Method for preparing nano gamma-AlOOH by utilizing sodium metaaluminate solution

A technology using sodium metaaluminate and sodium metaaluminate, which is applied in the field of preparing nano-γ-AlOOH, can solve the problems of high production cost, complicated preparation materials and low production efficiency of nano-alumina oxyhydroxide, and achieve easy implementation and popularization, The effect of simplifying the preparation process and requiring less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing nanometer gamma-AlOOH with sodium metaaluminate solution, comprising the steps:

[0049] Step 1, control the temperature of the sodium metaaluminate solution to 25°C, then add 0.29 mol of hydrogen peroxide solution to 0.26 mol of sodium metaaluminate solution, and after fully reacting for 5 minutes, collect the solid product in the reaction solution; wherein, The concentration of the sodium metaaluminate solution is 70g / L, the mass concentration of the hydrogen peroxide solution is 30%, and the ratio of the moles of aluminum in the sodium metaaluminate solution to the moles of hydrogen peroxide in the hydrogen peroxide solution is 1 : 22.5;

[0050] Step 2, washing the solid product until the pH of the product suspension is 7;

[0051] Step 3, drying the product suspension in a constant temperature drying oven at 105° C. for 12 hours to prepare nanometer γ-AlOOH.

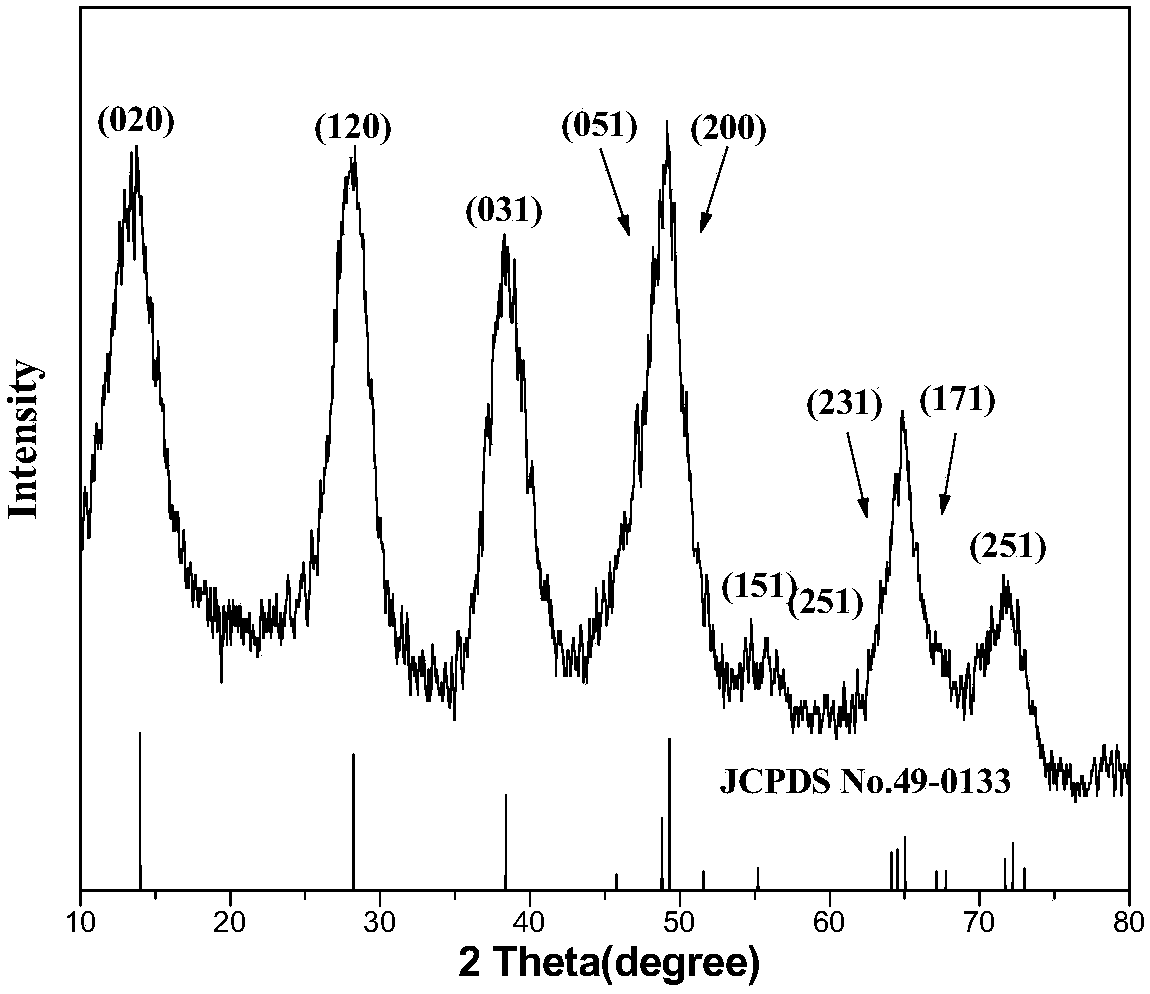

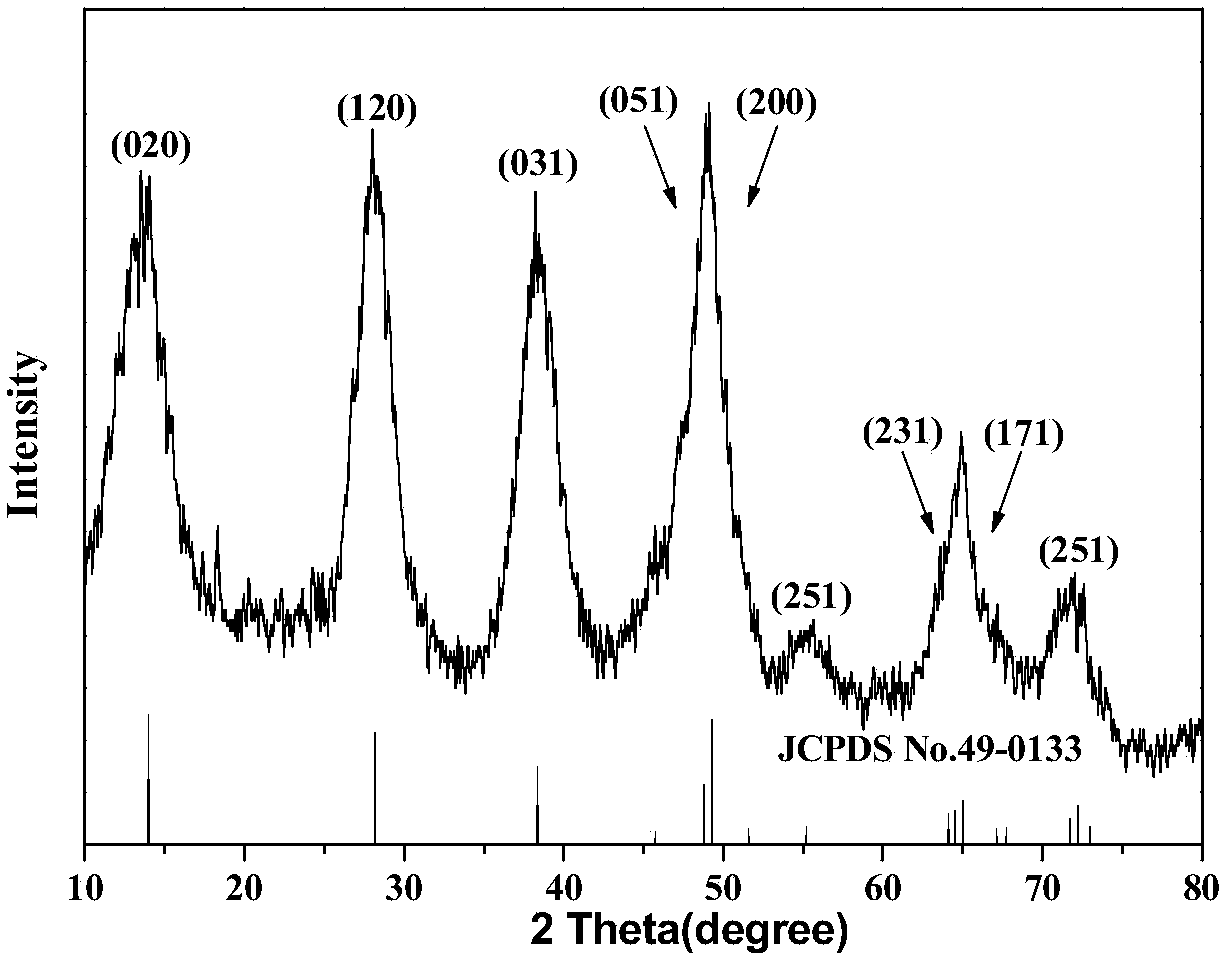

[0052] The nano γ-AlOOH prepared in this example is orthogonal γ-aluminum oxyhydr...

Embodiment 2

[0054] A method for preparing nanometer gamma-AlOOH with sodium metaaluminate solution, comprising the steps:

[0055] Step 1, control the temperature of the sodium metaaluminate solution to 25°C, then add 0.32 mol of hydrogen peroxide solution to 0.26 mol of sodium metaaluminate solution, and after fully reacting for 5 minutes, collect the solid product in the reaction solution; wherein, The concentration of the sodium metaaluminate solution is 70 / L, the mass concentration of the hydrogen peroxide solution is 30%, and the ratio of the moles of aluminum in the sodium metaaluminate solution to the moles of hydrogen peroxide in the hydrogen peroxide solution is 1 : 25;

[0056] Step 2, washing the solid product until the pH of the product suspension is 7;

[0057] Step 3, drying the product suspension in a constant temperature drying oven at 105° C. for 12 hours to prepare nanometer γ-AlOOH.

[0058] The XRD spectrum of the nanometer γ-AlOOH prepared in this embodiment is simi...

Embodiment 3

[0060] A method for preparing nanometer gamma-AlOOH with sodium metaaluminate solution, comprising the steps:

[0061] Step 1, control the temperature of the sodium metaaluminate solution to 25°C, then add 0.36 mol of hydrogen peroxide solution to 0.26 mol of sodium metaaluminate solution, and after fully reacting for 5 minutes, collect the solid product in the reaction solution; wherein, The concentration of the sodium metaaluminate solution is 70g / L, the mass concentration of the hydrogen peroxide solution is 30%, and the ratio of the moles of aluminum in the sodium metaaluminate solution to the moles of hydrogen peroxide in the hydrogen peroxide solution is 1 : 27.5;

[0062] Step 2, washing the solid product until the pH of the product suspension is 7;

[0063] Step 3, drying the product suspension in a constant temperature drying oven at 105° C. for 12 hours to prepare nanometer γ-AlOOH.

[0064] The XRD spectrogram of the nano-γ-AlOOH prepared by the present embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com