Multifunctional self-propelled potato combined harvester

A combine harvester and self-propelled technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of starch processing quality or variety selection, inconvenience, trouble, and lack of reliable mechanisms for fresh food packaging. , to achieve the effect of improving the cleaning rate, quick bag change, and increasing friction and pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

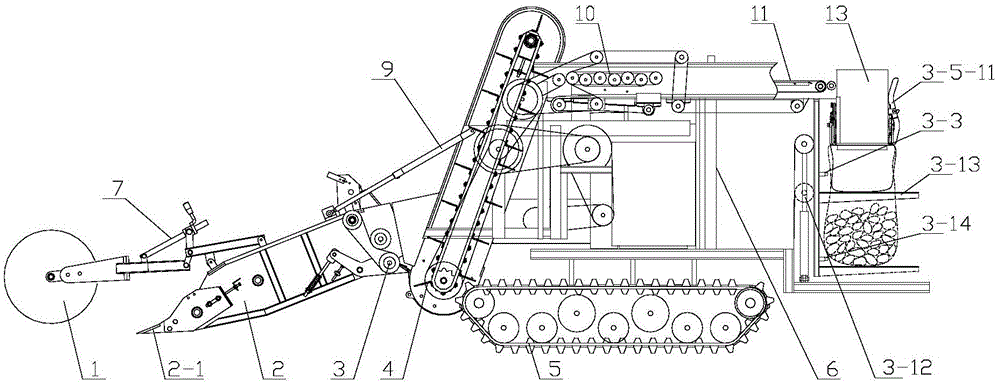

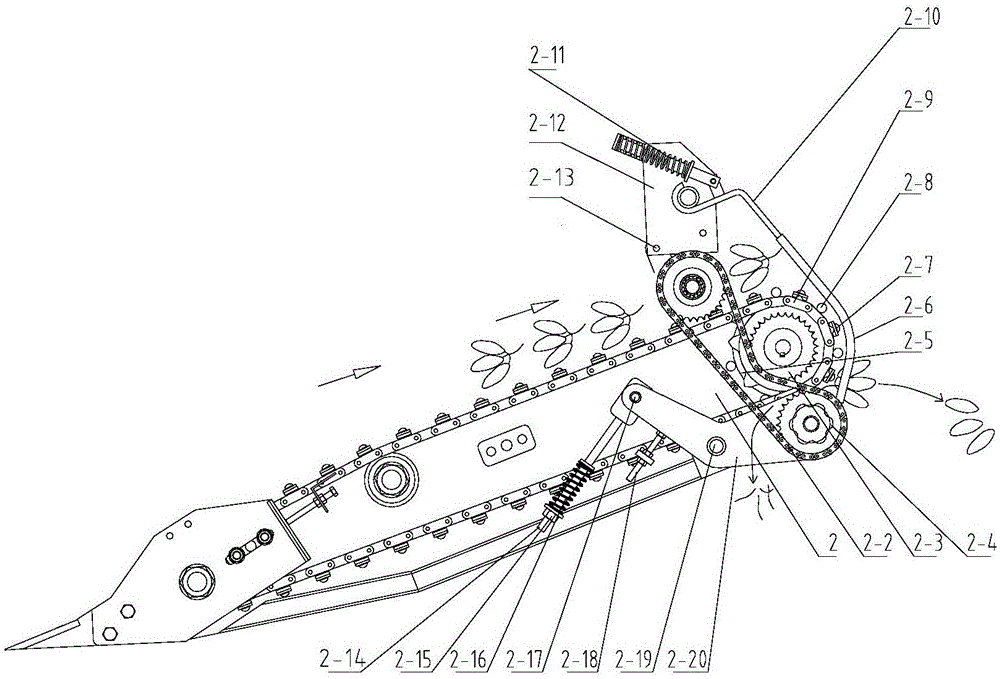

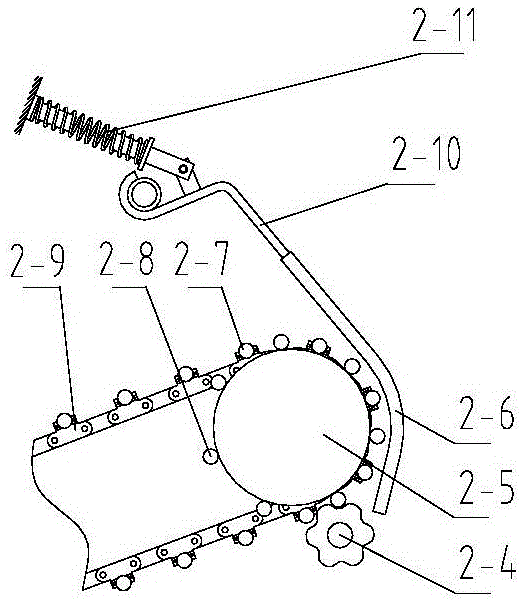

[0033] The basic structure of the multifunctional self-propelled potato combine harvester of the present embodiment is as follows: figure 1 As shown, the main frame 6 is supported on the walking chassis 5, and the front lower part of the main frame 6 is installed with the excavating conveying device 2 protruding forward and installing the excavating shovel 2-1. The front of the excavating conveying device 2 is equipped with a depth-limiting roller 1 through a hinged bracket with an adjusting screw 7, and the output end of the excavating conveying device 2 is connected to the lower part of the rod-plate elevator 4 arranged on the front side of the main frame 6 through a hinged structure. It is hinged with the piston rod of the hydraulic cylinder 9, and the cylinder body of the hydraulic cylinder 9 is hinged on the front side of the main frame 6, so the hydraulic cylinder 9 can be controlled to adjust the excavation inclination angle of the excavating conveying device 2. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com