Static mixer

A technology of static mixers and mixers, applied in the direction of fluid mixers, mixers, mixers with rotating containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

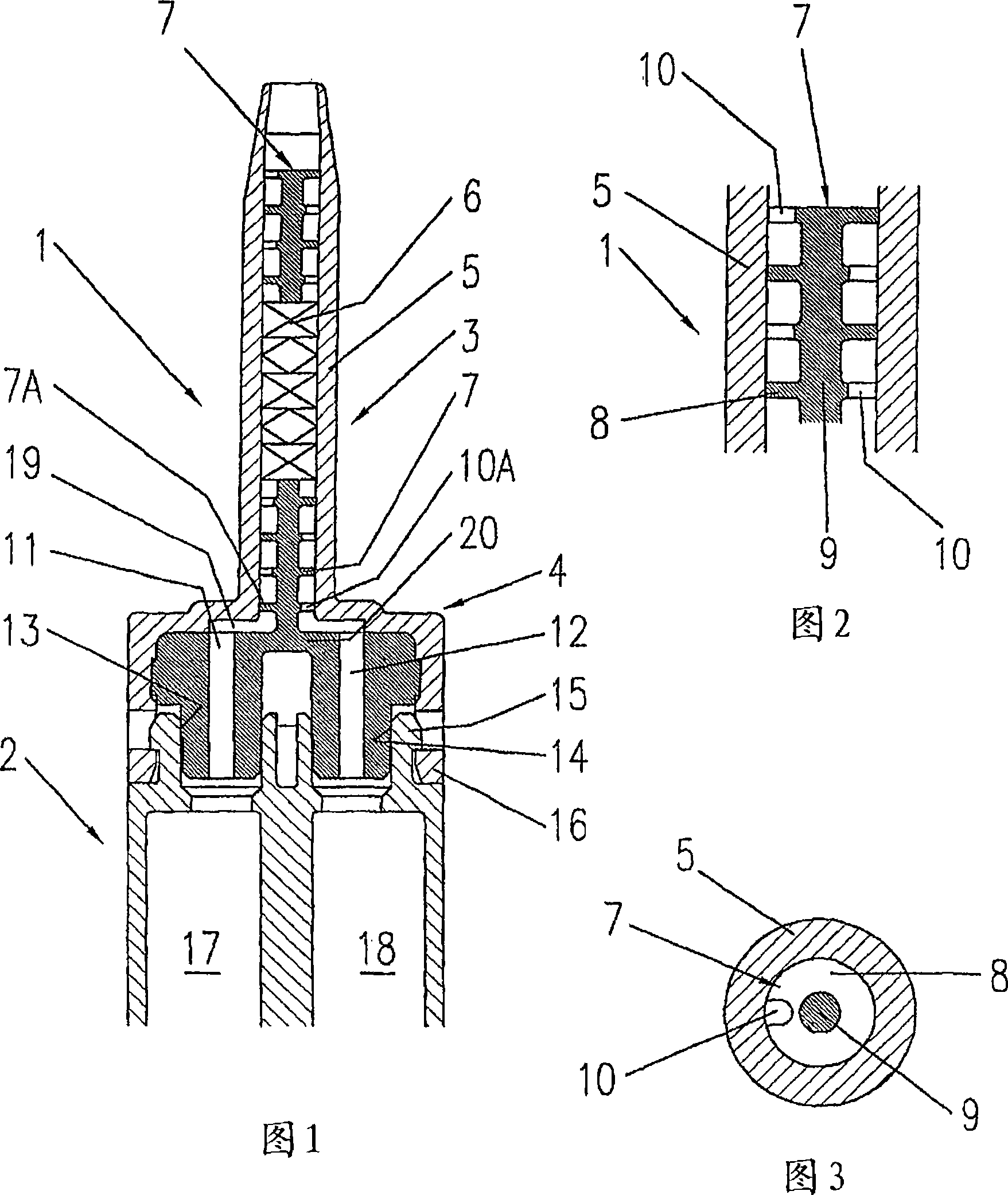

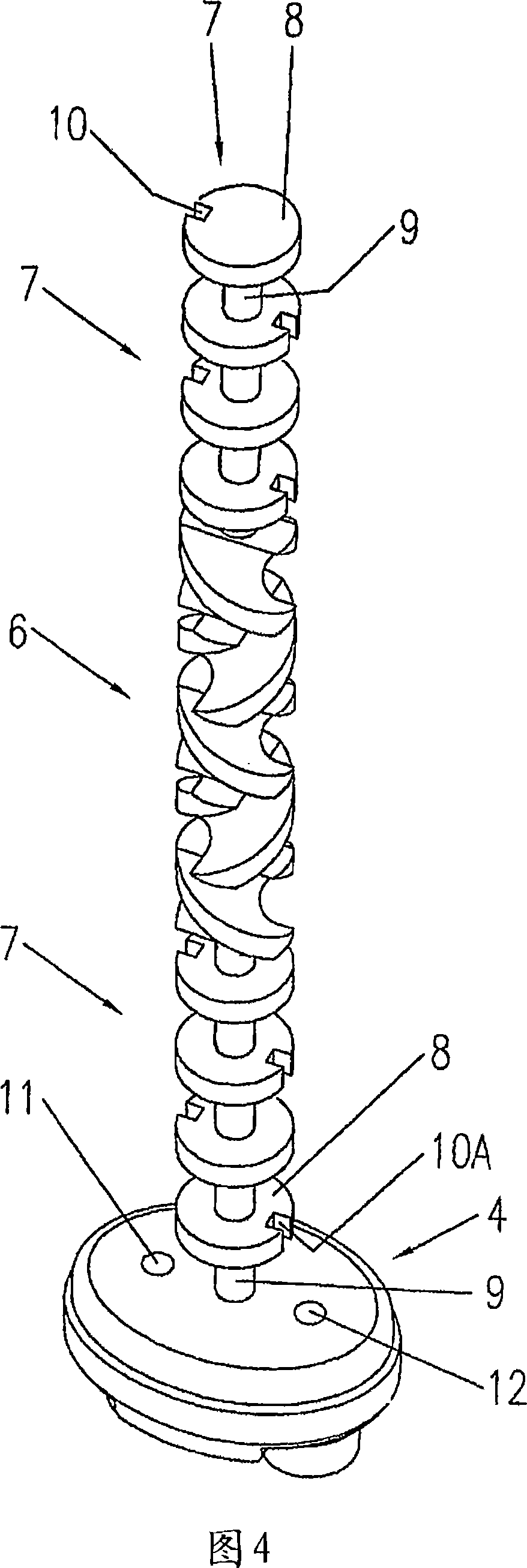

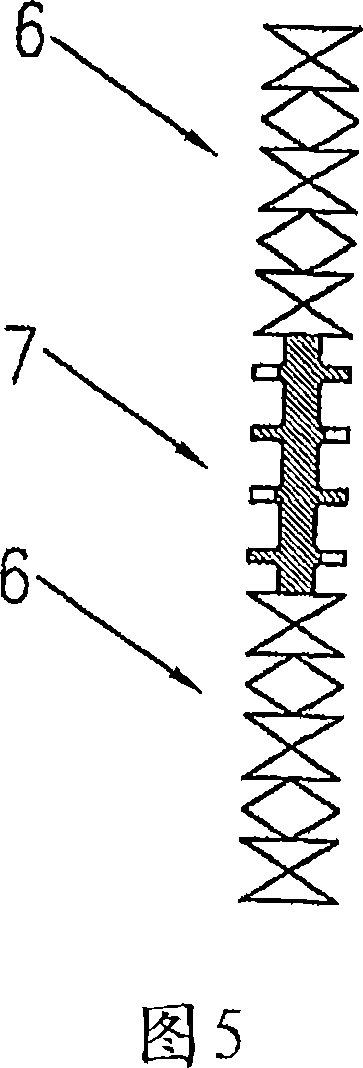

[0018] FIG. 1 shows a longitudinal section of a mixer 1 according to the invention fastened to a two-component cartridge 2 and having a housing 3 with an inlet portion 4 . Different types of mixing elements are arranged in the cylindrical housing part 5 . In the middle part of the mixing element, a conventional mixing spiral 6 is arranged, flanked by novel mixing elements 7 , see also FIGS. 2 and 3 .

[0019] The novel mixing element 7 is designed as a shear plate and comprises a disc 8 fastened to a hub 9 and having channels 10 . As shown particularly in FIG. 2 , the channels 10 are arranged such that each channel is rotationally offset, eg, by 180°, relative to an adjacent channel. The shape of the channel is chosen such that the liquid is subjected to high velocity or shear stress, respectively, so as to create subsequent eddies and ensure good mixing of even the smallest quantities. However, the specific shape is not limited to the illustrated shape and may be different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com