Method for preparing alumina ceramic membrance by ion exchange

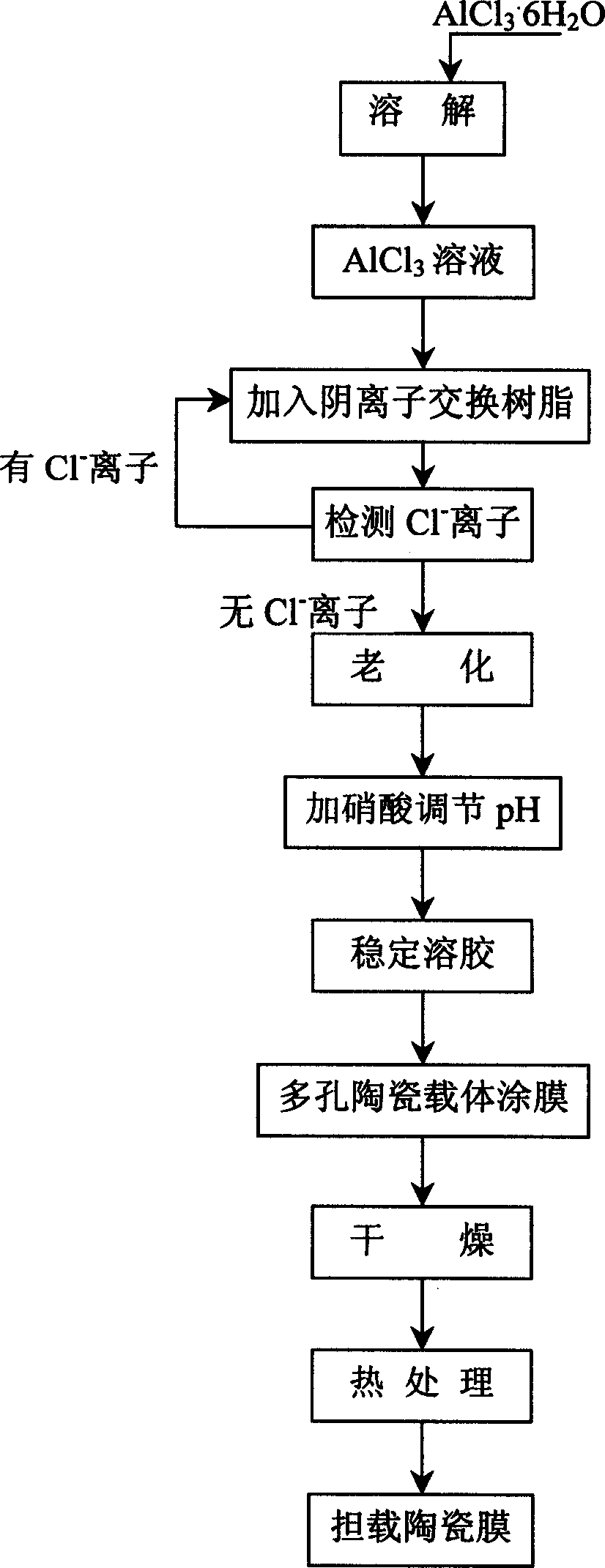

A technology of alumina ceramic membrane and ion exchange method, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. It can solve the problems that ions are difficult to remove and cannot obtain a continuous and complete alumina film layer, and achieve pore size distribution. Narrow, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] (1) A certain amount of AlCl 3 ·6H 2 O (analytical pure) was made into AlCl with a concentration of 1M 3 The solution is ready for use;

[0009] (2) Take 150ml of the above solution, add the regenerated 717 styrene anion exchange resin (Hefei University of Technology) to the AlCl in batches under the conditions of room temperature and magnetic stirring 3 in solution;

[0010] (3) AgNO should be used after adding the resin 3 Solution detection of Cl in solution - ions until no Cl is detected - After ionization, the resin is separated from the obtained sol;

[0011] (4) After aging the obtained sol in an 80°C water bath for 4 hours, adjust the pH value of the sol to about 3.7 with nitric acid, and continue to reflux in an 80°C water bath for 12 hours to obtain a clear aluminum sol;

[0012] (5) Mix the prepared sol with a 3% PVA aqueous solution in a ratio of 1:1, and coat the aluminum oxide hollow fiber by filtering and forming a film, and dry the coated carrier a...

Embodiment 2

[0015] According to the steps in Example 1, the sol was prepared, the film was coated, dried and heat-treated. The difference is that the aging time is 16 hours. The surface of the obtained hollow fiber supporting membrane is continuous and complete, and the crystal phase of the ceramic membrane is γ-Al 2 o 3 Crystalline state, the specific surface area is 176.9m 2 / g, the most accessible pore diameter is 3.65nm, and the pore volume is 0.184ml / g, which has certain gas selectivity. 2 / H 2 The separation factor is 2.80, and the gas permeation through the membrane is controlled by Knudsen diffusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com