Method and apparatus for cleaning objects in an automatic cleaning appliance using an oxidizing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

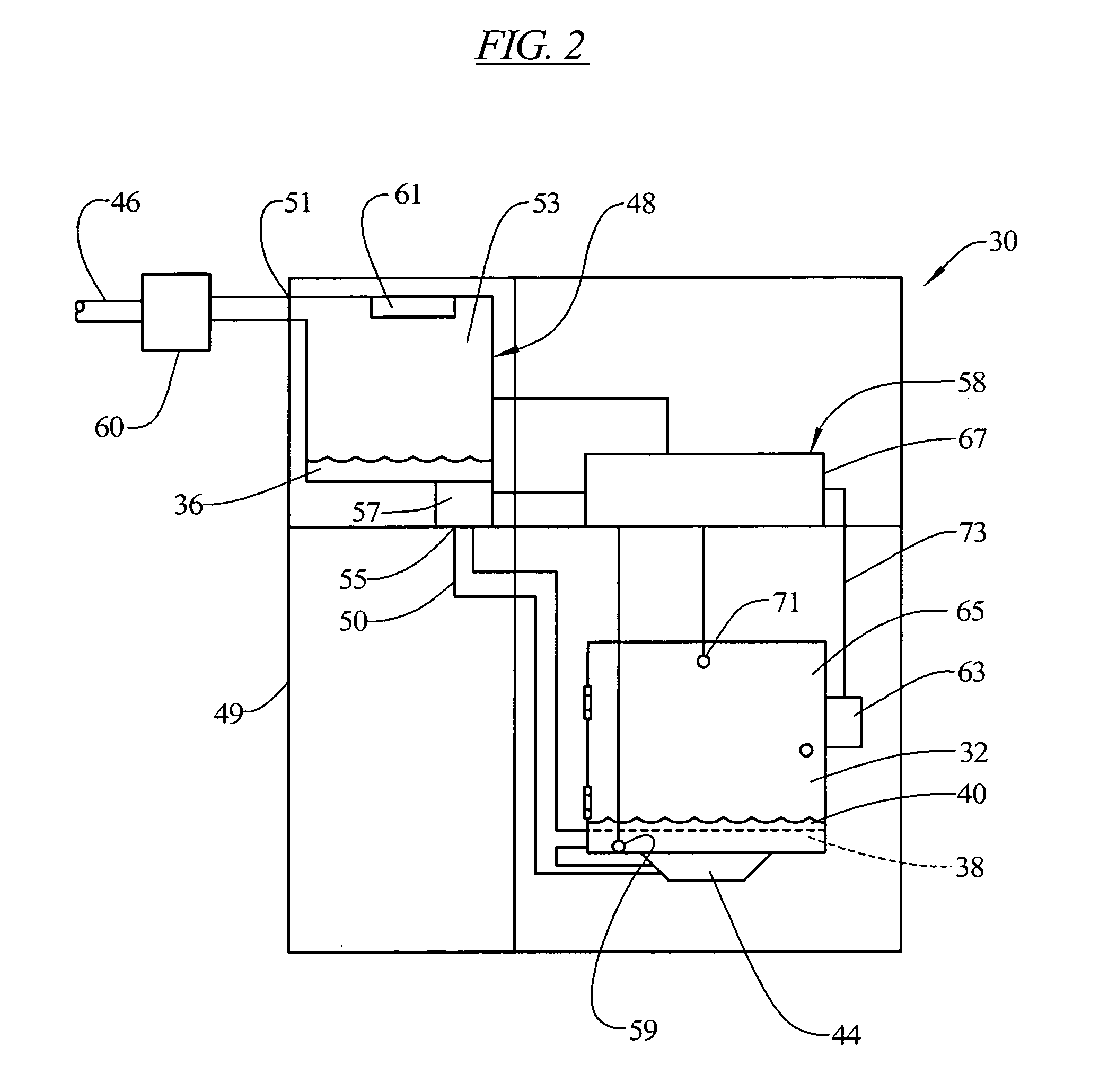

[0025] The present invention is directed to a method for cleaning objects in an automatic wash system or cleaning appliance using an oxidizing agent, as well as for an apparatus to effect such cleaning.

[0026] Although a variety of oxidizing agents may be used in the method of the invention, one such agent is hydrogen peroxide, and this particular agent is discussed in detail below. However, it should be understood that the present invention is not limited to this particular oxidizing agent. Some additional chemical compositions include ozone, percarbonate, perborate, singlet oxygen, peroxy acids (RCO3H), hypochlorite, chlorine and chlorine dioxide, metal oxyacids such as all forms of chromium (VI) and permanganate ion (KMnO4), nitric acid, nitrous acid, sodium peroxide, halogens, but more specifically Br2 and Cl2 and compounds containing Cl− and Br− and mild oxidizing agents such as Ag+ and Cu2+.

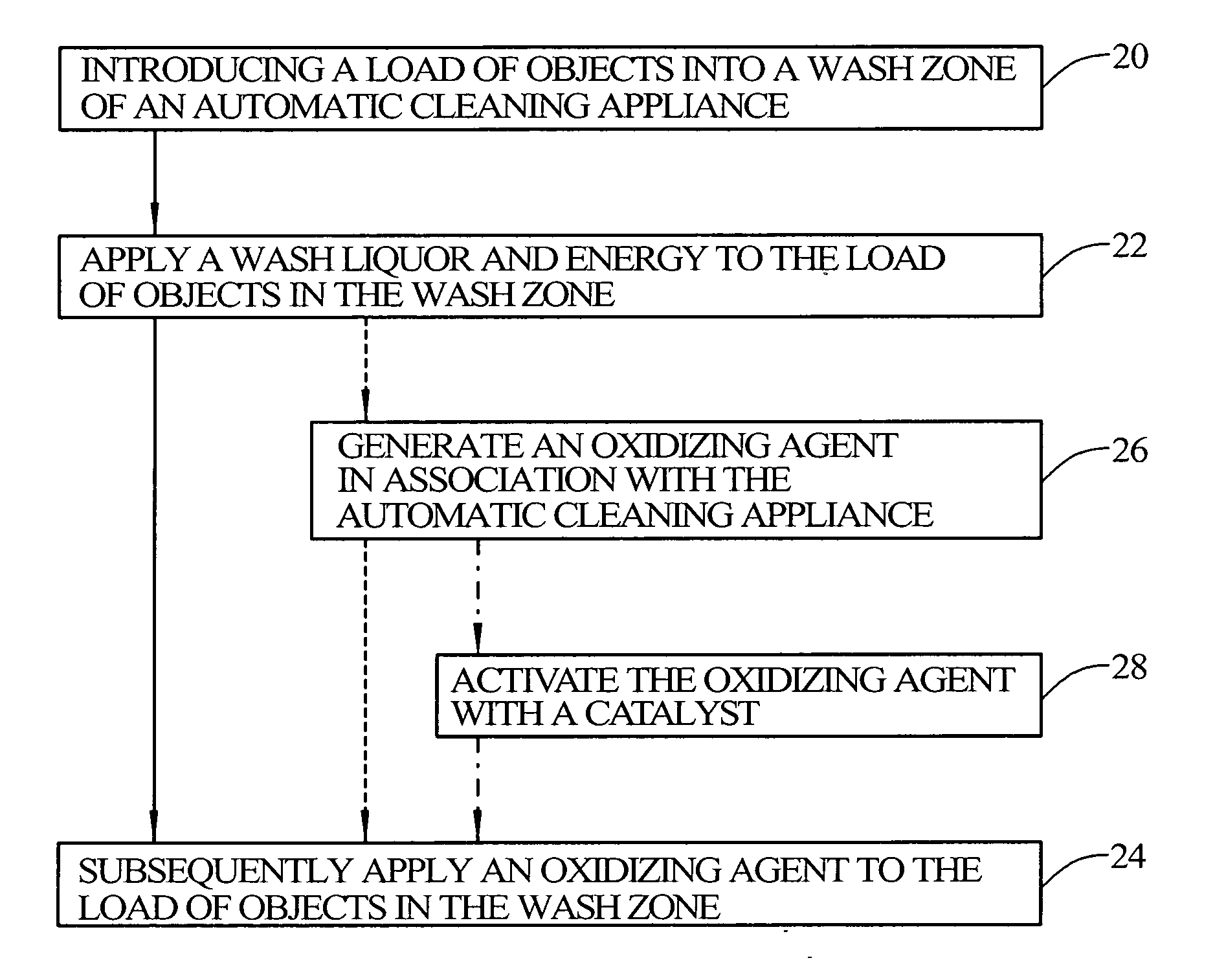

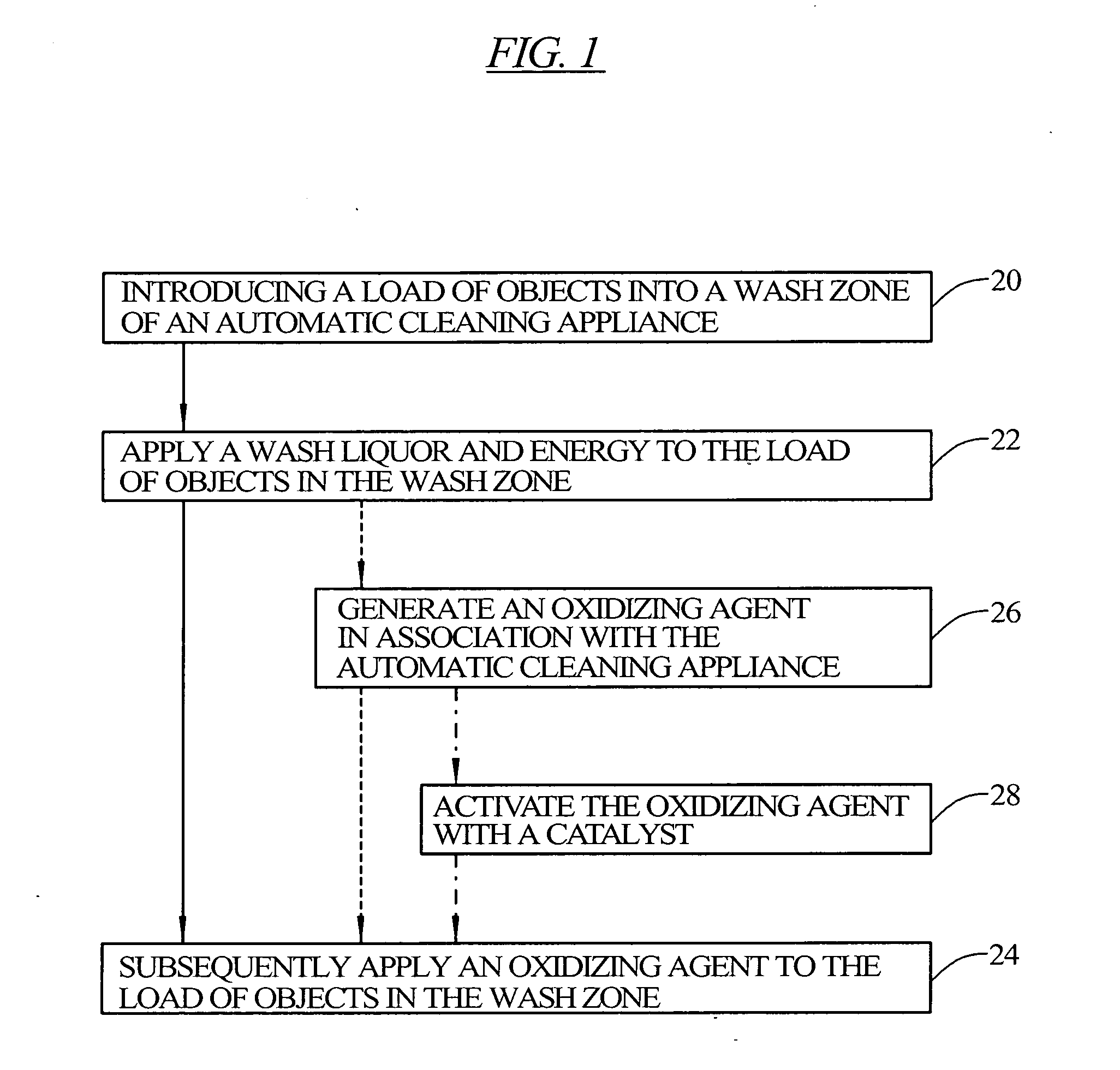

[0027]FIG. 1 illustrates an embodiment of the invention, which includes, in step 20, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com