Device for filtering impurities in the extruding process of PVC resin

A PVC resin and impurity filtration technology, applied in the field of plastic extrusion molding, can solve the problems of multiple wastes, clogging and accumulation of miscellaneous materials, etc., to reduce the generation of waste, improve product performance and finished product qualification rate, and avoid frequent shutdowns to clean impurities the effect of the cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

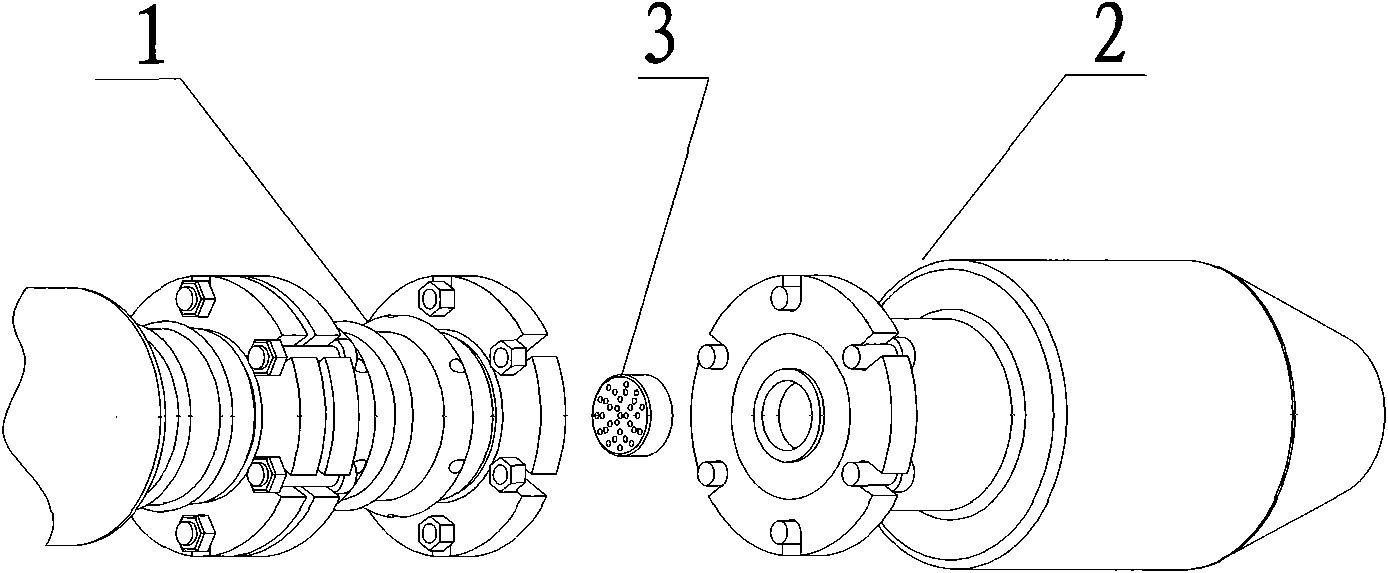

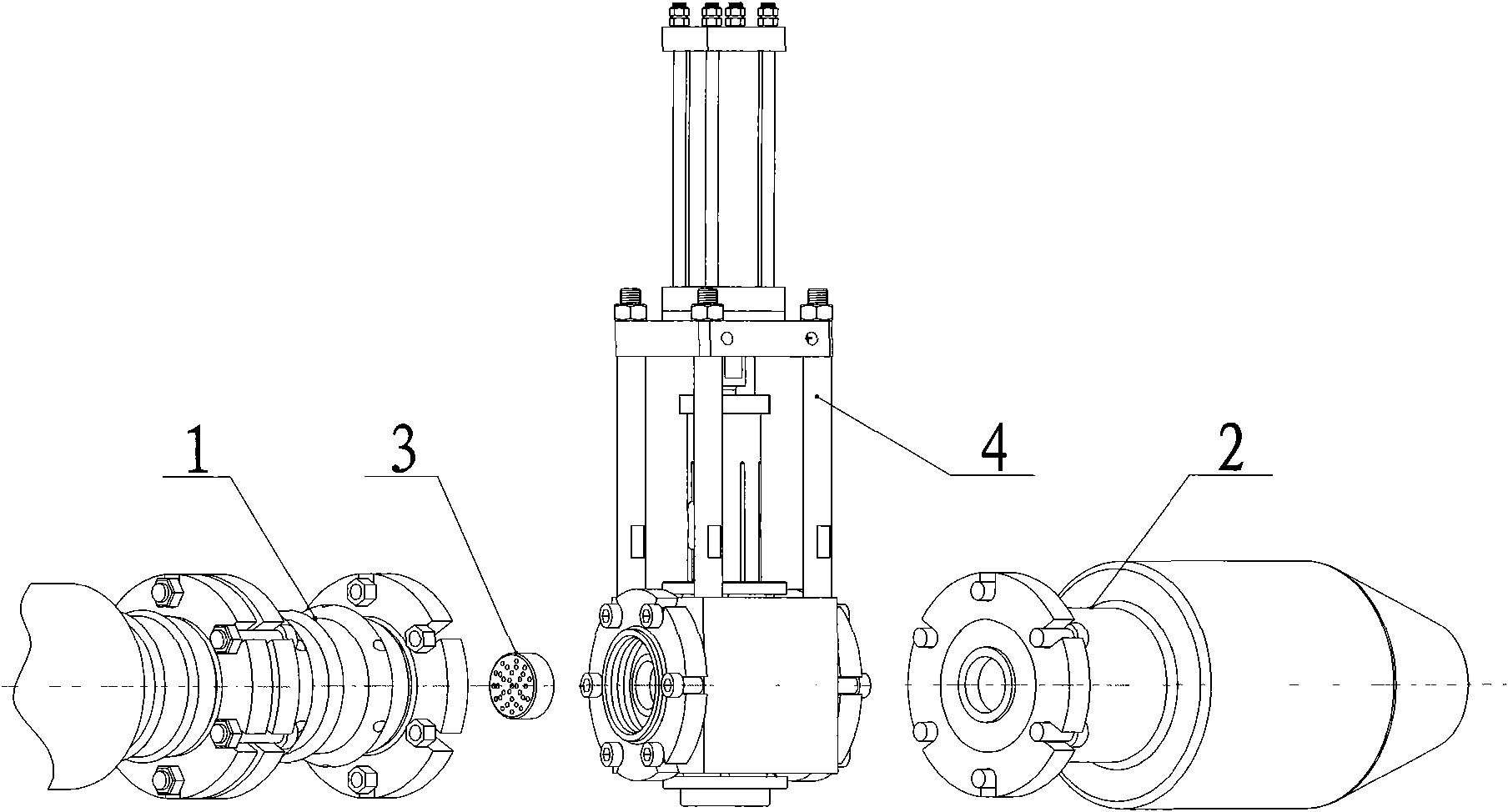

[0015] figure 2 It is a PVC-specific impurity filter device and its installation schematic diagram. A PVC resin extrusion processing impurity filter device 4 is placed between the extruder connector 1 and the die head 2, including the extruder connector 1 and the extruder die head 2. , perforated plate 3, also be provided with filtering device 4 between extruder connecting body 1 and extruder die head 2, described filtering device 4 is provided with at least two can be connected with extruder connecting body 1 and extruder The molten material channel connected to the die head 2, the perforated plate 3 is arranged in one of the molten material channels, and the filter device 4 is also provided with a device that can alternately rotate the molten material channel to connect with the extruder connecting body 1 and the extruder die head. 2 connected drives.

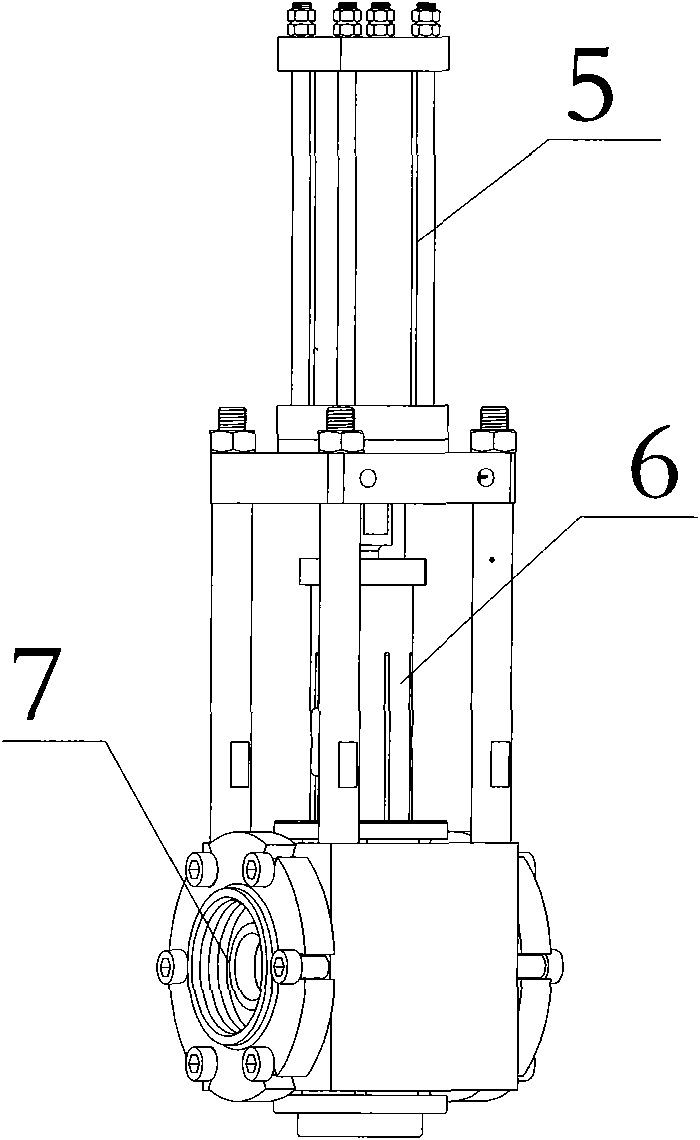

[0016] The screen changing piston 6 as a whole is a cylindrical structure that can move up and down. The cylindrical pist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com