Patents

Literature

148results about How to "Multiple interests" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SO file protection method and device and android installation package reinforcement method and system

InactiveCN104392181ARealize multiple protectionRealize hardened protectionDigital data protectionSoftware engineeringSecurity level

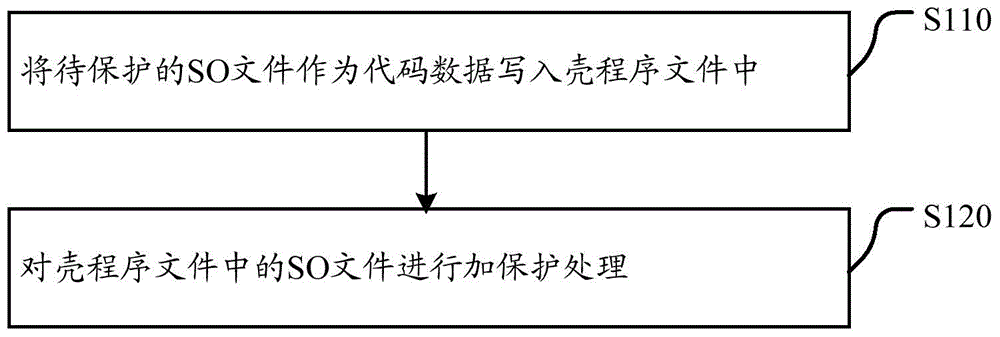

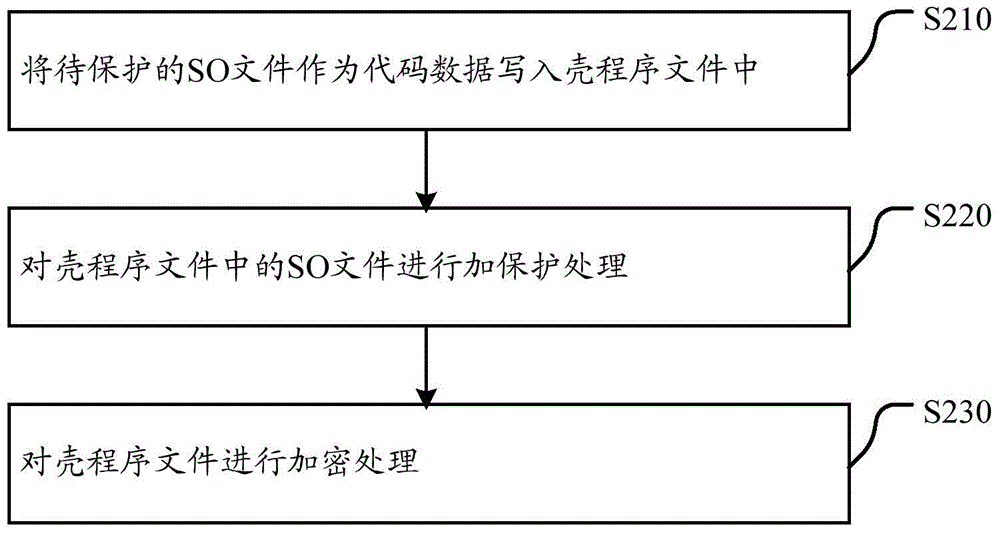

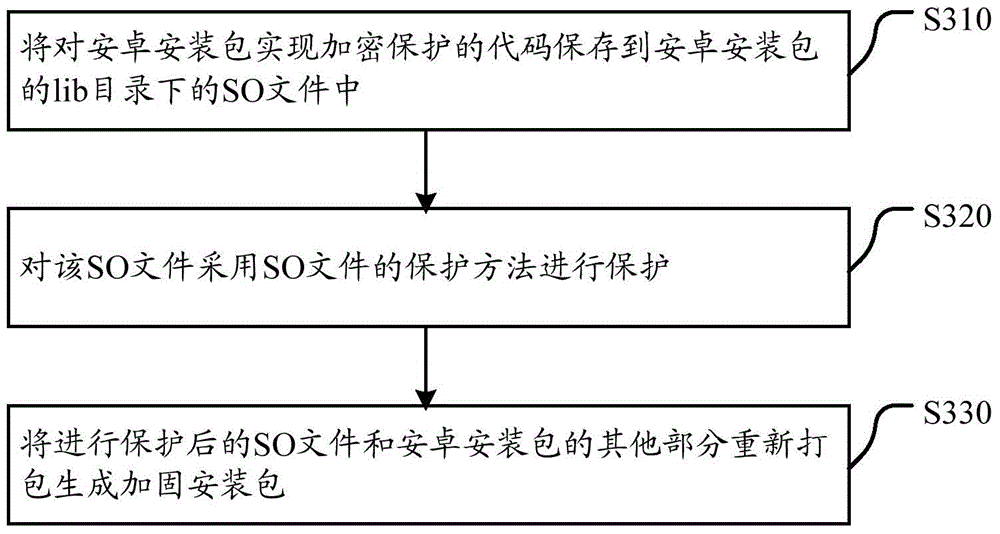

The invention discloses an SO file protection method and device and an android installation package reinforcement method and system. The SO file protection method includes the steps of writing a to-be-protected SO file in a shell procedure file as code data, and protecting the SO file in the shell procedure. According to the technical scheme, by adding a shell to the SO file and protecting the SO file, the multiple protection is achieved for the SO file, an important code of an android installation package is further stored in the SO file, the reinforcement protection is achieved for the android installation package with the protected SO file as a protection object, malicious programs can be effectively prevented from conducting disassembling analysis on the SO file, the security level of the content of the SO file is improved, and the safety level of the android installation package is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

Intelligent community integrated interconnected system

InactiveCN101826894AImprove intelligenceImprove network usagePower distribution line transmissionData switching by path configurationElectricityThe Internet

The invention discloses an intelligent community integrated interconnected system, which comprises an intelligent community integrated interconnected system server, a water-electricity-gas temperature measuring and managing center computer, an alarming joint-defense remote managing center computer, an expandable remote managing computer, a community property management interconnected system, a building interconnected system and an internet, wherein the community property management interconnected system comprises a community property management center, a firefighting and alarming interlockingmodule and a community broadcasting advertising subsystem which is connected with the community property management center; and the building interconnected system comprises a plurality of door control subsystems, a plurality of user terminal machines, and a building talkback module, a control module, a remote controller, a camera and a meter reading data collection layer, which are connected withthe user terminal machines, and the meter reading data collection layer is also connected with a meter reading signal conversion layer; and the internet is connected with all devices. The intelligentcommunity integrated interconnected system can really realize a real and comprehensive intelligent community integrated interconnected system.

Owner:深圳市鼎盛威电子有限公司

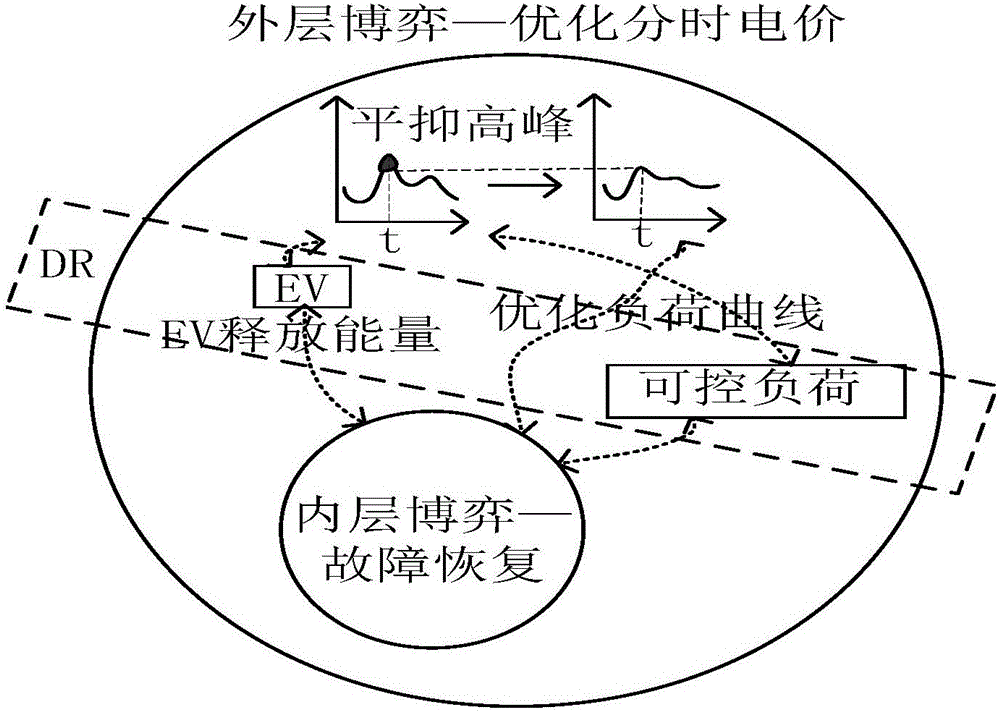

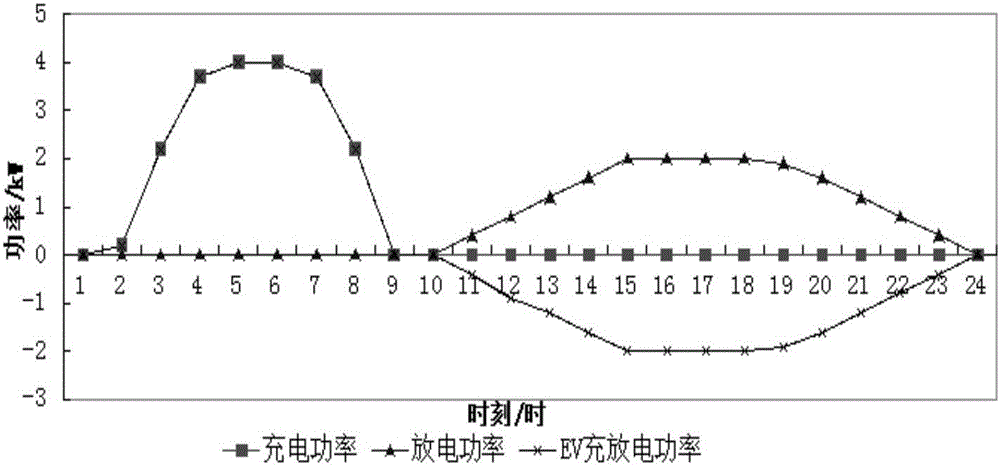

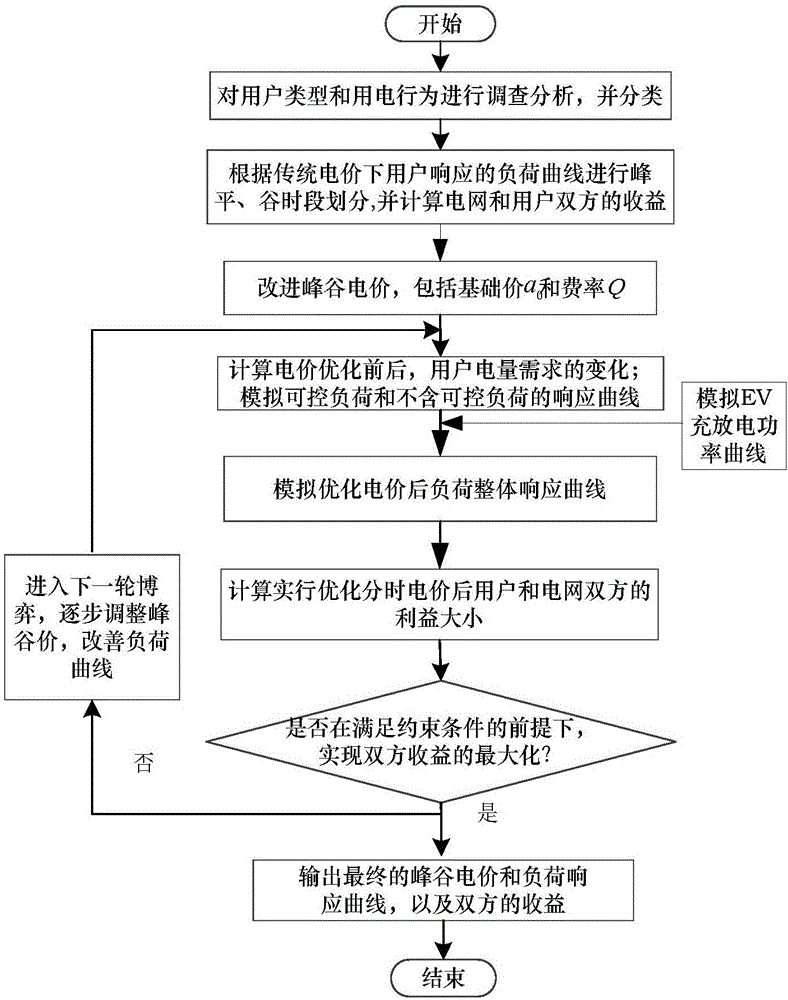

Active distribution network failure recovery strategy considering inside and outside games

ActiveCN106684869AOptimizing Load ProfilesRelieve pressurePower network operation systems integrationContigency dealing ac circuit arrangementsAnt colonyPower grid

The invention discloses an active distribution network failure recovery strategy considering inside and outside games. A failure recovery model considering the inside and outside double games is established through taking balance of interests of supply and requisitioning parties in a recovery process as the principle. In the outside game, an optimized time-of-use price is made through the game between a power grid and a user, so that the load peak is suppressed to reduce the pressure of recovery at the load peak. A dynamic game is solved through adoption of an inverse regression algorithm; in the inside game, collaborative recovery is carried out on an electric car, a distributed power supply and a controllable load based on an optimized load curve in order to realize maximum community of interest of the power grid and the user in the failure recovery. A modified ant colony algorithm is called to solve a failure recovery problem, and then each recovery scheme is taken as a game participant to transformer the failure recovery problem into a problem of the game between multiple recovery schemes. The power losses and the lowest node voltage value are taken as evaluation indexes, and the optimized scheme, namely a Nash equilibrium solution, is obtained through the games.

Owner:YANSHAN UNIV

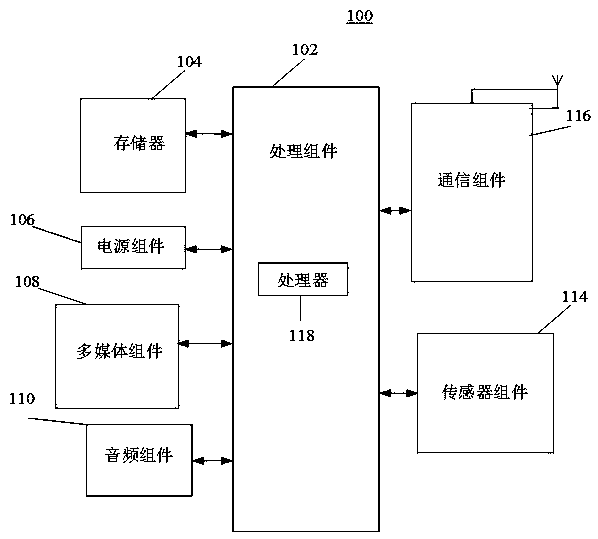

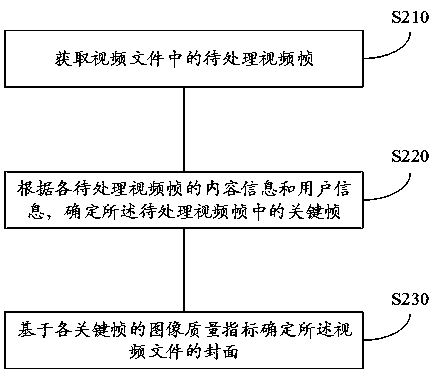

Method and device for generating video cover, electronic equipment and computer readable storage medium

InactiveCN109996091AAttract attentionImprove experienceSelective content distributionImaging qualityComputer science

The invention discloses a method and device for generating a video cover, electronic equipment and a computer readable storage medium. The method for generating the video cover comprises the steps ofobtaining a to-be-processed video frame in a video file; according to the content information and the user information of each to-be-processed video frame, determining a key frame in the to-be-processed video frame; and determining the cover of the video file based on the image quality index of each key frame. According to the technical scheme provided by the embodiment of the invention, the coverwhich is high in relevancy with the video content, conforms to user preferences and is good in quality can be automatically generated for the video.

Owner:苏州八叉树智能科技有限公司

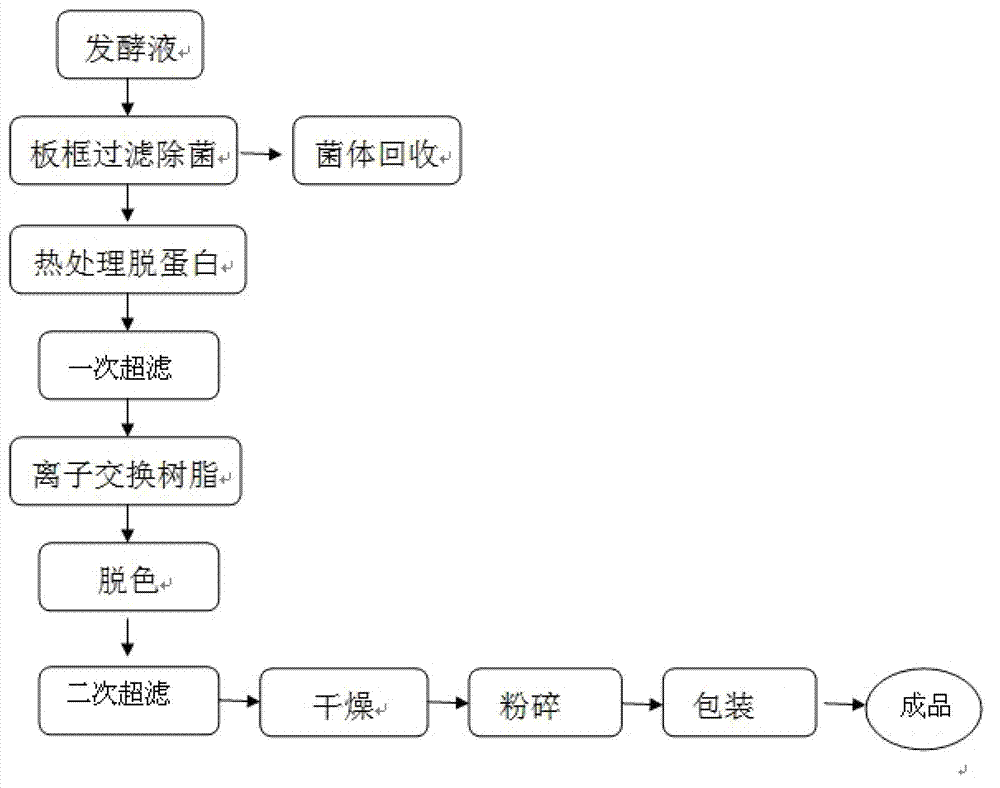

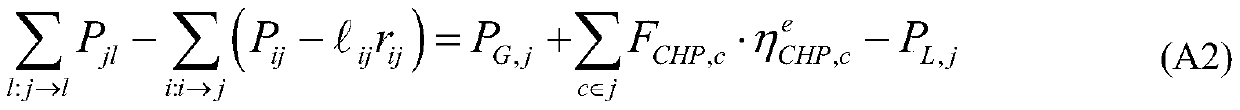

Extracting process of pulullan polysaccharide

The invention discloses an extracting process of pulullan polysaccharide and belongs to the technical field of biology. The extracting process mainly comprises the following steps of: (1), filtering by a plate frame to remove bacteria; (2), performing thermal treatment to remove protein; (3), carrying out primary ultra-filtration; (4), removing ion by use of ion exchange resin; (5), discoloring active carbon; (6), carrying out secondary ultra-filtration; and (7), drying, crushing and packaging. According to the extracting process of the pulullan polysaccharide disclosed by the invention, the bacteria in fermentation liquor are removed by adopting a plate frame filter, so that not only can solvent residue caused by adding an organic flocculating agent and inorganic flocculating agent be effectively avoided, but also the bacteria and diatomite can be recycled to obtain more benefits; meanwhile, potential unsafe factors caused by volatility of solvents (ethanol, methyl alcohol, isopropanol and the like) in the conventional process can be avoided by adopting a microwave drying process or a vacuum drying process; moreover, much steam consumed by recycling and distilling an organic solvent can be saved; the production cost is saved; the product yield can be up to 90%-96%, the purity is as high as 90%-98%, the quality is good, and the production process is safe, continuous and automatic.

Owner:天津慧智百川生物工程有限公司

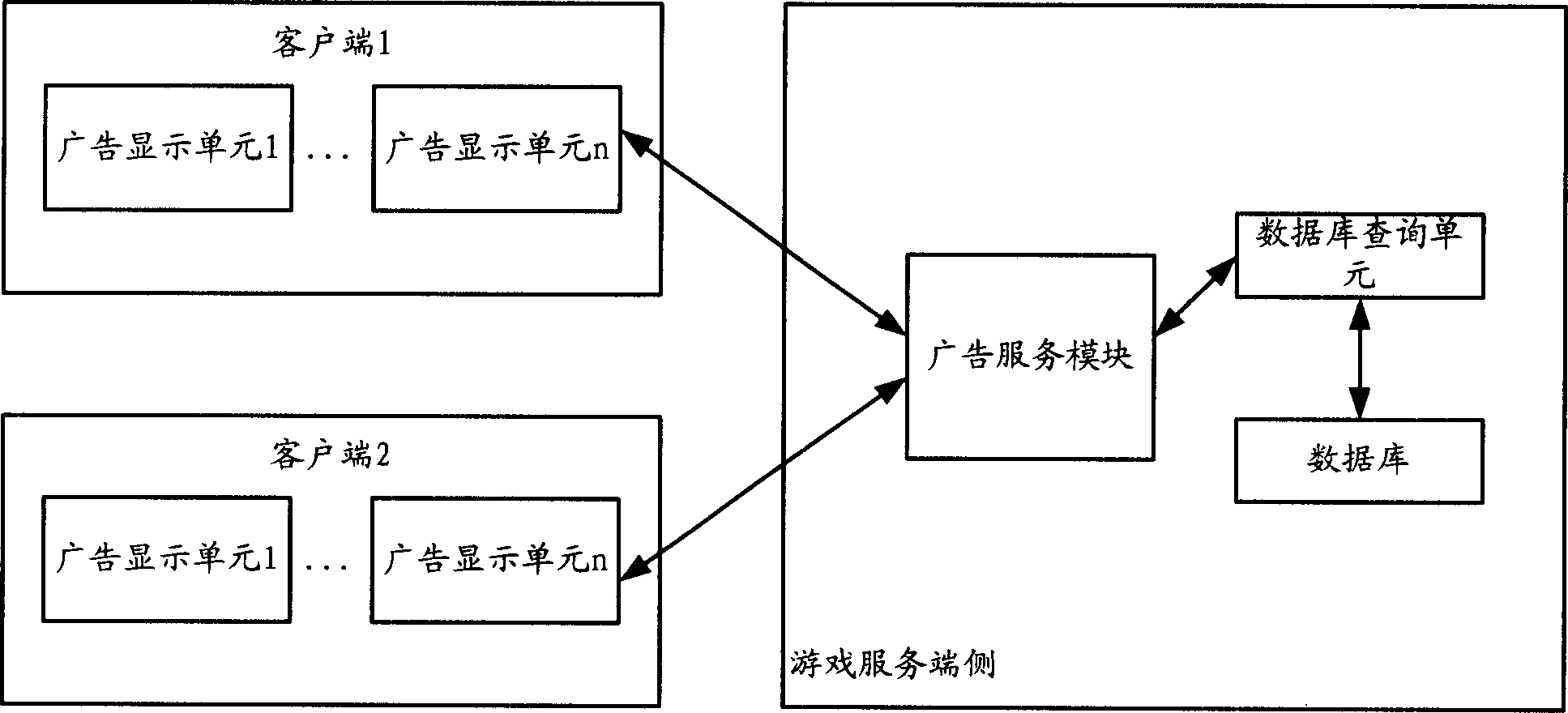

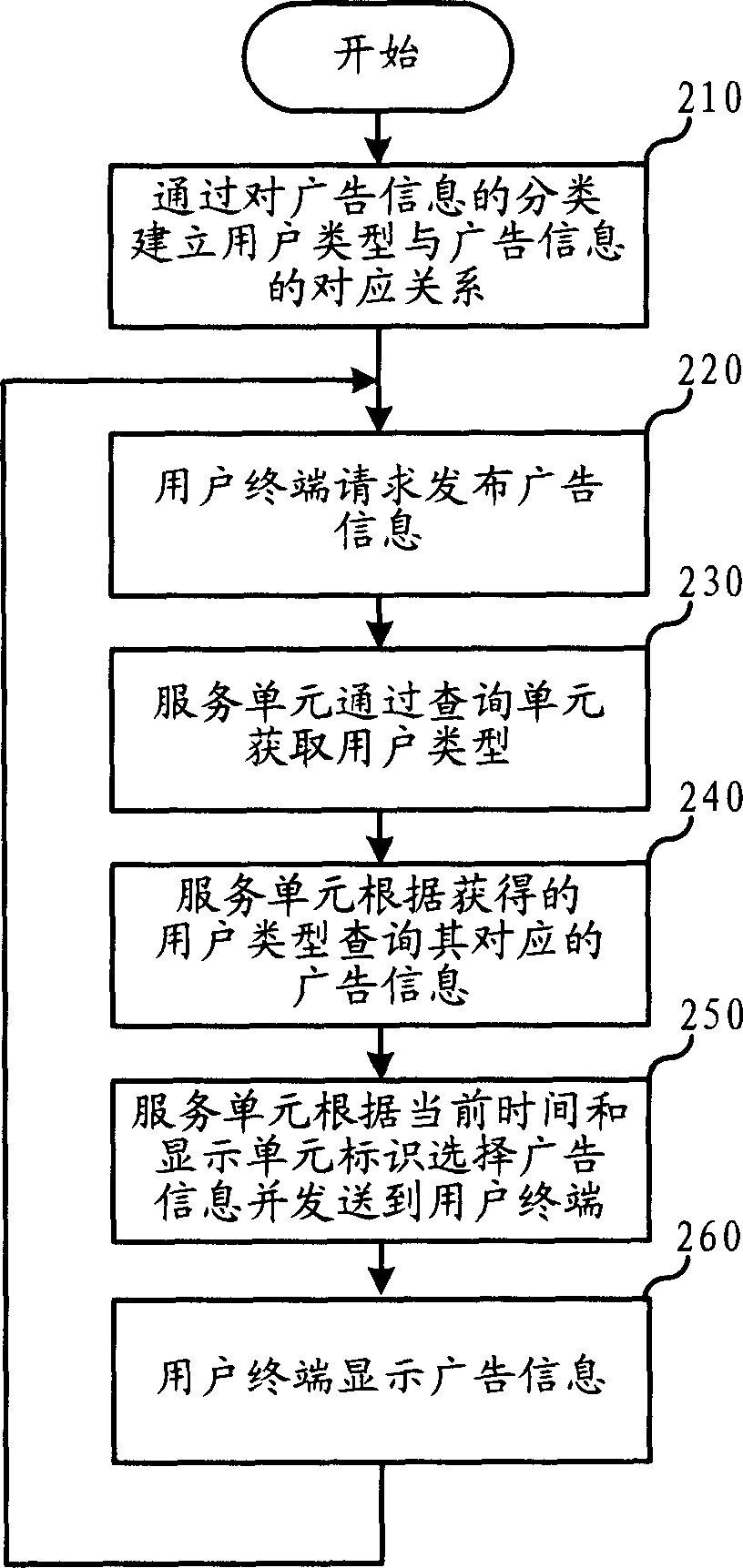

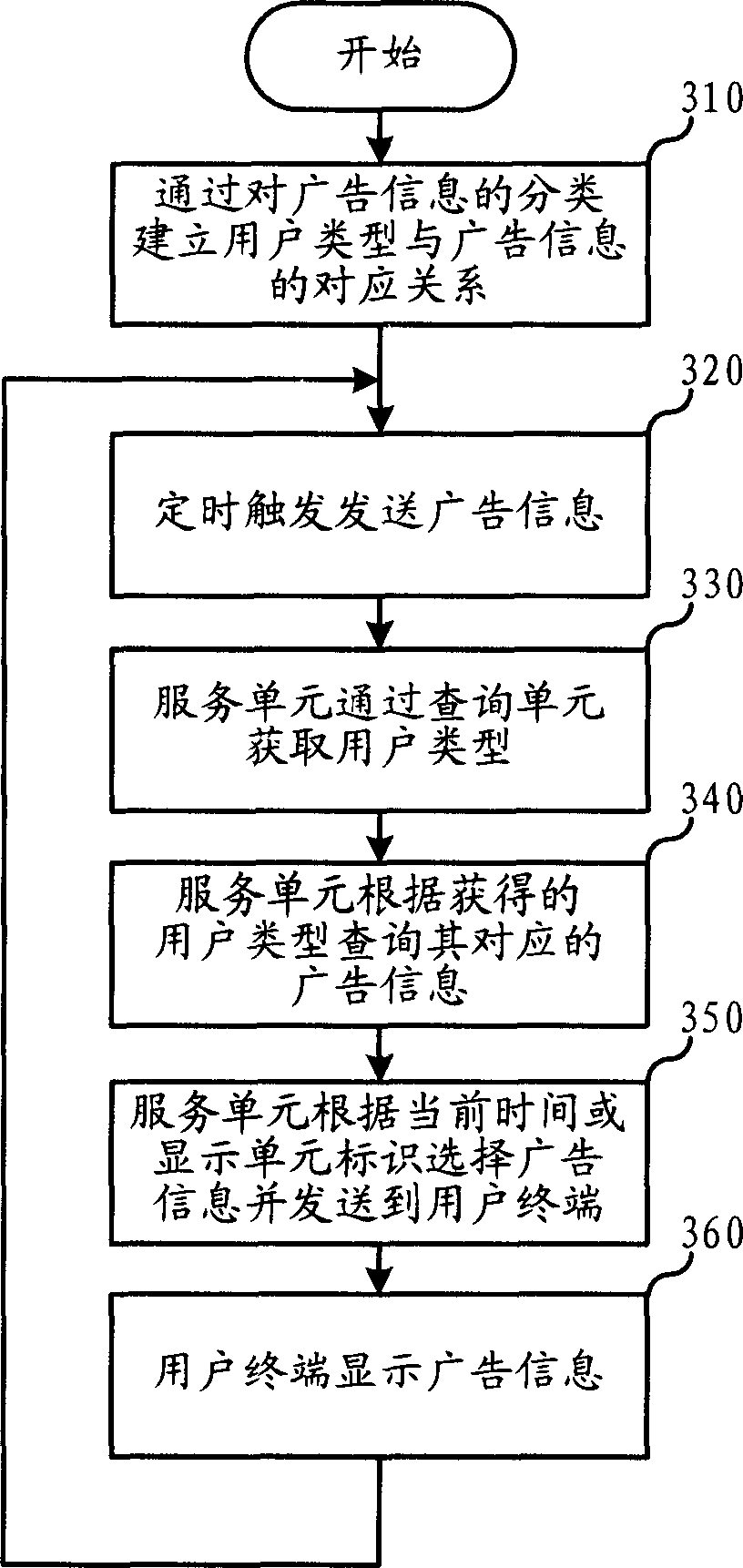

Method for issuing information in network game and system thereof

InactiveCN1862585AImprove efficiencyPlayer acceptsMarketingSpecial data processing applicationsWorld Wide Web

The present invention discloses a method for issuing information in network game and its system. It is characterized by that for different users the different information can be issued. The users and the information to be issued can be classified, the different user types can be corresponded to different information to be issued. When the information has need of issuing, the network side can utilize user identification to obtain user type, then utilize user type to inquire the correspondent information to be issued, and can transfer the correspondent information to user terminal, said information can be displayed in the user terminal.

Owner:HUAWEI TECH CO LTD

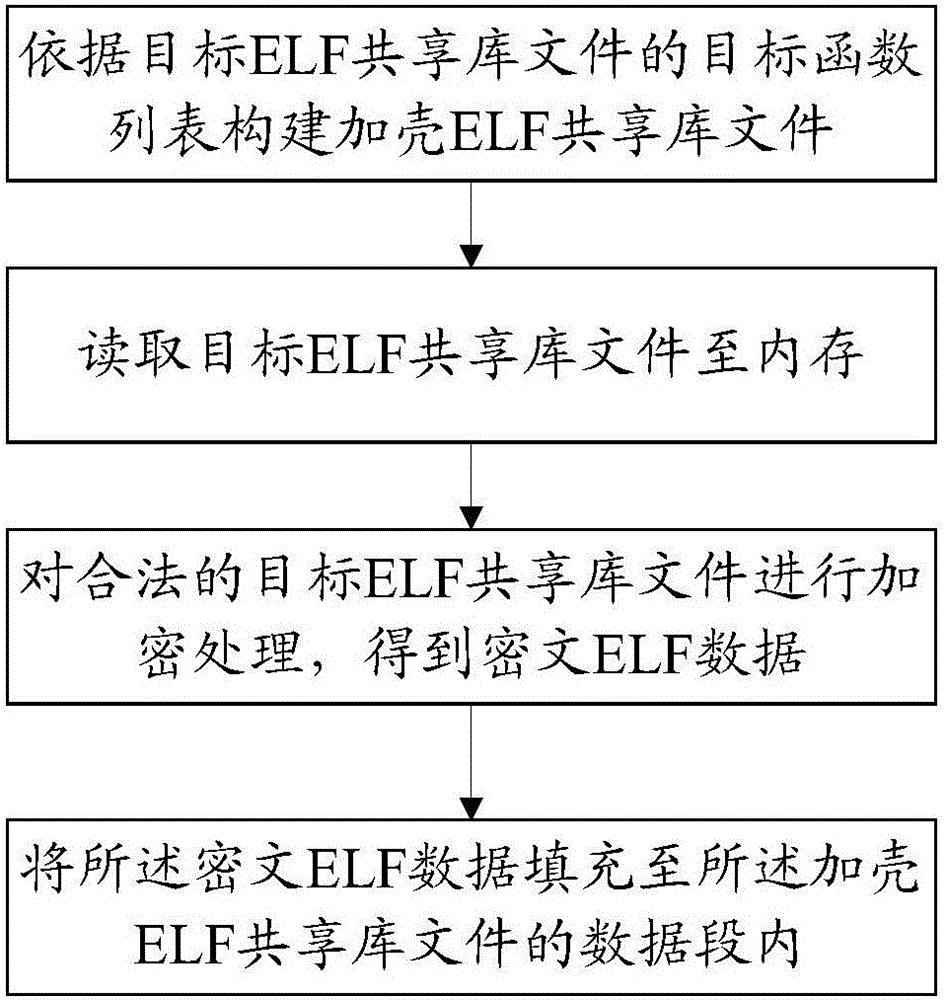

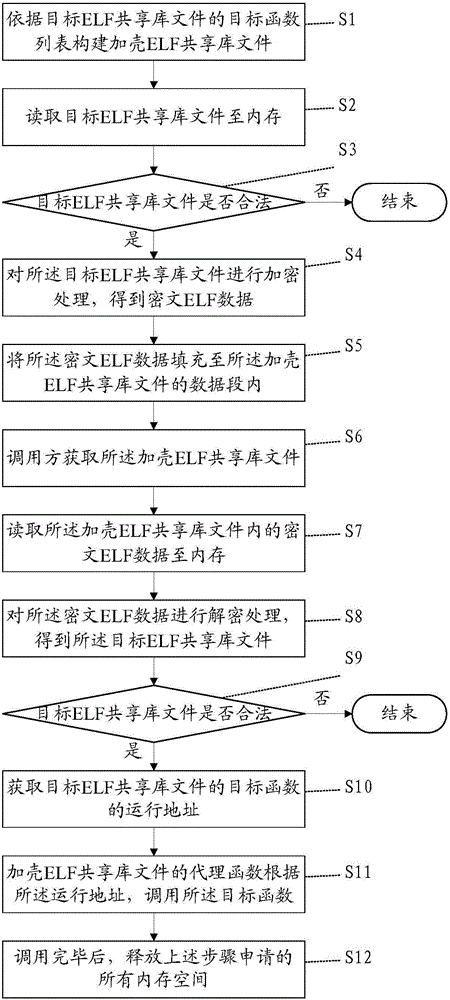

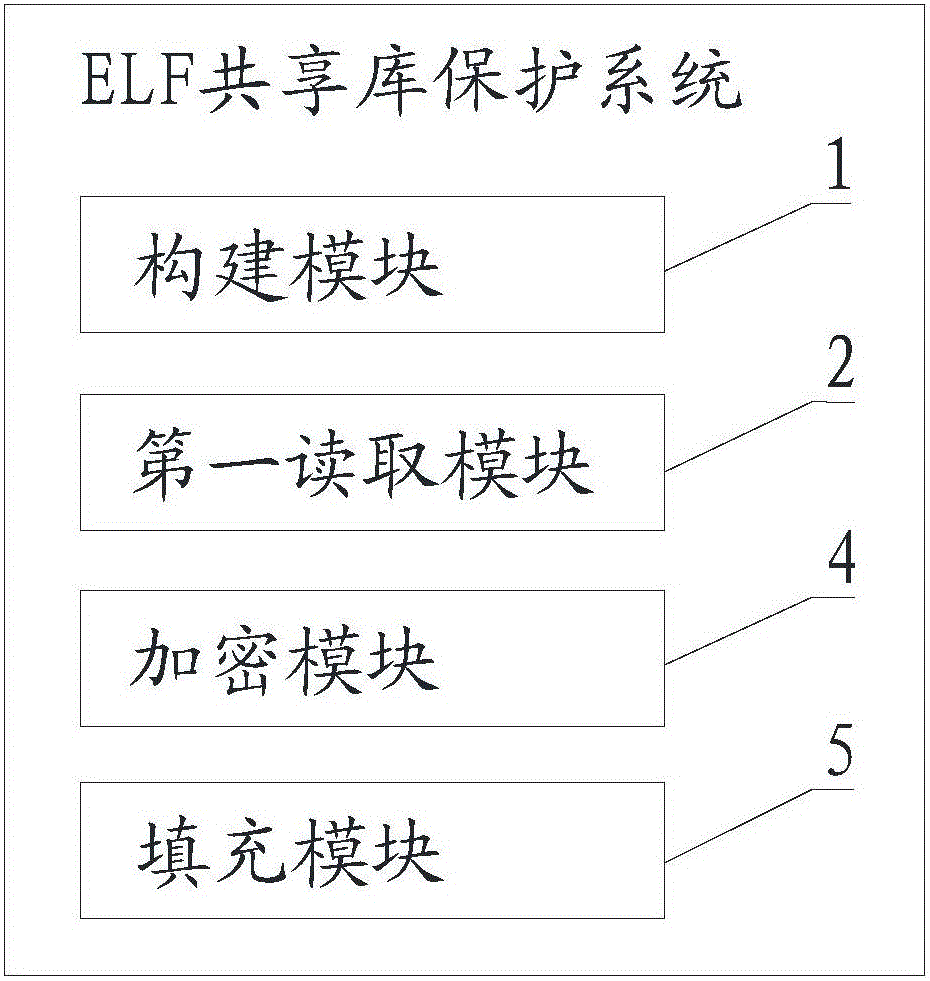

ELF shared library protection method and system thereof

ActiveCN105825087AImprove protectionAvoid economic lossDigital data protectionProgram/content distribution protectionComputer programmingSoftware development

The invention discloses an ELF shared library protection method and a system thereof. The method comprises the following steps of building an add shell ELF shared library file according to a target function list of a target ELF shared library file; reading the target ELF shared library file into a memory; performing encryption processing on the legal target ELF shared library file to obtain ciphertext ELF data; filling the ciphertext ELF data into a data segment of the add shell ELF shared library file. The method and the system have the advantages that the obtaining of the program design ideas of a designer or code execution details after a decompilation reverse analysis of a dynamic shared library can be prevented; the protection of software can be improved; the economic loss of software development enterprises is avoided; the benefits of customers are protected.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

Preparation of injecting soluble vitamines

InactiveCN1939333ARaise storage temperatureImprove antioxidant capacityOrganic active ingredientsMetabolism disorderGlycineVitamin C

A process for preparing the injection of water-soluble vitamin includes such steps as thermally dissolving glycine in the water for injection while filling inertial gas, adding 12 compounds including cysteine hydrochloride, endrate disodium, vitamin C sodium, folic acid, etc, stirring, regulating pH=5.6-6.1, adding the water for injection, stirring, aseptic filtering, pouring in containers, pre-freezing, vacuumizing, filling inertial gas, pre-freezing, heating to 30-35 deg.C, holding the temp for 6-10 hr, filling inertial gas, and sealing.

Owner:YAOPHARMA CO LTD

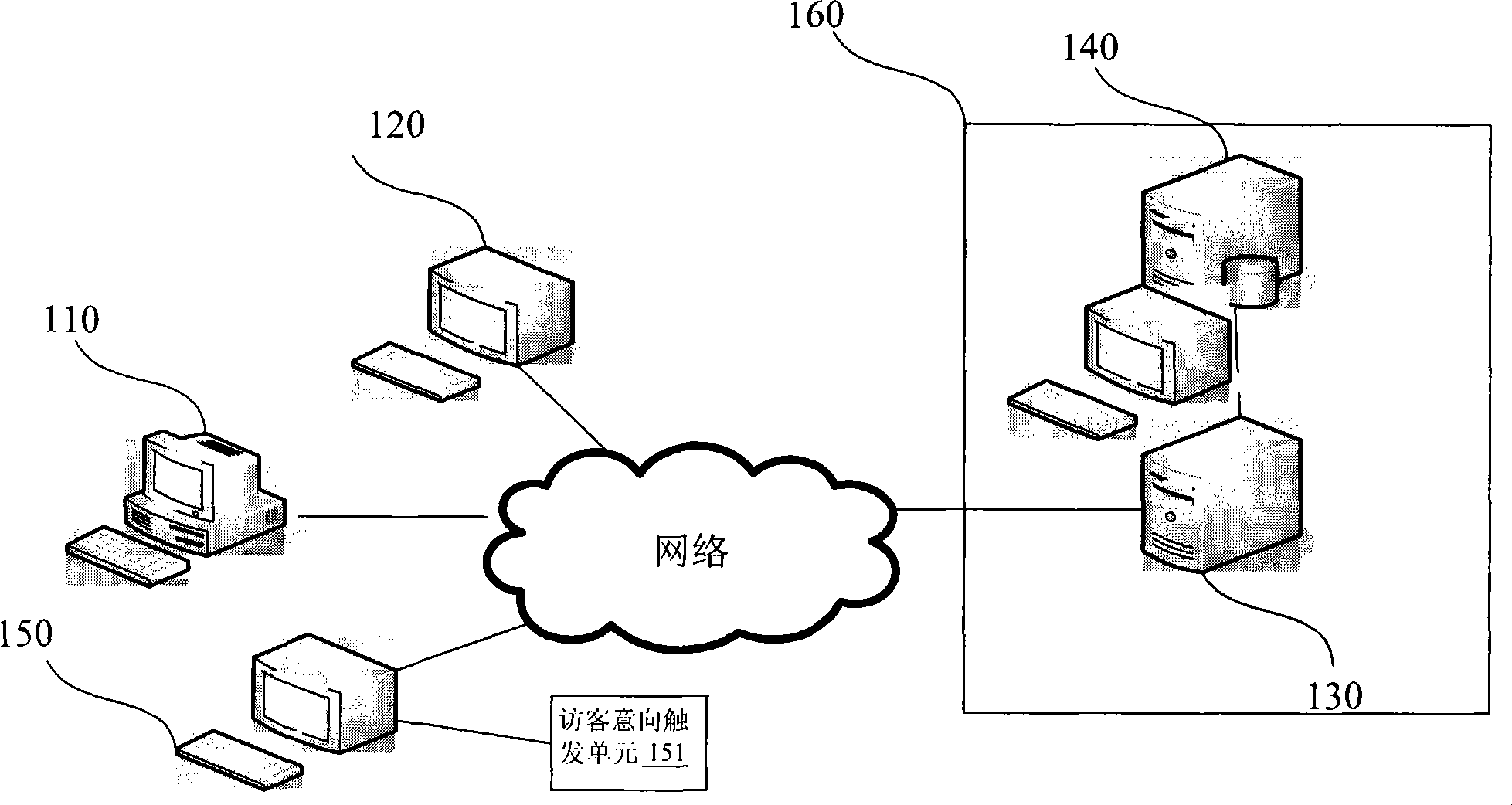

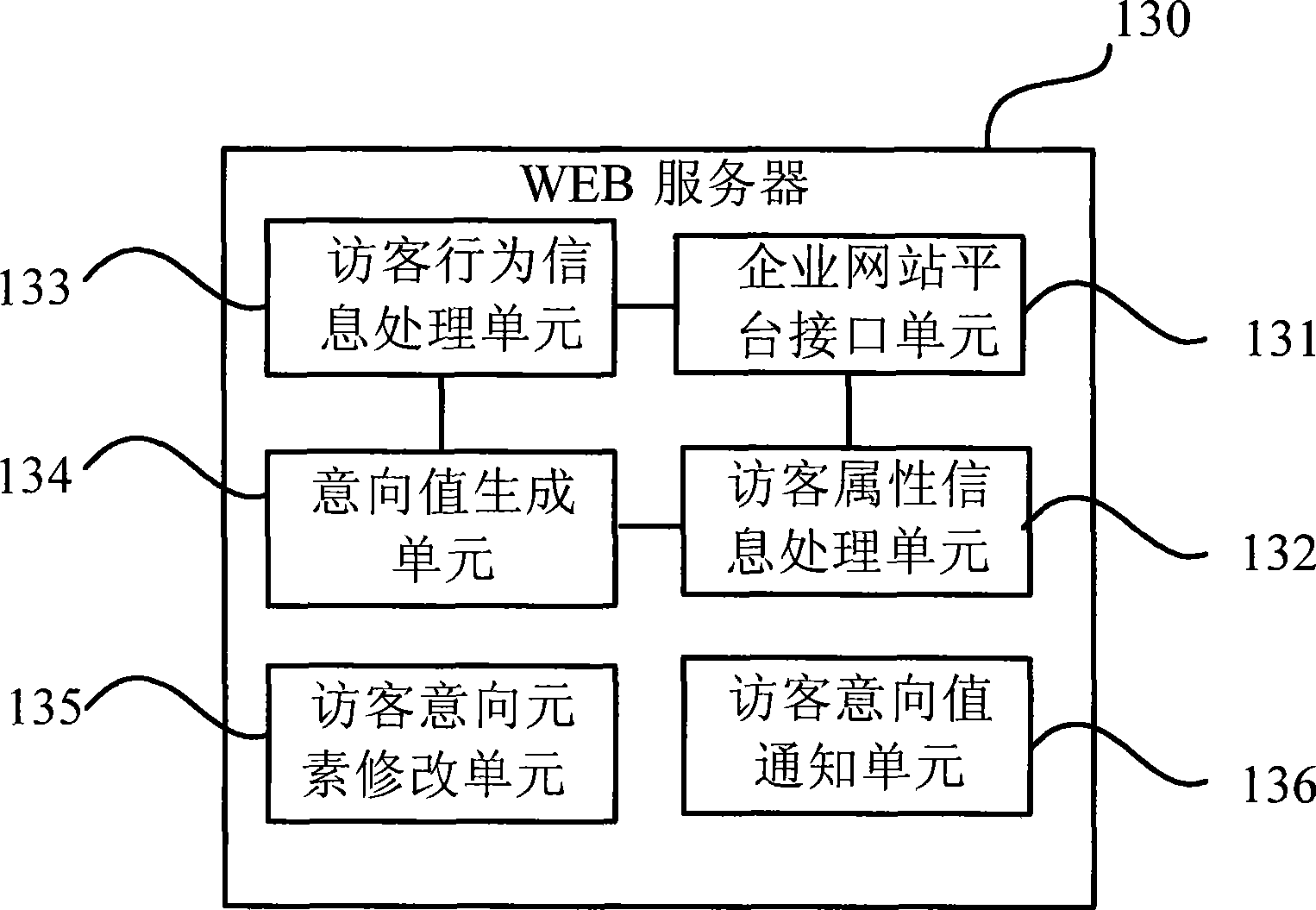

Caller intent recognition system and method and caller intent recognition platform

InactiveCN101441657AJudgment results are scientific and reasonableMultiple potential customersMarketingSpecial data processing applicationsWeb siteIntent recognition

The invention discloses a method and a system for identifying visitor intention, which are used for judging the degree of the intention when a visitor accesses a website. The method comprises the following steps: an indictor of the intention of the visitor is determined, and a quantitative formula of an indicator value is confirmed; when the visitor accesses the website, attribute information and behavior information of the visitor are obtained, wherein history access record information of the visitor is obtained, and a matching degree indicator of the intention of the visor can be obtained by quantifying the history access record information; obtained visitor information is matched with the indictor of access intention, and a visitor intention score which shows the degree of the intention of the visitor is computed according to a preset access intention computation formula. The method and the system obtain the score which can intuitively embody the access intention of the visitor by matching the visitor information and the indicator of the access intention and performing the quantitative computation, thereby bringing convenience for enterprises to develop potential customers. In addition, the method and the system take the history access record information with high intention value as one of intention indicators, which ensures that the method and the system are more scientific and reasonable.

Owner:ALIBABA GRP HLDG LTD

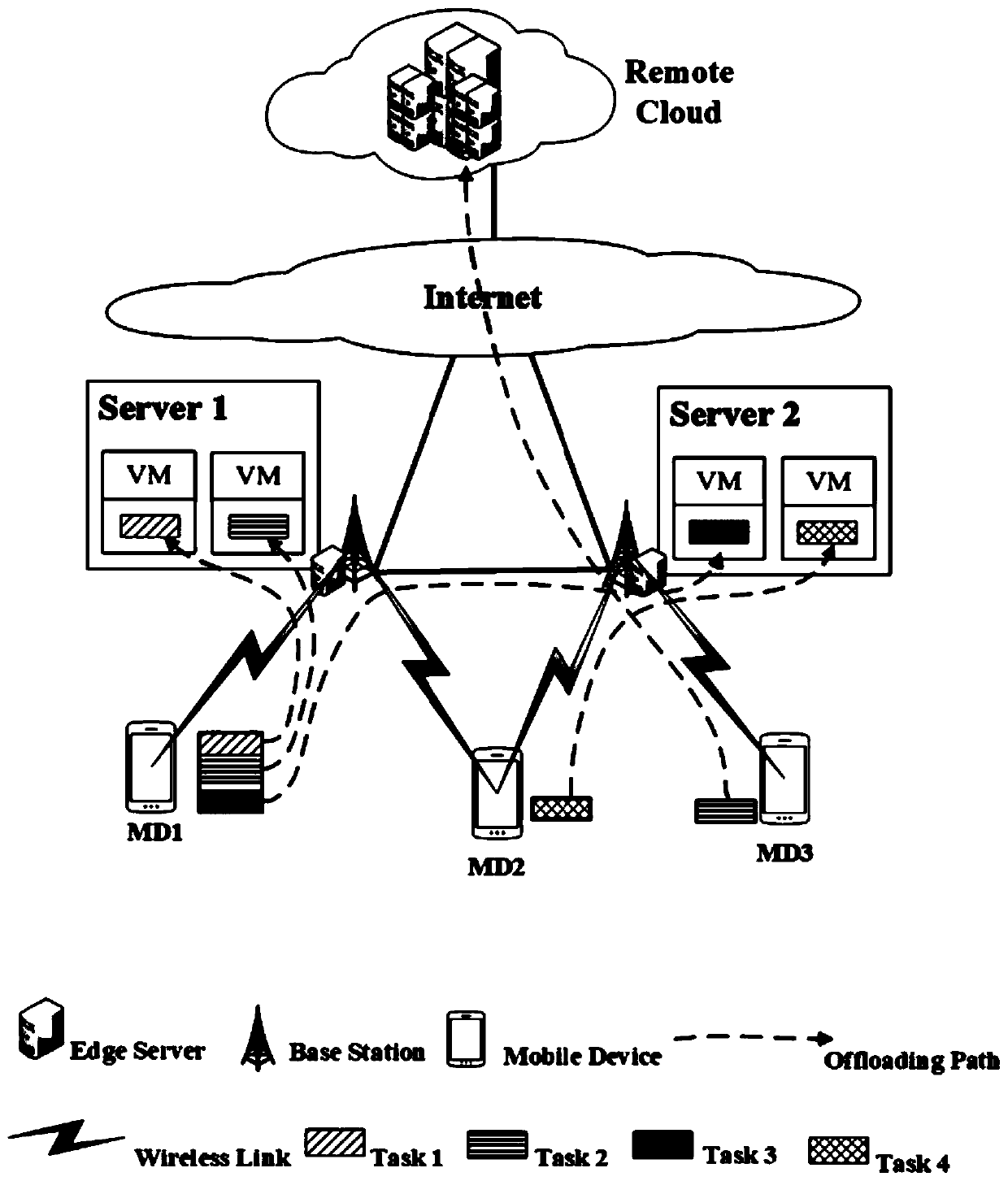

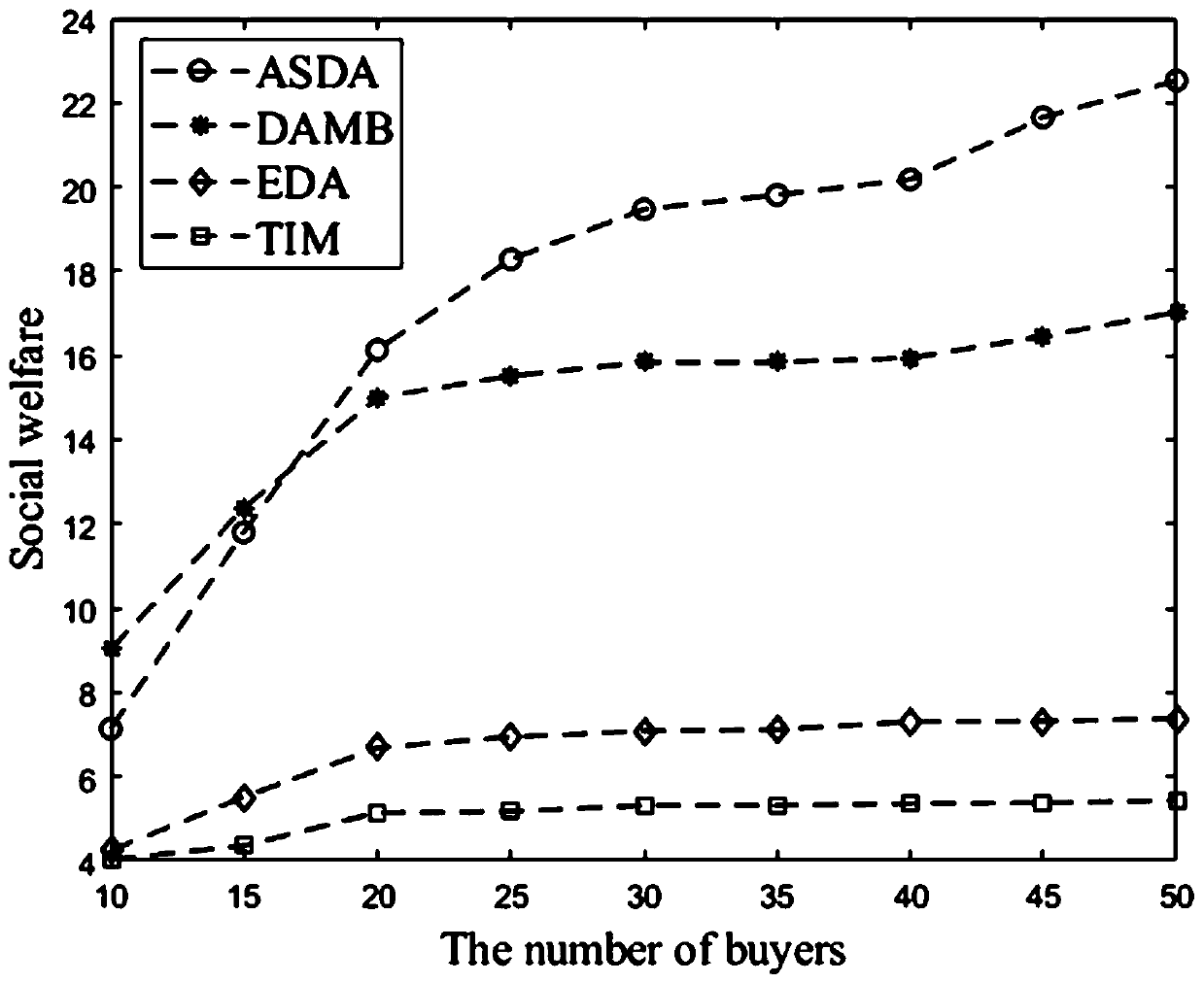

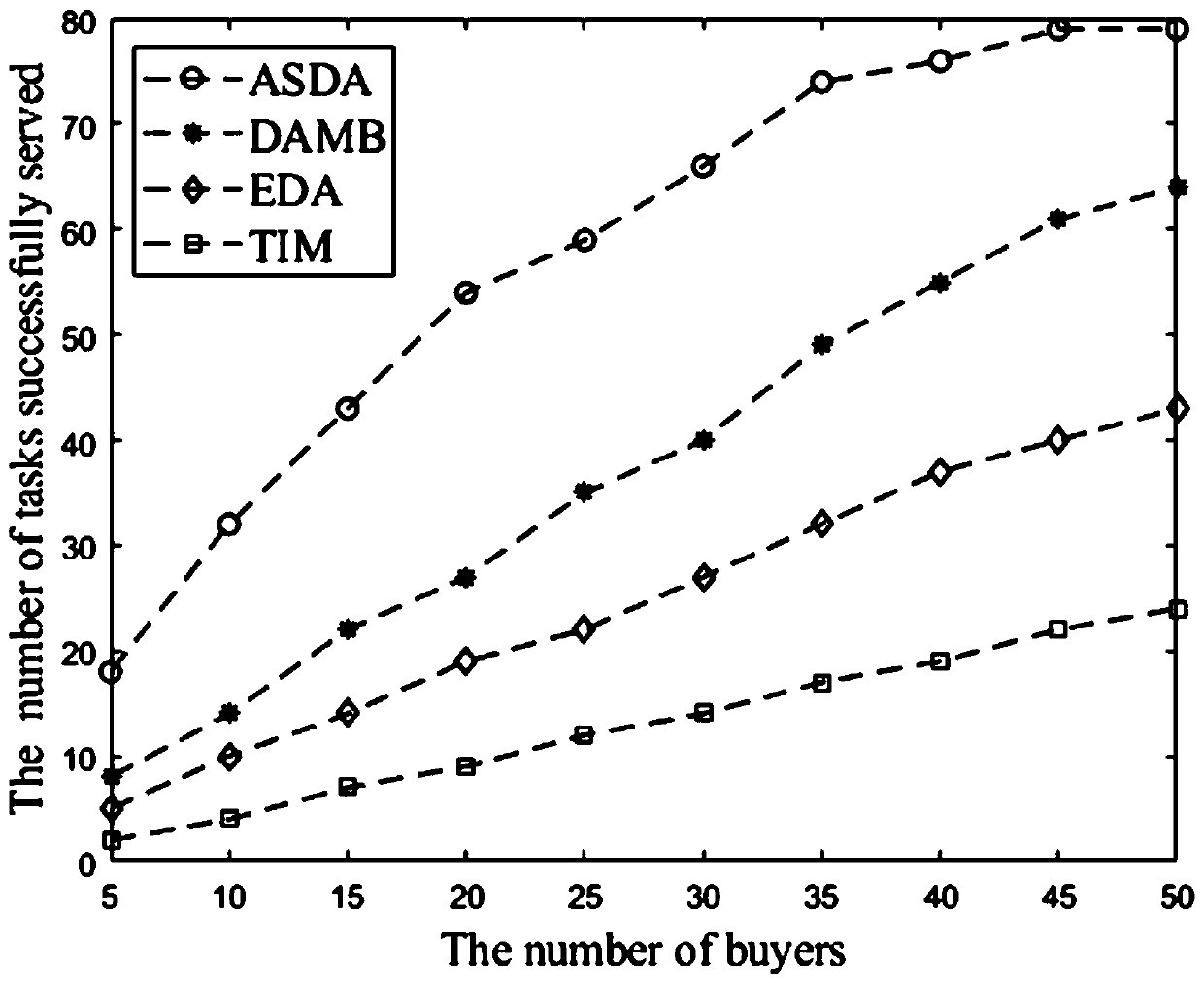

Multi-task cross-server resource allocation method based on bidirectional auction in MEC

ActiveCN110544147AMaximize the number of tasksNo lossResource allocationBuying/selling/leasing transactionsEdge serverLoss balance

The invention discloses a multi-task cross-server resource allocation method based on bidirectional auction in MEC. The multi-task cross-server resource allocation method comprises the following steps: acquiring the type and quantity information of an application program deployed by each edge server of a seller, and determining the price information of each edge server of the seller for processinga single task; acquiring the type, the number and the maximum tolerance delay information of the to-be-processed task of each mobile device of the buyer; determining bidding information of each to-be-processed task in each mobile device of the buyer; and only publishing the offer information and the bid information to the auction party, determining the price and the winner of the two parties according to the price strategy by the auction party, and completing resource allocation according to the winner information of the two parties, wherein the price strategy is a bidirectional auction mechanism based on a profit and loss balance point or a bidirectional auction mechanism applying separation. The multi-task cross-server resource allocation method provided by the invention has relativelyhigh system efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

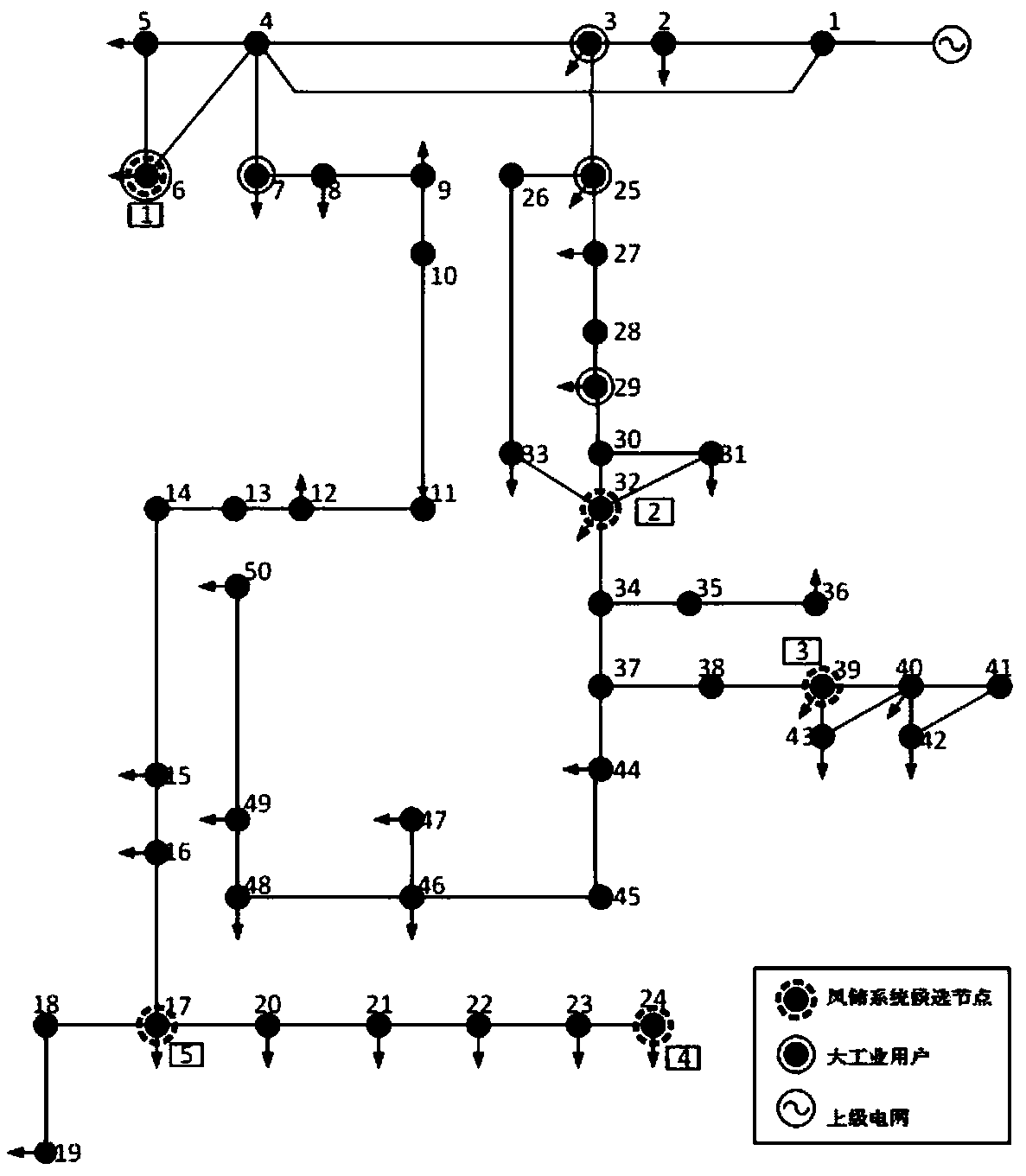

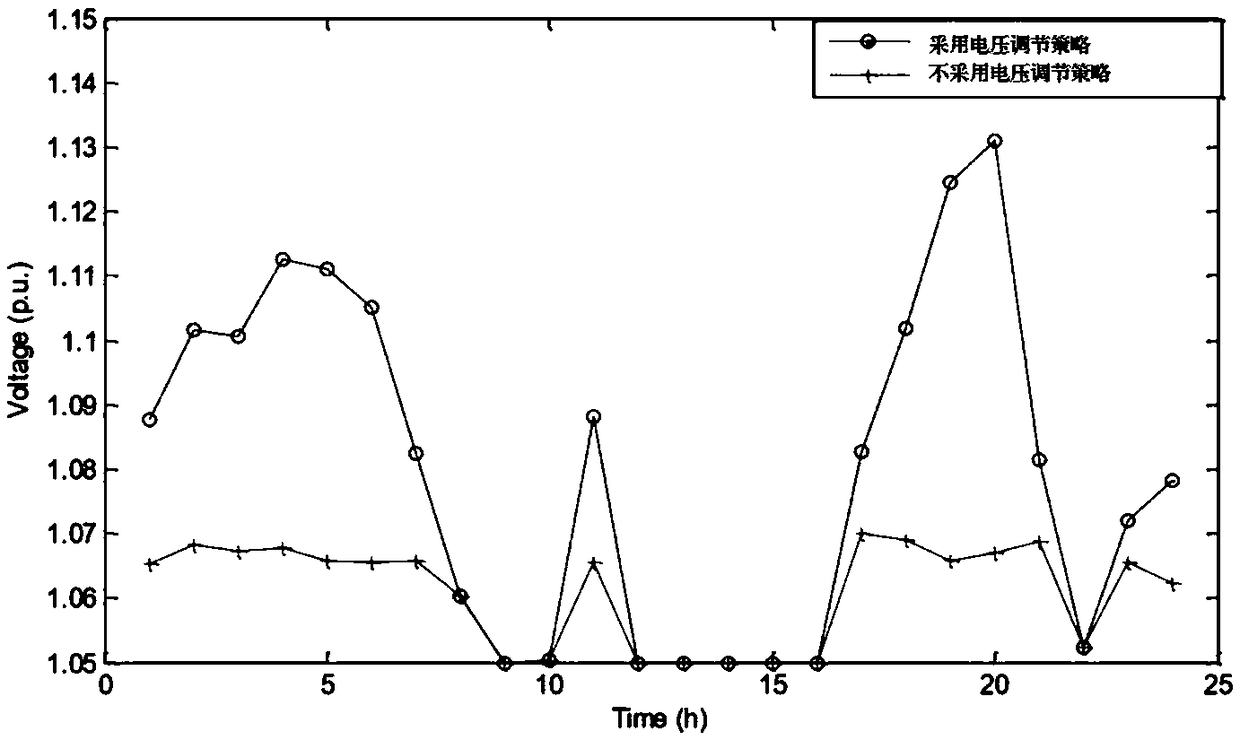

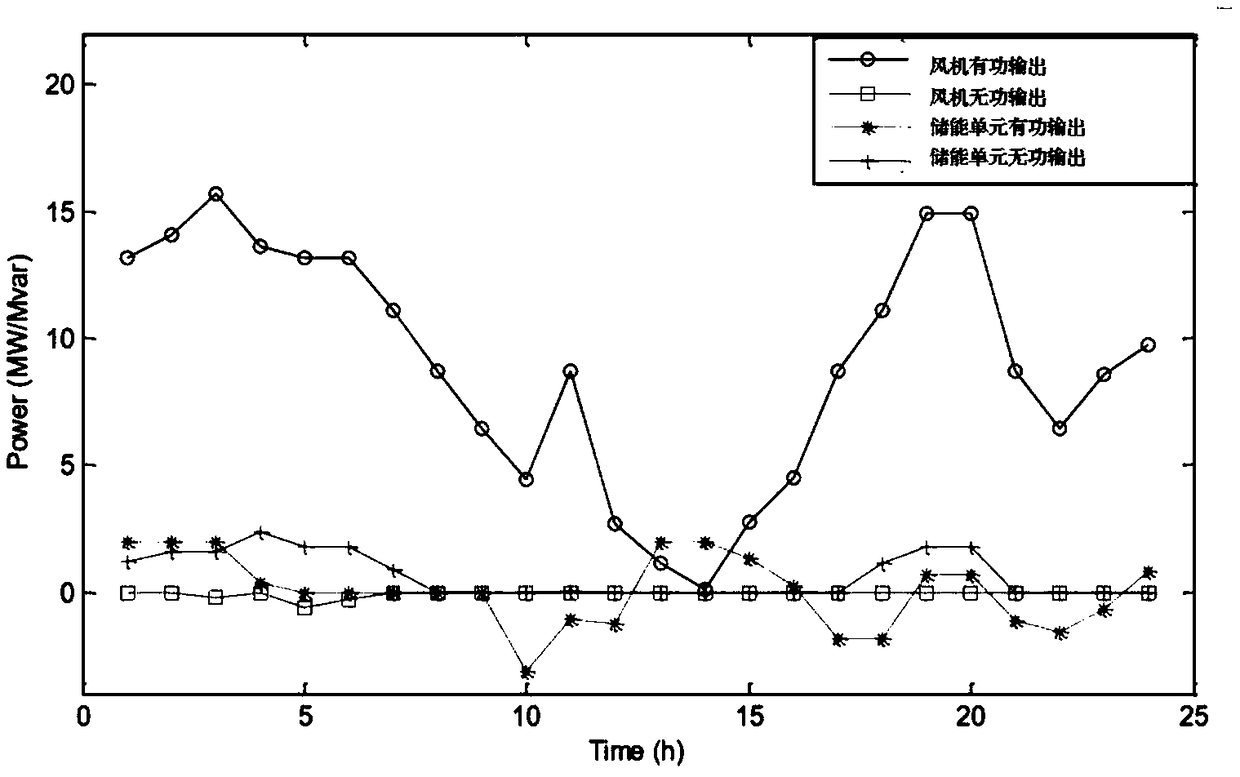

Distributed wind storage system optimization method considering source-network-load multi-party interests

The invention discloses a distributed wind storage system optimization method considering source-network-load multi-party interests. The method comprises the following steps of: taking a maximum operation cost difference value of a power distribution network operator before and after grid connection of a wind storage system as an optimization target; taking the maximum internal return rate of thedistributed power supply investor as the target; taking the maximum revenue of the user after performing the demand side response as the target; based on a multi-objective optimization planning modelof three interest subjects of a power distribution network operator, a distributed power supply investor and a user, a distributed wind storage system scheduling strategy is adopted, and the interestsof the power distribution network operator, the distributed power supply investor and the user are optimized under the condition that the reactive power regulation capability of the wind storage system is fully considered. In the distributed power supply planning process, considering the source-network-load three-party interest plan, the project has more practical engineering significance, the benefits of the distributed power supply investors can be improved, and the utilization rate of renewable energy sources is increased.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY

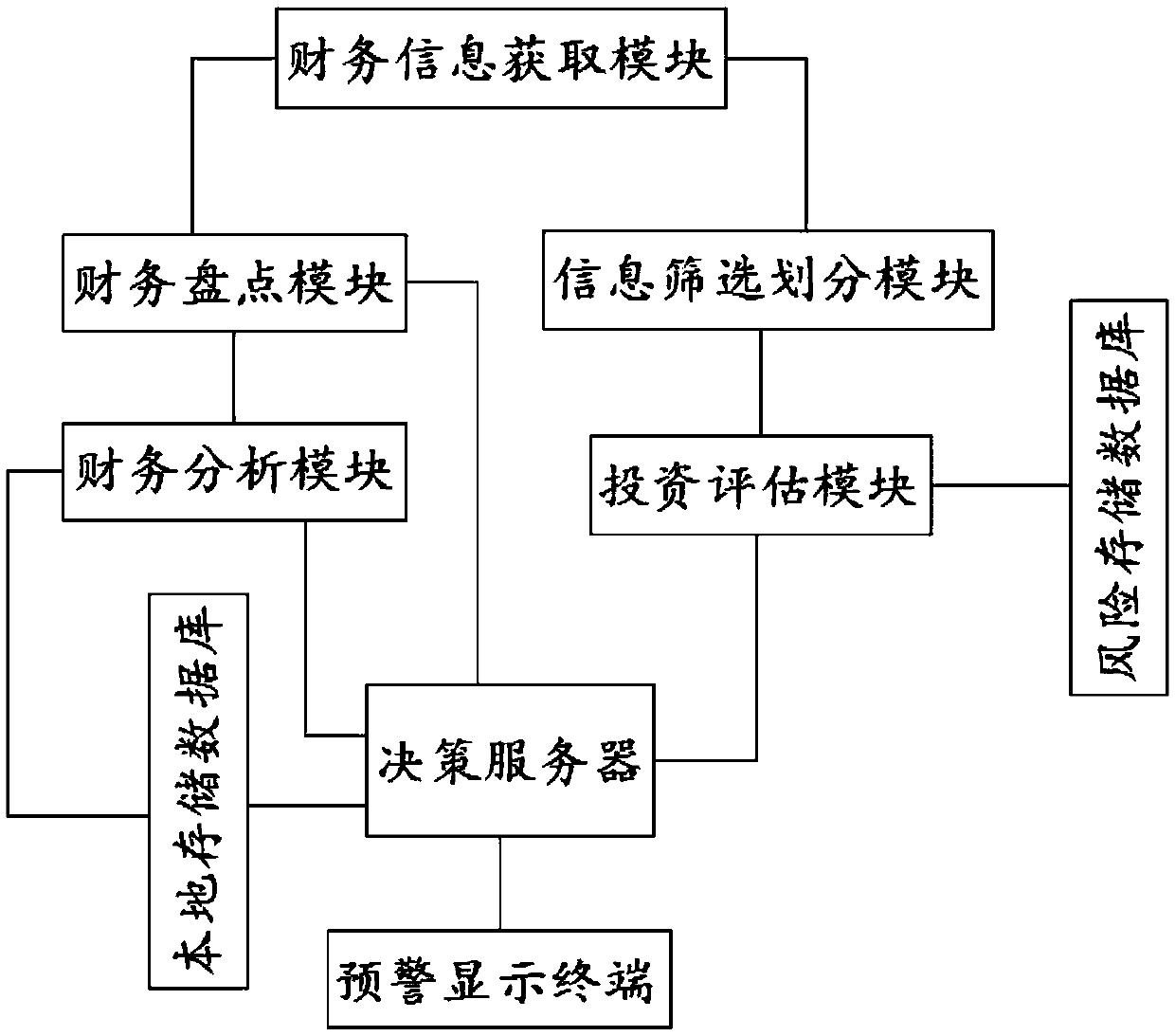

Intelligent financial decision big data analysis system

The invention discloses an intelligent financial decision big data analysis system which comprises a financial information acquisition module, an information screening and dividing module, an investment assessment module, a risk storage database, a financial checking module, a financial analysis module, a local storage database, a decision server and an early warning display terminal. The financial information obtaining module is connected with the information screening and dividing module and the financial checking module. wherein the investment assessment module is respectively connected with the information screening and dividing module and the risk storage database, the financial analysis module is respectively connected with the financial checking module and the local storage database, and the decision server is respectively connected with the investment assessment module, the financial checking module, the financial analysis module, the local storage database and the early warning display terminal. Risk assessment is carried out on enterprise finance, reliable prevention measures are provided, overall planning of the finance is achieved, reliable decision analysis and guidance are provided for management personnel in the aspect of financial management, and risks in the enterprise development process are reduced.

Owner:安徽经邦软件技术有限公司

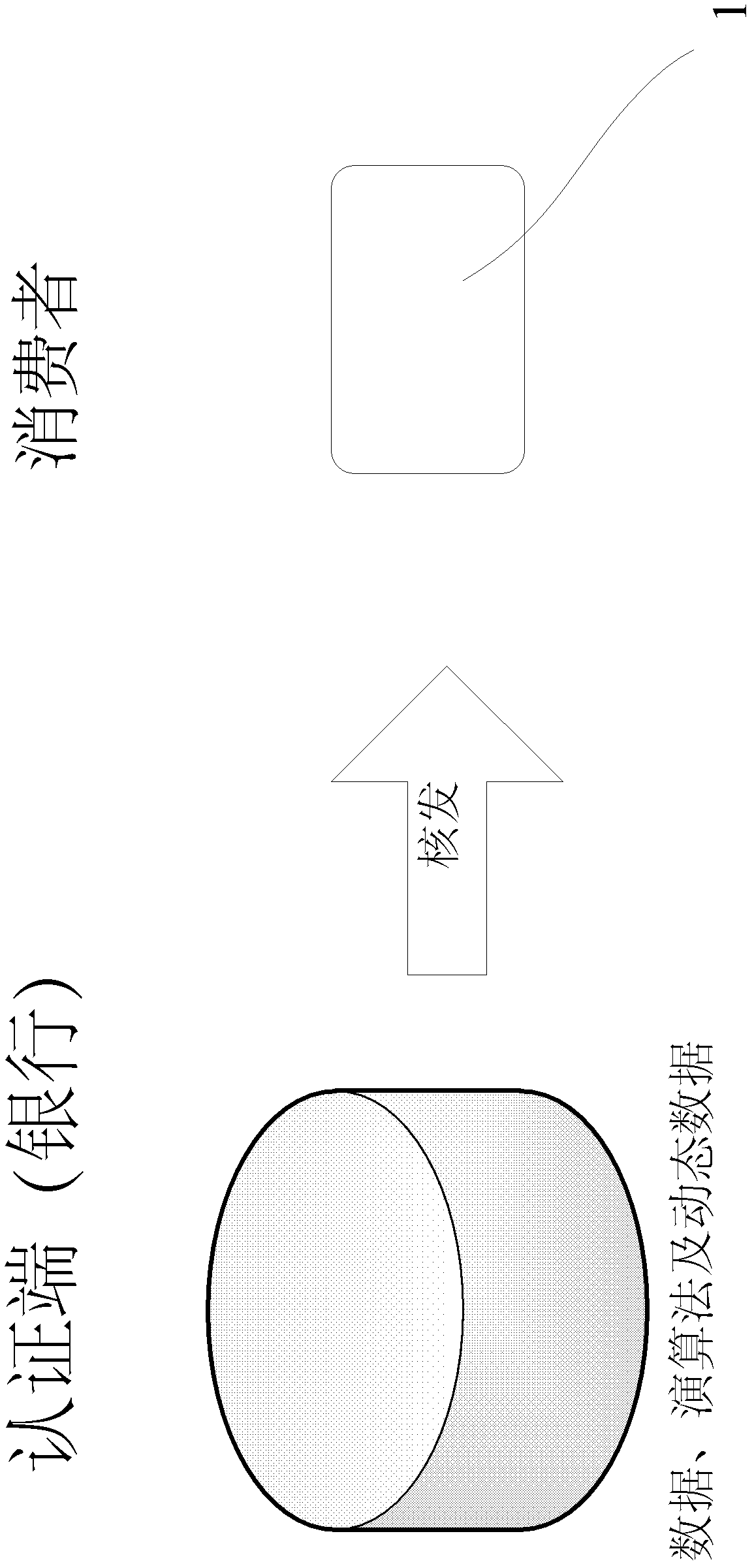

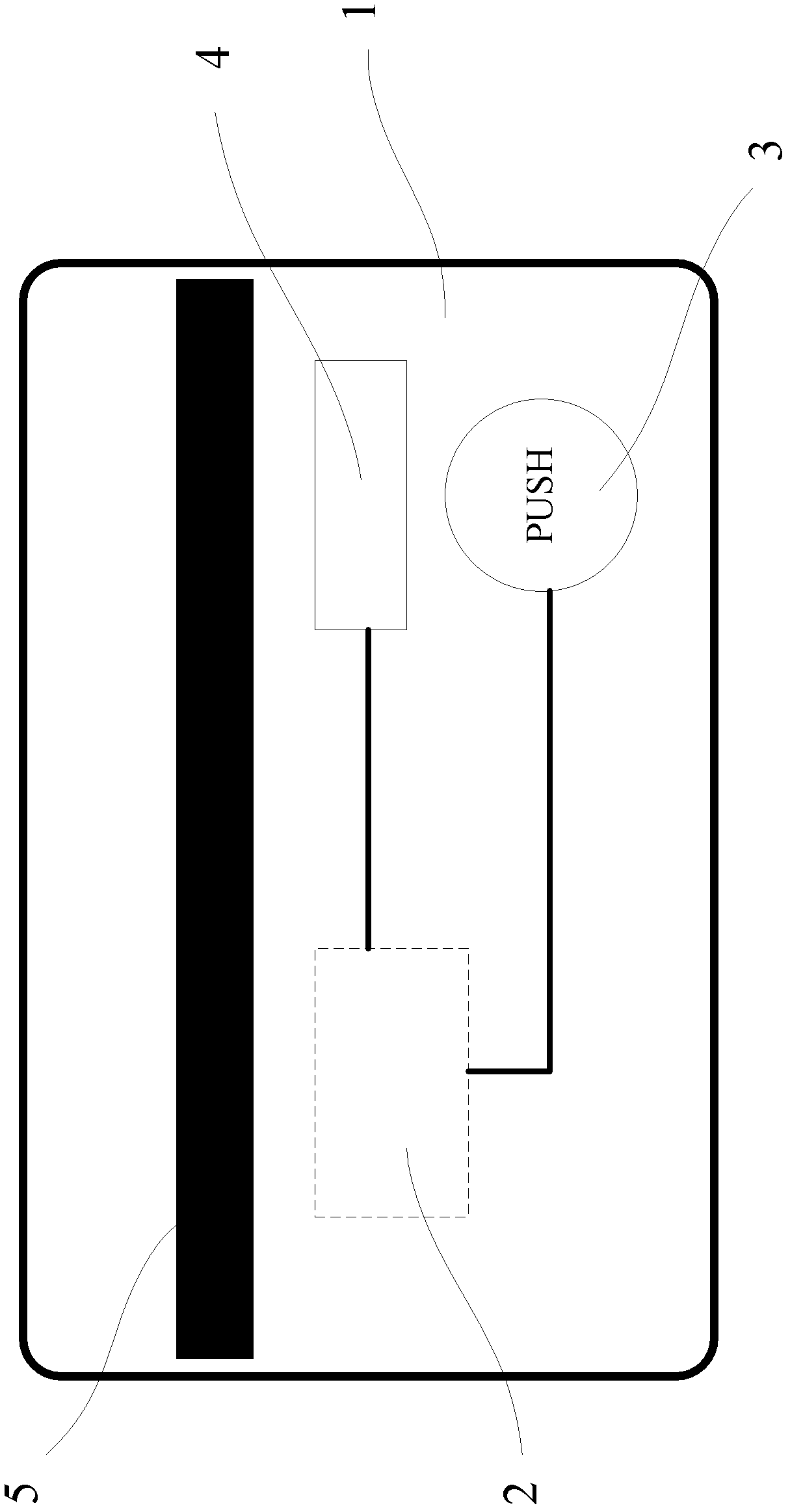

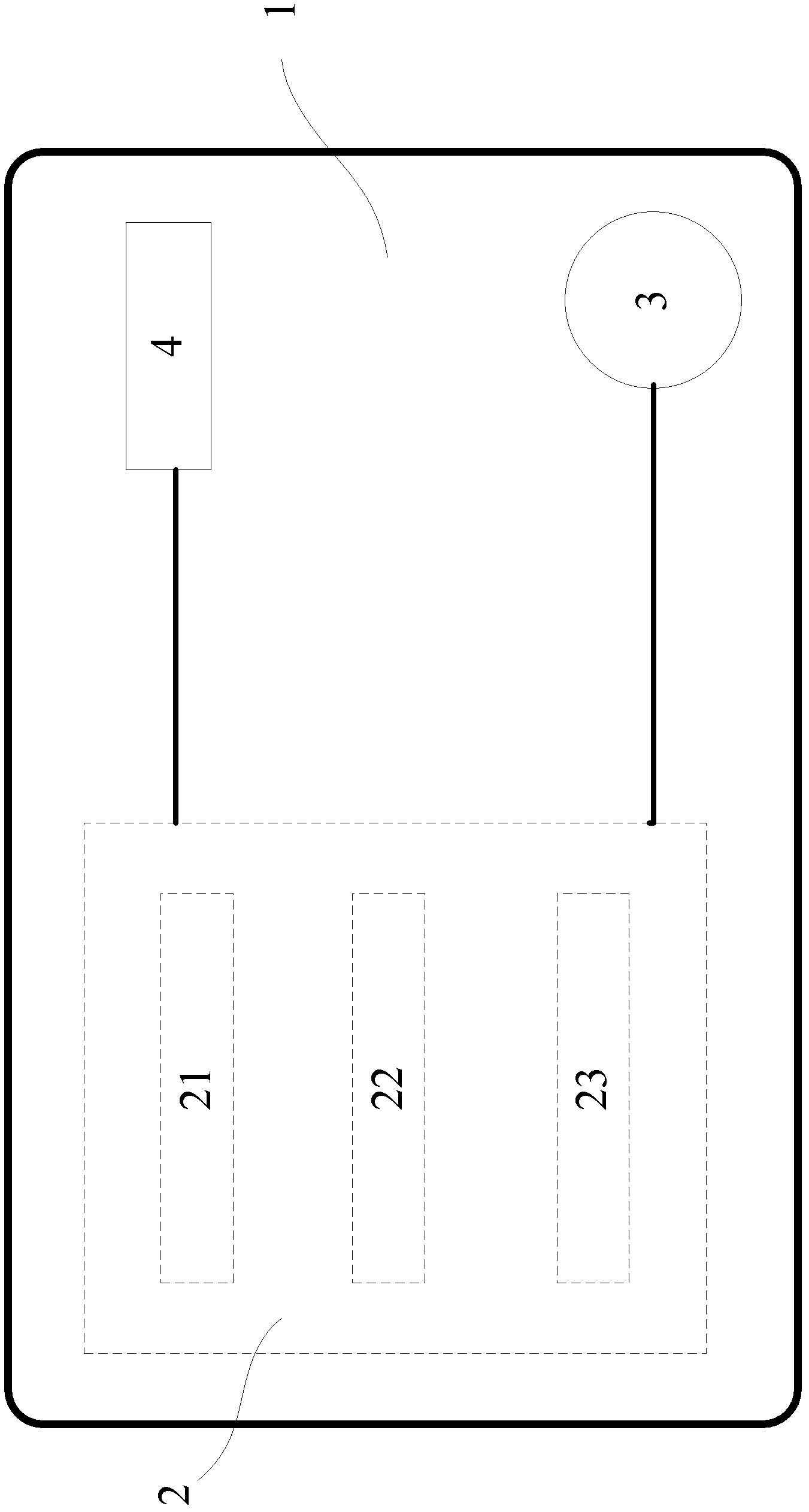

Dynamic safety code authentication method and intelligent card device thereof

InactiveCN103188079AMultiple interestsProtection of rights and interestsUser identity/authority verificationDigital data protectionCredit cardSmart card

The invention discloses a dynamic safety code authentication method and an intelligent card device of the dynamic safety code authentication method. The dynamic safety code authentication method includes the following steps: using dynamic numeral value additional calculation to produce a dynamic safety code at an authentication end, approving and issuing the intelligent card device capable of generating the same dynamic safety code for customers, when the customers need to authenticate the safety code during shopping, calculating the generated dynamic safety code through a start button which drives the intelligent card device, displaying the calculated dynamic safety code on a display screen of the intelligent card device, providing the customers with the dynamic safety code capable of being calculated with the authentication end through a telephone or a network during entity shopping or online shopping to confirm that the customers are card holders. The dynamic safety code authentication method and the intelligent card device of the dynamic safety code authentication method can enable the safety code to be changed from a fixed value to a dynamic value which is displayed in a dynamic mode whenever the customers authenticate, enable the dynamic safety code generated from drive calculations of each consumption behavior to be different due to dynamic numeral value addition, prevent consumer benefits from being damaged due to the fact that a credit card is stolen easily and misused or swiped in an unauthorized mode and effectively improve safety of usage of the credit card.

Owner:SMARTDISPLAYER TECH CO LTD

Method for preparing anhydrous boron oxide

ActiveCN103523793AMeet the process requirementsHigh purityBoron-oxygen compoundsCrucibleRoom temperature

The invention discloses a method for preparing anhydrous boron oxide. The method comprises the following steps: (1) carrying out vacuum dehydration treatment of boric acid to obtain boron oxide; (2) placing boron oxide in a crucible, heating to 400-500 DEG C, and then keeping for 30 min; (3) carrying out microwave heating dehydration treatment of boron oxide with the dehydration time of 10-40 min; and (4) under a normal temperature and normal pressure condition with the water content of less than 1 ppm, cooling to the room temperature to obtain anhydrous boron oxide. The method has the advantages of simple production process and low production cost, and the obtained product has the water content of below 150 ppm and the purity of up to 99.999%.

Owner:清远先导材料有限公司

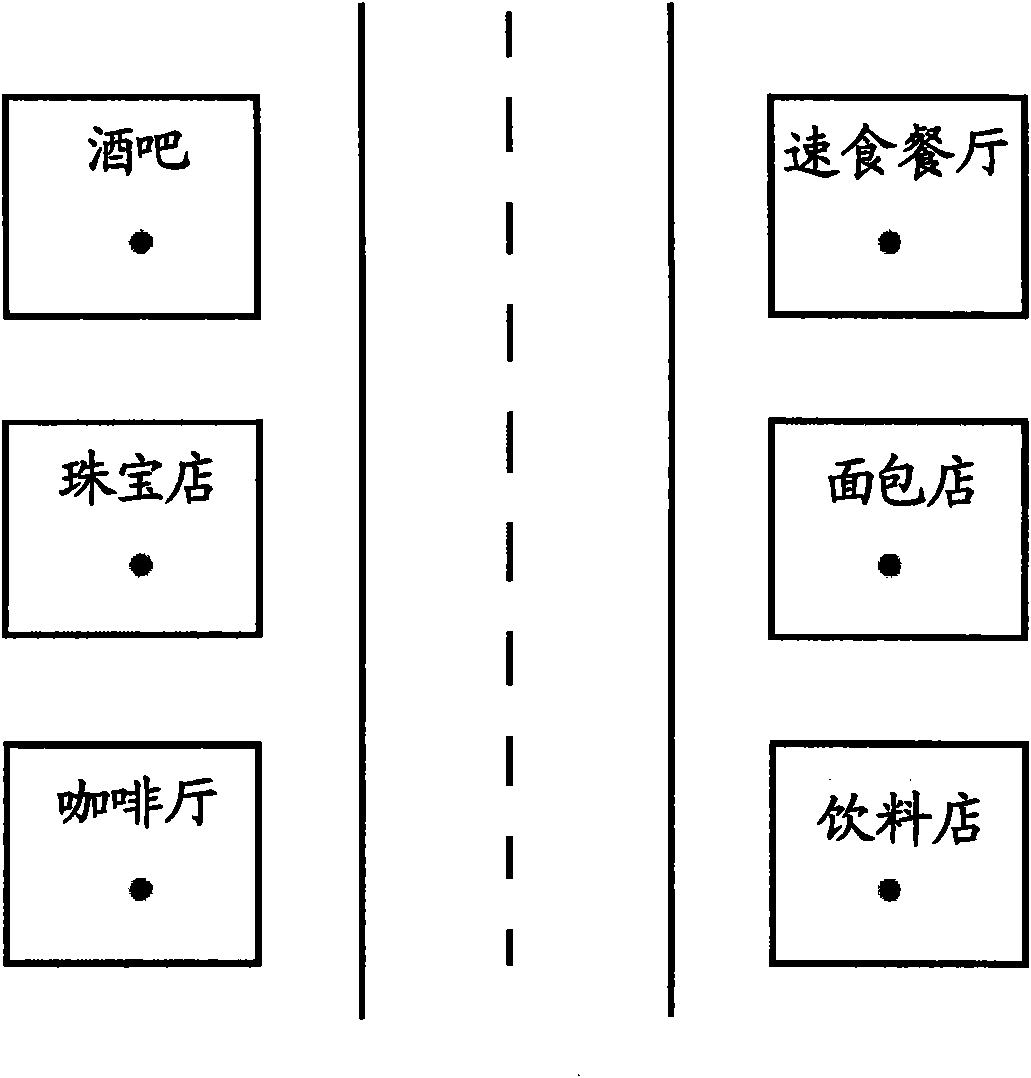

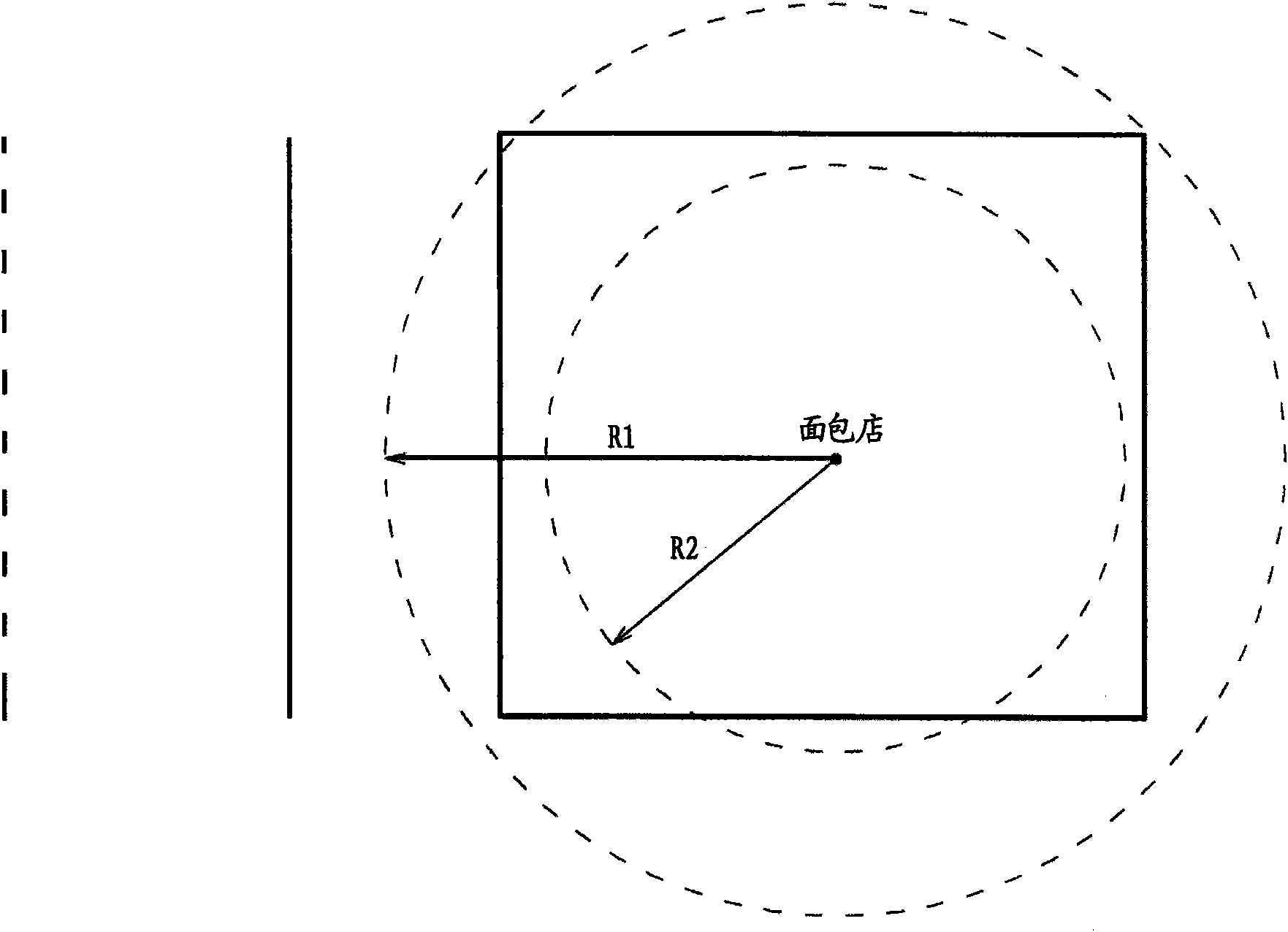

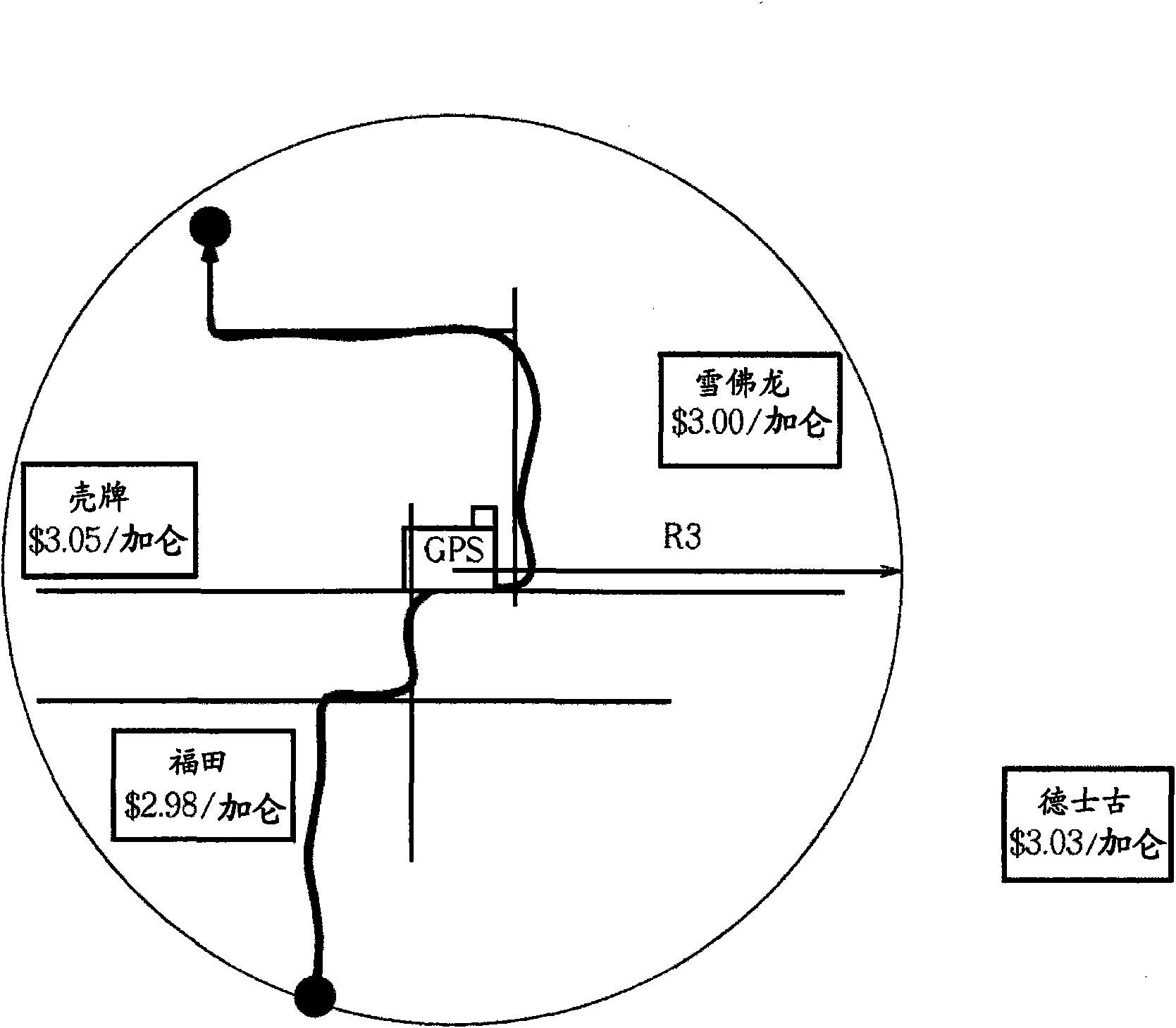

Method for implementing highlight indication of implementing personal navigation device

InactiveCN101881618AAvoid bad personal habitsCircumvention of personal habitsInstruments for road network navigationPersonal navigation deviceHabit

The invention relates to a method for implementing highlight indication of a personal navigation device, which is a sending method for implementing warming information on the personal navigation device for helping a user to avoid a purchasing habit with potential threat. The sending method of the warming information comprises the following steps: determining a position of the personal navigation device; comparing the position of the personal navigation device with a plurality of restraint interest points according to preset; and starting the warming information when the position of the personal navigation device is located in a critical distance of any restraint interest point.

Owner:MITAC INT CORP

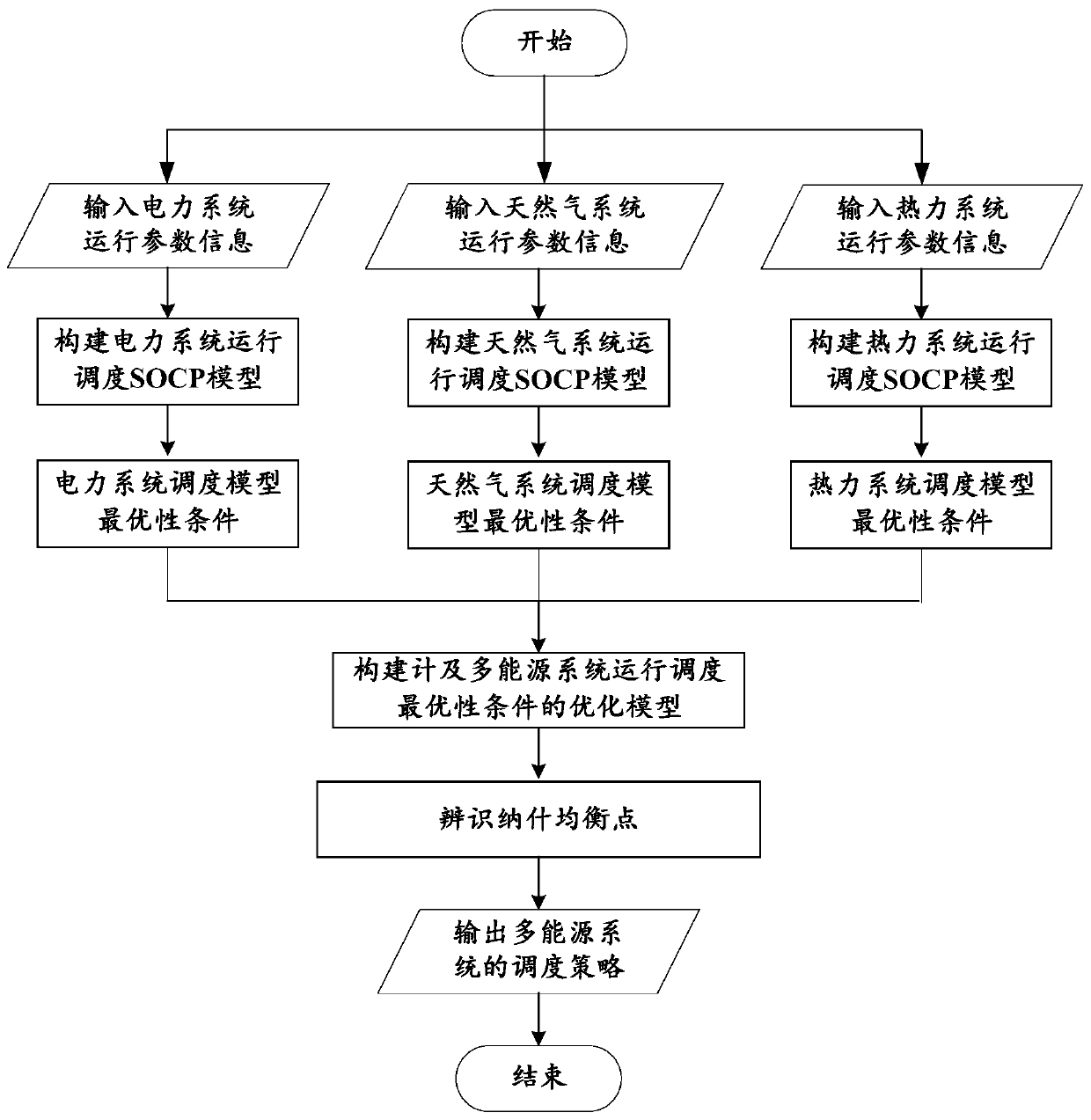

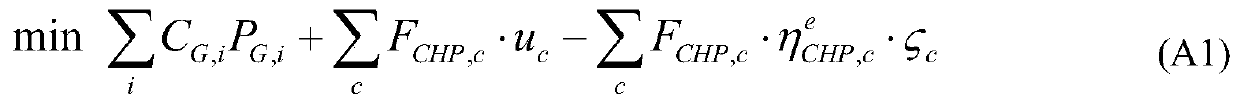

Multi-energy system operation scheduling method

ActiveCN110210104AExcellent and strictMultiple interestsForecastingSingle network parallel feeding arrangementsPower system schedulingEnergy system

The invention discloses a multi-energy system operation scheduling method. The method comprises the following steps: respectively constructing a power system operation scheduling model, a natural gassystem operation scheduling model and a thermal power system operation scheduling model in a multi-energy system; respectively solving the optimal conditions of the power system scheduling model, thenatural gas system scheduling model and the thermodynamic system scheduling model; constructing an operation scheduling target optimization function of the multi-energy system, and taking the solved optimality condition as a constraint; solving a target optimization function, and obtaining Nash equilibrium points of the non-cooperative game of the multi-energy system; and operating and schedulinga power system, a natural gas system and a thermodynamic system in the multi-energy system according to a scheduling strategy corresponding to the Nash equilibrium point. According to the invention, optimal operation scheduling can be realized.

Owner:NARI TECH CO LTD +1

Active component composition used as adjuvant drug for antitumor and preparation and application thereof

InactiveCN101239094AGood effectSignificant effectOrganic active ingredientsPharmaceutical delivery mechanismDiseaseAdditive ingredient

Disclosed is an active component composition as an assistant drug for tumor, wherein an actual total content of astragalus polysaccharide and angelica polysaccharide which are active components reaches above 50% of total extracts. The active component capable of forming a suitable formulation with an appropriate physiologically acceptable excipient, can enhance the immune function and the disease-resistant ability, and also works as raw material for producing adjuvant treatment drug and rehab treatment drug after radiotherapy, chemotherapy and surgical treatment for tumor.

Owner:酒泉大得利制药股份有限公司

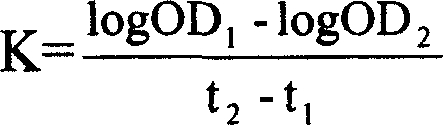

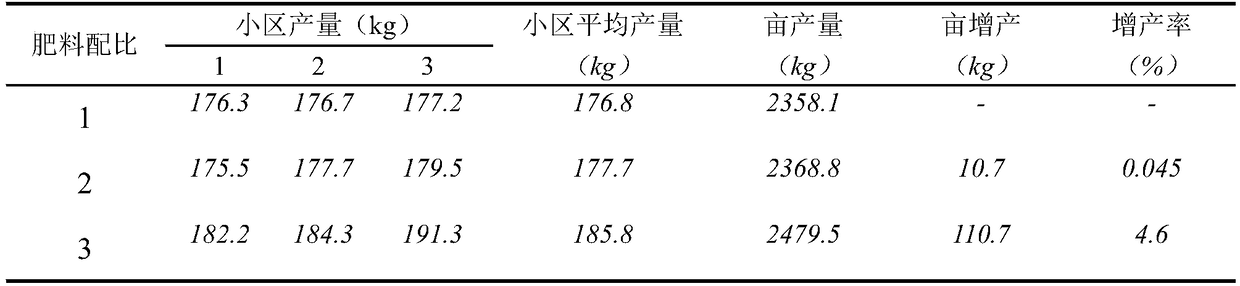

Fulvic acid-containing large-medium-trace element water-soluble fertilizer and preparation method thereof

InactiveCN109251087AMultiple interestsImprove absorption rateMagnesium fertilisersAlkali orthophosphate fertiliserWater solublePhosphate

The invention provides a fulvic acid-containing large-medium-trace element water-soluble fertilizer and a preparation method thereof, wherein the fulvic acid-containing large-medium-trace element water-soluble fertilizer comprises, by mass, 50-90% of fulvic acid, and 10-50% of water-soluble elements, wherein the water-soluble elements comprise large water-soluble elements of potassium dihydrogen phosphate and urea, medium water-soluble water-soluble elements of ammonium calcium nitrate and magnesium sulfate, trace water-soluble elements of zinc sulfate, manganese sulfate, ferrous sulfate, copper sulfate and ammonium tetramolybdate, alginic acid and a chelating agent. Compared with the preparation method in the prior art, the preparation method of the present invention has the following characteristics that fulvic acid is produced by using local straw, rape, corn stalk herb waste as raw materials, and a variety of large-medium-trace elements capable of improving the absorption rate of crops are added, such that the fulvic acid-containing large-medium-trace element water-soluble fertilizer is prepared, the environment is improved, the cost of the fulvic acid water-soluble fertilizeris reduced, the benefits of enterprises are increased, and the competitiveness of enterprises is enhanced.

Owner:萍乡市乐乐腐植酸厂

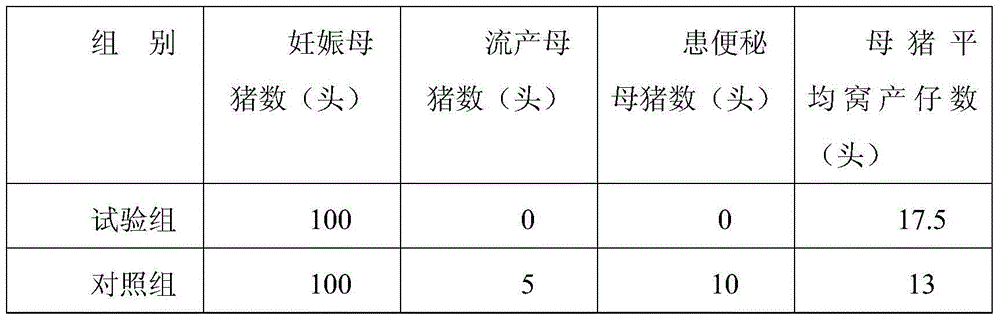

Pregnant sow feed for control of constipation and producing method thereof

InactiveCN104366039APrevention of Abortion and StillbirthPrevent constipationFood processingAnimal feeding stuffRapeseedMagnolia officinalis

The invention discloses a pregnant sow feed for control of constipation and a producing method thereof, and the pregnant sow feed comprises the following raw materials by weight: 150-180 parts of corn flour, 100-150 parts of soybean meal, 120-160 parts of wheat bran, 70-90 parts of flour, 100-130 parts of fresh chicken manure, 50-60 parts of rice bran, 30-50 parts of rapeseed cake, 30-40 parts of wheat straw powder, 0.5-1 part of lactic acid bacteria fermentation agent, 40-50 parts of withered leaves of grass and trees, 50-60 parts of crop straw, 8-10 parts of gracilaria lemaneiformis, 14-18 parts of germ polished rice, 5-6 parts of black sesame seed, 1-2 parts of dehydrated spinach, 1-2 parts of plant protein, 0.5-1 part of white sugar, 5-10 parts of hawthorn powder, 5-7 parts of amaranth leaf powder, 2-3 parts of peanut bran, 2-3 parts of white atractylodes rhizome, 2-3 parts of loranthus parasiticus, 0.5-1 part of plantain, 0.5-1 part of magnolia officinalis, 50-70 parts of silage, 20-30 parts of wheat middling, 3-5 parts of expanded vermiculite powder, 10-15 parts of an attractant, and the proper amount of water.

Owner:HUAIBEI ZHENGXING BIOLOGICAL FEED

Traditional medicine composition for treating cardiovascular and cerebrovascular diseases

InactiveCN1919239AConvenient sourceEasy to industrializePowder deliveryHydroxy compound active ingredientsDiseaseSalvianolic acid B

The invention discloses a Chinese medicinal composition for treating cardiovascular and cerebrovascular diseases, which is prepared from red sage root extract 60.0-95.0%, pseudo-ginseng extract 2.5-25.0%, and natural borneol or rosewood oil 2.5-15.0%. The content of danshensu in the salvia miltiorrhizae extract is 3-10%, the content of total savianolic acid is 50-75%, the content of salvianolic acid B is 20-45%, the content of total saponins in pseudo-ginseng extract is 70-98%. The composition has evident functions in resisting cerebral ischemia and myocardial ischemia, the curative effect is better than the application of single extract of red sage root or notoginseng, thus providing a more effective and more convenient Chinese medicinal composition and preparation clinically.

Owner:TIANJIN TASLY PHARMA CO LTD

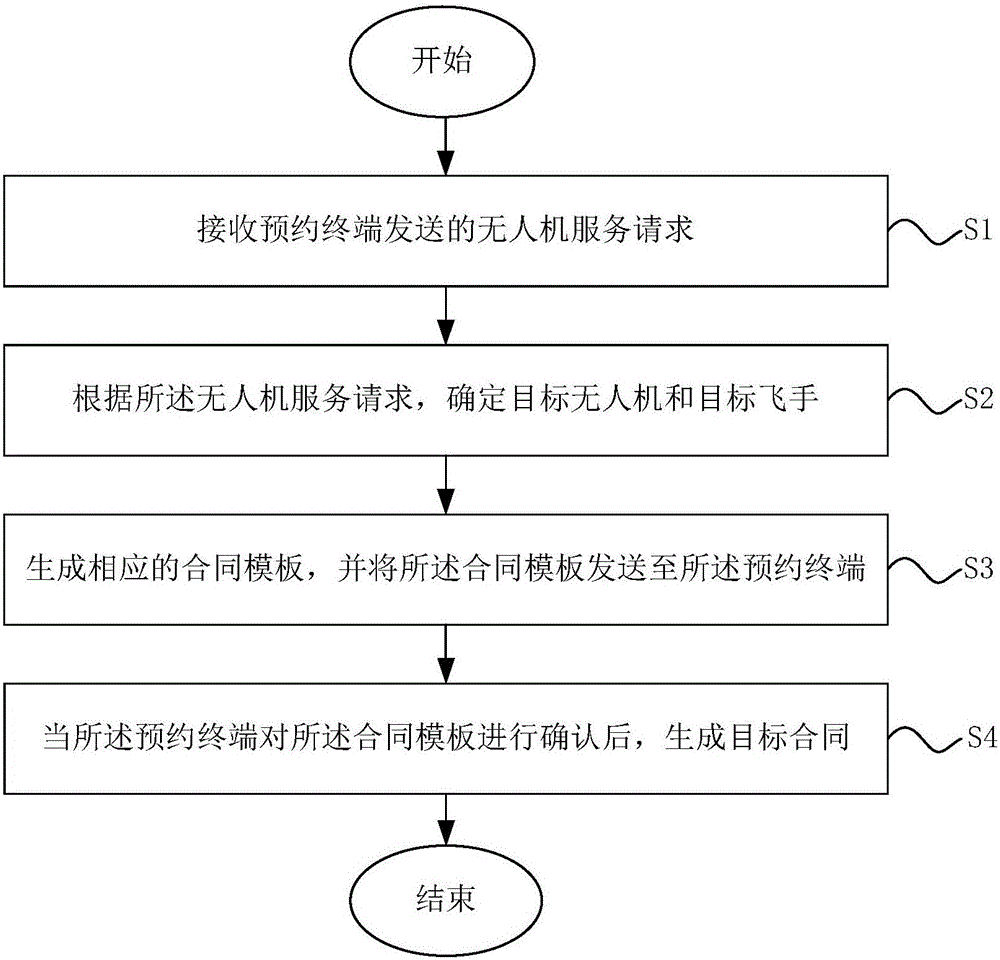

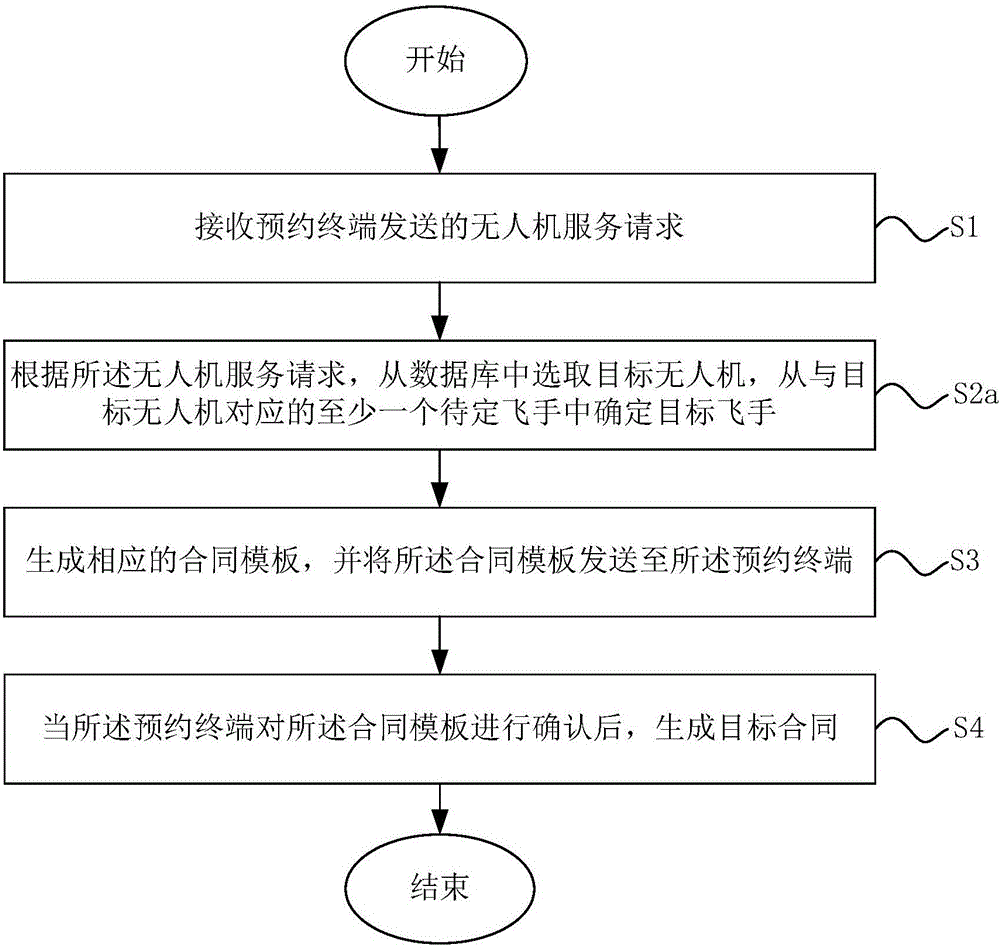

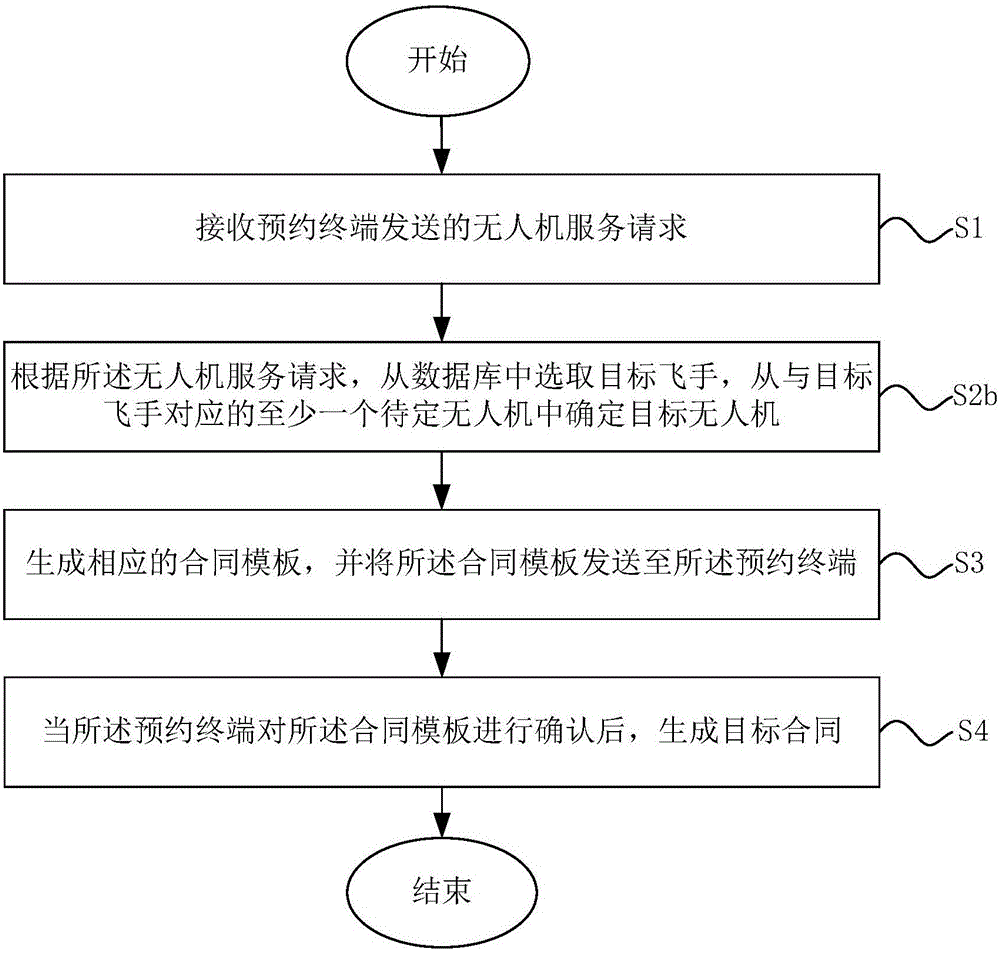

Unmanned plane service contract generation method and system

The invention discloses an unmanned plane service contract generation method and a system. The method comprises steps that S1, an unmanned plane service request sent by a reservation terminal is received; S2, a target unmanned plane and a target pilot are determined according to the unmanned plane service request; S3, a corresponding contract template is generated, and the contract template is sent to the reservation terminal; and S4, after the contract template is confirmed by the reservation terminal, a target contract is generated. According to the method, the target unmanned plane can be determined by a server according to the unmanned plane service request of a user, the target pilot is further determined according to the target unmanned plane, or the target unmanned plane can be determined by the server according to the unmanned plane service request of the user, the target pilot is further determined according to the target unmanned plane, and the final target contract is generated, so unmanned plane service can be improved, inconvenience in face-to-face contract signing can be avoided, new user experience is realized, the user is convenient to use the unmanned plane, and the time of the user and the business party can be saved.

Owner:POWERVISION TECH

Polluted air purifying system and work method thereof

ActiveCN104084015AEfficient purificationMultiple interestsDispersed particle separationChemical reactionExhaust fumes

The invention provides a polluted air purifying system and a work method thereof. The system has an advanced filter system to eliminate toxic emissions in exhaust gas. A new technology is used to capture toxic substances emitted from a pollution source or a chimney of a fire coal boiler, a nano-technology and advanced chemical reactions are used to remove pollutants in the exhaust gas, and principles of the interaction between the gas and a liquid and the interaction between the gas and a solid are applied, so a clean gas is finally emitted, and sulfuric acid and nitric acid generated in the above reaction process are recovered to make a filtering recovery system become beneficial circulation. The polluted air purifying system has a low cost, and benefits for popularized use.

Owner:林小晓 +1

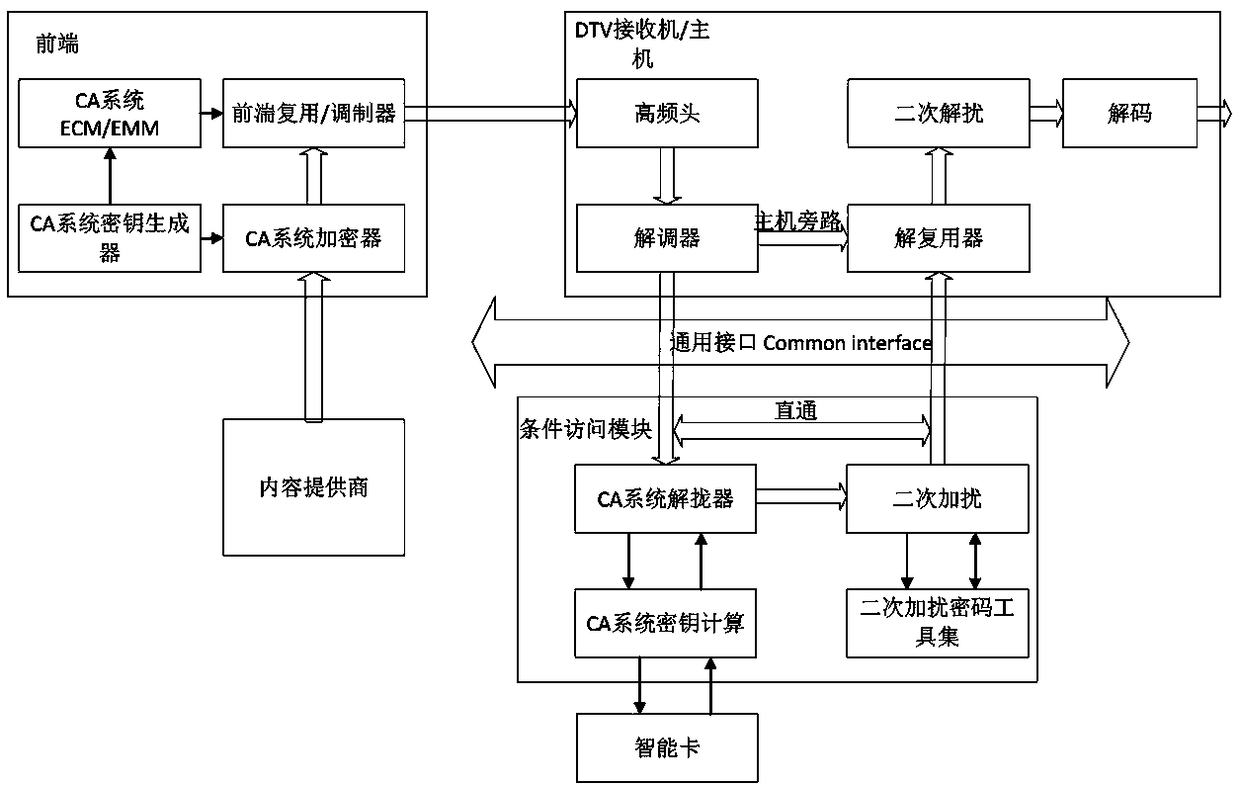

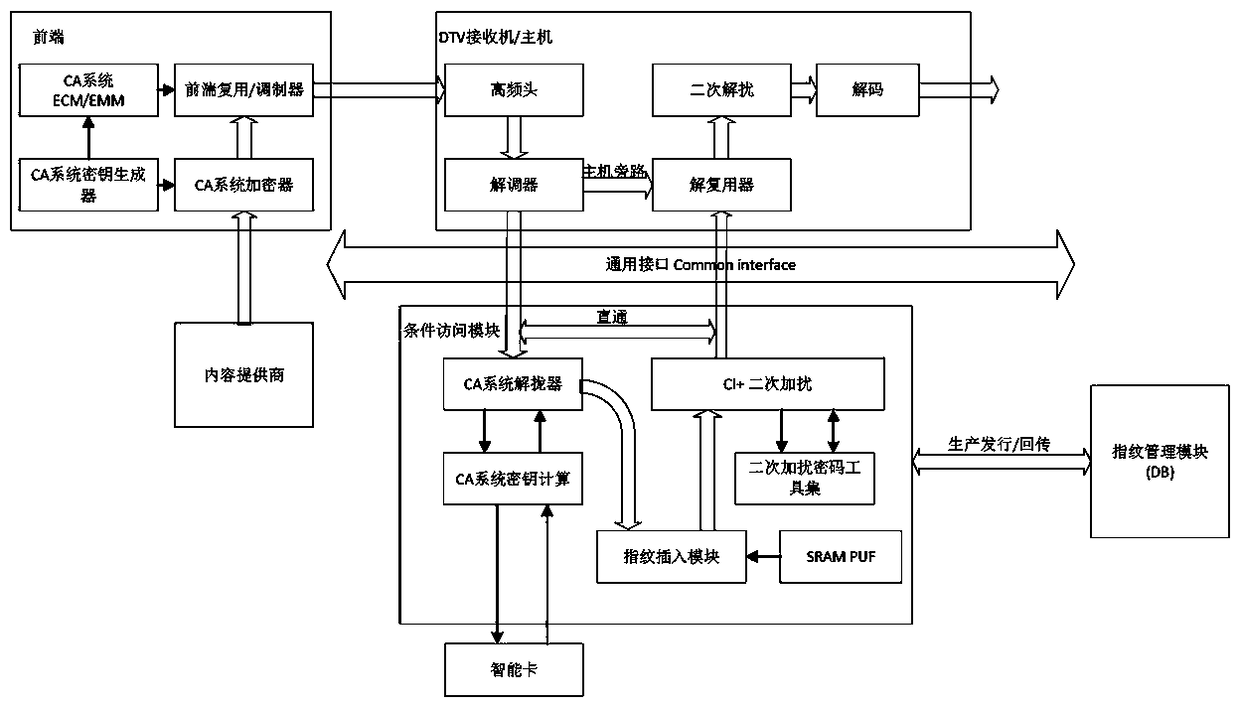

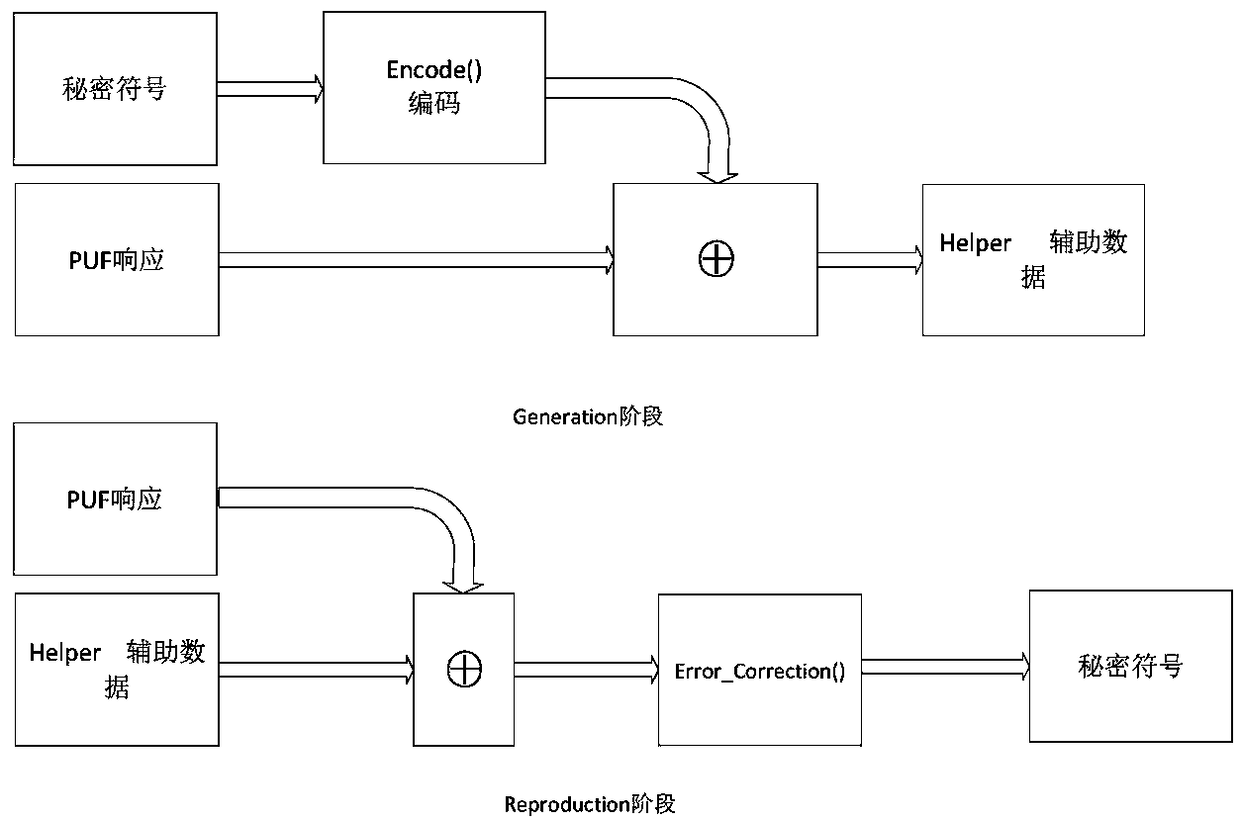

A digital stream media fingerprint watermark protection method and device

InactiveCN109040853ARich Content Protection MethodsLow power requirementsSelective content distributionFingerprintTerminal equipment

The invention relates to a digital stream media fingerprint watermark protection method and device, wherein, the digital stream media fingerprint watermark protection method is characterized in that the digital stream media fingerprint watermark protection method comprises the following steps of: sending a terminal receives audio and video data by an operator; Descrambling the audio and video data; Taking the response data of the PUF on the chip of the terminal as fingerprint watermark data; Inserting the fingerprint watermark data into the audio and video data according to a predetermined format and insertion position. The corresponding fingerprint function can be embedded into the existing terminal equipment chip, and the resource of the chip hardware itself can be used to reduce the implementation cost, so that the fingerprint function has strong implementability. Due to the use of PUF mechanism, the detection results can be relatively reliable to ensure uniqueness through the relevant detection mechanism, and the scheme is more fault-tolerant.

Owner:SHENZHEN STATE MICRO TECH

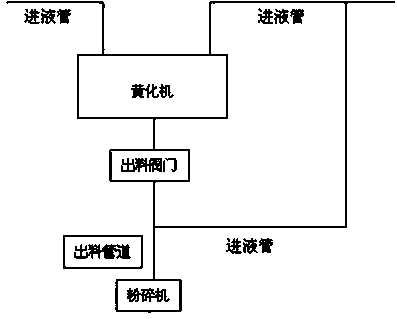

Yellowing process of viscose production

The invention provides a yellowing process of viscose production. The process comprises the following steps: (A) after yellowing reaction is ended, adding primary dissolution alkali and secondary dissolution alkali into a yellowing machine successively, and adding primary dissolution water while adding secondary dissolution alkali; (B) opening a discharging valve to enable cellulose sulfonate in the yellowing machine to flow to a grinding machine from a discharging pipeline, and adding secondary dissolution water into the discharging pipeline while opening the discharging valve; (C) when the discharging rate is more than 90%, adding flushing alkali into the yellowing machine, and fully discharging, namely ending a yellowing cycle. According to the process, the dissolution water is added while the dissolution alkali is added, so that the time for separately adding the dissolution water is saved and the purposes of shortening the production cycle of the yellowing machine, increasing the production capacity of the yellowing machine, improving the operating stability of equipment and reducing the current consumption of the equipment and the energy consumption are achieved.

Owner:CHENGDU GRACE FIBER +1

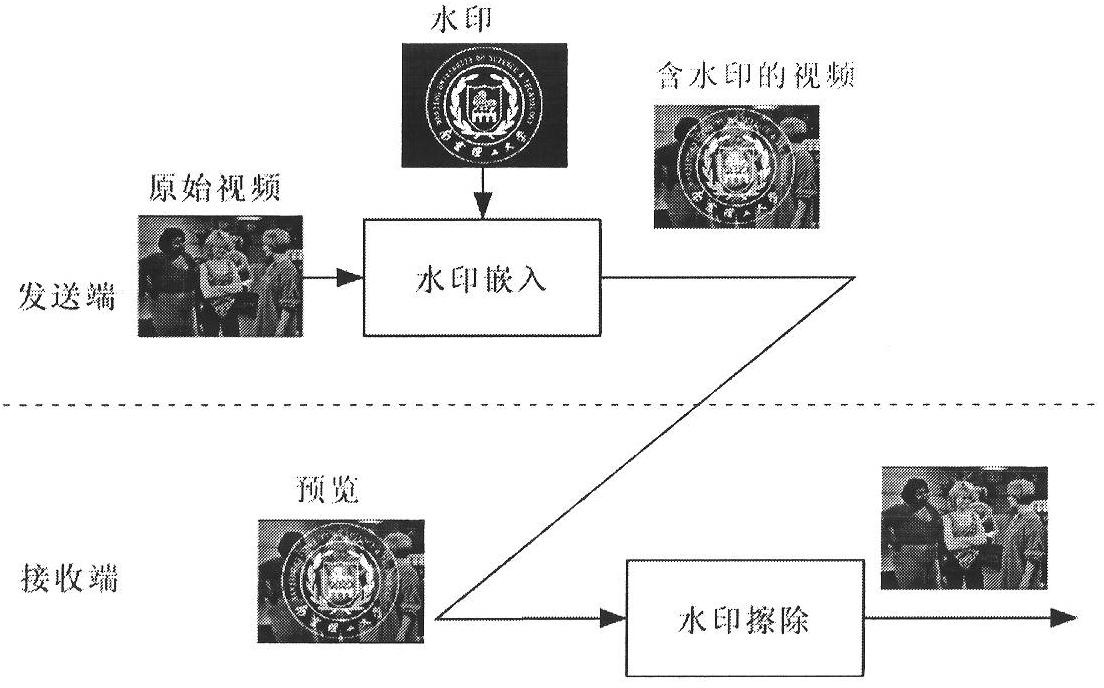

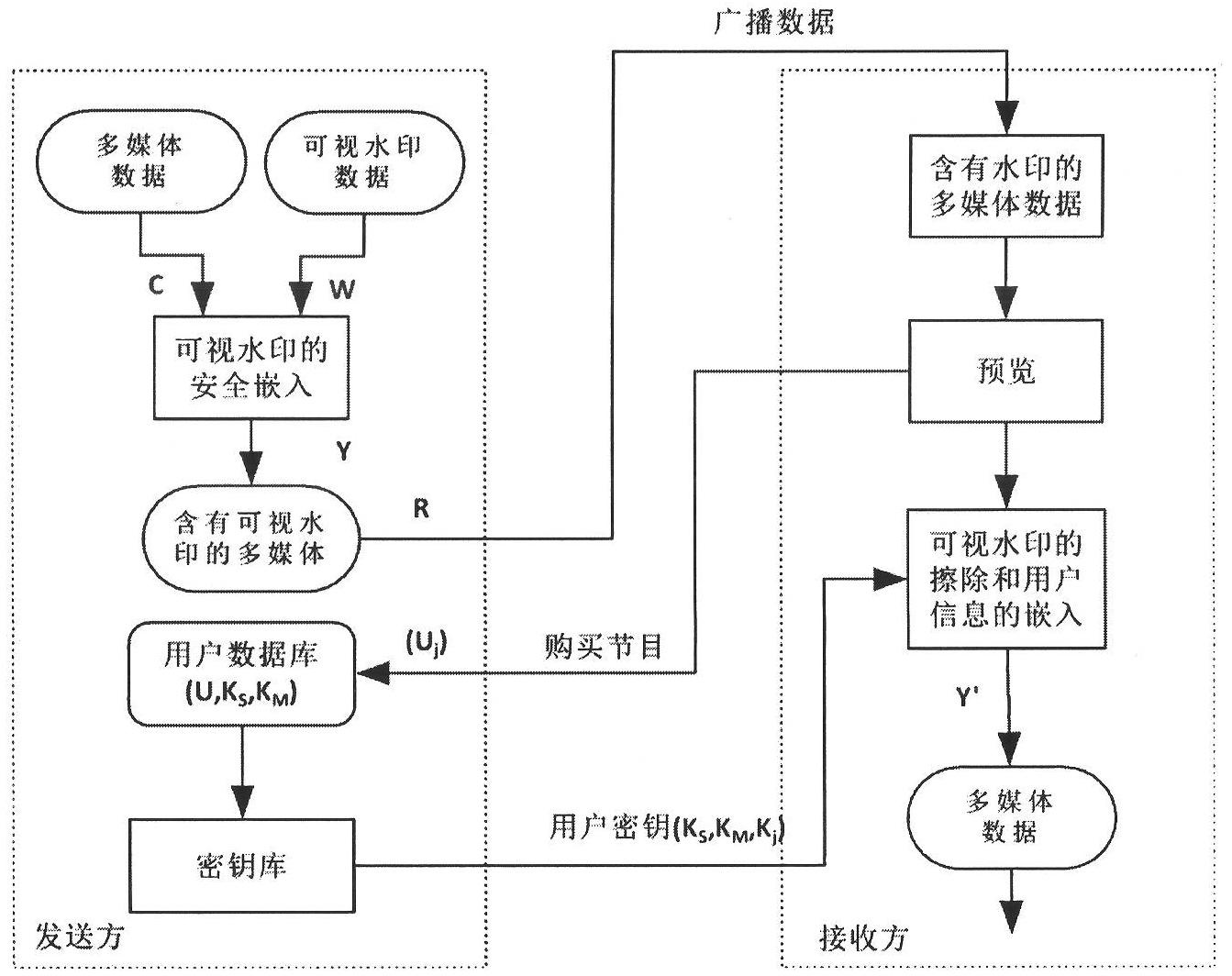

Multimedia copyright protection method for supporting preview and tracking unauthorized distribution

ActiveCN102065325AMultiple interestsProtect interestsTelevision systemsSelective content distributionDigital fingerprintDct coefficient

The invention discloses a multimedia copyright protection method for supporting preview and tracking unauthorized distribution, which comprises the following steps of: embedding a visible watermark, changing each discrete cosine transform (DCT) coefficient of the visible watermark at a transmitting end, then adding the image of each changed DCT coefficient to the DCT coefficient of video data, and transmitting the video data containing the watermark to a receiving end through a broadcast network for preview of the receiving end; interacting the receiving end with the transmitting end; erasingthe visible watermark by using a received watermark key at the receiving end by a user to recover high-quality video data; and when the visible watermark is erased, embedding digital fingerprints of the user into the video data, the visible watermark of which is erased, by the user by using the received digital fingerprint key. The broadcast signal provider only needs to broadcast the signals of the same path to all users, and the users can determine whether to purchase the higher-quality signals in a preview mode.

Owner:NANJING UNIV OF SCI & TECH

Method and nano device for removing heavy metal in flue gas

ActiveCN103949152AGuaranteed mixCheap manufacturingSucessive textile treatmentsCadmium sulfidesHeavy metalsFlue gas

The invention relates to a method for removing heavy metal in flue gas. The method comprises the following steps of (1) enabling a nanometer material to be embedded into a fiber substrate; (2) enabling the flue gas containing the heavy metal to pass through the fiber substrate in which the nanometer material is embedded; and (3) reacting the nanometer material with the heavy metal in the flue gas to capture the heavy metal in the flue gas. The invention also provides a nano device for removing heavy metal in flue gas, and the device is characterized by comprising the fiber substrate in which the nanometer material is embedded. The method and the nano device have the advantages that 1, mercury and other heavy metal substances such as lead generated by fire coal waste gas can be removed; 2, the recycling benefit is far higher than the operating cost of equipment, so that a user can obtain more profit; 3, the method and the device are suitable for other industrial markets such as a cement plant, an iron and steel plant, a municipal government waste burning plant, a medical waste burning plant, a chlorine manufacturer, and a pulp and paper manufacturing plant; 4, the device can produce centrifugal force by the rotation of a fan, so that the flue gas is guaranteed to be completely mixed without generating back pressure.

Owner:林小晓 +1

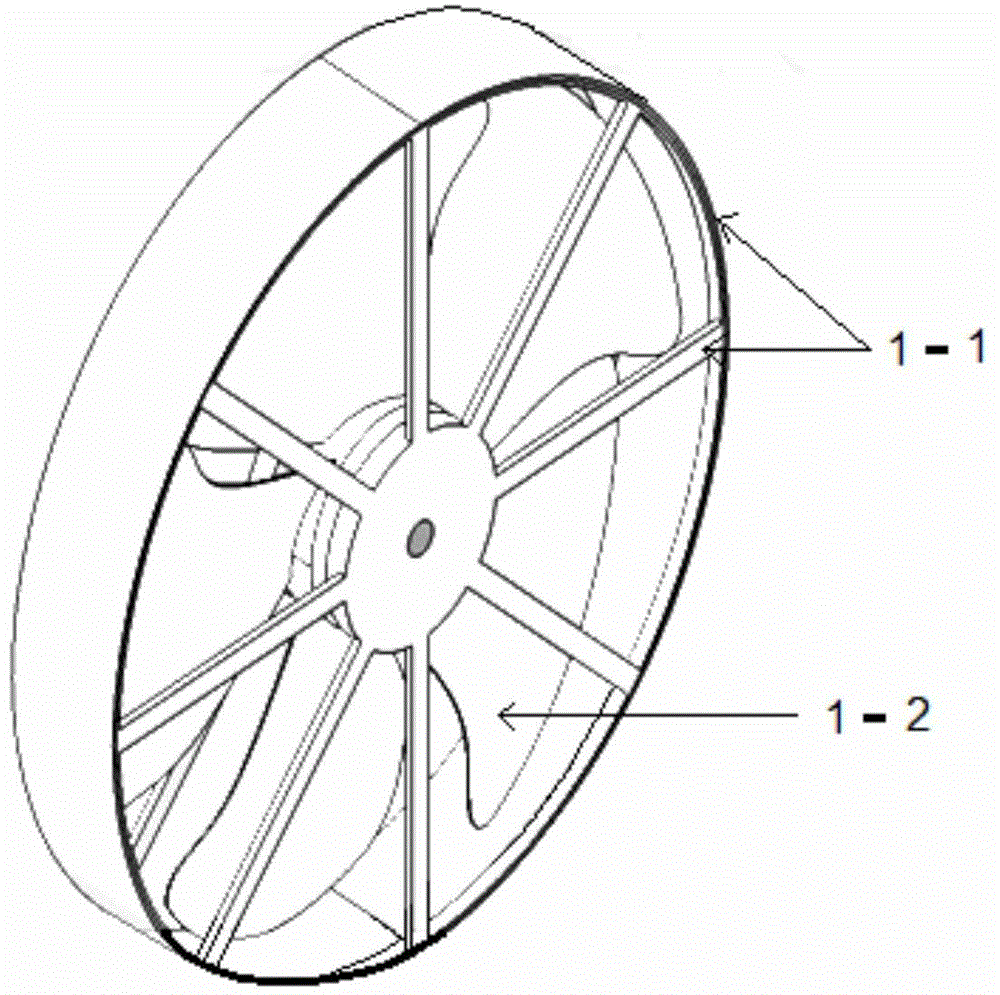

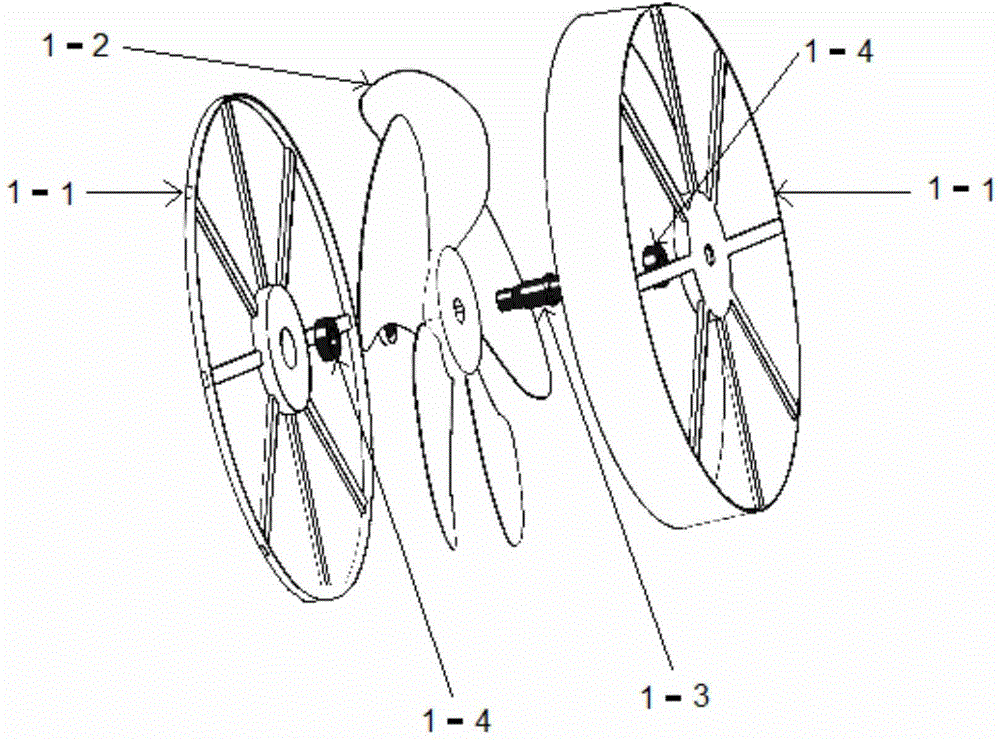

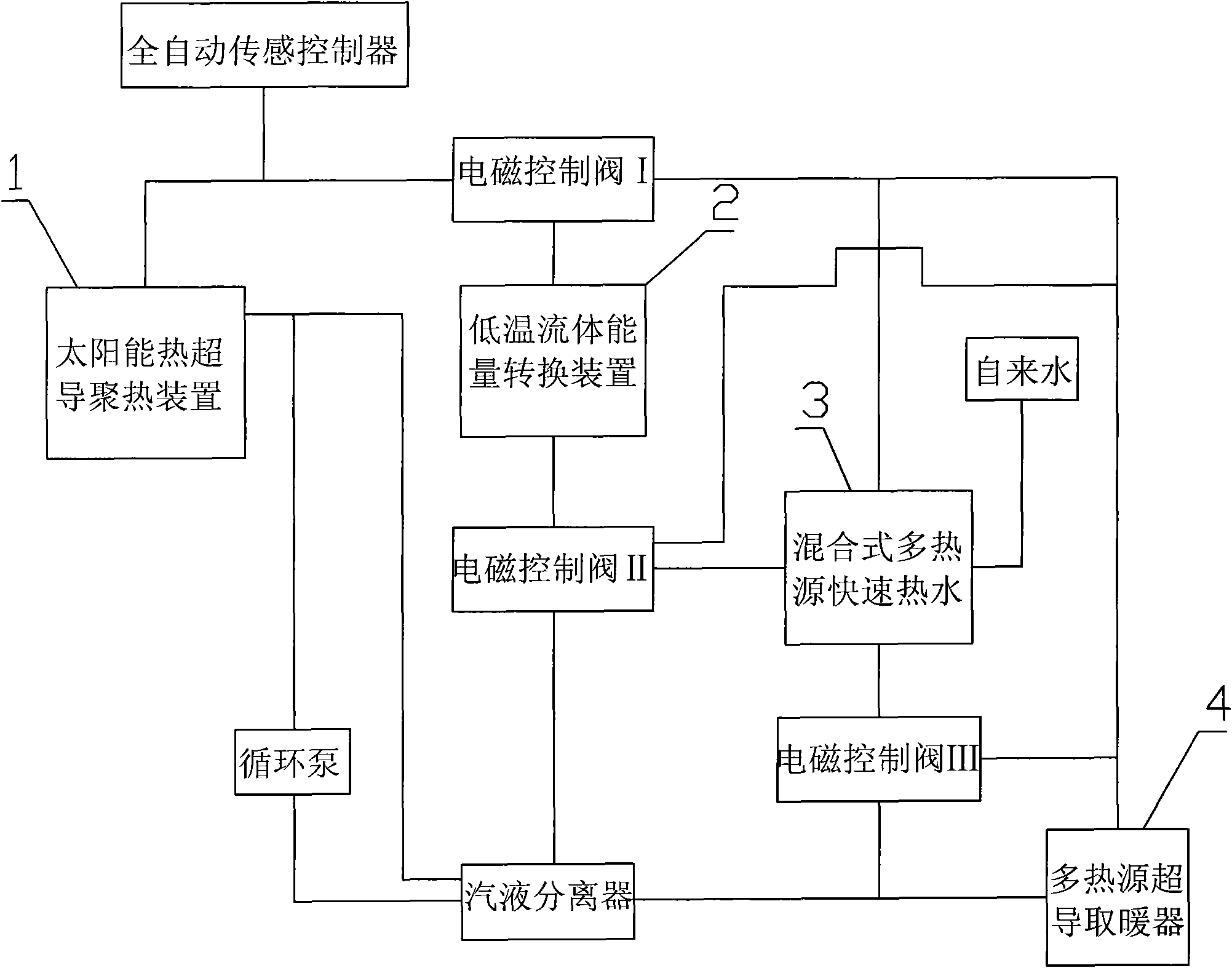

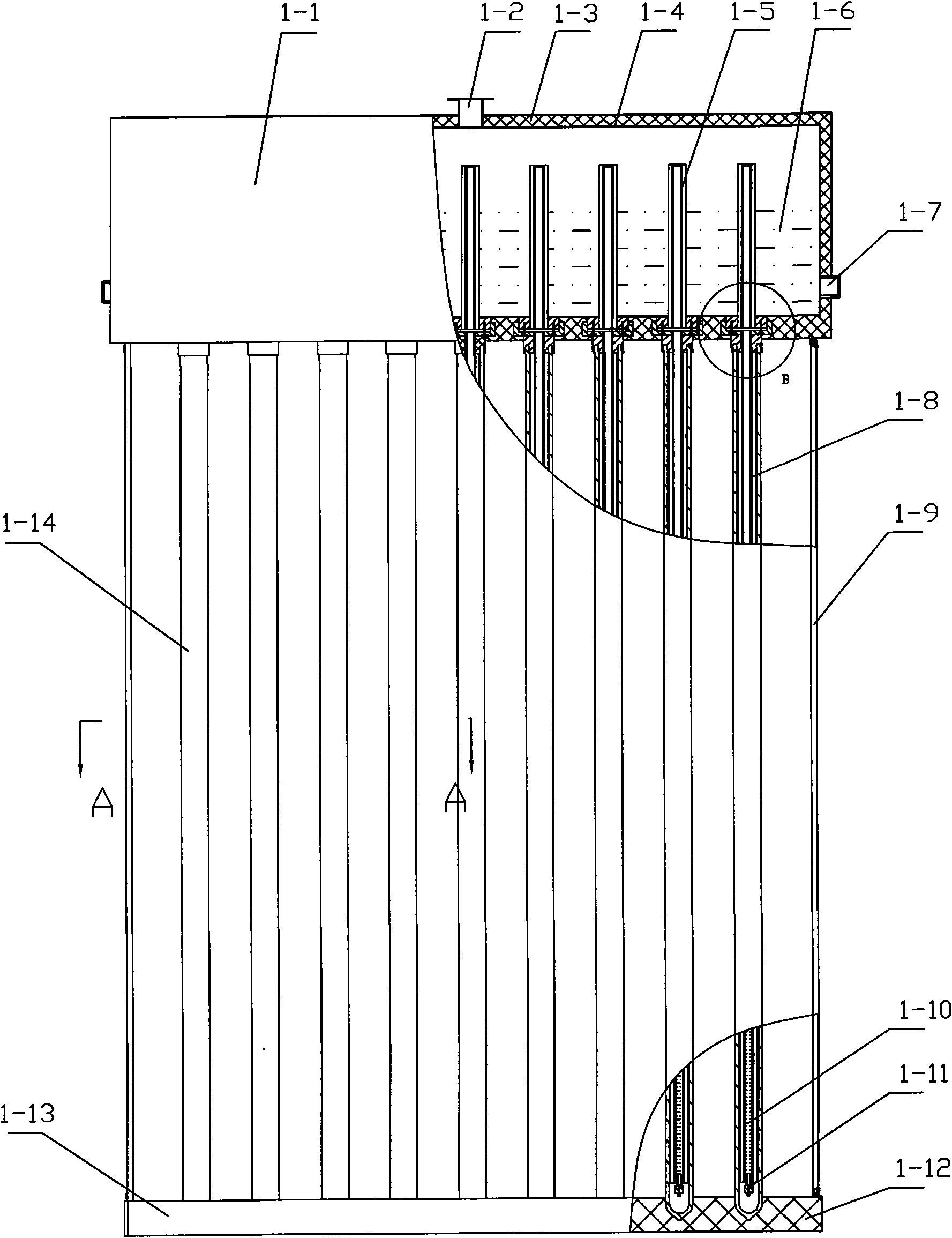

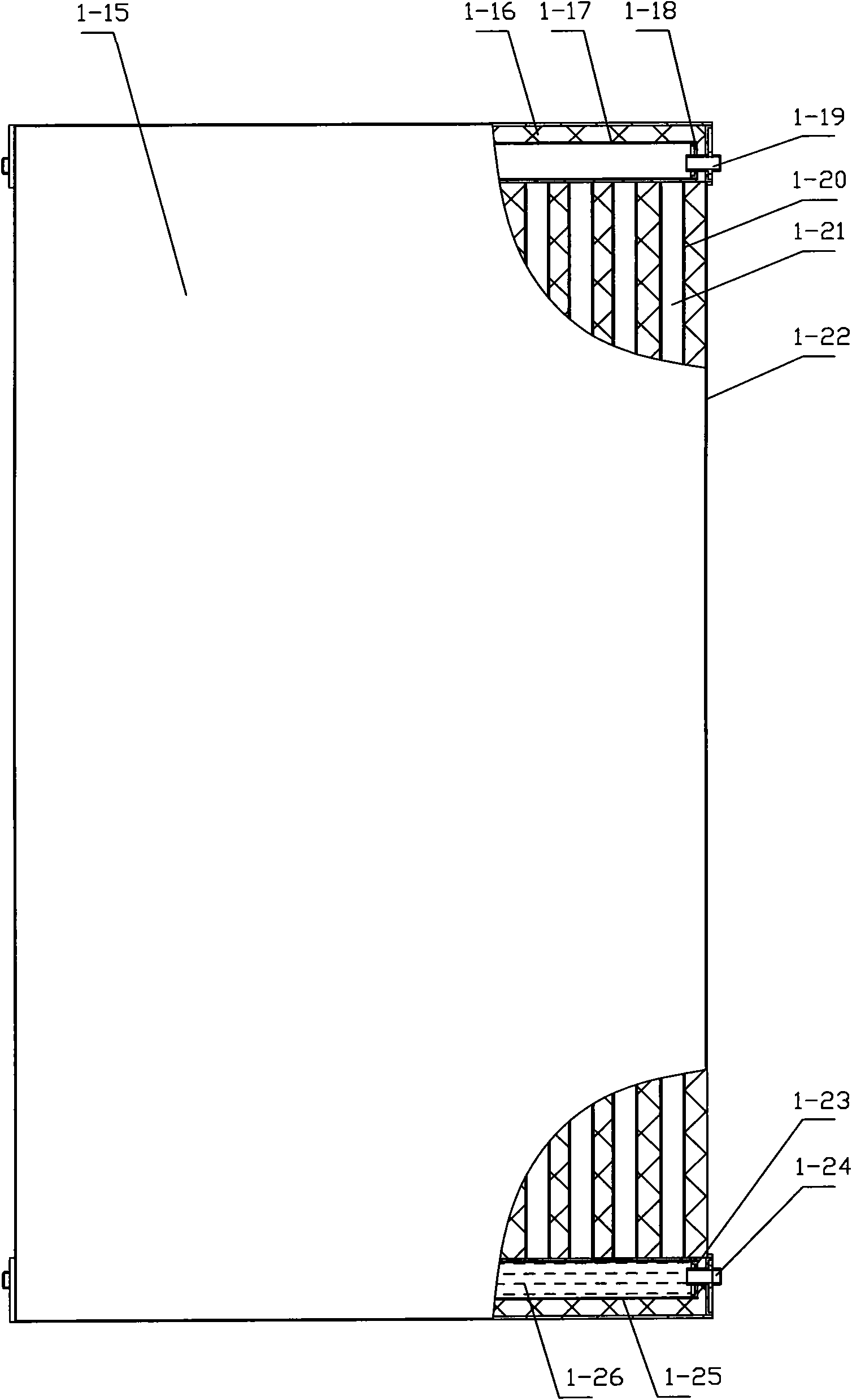

Heat collection type solar photothermoelectric system

InactiveCN101586881AWill not polluteReasonable designSolar heating energyFrom solar energyThermal energyVapor–liquid separator

The invention relates to a heat collection type solar photothermoelectric system, which converts solar light and heat energy into electrical energy, heat energy and other energy sources required for production and living. The system comprises a solar superconducting heat collection device, a cryogenic fluid energy conversion device, a combined type multi-heat source instantaneous water heater, a multi-heat source superconducting heater, a full automatic sensor controller, a gas-liquid separator and a recirculation pump; the solar superconducting heat collection device is connected with the cryogenic fluid energy conversion device, the combined type multi-heat source instantaneous water heater and the multi-heat source superconducting heater through pipes and solenoid electric valves I respectively; an air outlet of the cryogenic fluid energy conversion device is connected with the combined type multi-heat source instantaneous water heater and the gas-liquid separator through solenoid electric valves II and pipes respectively; a medium outlet of the combined type multi-heat source instantaneous water heater is connected with the multi-heat source superconducting heater and the gas-liquid separator through pipes and solenoid electric valves III respectively; and gas in the gas-liquid separator is connected with the medium circulation interface of the solar superconducting heat collection device through a pipe.

Owner:WUXI C SOLAR NEW ENERGY TECH

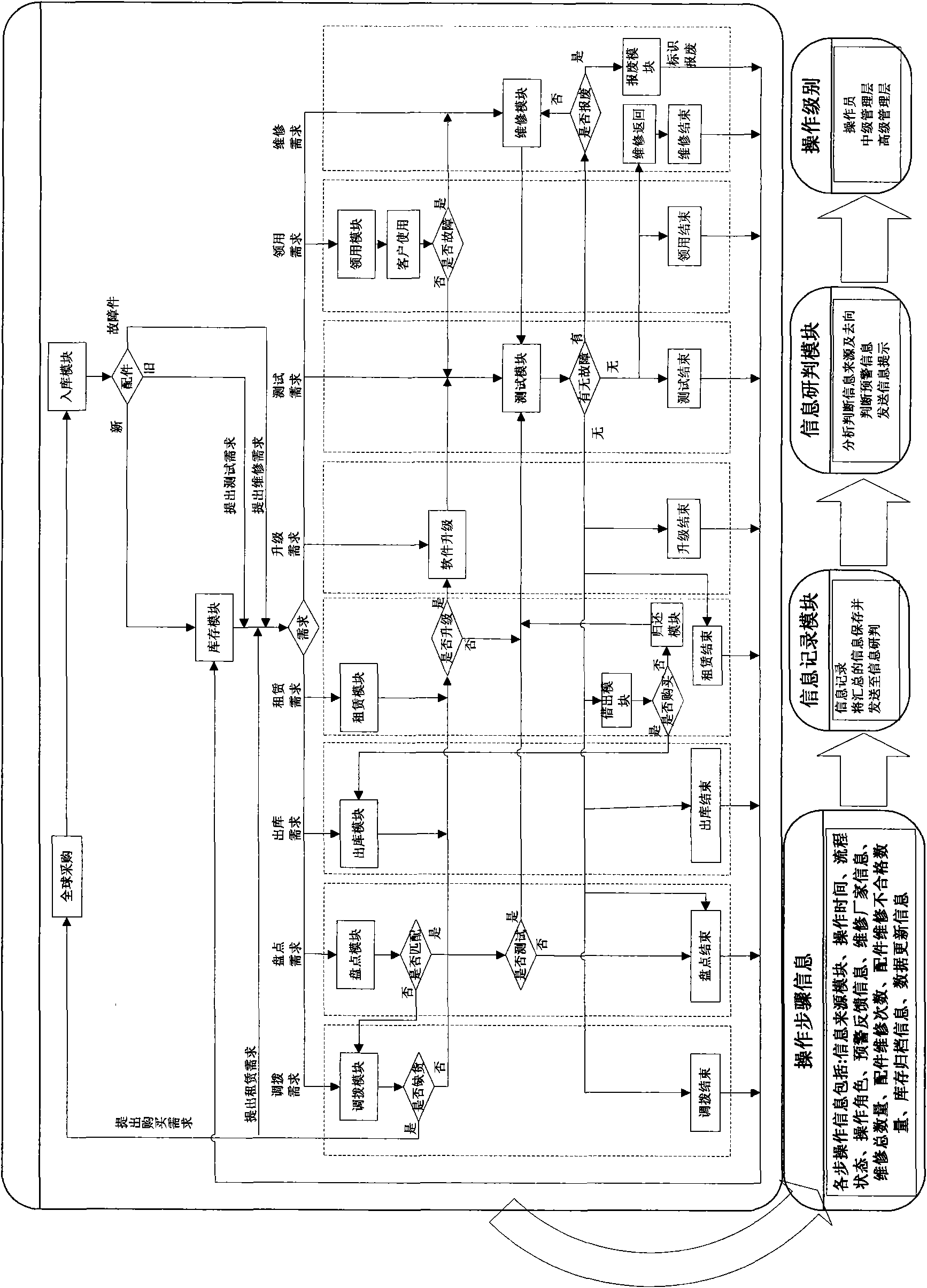

Testing and early warning electronic system for maintaining communication network

ActiveCN101639908ATimely processingMonitor and grasp the operation process throughout the processResourcesElectronic systemsBusiness management

The invention discloses a testing and early warning electronic system for maintaining communication network, effectively controlling interaction process and helping enterprises to track and control the interaction process. By controlling the each step of the process and collecting and analyzing the information, the system has a strong early warning function, can exactly record work flow time and inventory information, and reduces the error frequency of manual operation; and simultaneously, a perfect early warning information indicating function can automatically judge the urgent degree of theprompt message according to a prompt preset value, so as to send the prompt information to different management layers, not only enhance the layering of business management, but also better help the management operators to manage the weaknesses of the business, and promotes the enterprises to obtain greater benefit.

Owner:北京千禧维讯科技有限公司

Yellowing system for viscose fiber production

Owner:CHENGDU GRACE FIBER +1

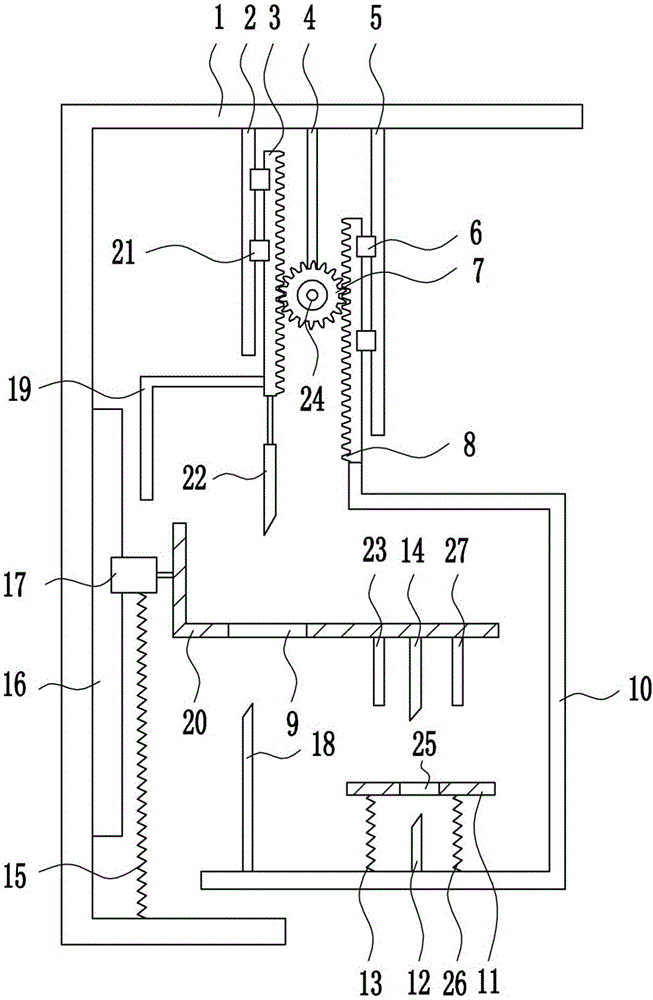

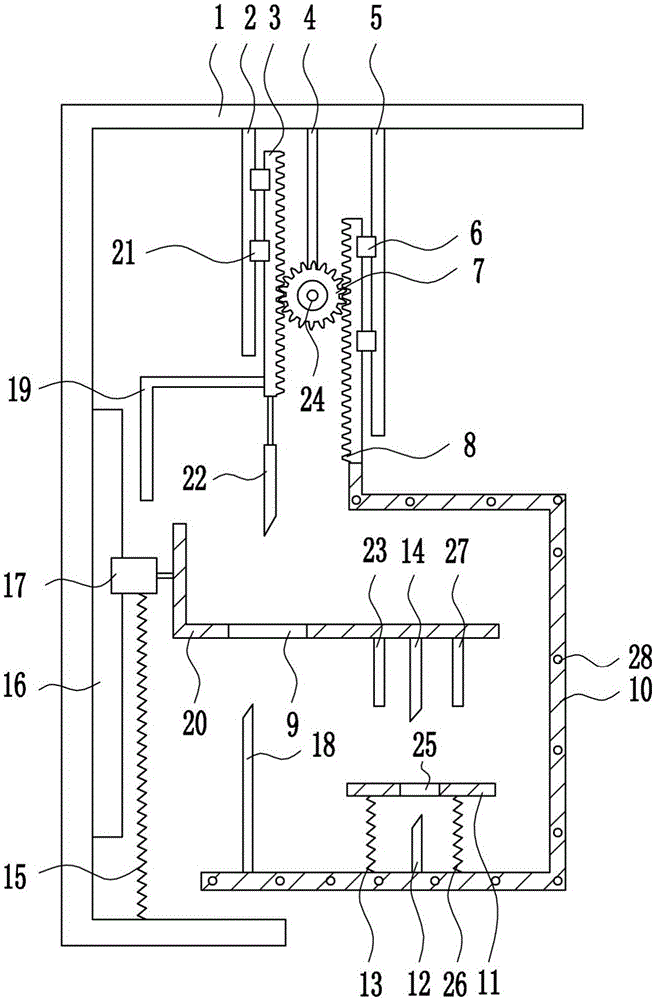

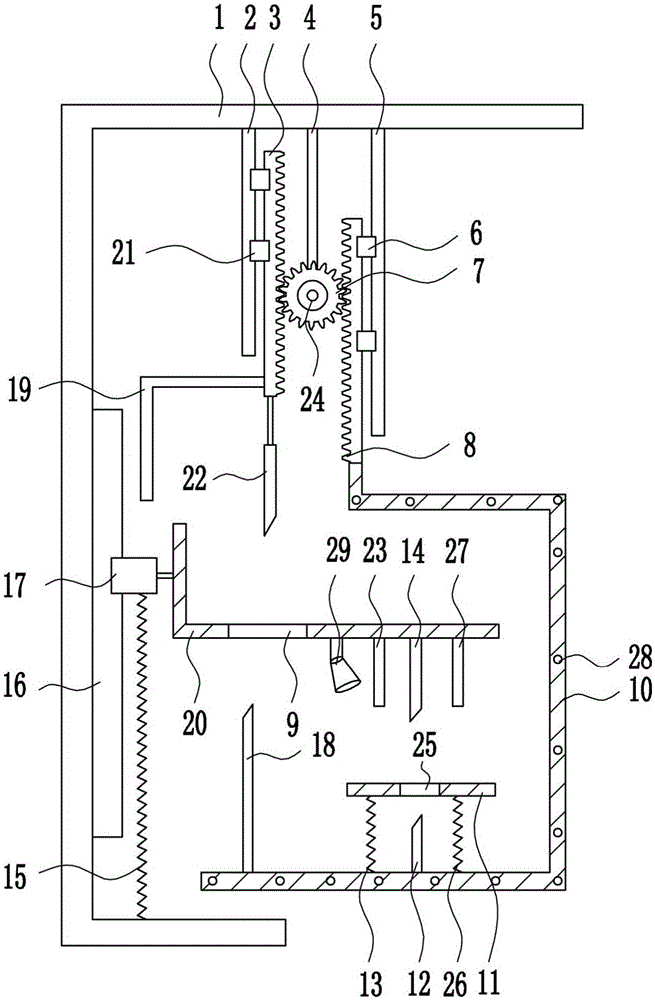

Rapid punching device for shoebox for shoemaking

The invention relates to a punching device, in particular to a rapid punching device for a shoebox for shoemaking. The invention aims to solve the technical problem of providing the rapid punching device for the shoebox for shoemaking which is high in punching efficiency. For solving the above technical problem, the rapid punching device for the shoebox for shoemaking is provided. The rapid punching device comprises a support, a first slideway, a first rack, a first connection rod, a second slideway, second sliding blocks, a gear, a second rack, a second connection rod, a placement plate, a second electric drill, a first spring, a first electric drill, a second spring, a third slideway, a third sliding block, a third electric drill, a first pushing rod and the like, wherein the first slideway, the first connection rod and the second slideway are sequentially arranged on the top in the support. According to the rapid punching device, the shoe box on an L-shaped support rod are punched through a fourth electric drill and the third electric drill, and the shoe box on the placement plate is punched through the first electric drill and the second electric drill, so that punching speed is enhanced.

Owner:浙江芙蓉印务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com