Method and nano device for removing heavy metal in flue gas

A technology for removing heavy metals and heavy metals, applied in metal/metal oxide/metal hydroxide catalysts, separation methods, chemical instruments and methods, etc., can solve problems such as mercury leakage and groundwater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: a kind of method for eliminating heavy metals in flue gas is characterized in that it comprises the following steps:

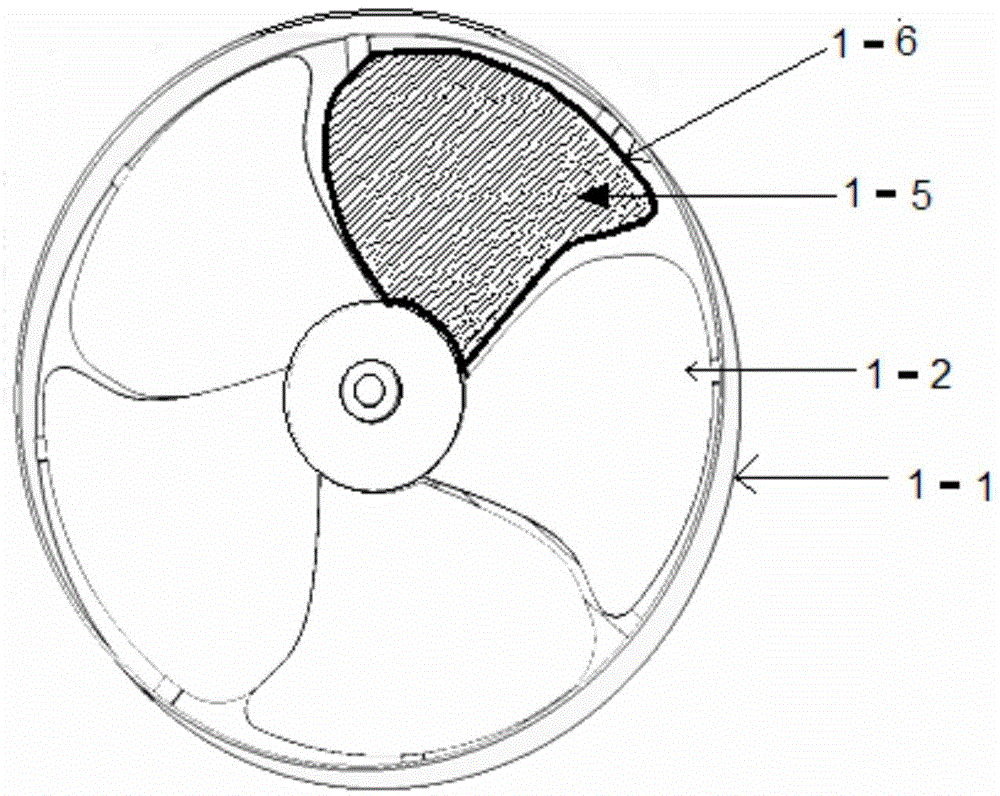

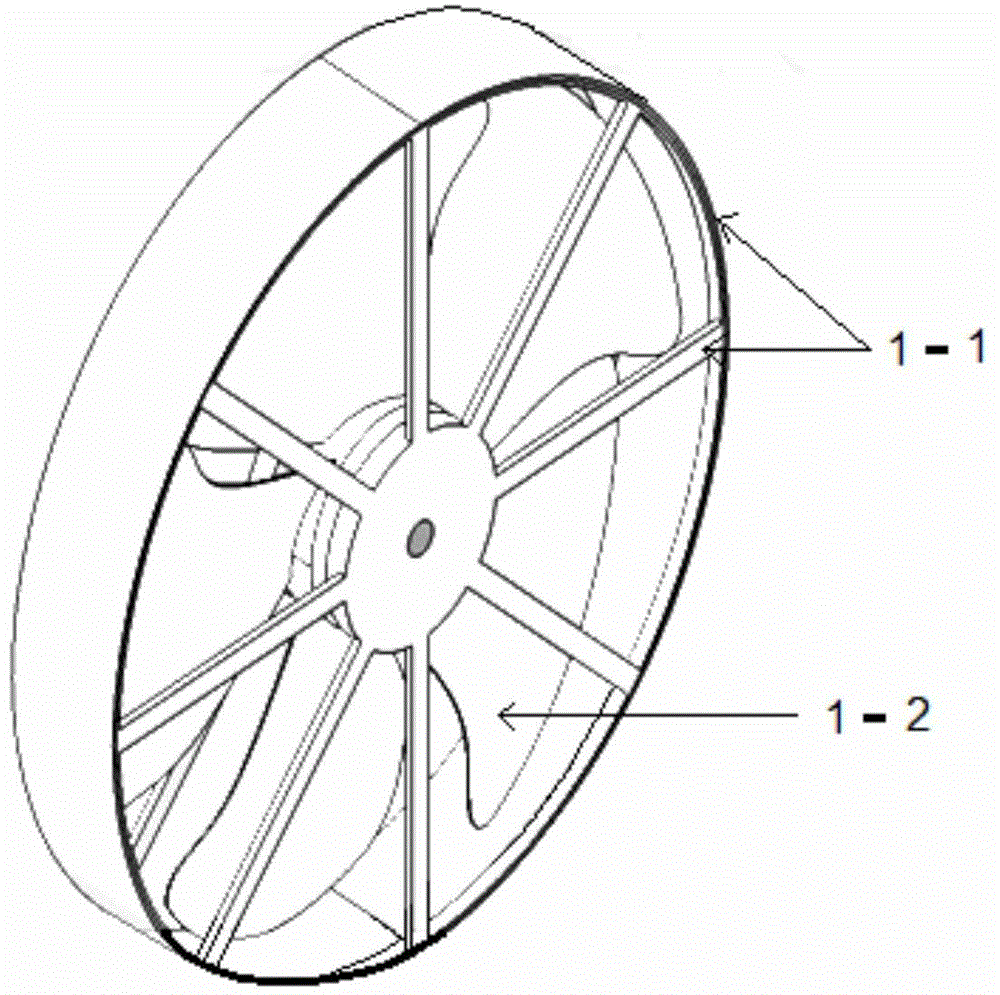

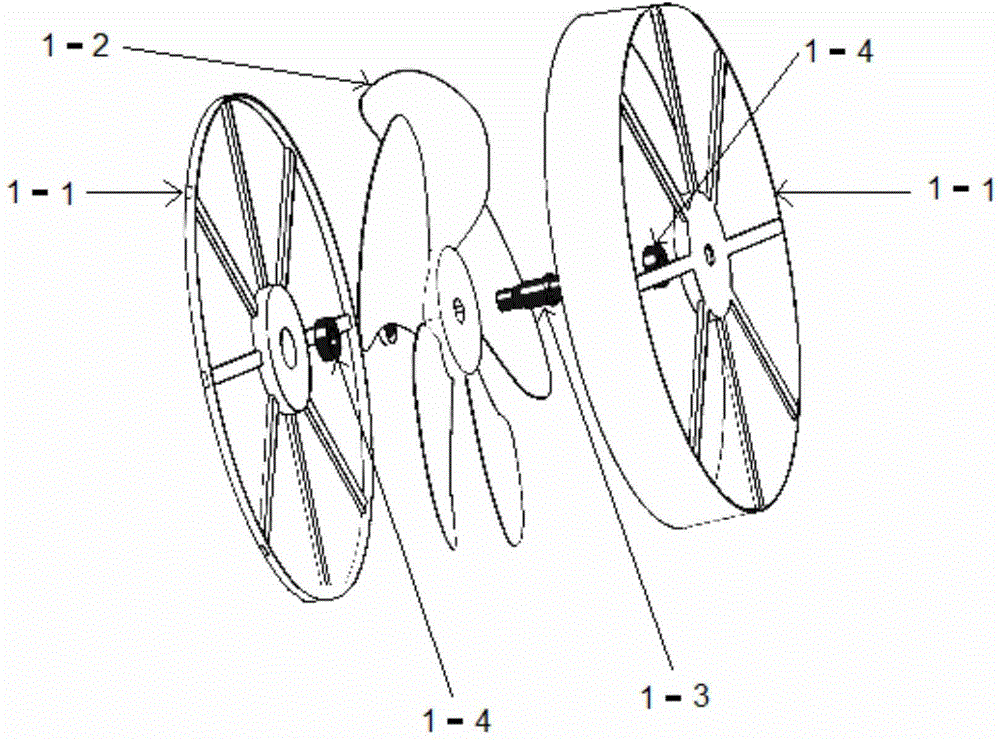

[0082] (1) Embedding nanomaterials on the fiber matrix; (see Figure 11-1 , Figure 11-2 , Figure 12-1 , Figure 12-2 )

[0083] (2) Make the flue gas containing heavy metals pass through the fiber matrix embedded with nanomaterials;

[0084] (3) The nanomaterial reacts with the heavy metals in the flue gas and captures the heavy metals in the flue gas.

[0085] The method of embedding nanomaterials on the fiber matrix is as follows:

[0086] Adhesive is attached to the fiber substrate; before the adhesive dries, the nanomaterial is sprayed onto the fabric by a nanosprayer; after the nanomaterial is sprayed, it is left at room temperature for at least 24 hours to fully cure. (See Figure 11-1 , Figure 11-2 , Figure 12-1 , Figure 12-2 )

[0087] The adhesive is selected REN50 to 80( ) of silicone resin solution. The R...

Embodiment 2

[0103] Embodiment 2: a kind of method for eliminating heavy metals in flue gas is characterized in that it comprises the following steps:

[0104] (1) Embedding nanomaterials on the fiber matrix;

[0105] (2) Make the flue gas containing heavy metals pass through the fiber matrix embedded with nanomaterials;

[0106] (3) The nanomaterial reacts with the heavy metals in the flue gas and captures the heavy metals in the flue gas.

[0107] The method for embedding the nanomaterials on the fiber matrix is: directly loading the nanomaterials on the fiber matrix: suspending the nanomaterials in a volatile solvent; soaking the fiber matrix in the nanomaterial suspension, or passing the nanomaterials through The sprayer is sprayed on the fiber substrate; the fiber substrate with nanomaterials attached is heated in an oven at 500 degrees for 3 to 4 hours; after the solution evaporates, nanowires and nanoparticles will be interwoven with the fiber network; cooling After reaching room te...

Embodiment 3

[0142] Embodiment 3: a kind of method for eliminating heavy metals in flue gas is characterized in that it comprises the following steps:

[0143] (1) Embedding nanomaterials on the fiber matrix;

[0144] (2) Make the flue gas containing heavy metals pass through the fiber matrix embedded with nanomaterials;

[0145] (3) The nanomaterial reacts with the heavy metals in the flue gas and captures the heavy metals in the flue gas.

[0146] The method of embedding nanomaterials on the fiber matrix is as follows:

[0147] Adhesive is attached to the fiber substrate; before the adhesive dries, the nanomaterial is sprayed onto the fabric by a nanosprayer; after the nanomaterial is sprayed, it is left at room temperature for at least 24 hours to fully cure

[0148] The adhesive epoxy.

[0149] The nanomaterial is CdS nanowire.

[0150] The synthetic method of described CdS nanowire is:

[0151] Put toluene, distilled water, and 1,12 alkanethiol in a picoclave high-pressure reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com