Method for preparing aerogel composite thermal insulation felt through normal pressure drying

A technology of atmospheric pressure drying and composite heat preservation, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of cumbersome graded replacement process, sodium salt impurity residue, energy waste, etc., to reduce the process flow and reduce organic Solvent loss, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

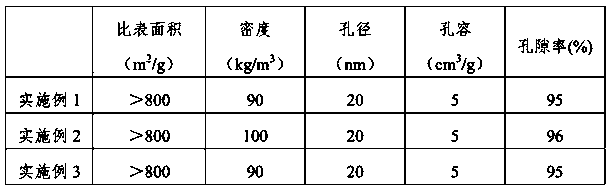

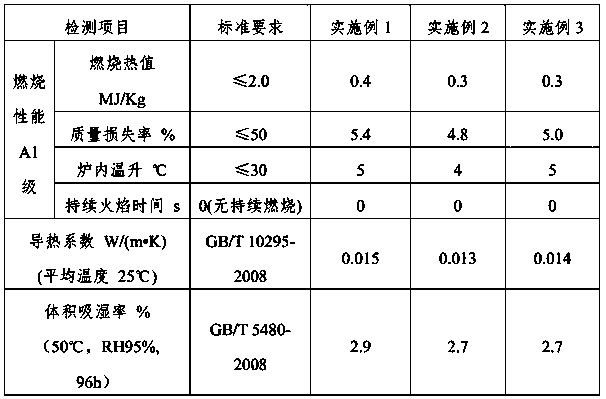

Embodiment 1

[0061] Place 45m long, 1.2m wide, and 10mm thick glass fiber mats in the form of rolls in a suitable container, take water glass and deionized water and mix them uniformly at a volume ratio of 1:2 to obtain a silicon-containing solution, and mix the silicon-containing solution with Add ethanol and 1 mol / L sulfuric acid solution into a stirring tank at a volume ratio of 3:1:2 and mix evenly. After stirring for 30 min, pour the sol into a container where glass fiber felt is placed, and keep it warm at 40°C for 6 hours until it gels. After gelling, put the glass fiber mat and gel complex as a whole into the acid alcoholization solution, the amount of the acid alcoholization solution is at least less than the glass fiber mat and the gel complex as a whole, keep warm at 60°C, and the acid alcoholization solution is mixed with 40% sulfuric acid solution Prepare with absolute ethanol at a volume ratio of 1:8. After 6 hours, put the glass fiber mat and gel composite into a mixed soluti...

Embodiment 2

[0063] Place 45m long, 1.5m wide, and 10mm thick glass fiber mats in the form of rolls in a suitable container, take water glass and deionized water and mix them uniformly at a volume ratio of 1:1 to obtain a silicon-containing solution, and mix the silicon-containing solution with Add ethanol and 1 mol / L sulfuric acid solution into a stirring tank at a volume ratio of 1:1:1 and mix evenly. After stirring for 30 min, pour the sol into a container with glass fiber mats and keep it warm at 60°C for 6 h until it gels. After gelling, put the glass fiber mat and gel complex as a whole into the acid alcoholization solution, the amount of the acid alcoholization solution is at least less than the glass fiber mat and the gel complex as a whole, keep warm at 60°C, and the acid alcoholization solution is mixed with 40% sulfuric acid solution Prepare with absolute ethanol at a volume ratio of 1:4. After 6 hours, put the glass fiber mat and gel composite into a mixed solution containing he...

Embodiment 3

[0065] Place a 45m long, 1.5m wide, 10mm thick glass fiber mat in the form of a roll in a suitable container, take tetraethyl orthosilicate and deionized water and mix them uniformly at a volume ratio of 1:1 to obtain a silicon-containing solution. Add the silicon-containing solution, ethanol, and 1 mol / L sulfuric acid solution into the mixing tank at a volume ratio of 1:1:1 and mix evenly. After stirring for 30 minutes, pour the sol into the container where the glass fiber mat is placed, and keep it warm at 60°C for 6 hours. glue. After gelling, put the glass fiber mat and gel complex as a whole into the acid alcoholization solution, the amount of the acid alcoholization solution is at least less than the glass fiber mat and the gel complex as a whole, keep warm at 60°C, and the acid alcoholization solution is mixed with 40% sulfuric acid solution Prepare with absolute ethanol at a volume ratio of 1:4. After 6 hours, put the glass fiber mat and gel composite into a mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com