Meso-microporous metal-organic compound and preparation method thereof

A technology of organic compounds and metal-inorganic salts, which is applied in the field of mesoporous metal-organic compounds and their preparation, achieving the effects of low cost, simple synthesis process and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

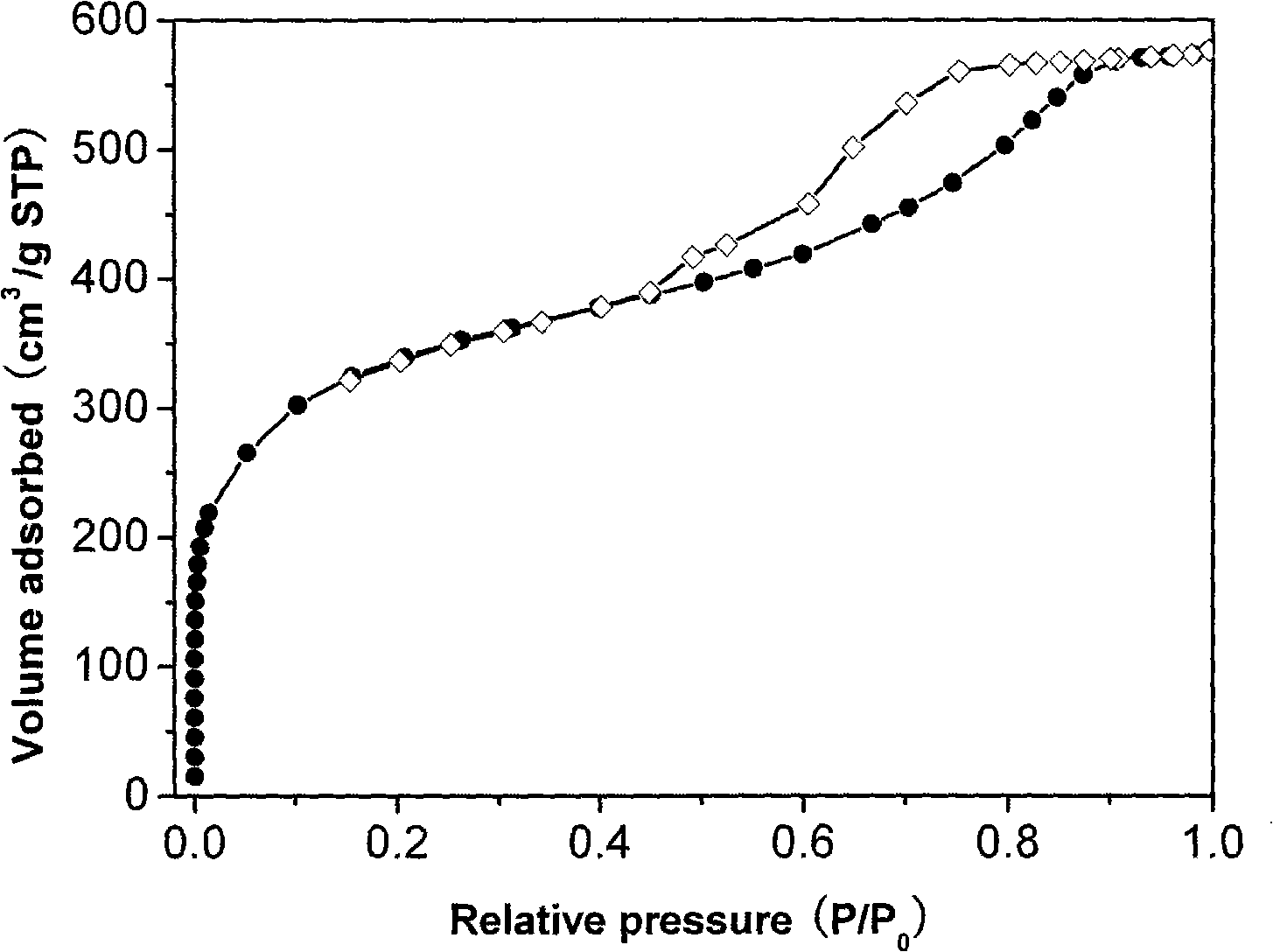

[0023] 1. Weigh 0.53g of chromium chloride and 0.50g of terephthalic acid and dissolve them in 20ml of N,N-dimethylformamide, stir them with magnetic force to fully dissolve them, then transfer the mixed solution into 30ml of stainless steel lined with polytetrafluoroethylene The reactor was crystallized in a synthesis oven at 190°C for 3 days, and cooled naturally to room temperature.

[0024] 2. Suction filter the product, wash with N,N-dimethylformamide, dry at 50°C, and finally roast at 250°C for 6 hours to obtain the target product.

[0025] 3. Low-temperature nitrogen isothermal adsorption performance test: the treatment conditions are 110°C degassing for 8 hours, and the temperature is raised to 200°C for 8 hours. The test condition is 77K, nitrogen isothermal adsorption.

Embodiment 2

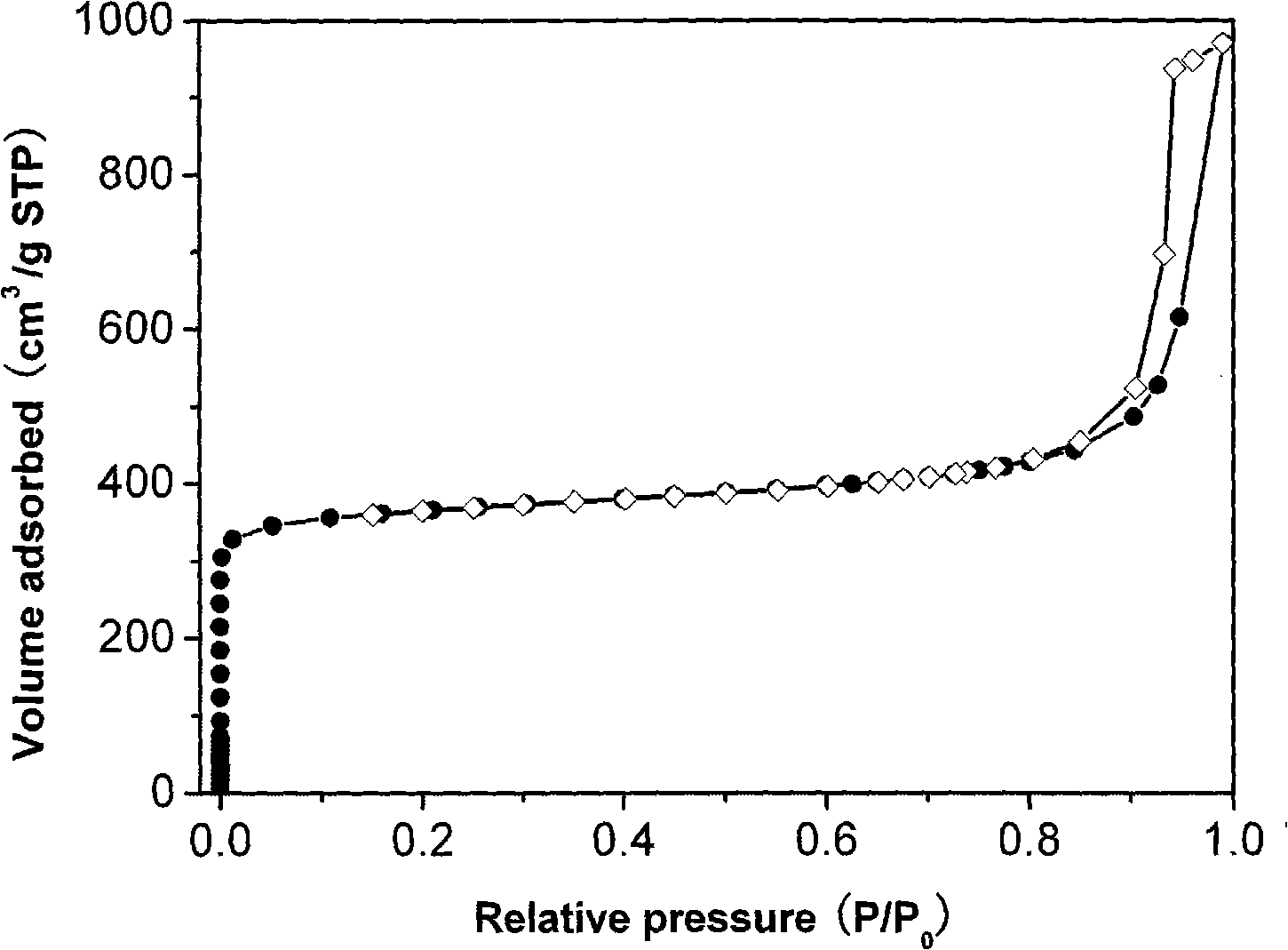

[0027] 1. Weigh 0.75g of aluminum nitrate and 0.50g of terephthalic acid and dissolve them in 20ml of N,N-dimethylformamide, stir them with magnetic force to fully dissolve them, then transfer the mixed solution into 30ml of stainless steel lined with polytetrafluoroethylene for reaction crystallized in a synthesis oven at 190°C for 3 days, and cooled naturally to room temperature.

[0028] 2. Suction filter the product, wash with N,N-dimethylformamide, dry at 50°C, and finally roast at 350°C for 6 hours to obtain the target product.

[0029] 3. Low-temperature nitrogen isothermal adsorption performance test: The treatment conditions are 110°C degassing for 8 hours, and the temperature is raised to 300°C for 8 hours. The test condition is 77K, nitrogen isothermal adsorption.

Embodiment 3

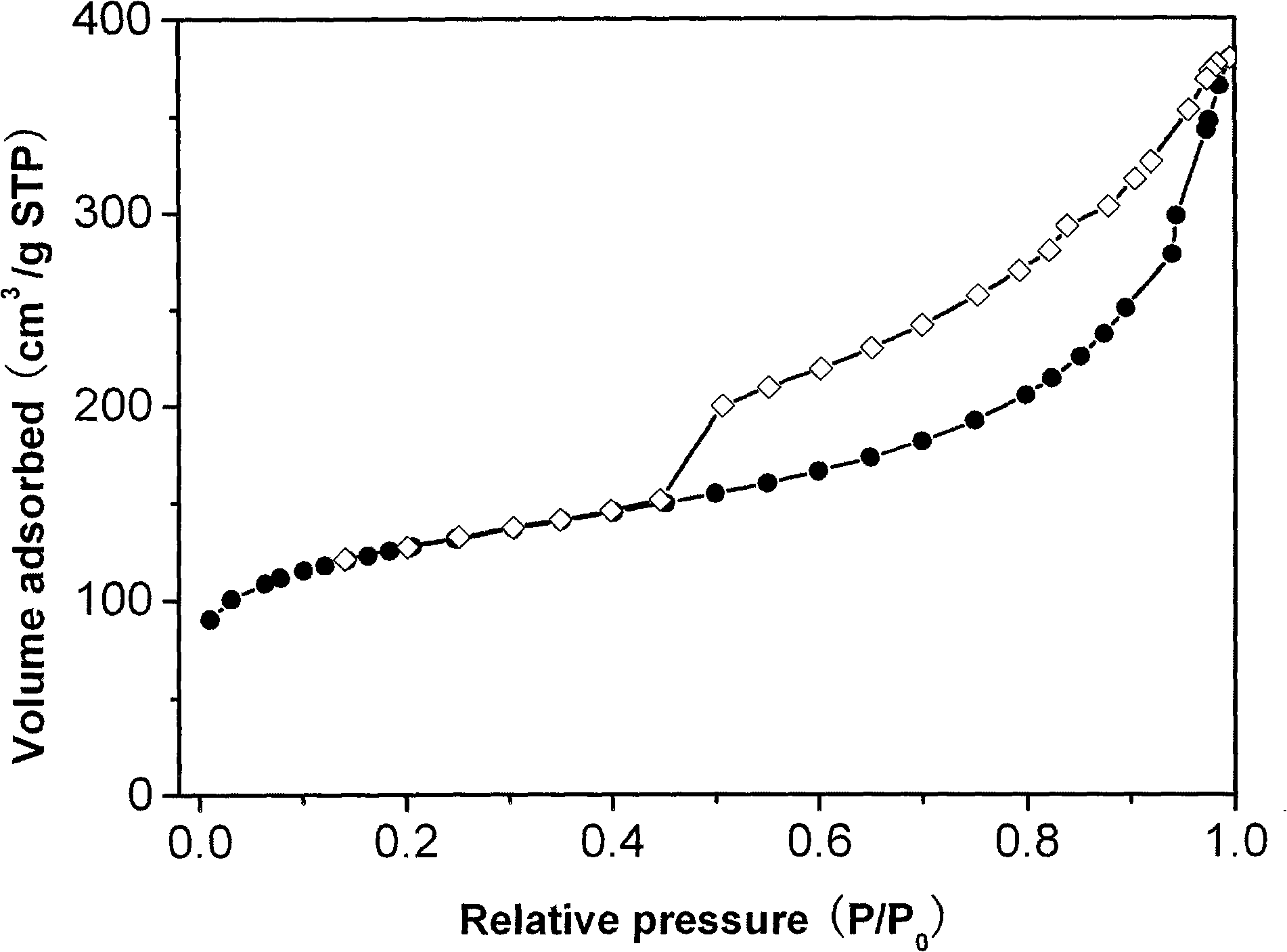

[0031] 1. Weigh 0.75g of aluminum nitrate and 0.50g of isophthalic acid and dissolve in 20ml of N,N-dimethylformamide and 1.4-dioxane mixed solution (1:1), magnetically stir to make it fully dissolved, Then the mixed solution was transferred into a 30ml polytetrafluoroethylene-lined stainless steel reactor, crystallized in a synthesis oven at 190°C for 3 days, and cooled naturally to room temperature.

[0032] 2. Suction filter the product, wash it with N,N-dimethylformamide, dry it at 50°C, and finally roast it at 300°C for 6 hours to obtain the target product.

[0033] 3. Low-temperature nitrogen isothermal adsorption performance test: the treatment conditions are 110°C degassing for 8 hours, and the temperature is raised to 250°C for 8 hours. The test condition is 77K, nitrogen isothermal adsorption.

[0034] Table 1 shows the channel structure parameters of the microporous samples in specific examples 1-3 of the present invention.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com