mechanism are additionally arranged on a coarse cloth roller mechanism, the combination of the three is utilized to form a composite cloth roller, the fine cloth roller mechanism is employed to generate static electricity through friction of the textile fabrics to absorb the dust impurity, the brush roll mechanism is employed to remove the dust impurity on the fine cloth roller mechanism, the dust impurity is stored in the coarse cloth roller mechanism, and the dust impurity can be rapidly extracted from the coarse cloth roller mechanism through a cleaner when cleaning. The problem is solved that the impurity on the textile fabrics cannot be removed through adoption of the cloth roller in the prior art so as to further solve the problem that the dust impurity is kicked up to be absorbed on the textile fabrics after the dust impurity is removed and solve the problem that the dust impurity is rapidly removed from the composite cloth roller.

Owner:南通滨海东泰纺织有限公司

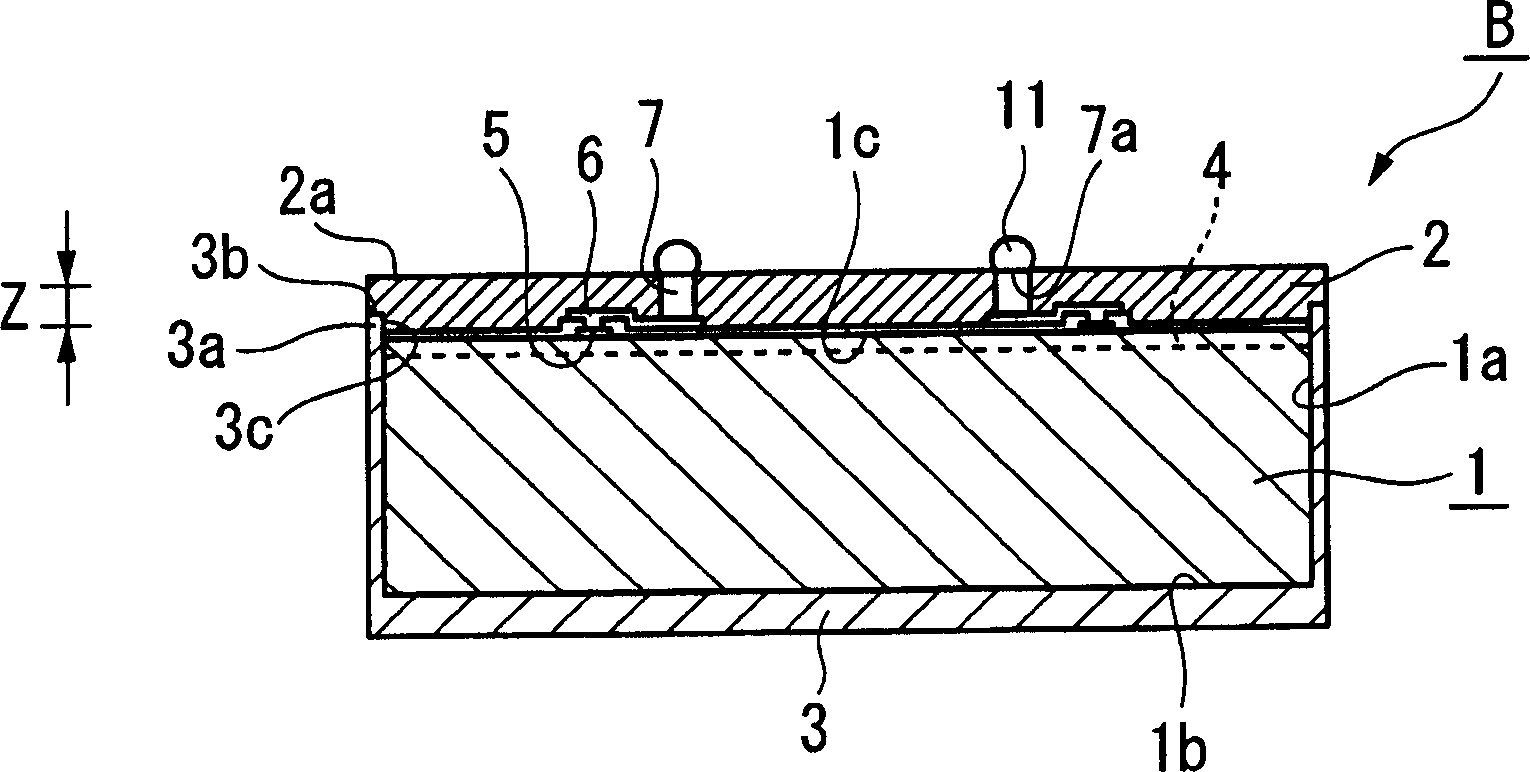

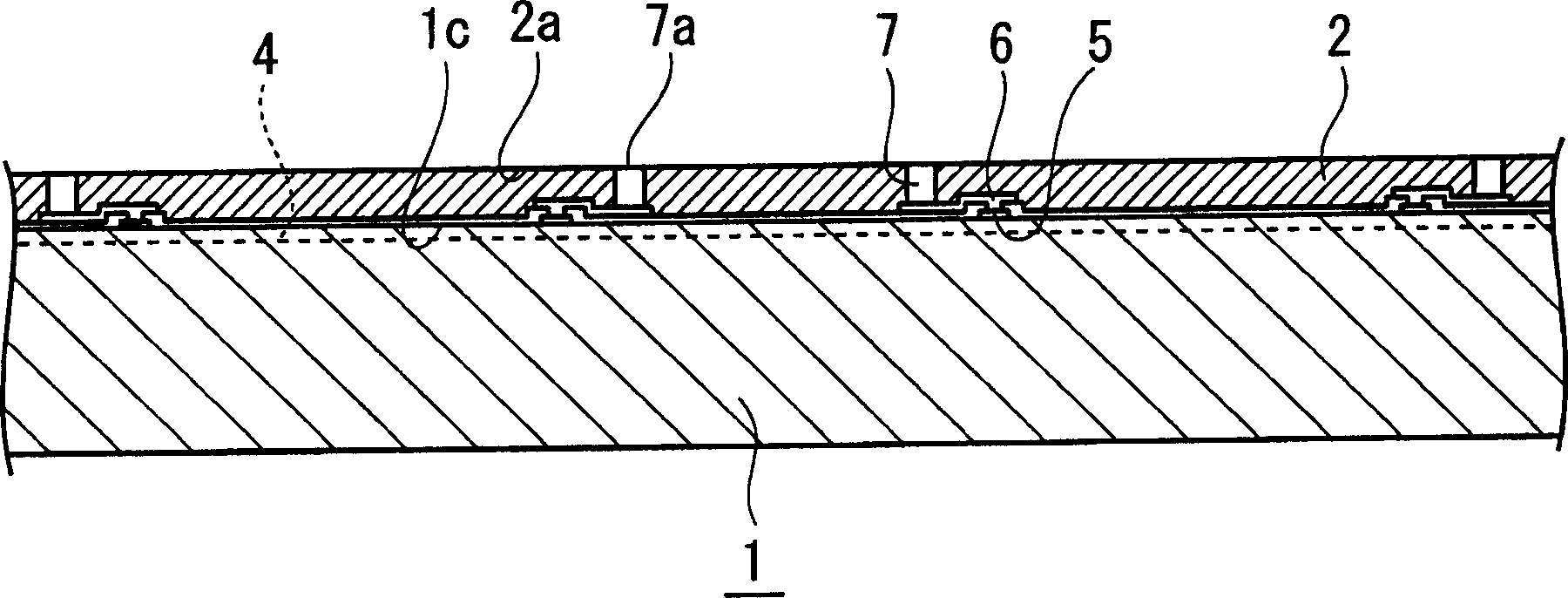

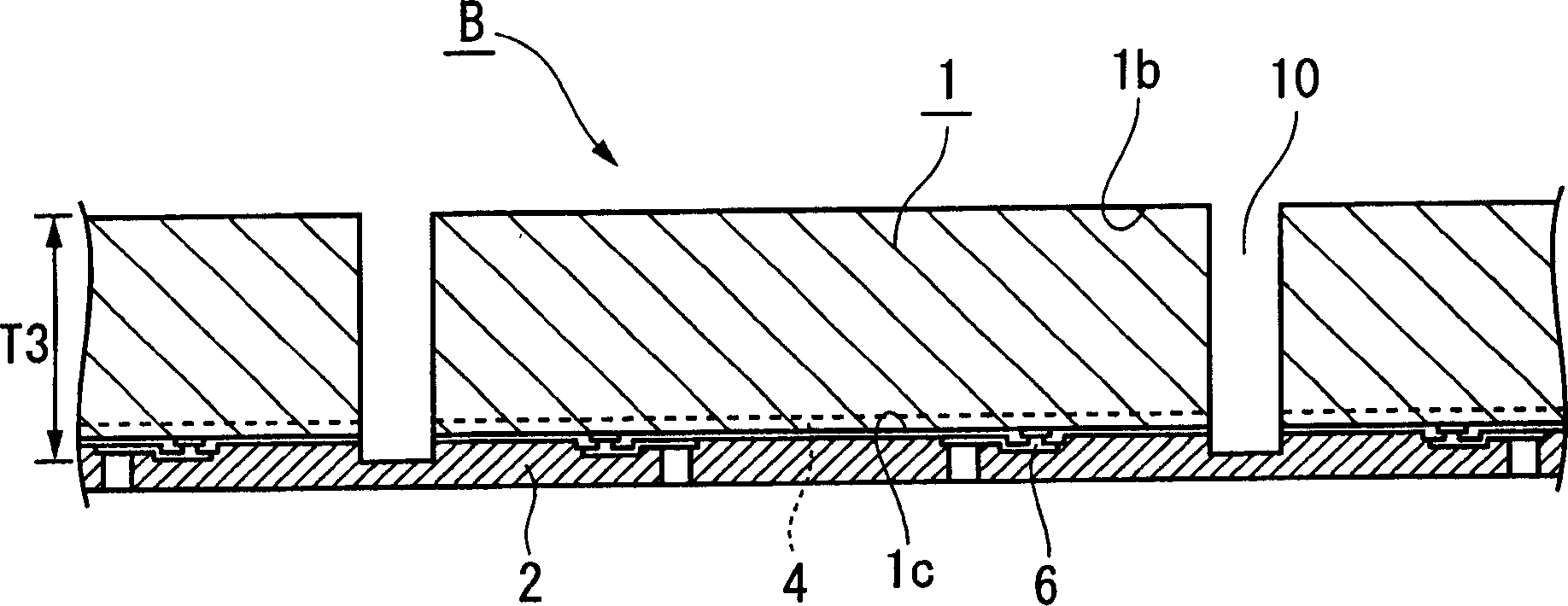

Method for manufacturing semiconductor device and semiconductor device

InactiveCN1835196ASimple designSolve the removal problemSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

A semiconductor device production method which includes steps of: preparing a wafer on which multiple integrated circuits are formed on a principal face; forming a rewiring which is electrically connected to the integrated circuits via a pad electrode; and dicing the wafer after forming an electrode terminal on the rewiring, including steps of: forming a first resin layer by sealing at least the rewiring and the electrode terminal formed on the principal face of the wafer with a first resin; processing a first dicing from a back face of the wafer to the principal face of the wafer or halfway to the first resin layer when the first resin layer is formed; forming a second resin layer by sealing a cut line outlined upon the first dicing and the back face of the wafer continuously with a first resin; and processing a second dicing while leaving the second resin layer which covers a side face outlined upon the first dicing.

Owner:YAMAHA CORP

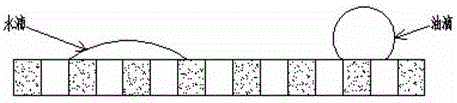

Preparation method of novel super-oleophylic and super-hydrophobic separation membrane

InactiveCN105749770AImprove lipophilicityImprove hydrophobicitySemi-permeable membranesMembranesMembrane surfaceSolvent

The invention relates to a preparation method of a novel super-oleophylic and super-hydrophobic separation membrane. The preparation method comprises steps as follows: (1) hydrophobic monomers are polymerized through free radical polymerization, precipitated in water and subjected to vacuum drying, and a hydrophobic modified polymer is obtained; (2) the hydrophobic modified polymer is dissolved in a solvent I, and a modified solution is obtained; (3) the modified solution is applied to the surface of a separation membrane and inner sides of membrane pores, and a hydrophobic membrane surface is obtained after the solvent is evaporated. The preparation method is simple and facilitates industrial production and amplification, and the separation membrane has great oil and water separation performance.

Owner:WUXI LVZHIXING ENVIRONMENTAL PROTECTION CO LTD

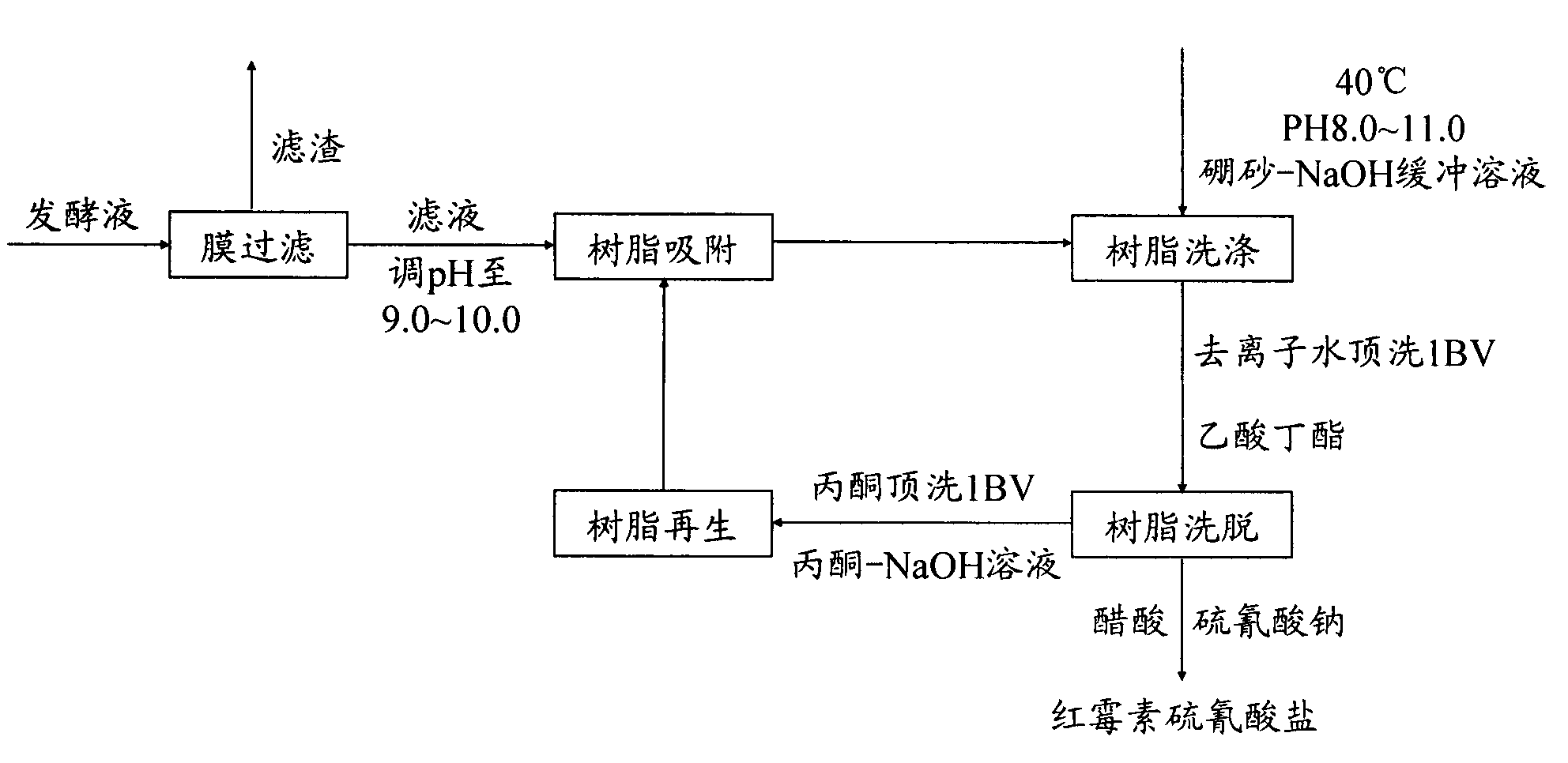

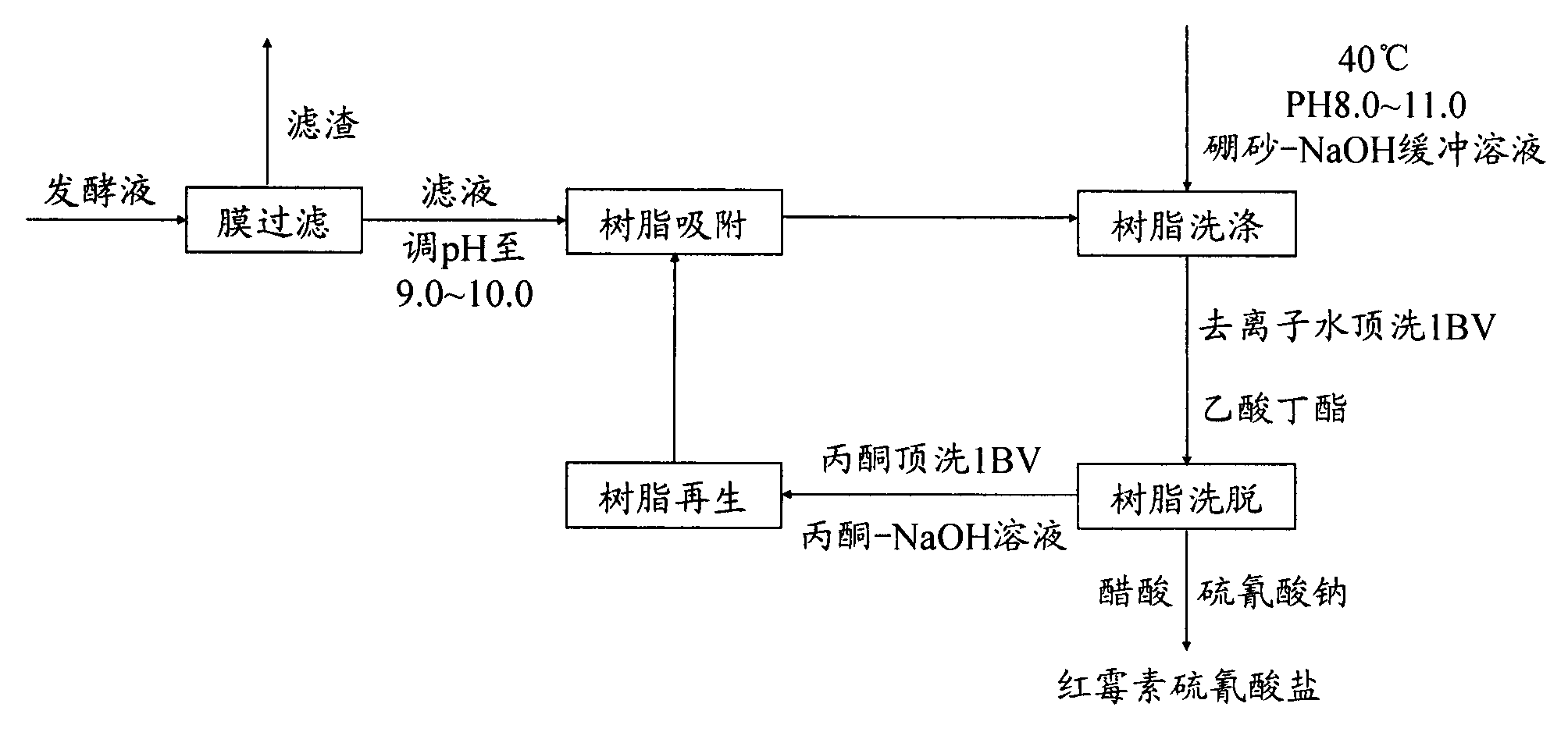

Improved method for purifying erythromycin A

InactiveCN102180922AGuaranteed to proceed normallyReduce dosageSugar derivativesSugar derivatives preparationOrganic solventDesorption

The invention relates to method for purifying erythromycin A from fermented liquid by adopting a resin adsorption method, which includes the following steps: (1) adsorption, (2) washing of impurities, (3) desorption, (4) salifying of eluent and the like. The method overcomes the defects of lower elution rate of 1BV erythromycin, more impurity contents in products and the like in the existing resin adsorption and separation technology. In addition, the invention also provides a resin regeneration method which includes the following main steps: mixed solution consisting of 0.1 mol / L-1.0 mol / L NaOH aqueous solution and a water soluble or partially water soluble organic solvent is adopted for washing resin to be regenerated, so as to solve the problem of poor resin regeneration effect in the prior art.

Owner:EAST CHINA UNIV OF SCI & TECH

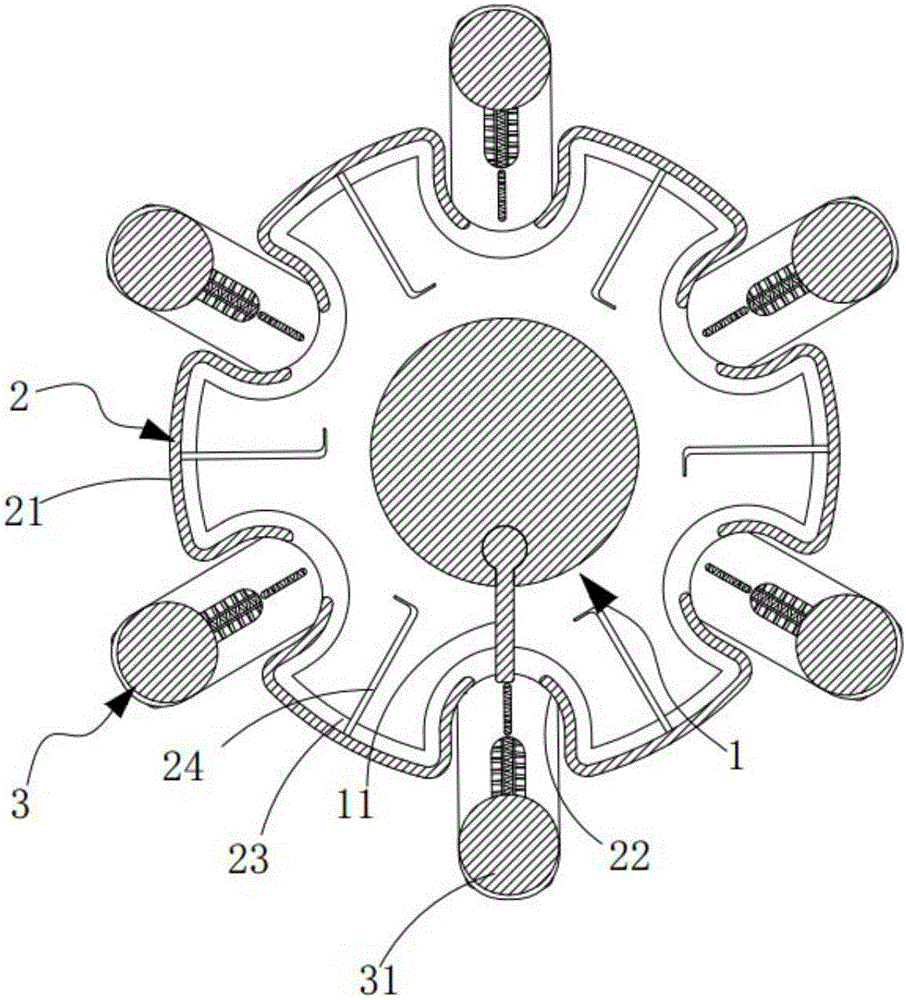

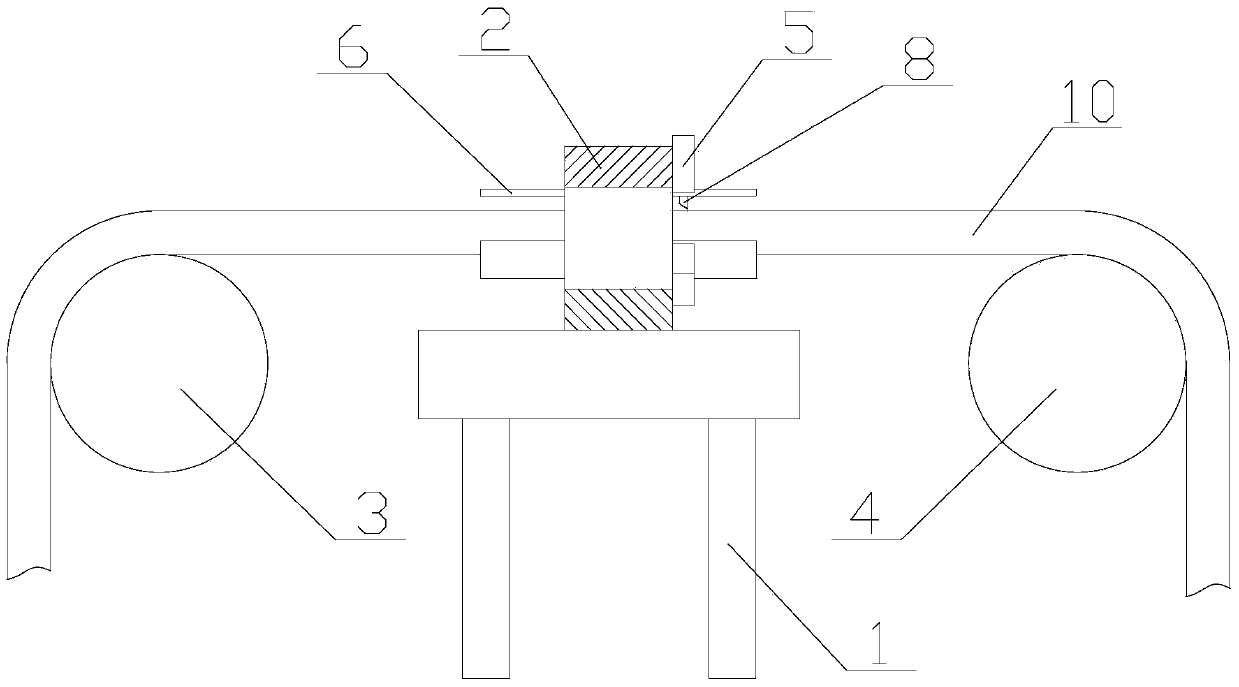

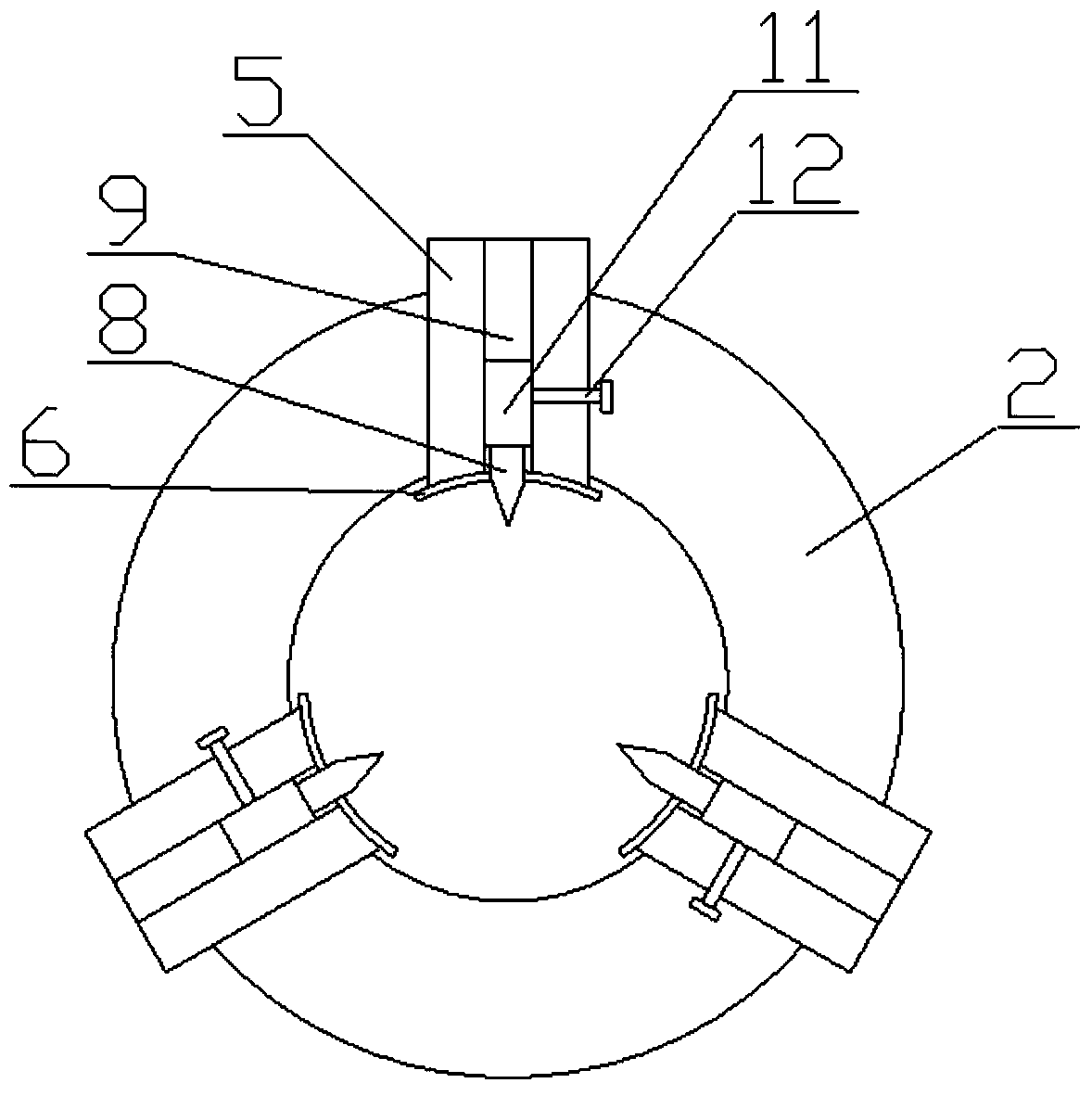

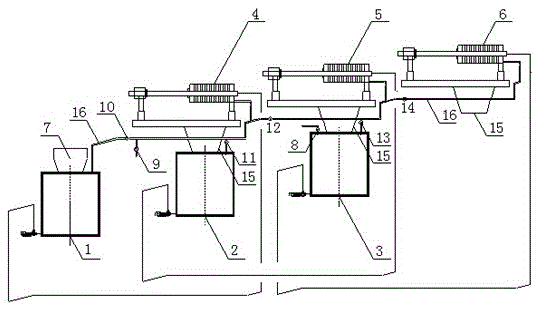

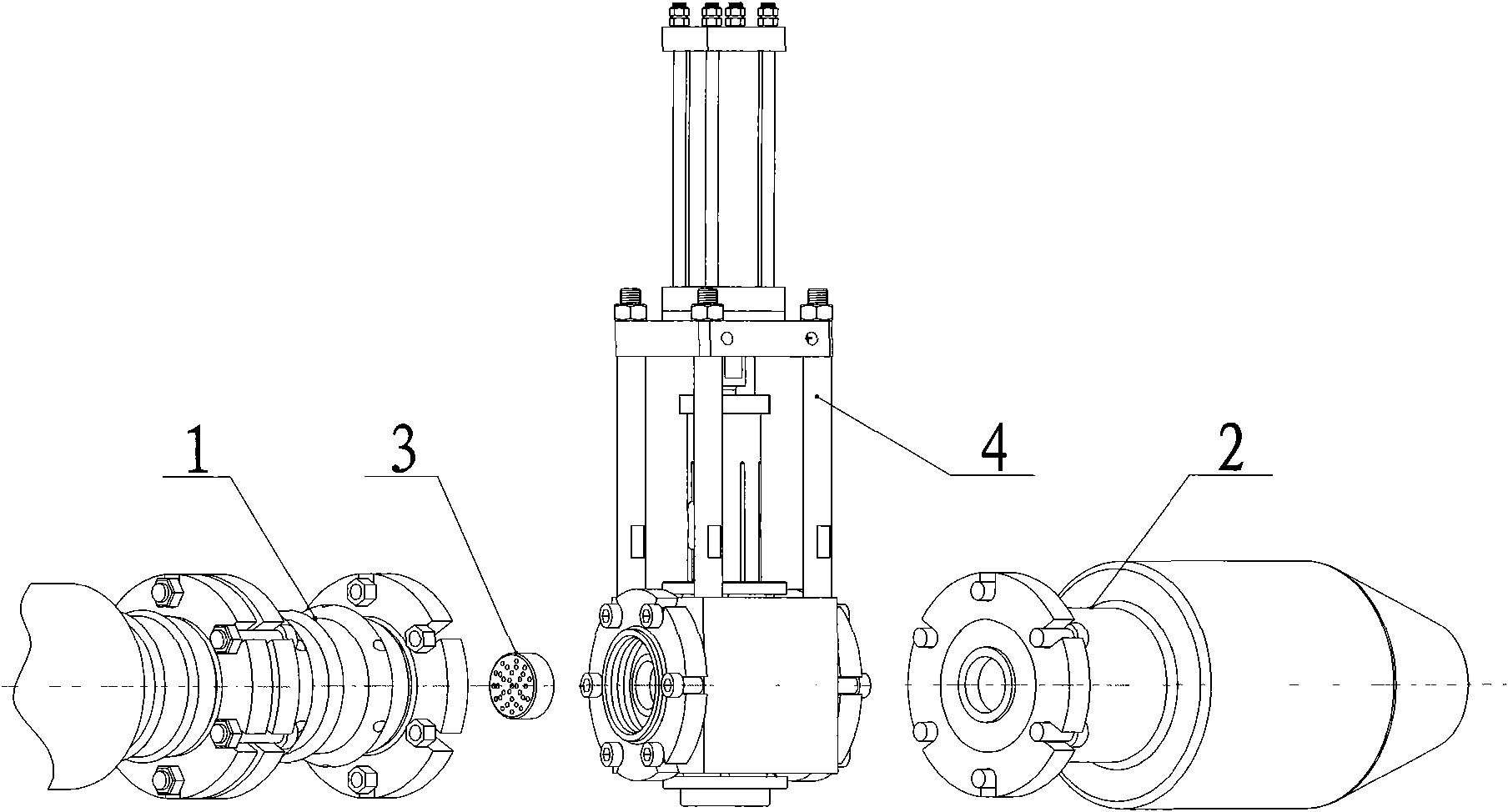

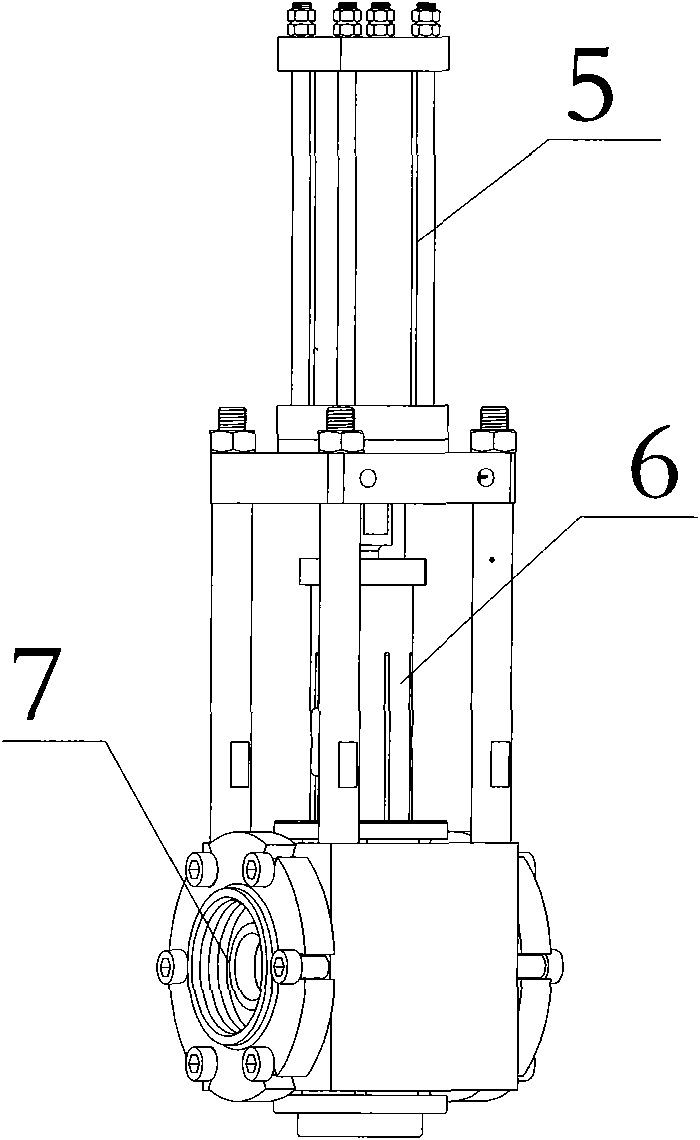

Electrical heating cigarette provided with annular tobacco taking assembly

The invention provides an electrical heating cigarette provided with an annular tobacco taking assembly. The electrical heating cigarette comprises a heating assembly and the annular tobacco taking assembly, wherein the heating assembly comprises a cigarette containing cavity and a heating element located in the cigarette containing cavity, the cigarette containing cavity is used for accommodatinga cigarette dispensing product, the annular tobacco taking assembly comprises a push and pull part capable of sliding along the outer wall of the housing of the cigarette containing cavity back and the forth and a sliding part in linkage with the push and pull part, the sliding part is located in the cigarette containing cavity, the middle penetrates through the heating element, the sliding partcan move in the direction, away from the heating element, of the axial direction of the cigarette containing cavity under the driving of the push and pull part, and accordingly the cigarette dispensing product in the cigarette containing cavity is moved out of the cigarette containing cavity. Heat harm of a heater of a heating device can be avoided, the problem that tobaccos are difficult to takeout due to misoperation after a low-temperature tobacco product is consumed can be solved, and thus clearing of residual tobaccos in a heating cavity is promoted.

Owner:HUBEI CHINA TOBACCO IND

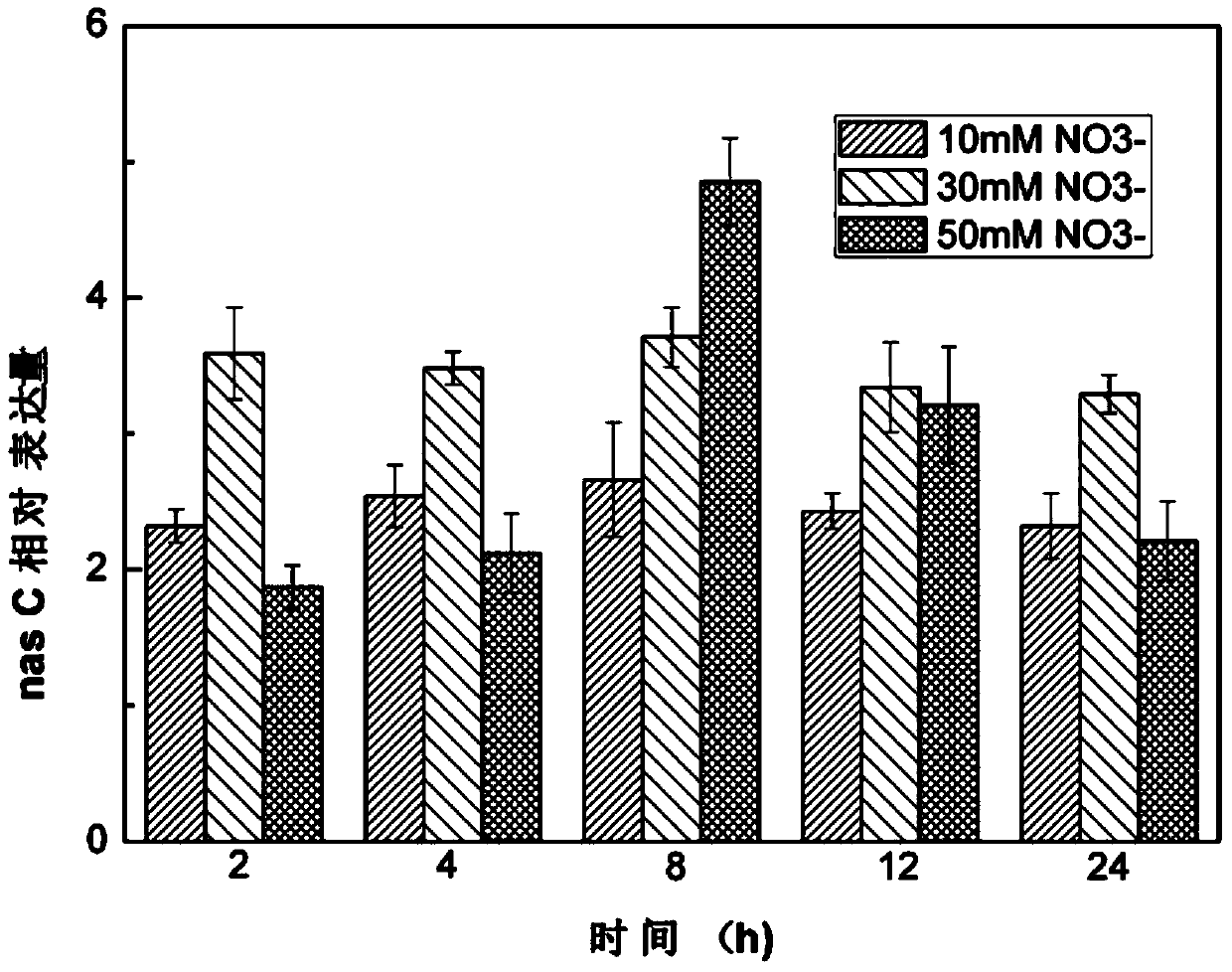

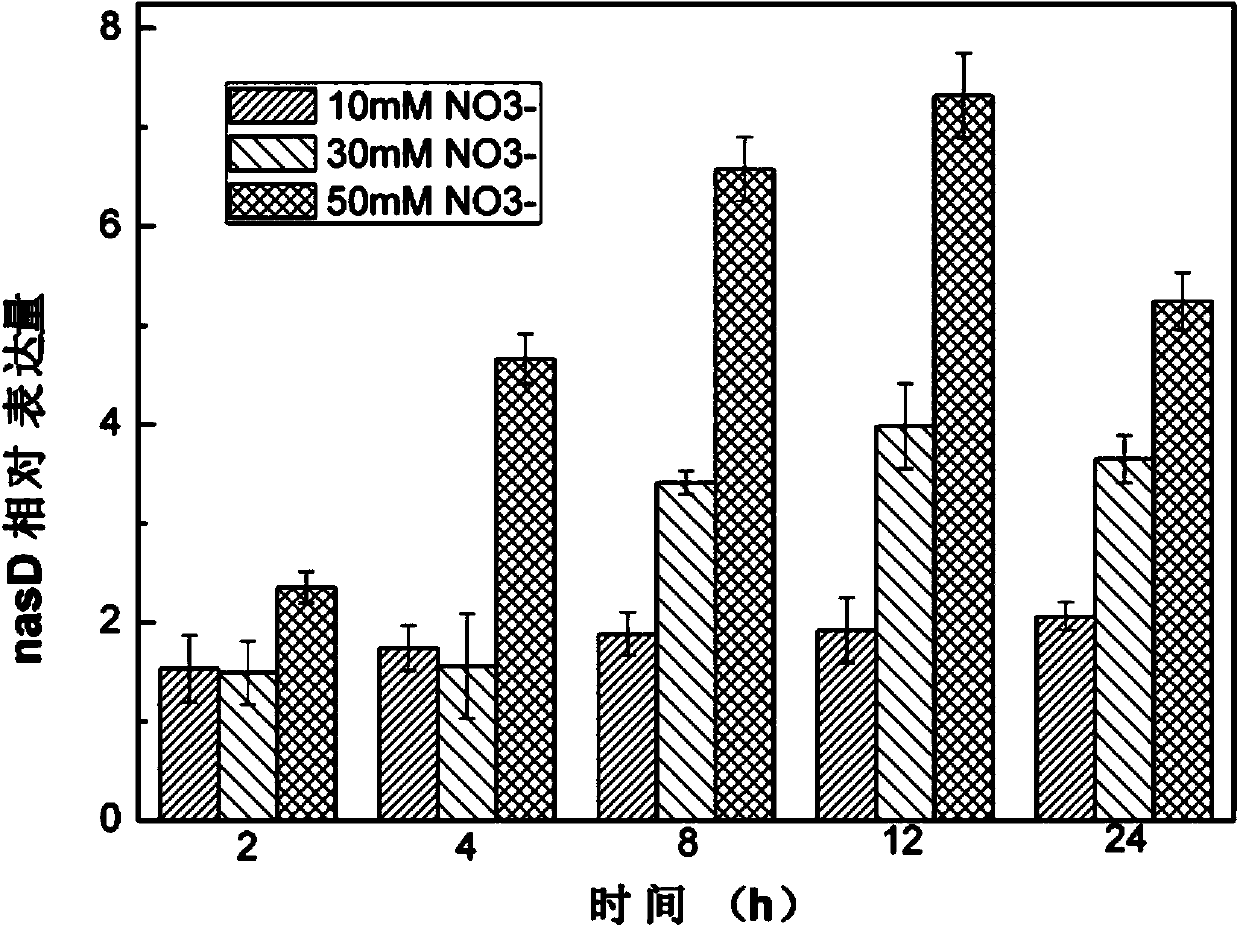

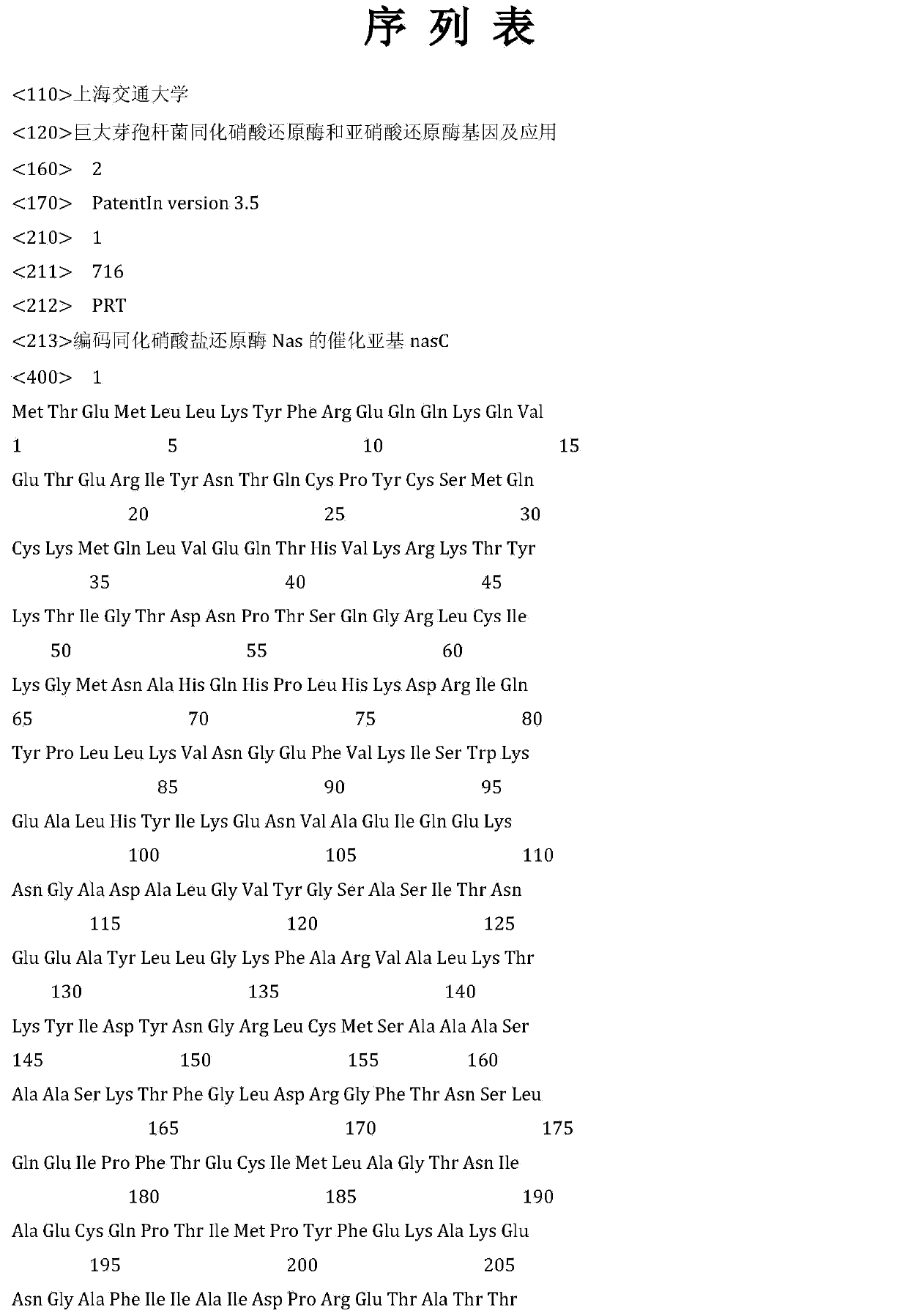

Assimilation nitrate reductase gene and assimilation nitrite reductase gene both extracted from bacillus megaterium as well as applications of assimilation nitrate reductase gene and assimilation nitrite reductase gene

InactiveCN103725654ASolve the removal problemMicrobiological testing/measurementContaminated soil reclamationBacillus megateriumTotal rna

The invention discloses an assimilation nitrate reductase gene and an assimilation nitrite reductase gene both extracted from bacillus megaterium as well as applications of the assimilation nitrate reductase gene and the assimilation nitrite reductase gene, and relates to the field of the biotechnology. The assimilation nitrate reductase gene is catalytic subunit nasC (Seq ID No.1) which codes assimilation nitrate reductase Nas; the assimilation nitrite reductase gene is large subunit nasD (Seq ID No.2) which codes assimilation nitrite reductase NiR. According to the invention, total RNA is extracted from the bacillus megaterium NCT-2, then cDNA synthesis is conducted to obtain a cDNA template, and function representation is realized through fluorogenic quantitative PCR. The assimilation nitrate reductase gene and the nitrite reductase gene can be further applied to research on removal of overmuch nitrate from soil.

Owner:SHANGHAI JIAO TONG UNIV

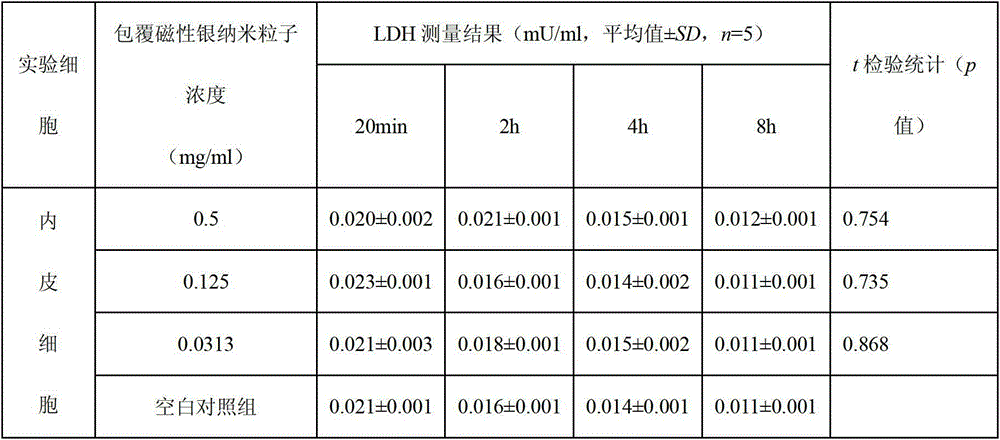

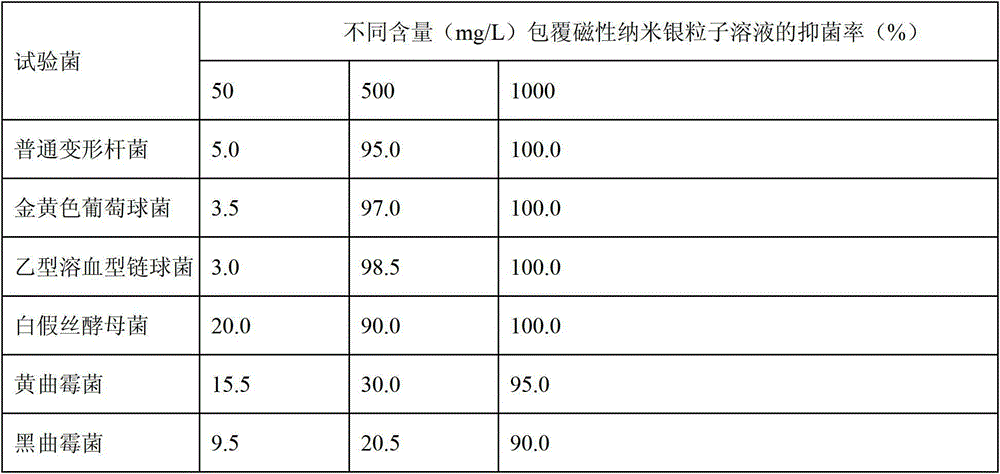

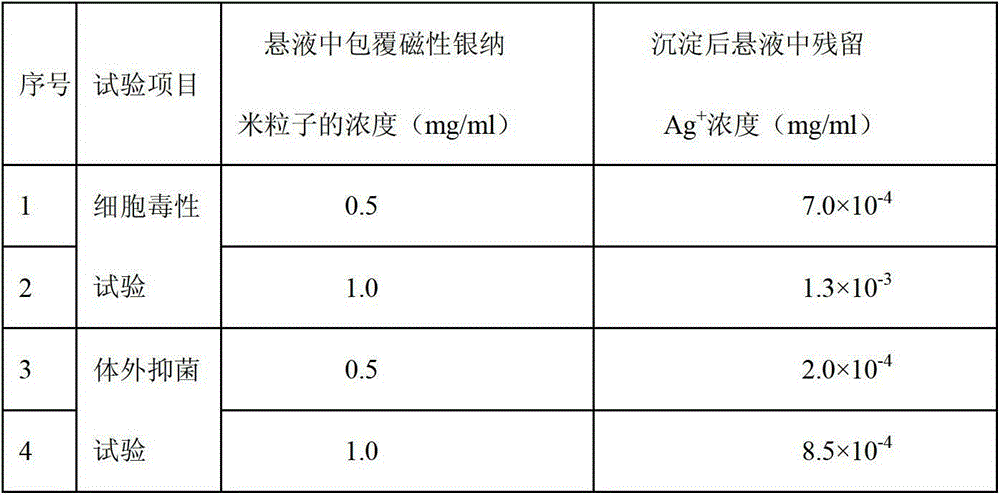

Preparation method of amylose-coated I3<->-complexed silver-coated iron composite nanoparticles

InactiveCN103142649AAddress targeting issuesAddress toxicityAntibacterial agentsEnergy modified materialsSilver iodideIron nanoparticle

The invention discloses a preparation method of amylose-coated I3<->-complexed silver-coated iron composite nanoparticles, which comprises the following steps: synthesizing silver-coated iron nanoparticles, coating amylose on the nanoparticles, and complexing the I3<-> into the amylose molecular spiral structure to finally form the composite magnetic silver nanoparticles. By designing and synthesizing the silver-coated iron composite nanoparticles, the invention solves the problem of targeted entry of silver; by coating the starch on the nano silver, the invention solves the problems of toxicity and stability in the nano silver; by complexing the iodine ions with the amylose, the invention solves the problem of introduction of iodine; under the magnetocaloric effect, the invention solves the problem of release of iodine complex ions; by using the specific fusion action of the iodine complex ions on the nano silver, the invention solves the problem of release of silver ions in the nano silver; and by generating the silver iodide, the invention solves the problem of removal of in-vivo silver ions. Meanwhile, the designed system can comprehensively utilize the thermotherapeutic benefit of magnetic particles as well as the broad spectrum and efficient sterilization characteristics of the silver.

Owner:赵华文

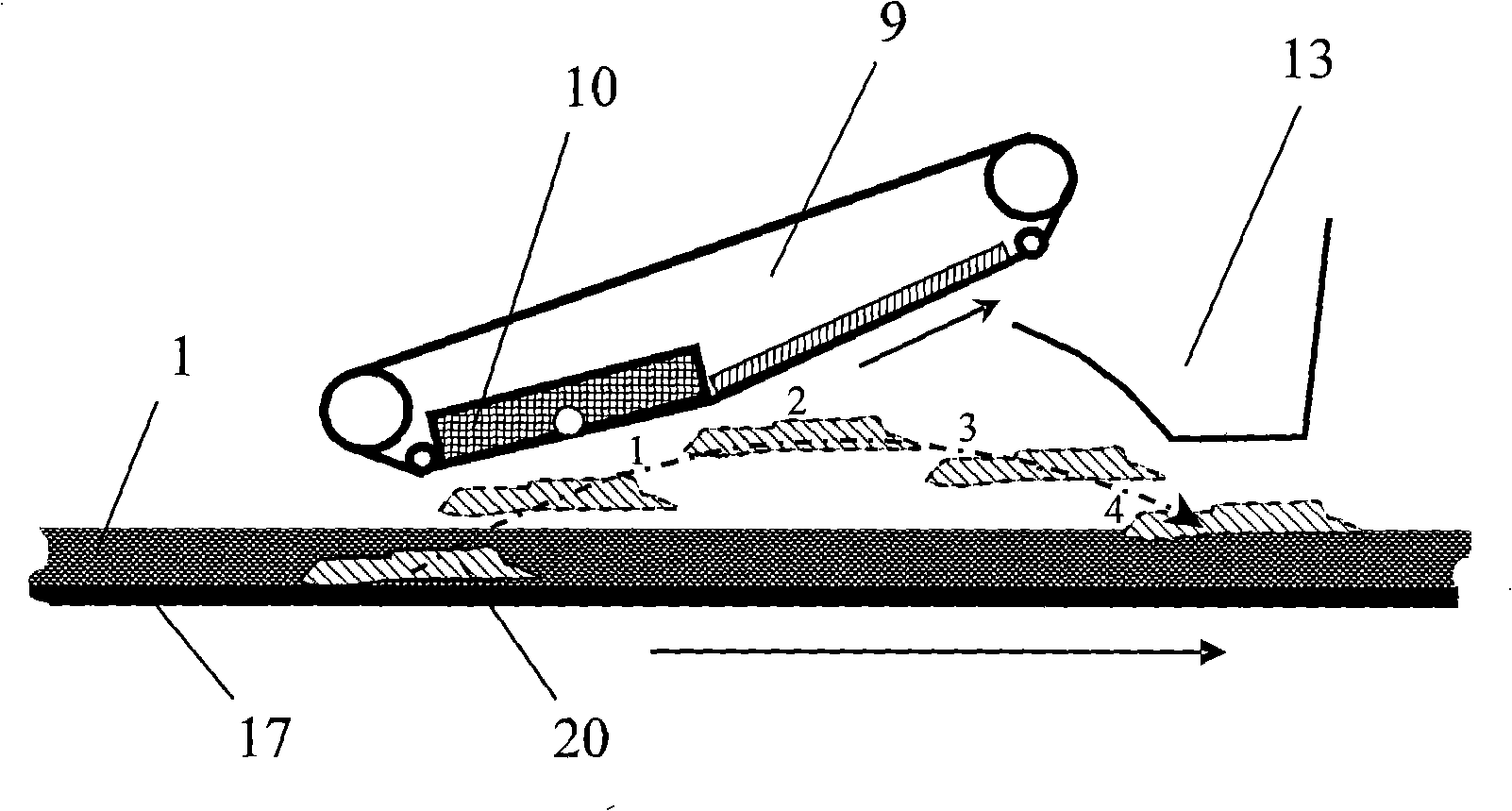

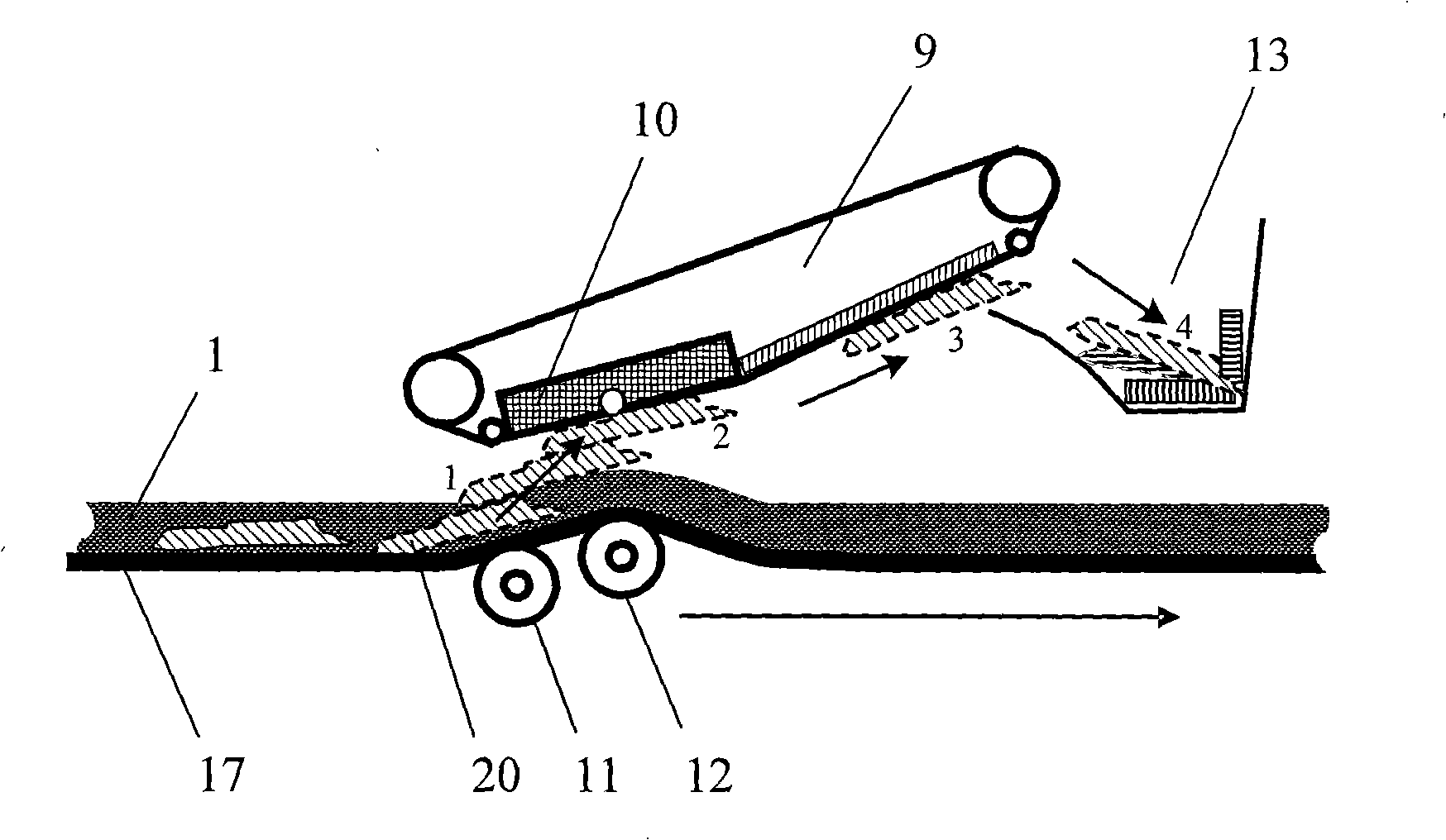

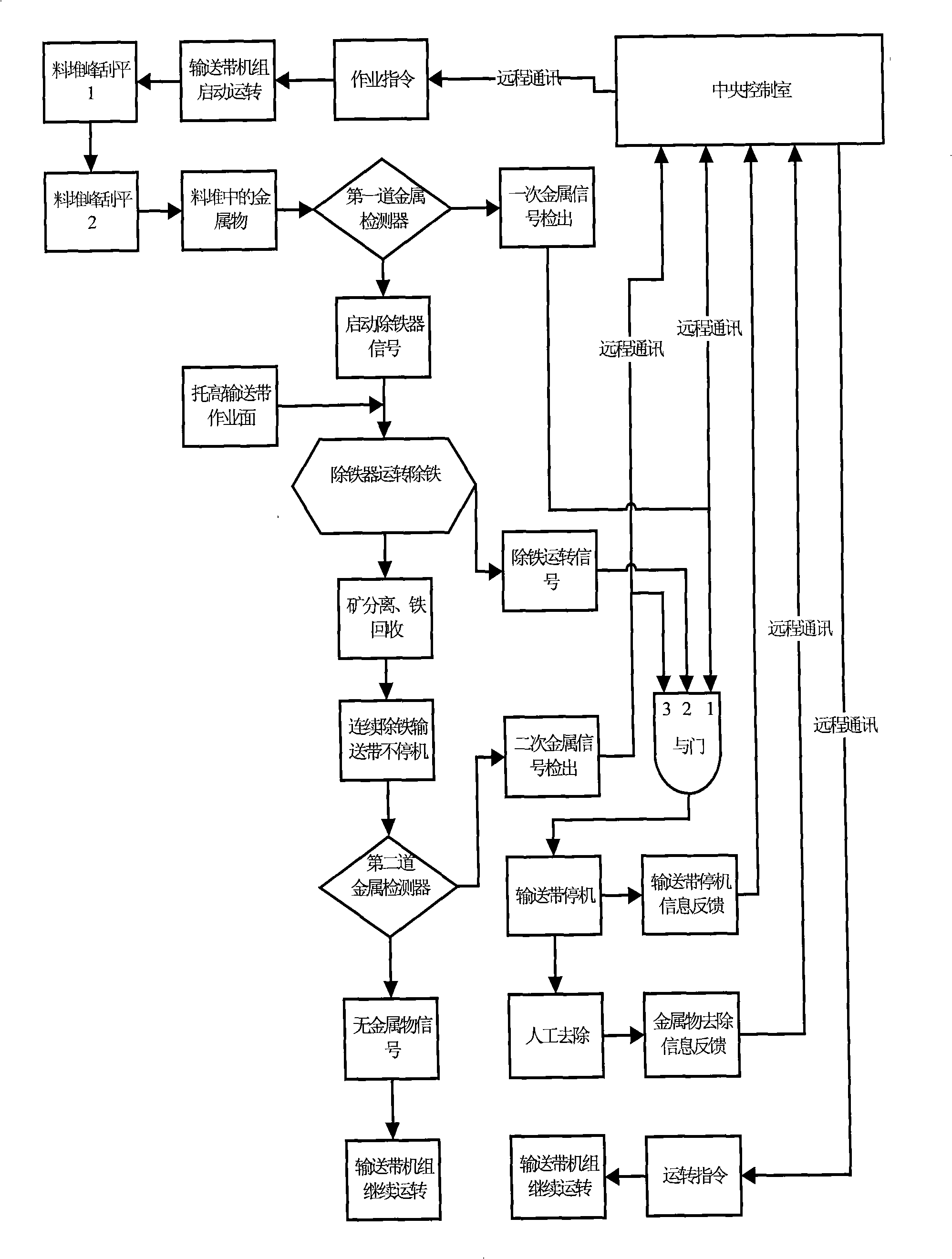

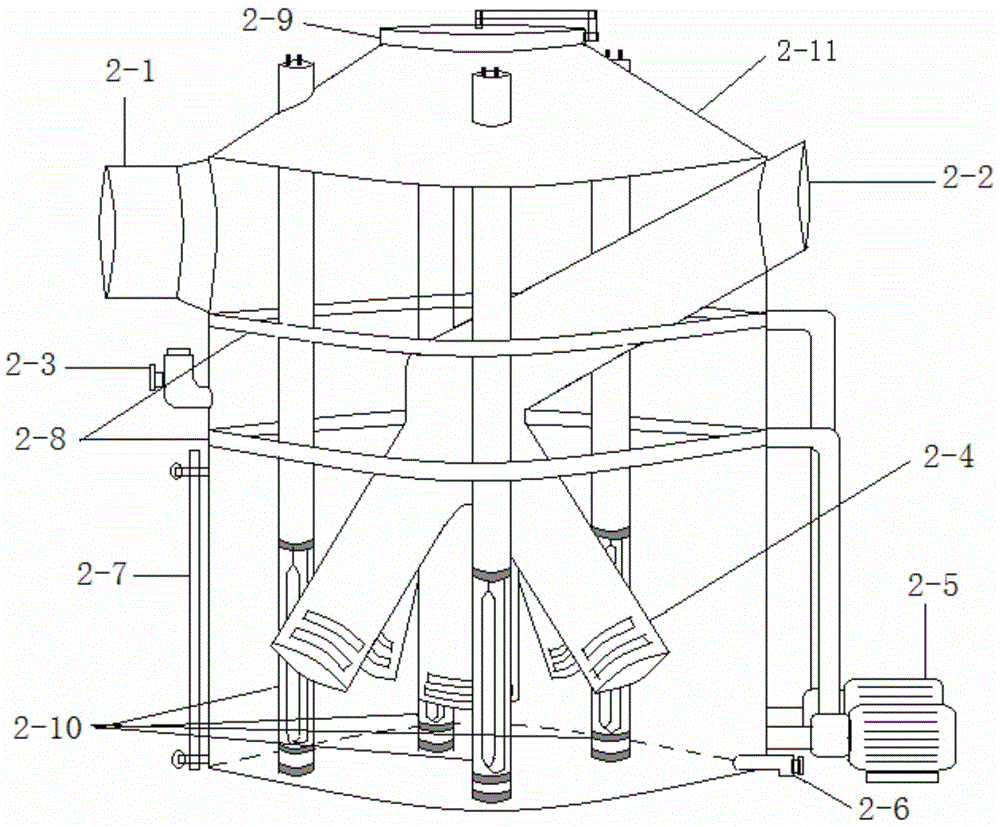

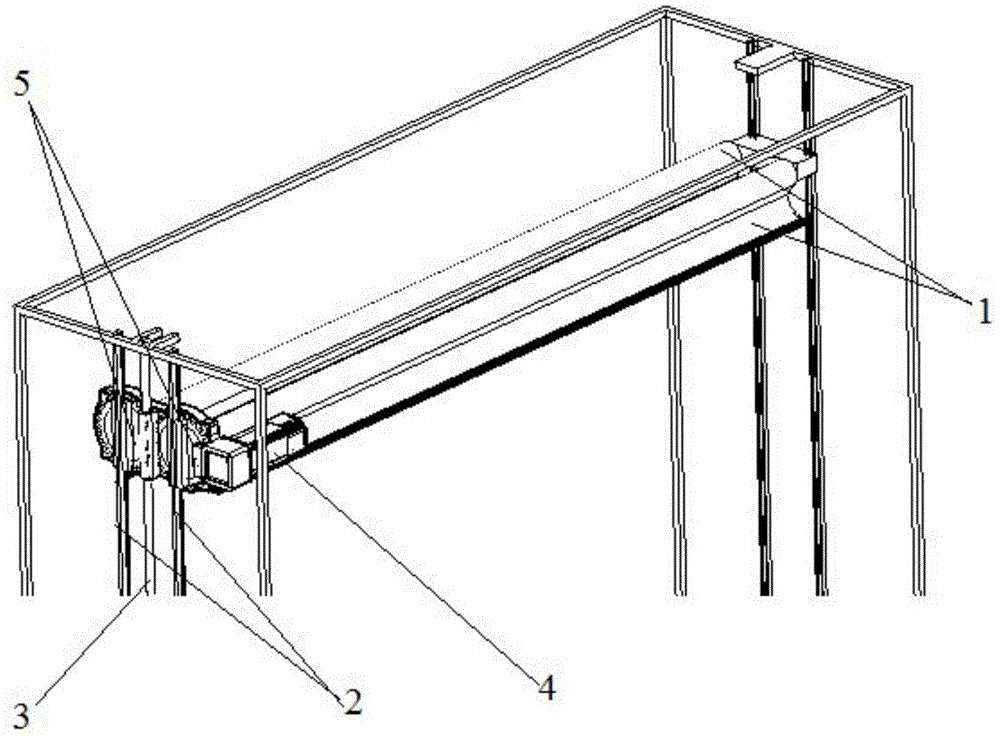

Method and device for removing metallic material of high-speed conveyer belt bulk cargo

ActiveCN101264824AImprove securityImprove delivery efficiencyControl devices for conveyorsMagnetic separationBulk cargoMetallic materials

The invention discloses a method and a device for removing metal in high-speed conveyer belt bulk materials. Compared with the prior art, the method is characterized in adding a second metal detector, an AND gate logic control circuit, a material pile strickle and a conveyer belt bracket; a plurality of single components form a control subsystem connected with a console cabinet. The method is suitable for conveying the bulk materials by means of conveyer belts in steel, wharf, logistics, mining and storage industry. The method has the advantages of integrating communication, control and data exchange, enabling linkage with the console cabinet, removing the non-magnetic metal of high-speed conveyer belt, and improving equipment safety and conveyance efficiency of the high-speed conveyer belt.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Polishing liquid for grinding and polishing micro crystal glass

InactiveCN1858132AIncrease reaction rateReduce surface roughnessAqueous dispersionsPolishing compositions with abrasivesIonChemistry

Owner:HEBEI UNIV OF TECH

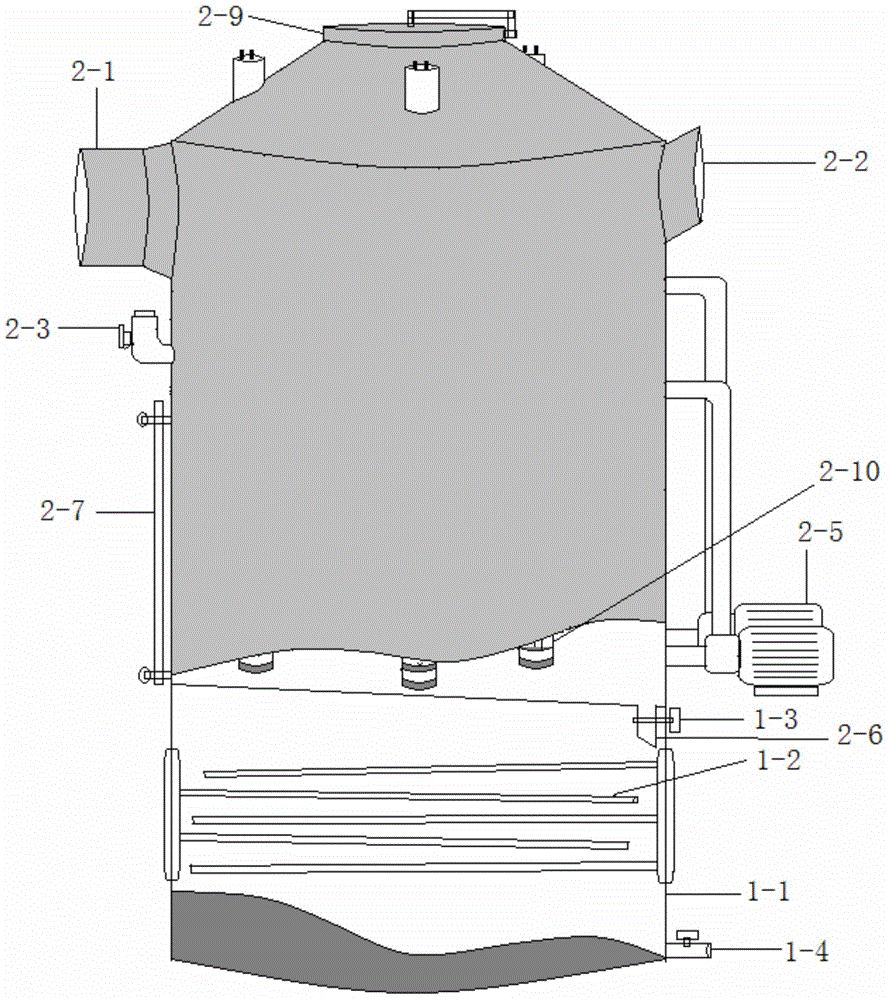

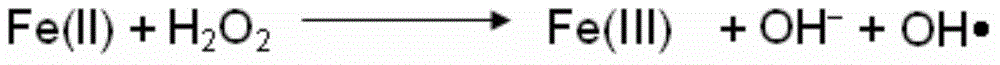

Method and device for purifying flue gas by utilizing photochemical Fenton reaction

ActiveCN103949153ASend each other quicklyExponentially faster chemical reactionsCombination devicesCoalIndustrial market

The invention discloses a method and a device for purifying flue gas by utilizing photochemical Fenton reaction. The method comprises the steps of converting particle powder into carbon dioxide and converting sulfur dioxide into sulfuric acid by utilizing the photochemical Fenton reaction. The device comprises a luminous energy bin and a purifying bin, so that the sulfuric acid recycling benefit of the device exceeds the running cost of the device, and users can obtain the relatively large profit. Additionally, the method is very flexible, can be accepted in existing systems of coal combustion boilers for improving the effectiveness of the coal combustion boilers, or can completely replace the original old system. The method and the device for purifying the flue gas by utilizing the photochemical Fenton reaction can be suitable for being used in any coal combustion boiler industrial market comprising cement plants, iron and steel plants, municipal government rubbish combustion plants, medical treatment rubbish combustion plants, chlorine manufacturers, paper pulp and paper production factories and the like.

Owner:林小晓 +1

Secondary battery top cover and secondary battery thereof

The invention provides a secondary battery top cover which comprises a top cover sheet and an anti-explosion valve, wherein the top cover sheet is provided with an anti-explosion hole; the anti-explosion valve is arranged in the anti-explosion hole; the top cover sheet and the anti-explosion valve are of an integrated structure; the top cover sheet extends around the anti-explosion hole towards adirection away from the anti-explosion valve, so as to form a boss; in the vertical direction, a length ratio of the top cover sheet to the anti-explosion valve ranges from 2.5 to 7; a ratio of the length of the boss in the horizontal direction to the length of the top cover sheet in the vertical direction ranges from 1 to 10. Through the integration of the top cover sheet and the anti-explosion valve, assembling and welding working procedures between the top cover sheet and the anti-explosion valve can be avoided, so that the working procedures are simple, and the airtightness is high; moreover, through the arrangement of the boss, the problem on removal of a redundant top cover sheet material can be solved, and the overall intensity of positions around the anti-explosion hole and even the top cover sheet can be also enhanced. In addition, the applicator of the invention also makes a further design for the sizes of the top cover sheet, the anti-explosion valve and the boss by a creative idea, so that the technical difficulty in integrally forming a relatively thin anti-explosion valve having the anti-explosion function on the top cover sheet can be solved.

Owner:东莞百思利新能源科技有限公司

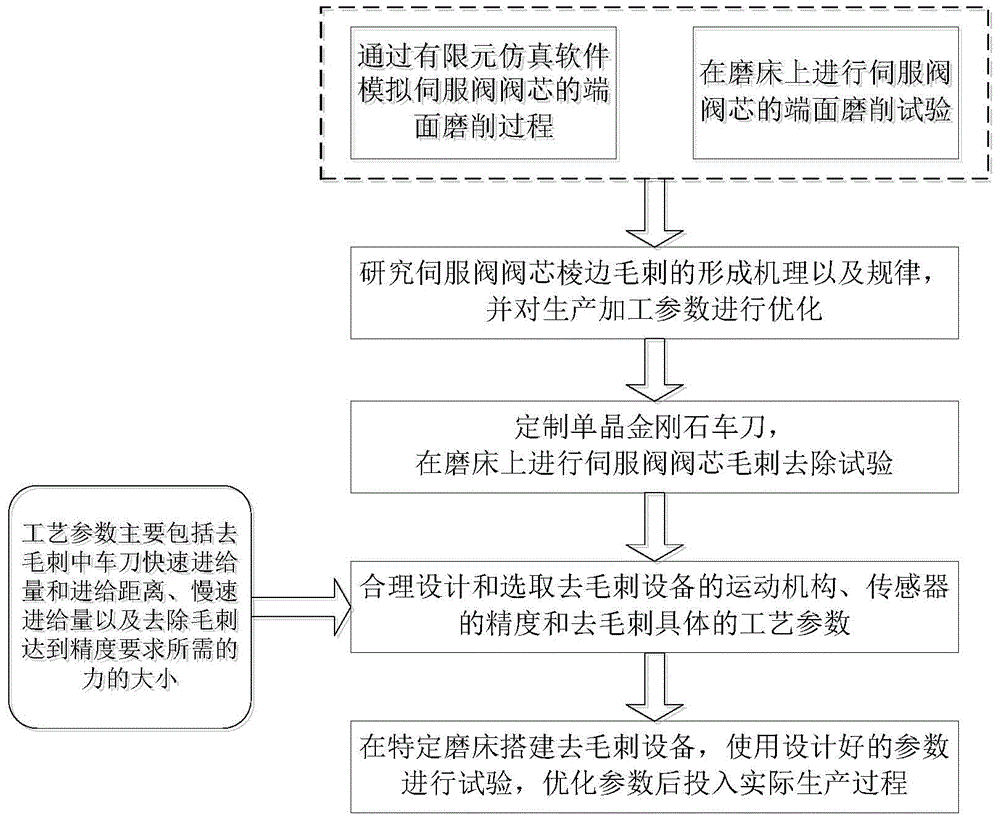

Optimization method for servo valve core working edge small burr online removal process system

An optimization method for a servo valve core working edge small burr online removal process system comprises the steps: (1) performing grinding simulation on the end face of a valve core by finite element software, measuring the height and width of generated burrs, and carrying out optimization on actual processing parameters; (2) carrying out a grinding experiment on the end face of the valve core, measuring the height and width of the generated burrs, and comparing with simulation results to obtain a relevant change rule between the sizes of the burrs and the actual processing parameters; (3) carrying out a working edge small burr removal experiment by using a turning way, and measuring the turning force in the process; (4) constructing an optimized process system and specific process parameters thereof according to the sizes of the burrs obtained in the steps (1) and (2) and the turning force in the step (4); (5) carrying out working edge small burr online removal on the optimized process system. By adopting the optimization method, the burr online removal process system is optimized, the production efficiency is improved, the part scrap rate is reduced, and the production cost is lowered.

Owner:SHANGHAI JIAO TONG UNIV +1

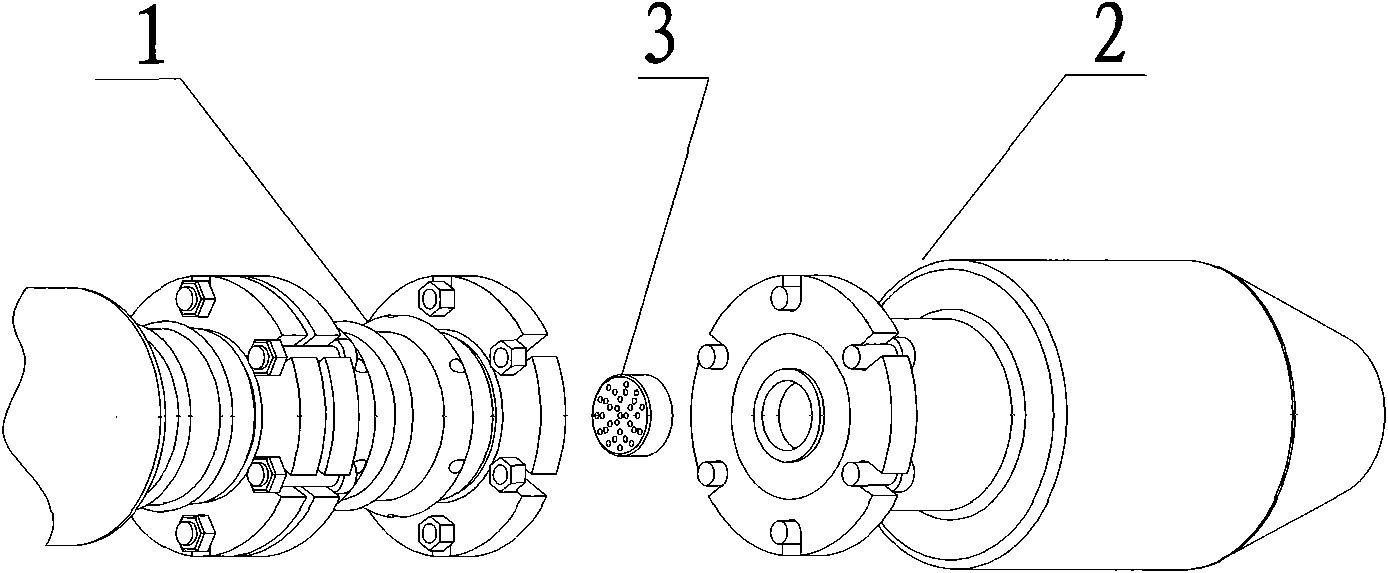

Stripping device for multi-layer cable

InactiveCN103795008AImprove consistencySolve the removal problemApparatus for removing/armouring cablesEngineeringUltimate tensile strength

The invention provides a stripping device for a multi-layer cable. The stripping device for the multi-layer cable comprises a support, a first guide wheel, a second guide wheel and a cable passing chuck. The cable passing chuck is arranged on the support. The first guide wheel and the second guide wheel are arranged on the two sides of the cable passing chuck. The cable horizontally passes through an axial through hole formed in the middle of the cable passing chuck via the first guide wheel and is output by the second guide wheel. A plurality of movable clamping jaws are evenly distributed on the cable passing chuck. The movable clamping jaws can conduct radial movement synchronously along the cable passing chuck so that the cable can be locked or loosened. Each movable clamping jaw is provided with a cable supporting plate which is used for preventing the cable from twisting, wherein the cable supporting plate is of an arc structure and transversely penetrates through the axial through hole of the cable passing chuck. The front end of each movable clamping jaw is provided with a blade used for stripping the multi-layer cable. The point of each blade extends inwards out of the corresponding cable supporting plate. By the adoption of the stripping device for the multi-layer cable, multiple protective layers of the cable can be automatically stripped, the problem that removal of the protective layers is influenced by the fact that the cable deviates vertically at the positions of the blades is solved, operation is easy, the operation intensity is relieved, and the consistency of cable stripping sizes is good.

Owner:ANHUI HUAXI CABLE TECH

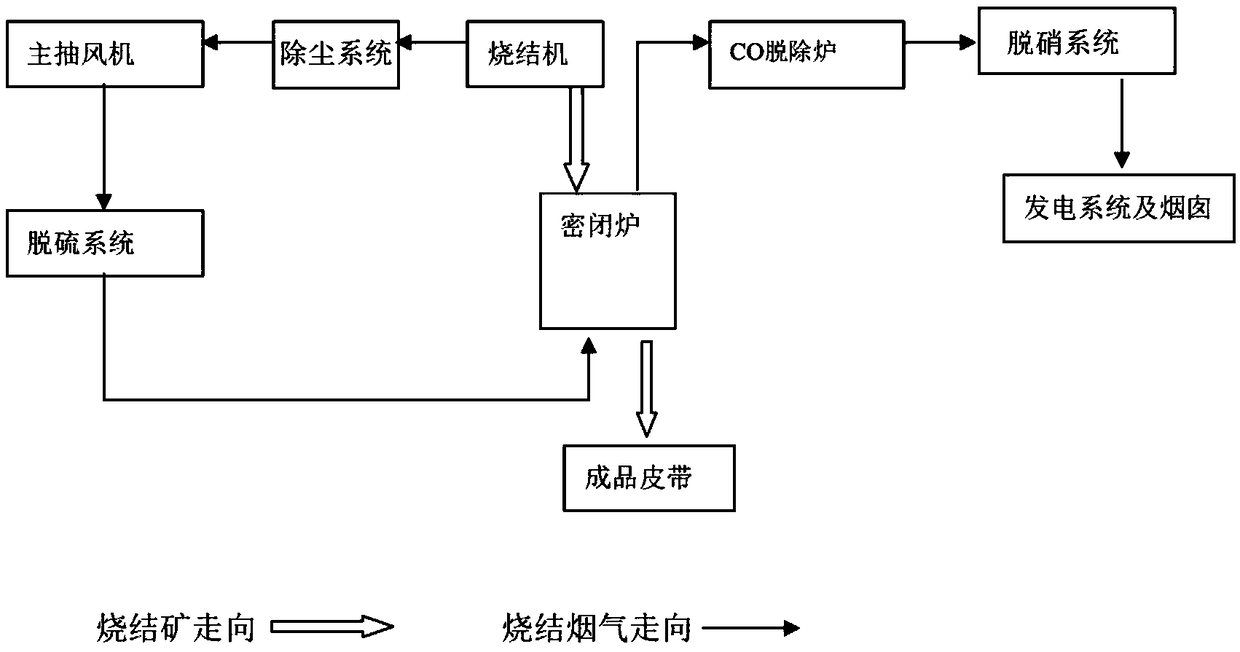

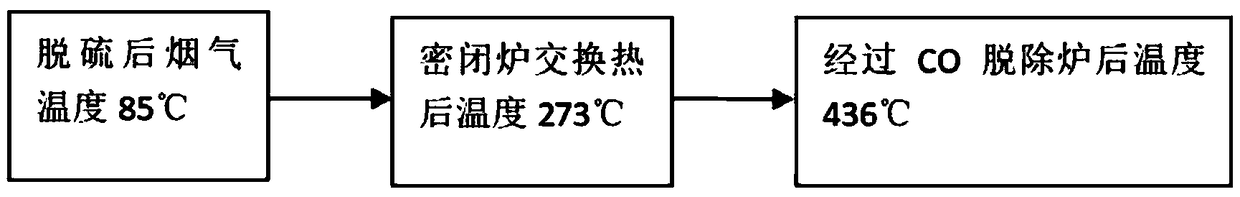

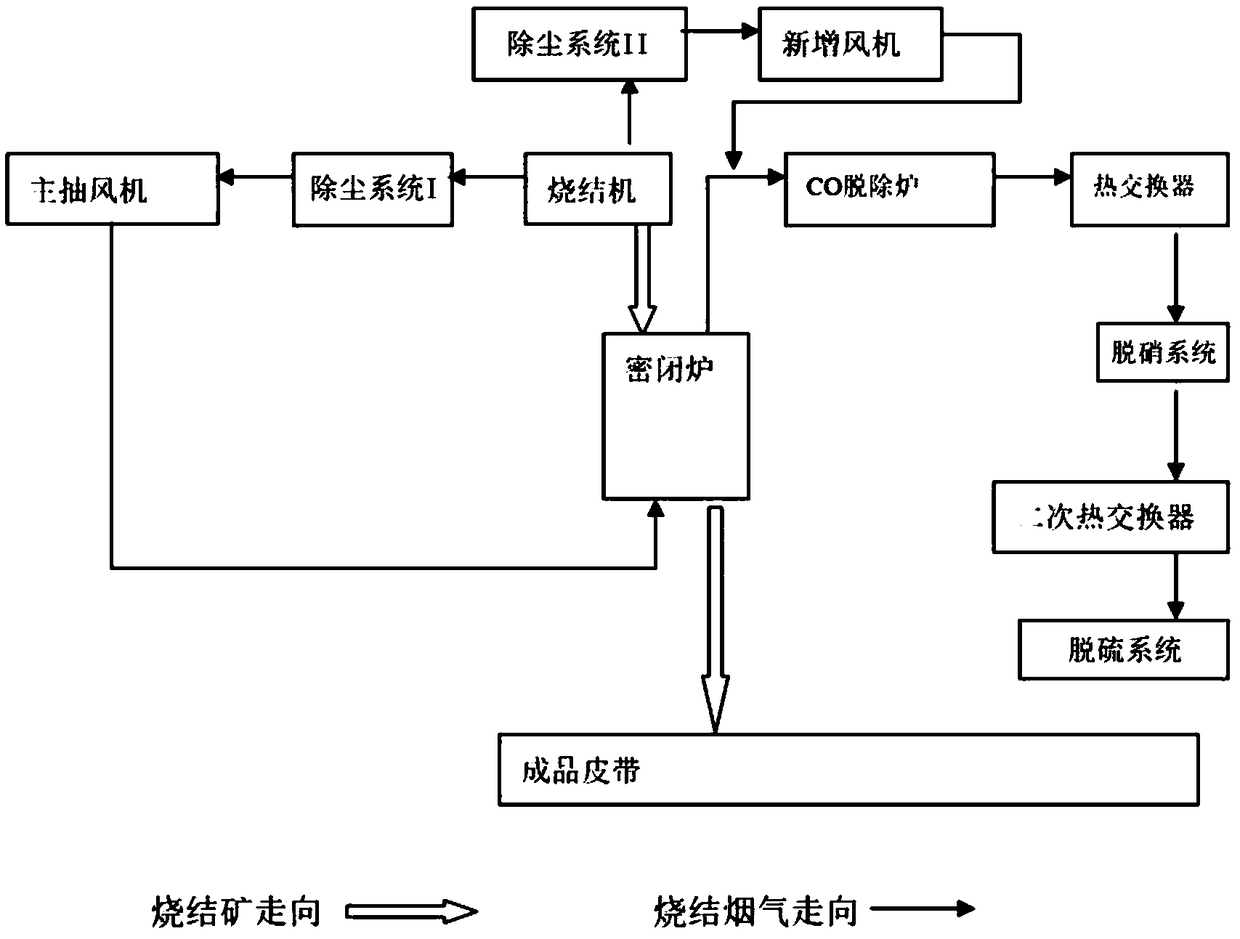

Sinter waste heat and sintering flue gas pollutant cooperative treatment process

InactiveCN108692579AHigh recovery rateSolve the problem that the temperature is low and cannot be recycledWaste heat treatmentParticulatesFlue gas

The invention relates to a sinter waste heat and sintering flue gas pollutant cooperative treatment process. The treatment process comprises the steps that sintering flue gas generated by metallurgy sintering is subjected to dedusting treatment to remove particulate matters to be then subjected to heat exchange treatment with sinter generated by metallurgy sintering, and at least part of CO in thesintering flue gas is oxidized and removed during heat exchange treatment; and the sintering flue gas is subjected to CO desorption treatment, and at least part of CO in the sintering flue gas is oxidized and removed during CO desorption treatment. According to the arrangement conditions of a sintering machine and a gas desulfurization system at present, the sintering flue gas can adopt the technology that SO2 is firstly or lastly desorbed. The cooperative treatment process solves the problems about CO desorption and utilization, and cooperative treatment of sinter waste heat and sintering flue gas pollutant is achieved.

Owner:杨清海

Method for removing dust and ion with non-dust cloth

ActiveCN101787642AEfficient removalSolve the removal problemPhysical treatmentDry-cleaning apparatus for textilesFiberRoom temperature

The invention discloses a method for removing dust and ions with non-dust cloth, which comprises the following steps: 1) preparing hot pure water of 50-100 DEG C and 16-18.2M Omega; 2) placing the non-dust cloth into the hot pure water for 30-60 minutes with the bath ratio of 1:10-1:40; 3) rinsing for once with room-temperature pure water of 16-18M Omega with the bath ratio of 1:10; 4) cleaning for three times at the room temperature with the bath ratio of 1:40 and then carrying out high-speed drying for three times; and 5) transferring the non-dust cloth after being cleaned to a drying box, thereby completing the flow of removing dust and ions. Due to the adoption of the heat extraction cleaning method, the invention effectively solves the problem of removing the contaminating ions on the ultra-fine fiber non-dust cloth, and can effectively remove contaminating particles and relevant ions on the surface of the non-dust cloth, and protect the cleanness and safety of relevant equipment to the largest extent. Compared with the traditional cleaning method, the method has the advantages of simple operation, high decontamination capability and low cost.

Owner:GUANGDONG SUOREC TECH

Cotton quilt filling cleaner

InactiveCN103603177ASolving Wet Dry ProblemsSolve the removal problemMechanical cleaningPressure cleaningInterior spaceAir filter

A cotton quilt filling cleaner comprises a wind screen machine, a cotton quilt lifting system, a motion module, a machine case rack, a fan, a lead screw motor and a dust collector, wherein the wind screen machine is installed on the top of the machine case rack and used for heating air; the fan is provided with an air filter, installed on the side face on the lower portion of the machine case rack and used as a channel of the air inside and outside the machine case rack; a sliding door is installed on the front side of the machine case rack and used for opening the inner space of the machine case rack; the cotton quilt lifting system and the motion module are installed on the top of the inner side of the machine case rack; the lead screw motor is installed in the machine case rack and used for driving the motion module; a cotton quilt filling is fixedly connected to the cotton quilt lifting system in an attached mode, thereby being capable of being driven by the cotton quilt lifting system to ascend and descend.

Owner:SHANGHAI DIANJI UNIV

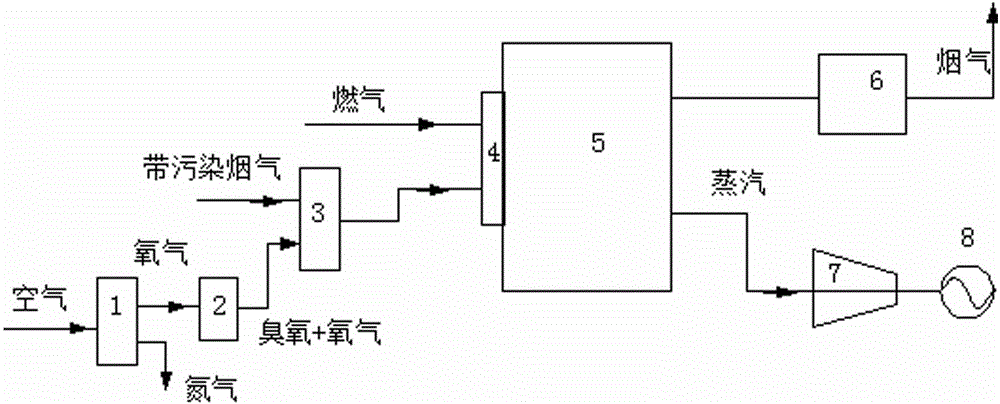

System capable of cooperatively removing multiple contaminants in smoke in ozone type high temperature flame device

InactiveCN104819457AImprove reliabilityPracticalSolid fuel combustionIndirect carbon-dioxide mitigationOxidation stateOxygen

The invention discloses a system capable of cooperatively removing multiple contaminants in smoke in an ozone type high temperature flame device, and belongs to the technical field of smoke pollution treatment. The system is mainly characterized in that strong oxidizing property of ozone in ozone type high temperature flames and high-temperature flames generated by combustion cooperatively remove the multiple contaminants in the pollution smoke. The system comprises an oxygen producing device, an ozone generator, a gas mixer, a combustor, a combustion device and a pollution removing device. The ozone type high temperature flames generated by combustion are utilized for oxidizing and decomposing the multiple components in the pollution smoke in the combustion process, SO2, NO, and Hg in the oxidized smoke are in high oxidation states, VOCs and dioxin are decomposed, finally, an alkalinity absorbent absorbs SO3 / NOx, and the multiple contaminants in the smoke are thoroughly removed.

Owner:SHANXI UNIV

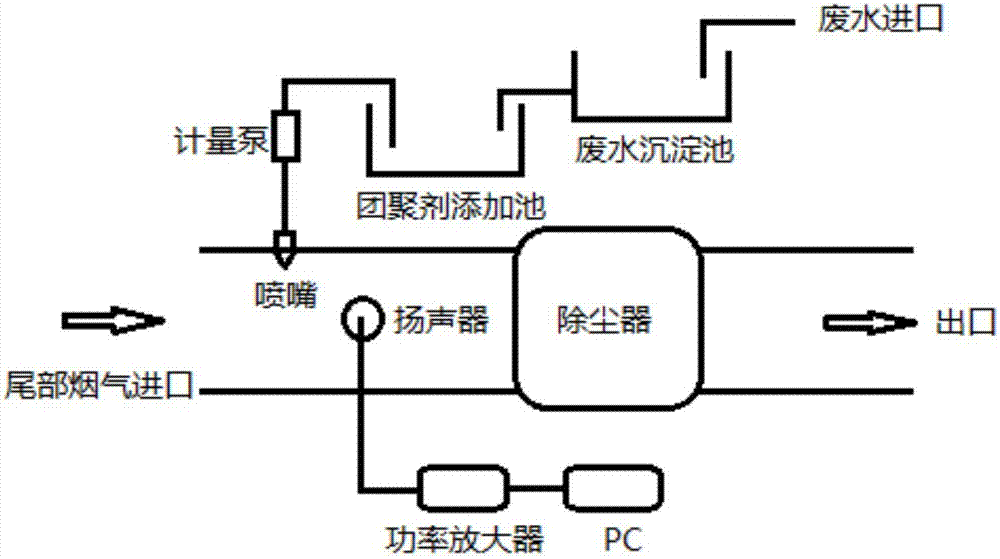

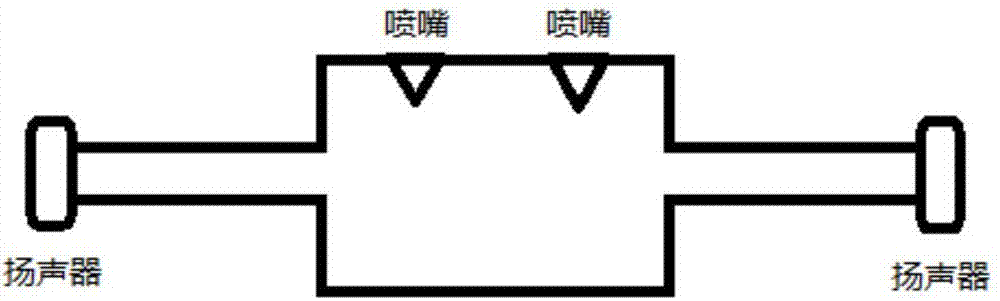

Method of removing small particulate matters in coal-fired flue gas by combining chemical agglomeration with acoustic agglomeration

The invention discloses a method of removing small particulate matters in coal-fired flue gas by combining chemical agglomeration with acoustic agglomeration to solve the problem that conventional dedusting equipment is hard to remove small particulate matters in flue gas for zero emission of desulfurization and denitrification wastewater in a coal-fired power plant. The method comprises the following steps: taking the supernate after the desulfurization and denitrification wastewater of the power plant is treated; adding a high polymer adhesive and a surfactant to prepare a chemical agglomerant; spraying the chemical agglomerant into a flue in front of a dedustor through an atomizing nozzle; adding a low-frequency sound field, wherein the small particulate matters of the coal-fired power plant are agglomerated under the combined action of chemistry and sound waves; and finally, removing the agglomerated particulate matters through a conventional dedustor. In a proper condition, 70% of the small particular matters which are smaller than 10 [mu]m can grow to 10[mu] or above through agglomeration. Therefore, the problem of zero emission of the wastewater is solved, and the problem of removal of small particulate matters in coal-fired flue gas is solved. The method has a wide application prospect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

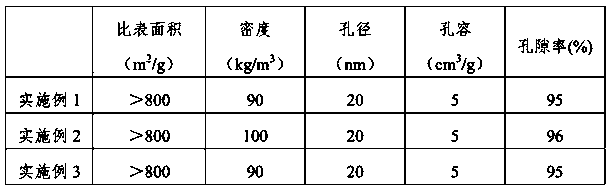

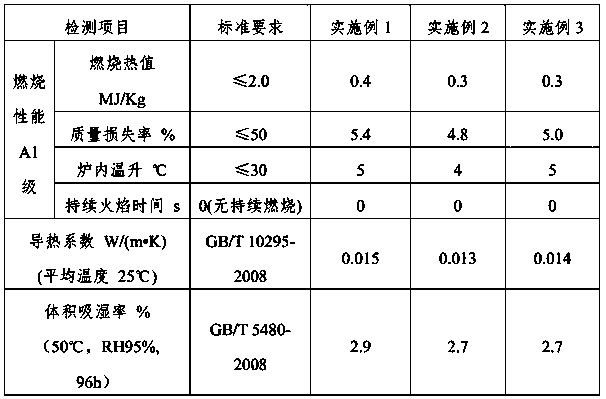

Method for preparing aerogel composite thermal insulation felt through normal pressure drying

The invention relates to a method for preparing an aerogel composite thermal insulation felt through normal pressure drying. The specific steps comprise: uniformly mixing a silicon source and deionized water to obtain a silicon-containing solution, uniformly mixing the silicon-containing solution, ethanol and an acidic catalyst, and stirring to obtain a sol; placing a composite material in a container, injecting the sol into the container loaded with the composite material, heating, and carrying out thermal insulation so as to wait gelation; placing the gel composite body obtained after the gelation into an acid alcoholization solution obtained by mixing anhydrous ethanol and sulfuric acid, heating, and carrying out thermal insulation; placing the gel composite body into a modified solution obtained by mixing a hydrophobic modifier and a solvent; and carrying out normal pressure drying on the modified gel composite body to obtain the aerogel composite thermal insulation felt material.According to the present invention, the technical scheme has advantages of low cost, less steps, less gel impurities, less energy consumption, simple equipment operation, and simple equipment maintenance.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Polluted air purifying system and work method thereof

ActiveCN104084015AEfficient purificationMultiple interestsDispersed particle separationChemical reactionExhaust fumes

The invention provides a polluted air purifying system and a work method thereof. The system has an advanced filter system to eliminate toxic emissions in exhaust gas. A new technology is used to capture toxic substances emitted from a pollution source or a chimney of a fire coal boiler, a nano-technology and advanced chemical reactions are used to remove pollutants in the exhaust gas, and principles of the interaction between the gas and a liquid and the interaction between the gas and a solid are applied, so a clean gas is finally emitted, and sulfuric acid and nitric acid generated in the above reaction process are recovered to make a filtering recovery system become beneficial circulation. The polluted air purifying system has a low cost, and benefits for popularized use.

Owner:林小晓 +1

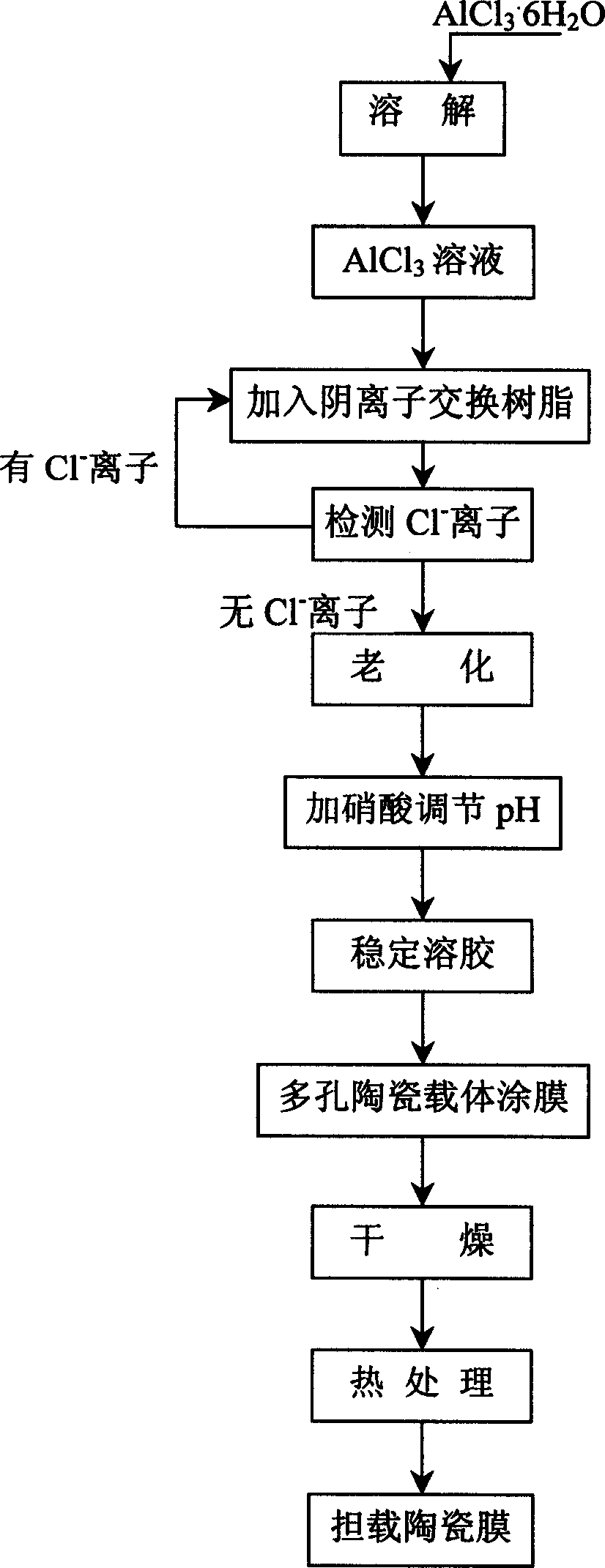

Method for preparing alumina ceramic membrance by ion exchange

InactiveCN1709559ANarrow pore size distributionLarge specific surface areaSemi-permeable membranesIon exchangeIon

The present invention relates to ion exchange method to make alumina pottery membrane. The step is: Confect AlCl3. 6H2O liquid, add anion exchange colophony step by step at room temperature magnetic force mixed; Check the Cl ion in the mixing process until all Cl ions eliminated; Getted sol is aging in hot water; adjust the PH value by nitric acid. Circumfluence and get clear aluminum sol; Mixing sol and PVA liquid, plating, drying, roasting and improve temperature and keep it; We get the complete Al2O3 membrane when the temperature of backstop decreases to room temperature. The present invention can eliminate Cl ions and get stable sol. The pottery membrane is complete, aperture is narrow and surface area is large. The membrane can be used for the filter of chemical plant, food, medicine and environment and used in katalyze reaction.

Owner:NANJING UNIV OF SCI & TECH

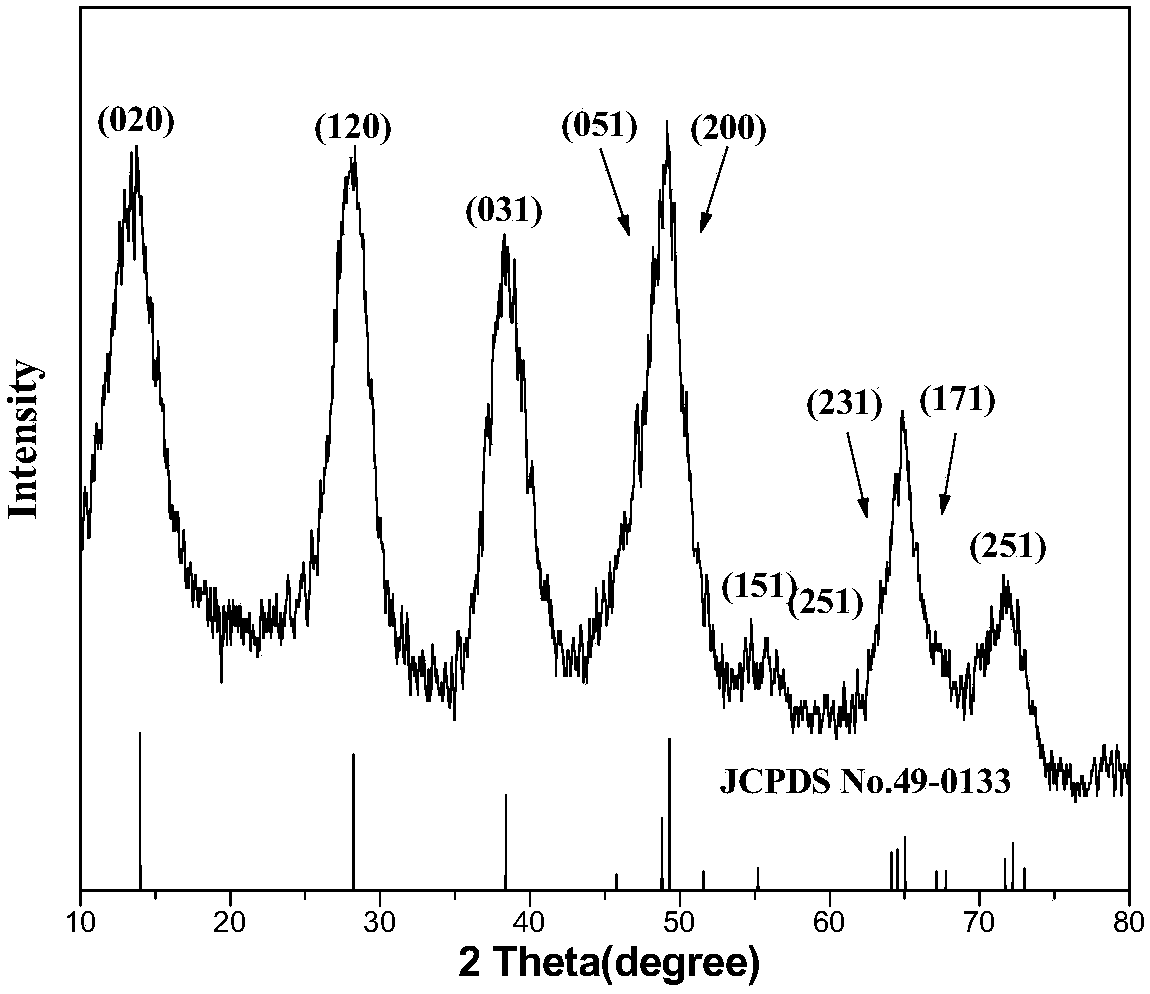

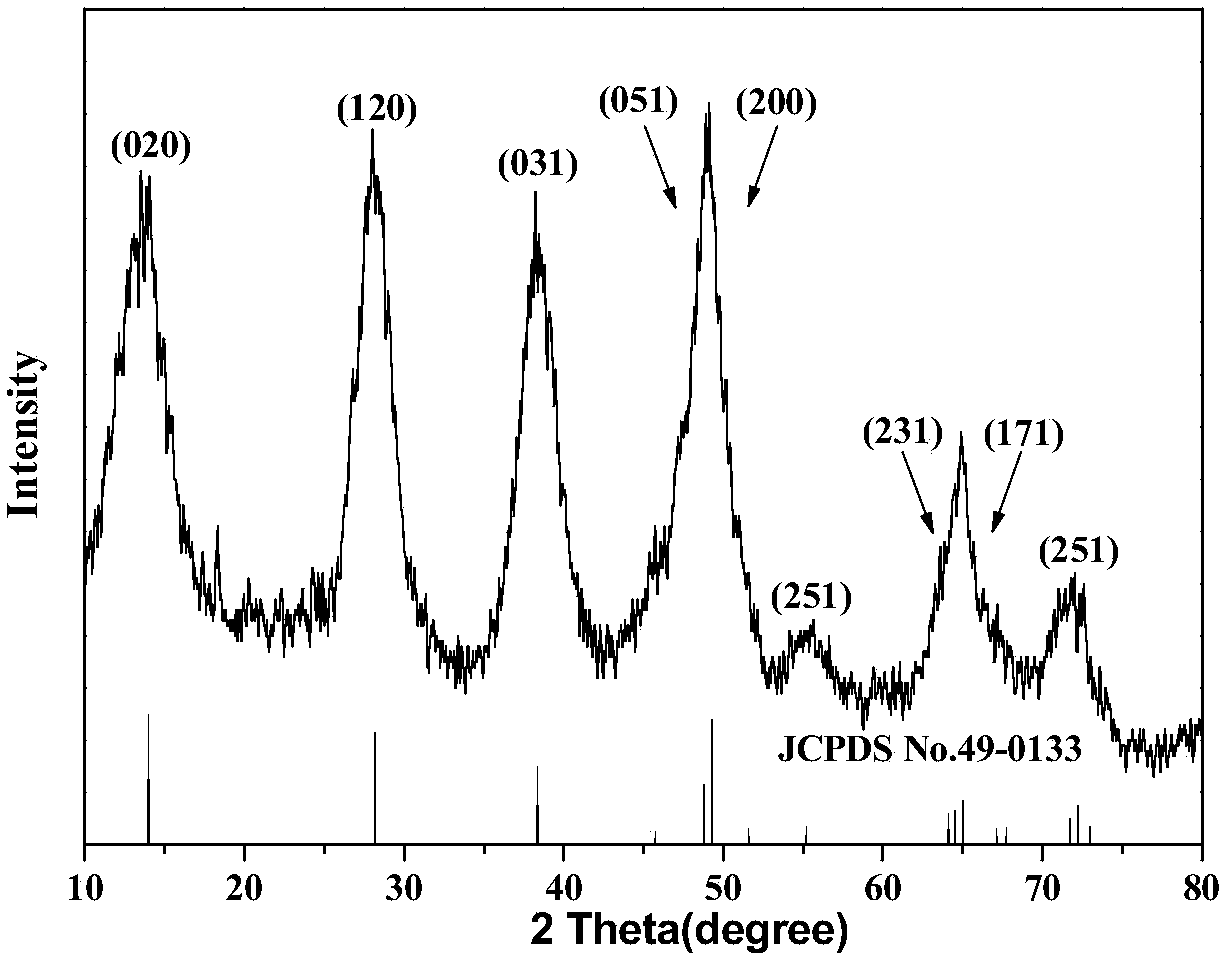

Method for preparing nano gamma-AlOOH by utilizing sodium metaaluminate solution

InactiveCN108383143AMild reaction conditionsLower requirementNanotechnologyAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHydrogenNanometre

The invention provides a method for preparing nano gamma-AlOOH by utilizing a sodium metaaluminate solution and belongs to the field of inorganic nano-materials. The method comprises the following steps: 1) controlling the temperature of the sodium metaaluminate solution to be 15 to 30 DEG C; then adding a hydrogen peroxide solution into the sodium metaaluminate solution; after sufficiently reacting, collecting solid product in a reaction solution; 2) washing the solid product until the pH (Potential of Hydrogen) of a product suspension solution is 6.8 to 7.2; 3) filtering the product suspension solution in vacuum and drying a solid to prepare the nano gamma-AlOOH. The nano gamma-AlOOH prepared by the method is orthorhombic system AlOOH with the grain diameter of 70 to 200nm and is of a laminated structure; when a lot of the nano gamma-AlOOH is gathered, a plate sheet structure, which is distributed in layers, is formed.

Owner:SHENYANG AEROSPACE UNIVERSITY

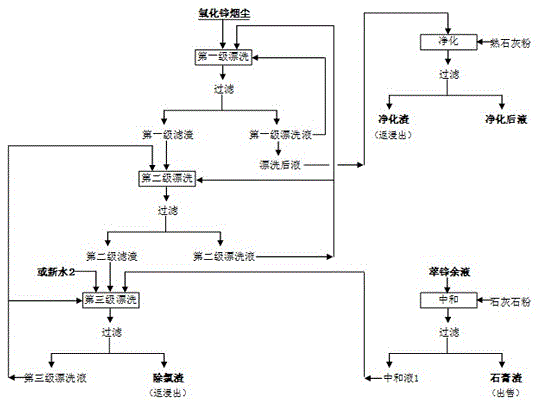

Multi-level countercurrent continuous rinsing and chlorine removing technology and device for zinc oxide smoke

ActiveCN105483362ARealize reverse flowEnsure balanceProcess efficiency improvementHydrometallurgyMetal salts

The invention discloses a multi-level countercurrent continuous rinsing and chlorine removing technology and device for zinc oxide smoke. Raw materials are chlorine containing zinc oxide smoke. The technology comprises the steps that neutralizing, rinsing and purifying are carried out; free acid in zinc extraction residual liquid of an extraction-electrodeposition method is neutralized through limestone flour; zinc oxide smoke rich in chlorine is rinsed through neutralized liquid; and zinc ions are deposited through slaked lime powder via rinsed liquid, zinc oxide residues subjected to chlorine removing are rinsed, and the chlorine residues are removed. According to the technology and device, reverse circulation of solid materials and liquid materials is achieved, a water-soluble compound in the solid materials can be deeply removed, and the problem of removing of a water-soluble chlorine fluorine compound in the zinc oxide smoke raw materials during zinc hydrometallurgy is solved. Meanwhile, the technology and device are suitable for rinsing and recycling of soluble valuable metal salt in various hydrometallurgy residues, and material balance, size balance and concentration balance in a multi-level countercurrent rinsing device system can be guaranteed; and it can also be guaranteed that chemical components of generated rinsed residues and the rinsed liquid are stable, and linkage with a next procedure is facilitated.

Owner:江西自立环保科技有限公司

Device for filtering impurities in the extruding process of PVC resin

The invention discloses a device for filtering in the extruding process of PVC resin. The device is arranged between a connection body of an extruding machine and a die head and has compact structure,small volume and convenient installation and disassembly; the internal diameters of a molten material passage of the device and the connection body of the extruding machine are the same, the molten material passage is a straight flow passage without an internal cavity, and a net exchange piston which is controlled by a hydraulic device and can move up and down is cylindrical; and two passages arearranged on the piston, wherein one passage is provided with a porous plate, and the other passage is a straight flow passage. The invention does not have the hiding dead angle of the PVC molten material, reduces the accumulation of impurities and scorched materials, removes a little small particles which exist in the molten material and are difficult to plasticize, avoids the phenomena of blackspots, fish eyes and the like existing at the surface of a product, and enhances the performance of the product, especially the performance of the products, such as PVC threading tubes and the like, which need to be processed by cold bending.

Owner:LIANSU TECH DEV WUHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com